Can SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 718 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-70 Automatic Transmission/Transaxle:

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Solenoid Control Circuit Range /

Performance

S6RW0D5104050

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed for 30 seconds or more.

5) Stop vehicle and check DTC.

12V

C06-5

C06-3

WHT/BLU

WHT/BLK

3

1

2

53

C06C07

[A]

I6RW0D510007-01

1. TCM 3. A/T

2. TCC solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Difference between actual current of TCC solenoid valve

circuit and current of TCC solenoid valve circuit calculated by

ECM is more than specification.• TCC solenoid valve or its circuit malfunction

•TCM

Page 720 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-72 Automatic Transmission/Transaxle:

DTC P2763: Torque Converter Clutch (TCC) Pressure Control Solenoid Control Circuit HighS6RW0D5104042

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 10 seconds or more.

5) Check DTC.

12V

C06-5

C06-3

WHT/BLU

WHT/BLK

3

1

2

53

C06C07

[A]

I6RW0D510007-01

1. TCM 3. A/T

2. TCC solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Voltage of TCC solenoid valve TCM terminal is high although

TCM is commanding TCC solenoid valve to turn OFF.• TCC solenoid valve circuit shorted to ground

• Malfunction of TCC solenoid valve

•TCM

Page 722 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-74 Automatic Transmission/Transaxle:

DTC P2764: Torque Converter Clutch (TCC) Circuit Pressure Control Solenoid Control Circuit LowS6RW0D5104043

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 20 seconds or more.

5) Check DTC.

12V

C06-5

C06-3

WHT/BLU

WHT/BLK

3

1

2

53

C06C07

[A]

I6RW0D510007-01

1. TCM 3. A/T

2. TCC solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Voltage of TCC solenoid valve TCM terminal is low although

TCM is commanding TCC solenoid valve to turn ON.• TCC solenoid valve circuit shorted to ground

• Malfunction of TCC solenoid valve

•TCM

Page 724 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-76 Automatic Transmission/Transaxle:

DTC U0073: Control Module Communication Bus OffS6RW0D5104051

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0100: Lost Communication with ECM / PCM “A”S6RW0D5104052

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

Inspection of TCM and Its CircuitsS6RW0D5104044

TCM and its circuits can be checked at TCM wiring connectors by measuring voltage, pulse signal and resistance.

CAUTION!

TCM cannot be checked by itself, it is strictly prohibited to connect voltmeter or ohmmeter to TCM with

connector disconnected from it.

1) Remove TCM (1) from vehicle referring to “Transmission Control Module (TCM) Removal and Installation”.

2) Connect TCM connectors (2) to TCM.

3) Check voltage and/or pulse signal at each terminal of connectors connected using voltmeter (3) and oscilloscope

(4).

NOTE

• As each terminal voltage is affected by battery voltage, confirm that it is 11 V or more when ignition

switch is ON.

• Voltage with asterisk(*) cannot be measured by voltmeter because it is pulse signal. Check it with

oscilloscope if necessary.

Terminal arrangement of TCM coupler (Viewed from harness side)

3

4

12

I4RS0A510021-02

65

16 15 14 13 12 1143

24 23 212210 9 8 721

19 20 18 17 C06

17 16

26 2515 14 65 342

13 12

23 22 2411 10 9

21 20 1987

18 1 C07

I6RW0B510018-01

Page 725 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-77

Connector “C06”

Terminal Wire color CircuitStandard

voltageCondition

1 BLK Ground 0 – 1 V Ignition switch ON

2LT GRN/

BLKPressure control

solenoid valve (–)0.6 – 1.0 V Ignition switch ON

3 WHT/BLK TCC solenoid valve (–) 0.6 – 1.0 V Ignition switch ON

4GRYPressure control

solenoid valve (+)*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform

No. 1: ”)Engine running at idling.

(Output signal is duty pulse. Duty ratio varies

depending on throttle valve opening.)

5 WHT/BLU TCC solenoid valve (+)*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform

No. 2: ”)Engine running at idling.

(Output signal is duty pulse. Duty ratio varies

depending on torque converter clutch operating

condition.)

6 YEL/BLK Power source 10 – 14 V Ignition switch ON

7WHTCAN communication

line (Low)*2.5 – 3.6 V

↑↓

1.6 – 2.5 V

(“Reference

waveform

No. 3: ”)Engine running at idling with after warming up.

(CAN communication signal is pulse. Pulse signal

frequency varies depending on engine condition.))

8— — — —

9— — — —

10 — — — —

11 LT G R NTransmission fluid

temperature sensor (+)2.9 – 3.1 V Ignition switch ON, fluid temperature is 20 °C (68 °F)

0.3 – 0.5 V Ignition switch ON, fluid temperature is 100 °C (212 °F)

12 ORNTransmission fluid

temperature sensor (–)0 – 1 V Ignition switch ON

13 — — — —

14 BLU/BLK Timing solenoid valve 0 – 1 V Ignition switch ON

15 BLK/YELShift solenoid valve-B

(No.2)9 – 14 V Ignition switch ON, select lever in “P” range

16 BRNShift solenoid valve-A

(No.1)9 – 14 V Ignition switch ON, select lever in “P” range

17 REDCAN communication

line (High)*2.5 – 3.6 V

↑↓

1.6 – 2.5 V

(“Reference

waveform

No. 3: ”)Engine running at idling with after warming up.

(CAN communication signal is pulse. Pulse signal

frequency varies depending on engine condition.)

18 — — — —

19 — — — —

20 — — — —

21 — — — —

22 — — — —

23 BLK Ground 0 – 1 V Ignition switch ON

24 WHT/REDPower source for back-

up10 – 14 V Constantly

Page 727 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-79

Reference waveform No. 1

Pressure control solenoid valve signal at engine idling.

Reference waveform No. 2

TCC pressure control solenoid valve signal at engine

idling.Reference waveform No. 3

CAN communication line (High & Low) signal at engine

idling.

Reference waveform No. 4

Input shaft speed sensor signal at engine idling. Measurement

terminalCH1: “C06-4” to “C06-1”

Oscilloscope

settingCH1: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine at specified idle speed

with “P” range.

Measurement

terminalCH1: “C06-5” to “C06-1”

Oscilloscope

settingCH1: 5 V/DIV

Time: 2 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine at specified idle speed

with “P” range

I3RM0B510029-01

I4RS0A510024-01

Measurement

terminalCH1: “C06-7” to “C06-1”

CH2: “C06-17” to “C06-1”

Oscilloscope

settingCH1: 1 V/DIV

TIME: 100 µs/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine at specified idle speed

with “P” range.

Measurement

terminalCH1: “C07-6” to “C06-1”

Oscilloscope

settingCH1: 2 V/DIV

TIME: 10 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine at specified idle speed

with “P” range.

I3RM0B510030-01

I3RM0B510027-01

Page 729 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-81

Troubleshooting

Brake Interlock System InspectionS6RW0D5104046

1) Check that select lever cannot be moved to any

other range from “P” range position when ignition

switch key is at ACC position, at LOCK position or it

is removed from keyhole of ignition switch, or brake

pedal is not depressed.2) Shift select lever to “P” range position, check for the

following.

• Ignition key can be turned between LOCK and

ACC positions back and forth and also it can be

removed from ignition switch. Step Action Yes No

1Check TCM back-up power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C06-24”

terminal.

3) If OK, check voltage at terminal “C06-24” of

disconnected TCM connector.

Is it 10 – 14 V?Go to Step 2. “WHT/RED” circuit open

or shorted to ground.

2Check TCM power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C06-6” terminal.

3) If OK, turn ignition switch ON and check voltage at

terminal “C06-6” of disconnected TCM connector.

Is it 10 – 14 V?Go to Step 4. Go to Step 3.

3Check A/T relay operation

1) Check A/T relay operation referring to “A/T Relay

Inspection”.

Is check result satisfactory?“YEL/BLK”, “YEL/BLU”,

“LT GRN/BLK” or “BLK”

circuit for power supply

open.Replace A/T relay.

4Check TCM ground circuit

1) Turn ignition switch OFF.

2) With TCM connectors disconnected, check for proper

connection to TCM at “C06-1” / “C06-23” terminal.

3) If OK, check resistance between “C06-1” / “C06-23”

terminal of disconnected TCM connector and body

ground.

Is continuity indicated?TCM power and ground

circuits are in good

condition.“BLK” circuit for TCM

ground open.

I4RS0A510047-01

I4RS0A510048-01

Page 730 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-82 Automatic Transmission/Transaxle:

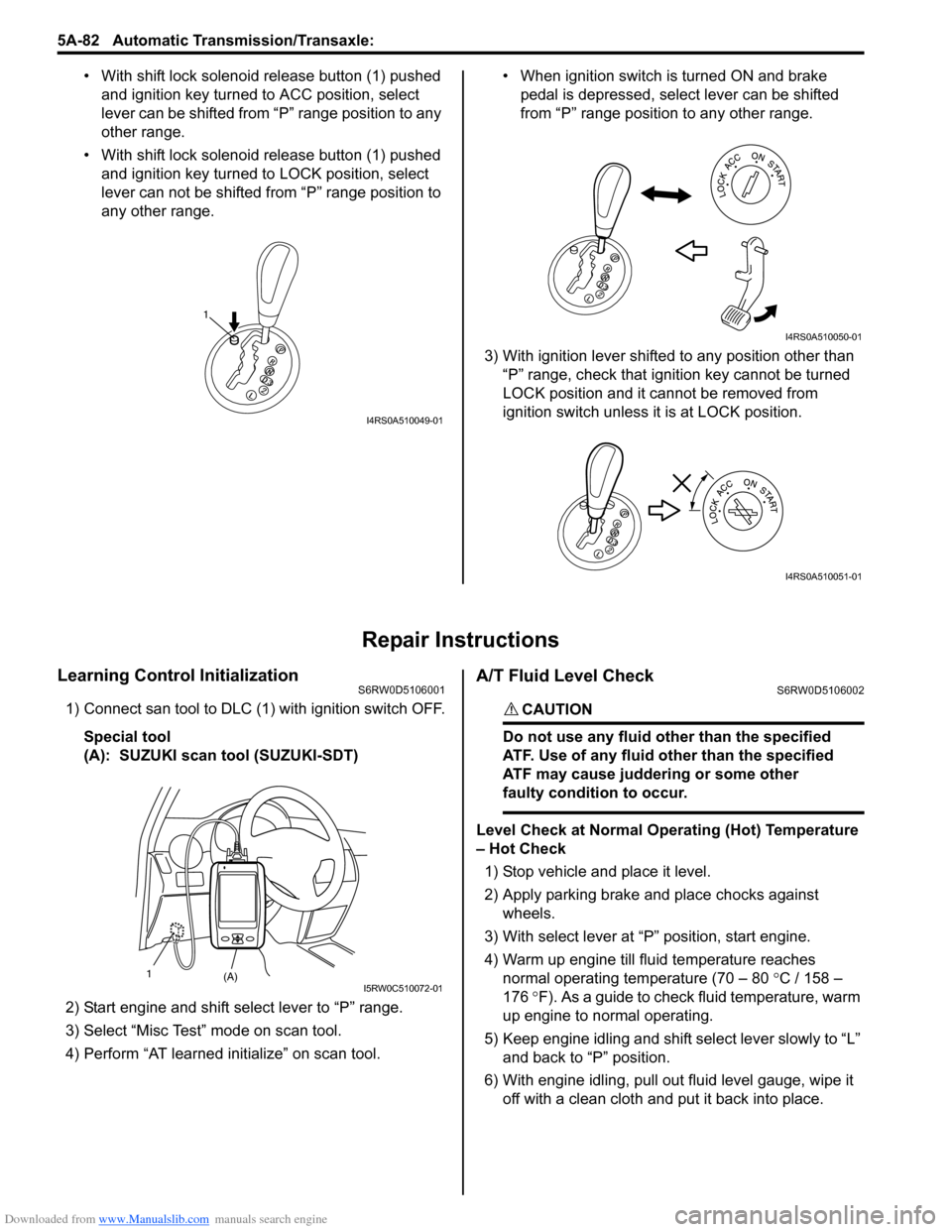

• With shift lock solenoid release button (1) pushed

and ignition key turned to ACC position, select

lever can be shifted from “P” range position to any

other range.

• With shift lock solenoid release button (1) pushed

and ignition key turned to LOCK position, select

lever can not be shifted from “P” range position to

any other range.• When ignition switch is turned ON and brake

pedal is depressed, select lever can be shifted

from “P” range position to any other range.

3) With ignition lever shifted to any position other than

“P” range, check that ignition key cannot be turned

LOCK position and it cannot be removed from

ignition switch unless it is at LOCK position.

Repair Instructions

Learning Control InitializationS6RW0D5106001

1) Connect san tool to DLC (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

2) Start engine and shift select lever to “P” range.

3) Select “Misc Test” mode on scan tool.

4) Perform “AT learned initialize” on scan tool.

A/T Fluid Level CheckS6RW0D5106002

CAUTION!

Do not use any fluid other than the specified

ATF. Use of any fluid other than the specified

ATF may cause juddering or some other

faulty condition to occur.

Level Check at Normal Operating (Hot) Temperature

– Hot Check

1) Stop vehicle and place it level.

2) Apply parking brake and place chocks against

wheels.

3) With select lever at “P” position, start engine.

4) Warm up engine till fluid temperature reaches

normal operating temperature (70 – 80 °C / 158 –

176 °F). As a guide to check fluid temperature, warm

up engine to normal operating.

5) Keep engine idling and shift select lever slowly to “L”

and back to “P” position.

6) With engine idling, pull out fluid level gauge, wipe it

off with a clean cloth and put it back into place.

1

I4RS0A510049-01

I4RS0A510050-01

I4RS0A510051-01

(A) 1I5RW0C510072-01

Page 731 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-83

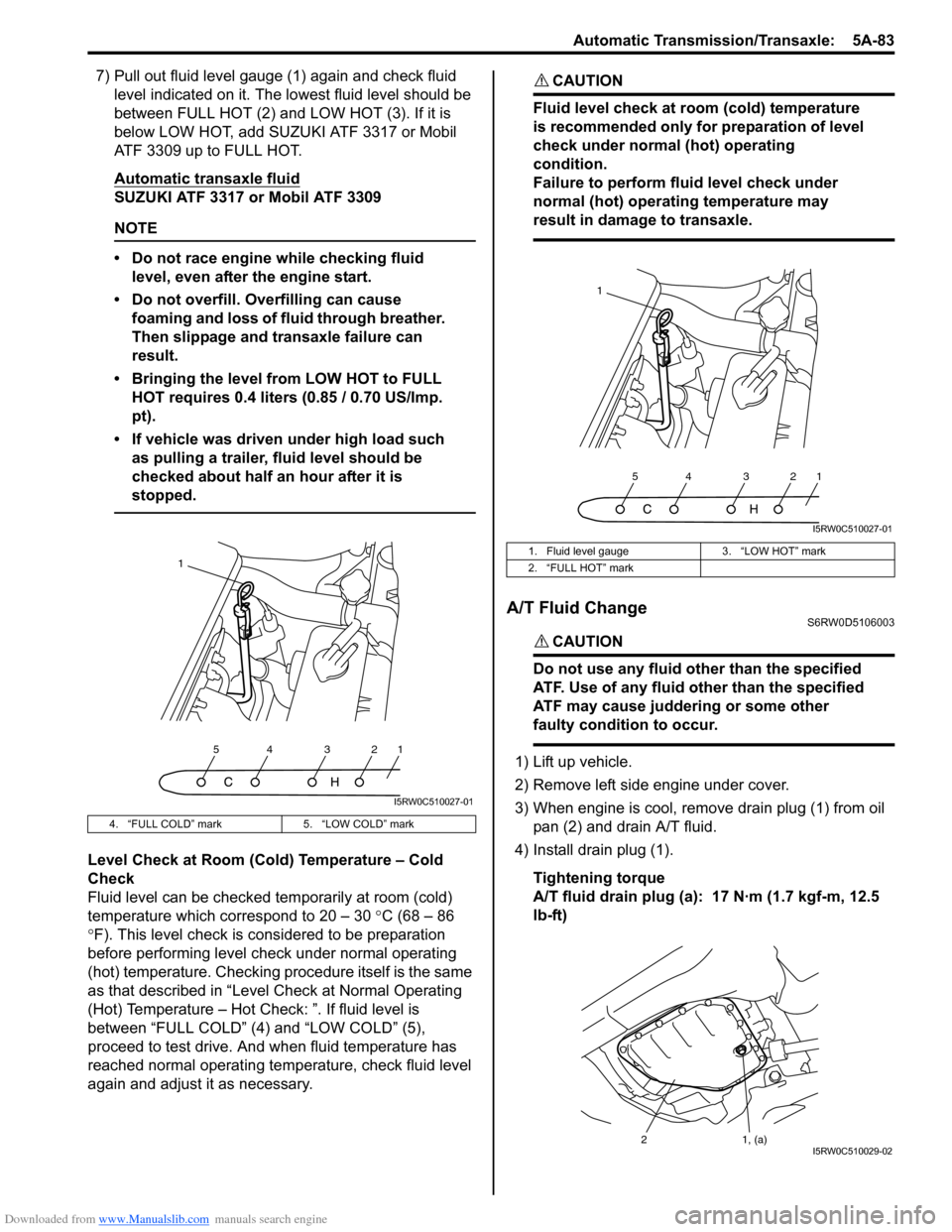

7) Pull out fluid level gauge (1) again and check fluid

level indicated on it. The lowest fluid level should be

between FULL HOT (2) and LOW HOT (3). If it is

below LOW HOT, add SUZUKI ATF 3317 or Mobil

ATF 3309 up to FULL HOT.

Automatic transaxle fluid

SUZUKI ATF 3317 or Mobil ATF 3309

NOTE

• Do not race engine while checking fluid

level, even after the engine start.

• Do not overfill. Overfilling can cause

foaming and loss of fluid through breather.

Then slippage and transaxle failure can

result.

• Bringing the level from LOW HOT to FULL

HOT requires 0.4 liters (0.85 / 0.70 US/Imp.

pt).

• If vehicle was driven under high load such

as pulling a trailer, fluid level should be

checked about half an hour after it is

stopped.

Level Check at Room (Cold) Temperature – Cold

Check

Fluid level can be checked temporarily at room (cold)

temperature which correspond to 20 – 30 °C (68 – 86

°F). This level check is considered to be preparation

before performing level check under normal operating

(hot) temperature. Checking procedure itself is the same

as that described in “Level Check at Normal Operating

(Hot) Temperature – Hot Check: ”. If fluid level is

between “FULL COLD” (4) and “LOW COLD” (5),

proceed to test drive. And when fluid temperature has

reached normal operating temperature, check fluid level

again and adjust it as necessary.

CAUTION!

Fluid level check at room (cold) temperature

is recommended only for preparation of level

check under normal (hot) operating

condition.

Failure to perform fluid level check under

normal (hot) operating temperature may

result in damage to transaxle.

A/T Fluid ChangeS6RW0D5106003

CAUTION!

Do not use any fluid other than the specified

ATF. Use of any fluid other than the specified

ATF may cause juddering or some other

faulty condition to occur.

1) Lift up vehicle.

2) Remove left side engine under cover.

3) When engine is cool, remove drain plug (1) from oil

pan (2) and drain A/T fluid.

4) Install drain plug (1).

Tightening torque

A/T fluid drain plug (a): 17 N·m (1.7 kgf-m, 12.5

lb-ft)

4. “FULL COLD” mark 5. “LOW COLD” mark

1

54 321

I5RW0C510027-01

1. Fluid level gauge 3. “LOW HOT” mark

2. “FULL HOT” mark

1

54 321

I5RW0C510027-01

21, (a)I5RW0C510029-02

Page 735 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-87

2) Remove adjuster (cable end) from select lever pin of

select lever assembly.

3) Remove adjuster (cable end) from select lever pin of

select lever assembly.

4) Release lock plate (1) which restrict moving of cable

end holder (2).

5) Push cable end holder (1) out from eye-end (2) using

an appropriate tool (3) to disengage cable.

6) Shift select lever to “N” position.

7) Apply grease to select lever pin and install adjuster

(cable end) to it.

: Grease 99000–25011 (SUZUKI Super Grease

A)

8) With both select lever and transmission range

sensor kept each “N” position, drive cable end holder

(1) in until it locks cable.

9) Slide lock plate (2) to secure cable end holder in

position.

10) After select cable was installed, check for the

following.

• Push vehicle with select lever shifted to “P” range.

Vehicle should not move.

• Vehicle can not be driven in “N” range.• Vehicle can be driven in “D”, “3”, “2” and “L”

ranges.

• Vehicle can be backed in “R” range.

Key Interlock Cable Removal and InstallationS6RW0D5106026

NOTE

Don’t bend interlock cable excessively when

removing and installing it, or system will not

operate correctly.

Removal

1) If the vehicle is equipped with air bag system,

disconnect negative cable at battery and disable air

bag system, referring to “Disabling Air Bag System in

Section 8B”.

2) Remove steering column cover.

3) Turn ignition switch to ACC position.

4) Pull out key interlock cable (1) from key cylinder

cover (2) while pressing checkhook with slotted

screwdriver (3) or the like.

5) Turn ignition switch to LOCK position.

6) Remove console box referring to “Console Box

Components in Section 9H”.

7) Detach cable end (1) from interlock cam (2) while

pressing claws (3) of interlock cam boss.

At this time, be careful not to cause damage to its

claws.

Detach cable casing cap (4) from bracket (5) while

pressing checkhook.

8) Remove interlock cable.

I2RH01510046-01

I2RH01510047-01

I3RM0B510037-01

2

13I5RW0C510045-01

4

5 3 12

4

I5RW0C510046-01