PPL SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1020 of 1556

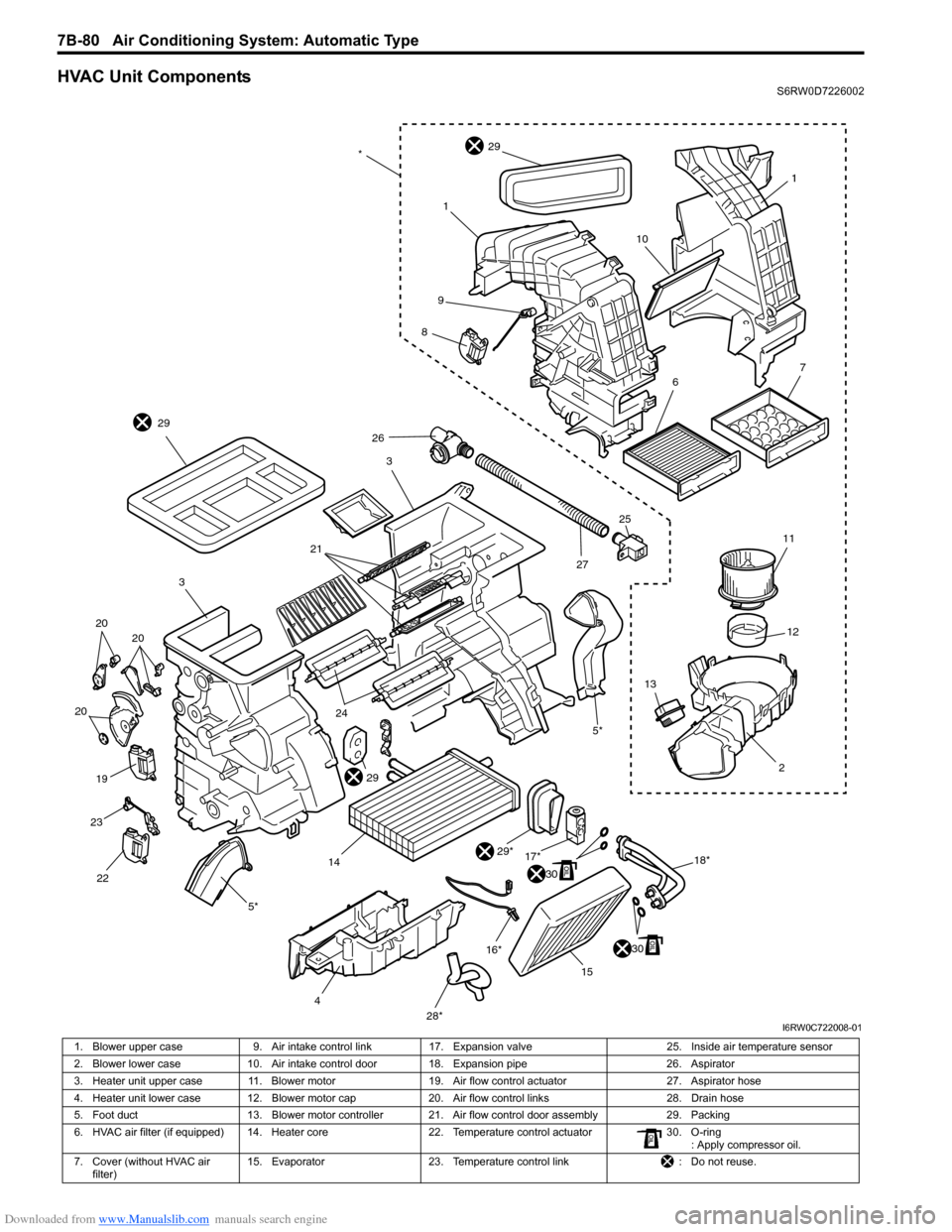

Downloaded from www.Manualslib.com manuals search engine 7B-80 Air Conditioning System: Automatic Type

HVAC Unit ComponentsS6RW0D7226002

1

10

1

29

9

8

3

29

21

3

20 20

20

19

23

22

5*

4

28*15 16*

30

29*

30

17*

18*2 1312 11

5*

26

2725

1424

29

67

*

I6RW0C722008-01

1. Blower upper case 9. Air intake control link 17. Expansion valve 25. Inside air temperature sensor

2. Blower lower case 10. Air intake control door 18. Expansion pipe 26. Aspirator

3. Heater unit upper case 11. Blower motor 19.Air flow control actuator 27. Aspirator hose

4. Heater unit lower case 12. Blower motor cap 20. Air flow control links 28. Drain hose

5. Foot duct 13. Blower motor controller 21. Air flow control door assembly 29. Packing

6. HVAC air filter (if equipped) 14. Heater core 22. Temperature control actuator 30. O-ring

: Apply compressor oil.

7. Cover (without HVAC air

filter)15. Evaporator 23. Temperature control link : Do not reuse.

Page 1029 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 8- i

8

Section 8

CONTENTS

Restraint

Precautions ................................................. 8-1

Precautions............................................................. 8-1

Precautions on Restraint ....................................... 8-1

Seat Belts ................................................. 8A-1

Precautions........................................................... 8A-1

Precautions on Service and Diagnosis of Seat

Belt .................................................................... 8A-1

General Description ............................................. 8A-2

Seat Belt Construction ........................................ 8A-2

Diagnostic Information and Procedures ............ 8A-3

Repair and Inspection Required after

Accident ............................................................ 8A-3

Repair Instructions .............................................. 8A-4

Front Seat Belt Components ............................... 8A-4

Front Seat Belt Removal and Installation ............ 8A-5

Front Seat Belt Inspection................................... 8A-6

Rear Seat Belt Components ............................... 8A-7

Rear Seat Belt Removal and Installation ............ 8A-8

Rear Seat Belt Inspection ................................... 8A-8

Specifications....................................................... 8A-8

Tightening Torque Specifications ........................ 8A-8

Air Bag System ........................................ 8B-1

Precautions........................................................... 8B-1

Precautions on Service and Diagnosis of Air

Bag System....................................................... 8B-1

Precautions on Handling and Storage of Air

Bag System Components ................................. 8B-1

Precautions on Disposal of Air Bag and Seat

Belt Pretensioner .............................................. 8B-5

General Description ............................................. 8B-5

Air Bag System Construction .............................. 8B-5

Air Bag System Block Diagram ........................... 8B-6

Air Bag System Input / Output Table .................. 8B-7

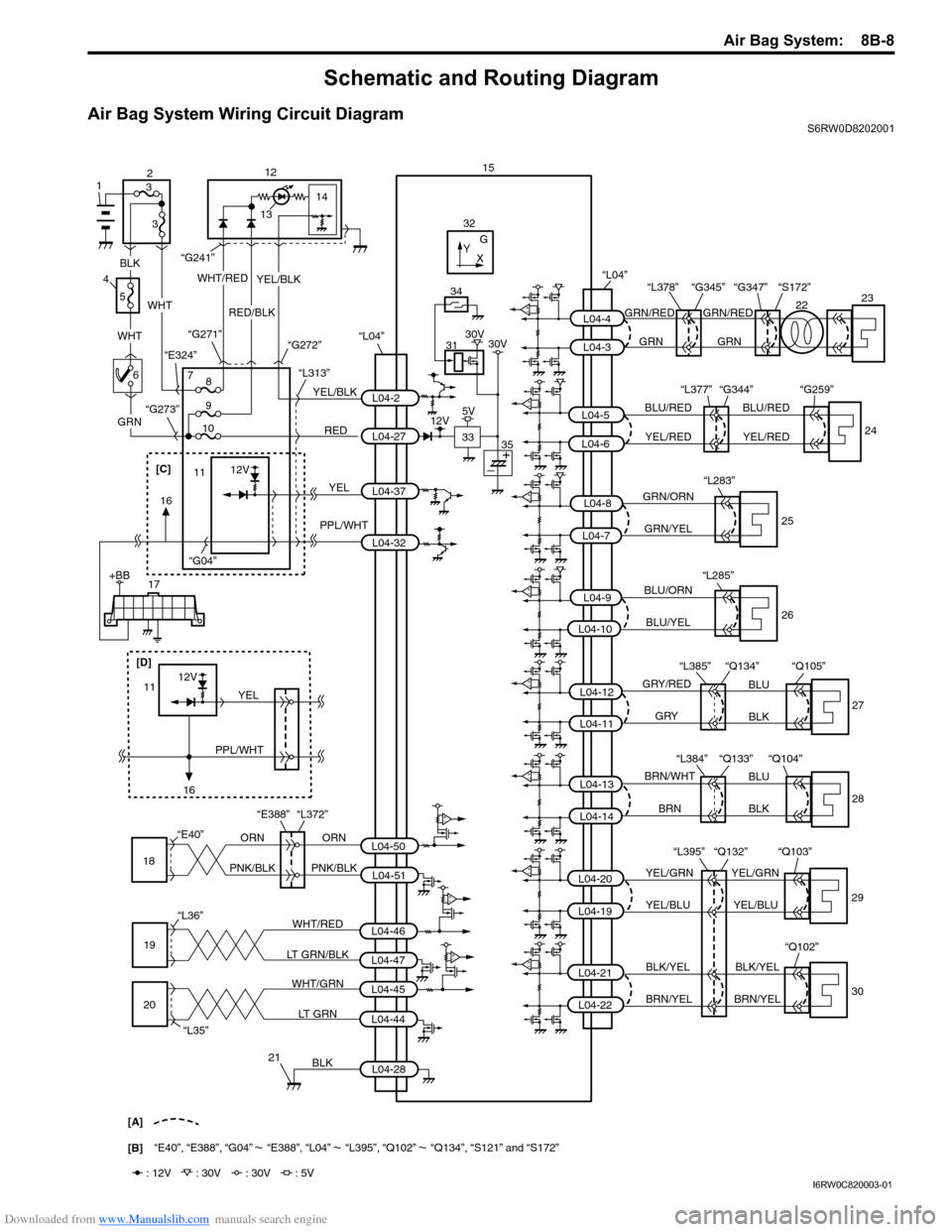

Schematic and Routing Diagram ........................ 8B-8

Air Bag System Wiring Circuit Diagram .............. 8B-8

Component Location ......................................... 8B-11

Air Bag System Components, Wiring and

Connectors Location ....................................... 8B-11

Diagnostic Information and Procedures .......... 8B-12

Air Bag Diagnostic System Check .................... 8B-12

Air Bag Diagnostic System Check Flow ............ 8B-13

DTC Table ......................................................... 8B-14DTC Check........................................................ 8B-18

DTC Clearance ................................................. 8B-18

Scan Tool Data ................................................. 8B-18

“AIR BAG” Warning Light Comes ON Steady ... 8B-19

“AIR BAG” Warning Light Does Not Come ON .. 8B-22

Serial Data Link Circuit Check .......................... 8B-23

DTC B1013: SDM Internal Failure .................... 8B-25

DTC B1014: “AIR BAG” Warning Light Circuit .. 8B-26

DTC B1016: Power Supply Voltage too High.... 8B-26

DTC B1017: Power Supply Voltage too Low .... 8B-27

DTC B1021: Front Air Bag Deployment

Record............................................................. 8B-28

DTC B1024 / B1025: Side Air-Bag

Deployment Record ........................................ 8B-29

DTC B1026: Seat Belt Pretensioner

Activation Record ............................................ 8B-29

DTC B1027: Number of Deployment Times

Exceeded Limit................................................ 8B-30

DTC B1031: Driver Air Bag Circuit High

Resistance ...................................................... 8B-31

DTC B1032: Driver Air Bag Circuit Low

Resistance ...................................................... 8B-33

DTC B1033: Driver Air Bag Circuit Shorted to

Ground ............................................................ 8B-35

DTC B1034: Driver Air Bag Circuit Shorted to

Power Supply .................................................. 8B-37

DTC B1041: Passenger Air Bag Circuit High

Resistance ...................................................... 8B-40

DTC B1042: Passenger Air Bag Circuit Low

Resistance ...................................................... 8B-43

DTC B1043: Passenger Air Bag Circuit

Shorted to Ground........................................... 8B-45

DTC B1044: Passenger Air Bag Circuit

Shorted to Power Supply ................................ 8B-46

DTC B1051 / B1055: Seat Belt Pretensioner

Circuit High Resistance ................................... 8B-48

DTC B1052 / B1056: Seat Belt Pretensioner

Circuit Low Resistance.................................... 8B-51

DTC B1053 / B1057: Seat Belt Pretensioner

Shorted to Ground........................................... 8B-52

DTC B1054 / B1058: Seat Belt Pretensioner

Circuit Shorted to Power Supply ..................... 8B-54

DTC B1061 / B1065: Side-Air Bag Circuit

High Resistance .............................................. 8B-55

Page 1030 of 1556

Downloaded from www.Manualslib.com manuals search engine 8-ii Table of Contents

DTC B1062 / B1066: Side-Air Bag Circuit Low

Resistance ...................................................... 8B-59

DTC B1063 / B1067: Side-Air Bag Circuit

Shorted to Ground .......................................... 8B-61

DTC B1064 / B1068: Side-Air Bag Circuit

Shorted to Power Supply ................................ 8B-64

DTC B1071: Driver Forward Impact-Sensor

Communication Data Inconsistent .................. 8B-66

DTC B1072: Driver Forward Impact-Sensor

Communication Data Invalid ........................... 8B-66

DTC B1073: Driver Forward Impact-Sensor

Circuit Shorted to Ground ............................... 8B-67

DTC B1074: Driver Forward Impact-Sensor

Circuit Open .................................................... 8B-68

DTC B1081 / B1091: Side Impact-Sensor No

Response ........................................................ 8B-70

DTC B1082 / B1092: Side Impact-Sensor

Communication DATA Invalid ......................... 8B-70

DTC B1083 / B1093: Side Impact-Sensor

Circuit Shorted to Ground ............................... 8B-71

DTC B1084 / B1094: Side Impact-Sensor

Circuit Open .................................................... 8B-73

DTC B1085 / B1095: Side Impact-Sensor

Communication DATA Inconsistent ................ 8B-74

DTC B1361 / B1365: Curtain-Air Bag Circuit

High Resistance .............................................. 8B-75

DTC B1362 / B1366: Curtain-Air Bag Circuit

Low Resistance ............................................... 8B-79

DTC B1363 / B1367: Curtain-Air Bag Circuit

Shorted to Ground .......................................... 8B-81

DTC B1364 / B1368: Curtain-Air Bag Circuit

Shorted to Power Supply ................................ 8B-83

SDM Power Supply and Ground Circuit

Check .............................................................. 8B-85

Contact Coil Cable and Its Circuit Check .......... 8B-87

Inspection of Intermittent and Poor

Connections .................................................... 8B-89Repair and Inspection Required after

Accident .......................................................... 8B-90

Repair Instructions ............................................8B-93

Disabling Air Bag System.................................. 8B-93

Enabling Air Bag System .................................. 8B-93

SDM Removal and Installation .......................... 8B-94

SDM Inspection ................................................. 8B-95

Driver Air Bag (Inflator) Module Removal and

Installation ....................................................... 8B-95

Driver Air Bag (Inflator) Module Inspection ....... 8B-97

Passenger Air Bag (Inflator) Module Removal

and Installation ................................................ 8B-97

Passenger Air Bag (Inflator) Module

Inspection ........................................................ 8B-99

Side-Air Bag (Inflator) Module Removal and

Installation ....................................................... 8B-99

Side-Air Bag (Inflator) Inspection .................... 8B-101

Side Curtain-Air Bag (Inflator) Module

Removal and Installation ............................... 8B-102

Side Curtain-Air Bag (Inflator) Module

Inspection ...................................................... 8B-103

Forward Impact-Sensor Removal and

Installation ..................................................... 8B-103

Forward Impact-Sensor Inspection ................. 8B-104

Side Impact-Sensor Removal and Installation 8B-105

Side Impact-Sensor Inspection ....................... 8B-105

Passenger Air Bag (Inflator) Module Repair

Harness Installation....................................... 8B-106

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal ................................... 8B-107

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal.... 8B-117

Specifications ...................................................8B-118

Tightening Torque Specifications .................... 8B-118

Special Tools and Equipment .........................8B-118

Use of Special Tools ....................................... 8B-118

Special Tool .................................................... 8B-120

Page 1032 of 1556

Downloaded from www.Manualslib.com manuals search engine 8A-1 Seat Belts:

Restraint

Seat Belts

Precautions

Precautions on Service and Diagnosis of Seat BeltS6RW0D8100001

WARNING!

If replacing seat belt is necessary, replace buckle and seat belt together as a set. This is for the reason

of ensuring locking of tongue plate with buckle. If these parts are replaced individually, such a locking

condition may become unreliable. For this reason, SUZUKI will supply only the spare buckle and seat

belt assembly in a set part.

Before servicing or replacing seat belts, refer to the following precautionary items.

• Seat belts should be normal relative to strap retractor and buckle portions.

• Keep sharp edges and damaging objects away from belts.

• Avoid bending or damaging any portion of belt buckle or latch plate.

• Do not bleach or dye belt webbing. (Use only mild soap and lukewarm water to clean it.)

• When installing a seat belt anchor bolt, it should be tightened by hand at first to prevent cross-threading and then to

specified torque.

• Do not attempt any repairs on retractor mechanisms or retractor covers. Replace defective assemblies with new

replacement parts.

• Keep belts dry and clean at all times.

• If there exist any parts in question, replace such parts.

• Replace belts whose webbing is cut or otherwise damaged.

• Do not put anything into trim panel opening which seat belt webbing passes through.

Page 1037 of 1556

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-6

Front Seat Belt InspectionS6RW0D8106003

WARNING!

• Never attempt to disassemble or repair the

seat belt pretensioner (retractor). If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Seat Belt”, before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

unactivation of the seat belt pretensioner

when necessary.

• Never measure resistance of pretensioner

or disassemble it. Otherwise, personal

injury may result.

CAUTION!

If seat belt pretensioner (retractor) was

dropped from a height of 30 cm (1 ft) or more,

it should be replaced.

Seat belts and attaching parts can affect the vital

components and systems of a vehicle.

Therefore, they should be inspected carefully and

replaced with genuine parts only.

Seat Belt

• The seat belt webbing or strap should be free from

damage.

Retractor (with Seat Belt Pretensioner)

1) Let the seat belt retract fully to confirm its easy

retraction.

• The retractor should lock webbing when pulled

quickly.

• The front seat belt retractor (1) should pass the

inspection and should lock webbing even when

tilted (approx. 15°) toward the fore and aft or right

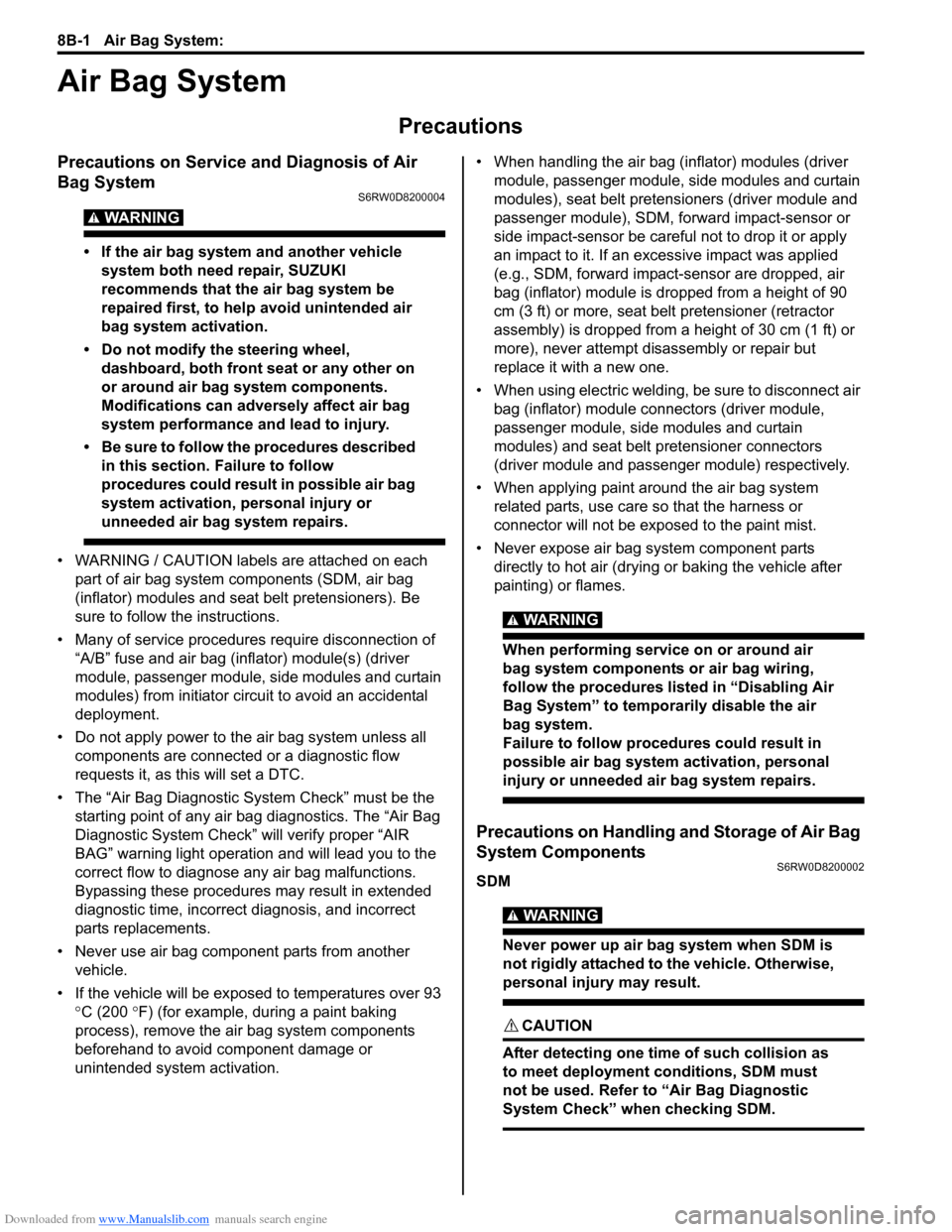

and left directions.2) Check retractor (1) with seat belt pretensioner

appearance visually for following symptoms and if

any one of them is applicable, replace it with a new

one as an assembly.

• Pretensioner has activated.

• There is a crack in seat belt pretensioner

(retractor).

• Seat belt pretensioner (retractor) is damaged or a

strong impact (e.g., dropping) was applied to it.

Anchor Bolt

• Anchor bolts should be torqued to specification.

Belt Latch

• It should be secure when latched.

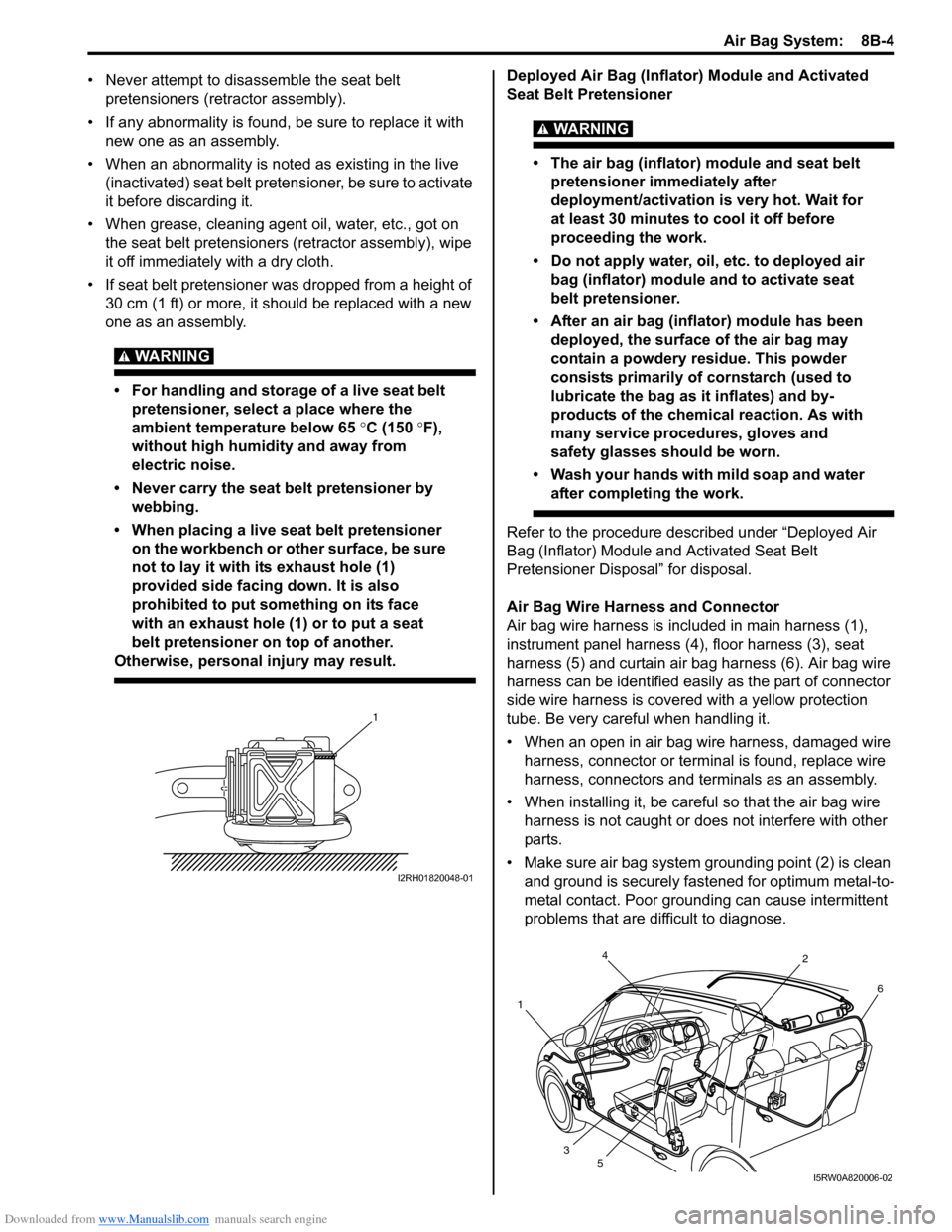

Seat Belt Buckle Switch

Check driver side seat belt switch and passenger side

seat belt switch for continuity by using ohmmeter.

Seat belt switch specification

Without inserted buckle tongue to buckle catch:

Terminal “A” and “B”: Continuity

With inserted buckle tongue to buckle catch:

Terminal “A” and “B”: No continuityI2RH01810004-01

1. Buckle tongue

2. Buckle catch

I2RH01810005-01

I4RS0B810001-01

Page 1040 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-1 Air Bag System:

Restraint

Air Bag System

Precautions

Precautions on Service and Diagnosis of Air

Bag System

S6RW0D8200004

WARNING!

• If the air bag system and another vehicle

system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel,

dashboard, both front seat or any other on

or around air bag system components.

Modifications can adversely affect air bag

system performance and lead to injury.

• Be sure to follow the procedures described

in this section. Failure to follow

procedures could result in possible air bag

system activation, personal injury or

unneeded air bag system repairs.

• WARNING / CAUTION labels are attached on each

part of air bag system components (SDM, air bag

(inflator) modules and seat belt pretensioners). Be

sure to follow the instructions.

• Many of service procedures require disconnection of

“A/B” fuse and air bag (inflator) module(s) (driver

module, passenger module, side modules and curtain

modules) from initiator circuit to avoid an accidental

deployment.

• Do not apply power to the air bag system unless all

components are connected or a diagnostic flow

requests it, as this will set a DTC.

• The “Air Bag Diagnostic System Check” must be the

starting point of any air bag diagnostics. The “Air Bag

Diagnostic System Check” will verify proper “AIR

BAG” warning light operation and will lead you to the

correct flow to diagnose any air bag malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

• Never use air bag component parts from another

vehicle.

• If the vehicle will be exposed to temperatures over 93

°C (200 °F) (for example, during a paint baking

process), remove the air bag system components

beforehand to avoid component damage or

unintended system activation.• When handling the air bag (inflator) modules (driver

module, passenger module, side modules and curtain

modules), seat belt pretensioners (driver module and

passenger module), SDM, forward impact-sensor or

side impact-sensor be careful not to drop it or apply

an impact to it. If an excessive impact was applied

(e.g., SDM, forward impact-sensor are dropped, air

bag (inflator) module is dropped from a height of 90

cm (3 ft) or more, seat belt pretensioner (retractor

assembly) is dropped from a height of 30 cm (1 ft) or

more), never attempt disassembly or repair but

replace it with a new one.

• When using electric welding, be sure to disconnect air

bag (inflator) module connectors (driver module,

passenger module, side modules and curtain

modules) and seat belt pretensioner connectors

(driver module and passenger module) respectively.

• When applying paint around the air bag system

related parts, use care so that the harness or

connector will not be exposed to the paint mist.

• Never expose air bag system component parts

directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING!

When performing service on or around air

bag system components or air bag wiring,

follow the procedures listed in “Disabling Air

Bag System” to temporarily disable the air

bag system.

Failure to follow procedures could result in

possible air bag system activation, personal

injury or unneeded air bag system repairs.

Precautions on Handling and Storage of Air Bag

System Components

S6RW0D8200002

SDM

WARNING!

Never power up air bag system when SDM is

not rigidly attached to the vehicle. Otherwise,

personal injury may result.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, SDM must

not be used. Refer to “Air Bag Diagnostic

System Check” when checking SDM.

Page 1043 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-4

• Never attempt to disassemble the seat belt

pretensioners (retractor assembly).

• If any abnormality is found, be sure to replace it with

new one as an assembly.

• When an abnormality is noted as existing in the live

(inactivated) seat belt pretensioner, be sure to activate

it before discarding it.

• When grease, cleaning agent oil, water, etc., got on

the seat belt pretensioners (retractor assembly), wipe

it off immediately with a dry cloth.

• If seat belt pretensioner was dropped from a height of

30 cm (1 ft) or more, it should be replaced with a new

one as an assembly.

WARNING!

• For handling and storage of a live seat belt

pretensioner, select a place where the

ambient temperature below 65 °C (150 °F),

without high humidity and away from

electric noise.

• Never carry the seat belt pretensioner by

webbing.

• When placing a live seat belt pretensioner

on the workbench or other surface, be sure

not to lay it with its exhaust hole (1)

provided side facing down. It is also

prohibited to put something on its face

with an exhaust hole (1) or to put a seat

belt pretensioner on top of another.

Otherwise, personal injury may result.

Deployed Air Bag (Inflator) Module and Activated

Seat Belt Pretensioner

WARNING!

• The air bag (inflator) module and seat belt

pretensioner immediately after

deployment/activation is very hot. Wait for

at least 30 minutes to cool it off before

proceeding the work.

• Do not apply water, oil, etc. to deployed air

bag (inflator) module and to activate seat

belt pretensioner.

• After an air bag (inflator) module has been

deployed, the surface of the air bag may

contain a powdery residue. This powder

consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-

products of the chemical reaction. As with

many service procedures, gloves and

safety glasses should be worn.

• Wash your hands with mild soap and water

after completing the work.

Refer to the procedure described under “Deployed Air

Bag (Inflator) Module and Activated Seat Belt

Pretensioner Disposal” for disposal.

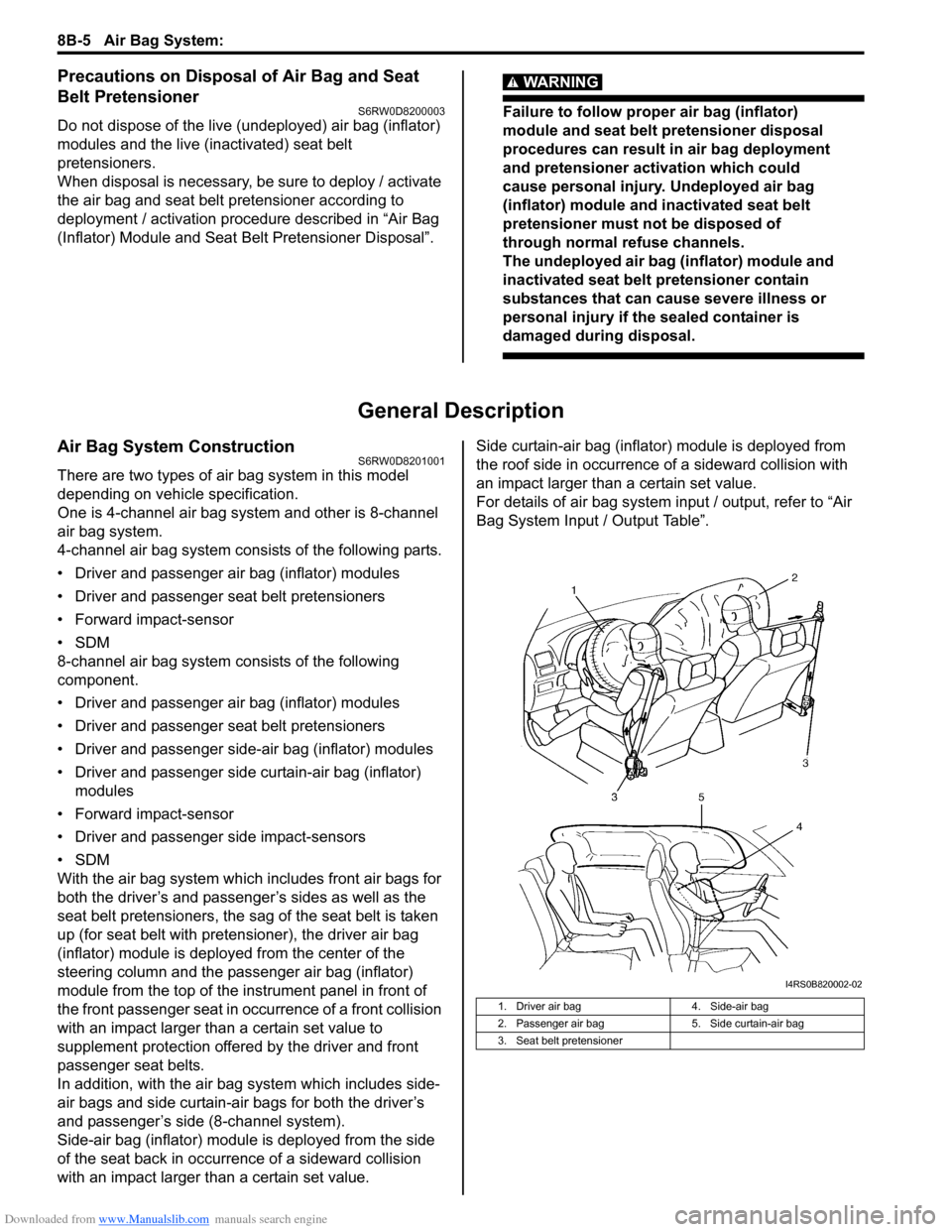

Air Bag Wire Harness and Connector

Air bag wire harness is included in main harness (1),

instrument panel harness (4), floor harness (3), seat

harness (5) and curtain air bag harness (6). Air bag wire

harness can be identified easily as the part of connector

side wire harness is covered with a yellow protection

tube. Be very careful when handling it.

• When an open in air bag wire harness, damaged wire

harness, connector or terminal is found, replace wire

harness, connectors and terminals as an assembly.

• When installing it, be careful so that the air bag wire

harness is not caught or does not interfere with other

parts.

• Make sure air bag system grounding point (2) is clean

and ground is securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent

problems that are difficult to diagnose.

1

I2RH01820048-01

4

12

6

3

5

I5RW0A820006-02

Page 1044 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-5 Air Bag System:

Precautions on Disposal of Air Bag and Seat

Belt Pretensioner

S6RW0D8200003

Do not dispose of the live (undeployed) air bag (inflator)

modules and the live (inactivated) seat belt

pretensioners.

When disposal is necessary, be sure to deploy / activate

the air bag and seat belt pretensioner according to

deployment / activation procedure described in “Air Bag

(Inflator) Module and Seat Belt Pretensioner Disposal”.

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which could

cause personal injury. Undeployed air bag

(inflator) module and inactivated seat belt

pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and

inactivated seat belt pretensioner contain

substances that can cause severe illness or

personal injury if the sealed container is

damaged during disposal.

General Description

Air Bag System ConstructionS6RW0D8201001

There are two types of air bag system in this model

depending on vehicle specification.

One is 4-channel air bag system and other is 8-channel

air bag system.

4-channel air bag system consists of the following parts.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• Forward impact-sensor

•SDM

8-channel air bag system consists of the following

component.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• Driver and passenger side-air bag (inflator) modules

• Driver and passenger side curtain-air bag (inflator)

modules

• Forward impact-sensor

• Driver and passenger side impact-sensors

•SDM

With the air bag system which includes front air bags for

both the driver’s and passenger’s sides as well as the

seat belt pretensioners, the sag of the seat belt is taken

up (for seat belt with pretensioner), the driver air bag

(inflator) module is deployed from the center of the

steering column and the passenger air bag (inflator)

module from the top of the instrument panel in front of

the front passenger seat in occurrence of a front collision

with an impact larger than a certain set value to

supplement protection offered by the driver and front

passenger seat belts.

In addition, with the air bag system which includes side-

air bags and side curtain-air bags for both the driver’s

and passenger’s side (8-channel system).

Side-air bag (inflator) module is deployed from the side

of the seat back in occurrence of a sideward collision

with an impact larger than a certain set value.Side curtain-air bag (inflator) module is deployed from

the roof side in occurrence of a sideward collision with

an impact larger than a certain set value.

For details of air bag system input / output, refer to “Air

Bag System Input / Output Table”.

1. Driver air bag 4. Side-air bag

2. Passenger air bag 5. Side curtain-air bag

3. Seat belt pretensioner

I4RS0B820002-02

Page 1047 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-8

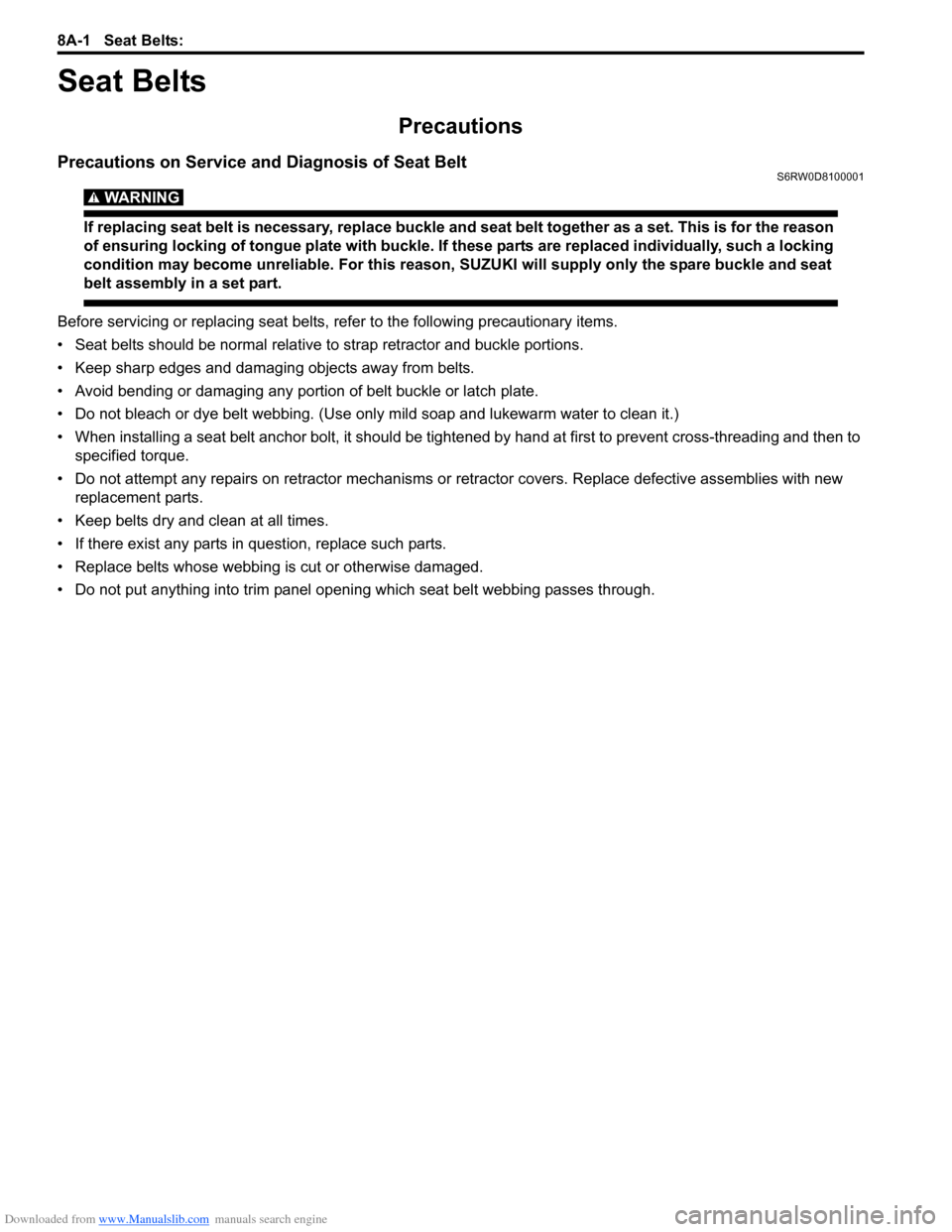

Schematic and Routing Diagram

Air Bag System Wiring Circuit DiagramS6RW0D8202001

BLK

YEL/GRN YEL/GRN

YEL/BLU YEL/BLU

WHT/RED

LT GRN/BLK

WHT/GRN

LT GRN

2223 15

29

21 19

20GRN/RED GRN/RED

GRN GRN

[A]

[B]“E40”, “E388”, “G04” “E388”, “L04” “L395”, “Q102” “Q134”, “S121” and “S172”

L04-4

L04-3

“L395” “Q132” “Q103”

L04-28 L04-46

L04-47

L04-45

L04-44 “L36”“G347” “S172” “L378” “G345”

“L35”ORN

18L04-50

L04-51 “E40”

“Q134” “Q105” “L385”

L04-12

L04-11

GRY/RED

GRY

BLK BLU

27

PNK/BLK ORN

PNK/BLK

BLU/RED

YEL/REDBLU/RED

YEL/RED

“L377” “G344” “G259”

24L04-5

L04-6

GRN/ORN

GRN/YEL

BLU/ORN

BLU/YEL

L04-9

L04-7

L04-8

25

26 “L283”

L04-10

“L285”

L04-20

L04-19“Q104” “Q133” “L384”

L04-13

L04-14BLK BLU BRN/WHT

BRN28

BLK/YEL

BRN/YELBLK/YEL

BRN/YEL30 “Q102”L04-21

L04-22

L04-2

L04-27

L04-37

“L04”

“L04”

“E388” “L372”

L04-32

32

31

G

33Y

X

34

: 12V : 30V : 30V : 5V

12V5V30V 30V

35RED 7

119

10“L313” “G272” “G271”

“G241”

“G273”

“G04”

YEL

1314

YEL/BLK

YEL/BLK

RED/BLK

12

12V

PPL/WHT

8

WHT/RED

WHT

WHT

GRN

12

3

3

5

4

6

BLK

“E324”

17+BB

[C]

16

[D]12V

PPL/WHTYEL11

16

I6RW0C820003-01

Page 1052 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-13 Air Bag System:

Air Bag Diagnostic System Check FlowS6RW0D8204002

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to each

flow.

• When measurement of resistance or voltage is required in the flow, use a tester along with a correct

terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor

Connections”.

• If an open circuit in the air bag wire harness damaged, connector or terminal is found, replace the

wire harness, connectors and terminals as an assembly.

Step Action Yes No

1Battery voltage check.

1) Measure battery voltage.

Is it 10 – 14 V?Go to Step 2. Proceed to “Battery

Inspection in Section

1J”.

2“AIR BAG” warning light check (6 times flushing check).

1) Turn ON ignition switch, and then check that “AIR BAG”

warning light flushes.

Does “AIR BAG” warning light flash 6 times?Go to Step 3. Go to Step 4.

3“AIR BAG” warning light check (turning off check).

1) In the state of Step 2. check that “AIR BAG” warning light

turn OFF after flashing 6 times.

Does “AIR BAG” warning light turn OFF?Go to Step 5. Go to Step 6.

4“AIR BAG” warning light circuit check

Does “AIR BAG” warning light come ON steady?Go to checking flow of

““AIR BAG” Warning

Light Comes ON

Steady”. After carrying

out it flow, proceed to

St ep 6 .Go to checking flow of

““AIR BAG” Warning

Light Does Not Come

ON”. After carrying out it

flow, proceed to Step 6.

5DTC check

1) Check DTC using SUZUKI scan tool referring to “DTC

Check”.

Is “NO CODES” displayed on SUZUKI scan tool?Air bag system is in

good condition.Check intermittent

troubles referring to

“Inspection of

Intermittent and Poor

Connections”.

If intermittent troubles

are OK, check and

repair applicable DTC

flow and then repeat

this flow.

6DTC check

1) Check DTC using SUZUKI scan tool, referring to “DTC

Check”.

Is “NO CODES” displayed on SUZUKI scan tool?Substitute a known-

good SDM and recheck.Check and repair

applicable DTC flow,

and then repeat this

flow.