BCM SUZUKI SX4 2006 1.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 606 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-1 ABS:

Brakes

ABS

Precautions

Precautions in Diagnosing TroublesS6RW0D4500001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow “ABS

Check”.

• Diagnostic information stored in ABS control module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before using scan tool, read its

Operator's (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicle was operated in any of the following

ways, ABS warning light may light momentarily but

this does not indicate anything abnormal in ABS.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked

up.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” and “Precaution for CAN

Communication System in Section 00” before

inspection and observe what is written there.

• Be sure to use the trouble diagnosis procedure as

described in “ABS Check”. Failure to follow it may

result in incorrect diagnosis. (Some other diagnosis

trouble code may be stored by mistake in the memory

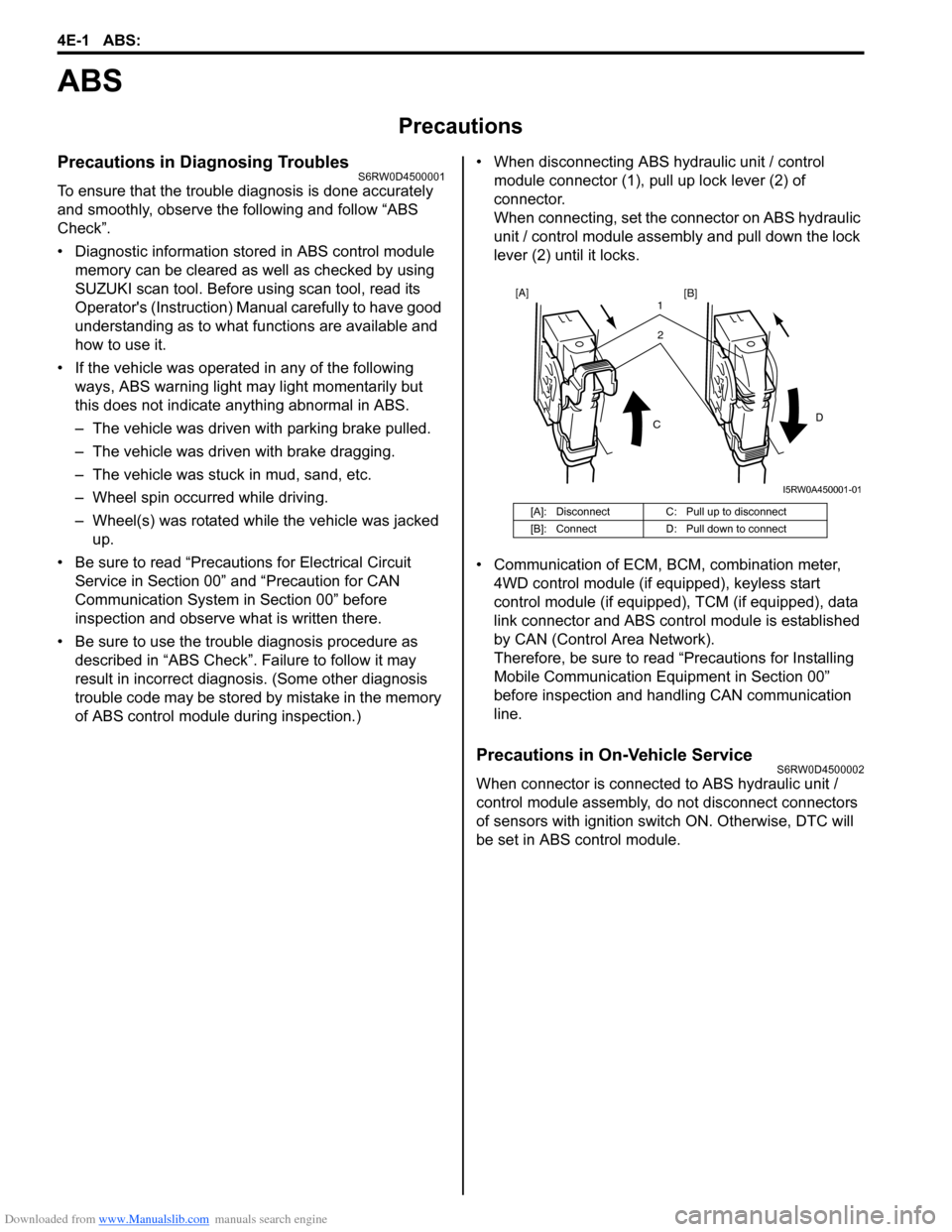

of ABS control module during inspection.)• When disconnecting ABS hydraulic unit / control

module connector (1), pull up lock lever (2) of

connector.

When connecting, set the connector on ABS hydraulic

unit / control module assembly and pull down the lock

lever (2) until it locks.

• Communication of ECM, BCM, combination meter,

4WD control module (if equipped), keyless start

control module (if equipped), TCM (if equipped), data

link connector and ABS control module is established

by CAN (Control Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handling CAN communication

line.

Precautions in On-Vehicle ServiceS6RW0D4500002

When connector is connected to ABS hydraulic unit /

control module assembly, do not disconnect connectors

of sensors with ignition switch ON. Otherwise, DTC will

be set in ABS control module.

[A]: Disconnect C: Pull up to disconnect

[B]: Connect D: Pull down to connect

2 1

CD

[A]

[B]

I5RW0A450001-01

Page 611 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-6

17+BB

18BLU

WHT12VGRN/ORN 34

30E08-9

RED

WHT 1226

WHT/RED

12V

E08-7

19GRN

GRN

E08-16

12V

5

76

21REDRED/BLK

12V

BLKWHTE08-22 E08-11

23BLKWHTLT GRN/BLKLT GRN

12V

E08-10 E08-21

E08-23

E08-26

E08-1E08-12

24BLKWHT

12V

YELBRNE08-19 E08-20

27

1 2

RED/BLK

WHTRED

WHTRED

WHTRED9

E08-2E08-13WHT

E08-6

RED

9

9

11

9

9

9

REDWHT

WHTRED

12VE08-25

M

BLK

BLK

WHT/BLUWHT/RED

WHT/BLUE08-24

WHT

E08 [A]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

GRN/WHT

22

12V

BLKWHTWHTWHT/BLKE08-17 E08-18

GRN/ORN28

2033

31

29

25

15

32

GRN/YELE08-3GRN/BLK

8

12V

12V

13

14RED/BLK

RED/BLU

WHTRED6

16

10

BLK [B]

I6RW0D450001-02

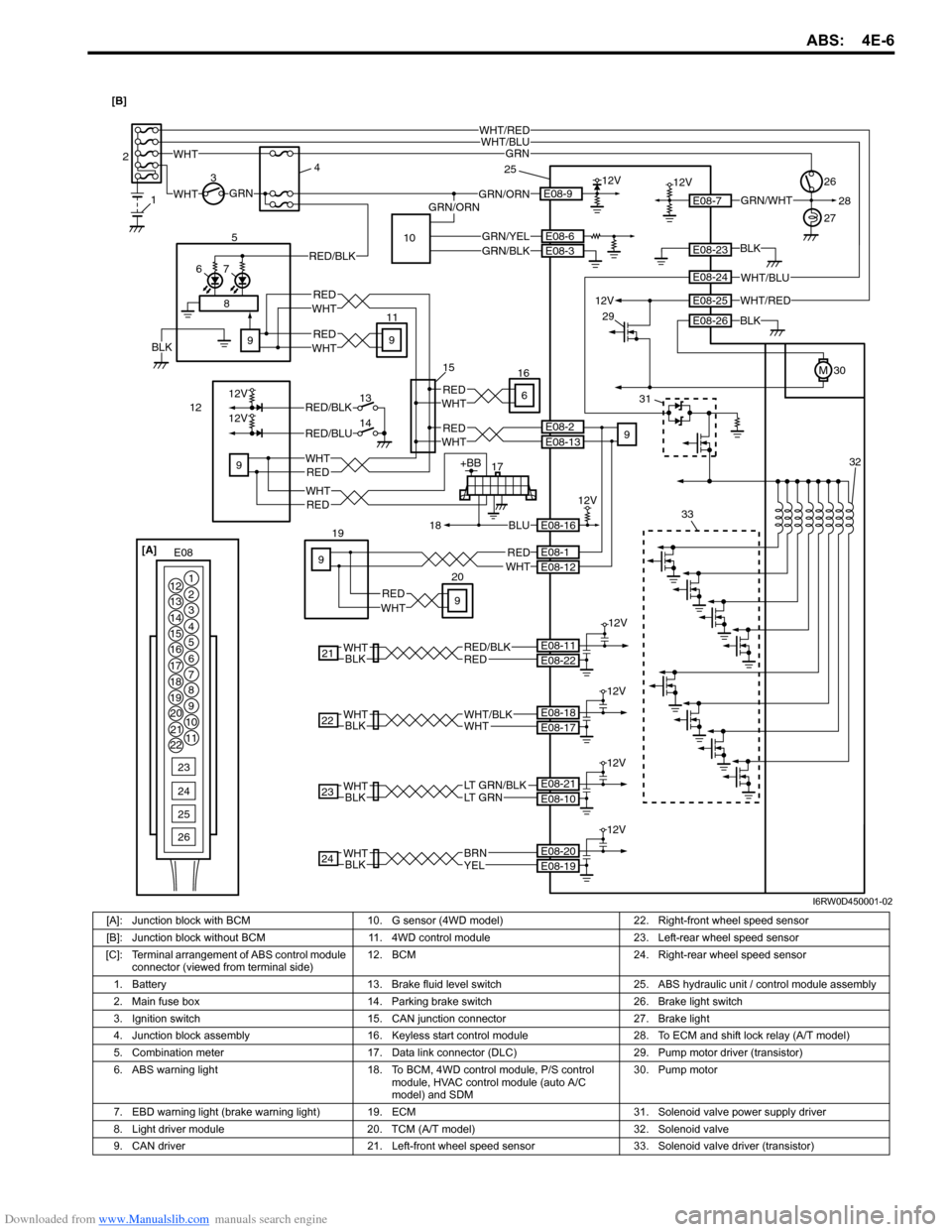

[A]: Junction block with BCM 10. G sensor (4WD model) 22. Right-front wheel speed sensor

[B]: Junction block without BCM 11. 4WD control module 23. Left-rear wheel speed sensor

[C]: Terminal arrangement of ABS control module

connector (viewed from terminal side)12. BCM 24. Right-rear wheel speed sensor

1. Battery 13. Brake fluid level switch 25. ABS hydraulic unit / control module assembly

2. Main fuse box 14. Parking brake switch 26. Brake light switch

3. Ignition switch 15. CAN junction connector 27. Brake light

4. Junction block assembly 16. Keyless start control module 28. To ECM and shift lock relay (A/T model)

5. Combination meter 17. Data link connector (DLC) 29. Pump motor driver (transistor)

6. ABS warning light 18. To BCM, 4WD control module, P/S control

module, HVAC control module (auto A/C

model) and SDM30. Pump motor

7. EBD warning light (brake warning light)19. ECM 31. Solenoid valve power supply driver

8. Light driver module 20. TCM (A/T model) 32. Solenoid valve

9. CAN driver 21. Left-front wheel speed sensor 33. Solenoid valve driver (transistor)

Page 612 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-7 ABS:

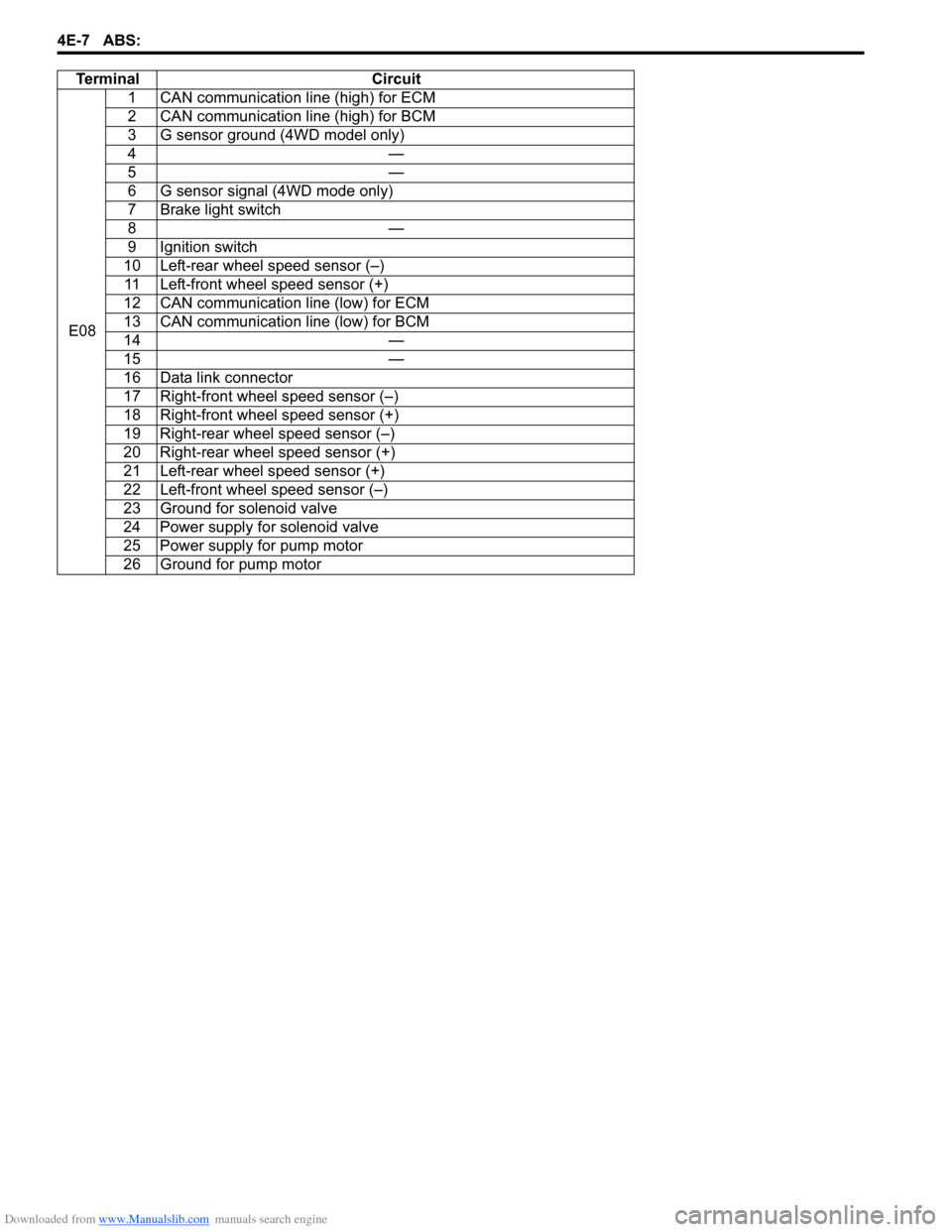

Te r m i n a l C i r c u i t

E081 CAN communication line (high) for ECM

2 CAN communication line (high) for BCM

3 G sensor ground (4WD model only)

4—

5—

6 G sensor signal (4WD mode only)

7 Brake light switch

8—

9 Ignition switch

10 Left-rear wheel speed sensor (–)

11 Left-front wheel speed sensor (+)

12 CAN communication line (low) for ECM

13 CAN communication line (low) for BCM

14 —

15 —

16 Data link connector

17 Right-front wheel speed sensor (–)

18 Right-front wheel speed sensor (+)

19 Right-rear wheel speed sensor (–)

20 Right-rear wheel speed sensor (+)

21 Left-rear wheel speed sensor (+)

22 Left-front wheel speed sensor (–)

23 Ground for solenoid valve

24 Power supply for solenoid valve

25 Power supply for pump motor

26 Ground for pump motor

Page 619 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-14

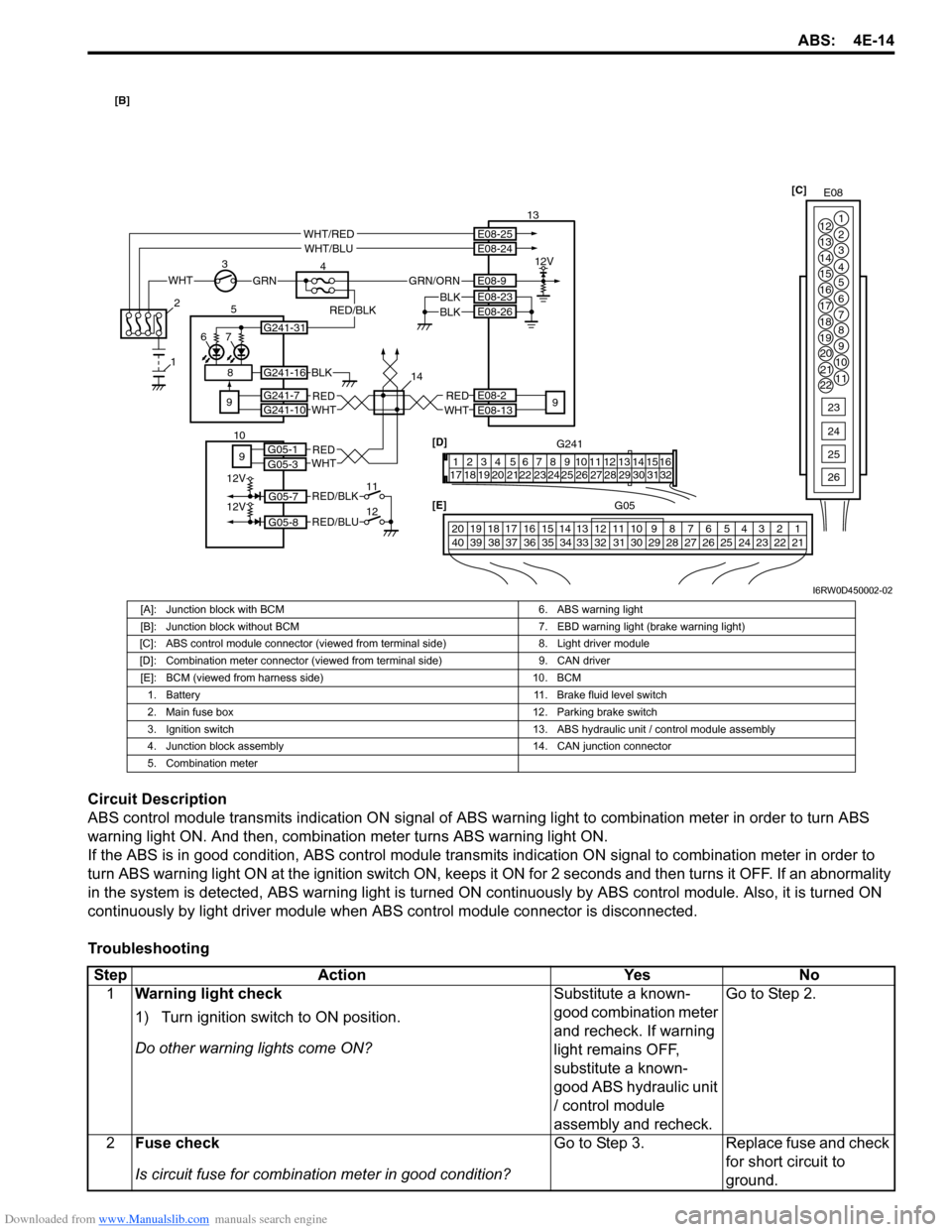

Circuit Description

ABS control module transmits indication ON signal of ABS warning light to combination meter in order to turn ABS

warning light ON. And then, combination meter turns ABS warning light ON.

If the ABS is in good condition, ABS control module transmits indication ON signal to combination meter in order to

turn ABS warning light ON at the ignition switch ON, keeps it ON for 2 seconds and then turns it OFF. If an abnormality

in the system is detected, ABS warning light is turned ON continuously by ABS control module. Also, it is turned ON

continuously by light driver module when ABS control module connector is disconnected.

Troubleshooting

G241 [D]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32E08 [C]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

G05 [E]

1 2 3 4 765 8 9 10 11 14 15 16

36 34 33 32 3135 24 23 2122 28 27 2526 37 39 38 4018 17 13 12 19 20

30 29

WHTGRN

3

E08-2

E08-13REDWHT 5

4 13

9

E08-23

E08-26BLKBLK

67

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

2

1

14

G241-31

RED/BLK

8

REDWHT9

12V

12V

11

12G05-7

G05-1G05-3

G05-8

RED/BLK

RED/BLU

10

[B]

I6RW0D450002-02

[A]: Junction block with BCM 6. ABS warning light

[B]: Junction block without BCM 7. EBD warning light (brake warning light)

[C]: ABS control module connector (viewed from terminal side) 8. Light driver module

[D]: Combination meter connector (viewed from terminal side) 9. CAN driver

[E]: BCM (viewed from harness side) 10. BCM

1. Battery 11. Brake fluid level switch

2. Main fuse box 12. Parking brake switch

3. Ignition switch 13. ABS hydraulic unit / control module assembly

4. Junction block assembly 14. CAN junction connector

5. Combination meter

Step Action Yes No

1Warning light check

1) Turn ignition switch to ON position.

Do other warning lights come ON?Substitute a known-

good combination meter

and recheck. If warning

light remains OFF,

substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Go to Step 2.

2Fuse check

Is circuit fuse for combination meter in good condition?Go to Step 3. Replace fuse and check

for short circuit to

ground.

Page 621 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-16

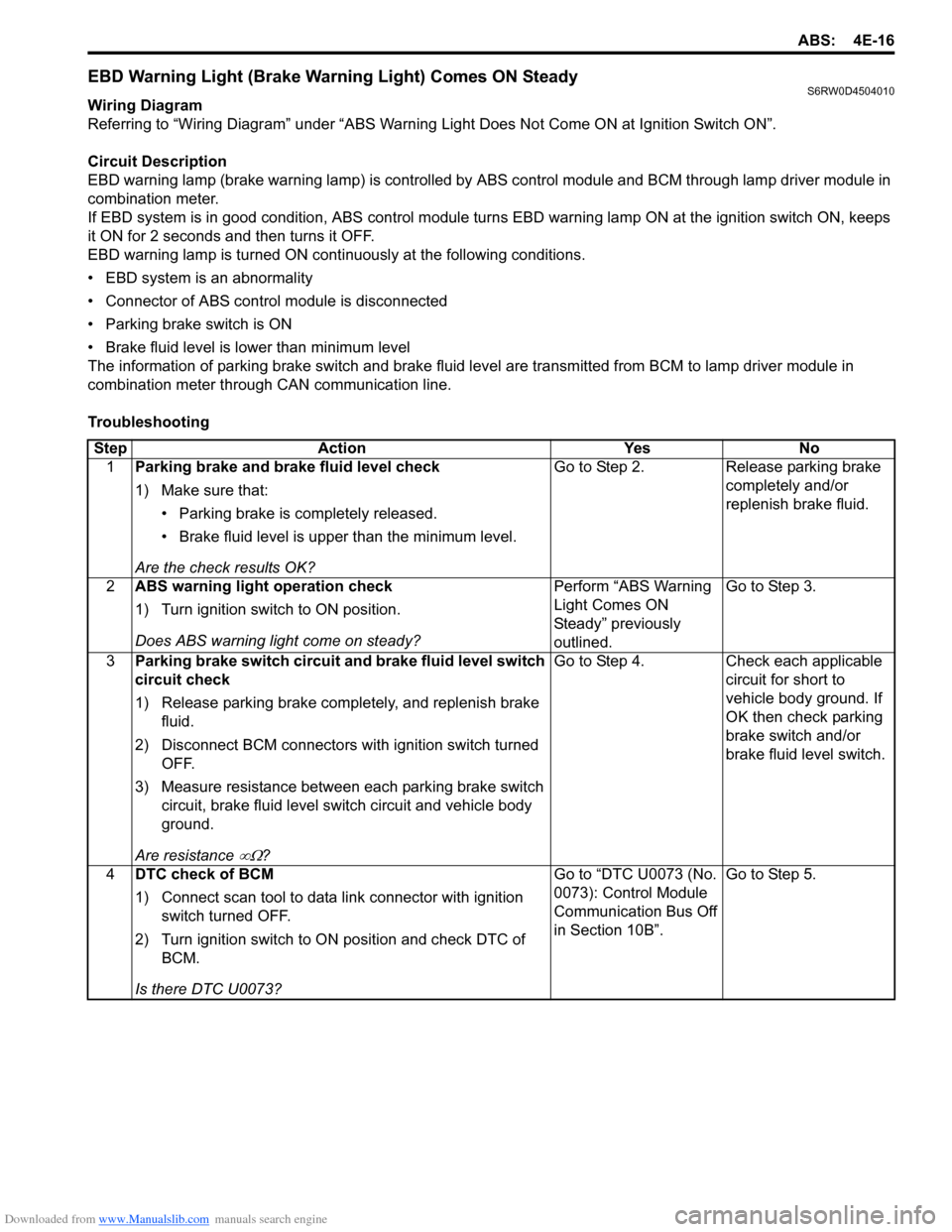

EBD Warning Light (Brake Warning Light) Comes ON SteadyS6RW0D4504010

Wiring Diagram

Referring to “Wiring Diagram” under “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

EBD warning lamp (brake warning lamp) is controlled by ABS control module and BCM through lamp driver module in

combination meter.

If EBD system is in good condition, ABS control module turns EBD warning lamp ON at the ignition switch ON, keeps

it ON for 2 seconds and then turns it OFF.

EBD warning lamp is turned ON continuously at the following conditions.

• EBD system is an abnormality

• Connector of ABS control module is disconnected

• Parking brake switch is ON

• Brake fluid level is lower than minimum level

The information of parking brake switch and brake fluid level are transmitted from BCM to lamp driver module in

combination meter through CAN communication line.

Troubleshooting

Step Action Yes No

1Parking brake and brake fluid level check

1) Make sure that:

• Parking brake is completely released.

• Brake fluid level is upper than the minimum level.

Are the check results OK?Go to Step 2. Release parking brake

completely and/or

replenish brake fluid.

2ABS warning light operation check

1) Turn ignition switch to ON position.

Does ABS warning light come on steady?Perform “ABS Warning

Light Comes ON

Steady” previously

outlined.Go to Step 3.

3Parking brake switch circuit and brake fluid level switch

circuit check

1) Release parking brake completely, and replenish brake

fluid.

2) Disconnect BCM connectors with ignition switch turned

OFF.

3) Measure resistance between each parking brake switch

circuit, brake fluid level switch circuit and vehicle body

ground.

Are resistance

∞Ω?Go to Step 4. Check each applicable

circuit for short to

vehicle body ground. If

OK then check parking

brake switch and/or

brake fluid level switch.

4DTC check of BCM

1) Connect scan tool to data link connector with ignition

switch turned OFF.

2) Turn ignition switch to ON position and check DTC of

BCM.

Is there DTC U0073?Go to “DTC U0073 (No.

0073): Control Module

Communication Bus Off

in Section 10B”.Go to Step 5.

Page 622 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-17 ABS:

Serial Data Link Circuit CheckS6RW0D4504011

Wiring Diagram5CAN communication line circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check for proper connection to CAN communication line

wire.

4) If OK then check CAN communication line circuit

between control modules for open, short and high

resistance.

Is each CAN communication line circuit in good condition?Substitute a known-

good combination meter

and recheck. If EBD

warning light remains

OFF, substitute a

known-good BCM and/

or ABS hydraulic unit /

control module

assembly and recheck.Repair CAN

communication line

circuit. Step Action Yes No

11+BBBG

G1

12V

14BLU

REDWHTE08 [C]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26WHTGRN

3

E08-2

E08-13REDWHT 5

4 12

9

E08-23BLK

67

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

2

1

13

G241-31

RED/BLK

8

REDWHTREDWHT

9

10

E08-16 G04-4

G04-2

G04-1

G04-3 E04-1

E04-2

[D]

1 2 3 4 5 6 7 8 9 10 11

12 13 14 15 16 17

18 19 20 21 22G041 2 3 4 5 6 7

8 9 10 11 12 13 14E04

G241 [E]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32 [A]

I6RW0D450008-01

Page 623 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-18

WHTGRN

3

E08-2

E08-13REDWHT 5

4 12

9

E08-23

E08-26BLKBLK

76

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

REDWHTG05-1G05-3

REDWHTG05-4G05-2

9

2

1

13

G241-31

RED/BLK

8

11+BBBG

G1

12V

E08-1614BLU 10

[C]E08

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

G05 [E]

1 2 3 4 765 8 9 10 11 14 15 16

36 34 33 32 3135 24 23 2122 28 27 2526 37 39 38 4018 17 13 12 19 20

30 29

G241 [D]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32 [B]

I6RW0D450003-02

[A]: Junction block with BCM 3. Ignition switch 10. BCM

[B]: Junction block without BCM 4. Junction block assembly 11. Data link connector (DLC)

[C]: ABS control module connector (viewed from

terminal side)5. Combination meter 12. ABS hydraulic unit / control module assembly

[D]: BCM connector (viewed from harness side) 6.ABS warning light 13. CAN junction connector

[E]: Combination meter connector (viewed from

terminal side)7. EBD warning light (brake

warning light)14. To TCM (A/T model), BCM, 4WD control module, P/S control

module (electric P/S model), HVAC control module (auto A/C

model) and SDM

1. Battery 8. Light driver module

2. Main fuse box 9. CAN driver

Page 624 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-19 ABS:

Trouble shooting

Step Action Yes No

1Scan tool communication check

Can scan tool communicate with BCM?Go to Step 2. Go to Step 3.

2ABS hydraulic unit / control module assembly power

and ground circuit check

1) Check that ABS hydraulic unit / control module assembly

power supply circuit and ground circuit is in good

condition referring to “ABS Hydraulic Unit / Control

Module Assembly Power and Ground Circuit Check”.

Are check results OK?Go to Step 3. Repair ABS hydraulic

unit / control module

assembly power or

ground circuit.

3Data link connector power source circuit check

1) Disconnect scan tool from data link connector.

2) Check for proper connection to scan tool.

3) If OK then turn ignition switch to ON position, and

measure voltage between terminal B of data link

connector and vehicle body ground.

Is voltage 10 – 12 V?Go to Step 4. Terminal B circuit open

or shorted to ground.

4Data link connector ground circuit check

1) Turn ignition switch to OFF position, and measure

resistance between the following terminals:

• Terminal G of data link connector and vehicle body

ground.

• Terminal G1 of data link connector and vehicle body

ground.

Are resistance less than 2

Ω?Go to Step 5. Terminal G and/or G1

wire circuit open or high

resistance.

5Serial communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by serial data circuit.

3) Check proper connection at serial data circuit terminals.

4) If OK, then check for high resistance, open or short to

power circuit or ground in serial data circuit.

Is check result in good condition?Go to Step 6. Repair serial data circuit

and recheck.

6CAN communication line circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check for proper connection to CAN communication line

wire.

3) If OK then check CAN communication line circuit

between control modules for open, short and high

resistance.

Is each CAN communication line circuit in good condition?Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Repair CAN

communication line

circuit and recheck.

Page 649 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-1

Transmission / Transaxle

Automatic Transmission/Transaxle

Precautions

Precautions in Diagnosing TroubleS6RW0D5100001

• Do not disconnect couplers from TCM, battery cable

from battery, TCM ground wire harness from engine or

main fuse before checking the diagnostic information

(DTC, freeze frame data, etc.) stored in TCM memory.

Such disconnection will clear memorized information

in TCM memory.

• Diagnostic information stored in TCM memory can be

cleared as well as checked by using SUZUKI scan

tool or CAN communication OBD generic scan tool.

Before using scan tool, read its Operator’s

(Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

It is indistinguishable which module turns on MIL

because not only ECM but also TCM turns on MIL.

Therefore, check both ECM and TCM for DTC when

MIL lights on.

When checking TCM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by TCM.

– CAN communication OBD generic scan tool

displays DTC detected by each of ECM and TCM

simultaneously.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection and observe

what is written there.

• TCM replacement

– When substituting a known-good TCM, check that

all relays and actuators have resistance of

specified value.

Neglecting this check may result in damage to good

TCM.

• Communication of ECM, BCM, combination meter,

keyless start control module (if equipped), ABS

control module, 4WD control module (if equipped),

TCM and DLC, is established by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

Precautions for Disassembly and ReassemblyS6RW0D5100002

When repairing automatic transaxle, it is necessary to

conduct the on-vehicle test to investigate where the

cause of the trouble lies first.

Then whether overhaul should be done or not is

determined. If the transaxle is disassembled without

such preliminary procedure, not only the cause of the

trouble would be unknown, but also a secondary trouble

may occur and often time would be wasted.

As the automatic transaxle consists of high precision

component, the following cautions should be strictly

observed when handling its parts in disassembly and

reassembly.

• Disassembling valve body assembly is prohibited

essentially. However, a few parts can be

disassembled. When disassembling valve body

component parts, confirm whether their parts are

allowed to disassemble or not referring to “Valve Body

Assembly Disassembly and Reassembly”.

• When component part of forward clutch, direct clutch,

2nd brake and/or O/D and 2nd coast brake, namely

clutch disc, brake disc, retaining plate and/or

separator plate, have been replaced, all learned

contents, which have been stored in TCM memory by

executing learning control, should be initialized

referring to “Learning Control Initialization”.

• Make sure to wash dirt off from the transaxle so that

no such dirt will enter the transaxle during

dismounting and remounting.

• Select a clean place free from dust and dirt for

overhauling.

• Place a rubber mat on the work bench to protect parts

from damage.

• Work gloves or shop cloth should not be used. (Use a

nylon cloth or a paper towel.)

• When separating the case joint, do not pry with a

screwdriver or such but tap with a plastic hammer

lightly.

• Make sure to wash dirt off from the transaxle so that

no such dirt will enter the transaxle during

disassembly and reassembly.

• Wash the disassembled parts in ATF (Automatic

Transaxle Fluid) or kerosene (using care not to allow

ATF or kerosene to get on your face, etc.) and confirm

that each fluid passage is not clogged by blowing air

into it. But use kerosene to wash the discs, resin

washers and rubber parts.

• Replace each gasket, oil seal and O-ring with a new

one.

• Apply ATF to sliding or rotating parts before

reassembly.

Page 657 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-9

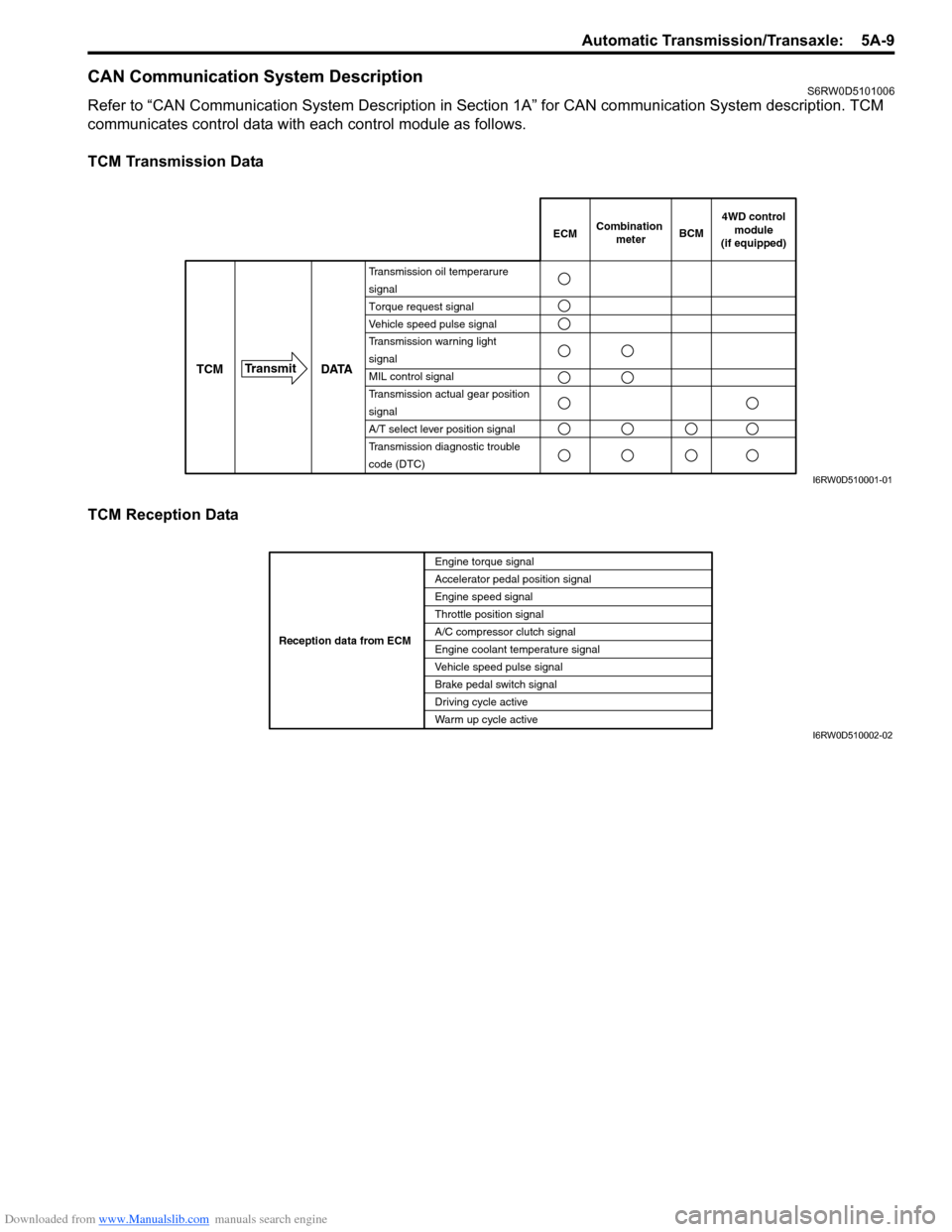

CAN Communication System DescriptionS6RW0D5101006

Refer to “CAN Communication System Description in Section 1A” for CAN communication System description. TCM

communicates control data with each control module as follows.

TCM Transmission Data

TCM Reception Data

DATA TCMTransmit

Transmission oil temperarure

signal

Torque request signal

Vehicle speed pulse signal

Transmission warning light

signal

MIL control signal

Transmission actual gear position

signal

A/T select lever position signal

Transmission diagnostic trouble

code (DTC)

ECMCombination

meterBCM

4WD control

module

(if equipped)

I6RW0D510001-01

Engine torque signal

Accelerator pedal position signal

Engine speed signal

Throttle position signal

A/C compressor clutch signal

Engine coolant temperature signal

Vehicle speed pulse signal

Brake pedal switch signal

Driving cycle active

Warm up cycle active Reception data from ECM

I6RW0D510002-02