BCM SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 895 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-15

3Communication check

1) Check DLC terminal for deformation and wear.

2) If it is in good condition, connect SUZUKI scan tool to

DLC with ignition switch tuned OFF.

3) Check if communication is possible by making

communication with other control modules (BCM, ABS,

HVAC control module or SDM).

Is it possible to communicate with the other control

modules?Go to Step 4. Go to Step 6.

4Serial communication circuit check

1) With ignition switch turned OFF, disconnect “E11”

connector from P/S control module and check for proper

connection at P/S control module connector terminal.

2) If connections are OK, check that “Serial data circuit” is

as follows.

• Wiring resistance of “Serial data circuit” wire between

DLC connector and P/S control module connector is

less than 1 Ω.

Is it resistance less than 1

Ω?Go to Step 5. “Serial data circuit” is

open or high resistance.

5P/S control module power and ground circuit check

1) Check power supply circuit and ground circuit for P/S

control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition?Substitute a known-

good P/S control

module and recheck.Repair or replace

defective circuit.

6DLC power and ground circuit check

1) Check power supply circuit and ground circuit for DLC

connector as follows.

• Voltage of “DLC connector power supply circuit”

between DLC connector terminal and vehicle body

ground is 10 –14 V with ignition switch turned ON.

• Wire resistance of each “DLC connector ground

circuit” between DLC connector terminal and vehicle

body ground is less than 1 Ω.

Is check result in good condition?Go to Step 7. Repair or replace

defective circuit.

7Serial communication circuit check

1) With ignition switch turned OFF, disconnect “E11”

connector from P/S control module and check for

terminal to P/S control module connector.

2) If connections are OK, check that “Serial data circuit” is

as follows.

• Insulation resistance of “Serial data circuit” wire is

infinity between its terminal and other terminals at P/S

control module connector.

• Insulation resistance of “Serial data circuit” wire is

infinity between its terminal and vehicle body ground.

Is circuit in good condition?Go to Step 8. Repair or replace

defective circuit. Step Action Yes No

Page 902 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-22 Power Assisted Steering System:

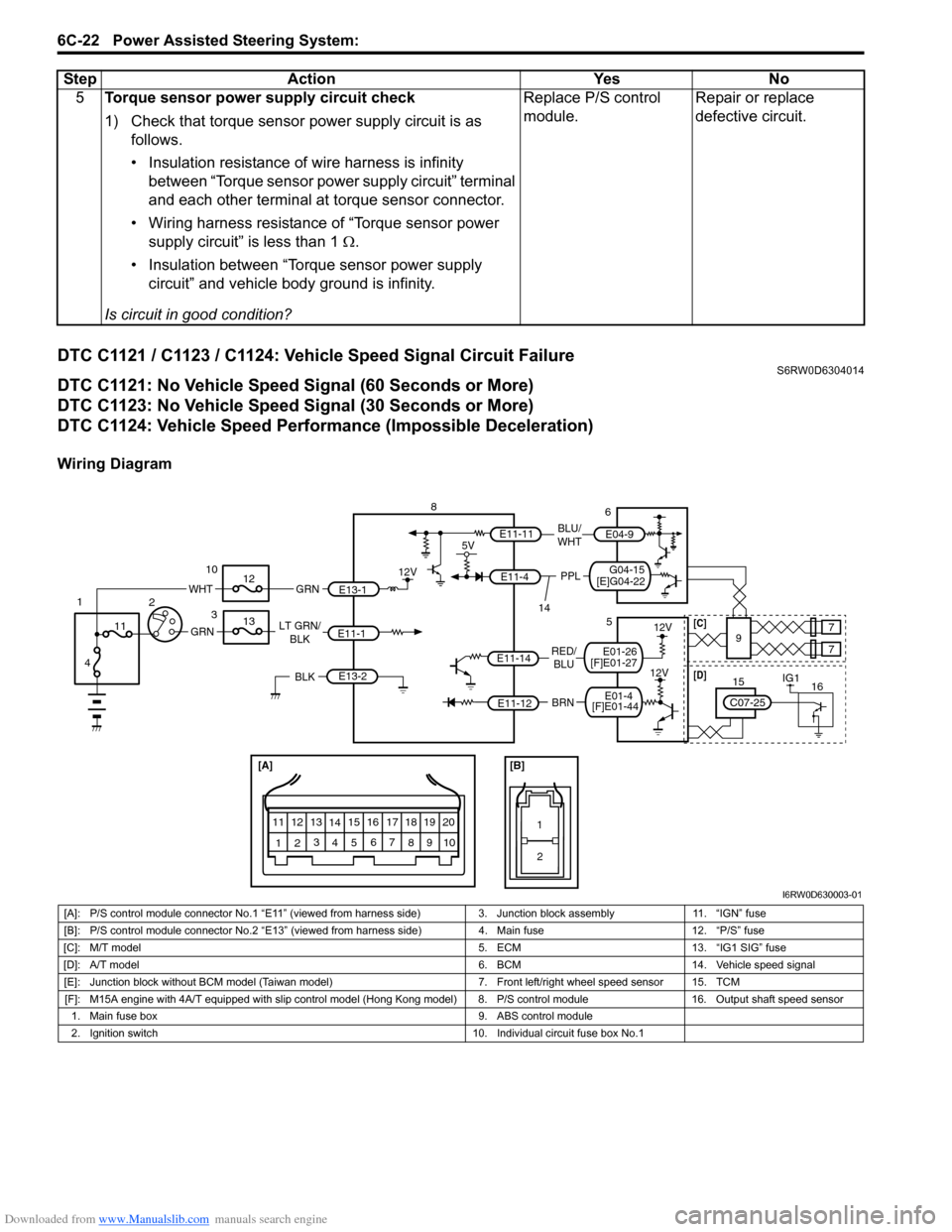

DTC C1121 / C1123 / C1124: Vehicle Speed Signal Circuit FailureS6RW0D6304014

DTC C1121: No Vehicle Speed Signal (60 Seconds or More)

DTC C1123: No Vehicle Speed Signal (30 Seconds or More)

DTC C1124: Vehicle Speed Performance (Impossible Deceleration)

Wiring Diagram5Torque sensor power supply circuit check

1) Check that torque sensor power supply circuit is as

follows.

• Insulation resistance of wire harness is infinity

between “Torque sensor power supply circuit” terminal

and each other terminal at torque sensor connector.

• Wiring harness resistance of “Torque sensor power

supply circuit” is less than 1 Ω.

• Insulation between “Torque sensor power supply

circuit” and vehicle body ground is infinity.

Is circuit in good condition?Replace P/S control

module.Repair or replace

defective circuit. Step Action Yes No

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

BRN RED/

BLU LT GRN/

BLK

E11-1

E11-14

E11-12

E13-1 GRN

GRN

WHT

8

3 10

12

13

11

4 1

2

12V

E13-2BLK

12V

12V

9 5

77

E11-11

G04-15

[E]G04-22

5V

PPL

E11-4

BLU/

WHTE04-9

6

14

IG11615

C07-25

[D][C]

[F]E01-44E01-4

[F]E01-27E01-26

I6RW0D630003-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 11. “IGN” fuse

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 12. “P/S” fuse

[C]: M/T model 5. ECM 13. “IG1 SIG” fuse

[D]: A/T model 6. BCM 14. Vehicle speed signal

[E]: Junction block without BCM model (Taiwan model) 7. Front left/right wheel speed sensor 15. TCM

[F]: M15A engine with 4A/T equipped with slip control model (Hong Kong model) 8. P/S control module 16. Output shaft speed sensor

1. Main fuse box 9. ABS control module

2. Ignition switch 10. Individual circuit fuse box No.1

Page 903 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-23

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

DTC C1121:

Vehicle speed signal is 0 km/h even though engine speed

is more than 4000 rpm for more than 60 seconds

continuously (before elapse of 5 min from engine start)

or

Vehicle speed signal is 0 km/h even though engine speed

is more than 2500 rpm for more than 60 seconds

continuously (after elapse of 5 min for engine start).

(1 driving cycle detection logic but “EPS” warning light

does not light up)

DTC C1123:

Vehicle speed signal is 0 km/h with continuously more

than 3 driving cycles even though engine speed is more

than 4000 rpm for more than 30 seconds continuously

(before elapse of 5 min from engine start)

or

Vehicle speed signal is 0 km/h with continuously more

than 3 driving cycles even though engine speed is more

than 2500 rpm for more than 30 seconds continuously

(after elapse of 5 min for engine start).

(3 driving cycle detection logic)

DTC C1124:

Vehicle speed signal is less than 5 km/h for more than 5

seconds continuously with more than specified

deceleration speed (–20 m/s

2) from over 20 km/h.

(1 driving cycle detection logic but “EPS” warning light

does not light up)• Vehicle speed signal circuit

•BCM

•ECM

• TCM (A/T model)

• ABS control module (M/T model)

• P/S control module

• CAN communication line circuit

Step Action Yes No

1Was “EPS System Check” performed?Go to Step 2. Go to “EPS System

Check”.

2DTC check

1) DTC check for ECM referring to “DTC Check in Section

1A”.

Is there any DTC detected?Go to applicable DTC

diag. flow.Go to Step 3.

3Vehicle spec check

Is vehicle equipped with A/T?Go to Step 4 Go to Step 5

4DTC check

1) Check TCM for DTC referring to “DTC Check in Section

5A”.

Is there any DTC detected?Go to applicable DTC

diag. flow.Go to Step 6.

5DTC check

1) Check ABS control module and BCM for DTC referring

to “DTC Check in Section 4E” and “DTC Check in

Section 10B”.

Is there any DTC detected?Go to applicable DTC

diag. flow.Go to Step 6.

Page 904 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-24 Power Assisted Steering System:

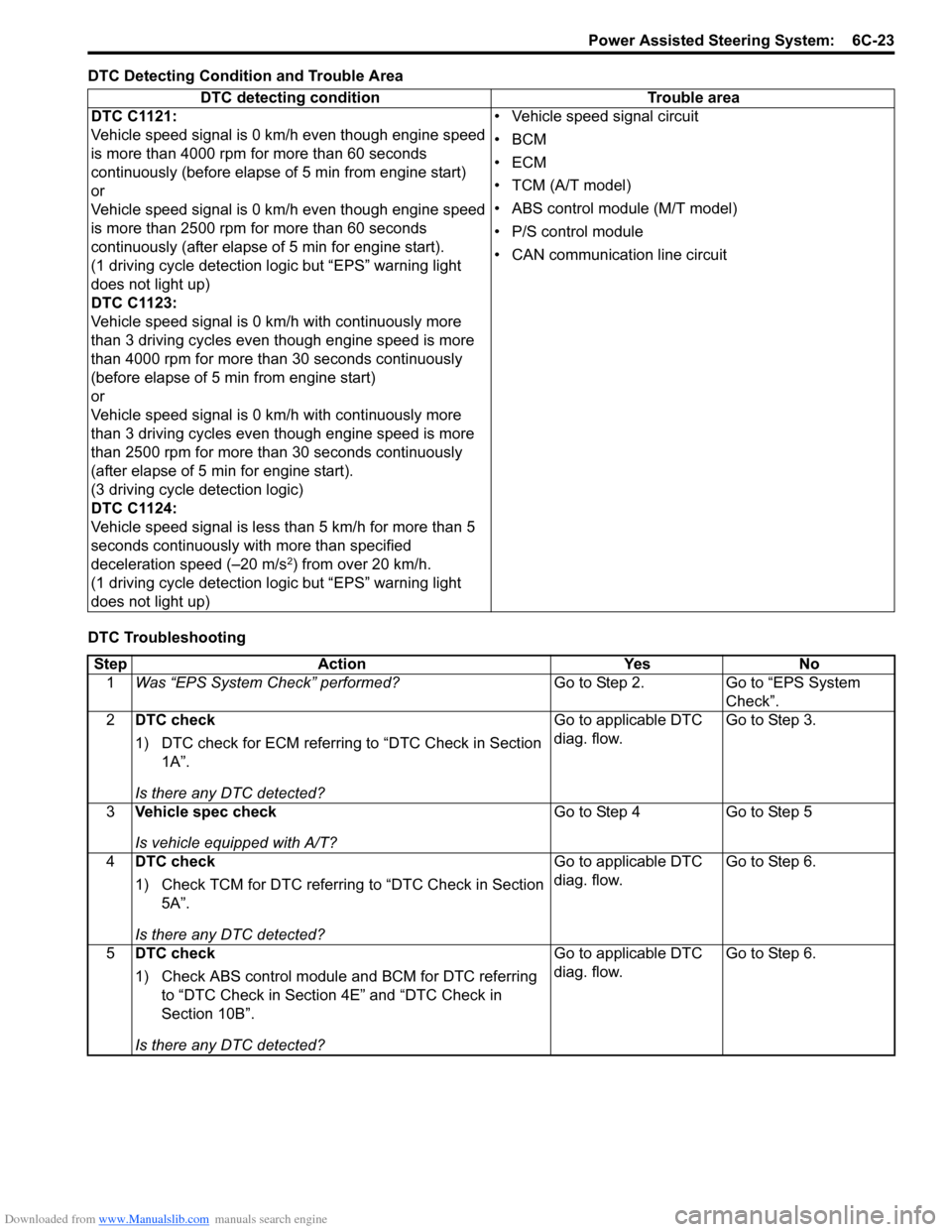

DTC C1122: Engine Speed SignalS6RW0D6304015

Wiring Diagram6Vehicle speed signal circuit check

1) With ignition switch turned OFF, disconnect connectors

from BCM.

2) Check BCM connector for proper connection.

3) If OK, turn ON ignition switch, measure voltage between

“G04-15” or “G04-22” wire terminal of BCM connector

and body ground.

Is voltage 4 – 5 V?Go to Step 7. Go to Step 8.

7BCM voltage check

1) With ignition switch turned OFF, connect BCM

connector.

2) Check BCM for vehicle speed signal output referring to

“Inspection of P/S Control Module and Its Circuits”.

Is it in good condition?Replace P/S control

module.Replace BCM.

8Vehicle speed signal circuit check

1) Check that vehicle speed signal circuit is as follows.

• Insulation resistance of wire harness is infinity

between “Vehicle speed signal” terminal and other

terminal at P/S control module connector.

• Wiring harness resistance of “Vehicle speed signal”

circuit is less than 1Ω.

• Insulation resistance between “Vehicle speed signal”

circuit and vehicle body ground is infinity.

• Circuit voltage between “Vehicle speed signal” circuit

and ground circuit is 0 – 1 V with ignition switch turned

ON.

Is it in good condition?Replace P/S control

module.Repair or replace

defective circuit. Step Action Yes No

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

BRN LT GRN/

BLK

E11-1

E11-12

E13-1 GRN

GRN

WHT

6

37

9

10

8

4 12

12V

E13-2BLK12V5

11

[C]E01-44E01-4

I6RW0D630004-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 8. “IGN” fuse

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 9. “P/S” fuse

[C]: M15A engine with 4A/T equipped with slip control model (Hong Kong model) 5. ECM 10. “IG1 SIG” fuse

1. Main fuse box 6. P/S control module 11. Engine speed signal circuit

2. Ignition switch 7. Individual circuit fuse box No.1

Page 911 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-31

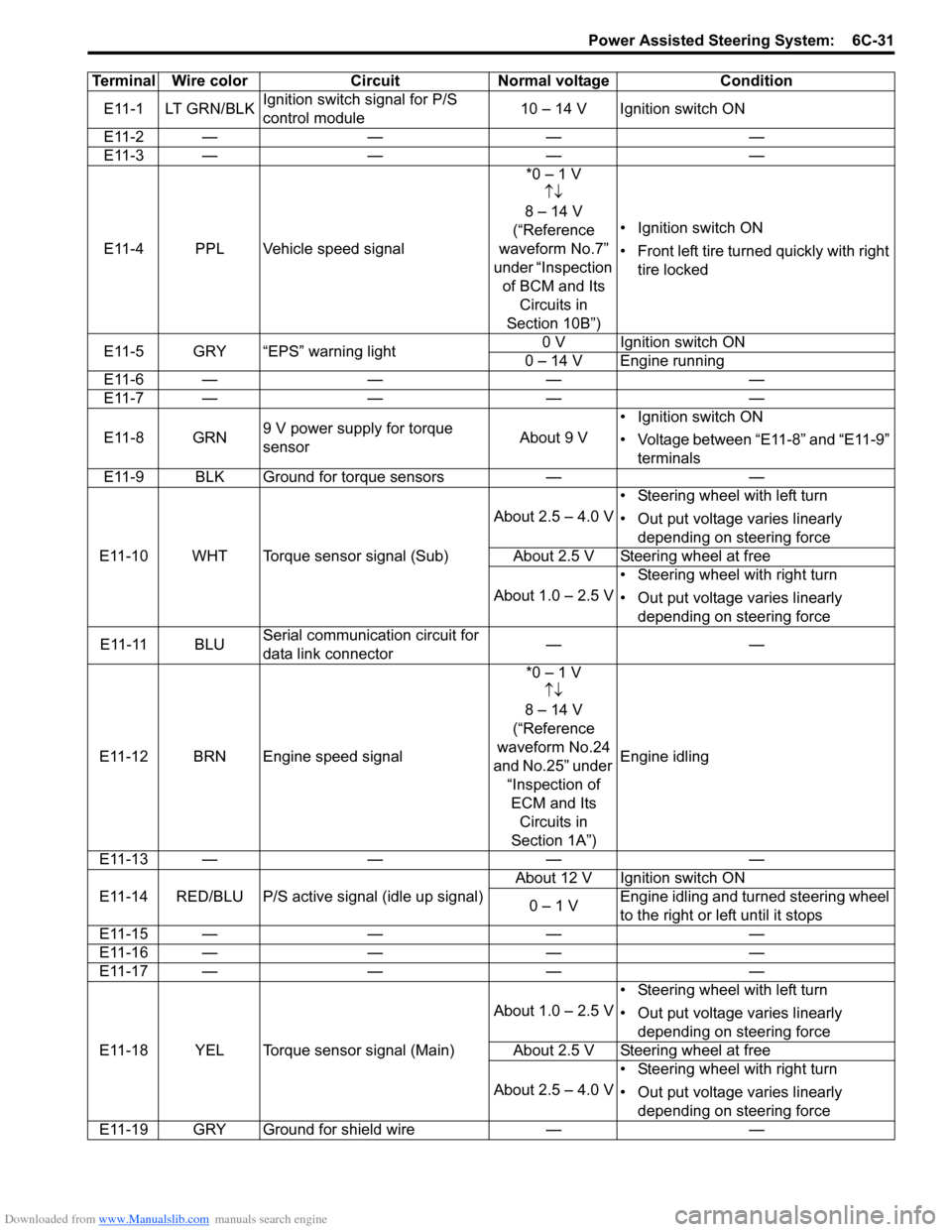

Terminal Wire color Circuit Normal voltage Condition

E11-1 LT GRN/BLKIgnition switch signal for P/S

control module10 – 14 V Ignition switch ON

E11-2 — — — —

E11-3 — — — —

E11-4 PPL Vehicle speed signal*0 – 1 V

↑↓

8 – 14 V

(“Reference

waveform No.7”

under “Inspection

of BCM and Its

Circuits in

Section 10B”)• Ignition switch ON

• Front left tire turned quickly with right

tire locked

E11-5 GRY “EPS” warning light0 V Ignition switch ON

0 – 14 V Engine running

E11-6 — — — —

E11-7 — — — —

E11-8 GRN9 V power supply for torque

sensorAbout 9 V• Ignition switch ON

• Voltage between “E11-8” and “E11-9”

terminals

E11-9 BLK Ground for torque sensors — —

E11-10 WHT Torque sensor signal (Sub)About 2.5 – 4.0 V• Steering wheel with left turn

• Out put voltage varies linearly

depending on steering force

About 2.5 V Steering wheel at free

About 1.0 – 2.5 V• Steering wheel with right turn

• Out put voltage varies linearly

depending on steering force

E11-11 BLUSerial communication circuit for

data link connector——

E11-12 BRN Engine speed signal*0 – 1 V

↑↓

8 – 14 V

(“Reference

waveform No.24

and No.25” under

“Inspection of

ECM and Its

Circuits in

Section 1A”)Engine idling

E11-13 — — — —

E11-14 RED/BLU P/S active signal (idle up signal)About 12 V Ignition switch ON

0 – 1 VEngine idling and turned steering wheel

to the right or left until it stops

E11-15 — — — —

E11-16 — — — —

E11-17 — — — —

E11-18 YEL Torque sensor signal (Main)About 1.0 – 2.5 V• Steering wheel with left turn

• Out put voltage varies linearly

depending on steering force

About 2.5 V Steering wheel at free

About 2.5 – 4.0 V• Steering wheel with right turn

• Out put voltage varies linearly

depending on steering force

E11-19 GRY Ground for shield wire — —

Page 930 of 1556

Downloaded from www.Manualslib.com manuals search engine 7A-2 Heater and Ventilation:

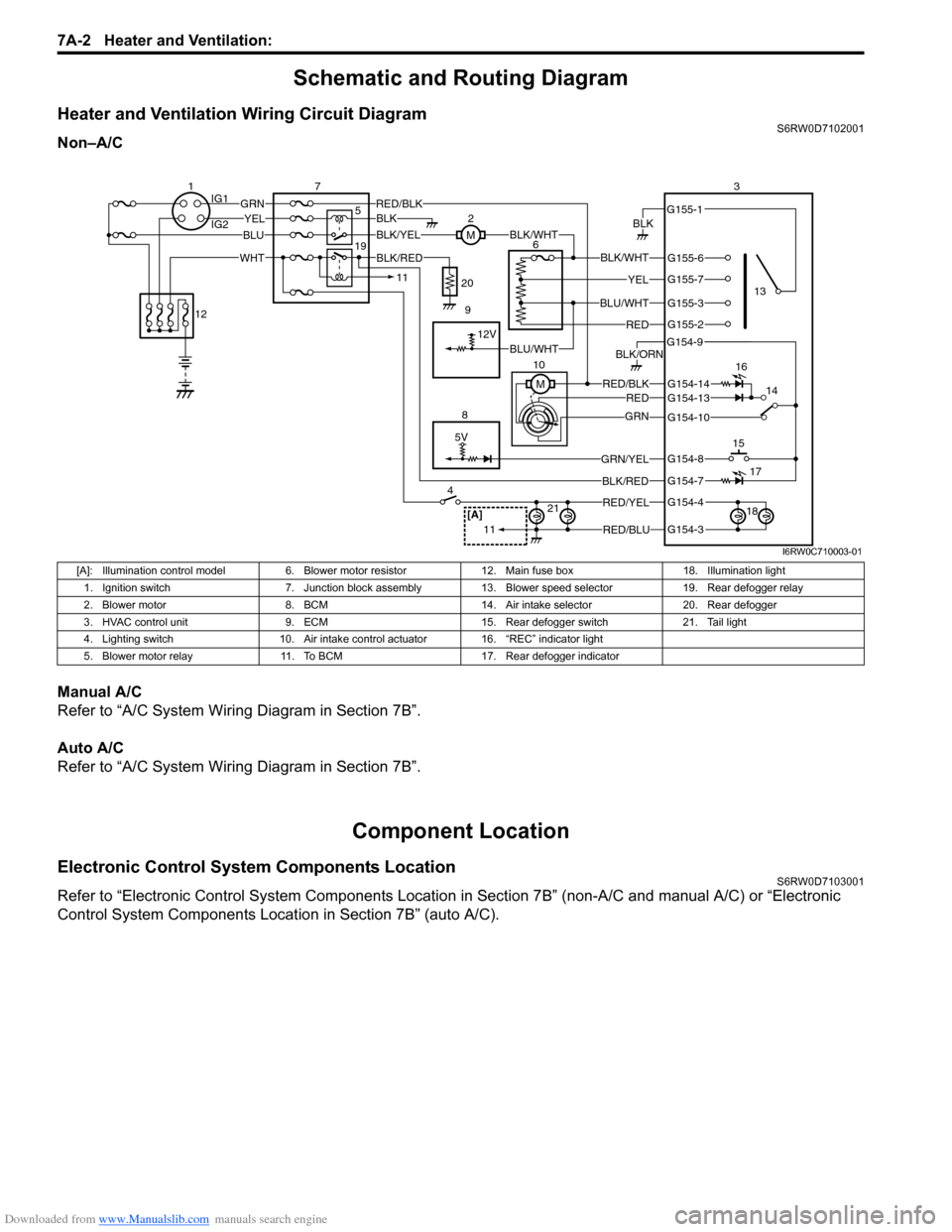

Schematic and Routing Diagram

Heater and Ventilation Wiring Circuit DiagramS6RW0D7102001

Non–A/C

Manual A/C

Refer to “A/C System Wiring Diagram in Section 7B”.

Auto A/C

Refer to “A/C System Wiring Diagram in Section 7B”.

Component Location

Electronic Control System Components LocationS6RW0D7103001

Refer to “Electronic Control System Components Location in Section 7B” (non-A/C and manual A/C) or “Electronic

Control System Components Location in Section 7B” (auto A/C).

5V

BLK

RED/BLK3

5 72

G154-3

G154-4

G154-7

G154-8

G154-10

G154-13

G155-2

G155-3

G155-7

G155-6

G155-1

G154-9

G154-14

BLK/WHT

YEL

BLU/WHT

RED

RED/BLKRED

GRN

GRN/YEL

RED/YEL

RED/BLU

BLK/ORN

46

8

BLU

YELGRN

WHT

13

1514

[A]21

BLK/RED

12V

BLK/YELBLK/WHTM

BLK

1IG1

IG2

12

BLK/RED

M 10

11

11

BLU/WHT 19

16

17

18 9 20

I6RW0C710003-01

[A]: Illumination control model 6. Blower motor resistor 12. Main fuse box 18. Illumination light

1. Ignition switch 7. Junction block assembly 13. Blower speed selector 19. Rear defogger relay

2. Blower motor 8. BCM 14. Air intake selector 20. Rear defogger

3. HVAC control unit 9. ECM 15. Rear defogger switch 21. Tail light

4. Lighting switch 10. Air intake control actuator 16. “REC” indicator light

5. Blower motor relay 11. To BCM 17. Rear defogger indicator

Page 943 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-3

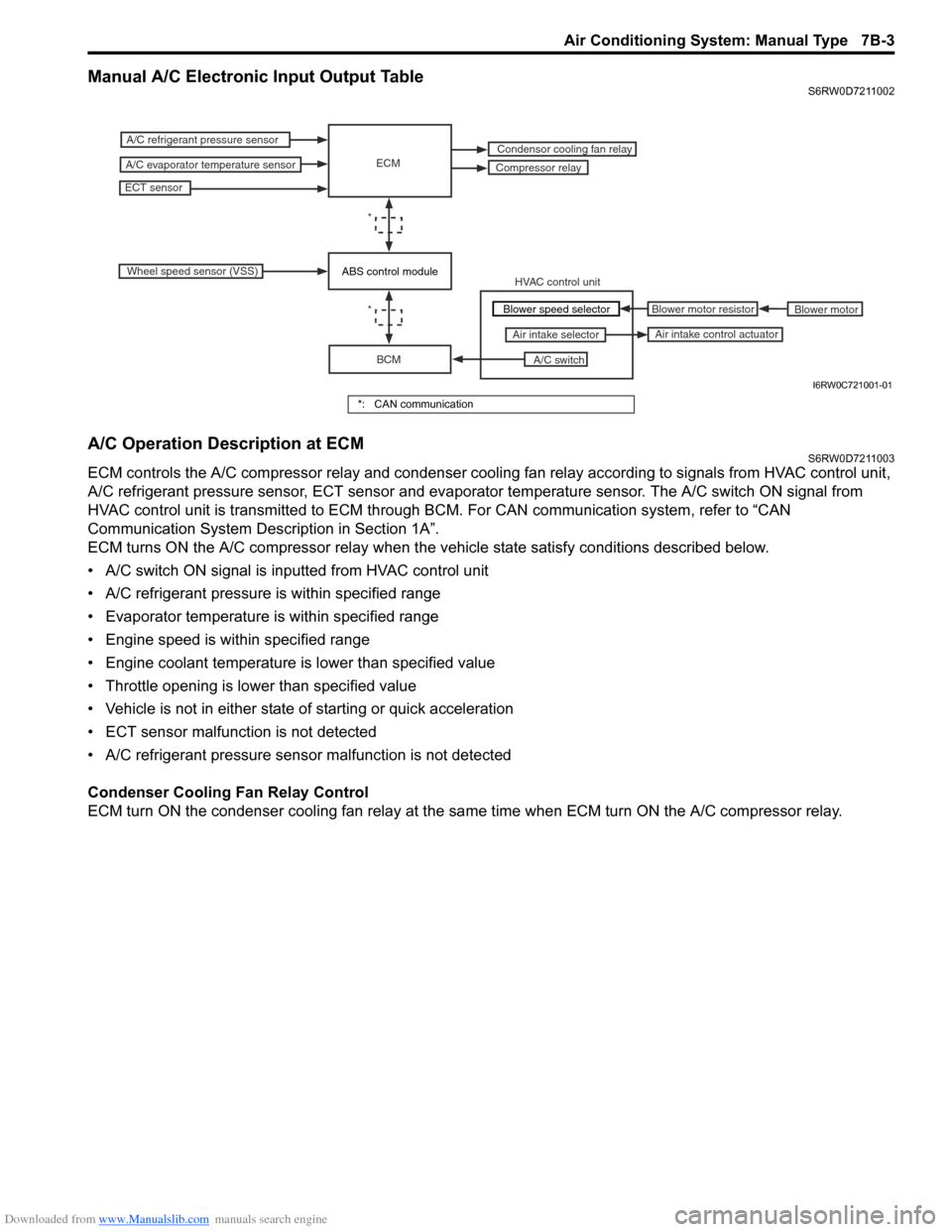

Manual A/C Electronic Input Output TableS6RW0D7211002

A/C Operation Description at ECMS6RW0D7211003

ECM controls the A/C compressor relay and condenser cooling fan relay according to signals from HVAC control unit,

A/C refrigerant pressure sensor, ECT sensor and evaporator temperature sensor. The A/C switch ON signal from

HVAC control unit is transmitted to ECM through BCM. For CAN communication system, refer to “CAN

Communication System Description in Section 1A”.

ECM turns ON the A/C compressor relay when the vehicle state satisfy conditions described below.

• A/C switch ON signal is inputted from HVAC control unit

• A/C refrigerant pressure is within specified range

• Evaporator temperature is within specified range

• Engine speed is within specified range

• Engine coolant temperature is lower than specified value

• Throttle opening is lower than specified value

• Vehicle is not in either state of starting or quick acceleration

• ECT sensor malfunction is not detected

• A/C refrigerant pressure sensor malfunction is not detected

Condenser Cooling Fan Relay Control

ECM turn ON the condenser cooling fan relay at the same time when ECM turn ON the A/C compressor relay.

ECM

BCM

A/C switch Air intake selector

A/C refrigerant pressure sensor

A/C evaporator temperature sensorCompressor relay

ECT sensor

Condensor cooling fan relay

*

Wheel speed sensor (VSS)

HVAC control unit

Blower motor Blower motor resistor

Air intake control actuator

*Blower speed selector

ABS control module

I6RW0C721001-01

*: CAN communication

Page 945 of 1556

![SUZUKI SX4 2006 1.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-5

A/C System Wiring DiagramS6RW0D7212002

[A]

7

WHT

GRN5YELBLK

3

G154-3

G154-4

G154-7

G154-8

G154-10

G15 SUZUKI SX4 2006 1.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-5

A/C System Wiring DiagramS6RW0D7212002

[A]

7

WHT

GRN5YELBLK

3

G154-3

G154-4

G154-7

G154-8

G154-10

G15](/img/20/7612/w960_7612-944.png)

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-5

A/C System Wiring DiagramS6RW0D7212002

[A]

7

WHT

GRN5YELBLK

3

G154-3

G154-4

G154-7

G154-8

G154-10

G154-13

G154-5

G154-6

G155-5

G155-2

G155-3

G155-7

G155-6

G155-1

G154-9

G154-14

BLK/WHT

YEL

BLU/WHT

RED

BRN

GRN/WHT

RED/BLK

RED

GRN

GRN/YEL

RED/YEL

RED/BLU

20

21

23 22

BLK/RED

6 2

MBLK/WHTBLK/YEL

M

11

4RED/YEL 1

E01-49

12

E01-16

GRY 13

12V

BLU/WHTE01-3510

E01-48

18

19RED/BLK

BLK/RED

BLK/RED

BRN/WHTE01-60

E01-1

E01-29BLK/WHT

M

BLU/YELBLK/YEL

5V5V 5V

WHT/BLK

9

ORN

14E01-36

C01-12C01-14GRY/REDRED/BLU

E01-41

RED/BLK

RED

WHT

8

BLK

BLK/ORN

BLU IG1

IG2

5V

17

28

29

31

2726 2524

16

16

30

34

33E01-4 E01-19WHTRED

C01-50C01-49WHTRED

32

LT GRN

C01-57

C01-2415

GRY/BLU5V

I6RW0C721002-01

[A]: Illumination control model 9. A/C refrigerant pressure

sensor18. Condenser cooling fan relay 27. Illumination light

1. Ignition switch 10. ECM 19. Condenser cooling fan motor 28. Rear defogger relay

2. Blower motor 11. Air intake control actuator 20. Blower speed selector 29. Rear defogger

3. HVAC control unit 12. Compressor relay 21. A/C switch 30. Main relay

4. Lighting switch 13. Compressor 22. Air intake selector 31. Tail light

5. Blower motor relay 14. Evaporator temperature

sensor23. Rear defogger switch 32. TCM

6. Blower motor resistor 15. ECT sensor 24. “A/C” indicator light 33. To other control module and DLC

7. Junction block assembly 16. To BCM 25. “REC” indicator light 34. ABS control module

8. BCM 17. Main fuse box 26. Rear defogger indicator

Page 953 of 1556

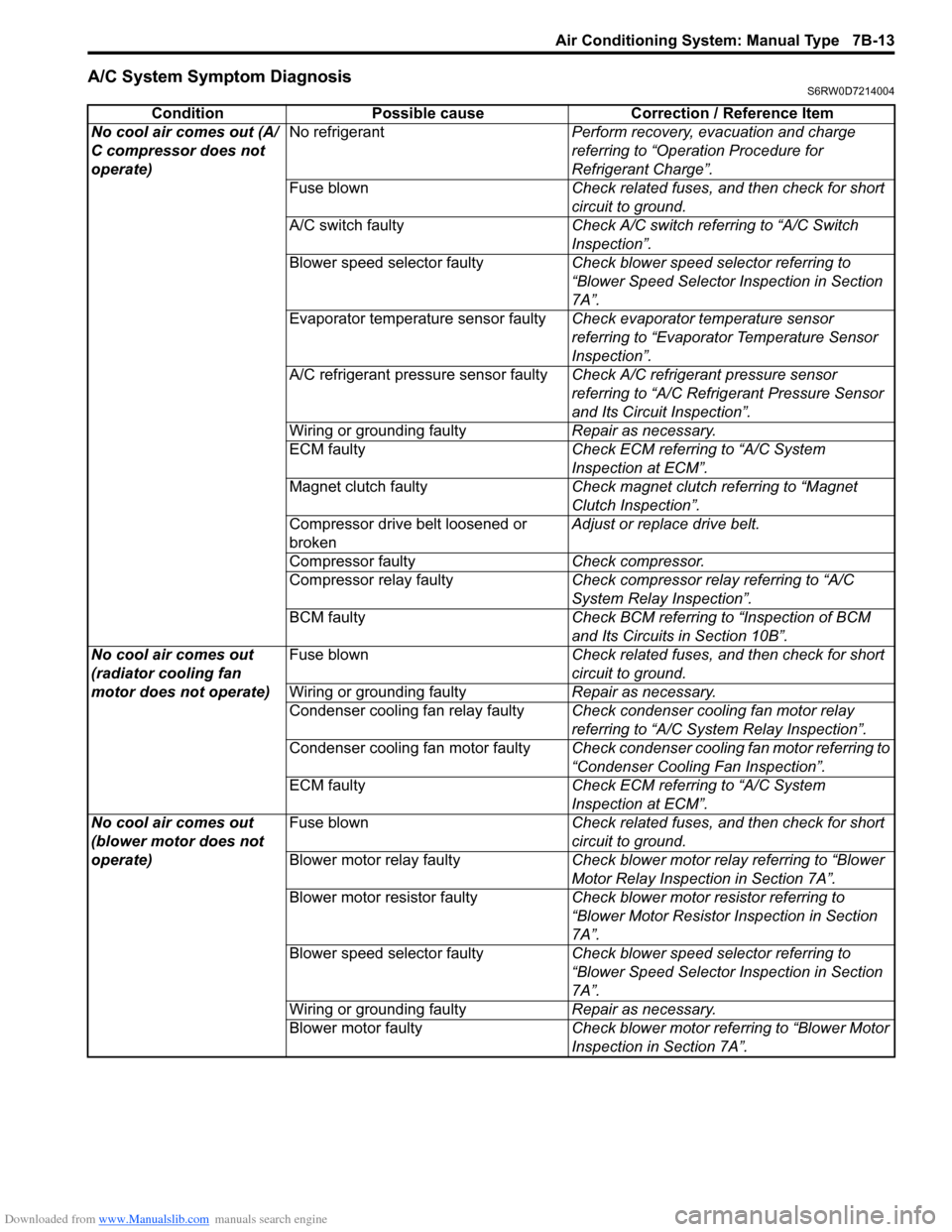

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-13

A/C System Symptom DiagnosisS6RW0D7214004

Condition Possible cause Correction / Reference Item

No cool air comes out (A/

C compressor does not

operate)No refrigerantPerform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blownCheck related fuses, and then check for short

circuit to ground.

A/C switch faultyCheck A/C switch referring to “A/C Switch

Inspection”.

Blower speed selector faultyCheck blower speed selector referring to

“Blower Speed Selector Inspection in Section

7A”.

Evaporator temperature sensor faultyCheck evaporator temperature sensor

referring to “Evaporator Temperature Sensor

Inspection”.

A/C refrigerant pressure sensor faultyCheck A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faultyRepair as necessary.

ECM faultyCheck ECM referring to “A/C System

Inspection at ECM”.

Magnet clutch faultyCheck magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

brokenAdjust or replace drive belt.

Compressor faultyCheck compressor.

Compressor relay faultyCheck compressor relay referring to “A/C

System Relay Inspection”.

BCM faultyCheck BCM referring to “Inspection of BCM

and Its Circuits in Section 10B”.

No cool air comes out

(radiator cooling fan

motor does not operate)Fuse blownCheck related fuses, and then check for short

circuit to ground.

Wiring or grounding faultyRepair as necessary.

Condenser cooling fan relay faultyCheck condenser cooling fan motor relay

referring to “A/C System Relay Inspection”.

Condenser cooling fan motor faultyCheck condenser cooling fan motor referring to

“Condenser Cooling Fan Inspection”.

ECM faultyCheck ECM referring to “A/C System

Inspection at ECM”.

No cool air comes out

(blower motor does not

operate)Fuse blownCheck related fuses, and then check for short

circuit to ground.

Blower motor relay faultyCheck blower motor relay referring to “Blower

Motor Relay Inspection in Section 7A”.

Blower motor resistor faultyCheck blower motor resistor referring to

“Blower Motor Resistor Inspection in Section

7A”.

Blower speed selector faultyCheck blower speed selector referring to

“Blower Speed Selector Inspection in Section

7A”.

Wiring or grounding faultyRepair as necessary.

Blower motor faultyCheck blower motor referring to “Blower Motor

Inspection in Section 7A”.

Page 979 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-39

General Description

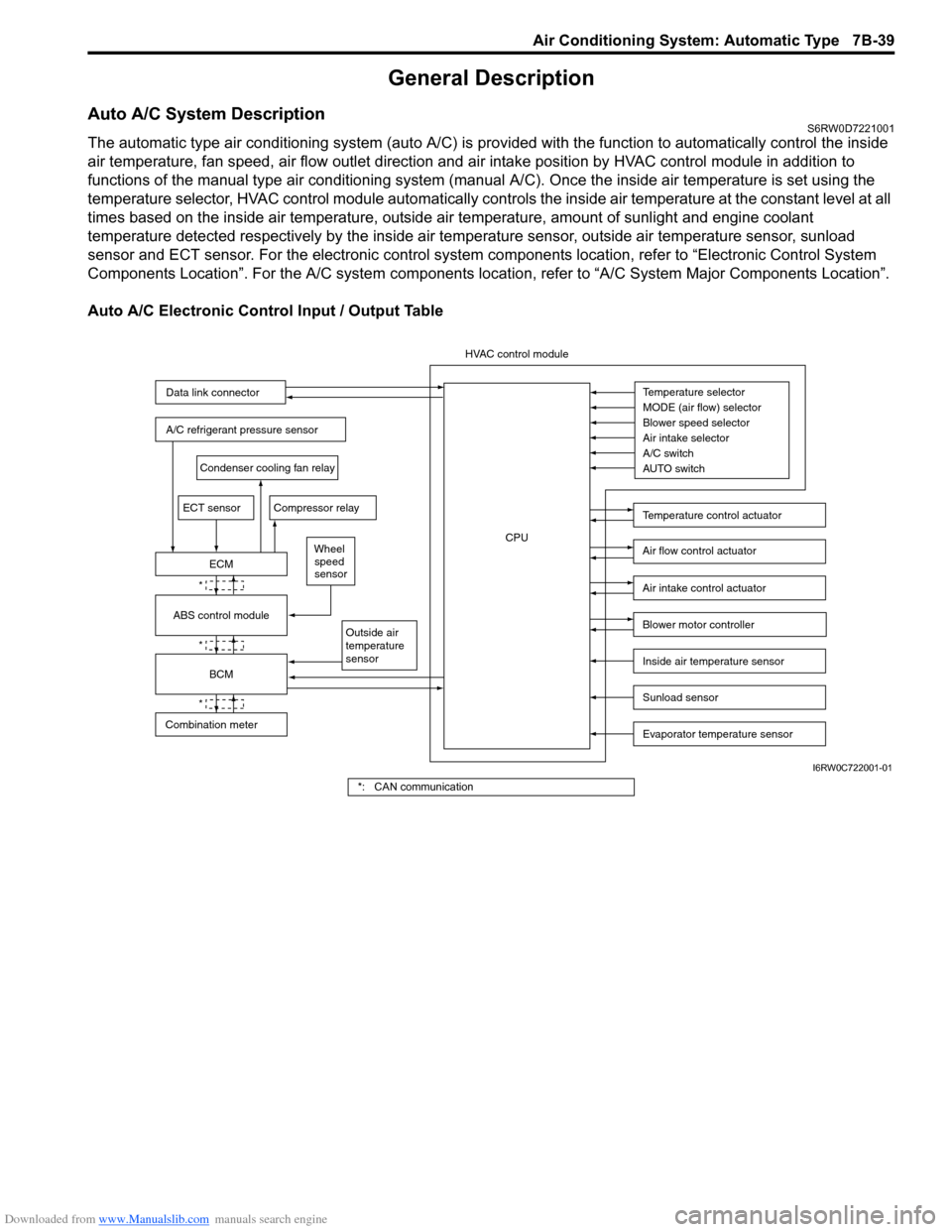

Auto A/C System DescriptionS6RW0D7221001

The automatic type air conditioning system (auto A/C) is provided with the function to automatically control the inside

air temperature, fan speed, air flow outlet direction and air intake position by HVAC control module in addition to

functions of the manual type air conditioning system (manual A/C). Once the inside air temperature is set using the

temperature selector, HVAC control module automatically controls the inside air temperature at the constant level at all

times based on the inside air temperature, outside air temperature, amount of sunlight and engine coolant

temperature detected respectively by the inside air temperature sensor, outside air temperature sensor, sunload

sensor and ECT sensor. For the electronic control system components location, refer to “Electronic Control System

Components Location”. For the A/C system components location, refer to “A/C System Major Components Location”.

Auto A/C Electronic Control Input / Output Table

Temperature selector

MODE (air flow) selector

Blower speed selector

Air intake selector

AUTO switch A/C switch

Outside air

temperature

sensor

A/C refrigerant pressure sensor

Compressor relay

Blower motor controller

Temperature control actuator

Air flow control actuator

Air intake control actuator

BCM

ECM

Data link connector

HVAC control module

CPU

ECT sensor

Sunload sensor

Inside air temperature sensor

Evaporator temperature sensor

Condenser cooling fan relay

Wheel

speed

sensor

*

*

*

Combination meterABS control module

I6RW0C722001-01

*: CAN communication