wheel SUZUKI SX4 2006 1.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 288 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-6 Engine Mechanical:

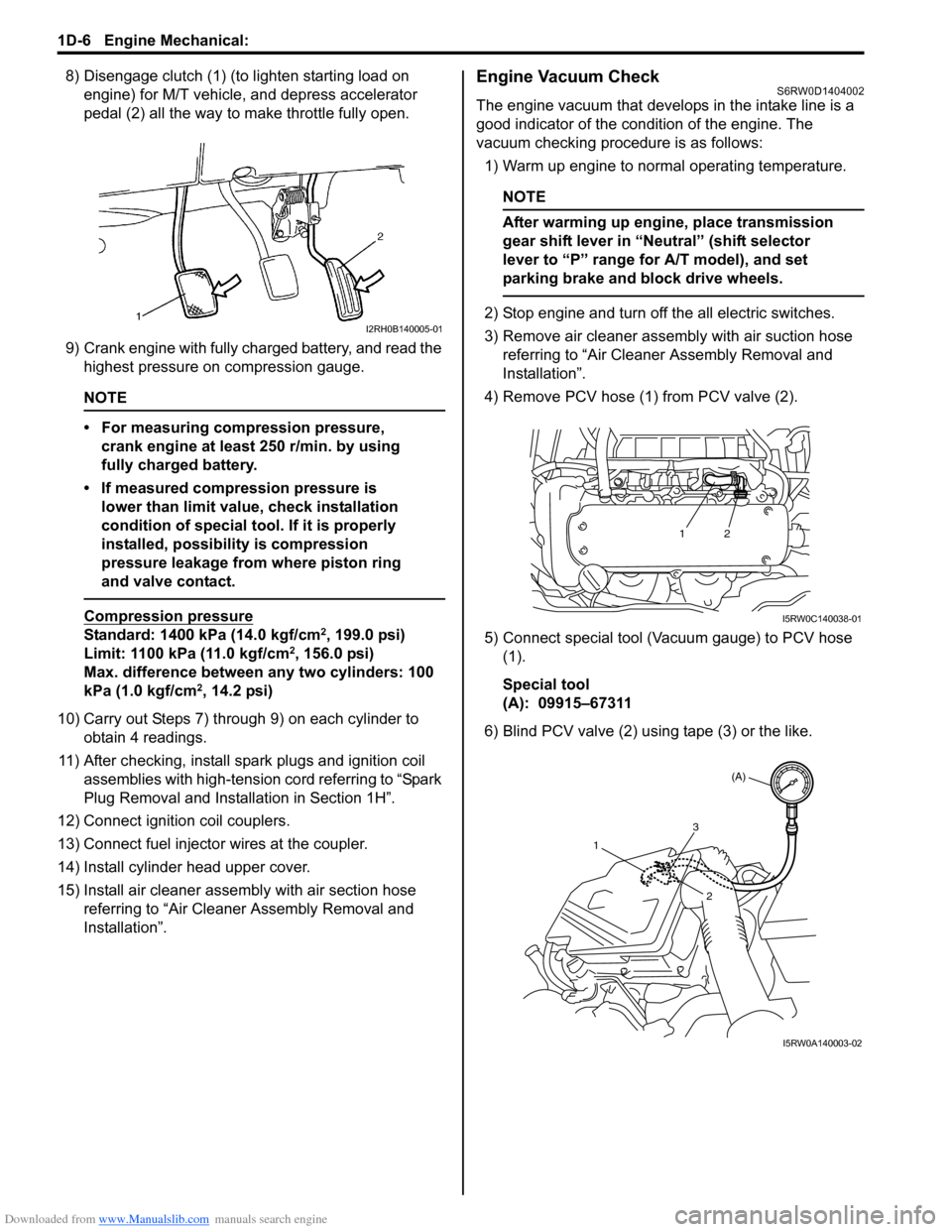

8) Disengage clutch (1) (to lighten starting load on

engine) for M/T vehicle, and depress accelerator

pedal (2) all the way to make throttle fully open.

9) Crank engine with fully charged battery, and read the

highest pressure on compression gauge.

NOTE

• For measuring compression pressure,

crank engine at least 250 r/min. by using

fully charged battery.

• If measured compression pressure is

lower than limit value, check installation

condition of special tool. If it is properly

installed, possibility is compression

pressure leakage from where piston ring

and valve contact.

Compression pressure

Standard: 1400 kPa (14.0 kgf/cm2, 199.0 psi)

Limit: 1100 kPa (11.0 kgf/cm2, 156.0 psi)

Max. difference between any two cylinders: 100

kPa (1.0 kgf/cm

2, 14.2 psi)

10) Carry out Steps 7) through 9) on each cylinder to

obtain 4 readings.

11) After checking, install spark plugs and ignition coil

assemblies with high-tension cord referring to “Spark

Plug Removal and Installation in Section 1H”.

12) Connect ignition coil couplers.

13) Connect fuel injector wires at the coupler.

14) Install cylinder head upper cover.

15) Install air cleaner assembly with air section hose

referring to “Air Cleaner Assembly Removal and

Installation”.

Engine Vacuum CheckS6RW0D1404002

The engine vacuum that develops in the intake line is a

good indicator of the condition of the engine. The

vacuum checking procedure is as follows:

1) Warm up engine to normal operating temperature.

NOTE

After warming up engine, place transmission

gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T model), and set

parking brake and block drive wheels.

2) Stop engine and turn off the all electric switches.

3) Remove air cleaner assembly with air suction hose

referring to “Air Cleaner Assembly Removal and

Installation”.

4) Remove PCV hose (1) from PCV valve (2).

5) Connect special tool (Vacuum gauge) to PCV hose

(1).

Special tool

(A): 09915–67311

6) Blind PCV valve (2) using tape (3) or the like.I2RH0B140005-01

12

I5RW0C140038-01

(A)

1

2

3

I5RW0A140003-02

Page 301 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-19

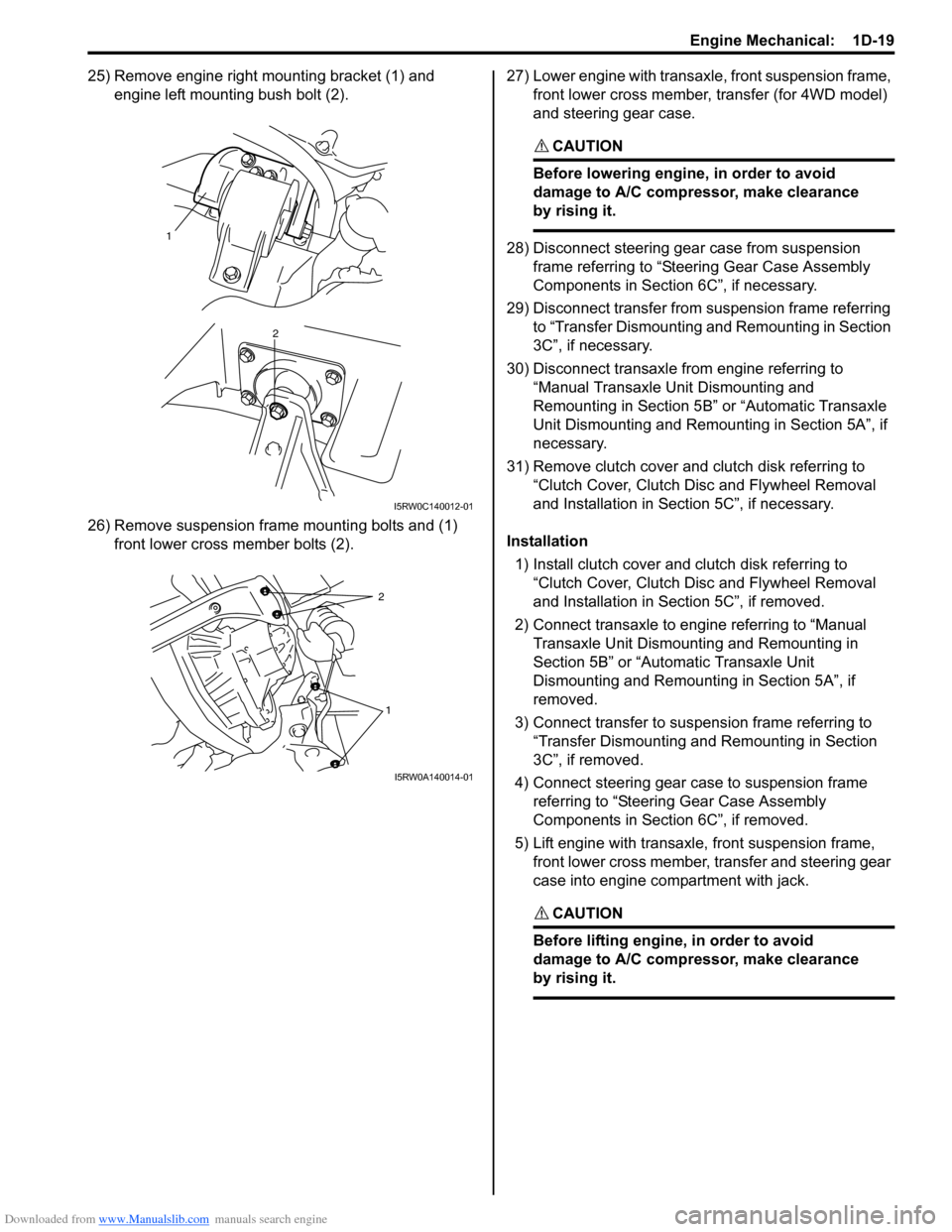

25) Remove engine right mounting bracket (1) and

engine left mounting bush bolt (2).

26) Remove suspension frame mounting bolts and (1)

front lower cross member bolts (2).27) Lower engine with transaxle, front suspension frame,

front lower cross member, transfer (for 4WD model)

and steering gear case.

CAUTION!

Before lowering engine, in order to avoid

damage to A/C compressor, make clearance

by rising it.

28) Disconnect steering gear case from suspension

frame referring to “Steering Gear Case Assembly

Components in Section 6C”, if necessary.

29) Disconnect transfer from suspension frame referring

to “Transfer Dismounting and Remounting in Section

3C”, if necessary.

30) Disconnect transaxle from engine referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B” or “Automatic Transaxle

Unit Dismounting and Remounting in Section 5A”, if

necessary.

31) Remove clutch cover and clutch disk referring to

“Clutch Cover, Clutch Disc and Flywheel Removal

and Installation in Section 5C”, if necessary.

Installation

1) Install clutch cover and clutch disk referring to

“Clutch Cover, Clutch Disc and Flywheel Removal

and Installation in Section 5C”, if removed.

2) Connect transaxle to engine referring to “Manual

Transaxle Unit Dismounting and Remounting in

Section 5B” or “Automatic Transaxle Unit

Dismounting and Remounting in Section 5A”, if

removed.

3) Connect transfer to suspension frame referring to

“Transfer Dismounting and Remounting in Section

3C”, if removed.

4) Connect steering gear case to suspension frame

referring to “Steering Gear Case Assembly

Components in Section 6C”, if removed.

5) Lift engine with transaxle, front suspension frame,

front lower cross member, transfer and steering gear

case into engine compartment with jack.

CAUTION!

Before lifting engine, in order to avoid

damage to A/C compressor, make clearance

by rising it.

1

2

I5RW0C140012-01

2

1

I5RW0A140014-01

Page 332 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-50 Engine Mechanical:

Installation

1) Apply engine oil to pistons, rings, cylinder walls,

connecting rod bearings and crank pins.

NOTE

Do not apply oil between connecting rod and

bearing or between bearing cap and bearing.

2) Install guide hoses (1) over connecting rod bolts.

These guide hoses protect crank pin and threads of

rod bolt from damage during installation of

connecting rod and piston assembly.

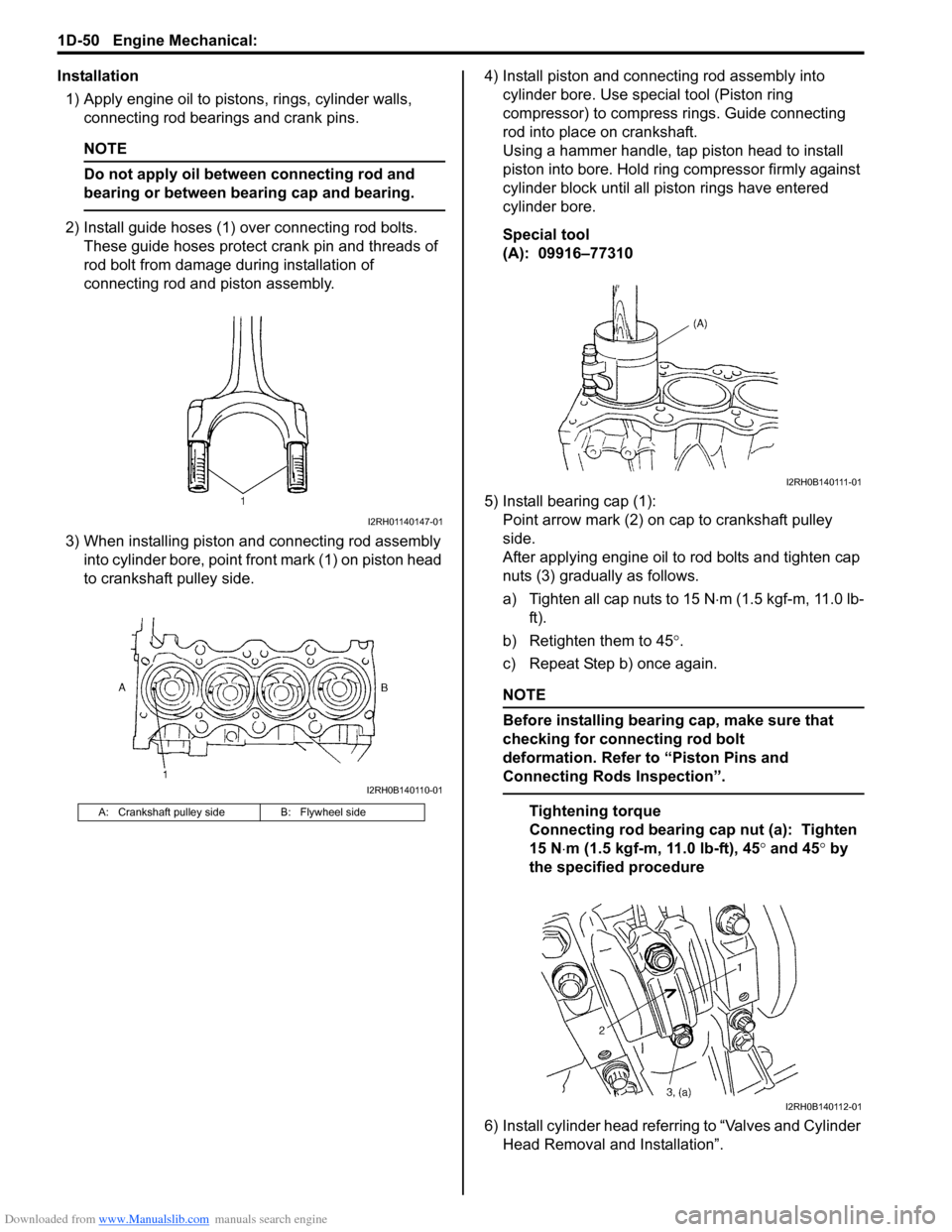

3) When installing piston and connecting rod assembly

into cylinder bore, point front mark (1) on piston head

to crankshaft pulley side.4) Install piston and connecting rod assembly into

cylinder bore. Use special tool (Piston ring

compressor) to compress rings. Guide connecting

rod into place on crankshaft.

Using a hammer handle, tap piston head to install

piston into bore. Hold ring compressor firmly against

cylinder block until all piston rings have entered

cylinder bore.

Special tool

(A): 09916–77310

5) Install bearing cap (1):

Point arrow mark (2) on cap to crankshaft pulley

side.

After applying engine oil to rod bolts and tighten cap

nuts (3) gradually as follows.

a) Tighten all cap nuts to 15 N⋅m (1.5 kgf-m, 11.0 lb-

ft).

b) Retighten them to 45°.

c) Repeat Step b) once again.

NOTE

Before installing bearing cap, make sure that

checking for connecting rod bolt

deformation. Refer to “Piston Pins and

Connecting Rods Inspection”.

Tightening torque

Connecting rod bearing cap nut (a): Tighten

15 N⋅m (1.5 kgf-m, 11.0 lb-ft), 45° and 45° by

the specified procedure

6) Install cylinder head referring to “Valves and Cylinder

Head Removal and Installation”.A: Crankshaft pulley side B: Flywheel side

I2RH01140147-01

I2RH0B140110-01

I2RH0B140111-01

I2RH0B140112-01

Page 341 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-59

Main Bearings, Crankshaft and Cylinder Block ComponentsS6RW0D1406037

I6RW0D140003-01

1. CKP sensor

: See “A”11. Rear oil seal 21. Oil filter adapter bolt

2. Knock sensor 12. Input shaft bearing 22. Spring pin

3. Cylinder block 13. Flywheel or drive plate 23. Sensor plate bolt

4. Venturi plug 14. Main bearing cap 24. Oil pressure switch

Page 342 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-60 Engine Mechanical:

Main Bearings, Crankshaft and Cylinder Block

Removal and Installation

S6RW0D1406038

Removal

1) Remove engine assembly from vehicle referring to

“Engine Assembly Removal and Installation”.

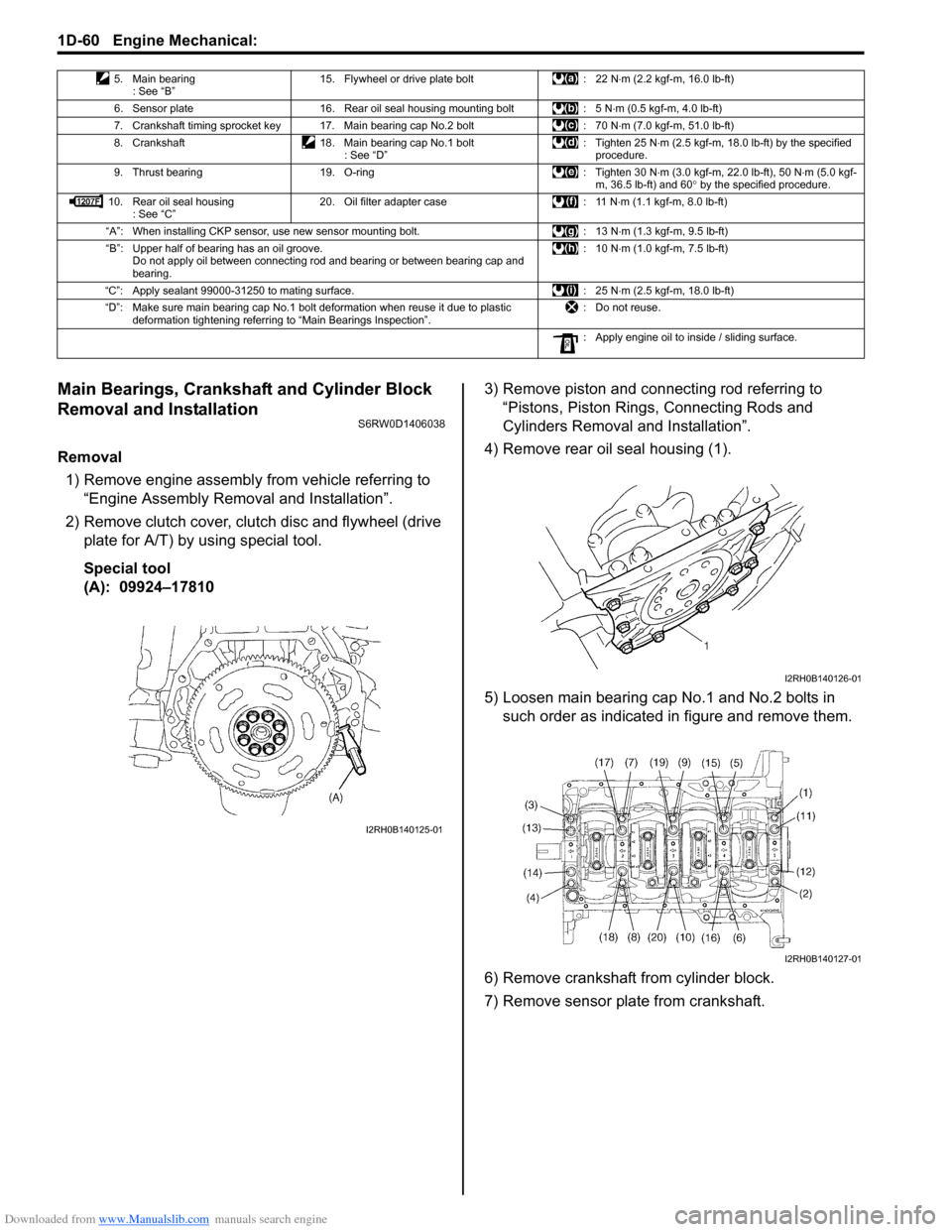

2) Remove clutch cover, clutch disc and flywheel (drive

plate for A/T) by using special tool.

Special tool

(A): 09924–178103) Remove piston and connecting rod referring to

“Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

4) Remove rear oil seal housing (1).

5) Loosen main bearing cap No.1 and No.2 bolts in

such order as indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

7) Remove sensor plate from crankshaft.

5. Main bearing

: See “B”15. Flywheel or drive plate bolt : 22 N⋅m (2.2 kgf-m, 16.0 lb-ft)

6. Sensor plate 16. Rear oil seal housing mounting bolt : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

7. Crankshaft timing sprocket key 17. Main bearing cap No.2 bolt : 70 N⋅m (7.0 kgf-m, 51.0 lb-ft)

8. Crankshaft 18. Main bearing cap No.1 bolt

: See “D”: Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) by the specified

procedure.

9. Thrust bearing 19. O-ring : Tighten 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N⋅m (5.0 kgf-

m, 36.5 lb-ft) and 60° by the specified procedure.

10. Rear oil seal housing

: See “C”20. Oil filter adapter case : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

“A”: When installing CKP sensor, use new sensor mounting bolt. : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

“B”: Upper half of bearing has an oil groove.

Do not apply oil between connecting rod and bearing or between bearing cap and

bearing.:10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

“C”: Apply sealant 99000-31250 to mating surface. : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

“D”: Make sure main bearing cap No.1 bolt deformation when reuse it due to plastic

deformation tightening referring to “Main Bearings Inspection”.: Do not reuse.

: Apply engine oil to inside / sliding surface.

I2RH0B140125-01

I2RH0B140126-01

I2RH0B140127-01

Page 345 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-63

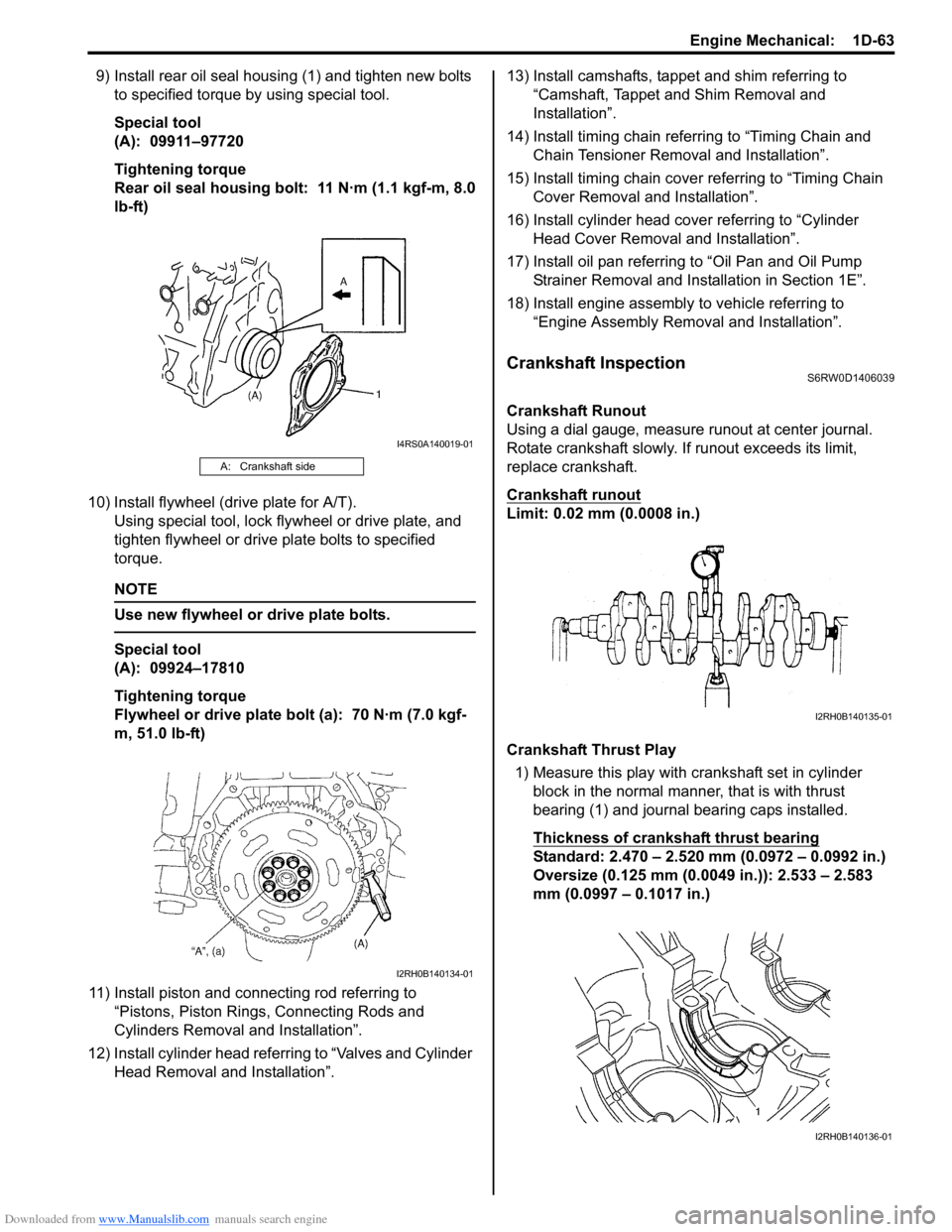

9) Install rear oil seal housing (1) and tighten new bolts

to specified torque by using special tool.

Special tool

(A): 09911–97720

Tightening torque

Rear oil seal housing bolt: 11 N·m (1.1 kgf-m, 8.0

lb-ft)

10) Install flywheel (drive plate for A/T).

Using special tool, lock flywheel or drive plate, and

tighten flywheel or drive plate bolts to specified

torque.

NOTE

Use new flywheel or drive plate bolts.

Special tool

(A): 09924–17810

Tightening torque

Flywheel or drive plate bolt (a): 70 N·m (7.0 kgf-

m, 51.0 lb-ft)

11) Install piston and connecting rod referring to

“Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

12) Install cylinder head referring to “Valves and Cylinder

Head Removal and Installation”.13) Install camshafts, tappet and shim referring to

“Camshaft, Tappet and Shim Removal and

Installation”.

14) Install timing chain referring to “Timing Chain and

Chain Tensioner Removal and Installation”.

15) Install timing chain cover referring to “Timing Chain

Cover Removal and Installation”.

16) Install cylinder head cover referring to “Cylinder

Head Cover Removal and Installation”.

17) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

18) Install engine assembly to vehicle referring to

“Engine Assembly Removal and Installation”.

Crankshaft InspectionS6RW0D1406039

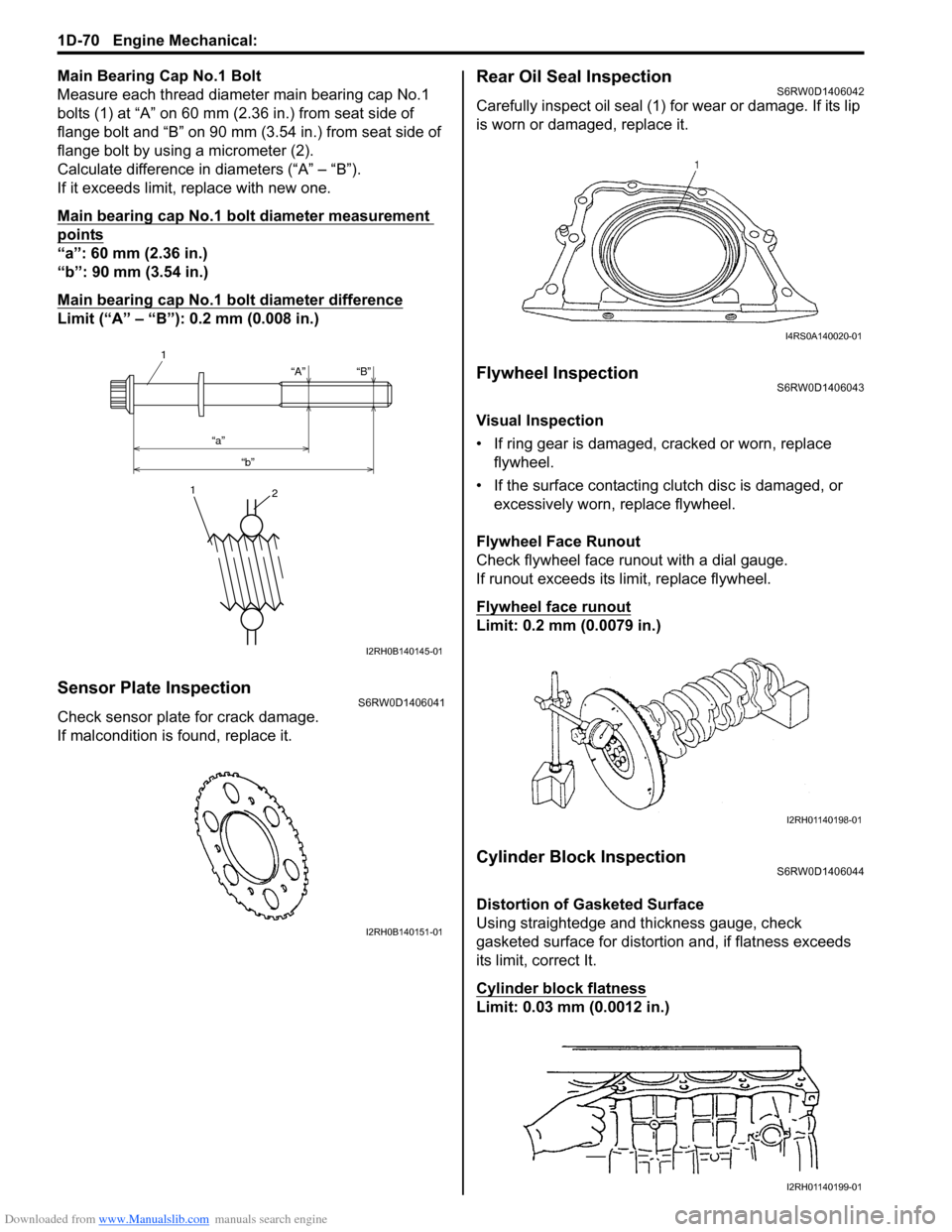

Crankshaft Runout

Using a dial gauge, measure runout at center journal.

Rotate crankshaft slowly. If runout exceeds its limit,

replace crankshaft.

Crankshaft runout

Limit: 0.02 mm (0.0008 in.)

Crankshaft Thrust Play

1) Measure this play with crankshaft set in cylinder

block in the normal manner, that is with thrust

bearing (1) and journal bearing caps installed.

Thickness of crankshaft thrust bearing

Standard: 2.470 – 2.520 mm (0.0972 – 0.0992 in.)

Oversize (0.125 mm (0.0049 in.)): 2.533 – 2.583

mm (0.0997 – 0.1017 in.)

A: Crankshaft side

I4RS0A140019-01

I2RH0B140134-01

I2RH0B140135-01

I2RH0B140136-01

Page 352 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-70 Engine Mechanical:

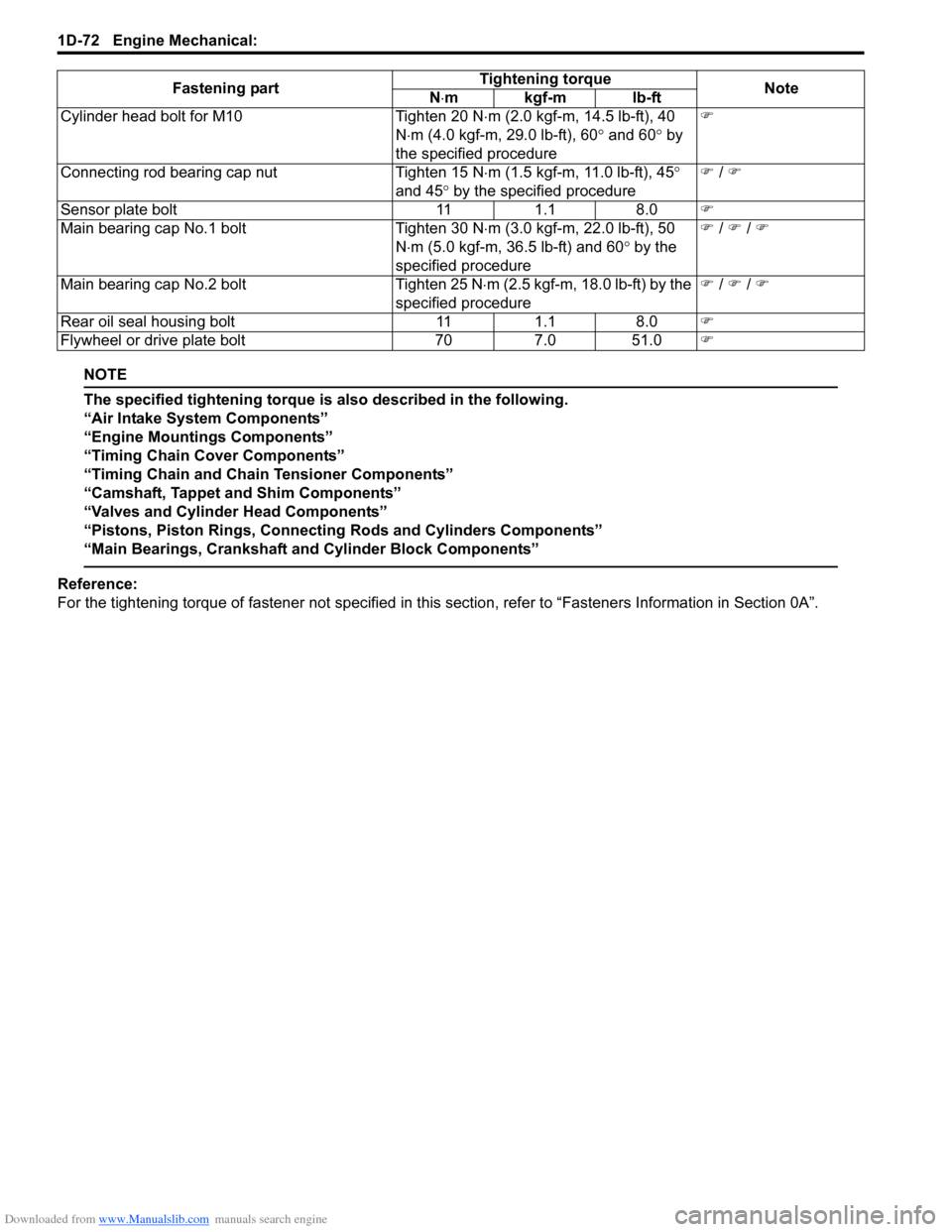

Main Bearing Cap No.1 Bolt

Measure each thread diameter main bearing cap No.1

bolts (1) at “A” on 60 mm (2.36 in.) from seat side of

flange bolt and “B” on 90 mm (3.54 in.) from seat side of

flange bolt by using a micrometer (2).

Calculate difference in diameters (“A” – “B”).

If it exceeds limit, replace with new one.

Main bearing cap No.1 bolt diameter measurement

points

“a”: 60 mm (2.36 in.)

“b”: 90 mm (3.54 in.)

Main bearing cap No.1 bolt diameter difference

Limit (“A” – “B”): 0.2 mm (0.008 in.)

Sensor Plate InspectionS6RW0D1406041

Check sensor plate for crack damage.

If malcondition is found, replace it.

Rear Oil Seal InspectionS6RW0D1406042

Carefully inspect oil seal (1) for wear or damage. If its lip

is worn or damaged, replace it.

Flywheel InspectionS6RW0D1406043

Visual Inspection

• If ring gear is damaged, cracked or worn, replace

flywheel.

• If the surface contacting clutch disc is damaged, or

excessively worn, replace flywheel.

Flywheel Face Runout

Check flywheel face runout with a dial gauge.

If runout exceeds its limit, replace flywheel.

Flywheel face runout

Limit: 0.2 mm (0.0079 in.)

Cylinder Block InspectionS6RW0D1406044

Distortion of Gasketed Surface

Using straightedge and thickness gauge, check

gasketed surface for distortion and, if flatness exceeds

its limit, correct It.

Cylinder block flatness

Limit: 0.03 mm (0.0012 in.)

“A”

“a”

“b”“B”

1

1

2

I2RH0B140145-01

I2RH0B140151-01

I4RS0A140020-01

I2RH01140198-01

I2RH01140199-01

Page 354 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-72 Engine Mechanical:

NOTE

The specified tightening torque is also described in the following.

“Air Intake System Components”

“Engine Mountings Components”

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”. Cylinder head bolt for M10 Tighten 20 N⋅m (2.0 kgf-m, 14.5 lb-ft), 40

N⋅m (4.0 kgf-m, 29.0 lb-ft), 60° and 60° by

the specified procedure�)

Connecting rod bearing cap nut Tighten 15 N⋅m (1.5 kgf-m, 11.0 lb-ft), 45°

and 45° by the specified procedure�) / �)

Sensor plate bolt 11 1.1 8.0�)

Main bearing cap No.1 bolt Tighten 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50

N⋅m (5.0 kgf-m, 36.5 lb-ft) and 60° by the

specified procedure�) / �) / �)

Main bearing cap No.2 bolt Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) by the

specified procedure�) / �) / �)

Rear oil seal housing bolt 11 1.1 8.0�)

Flywheel or drive plate bolt 70 7.0 51.0�) Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Page 356 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-74 Engine Mechanical:

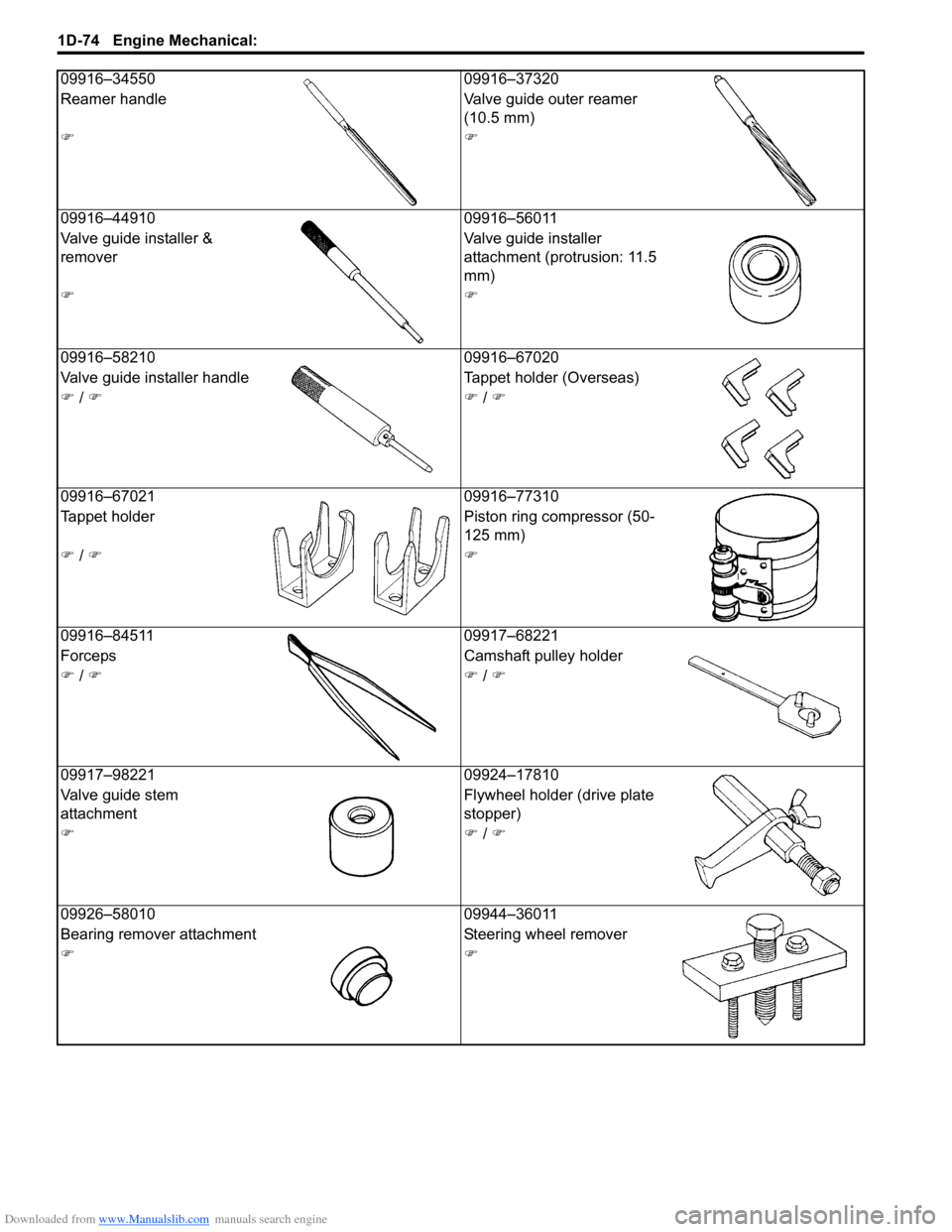

09916–34550 09916–37320

Reamer handle Valve guide outer reamer

(10.5 mm)

�)�)

09916–44910 09916–56011

Valve guide installer &

removerValve guide installer

attachment (protrusion: 11.5

mm)

�)�)

09916–58210 09916–67020

Valve guide installer handle Tappet holder (Overseas)

�) / �)�) / �)

09916–67021 09916–77310

Tappet holder Piston ring compressor (50-

125 mm)

�) / �)�)

09916–84511 09917–68221

Forceps Camshaft pulley holder

�) / �)�) / �)

09917–98221 09924–17810

Valve guide stem

attachmentFlywheel holder (drive plate

stopper)

�)�) / �)

09926–58010 09944–36011

Bearing remover attachment Steering wheel remover

�)�)

Page 358 of 1556

Downloaded from www.Manualslib.com manuals search engine 1E-2 Engine Lubrication System:

Diagnostic Information and Procedures

Oil Pressure CheckS6RW0D1504001

WARNING!

To avoid the danger of being burned, do not

touch the exhaust system when the system is

hot. Any service on the exhaust system

should be performed when the system is

cool.

NOTE

Prior to checking oil pressure, check the

following.

• Oil level in oil pan

If oil level is low, add oil up to full level

mark (hole) (1) on oil level gauge referring

to “Engine Oil and Filter Change in Section

0B”.

• Oil quality

If oil is discolored or deteriorated, change

it. For particular oil to be used, refer to

“Engine Oil and Filter Change in Section

0B”.

• Oil leaks

If leak is found, repair it.

1) Disconnect oil pressure switch coupler (1).

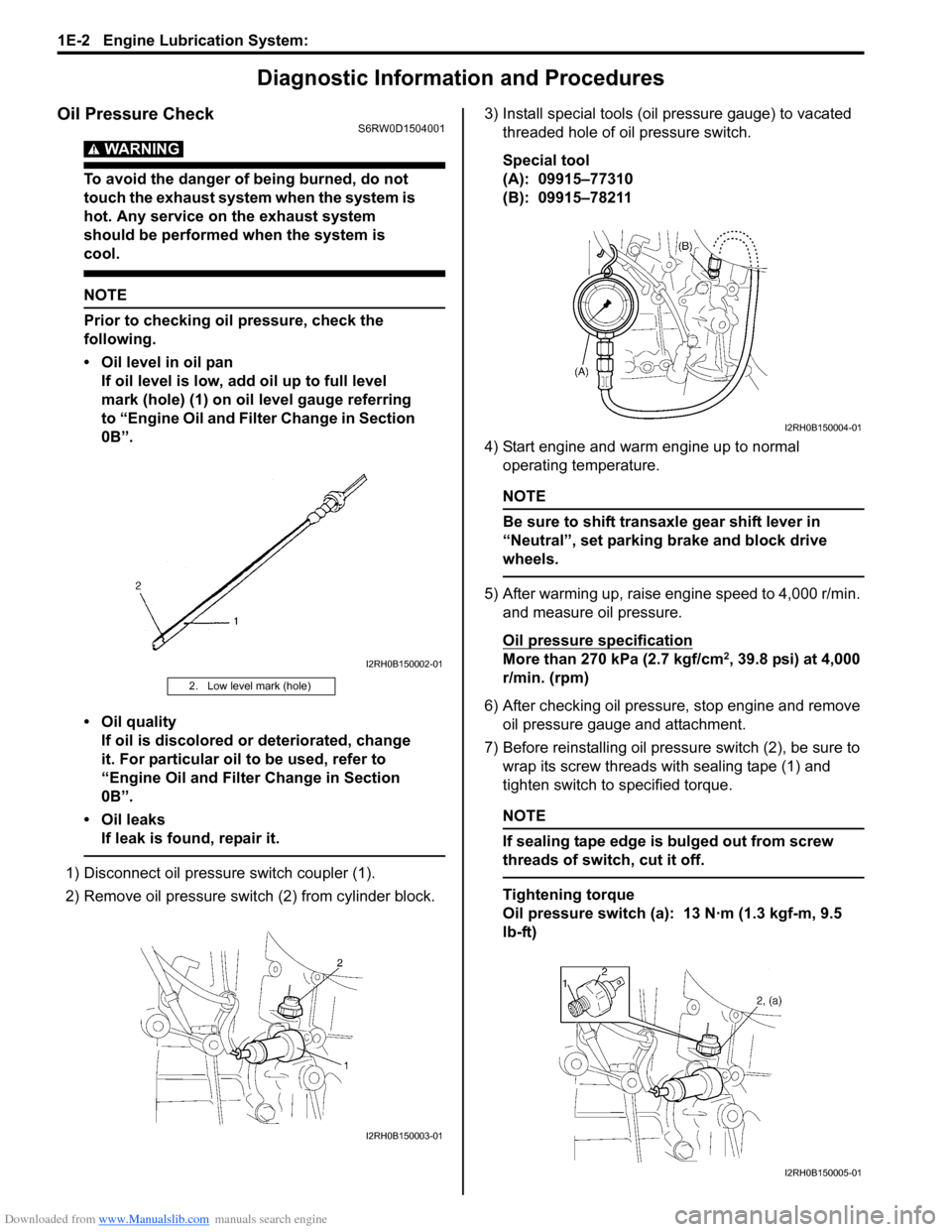

2) Remove oil pressure switch (2) from cylinder block.3) Install special tools (oil pressure gauge) to vacated

threaded hole of oil pressure switch.

Special tool

(A): 09915–77310

(B): 09915–78211

4) Start engine and warm engine up to normal

operating temperature.

NOTE

Be sure to shift transaxle gear shift lever in

“Neutral”, set parking brake and block drive

wheels.

5) After warming up, raise engine speed to 4,000 r/min.

and measure oil pressure.

Oil pressure specification

More than 270 kPa (2.7 kgf/cm2, 39.8 psi) at 4,000

r/min. (rpm)

6) After checking oil pressure, stop engine and remove

oil pressure gauge and attachment.

7) Before reinstalling oil pressure switch (2), be sure to

wrap its screw threads with sealing tape (1) and

tighten switch to specified torque.

NOTE

If sealing tape edge is bulged out from screw

threads of switch, cut it off.

Tightening torque

Oil pressure switch (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft)

2. Low level mark (hole)

I2RH0B150002-01

I2RH0B150003-01

I2RH0B150004-01

I2RH0B150005-01