SUZUKI SX4 2006 1.G Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 391 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-14

Installation

CAUTION!

• When connecting joint, clean outside

surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS

sensor harness (if equipped).

1) If parts have been removed from fuel tank, install

them before installing fuel tank to vehicle.

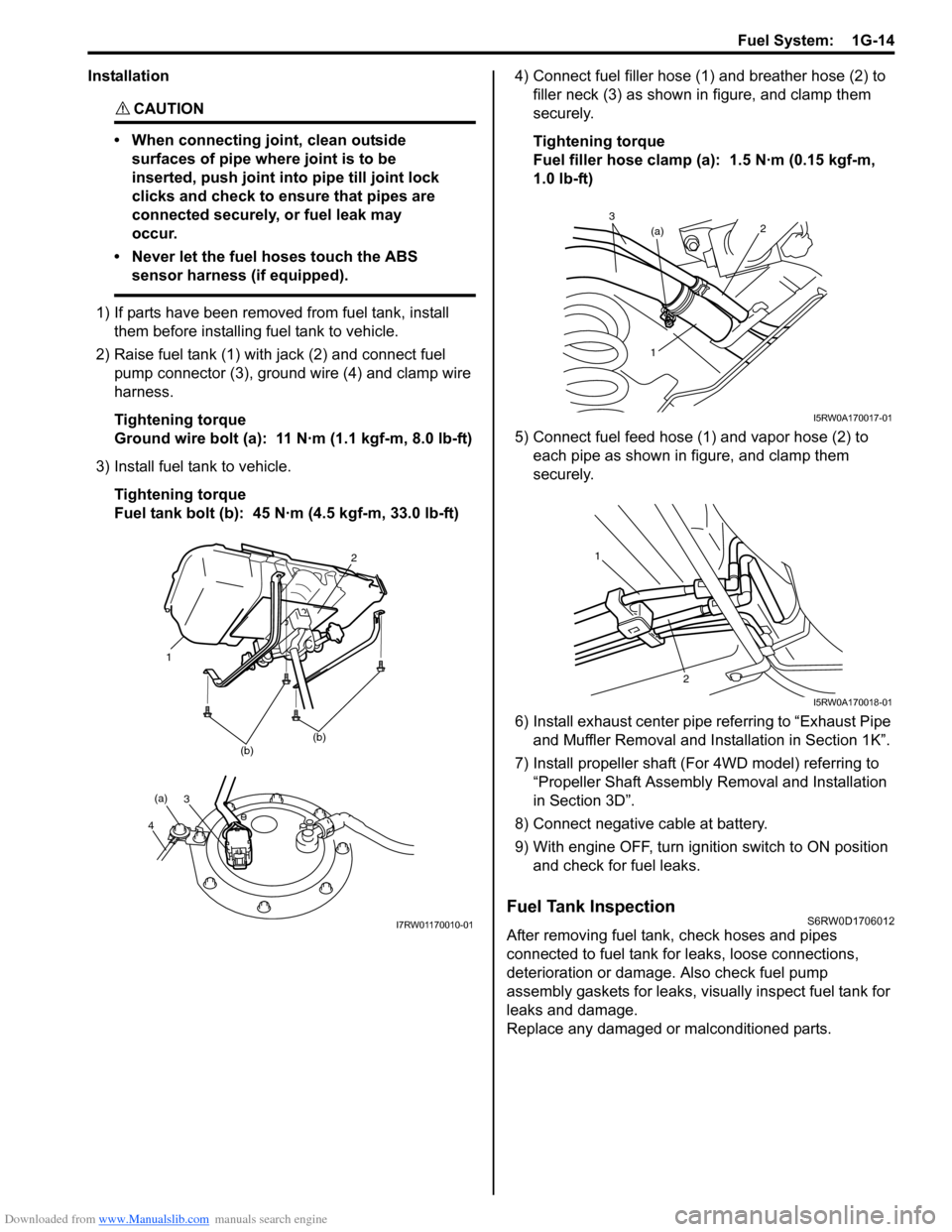

2) Raise fuel tank (1) with jack (2) and connect fuel

pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle.

Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft)4) Connect fuel filler hose (1) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 1.5 N·m (0.15 kgf-m,

1.0 lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to

each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe

and Muffler Removal and Installation in Section 1K”.

7) Install propeller shaft (For 4WD model) referring to

“Propeller Shaft Assembly Removal and Installation

in Section 3D”.

8) Connect negative cable at battery.

9) With engine OFF, turn ignition switch to ON position

and check for fuel leaks.

Fuel Tank InspectionS6RW0D1706012

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I7RW01170010-01

1(a)2

3

I5RW0A170017-01

1

2

I5RW0A170018-01

Page 392 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-15 Fuel System:

Fuel Tank Purging ProcedureS6RW0D1706013

WARNING!

• Before starting the following procedure, be

sure to observe “Precautions on Fuel

System Service” in order to reduce the risk

of fire and personal injury.

• This purging procedure will not remove all

fuel vapor.

Do not attempt any repair on tank using

heat of flame as an explosion resulting in

personal injury could occur.

CAUTION!

Never remain water in fuel tank after washing,

or fuel tank inside will get corrosion.

The following procedure are used for purging fuel tank.

1) After removing fuel tank, remove all hoses, pipes

and fuel pump assembly from fuel tank.

2) Drain all remaining fuel from tank.

3) Place fuel tank to flushing area.

4) Fill tank with warm water or tap water, and agitate

vigorously and drain. Repeat this washing until

inside of tank is clean. Replace tank if its inside is

rusty.

5) Completely flush out remaining water after washing.

6) Be sure to dry fuel tank assembly thoroughly out of

direct sunlight after washing.

Fuel Pump On-Vehicle InspectionS6RW0D1706014

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk of fire and

personal injury.

NOTE

The fuel pressure regulator is incorporated

with the fuel pump assembly so individual

inspection of it is impossible.

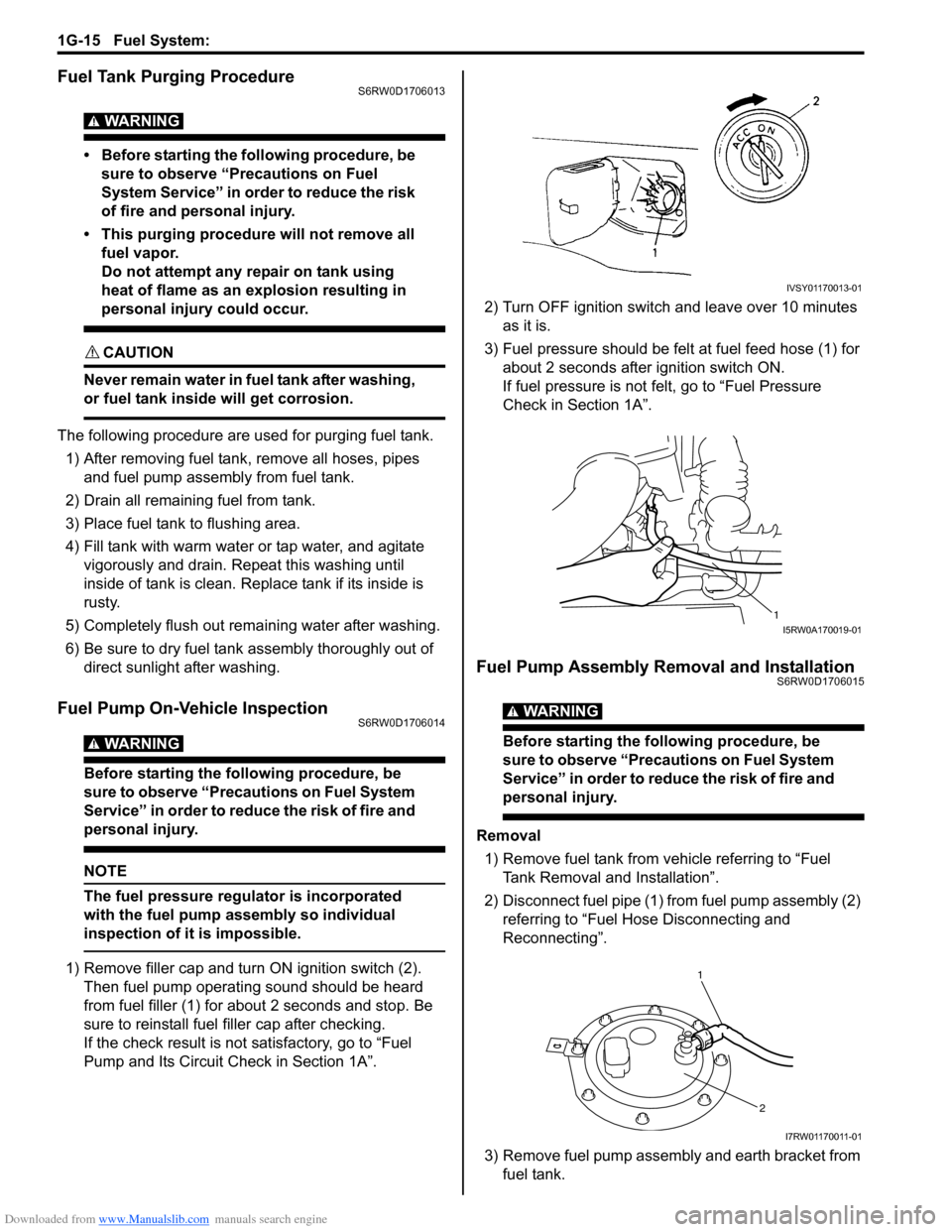

1) Remove filler cap and turn ON ignition switch (2).

Then fuel pump operating sound should be heard

from fuel filler (1) for about 2 seconds and stop. Be

sure to reinstall fuel filler cap after checking.

If the check result is not satisfactory, go to “Fuel

Pump and Its Circuit Check in Section 1A”.2) Turn OFF ignition switch and leave over 10 minutes

as it is.

3) Fuel pressure should be felt at fuel feed hose (1) for

about 2 seconds after ignition switch ON.

If fuel pressure is not felt, go to “Fuel Pressure

Check in Section 1A”.

Fuel Pump Assembly Removal and InstallationS6RW0D1706015

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk of fire and

personal injury.

Removal

1) Remove fuel tank from vehicle referring to “Fuel

Tank Removal and Installation”.

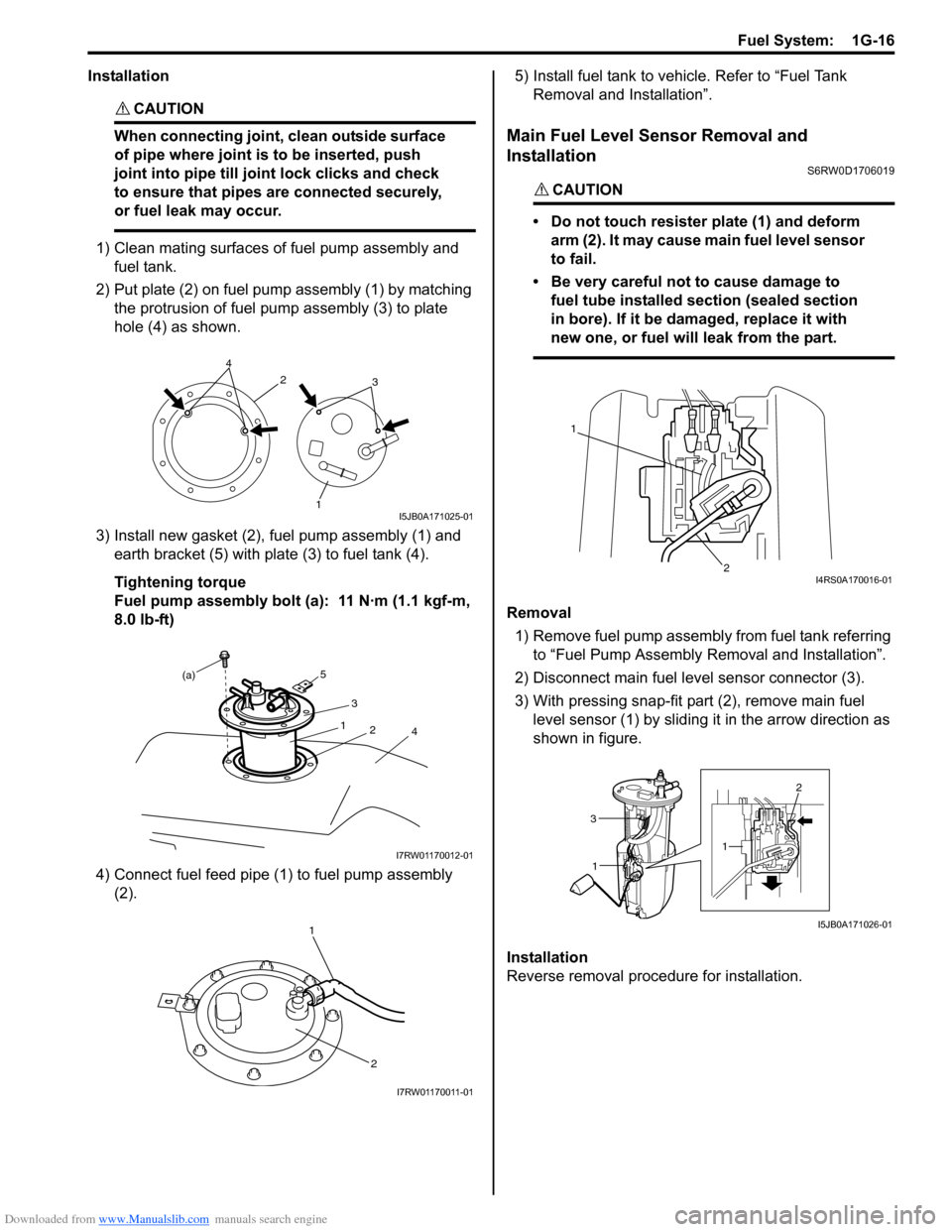

2) Disconnect fuel pipe (1) from fuel pump assembly (2)

referring to “Fuel Hose Disconnecting and

Reconnecting”.

3) Remove fuel pump assembly and earth bracket from

fuel tank.

IVSY01170013-01

1I5RW0A170019-01

1

2

I7RW01170011-01

Page 393 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-16

Installation

CAUTION!

When connecting joint, clean outside surface

of pipe where joint is to be inserted, push

joint into pipe till joint lock clicks and check

to ensure that pipes are connected securely,

or fuel leak may occur.

1) Clean mating surfaces of fuel pump assembly and

fuel tank.

2) Put plate (2) on fuel pump assembly (1) by matching

the protrusion of fuel pump assembly (3) to plate

hole (4) as shown.

3) Install new gasket (2), fuel pump assembly (1) and

earth bracket (5) with plate (3) to fuel tank (4).

Tightening torque

Fuel pump assembly bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

4) Connect fuel feed pipe (1) to fuel pump assembly

(2).5) Install fuel tank to vehicle. Refer to “Fuel Tank

Removal and Installation”.

Main Fuel Level Sensor Removal and

Installation

S6RW0D1706019

CAUTION!

• Do not touch resister plate (1) and deform

arm (2). It may cause main fuel level sensor

to fail.

• Be very careful not to cause damage to

fuel tube installed section (sealed section

in bore). If it be damaged, replace it with

new one, or fuel will leak from the part.

Removal

1) Remove fuel pump assembly from fuel tank referring

to “Fuel Pump Assembly Removal and Installation”.

2) Disconnect main fuel level sensor connector (3).

3) With pressing snap-fit part (2), remove main fuel

level sensor (1) by sliding it in the arrow direction as

shown in figure.

Installation

Reverse removal procedure for installation.

3

1 2 4

I5JB0A171025-01

3

1

2

(a)

4

5

I7RW01170012-01

1

2

I7RW01170011-01

1

2I4RS0A170016-01

1 3

12

I5JB0A171026-01

Page 394 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-17 Fuel System:

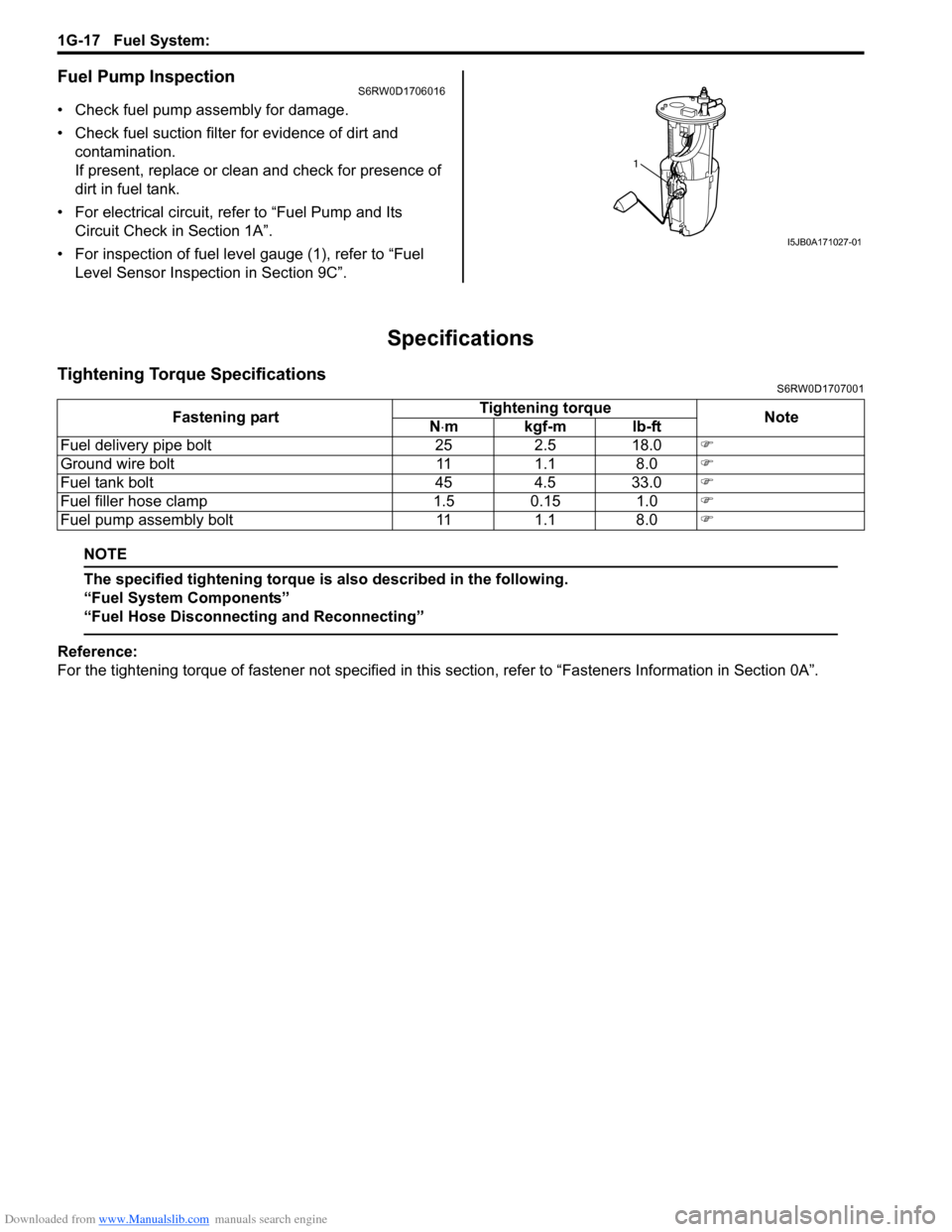

Fuel Pump InspectionS6RW0D1706016

• Check fuel pump assembly for damage.

• Check fuel suction filter for evidence of dirt and

contamination.

If present, replace or clean and check for presence of

dirt in fuel tank.

• For electrical circuit, refer to “Fuel Pump and Its

Circuit Check in Section 1A”.

• For inspection of fuel level gauge (1), refer to “Fuel

Level Sensor Inspection in Section 9C”.

Specifications

Tightening Torque SpecificationsS6RW0D1707001

NOTE

The specified tightening torque is also described in the following.

“Fuel System Components”

“Fuel Hose Disconnecting and Reconnecting”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

1

I5JB0A171027-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Fuel delivery pipe bolt 25 2.5 18.0�)

Ground wire bolt 11 1.1 8.0�)

Fuel tank bolt 45 4.5 33.0�)

Fuel filler hose clamp 1.5 0.15 1.0�)

Fuel pump assembly bolt 11 1.1 8.0�)

Page 395 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-18

Special Tools and Equipment

Special ToolS6RW0D1708001

09912–57610 09912–58421

Injector checking tool plate Checking tool set

�)This kit includes the

following items. 1. Tool body

and washer, 2. Body plug, 3.

Body attachment-1, 4.

Holder, 5. Return hose and

clamp, 6. Body attachment-2

and washer, 7. Hose

attachment-1, 8. Hose

attachment-2 �)

09912–58432 09912–58442

Fuel pressure gauge hose Fuel pressure gauge

This tool is included in fuel

pressure gauge set (09912-

58413). �)This tool is included in fuel

pressure gauge set (09912-

58413). �)

09912–58490 09919–47020

3-way joint & hose Quick joint remover

�)�)

09930–88530 SUZUKI scan tool (SUZUKI-

SDT)

Injector test lead —

�)This kit includes following

items. 1. SUZUKI-SDT 2.

DLC3 cable 3. USB cable 4.

AC/DC power supply 5.

Voltage meter probe 6.

Storage case �)

1

2

34

56

Page 396 of 1556

Downloaded from www.Manualslib.com manuals search engine 1H-1 Ignition System:

Engine

Ignition System

General Description

Ignition System ConstructionS6RW0D1801001

The ignition system is an electronic (distributorless) ignition system. It consists of the parts as described below.

•ECM

It detects the engine and vehicle conditions through the signals from the sensors, determines the most suitable

ignition timing and time for electricity to flow to the primary coil and sends a signal to the ignitor (power unit) in the

ignition coil assembly.

•Ignition coil assembly (including an ignitor)

The ignition coil assembly has a built-in ignitor which turns ON and OFF the current flow to the primary coil

according to the signal from ECM. When the current flow to the primary coil is turned OFF, a high voltage is induced

in the secondary coil.

•High-tension cords and spark plugs

•CMP sensor (Camshaft position sensor) and CKP sensor (Crankshaft position sensor)

Using signals from these sensors, ECM identifies the specific cylinder whose piston is in the compression stroke,

detects the crank angle and adjusts initial ignition timing automatically.

•TP sensor, ECT sensor, MAP sensor, MAF sensor, IAT sensor, knock sensor and other sensors / switches

Although this ignition system does not have a distributor, it has two ignition coil assemblies (one is for No.1 and No.4

spark plugs and the other is for No.2 and No.3 spark plugs). When an ignition signal is sent from ECM to the ignitor in

the ignition coil assembly for No.1 and No.4 spark plugs, a high voltage is induced in the secondary coil and that

passes through the high-tension cords and causes No.1 and No.4 spark plugs to spark simultaneously. Likewise,

when an ignition signal is sent to the ignitor in the other ignition coil assembly, No.2 and No.3 spark plugs spark

simultaneously.

Page 397 of 1556

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-2

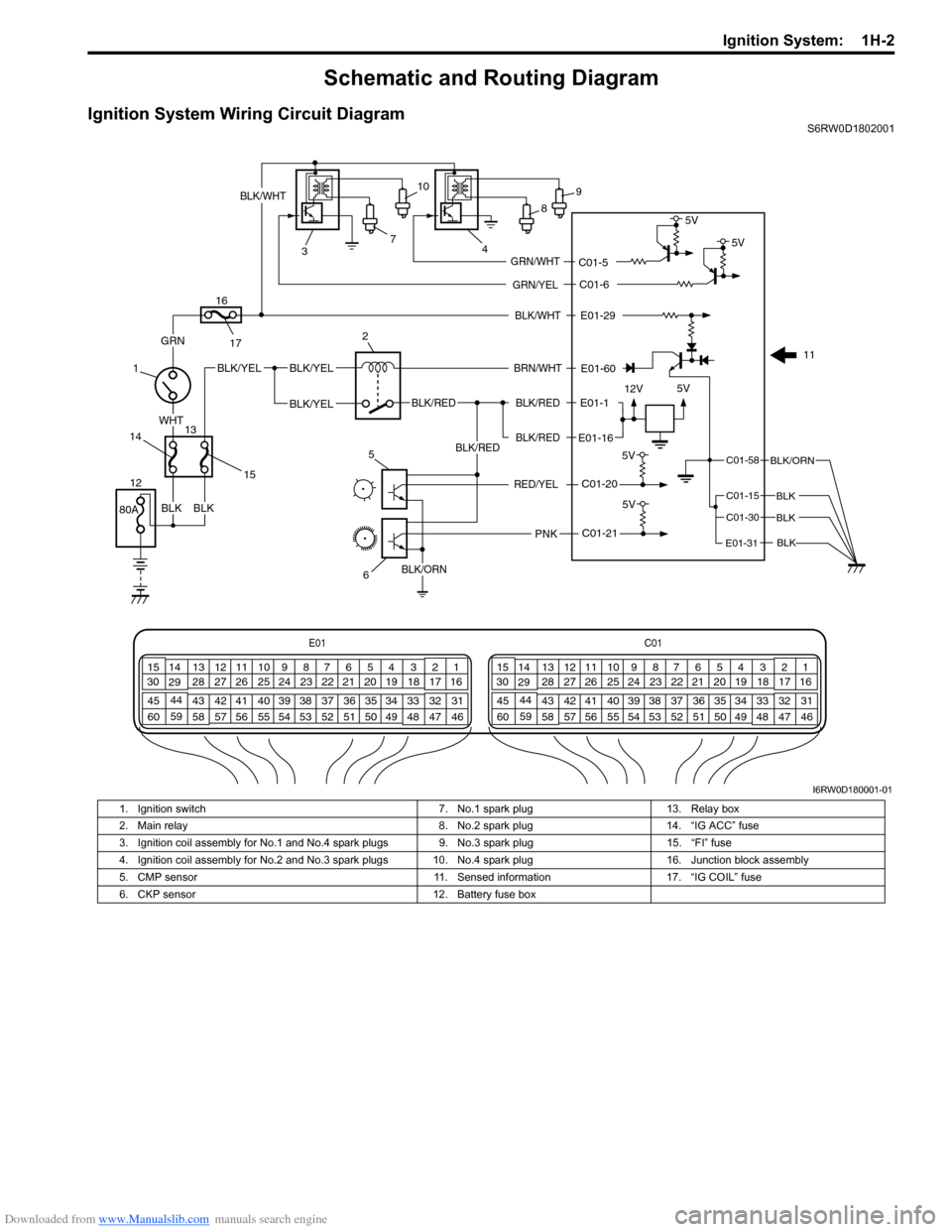

Schematic and Routing Diagram

Ignition System Wiring Circuit DiagramS6RW0D1802001

E01-60

E01-29

12V5V

5V

E01-1

E01-16

BLK/WHT

BLK/RED

BLK/RED

BLK/RED

80A

BLK/YELBLK/YEL

BLK/YEL

GRN

BLK

WHT

BRN/WHT

BLK/ORN

BLK

BLK

BLK

C01-20

BLK/RED

PNK

BLK/ORN

5V

C01-21

BLK/WHT

7

34

1

125

6 2

11 89 10

GRN/YEL

GRN/WHT

C01-6

C01-55V

5V

RED/YEL

C01-58

C01-15

C01-30

E01-31

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

13

14

15

16

17

BLK

I6RW0D180001-01

1. Ignition switch 7. No.1 spark plug 13. Relay box

2. Main relay 8. No.2 spark plug 14. “IG ACC” fuse

3. Ignition coil assembly for No.1 and No.4 spark plugs 9. No.3 spark plug 15. “FI” fuse

4. Ignition coil assembly for No.2 and No.3 spark plugs 10. No.4 spark plug 16. Junction block assembly

5. CMP sensor 11. Sensed information 17. “IG COIL” fuse

6. CKP sensor 12. Battery fuse box

Page 398 of 1556

Downloaded from www.Manualslib.com manuals search engine 1H-3 Ignition System:

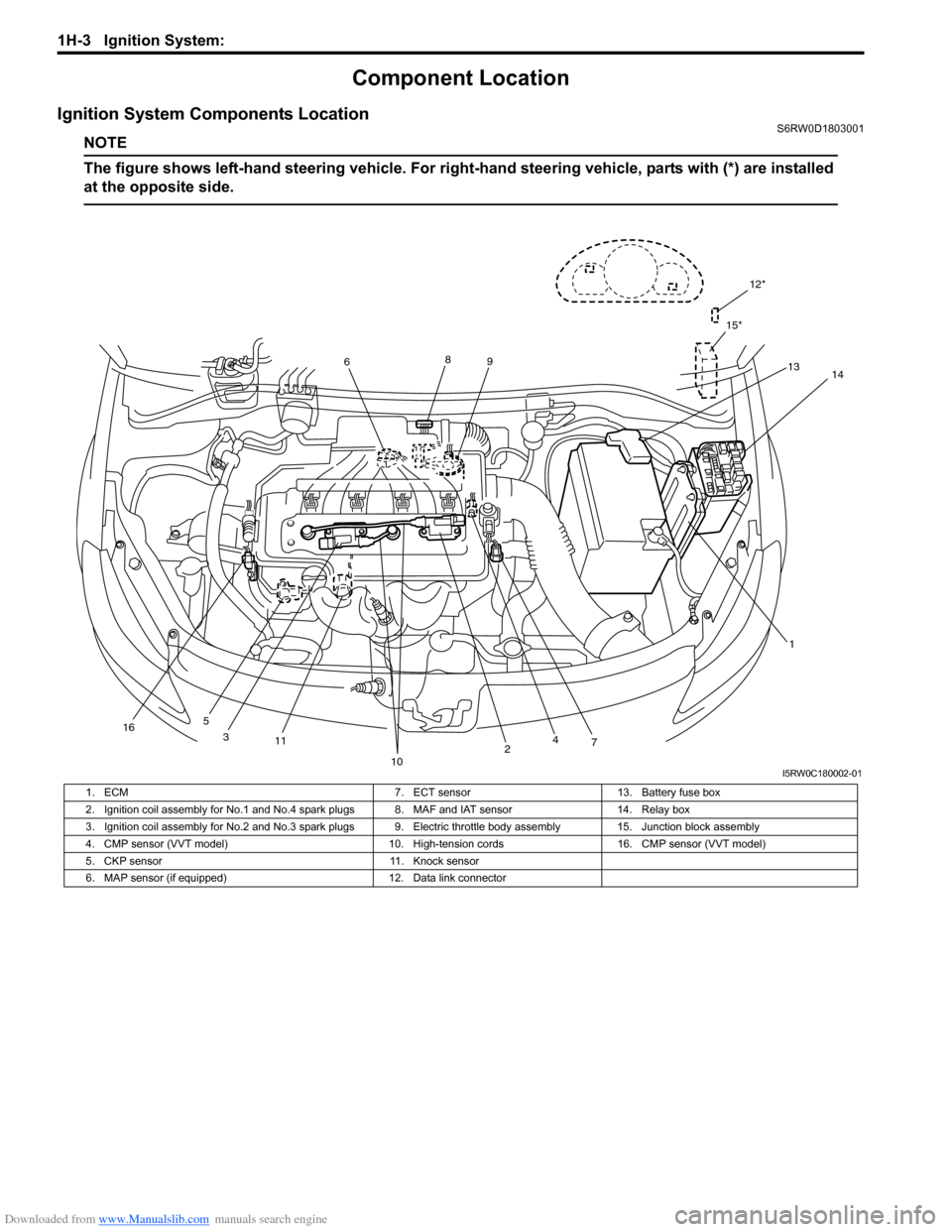

Component Location

Ignition System Components LocationS6RW0D1803001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

12*

15*

13

1 689

11

10

74

5

14

2 3

16

I5RW0C180002-01

1. ECM 7. ECT sensor 13. Battery fuse box

2. Ignition coil assembly for No.1 and No.4 spark plugs 8. MAF and IAT sensor 14. Relay box

3. Ignition coil assembly for No.2 and No.3 spark plugs 9. Electric throttle body assembly 15. Junction block assembly

4. CMP sensor (VVT model) 10. High-tension cords 16. CMP sensor (VVT model)

5. CKP sensor 11. Knock sensor

6. MAP sensor (if equipped) 12. Data link connector

Page 399 of 1556

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-4

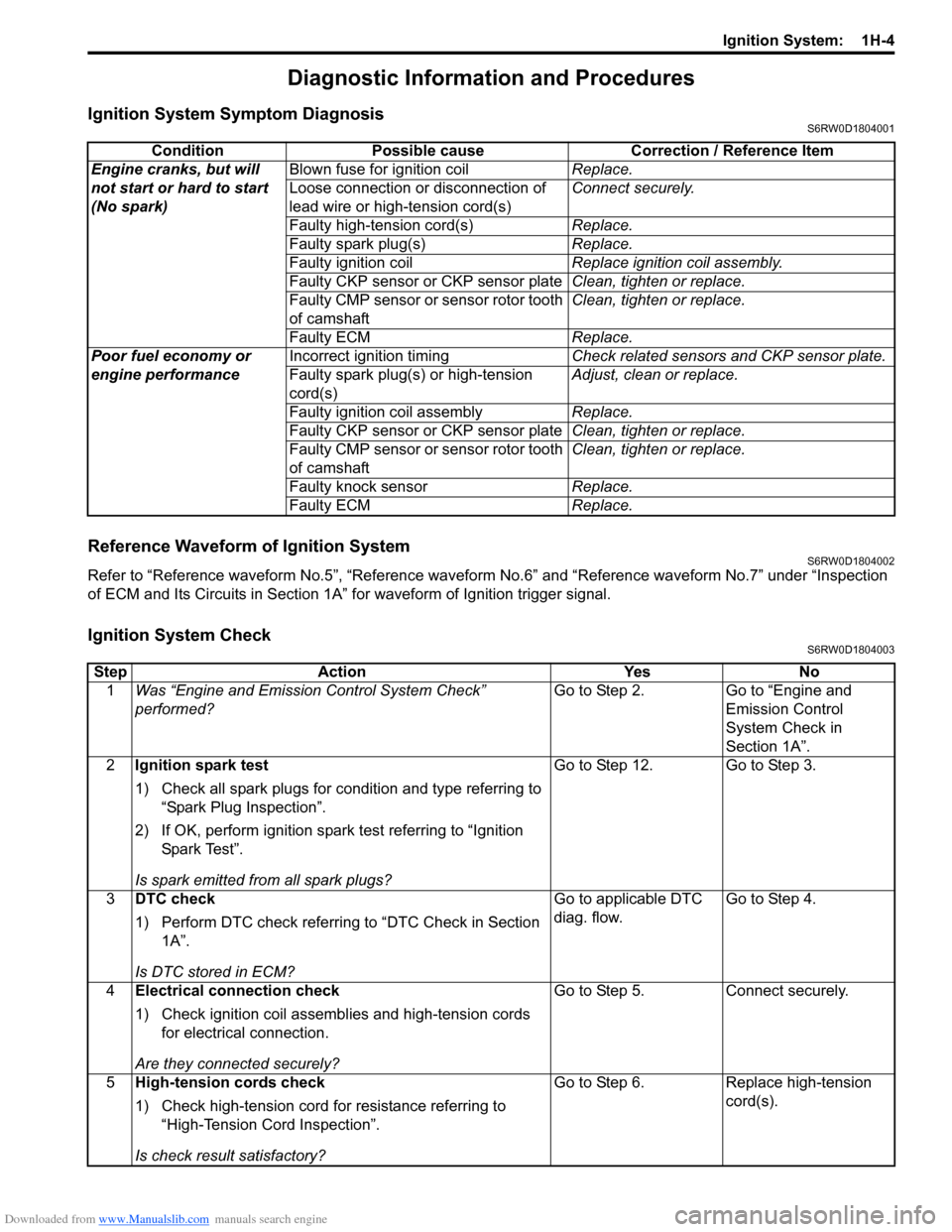

Diagnostic Information and Procedures

Ignition System Symptom DiagnosisS6RW0D1804001

Reference Waveform of Ignition SystemS6RW0D1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS6RW0D1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark)Blown fuse for ignition coilReplace.

Loose connection or disconnection of

lead wire or high-tension cord(s)Connect securely.

Faulty high-tension cord(s)Replace.

Faulty spark plug(s)Replace.

Faulty ignition coilReplace ignition coil assembly.

Faulty CKP sensor or CKP sensor plateClean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaftClean, tighten or replace.

Faulty ECMReplace.

Poor fuel economy or

engine performanceIncorrect ignition timingCheck related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s)Adjust, clean or replace.

Faulty ignition coil assemblyReplace.

Faulty CKP sensor or CKP sensor plateClean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaftClean, tighten or replace.

Faulty knock sensorReplace.

Faulty ECMReplace.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check in

Section 1A”.

2Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition

Spar k Tes t”.

Is spark emitted from all spark plugs?Go to Step 12. Go to Step 3.

3DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM?Go to applicable DTC

diag. flow.Go to Step 4.

4Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely?Go to Step 5. Connect securely.

5High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory?Go to Step 6. Replace high-tension

cord(s).

Page 400 of 1556

Downloaded from www.Manualslib.com manuals search engine 1H-5 Ignition System:

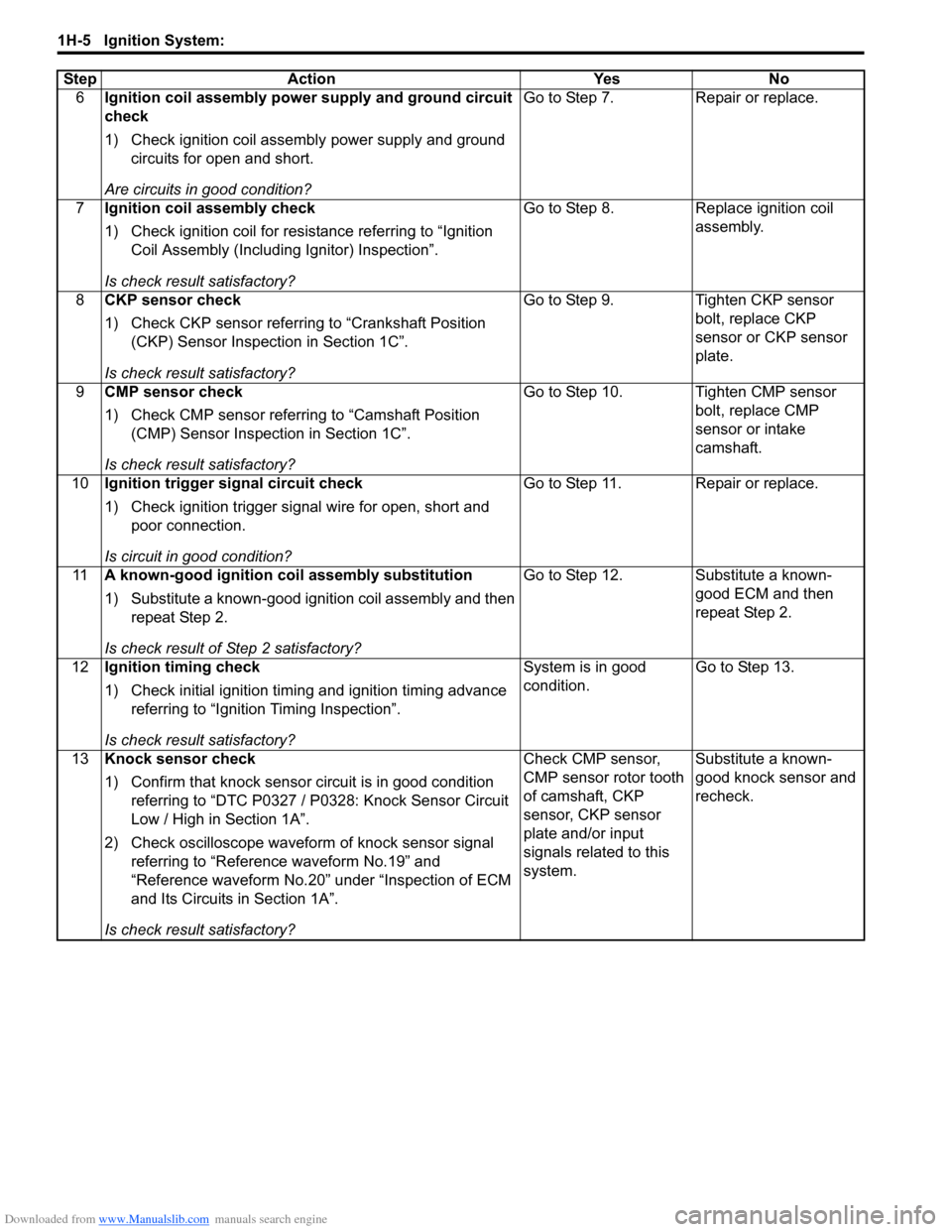

6Ignition coil assembly power supply and ground circuit

check

1) Check ignition coil assembly power supply and ground

circuits for open and short.

Are circuits in good condition?Go to Step 7. Repair or replace.

7Ignition coil assembly check

1) Check ignition coil for resistance referring to “Ignition

Coil Assembly (Including Ignitor) Inspection”.

Is check result satisfactory?Go to Step 8. Replace ignition coil

assembly.

8CKP sensor check

1) Check CKP sensor referring to “Crankshaft Position

(CKP) Sensor Inspection in Section 1C”.

Is check result satisfactory?Go to Step 9. Tighten CKP sensor

bolt, replace CKP

sensor or CKP sensor

plate.

9CMP sensor check

1) Check CMP sensor referring to “Camshaft Position

(CMP) Sensor Inspection in Section 1C”.

Is check result satisfactory?Go to Step 10. Tighten CMP sensor

bolt, replace CMP

sensor or intake

camshaft.

10Ignition trigger signal circuit check

1) Check ignition trigger signal wire for open, short and

poor connection.

Is circuit in good condition?Go to Step 11. Repair or replace.

11A known-good ignition coil assembly substitution

1) Substitute a known-good ignition coil assembly and then

repeat Step 2.

Is check result of Step 2 satisfactory?Go to Step 12. Substitute a known-

good ECM and then

repeat Step 2.

12Ignition timing check

1) Check initial ignition timing and ignition timing advance

referring to “Ignition Timing Inspection”.

Is check result satisfactory?System is in good

condition.Go to Step 13.

13Knock sensor check

1) Confirm that knock sensor circuit is in good condition

referring to “DTC P0327 / P0328: Knock Sensor Circuit

Low / High in Section 1A”.

2) Check oscilloscope waveform of knock sensor signal

referring to “Reference waveform No.19” and

“Reference waveform No.20” under “Inspection of ECM

and Its Circuits in Section 1A”.

Is check result satisfactory?Check CMP sensor,

CMP sensor rotor tooth

of camshaft, CKP

sensor, CKP sensor

plate and/or input

signals related to this

system.Substitute a known-

good knock sensor and

recheck. Step Action Yes No