Sas SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 646 of 1556

Downloaded from www.Manualslib.com manuals search engine 5-ii Table of Contents

DTC P1723: Range Select Switch

Malfunction ...................................................... 5A-68

DTC P1878: Torque Converter Clutch

Shudder .......................................................... 5A-69

DTC P2762: Torque Converter Clutch (TCC)

Pressure Control Solenoid Control Circuit

Range / Performance ...................................... 5A-70

DTC P2763: Torque Converter Clutch (TCC)

Pressure Control Solenoid Control Circuit

High ................................................................. 5A-72

DTC P2764: Torque Converter Clutch (TCC)

Circuit Pressure Control Solenoid Control

Circuit Low ...................................................... 5A-74

DTC U0073: Control Module Communication

Bus Off ............................................................ 5A-76

DTC U0100: Lost Communication with ECM /

PCM “A” .......................................................... 5A-76

Inspection of TCM and Its Circuits .................... 5A-76

TCM Power and Ground Circuit Check ............. 5A-80

Brake Interlock System Inspection .................... 5A-81

Repair Instructions ............................................5A-82

Learning Control Initialization ............................ 5A-82

A/T Fluid Level Check ....................................... 5A-82

A/T Fluid Change .............................................. 5A-83

Select Lever Components ................................. 5A-84

Select Lever Assembly Removal and

Installation ....................................................... 5A-84

Select Lever Knob Installation........................... 5A-84

Select Lever Inspection ..................................... 5A-85

“3” Position Switch Inspection ........................... 5A-85

Shift Lock Solenoid Inspection .......................... 5A-85

Shift Lock Solenoid Replacement ..................... 5A-85

Select Cable Components ................................ 5A-86

Select Cable Removal and Installation ............. 5A-86

Select Cable Adjustment ................................... 5A-86

Key Interlock Cable Removal and Installation... 5A-87

Transmission Range Sensor Inspection and

Adjustment ...................................................... 5A-89

Output Shaft Speed Sensor (VSS) Removal

and Installation ................................................ 5A-90

Output Shaft Speed Sensor (VSS) Inspection .. 5A-90

Input Shaft Speed Sensor Removal and

Installation ....................................................... 5A-91

Input Shaft Speed Sensor Inspection................ 5A-91

Transmission Fluid Temperature Sensor

Removal and Installation ................................. 5A-91

Transmission Fluid Temperature Sensor

Inspection ........................................................ 5A-92

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Removal and

Installation ....................................................... 5A-92

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Inspection .................. 5A-94

Pressure Control Solenoid Valves (Pressure

Control Solenoid and TCC Solenoid)

Removal and Installation ................................. 5A-95

Pressure Control Solenoid Valves Inspection ... 5A-96

Transmission Control Module (TCM)

Removal and Installation ................................. 5A-97

A/T Relay Inspection ......................................... 5A-97Differential Side Oil Seal Replacement ............. 5A-98

A/T Fluid Cooler Hoses Replacement ............... 5A-98

Automatic Transaxle Unit Components............. 5A-99

Automatic Transaxle Unit Dismounting and

Remounting ................................................... 5A-100

Automatic Transaxle Assembly Components . 5A-102

Automatic Transaxle Unit Disassembly........... 5A-104

Oil Pump Assembly Components ................... 5A-116

Oil Pump Assembly Disassembly and

Reassembly .................................................. 5A-116

Oil Pump Assembly Inspection ....................... 5A-117

Direct Clutch Assembly Components.............. 5A-119

Direct Clutch Assembly Preliminary Check ..... 5A-119

Direct Clutch Assembly Disassembly and

Reassembly .................................................. 5A-120

Direct Clutch Assembly Inspection.................. 5A-122

Forward and Reverse Clutch Assembly

Components .................................................. 5A-123

Forward and Reverse Clutch Assembly

Preliminary Check ......................................... 5A-123

Forward and Reverse Clutch Assembly

Disassembly and Reassembly ...................... 5A-124

Forward and Reverse Clutch Assembly

Inspection ...................................................... 5A-127

2nd Brake Piston Assembly Components ....... 5A-128

2nd Brake Piston Assembly Disassembly and

Reassembly .................................................. 5A-128

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Components........... 5A-129

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Disassembly and

Reassembly .................................................. 5A-130

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Inspection............... 5A-131

Countershaft Assembly Components.............. 5A-132

Countershaft Assembly Disassembly and

Reassembly .................................................. 5A-132

Valve Body Assembly Components ................ 5A-133

Valve Body Assembly Disassembly and

Reassembly .................................................. 5A-134

Differential Assembly Components ................. 5A-135

Differential Assembly Disassembly and

Reassembly .................................................. 5A-136

Differential Assembly Inspection ..................... 5A-137

Torque Converter Housing Disassembly and

Reassembly .................................................. 5A-138

Transaxle Case Disassembly and

Reassembly .................................................. 5A-140

Automatic Transaxle Unit Inspection and

Adjustment .................................................... 5A-141

Automatic Transaxle Unit Assembly ............... 5A-144

Specifications ...................................................5A-161

Tightening Torque Specifications .................... 5A-161

Special Tools and Equipment .........................5A-162

Recommended Service Material ..................... 5A-162

Special Tool .................................................... 5A-162

Manual Transmission/Transaxle ............ 5B-1

General Description .............................................5B-1

Manual Transaxle Construction .......................... 5B-1

Page 647 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5-iii

Diagnostic Information and Procedures ............ 5B-5

Manual Transaxle Symptom Diagnosis............... 5B-5

Repair Instructions .............................................. 5B-5

Manual Transaxle Oil Level Check ..................... 5B-5

Manual Transaxle Oil Change ............................ 5B-6

Differential Side Oil Seal Replacement ............... 5B-7

Gear Shift Control Lever and Cable

Components...................................................... 5B-8

Gear Shift Control Lever and Cable Removal

and Installation .................................................. 5B-9

Gear Select Control Cable Adjustment ............... 5B-9

Back Up Light Switch Removal and

Installation ....................................................... 5B-10

Back Up Light Switch Inspection ....................... 5B-10

Manual Transaxle Unit Components ................. 5B-11

Manual Transaxle Unit Dismounting and

Remounting..................................................... 5B-12

Gear Shift and Select Shaft Assembly

Components.................................................... 5B-13

Gear Shift and Select Shaft Assembly

Removal and Installation................................. 5B-14

Gear Shift and Select Shaft Assembly

Disassembly and Reassembly ........................ 5B-15

Manual Transaxle Assembly Components........ 5B-16

Fifth Gear Disassembly and Reassembly ......... 5B-17

Manual Transaxle Assembly Disassembly

and Reassembly ............................................. 5B-19

Right Case Disassembly and Reassembly ....... 5B-24

Left Case Disassembly and Reassembly.......... 5B-25

Input Shaft and Countershaft Components....... 5B-27

Input Shaft Disassembly and Reassembly........ 5B-28

Countershaft Disassembly and Reassembly .... 5B-31

Gear Shift Shaft Components ........................... 5B-35

5th and Reverse Gear Shift Shafts

Disassembly and Reassembly ........................ 5B-35

Gear Shift Shaft and Fork Inspection ................ 5B-35

Differential Components ................................... 5B-36Differential Disassembly and Reassembly ........ 5B-36

Specifications .....................................................5B-38

Tightening Torque Specifications ...................... 5B-38

Special Tools and Equipment ...........................5B-39

Recommended Service Material ....................... 5B-39

Special Tool ...................................................... 5B-39

Clutch ....................................................... 5C-1

General Description .............................................5C-1

Clutch (Hydraulic Type) Construction .................5C-1

Diagnostic Information and Procedures ............5C-2

Clutch System Symptom Diagnosis ....................5C-2

Repair Instructions ..............................................5C-3

Clutch Pedal Inspection ......................................5C-3

Clutch Fluid Level Inspection ..............................5C-3

Air Bleeding of Clutch System.............................5C-3

Clutch Fluid Pipe and Hose Location ..................5C-4

Clutch Fluid Pipe Removal and Installation.........5C-4

Clutch Fluid Pipe Inspection................................5C-4

Clutch Master Cylinder Removal and

Installation .........................................................5C-5

Clutch Operating Cylinder Assembly

Removal and Installation ...................................5C-5

Clutch Operating Cylinder Assembly

Inspection ..........................................................5C-6

Clutch Cover, Clutch Disc and Flywheel

Components ......................................................5C-6

Clutch Cover, Clutch Disc and Flywheel

Removal and Installation ...................................5C-7

Clutch Cover, Clutch Disc and Flywheel

Inspection ..........................................................5C-8

Specifications .......................................................5C-9

Tightening Torque Specifications ........................5C-9

Special Tools and Equipment ...........................5C-10

Recommended Service Material .......................5C-10

Special Tool ......................................................5C-10

Page 648 of 1556

Downloaded from www.Manualslib.com manuals search engine 5-1 Precautions:

Transmission / Transaxle

Precautions

Precautions

Precautions on Transmission / TransaxleS6RW0D5000001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Precautions in Diagnosing Trouble

Refer to “Precautions in Diagnosing Trouble in Section 5A”.

Precautions for Disassembly and Reassembly

Refer to “Precautions for Disassembly and Reassembly in Section 5A”.

Precaution on CAN Troubleshooting

Refer to “Precaution on CAN Troubleshooting in Section 1A”.

Page 649 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-1

Transmission / Transaxle

Automatic Transmission/Transaxle

Precautions

Precautions in Diagnosing TroubleS6RW0D5100001

• Do not disconnect couplers from TCM, battery cable

from battery, TCM ground wire harness from engine or

main fuse before checking the diagnostic information

(DTC, freeze frame data, etc.) stored in TCM memory.

Such disconnection will clear memorized information

in TCM memory.

• Diagnostic information stored in TCM memory can be

cleared as well as checked by using SUZUKI scan

tool or CAN communication OBD generic scan tool.

Before using scan tool, read its Operator’s

(Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

It is indistinguishable which module turns on MIL

because not only ECM but also TCM turns on MIL.

Therefore, check both ECM and TCM for DTC when

MIL lights on.

When checking TCM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by TCM.

– CAN communication OBD generic scan tool

displays DTC detected by each of ECM and TCM

simultaneously.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection and observe

what is written there.

• TCM replacement

– When substituting a known-good TCM, check that

all relays and actuators have resistance of

specified value.

Neglecting this check may result in damage to good

TCM.

• Communication of ECM, BCM, combination meter,

keyless start control module (if equipped), ABS

control module, 4WD control module (if equipped),

TCM and DLC, is established by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

Precautions for Disassembly and ReassemblyS6RW0D5100002

When repairing automatic transaxle, it is necessary to

conduct the on-vehicle test to investigate where the

cause of the trouble lies first.

Then whether overhaul should be done or not is

determined. If the transaxle is disassembled without

such preliminary procedure, not only the cause of the

trouble would be unknown, but also a secondary trouble

may occur and often time would be wasted.

As the automatic transaxle consists of high precision

component, the following cautions should be strictly

observed when handling its parts in disassembly and

reassembly.

• Disassembling valve body assembly is prohibited

essentially. However, a few parts can be

disassembled. When disassembling valve body

component parts, confirm whether their parts are

allowed to disassemble or not referring to “Valve Body

Assembly Disassembly and Reassembly”.

• When component part of forward clutch, direct clutch,

2nd brake and/or O/D and 2nd coast brake, namely

clutch disc, brake disc, retaining plate and/or

separator plate, have been replaced, all learned

contents, which have been stored in TCM memory by

executing learning control, should be initialized

referring to “Learning Control Initialization”.

• Make sure to wash dirt off from the transaxle so that

no such dirt will enter the transaxle during

dismounting and remounting.

• Select a clean place free from dust and dirt for

overhauling.

• Place a rubber mat on the work bench to protect parts

from damage.

• Work gloves or shop cloth should not be used. (Use a

nylon cloth or a paper towel.)

• When separating the case joint, do not pry with a

screwdriver or such but tap with a plastic hammer

lightly.

• Make sure to wash dirt off from the transaxle so that

no such dirt will enter the transaxle during

disassembly and reassembly.

• Wash the disassembled parts in ATF (Automatic

Transaxle Fluid) or kerosene (using care not to allow

ATF or kerosene to get on your face, etc.) and confirm

that each fluid passage is not clogged by blowing air

into it. But use kerosene to wash the discs, resin

washers and rubber parts.

• Replace each gasket, oil seal and O-ring with a new

one.

• Apply ATF to sliding or rotating parts before

reassembly.

Page 739 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-91

Input Shaft Speed Sensor Removal and

Installation

S6RW0D5106012

Removal

1) Disconnect negative cable at battery.

2) Disconnect input shaft speed sensor connector (2).

3) Remove input shaft speed sensor (1) by removing its

bolt.

Installation

1) Apply A/T fluid to input shaft speed sensor O-ring.

2) Install input shaft speed sensor (1) to A/T case and

tighten bolt to specified torque.

Tightening torque

Input shaft speed sensor bolt (a): 5.5 N·m (0.55

kgf-m, 4.0 lb-ft)

3) Connect input shaft speed sensor connector (2) to

input shaft speed sensor (1).

4) Connect negative cable to battery.

Input Shaft Speed Sensor InspectionS6RW0D5106013

1) Disconnect negative cable at battery.

2) Disconnect input shaft speed sensor connector (2).

3) Check resistance between input shaft speed sensor

(1) terminals.

Input shaft speed sensor resistance

Standard: 560 – 680 Ω at 20 °C (68 °F)

Transmission Fluid Temperature Sensor

Removal and Installation

S6RW0D5106014

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove left side engine under cover.

4) With engine is cool, remove drain plug and drain A/T

fluid.

5) Install drain plug. Refer to “A/T Fluid Change”.

6) Remove A/T oil pan.

7) Remove oil strainer assembly.

8) Remove valve body assembly referring to

“Automatic Transaxle Unit Disassembly”.

CAUTION!

When pulling valve body harness out of

transaxle case, take care not to damage

transmission fluid temperature sensor at

narrow exit of case.

Careless sensor treatment might cause

sensor malfunction.

9) Remove valve body harness (1).

12

I5RW0C510034-01

12

(a)I5RW0C510035-01

12I5RW0C510036-01

I2RH0B510050-01

Page 744 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-96 Automatic Transmission/Transaxle:

10) Remove valve body assembly referring to

“Automatic Transaxle Unit Disassembly”.

11) Remove pressure control solenoid valve and TCC

pressure control solenoid valve referring to “Valve

Body Assembly Disassembly and Reassembly”.

Installation

Reverse removal procedure to install pressure control

solenoid valve and valve body assembly noting the

following points.

• For detail of pressure control solenoid valve and TCC

pressure control solenoid valve installation, refer to

“Valve Body Assembly Disassembly and

Reassembly”.

• For detail of valve body assembly installation, refer to

“Automatic Transaxle Unit Assembly”.

• For detail of installing wire harness for solenoid valves

and sensor, refer to “Automatic Transaxle Unit

Assembly”. Use new O-rings.

• For detail of A/T oil pan and oil strainer assembly

installation, refer to “Automatic Transaxle Unit

Assembly”. Use new oil pan gasket.

• Pour A/T fluid and check fluid level according to

procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

Pressure Control Solenoid Valves InspectionS6RW0D5106020

CAUTION!

• Be very careful as dust etc. does enter

when pressure control solenoid valves are

inspected.

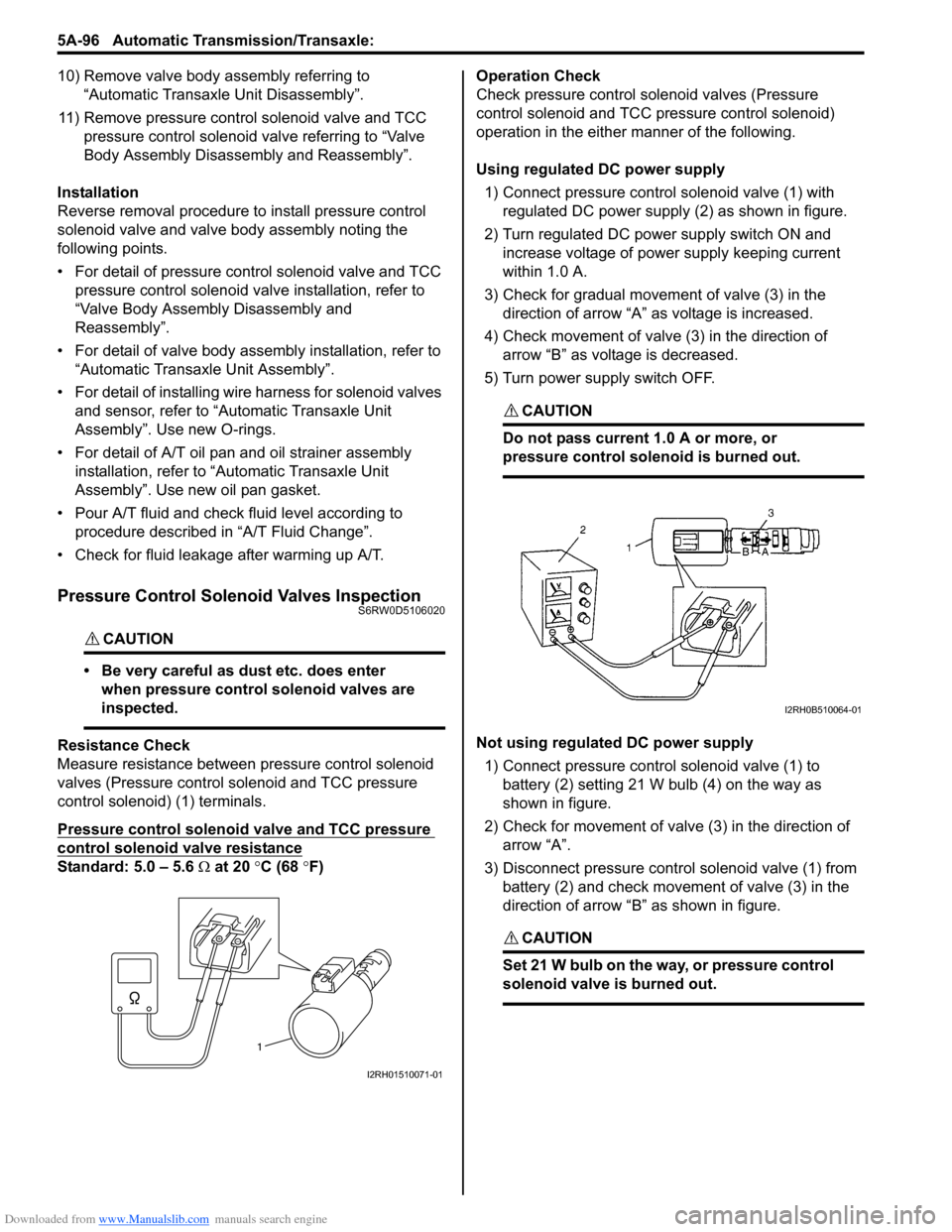

Resistance Check

Measure resistance between pressure control solenoid

valves (Pressure control solenoid and TCC pressure

control solenoid) (1) terminals.

Pressure control solenoid valve and TCC pressure

control solenoid valve resistance

Standard: 5.0 – 5.6 Ω at 20 °C (68 °F)Operation Check

Check pressure control solenoid valves (Pressure

control solenoid and TCC pressure control solenoid)

operation in the either manner of the following.

Using regulated DC power supply

1) Connect pressure control solenoid valve (1) with

regulated DC power supply (2) as shown in figure.

2) Turn regulated DC power supply switch ON and

increase voltage of power supply keeping current

within 1.0 A.

3) Check for gradual movement of valve (3) in the

direction of arrow “A” as voltage is increased.

4) Check movement of valve (3) in the direction of

arrow “B” as voltage is decreased.

5) Turn power supply switch OFF.

CAUTION!

Do not pass current 1.0 A or more, or

pressure control solenoid is burned out.

Not using regulated DC power supply

1) Connect pressure control solenoid valve (1) to

battery (2) setting 21 W bulb (4) on the way as

shown in figure.

2) Check for movement of valve (3) in the direction of

arrow “A”.

3) Disconnect pressure control solenoid valve (1) from

battery (2) and check movement of valve (3) in the

direction of arrow “B” as shown in figure.

CAUTION!

Set 21 W bulb on the way, or pressure control

solenoid valve is burned out.

1

I2RH01510071-01

I2RH0B510064-01

Page 752 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-104 Automatic Transmission/Transaxle:

Automatic Transaxle Unit DisassemblyS6RW0D5106031

CAUTION!

• Thoroughly clean transaxle exterior before

overhauling it.

• Keep working table, tools and hands clean

while overhauling.

• Use special care to handle aluminum parts

so as not to damage them.

• Do not expose removed parts to dust.

Keep them always clean.

1) Remove torque converter (1).

CAUTION!

Remove torque converter as much straight

as possible. Leaning it may cause to damage

oil seal lip.

2) Remove engine mounting LH bracket (1).

3) Remove manual select lever (1).4) Uncaulk lock washer (1), then remove lock nut (2)

and lock washer.

5) Remove transmission range sensor (1).

6) Remove output shaft speed sensor (VSS) (2) and

input shaft speed sensor (1).

7) Remove harness bracket and select cable clamp (3).

8) Remove select cable bracket (1).

I2RH0B510078-01

1

I5RW0C510058-01

1I2RH0B510080-01

I2RH0B510081-01

1I2RH0B510082-01

2 3

1

I2RH0B510083-01

1

I5RW0C510059-01

Page 759 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-111

48) Remove O/D and 2nd coast brake retaining plate

snap ring (1).

49) Remove front planetary sun gear (1).

50) Remove front sun gear thrust bearing race (2) from

front planetary sun gear (1).

51) Before disassembling 2nd brake piston assembly

(4), check 2nd brake piston stroke by measuring

clearance between 2nd brake separator plate (1)

and piston (2) with feeler gauge (3).

If clearance, that is, piston stroke is out of

specification, replace brake discs and plates with

new ones.

CAUTION!

When brake disc, retaining plate and/or

separator plate of 2nd brake have been

replaced, all learned contents, which have

been stored in TCM memory by executing

learning control, should be initialized

referring to “Learning Control Initialization”.

Neglecting this initialization may cause

excessive shift shock.

2nd brake piston stroke

“a”: 0.40 – 1.25 mm (0.016 – 0.049 in.)

52) Using special tool and hydraulic press, remove 2nd

brake piston snap ring (1).

CAUTION!

Do not press 2nd brake piston assembly in

over 0.4 mm (0.016 in.).

Excessive compression may cause damage

to piston assembly, return spring, plates and/

or discs.

Special tool

(A): 09926–96050

I2RH0B510120-01

I2RH0B510121-01

I2RH0B510122-01

3

4 1 2

“a”4

I2RH0B510123-01

I2RH0B510124-01

Page 761 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-113

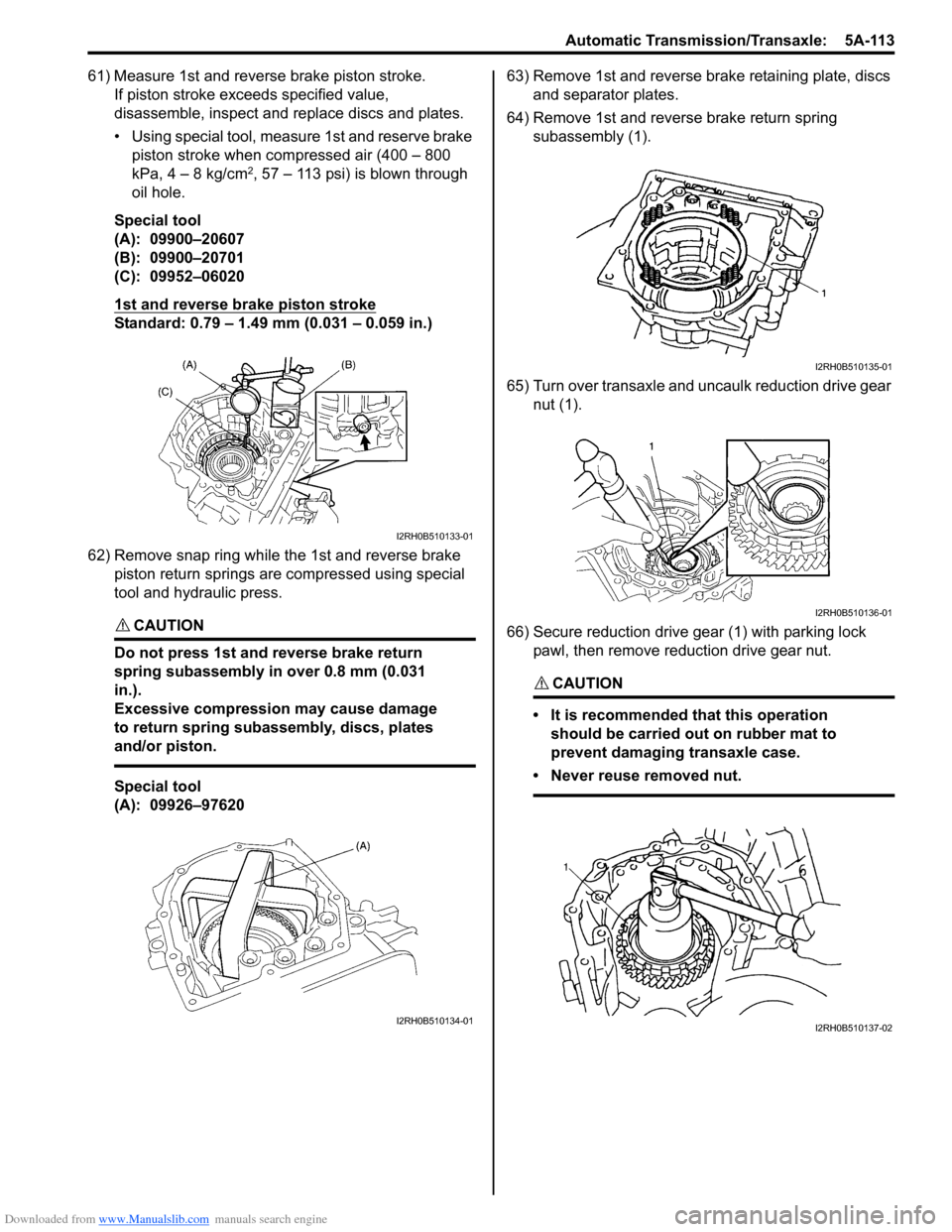

61) Measure 1st and reverse brake piston stroke.

If piston stroke exceeds specified value,

disassemble, inspect and replace discs and plates.

• Using special tool, measure 1st and reserve brake

piston stroke when compressed air (400 – 800

kPa, 4 – 8 kg/cm

2, 57 – 113 psi) is blown through

oil hole.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

1st and reverse brake piston stroke

Standard: 0.79 – 1.49 mm (0.031 – 0.059 in.)

62) Remove snap ring while the 1st and reverse brake

piston return springs are compressed using special

tool and hydraulic press.

CAUTION!

Do not press 1st and reverse brake return

spring subassembly in over 0.8 mm (0.031

in.).

Excessive compression may cause damage

to return spring subassembly, discs, plates

and/or piston.

Special tool

(A): 09926–9762063) Remove 1st and reverse brake retaining plate, discs

and separator plates.

64) Remove 1st and reverse brake return spring

subassembly (1).

65) Turn over transaxle and uncaulk reduction drive gear

nut (1).

66) Secure reduction drive gear (1) with parking lock

pawl, then remove reduction drive gear nut.

CAUTION!

• It is recommended that this operation

should be carried out on rubber mat to

prevent damaging transaxle case.

• Never reuse removed nut.

I2RH0B510133-01

I2RH0B510134-01

I2RH0B510135-01

I2RH0B510136-01

I2RH0B510137-02

Page 764 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-116 Automatic Transmission/Transaxle:

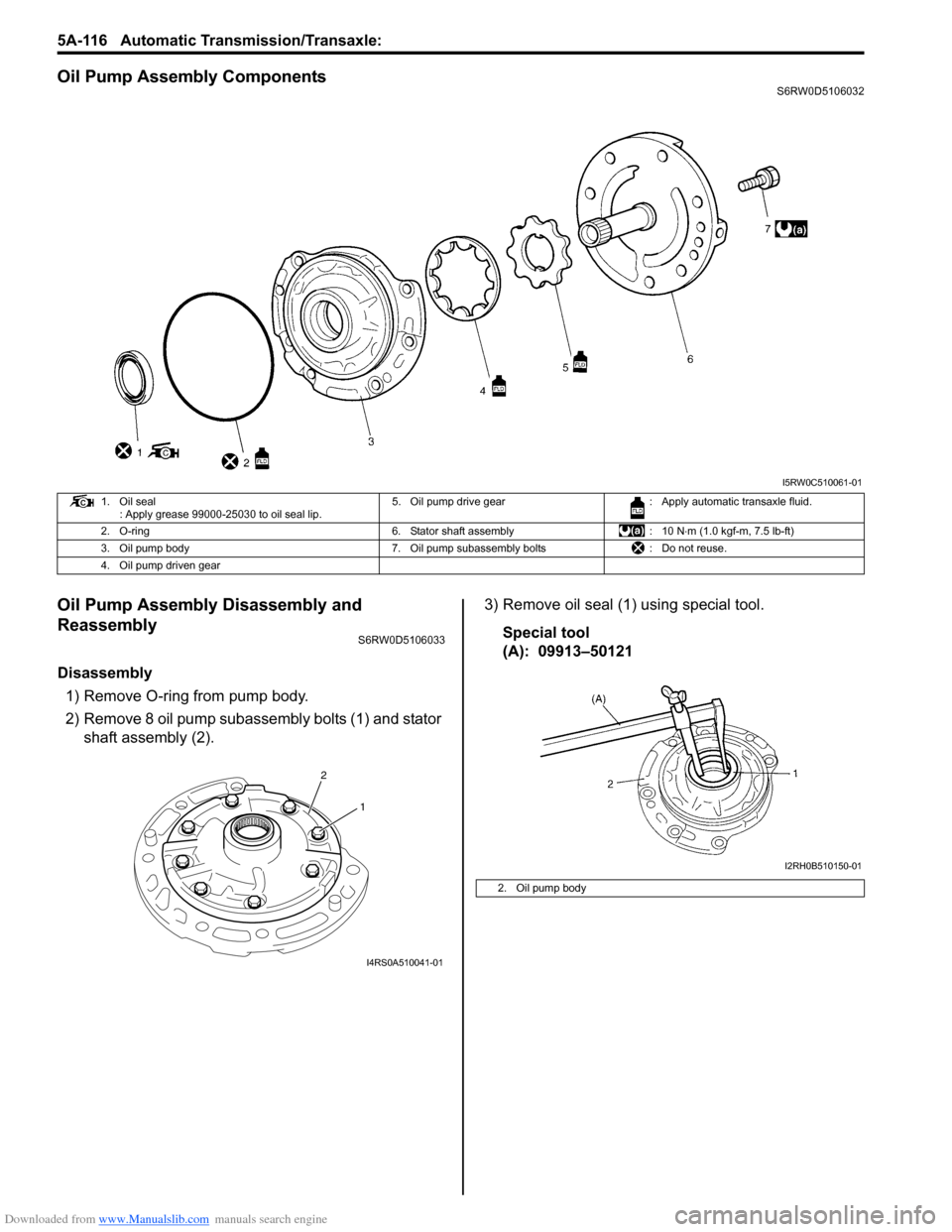

Oil Pump Assembly ComponentsS6RW0D5106032

Oil Pump Assembly Disassembly and

Reassembly

S6RW0D5106033

Disassembly

1) Remove O-ring from pump body.

2) Remove 8 oil pump subassembly bolts (1) and stator

shaft assembly (2).3) Remove oil seal (1) using special tool.

Special tool

(A): 09913–50121

I5RW0C510061-01

1. Oil seal

: Apply grease 99000-25030 to oil seal lip.5. Oil pump drive gear : Apply automatic transaxle fluid.

2. O-ring 6. Stator shaft assembly : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

3. Oil pump body 7. Oil pump subassembly bolts : Do not reuse.

4. Oil pump driven gear

2

1

I4RS0A510041-01

2. Oil pump body

I2RH0B510150-01