Sas SUZUKI SX4 2006 1.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 837 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-25

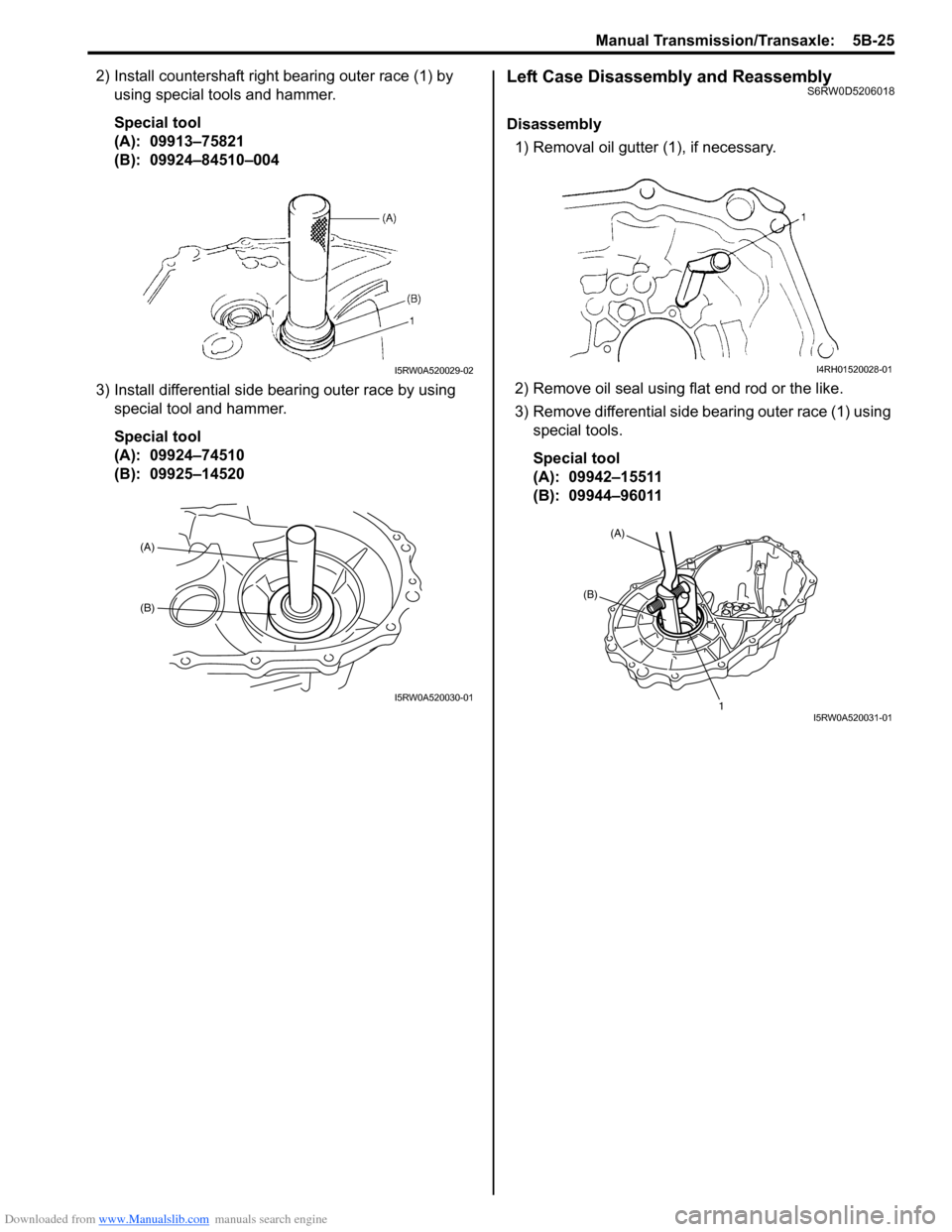

2) Install countershaft right bearing outer race (1) by

using special tools and hammer.

Special tool

(A): 09913–75821

(B): 09924–84510–004

3) Install differential side bearing outer race by using

special tool and hammer.

Special tool

(A): 09924–74510

(B): 09925–14520Left Case Disassembly and ReassemblyS6RW0D5206018

Disassembly

1) Removal oil gutter (1), if necessary.

2) Remove oil seal using flat end rod or the like.

3) Remove differential side bearing outer race (1) using

special tools.

Special tool

(A): 09942–15511

(B): 09944–96011

I5RW0A520029-02

(A)

(B)

I5RW0A520030-01

I4RH01520028-01

(A)

(B)

1I5RW0A520031-01

Page 840 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-28 Manual Transmission/Transaxle:

Input Shaft Disassembly and ReassemblyS6RW0D5206020

Disassembly

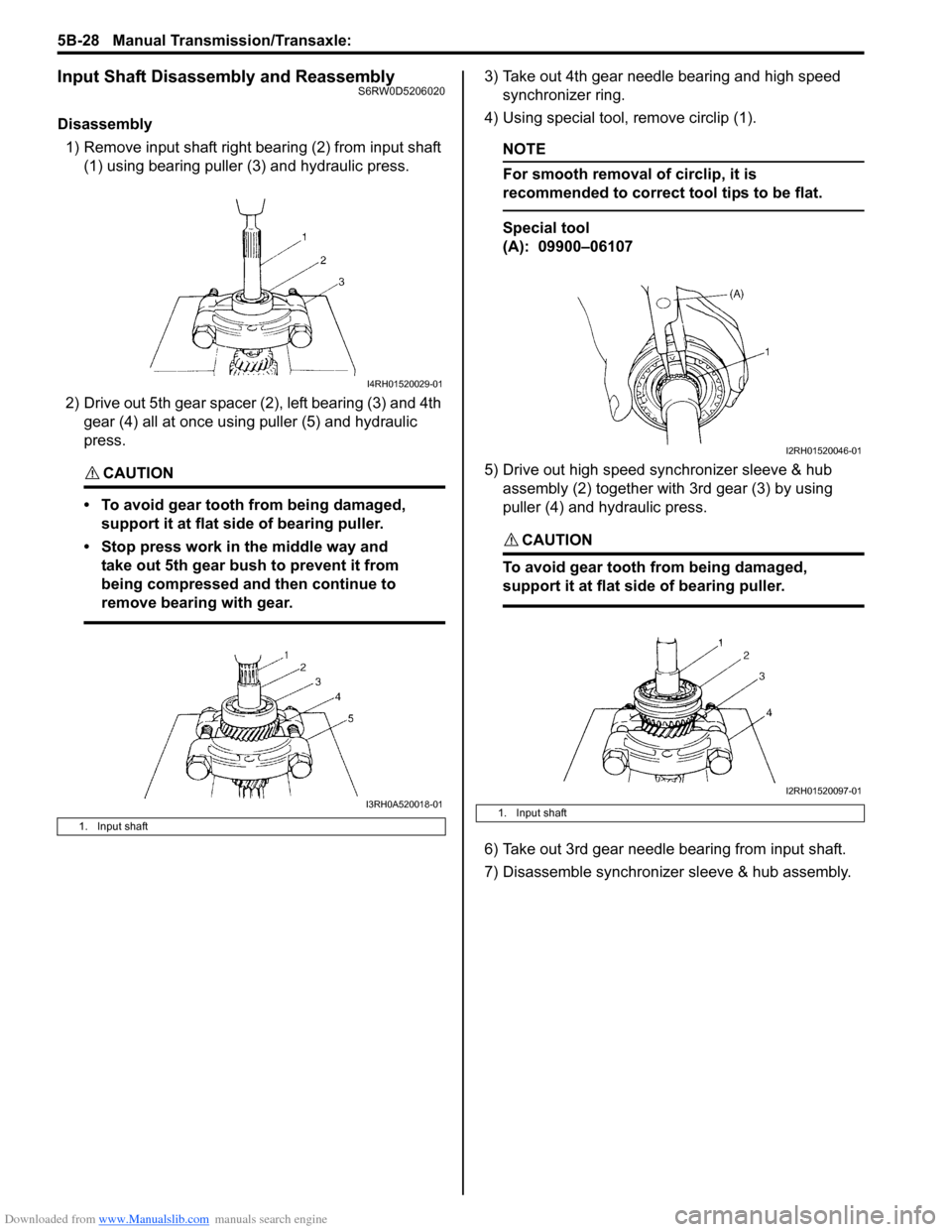

1) Remove input shaft right bearing (2) from input shaft

(1) using bearing puller (3) and hydraulic press.

2) Drive out 5th gear spacer (2), left bearing (3) and 4th

gear (4) all at once using puller (5) and hydraulic

press.

CAUTION!

• To avoid gear tooth from being damaged,

support it at flat side of bearing puller.

• Stop press work in the middle way and

take out 5th gear bush to prevent it from

being compressed and then continue to

remove bearing with gear.

3) Take out 4th gear needle bearing and high speed

synchronizer ring.

4) Using special tool, remove circlip (1).

NOTE

For smooth removal of circlip, it is

recommended to correct tool tips to be flat.

Special tool

(A): 09900–06107

5) Drive out high speed synchronizer sleeve & hub

assembly (2) together with 3rd gear (3) by using

puller (4) and hydraulic press.

CAUTION!

To avoid gear tooth from being damaged,

support it at flat side of bearing puller.

6) Take out 3rd gear needle bearing from input shaft.

7) Disassemble synchronizer sleeve & hub assembly.

1. Input shaft

I4RH01520029-01

I3RH0A520018-011. Input shaft

I2RH01520046-01

I2RH01520097-01

Page 843 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-31

Countershaft Disassembly and ReassemblyS6RW0D5206021

Disassembly

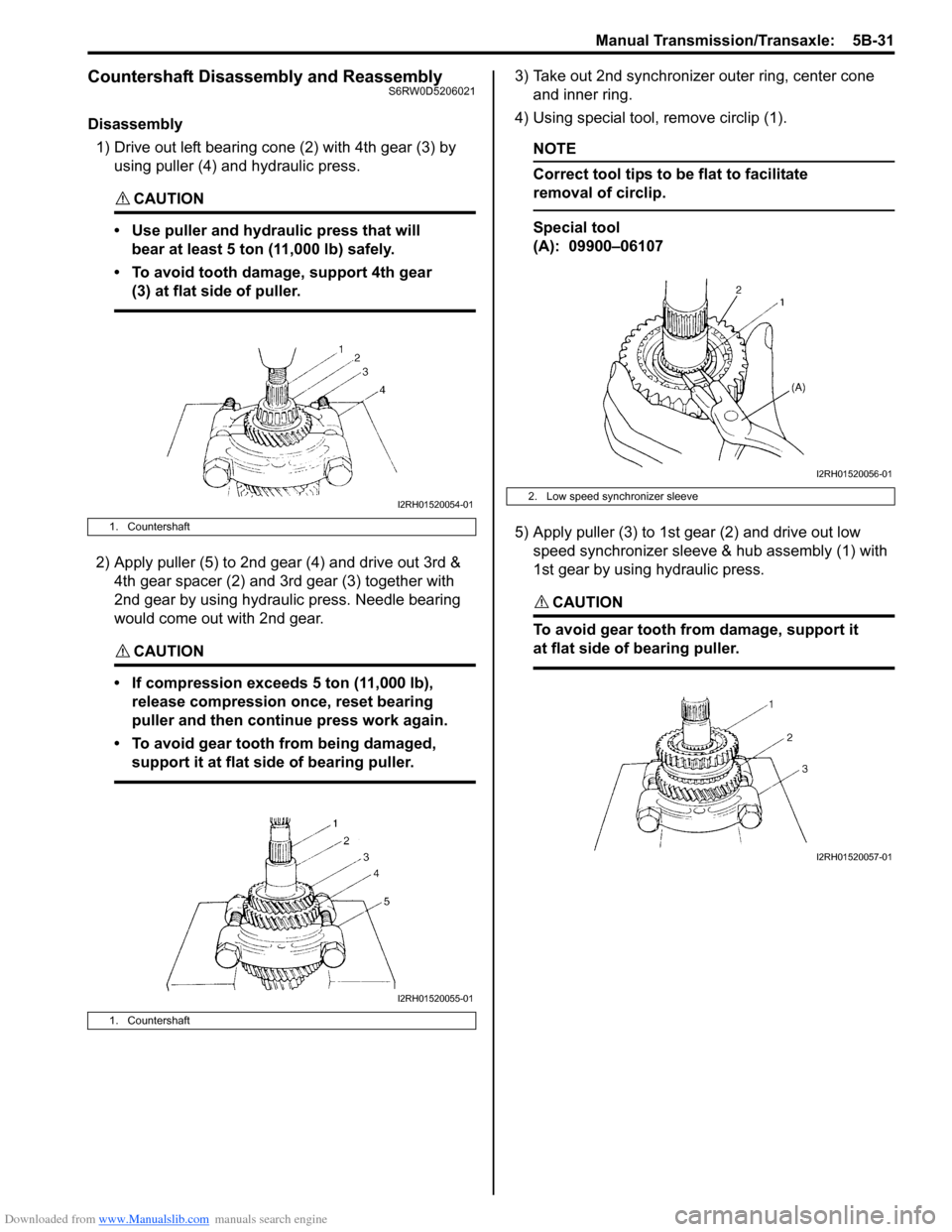

1) Drive out left bearing cone (2) with 4th gear (3) by

using puller (4) and hydraulic press.

CAUTION!

• Use puller and hydraulic press that will

bear at least 5 ton (11,000 lb) safely.

• To avoid tooth damage, support 4th gear

(3) at flat side of puller.

2) Apply puller (5) to 2nd gear (4) and drive out 3rd &

4th gear spacer (2) and 3rd gear (3) together with

2nd gear by using hydraulic press. Needle bearing

would come out with 2nd gear.

CAUTION!

• If compression exceeds 5 ton (11,000 lb),

release compression once, reset bearing

puller and then continue press work again.

• To avoid gear tooth from being damaged,

support it at flat side of bearing puller.

3) Take out 2nd synchronizer outer ring, center cone

and inner ring.

4) Using special tool, remove circlip (1).

NOTE

Correct tool tips to be flat to facilitate

removal of circlip.

Special tool

(A): 09900–06107

5) Apply puller (3) to 1st gear (2) and drive out low

speed synchronizer sleeve & hub assembly (1) with

1st gear by using hydraulic press.

CAUTION!

To avoid gear tooth from damage, support it

at flat side of bearing puller.

1. Countershaft

1. Countershaft

I2RH01520054-01

I2RH01520055-01

2. Low speed synchronizer sleeve

I2RH01520056-01

I2RH01520057-01

Page 844 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-32 Manual Transmission/Transaxle:

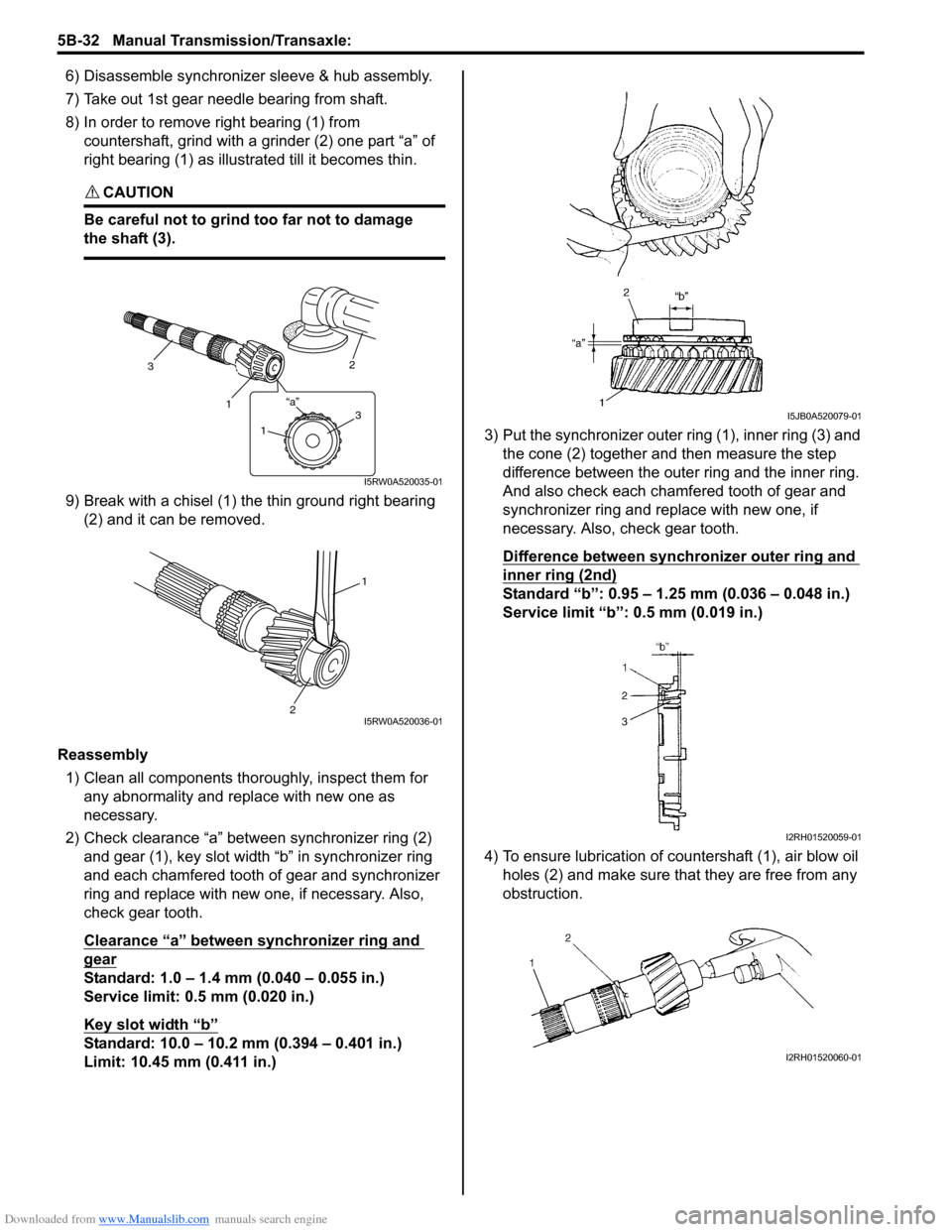

6) Disassemble synchronizer sleeve & hub assembly.

7) Take out 1st gear needle bearing from shaft.

8) In order to remove right bearing (1) from

countershaft, grind with a grinder (2) one part “a” of

right bearing (1) as illustrated till it becomes thin.

CAUTION!

Be careful not to grind too far not to damage

the shaft (3).

9) Break with a chisel (1) the thin ground right bearing

(2) and it can be removed.

Reassembly

1) Clean all components thoroughly, inspect them for

any abnormality and replace with new one as

necessary.

2) Check clearance “a” between synchronizer ring (2)

and gear (1), key slot width “b” in synchronizer ring

and each chamfered tooth of gear and synchronizer

ring and replace with new one, if necessary. Also,

check gear tooth.

Clearance “a” between synchronizer ring and

gear

Standard: 1.0 – 1.4 mm (0.040 – 0.055 in.)

Service limit: 0.5 mm (0.020 in.)

Key slot width “b”

Standard: 10.0 – 10.2 mm (0.394 – 0.401 in.)

Limit: 10.45 mm (0.411 in.)3) Put the synchronizer outer ring (1), inner ring (3) and

the cone (2) together and then measure the step

difference between the outer ring and the inner ring.

And also check each chamfered tooth of gear and

synchronizer ring and replace with new one, if

necessary. Also, check gear tooth.

Difference between synchronizer outer ring and

inner ring (2nd)

Standard “b”: 0.95 – 1.25 mm (0.036 – 0.048 in.)

Service limit “b”: 0.5 mm (0.019 in.)

4) To ensure lubrication of countershaft (1), air blow oil

holes (2) and make sure that they are free from any

obstruction.

3

1

2

“a”31

I5RW0A520035-01

1

2I5RW0A520036-01

I5JB0A520079-01

I2RH01520059-01

I2RH01520060-01

Page 847 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-35

Gear Shift Shaft ComponentsS6RW0D5206022

5th and Reverse Gear Shift Shafts Disassembly

and Reassembly

S6RW0D5206023

Disassembly

Disassemble component parts by using special tool and

hammer.

Special tool

: 09922–85811

Reassembly

Replace or correct parts as required and assemble

shafts making sure that component parts are in proper

order as shown in figure.

NOTE

Install 2 steel balls (3) in reverse gear shift

arm (1) without fail.

Gear Shift Shaft and Fork InspectionS6RW0D5206024

1) Using feeler gauge, check clearance between fork

(1) and sleeve (2) and replace those parts if it

exceeds limit of 1.0 mm (0.039 in.).

NOTE

For correct judgement of parts replacement,

carefully inspect contact portion of fork and

sleeve.

Clearance “a” between fork and sleeve

Service limit: 1.0 mm (0.039 in.)

2) Insert each gear shift shaft into case and check that

it moves smoothly. If it doesn’t, correct by using

oilstone, reamer or the like.

I5RW0A520041-01

1. Low speed gear shift shaft 4. 5th & reverse gear shift guide shaft 7. 5th & reverse gear shift yoke

2. High speed gear shift shaft 5. Reverse gear shift arm : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

3. 5th & reverse gear shift shaft 6. Gear shift locating bolt

: Apply sealant 99000-31260 to bolt thread.

2. Spring 6. 5th & reverse gear shift yoke

4. Spring pin 7. 5th & reverse gear shift guide shaft

5. 5th & reverse gear shift shaft

I5RW0A520042-01

I2RH01520068-01

Page 848 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-36 Manual Transmission/Transaxle:

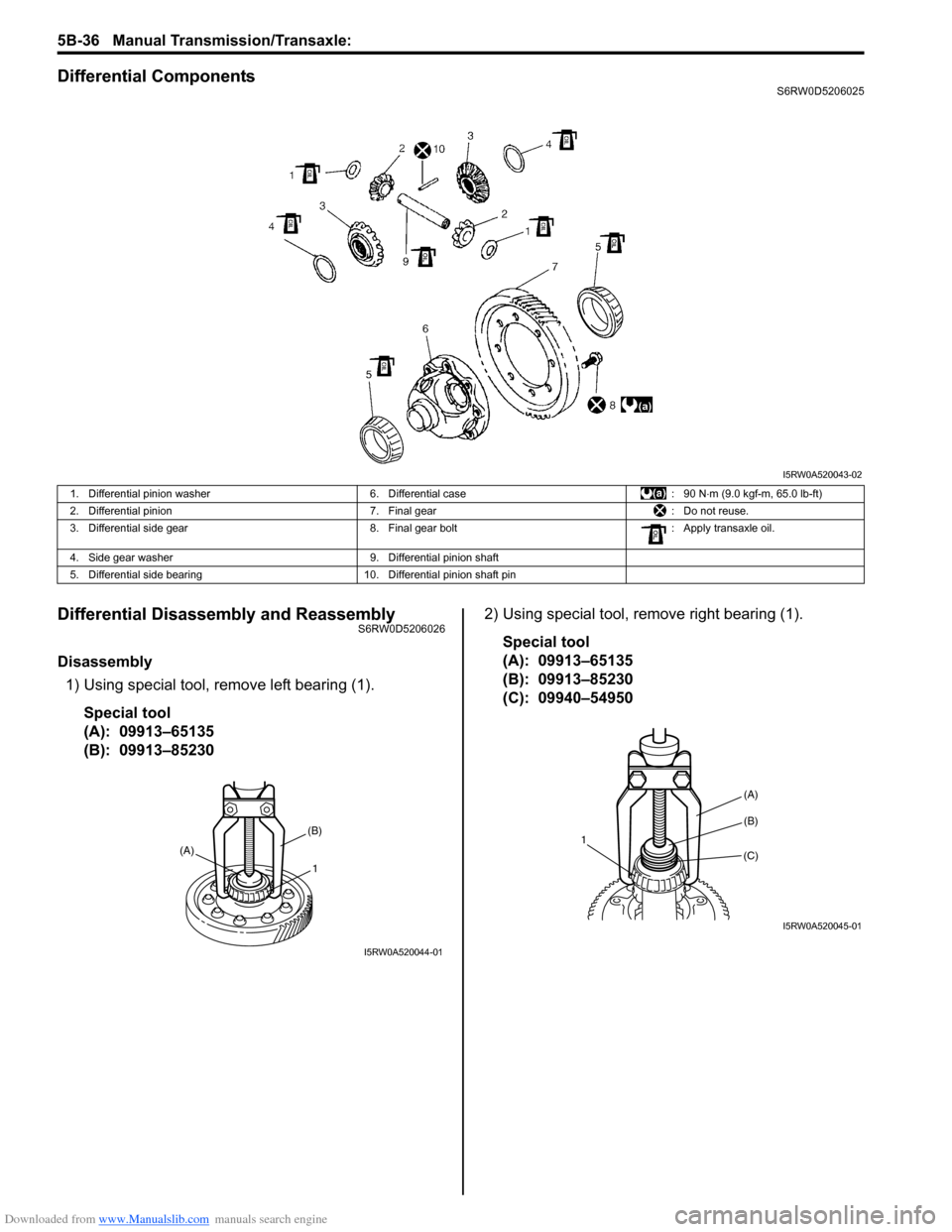

Differential ComponentsS6RW0D5206025

Differential Disassembly and ReassemblyS6RW0D5206026

Disassembly

1) Using special tool, remove left bearing (1).

Special tool

(A): 09913–65135

(B): 09913–852302) Using special tool, remove right bearing (1).

Special tool

(A): 09913–65135

(B): 09913–85230

(C): 09940–54950

I5RW0A520043-02

1. Differential pinion washer 6. Differential case : 90 N⋅m (9.0 kgf-m, 65.0 lb-ft)

2. Differential pinion 7. Final gear : Do not reuse.

3. Differential side gear 8. Final gear bolt : Apply transaxle oil.

4. Side gear washer 9. Differential pinion shaft

5. Differential side bearing 10. Differential pinion shaft pin

(B)

(A)

1

I5RW0A520044-01

(A)

1

(B)

(C)

I5RW0A520045-01

Page 849 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-37

3) Support differential case (1) with soft jawed vise and

remove final gear bolts then take out final gear.

4) Drive out differential pinion shaft (3) pin by using

special tool and hammer and then disassemble

components parts.

Special tool

(A): 09922–85811

Reassembly

Judging from abnormality noted before disassembly and

what is found through visual check of component parts

after disassembly, prepare replacing parts and proceed

to reassembly. Make sure that all parts are clean.

1) Install differential pinion, side gear and pinion shaft

to differential case and measure back rash and

thrust play of differential side gear as follows.

If measured value is out of specification, select

suitable side gear washer from among the following

available size, install it and check again.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06010

a) Differential side gear backlash

• Hold differential assembly with soft jawed vise

and apply measuring tip of dial gauge to side

gear as shown in figure.

• Fixing differential pinion, turn side gear back

and forth and read dial gauge.

Differential side gear backlash

0.10 – 0.15 mm (0.003 – 0.005 in.)

b) Differential side gear thrust play

• Hold differential assembly with soft jawed vise

and apply measuring tip of dial gauge to side

gear as shown in figure.

• Move side gear up and down by hand and

read dial gauge.

Differential side gear thrust play

0.03 – 0.31 mm (0.001 – 0.012 in.)Available side gear washer thickness

2) Drive in spring pin from right side till it is flush with

differential case surface.

3) Press-fit left bearing (1) by using special tool and

hydraulic press.

Special tool

(A): 09913–70123

2. Differential side gear

I5RW0A520046-01

0.85 mm (0.033 in.) 1.05 mm (0.041 in.)

0.9 mm (0.035 in.) 1.1 mm (0.043 in.)

0.95 mm (0.037 in.) 1.15 mm (0.045 in.)

1.0 mm (0.039 in.)

2. Differential case

(B)

(B)

(C)

(A)

(A)

I5RW0A520047-01

I2RH01520074-01

Page 858 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-5 Clutch:

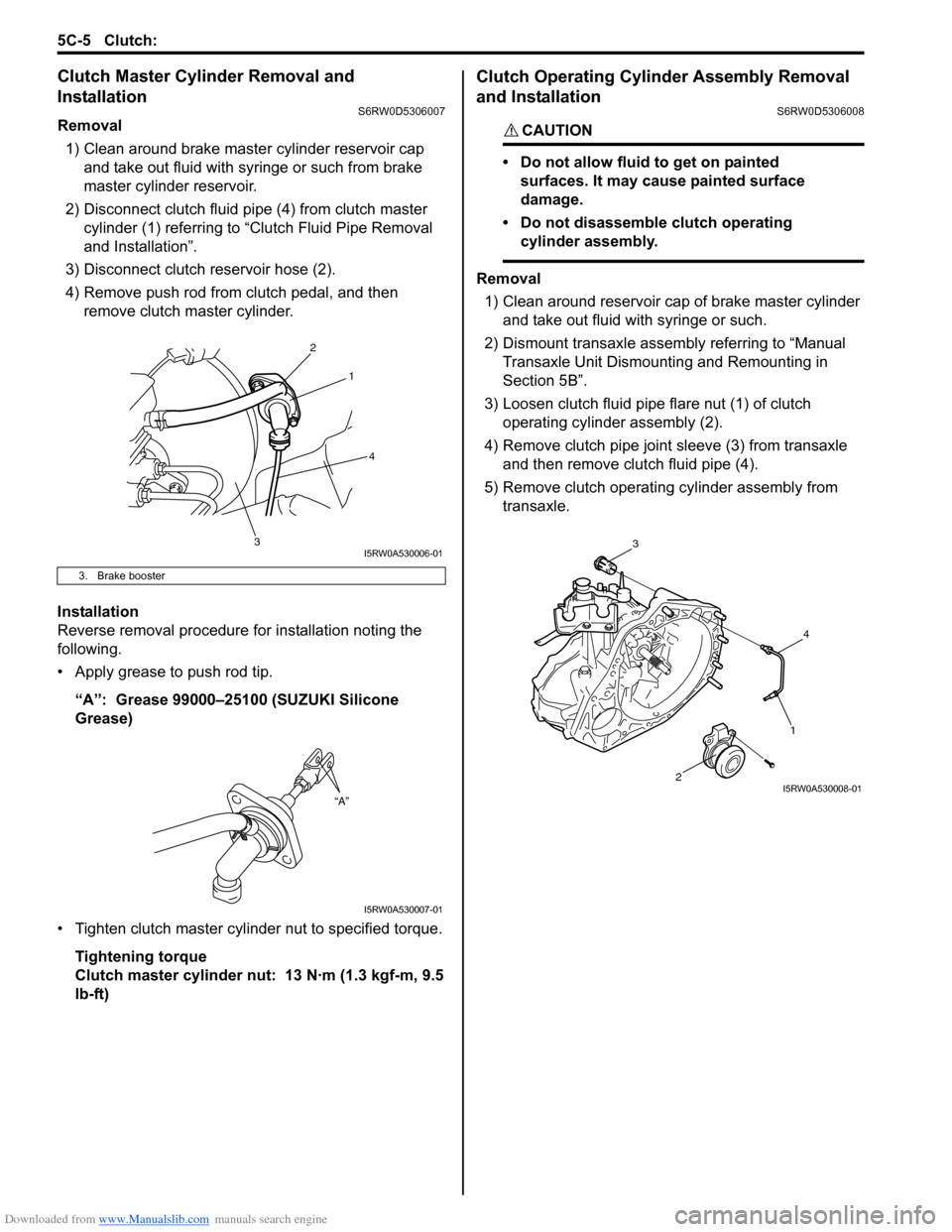

Clutch Master Cylinder Removal and

Installation

S6RW0D5306007

Removal

1) Clean around brake master cylinder reservoir cap

and take out fluid with syringe or such from brake

master cylinder reservoir.

2) Disconnect clutch fluid pipe (4) from clutch master

cylinder (1) referring to “Clutch Fluid Pipe Removal

and Installation”.

3) Disconnect clutch reservoir hose (2).

4) Remove push rod from clutch pedal, and then

remove clutch master cylinder.

Installation

Reverse removal procedure for installation noting the

following.

• Apply grease to push rod tip.

“A”: Grease 99000–25100 (SUZUKI Silicone

Grease)

• Tighten clutch master cylinder nut to specified torque.

Tightening torque

Clutch master cylinder nut: 13 N·m (1.3 kgf-m, 9.5

lb-ft)

Clutch Operating Cylinder Assembly Removal

and Installation

S6RW0D5306008

CAUTION!

• Do not allow fluid to get on painted

surfaces. It may cause painted surface

damage.

• Do not disassemble clutch operating

cylinder assembly.

Removal

1) Clean around reservoir cap of brake master cylinder

and take out fluid with syringe or such.

2) Dismount transaxle assembly referring to “Manual

Transaxle Unit Dismounting and Remounting in

Section 5B”.

3) Loosen clutch fluid pipe flare nut (1) of clutch

operating cylinder assembly (2).

4) Remove clutch pipe joint sleeve (3) from transaxle

and then remove clutch fluid pipe (4).

5) Remove clutch operating cylinder assembly from

transaxle.

3. Brake booster

1

3

2

4

I5RW0A530006-01

“A”

I5RW0A530007-01

3

4

2

1

I5RW0A530008-01

Page 862 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-9 Clutch:

Clutch Disc

Measure depth of rivet head depression, i.e. distance

between rivet head and facing surface.

If depression is found to have reached service limit at

any of rivet holes (2), replace clutch disc assembly (1).

Rivet head depth

Standard: 1.65 – 2.25 mm (0.06 – 0.09 in.)

Limit: 0.5 mm (0.02 in.)Clutch Cover

1) Check diaphragm spring (1) for abnormal wear or

damage.

2) Inspect pressure plate (2) for wear or heat spots.

3) If abnormality is found, replace clutch cover.

Do not disassemble it into diaphragm spring and

pressure plate.

Flywheel

Check surface contacting clutch disc for abnormal wear

or heat spots. Replace or repair as required.

Specifications

Tightening Torque SpecificationsS6RW0D5307001

NOTE

The specified tightening torque is also described in the following.

“Clutch Cover, Clutch Disc and Flywheel Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I4RS0A530019-01

I3RM0A530015-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Clutch master cylinder nut 13 1.3 9.5�)

Clutch operating cylinder assembly mounting

bolt10 1.0 7.5�)

Clutch fluid pipe flare nut 16 1.6 11.5�)

Flywheel bolt 70 7.0 51.0�)

Clutch cover bolt 23 2.3 17.0�)

Page 967 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-27

Installation

Reverse removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Install the padding (1) to the installation hole

uniformly.

• Evacuate and charge the A/C system referring to

“Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Refill cooling system with coolant referring to “Cooling

System Flush and Refill in Section 1F”.

• Adjust control cables referring to “HVAC Control Unit

Removal and Installation in Section 7A”. (vehicle with

manual type A/C)

Evaporator InspectionS6RW0D7216009

Check the followings.

• Clog of A/C evaporator fins.

If any clogs are found, A/C evaporator fins should be

washed with water, and then should be dried with

compressed air.

• A/C evaporator fins for leakage and breakage.

If any defects are found, repair or replace A/C

evaporator.

• A/C evaporator fittings for leakage.

If any defects are found, repair or replace A/C

evaporator.

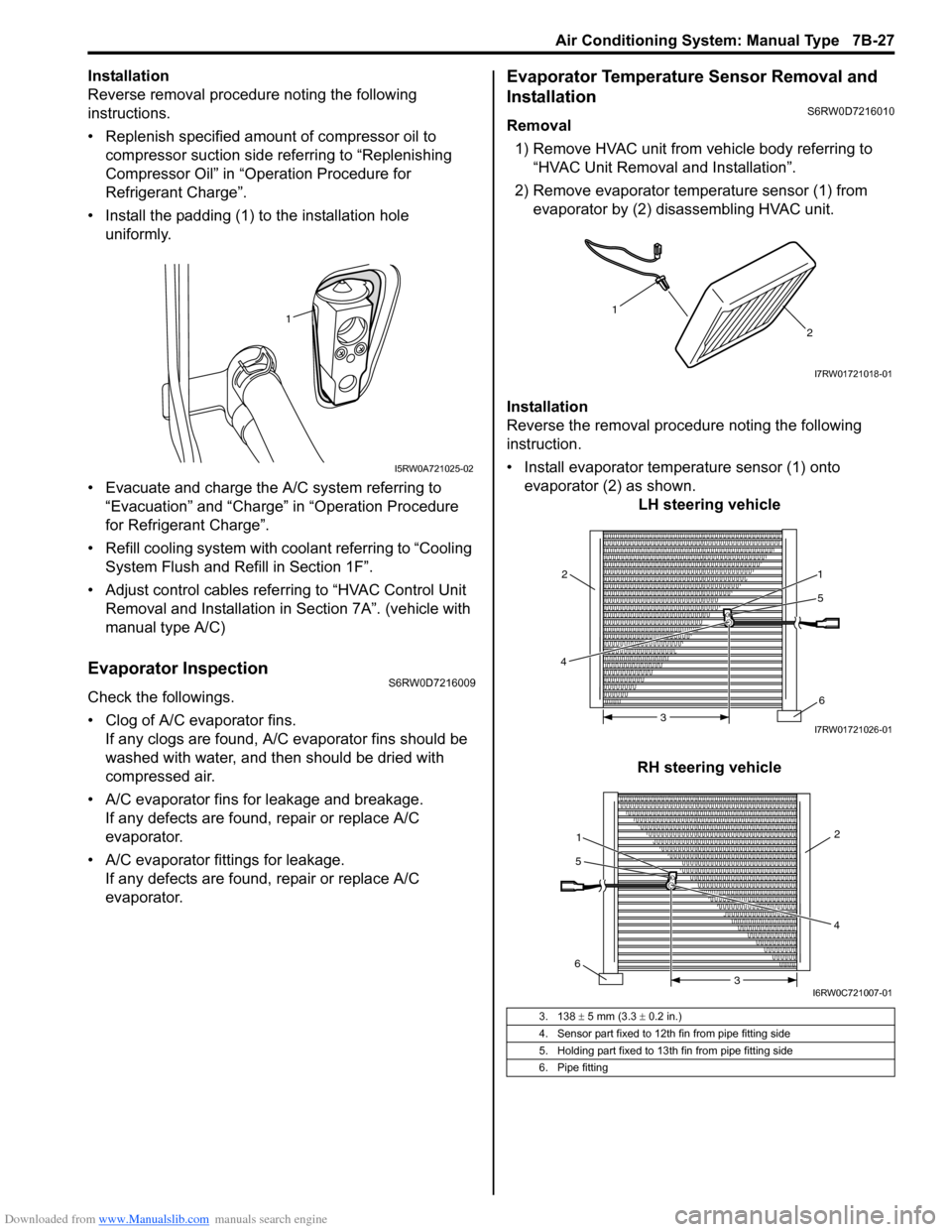

Evaporator Temperature Sensor Removal and

Installation

S6RW0D7216010

Removal

1) Remove HVAC unit from vehicle body referring to

“HVAC Unit Removal and Installation”.

2) Remove evaporator temperature sensor (1) from

evaporator by (2) disassembling HVAC unit.

Installation

Reverse the removal procedure noting the following

instruction.

• Install evaporator temperature sensor (1) onto

evaporator (2) as shown.

LH steering vehicle

RH steering vehicle

1

I5RW0A721025-02

3. 138 ± 5 mm (3.3 ± 0.2 in.)

4. Sensor part fixed to 12th fin from pipe fitting side

5. Holding part fixed to 13th fin from pipe fitting side

6. Pipe fitting

1

2

I7RW01721018-01

5

4

6 1

2

3I7RW01721026-01

1

5

642

3

I6RW0C721007-01