esp SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 990 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-50 Air Conditioning System: Automatic Type

Not Using SUZUKI Scan Tool

NOTE

In case of malfunction of temperature

selector, blower speed selector and air flow

selector, DTC can not be checked by the

following procedure. Use SUZUKI scan tool

for DTC check.

1) Light over sunload sensor vertically with an

incandescent light of approximately 100 W apart

from about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent light, DTC of sunload sensor is

detected as current DTC even though there is

not any malfunction.

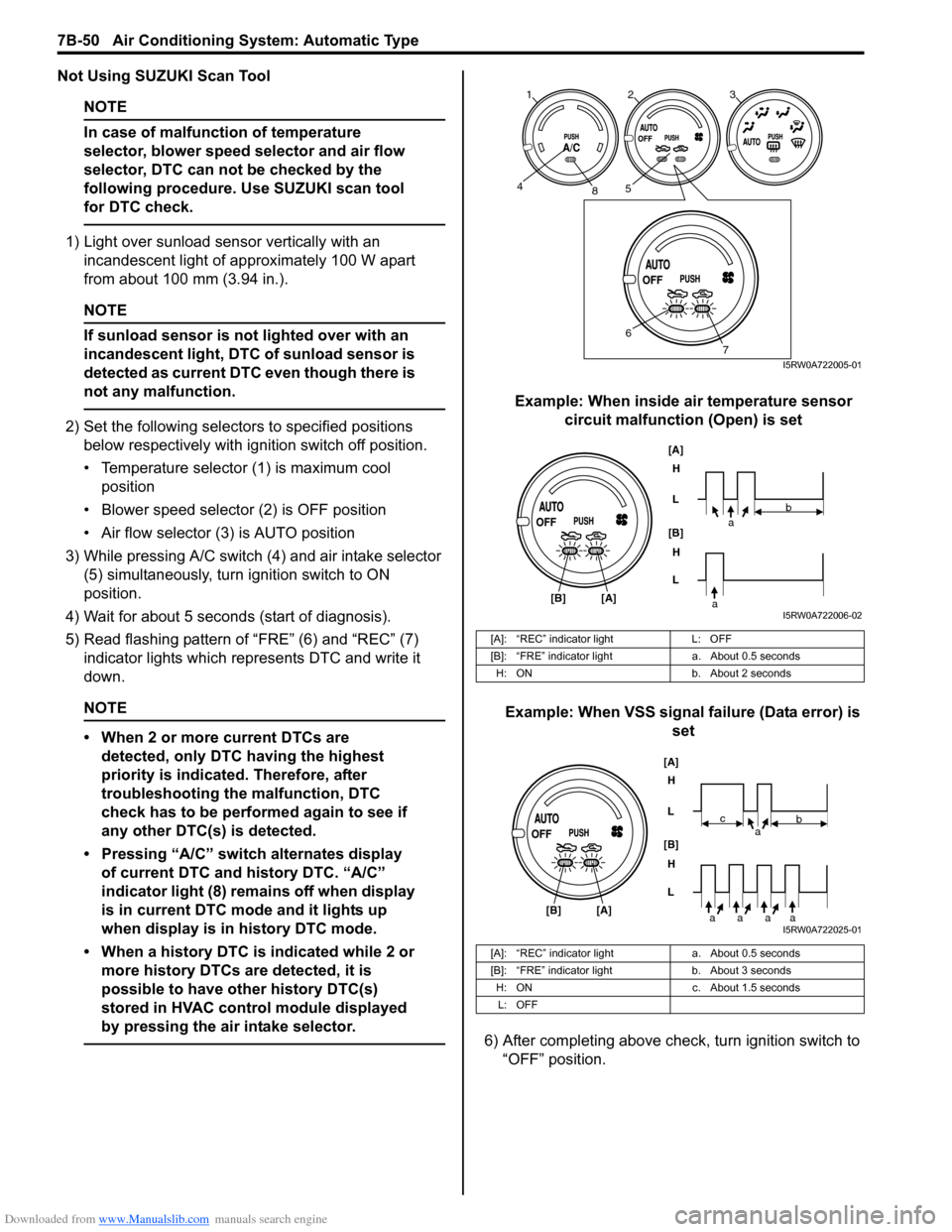

2) Set the following selectors to specified positions

below respectively with ignition switch off position.

• Temperature selector (1) is maximum cool

position

• Blower speed selector (2) is OFF position

• Air flow selector (3) is AUTO position

3) While pressing A/C switch (4) and air intake selector

(5) simultaneously, turn ignition switch to ON

position.

4) Wait for about 5 seconds (start of diagnosis).

5) Read flashing pattern of “FRE” (6) and “REC” (7)

indicator lights which represents DTC and write it

down.

NOTE

• When 2 or more current DTCs are

detected, only DTC having the highest

priority is indicated. Therefore, after

troubleshooting the malfunction, DTC

check has to be performed again to see if

any other DTC(s) is detected.

• Pressing “A/C” switch alternates display

of current DTC and history DTC. “A/C”

indicator light (8) remains off when display

is in current DTC mode and it lights up

when display is in history DTC mode.

• When a history DTC is indicated while 2 or

more history DTCs are detected, it is

possible to have other history DTC(s)

stored in HVAC control module displayed

by pressing the air intake selector.

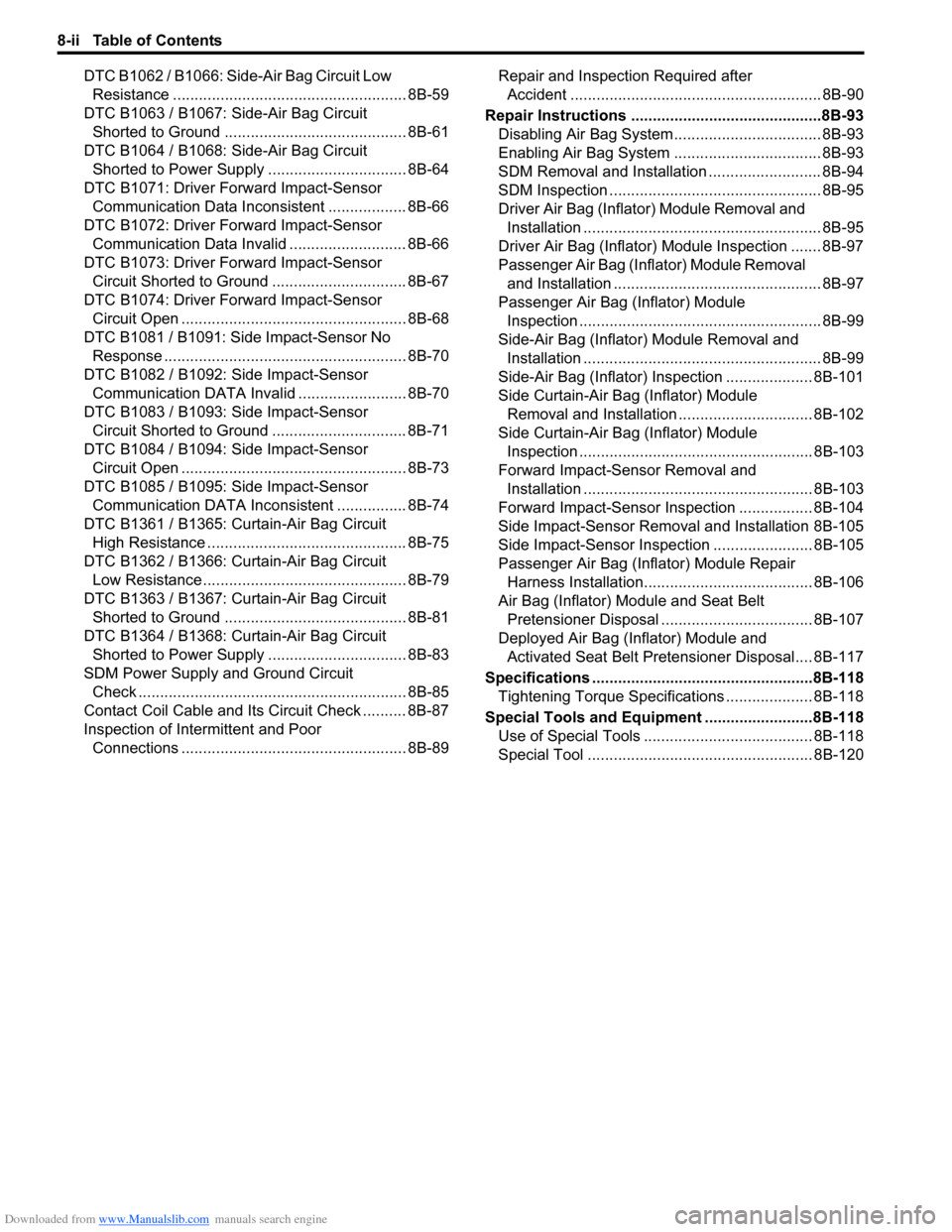

Example: When inside air temperature sensor

circuit malfunction (Open) is set

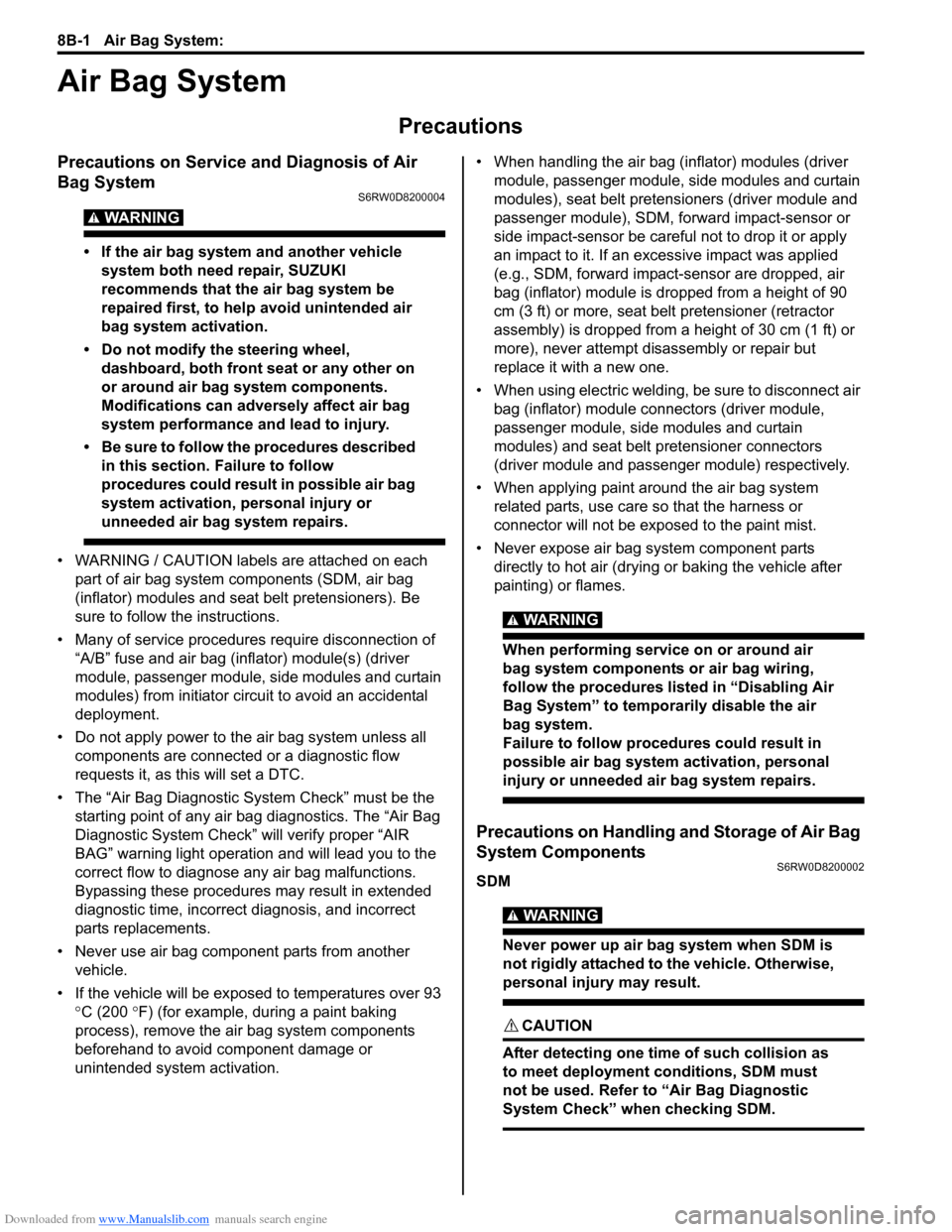

Example: When VSS signal failure (Data error) is

set

6) After completing above check, turn ignition switch to

“OFF” position.

[A]: “REC” indicator light L: OFF

[B]: “FRE” indicator light a. About 0.5 seconds

H: ON b. About 2 seconds

[A]: “REC” indicator light a. About 0.5 seconds

[B]: “FRE” indicator light b. About 3 seconds

H: ON c. About 1.5 seconds

L: OFF

123

458

6

7I5RW0A722005-01

[A]

[B]H

L

H

L [B]

[A]

ab

aI5RW0A722006-02

[A]

[B]H

L

H

L [B]

[A]

ab

aaaa

c

I5RW0A722025-01

Page 1030 of 1556

Downloaded from www.Manualslib.com manuals search engine 8-ii Table of Contents

DTC B1062 / B1066: Side-Air Bag Circuit Low

Resistance ...................................................... 8B-59

DTC B1063 / B1067: Side-Air Bag Circuit

Shorted to Ground .......................................... 8B-61

DTC B1064 / B1068: Side-Air Bag Circuit

Shorted to Power Supply ................................ 8B-64

DTC B1071: Driver Forward Impact-Sensor

Communication Data Inconsistent .................. 8B-66

DTC B1072: Driver Forward Impact-Sensor

Communication Data Invalid ........................... 8B-66

DTC B1073: Driver Forward Impact-Sensor

Circuit Shorted to Ground ............................... 8B-67

DTC B1074: Driver Forward Impact-Sensor

Circuit Open .................................................... 8B-68

DTC B1081 / B1091: Side Impact-Sensor No

Response ........................................................ 8B-70

DTC B1082 / B1092: Side Impact-Sensor

Communication DATA Invalid ......................... 8B-70

DTC B1083 / B1093: Side Impact-Sensor

Circuit Shorted to Ground ............................... 8B-71

DTC B1084 / B1094: Side Impact-Sensor

Circuit Open .................................................... 8B-73

DTC B1085 / B1095: Side Impact-Sensor

Communication DATA Inconsistent ................ 8B-74

DTC B1361 / B1365: Curtain-Air Bag Circuit

High Resistance .............................................. 8B-75

DTC B1362 / B1366: Curtain-Air Bag Circuit

Low Resistance ............................................... 8B-79

DTC B1363 / B1367: Curtain-Air Bag Circuit

Shorted to Ground .......................................... 8B-81

DTC B1364 / B1368: Curtain-Air Bag Circuit

Shorted to Power Supply ................................ 8B-83

SDM Power Supply and Ground Circuit

Check .............................................................. 8B-85

Contact Coil Cable and Its Circuit Check .......... 8B-87

Inspection of Intermittent and Poor

Connections .................................................... 8B-89Repair and Inspection Required after

Accident .......................................................... 8B-90

Repair Instructions ............................................8B-93

Disabling Air Bag System.................................. 8B-93

Enabling Air Bag System .................................. 8B-93

SDM Removal and Installation .......................... 8B-94

SDM Inspection ................................................. 8B-95

Driver Air Bag (Inflator) Module Removal and

Installation ....................................................... 8B-95

Driver Air Bag (Inflator) Module Inspection ....... 8B-97

Passenger Air Bag (Inflator) Module Removal

and Installation ................................................ 8B-97

Passenger Air Bag (Inflator) Module

Inspection ........................................................ 8B-99

Side-Air Bag (Inflator) Module Removal and

Installation ....................................................... 8B-99

Side-Air Bag (Inflator) Inspection .................... 8B-101

Side Curtain-Air Bag (Inflator) Module

Removal and Installation ............................... 8B-102

Side Curtain-Air Bag (Inflator) Module

Inspection ...................................................... 8B-103

Forward Impact-Sensor Removal and

Installation ..................................................... 8B-103

Forward Impact-Sensor Inspection ................. 8B-104

Side Impact-Sensor Removal and Installation 8B-105

Side Impact-Sensor Inspection ....................... 8B-105

Passenger Air Bag (Inflator) Module Repair

Harness Installation....................................... 8B-106

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal ................................... 8B-107

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal.... 8B-117

Specifications ...................................................8B-118

Tightening Torque Specifications .................... 8B-118

Special Tools and Equipment .........................8B-118

Use of Special Tools ....................................... 8B-118

Special Tool .................................................... 8B-120

Page 1040 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-1 Air Bag System:

Restraint

Air Bag System

Precautions

Precautions on Service and Diagnosis of Air

Bag System

S6RW0D8200004

WARNING!

• If the air bag system and another vehicle

system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel,

dashboard, both front seat or any other on

or around air bag system components.

Modifications can adversely affect air bag

system performance and lead to injury.

• Be sure to follow the procedures described

in this section. Failure to follow

procedures could result in possible air bag

system activation, personal injury or

unneeded air bag system repairs.

• WARNING / CAUTION labels are attached on each

part of air bag system components (SDM, air bag

(inflator) modules and seat belt pretensioners). Be

sure to follow the instructions.

• Many of service procedures require disconnection of

“A/B” fuse and air bag (inflator) module(s) (driver

module, passenger module, side modules and curtain

modules) from initiator circuit to avoid an accidental

deployment.

• Do not apply power to the air bag system unless all

components are connected or a diagnostic flow

requests it, as this will set a DTC.

• The “Air Bag Diagnostic System Check” must be the

starting point of any air bag diagnostics. The “Air Bag

Diagnostic System Check” will verify proper “AIR

BAG” warning light operation and will lead you to the

correct flow to diagnose any air bag malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

• Never use air bag component parts from another

vehicle.

• If the vehicle will be exposed to temperatures over 93

°C (200 °F) (for example, during a paint baking

process), remove the air bag system components

beforehand to avoid component damage or

unintended system activation.• When handling the air bag (inflator) modules (driver

module, passenger module, side modules and curtain

modules), seat belt pretensioners (driver module and

passenger module), SDM, forward impact-sensor or

side impact-sensor be careful not to drop it or apply

an impact to it. If an excessive impact was applied

(e.g., SDM, forward impact-sensor are dropped, air

bag (inflator) module is dropped from a height of 90

cm (3 ft) or more, seat belt pretensioner (retractor

assembly) is dropped from a height of 30 cm (1 ft) or

more), never attempt disassembly or repair but

replace it with a new one.

• When using electric welding, be sure to disconnect air

bag (inflator) module connectors (driver module,

passenger module, side modules and curtain

modules) and seat belt pretensioner connectors

(driver module and passenger module) respectively.

• When applying paint around the air bag system

related parts, use care so that the harness or

connector will not be exposed to the paint mist.

• Never expose air bag system component parts

directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING!

When performing service on or around air

bag system components or air bag wiring,

follow the procedures listed in “Disabling Air

Bag System” to temporarily disable the air

bag system.

Failure to follow procedures could result in

possible air bag system activation, personal

injury or unneeded air bag system repairs.

Precautions on Handling and Storage of Air Bag

System Components

S6RW0D8200002

SDM

WARNING!

Never power up air bag system when SDM is

not rigidly attached to the vehicle. Otherwise,

personal injury may result.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, SDM must

not be used. Refer to “Air Bag Diagnostic

System Check” when checking SDM.

Page 1046 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-7 Air Bag System:

Air Bag System Input / Output TableS6RW0D8201002

Forward inpact-sensor

Driver side inpact-

sensor

Passenger side inpact-

sensor Mecanical longitudinal

G sensor in SDMX-Y G sensor

(longitudinal / lateral

acceleration) in SDM

OUTPUT

(deployment &

activation

device) INPUT

(sensor signal)

Driver & Passenger

air bag inflator

modulesDriver & Passenger

seat belt

pretentionersDriver side-air bag

& driver side

curtain-air bag

inflator modulesPassenger side-air

bag & passenger

side curtain-air bag

inflator modules

I6RW0C820002-01

Page 1055 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-16

�) B1057Passenger seat belt

pretensioner circuit shorted to

groundPassenger seat belt pretensioner

circuit has been shorted to

ground for more than 4 sec.• Passenger seat belt

pretensioner circuit

•SDM

�) B1058Passenger seat belt

pretensioner circuit shorted to

power supplyPassenger seat belt pretensioner

circuit has been shorted to power

circuit for more than 4 sec.

�) B1061Driver side-air bag circuit high

resistance Driver side-air bag circuit is more

than 3.7 Ω for more than 4 sec.• Driver side-air bag circuit

• Driver side-air bag module

•SDM �) B1062Driver side-air bag circuit low

resistance Driver side-air bag circuit is less

than 1.0 Ω for more than 4 sec.

�) B1063Driver side-air bag circuit

shorted to groundDriver side-air bag circuit has

been shorted to ground for more

than 4 sec.• Driver side-air bag circuit

•SDM

�) B1064Driver side-air bag circuit

shorted to power supplyDriver side-air bag circuit has

been shorted to power supply for

more than 4 sec.

�) B1065Passenger side-air bag circuit

high resistance Passenger side-air bag circuit is

more than 3.7 Ω for more than 4

sec.• Passenger side-air bag circuit

• Driver side-air bag module

•SDM

�) B1066Passenger side-air bag circuit

low resistance Passenger side-air bag circuit is

less than 1.0 Ω for more than 4

sec.

�) B1067Passenger side-air bag circuit

shorted to groundPassenger side-air bag circuit

has been shorted to ground for

more than 4 sec.• Passenger side-air bag circuit

•SDM

�) B1068Passenger side-air bag circuit

shorted to powerPassenger side-air bag circuit

has been shorted to power circuit

for more than 4 sec.

�) B1071Driver forward impact-sensor

communication data

inconsistent Driver forward impact-sensor

has been communicated with no

response or inconsistent ID code

for more than 4 sec.• Driver forward impact-sensor

• Driver forward impact-sensor

circuit

•SDM

�) B1072Driver forward impact-sensor

communication data invalid Driver forward impact-sensor

has been communicated with

invalid data for more than 4 sec.• Driver forward impact-sensor

•SDM

�)

B1073Driver forward impact-sensor

circuit shorted to groundDriver forward impact-sensor

circuit has been shorted to

ground for more than 4 sec.• Driver forward impact-sensor

• Driver forward impact-sensor

circuit

•SDM �) B1074Driver forward impact-sensor

circuit openDriver forward impact-sensor

circuit has been shorted to power

circuit or opened for more than 4

sec.

�) B1081Driver side impact-sensor no

responseDriver side impact-sensor has

been communicated with no

response for more than 4 sec.• Driver side impact-sensor

circuit

• Driver side impact-sensor

•SDM

�) B1082Driver side impact-sensor

communication data invalidDriver side impact-sensor has

been communicated with invalid

data for more than 4 sec.• Driver side impact-sensor

•SDM

�) B1083Driver side impact-sensor

circuit shorted to groundDriver side impact-sensor circuit

has been shorted to ground for

more than 4 sec.• Driver side impact-sensor

circuit

• Driver side impact-sensor

•SDM �) B1084Driver side impact-sensor

circuit openDriver side impact-sensor circuit

has been shorted to power circuit

or opened for more than 4 sec. DTC No. Detecting itemDetecting condition

(DTC will set when detecting)Trouble area

Page 1056 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-17 Air Bag System:

�) B1085Driver side impact-sensor

communication data

inconsistent Driver side impact-sensor has

been communicated with

inconsistent ID code for more

than 4 sec.• Driver side impact-sensor

•SDM

�) B1091Passenger side impact-sensor

no responseCommunication with passenger

side impact-sensor has been no

response for more than 4 sec.• Passenger side impact-sensor

circuit

• Passenger side impact-sensor

•SDM

�) B1092Passenger side impact-sensor

communication data invalidPassenger side impact-sensor

has been communicated with

invalid data for more than 4 sec.• Passenger side impact-sensor

circuit

•SDM

�) B1093Passenger side impact-sensor

circuit shorted to groundPassenger side impact-sensor

circuit has been shorted to

ground for more than 4 sec.

• Passenger side impact-sensor

•SDM

�) B1094Passenger side impact-sensor

circuit openPassenger side impact-sensor

circuit has been shorted to power

circuit or opened for more than 4

sec.

�) B1095Passenger side impact-sensor

communication data

inconsistentPassenger side impact-sensor

has been communicated with

inconsistent ID code for more

than 4 sec.• Passenger side impact-sensor

•SDM

�) B1361Driver curtain-air bag circuit

high resistanceDriver curtain-air bag circuit is

more than 3.8 Ω for more than 4

sec. • Driver curtain-air bag circuit

• Driver curtain-air bag module

•SDM

�) B1362Driver curtain-air bag circuit low

resistanceDriver curtain-air bag circuit is

less than 1.0 Ω for more than 4

sec.

�) B1363Driver curtain-air bag circuit

shorted to groundDriver curtain-air bag circuit has

been shorted to ground for more

than 4 sec.• Driver curtain-air bag circuit

•SDM

�) B1364Driver curtain-air bag circuit

shorted to powerDriver curtain-air bag circuit has

been shorted to power circuit for

more than 4 sec.

�) B1365Passenger curtain-air bag

circuit high resistancePassenger curtain-air bag circuit

is more than 3.8 Ω for more than

4 sec.• Passenger curtain-air bag

circuit

• Passenger curtain-air bag

module

•SDM �) B1366Passenger curtain-air bag

circuit low resistancePassenger curtain-air bag circuit

is less than 1.0 Ω for more than 4

sec.

�) B1367Passenger curtain-air bag

circuit shorted to groundPassenger curtain-air bag circuit

has been shorted to ground for

more than 4 sec.• Passenger curtain-air bag

circuit

•SDM

�) B1368Passenger curtain-air bag

circuit shorted to powerPassenger curtain-air bag circuit

has been shorted to power circuit

for more than 4 sec. DTC No. Detecting itemDetecting condition

(DTC will set when detecting)Trouble area

Page 1105 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-66

DTC B1071: Driver Forward Impact-Sensor Communication Data InconsistentS6RW0D8204034

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1072: Driver Forward Impact-Sensor Communication Data InvalidS6RW0D8204035

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Forward impact-sensor has been communicated with no

response or inconsistent ID code for more than 4 sec.• Forward impact-sensor

• Forward impact-sensor circuit

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check SDM for DTC.

Are there any DTC(s) B1073, B1074?Go to applicable DTC

diag. flow.Replace defective

forward impact-sensor

and recheck.

If this DTC still detected,

replace SDM.

DTC detecting condition Trouble area

Forward impact-sensor has been communicated with

invalid data for more than 4 sec.• Forward impact-sensor

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check SDM for DTC.

Are there any DTC(s) B1071, B1073, B1074?Go to applicable DTC

diag. flow.Replace defective

forward impact-sensor

and recheck.

If this DTC still detected,

replace SDM.

Page 1109 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-70

DTC B1081 / B1091: Side Impact-Sensor No ResponseS6RW0D8204066

DTC B1081: Driver Side Impact-Sensor No Response

DTC B1091: Passenger Side Impact-Sensor No Response

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1082 / B1092: Side Impact-Sensor Communication DATA InvalidS6RW0D8204058

DTC B1082: Driver Side Impact-Sensor Communication DATA Invalid

DTC B1092: Passenger Side Impact-Sensor Communication DATA Invalid

DTC Detecting Condition and Trouble AreaDTC detecting condition Trouble area

DTC B1081:

Driver side impact-sensor has been communicated with

no response for more than 4 sec.

DTC B1091:

Passenger side impact-sensor has been communicated

with no response for more than 4 sec.• Driver / passenger side impact-sensor circuit

• Driver / passenger side impact-sensor

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check SDM for DTC.

Are there any DTCs B1083, B1084 (for DTC B1081) or

B1093, B1094 (for DTC B1091)?Go to applicable DTC

diag. flow.Replace defective side

impact-sensor and

recheck.

If this DTC still detected,

replace SDM.

DTC detecting condition Trouble area

DTC B1082:

Driver side impact-sensor has been communicated with

invalid data for more than 4 sec.

DTC B1092:

Passenger side impact-sensor has been communicated

with invalid data for more than 4 sec.• Driver / passenger side impact-sensor

•SDM

Page 1129 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-90

• Improperly formed or damaged terminals.

Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal included in the

connector test adapter kit (special tool).

If contact tension is not enough, reform the terminal to

increase contact tension or replace it.

Special tool

(A): 09932–76010 Connector test adapter kit

• Poor terminal-to-wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, change the wire harness

assembly or component parts with new ones.

• Wire insulation which is rubbed through, causing an

intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wire broken inside the insulation. This condition could

cause a continuity check to show a good circuit, but if

only 1 or 2 strands of a multi-strand-type wire are

intact, resistance could be far too high.

Repair and Inspection Required after AccidentS6RW0D8204048

CAUTION!

• All air bag system components, including

the electrical harness (component

mounting points), must be inspected after

an accident. If any components are

damaged or bent, they must be replaced

even if air bag system activation did not

occur.

• Never use air bag system parts from

another vehicle.

• Do not attempt to service the parts below.

Service of these parts is by replacement

only.

– Driver / Passenger air bag (inflator)

modules

– Driver / Passenger side-air bag (inflator)

modules

– Driver / Passenger side curtain-air bag

(inflator) modules

– Driver / Passenger seat belt

pretensioners

– Forward impact-sensor

– Driver / Passenger side impact-sensors

–SDM

– Contact coil and combination switch

assembly

– Air bag wire harness in main harness,

instrument panel harness, floor harness,

passenger air bag harness, side-air bag

harness and side curtain-air bag

harness.

• Proper operation of the sensors and air

bag system requires that any repairs to the

vehicle structure return it to its original

production configuration.

(A)

I4RS0A820045-01

IYSQ01010028-01

IYSQ01820025-01

Page 1168 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-1 Wiring Systems:

Body, Cab and Accessories

Wiring Systems

Precautions

Cautions in Body Electrical System ServicingS6RW0D9100001

When servicing the electric systems, observe the cautions described in “Air Bag Warning in Section 00” to protect

electrical parts and to prevent a fire.

General Description

AbbreviationsS6RW0D9101001

Refer to the “Abbreviations in Section 0A” for the general abbreviations.

ESP

® is a registered trademark of Daimler Chrysler AG.

Wire / Connector Color SymbolsS6RW0D9101002

Refer to “Wire Color Symbols in Section 0A”. Abbreviation Full term Abbreviation Full term

2WD 2 wheel drive vehicles J/B Junction block

4WD 4 wheel drive vehicles J/C Joint connector

A/B Air bag KLS Keyless start system

ACC Accessory L Left

CAN Controller area network LED Light emitting diode

COMB Combination LHD Left hand drive vehicle

DSL Diesel engine LO Low

ELCM EVAP leak check module OCV Oil control valve

ESP

®Electronic stability program P/N Power normal

FWD Forward R Right

HI High RHD Right hand drive vehicle

IF EQPD If equipped ST Starter

IG COIL Ignition coil TPMS Tire pressure monitoring system

ILL Illumination VIM Valiable intake manifold

IND Indicator VSV Vacuum switching valve

INT Intermittent 5 dr 5 door