meter SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 351 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-69

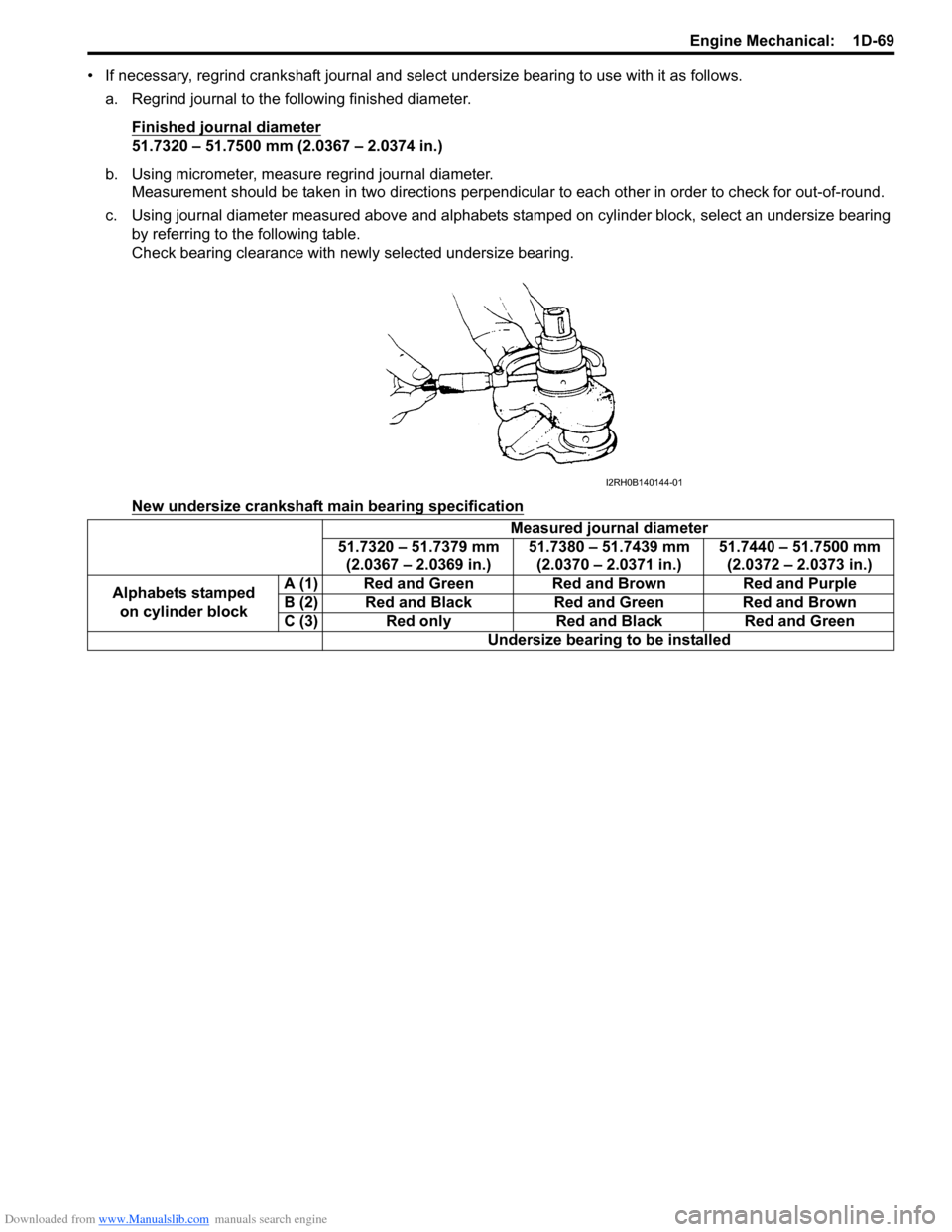

• If necessary, regrind crankshaft journal and select undersize bearing to use with it as follows.

a. Regrind journal to the following finished diameter.

Finished journal diameter

51.7320 – 51.7500 mm (2.0367 – 2.0374 in.)

b. Using micrometer, measure regrind journal diameter.

Measurement should be taken in two directions perpendicular to each other in order to check for out-of-round.

c. Using journal diameter measured above and alphabets stamped on cylinder block, select an undersize bearing

by referring to the following table.

Check bearing clearance with newly selected undersize bearing.

New undersize crankshaft main bearing specification

Measured journal diameter

51.7320 – 51.7379 mm

(2.0367 – 2.0369 in.)51.7380 – 51.7439 mm

(2.0370 – 2.0371 in.)51.7440 – 51.7500 mm

(2.0372 – 2.0373 in.)

Alphabets stamped

on cylinder blockA (1) Red and Green Red and Brown Red and Purple

B (2) Red and Black Red and Green Red and Brown

C (3) Red only Red and Black Red and Green

Undersize bearing to be installed

I2RH0B140144-01

Page 352 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-70 Engine Mechanical:

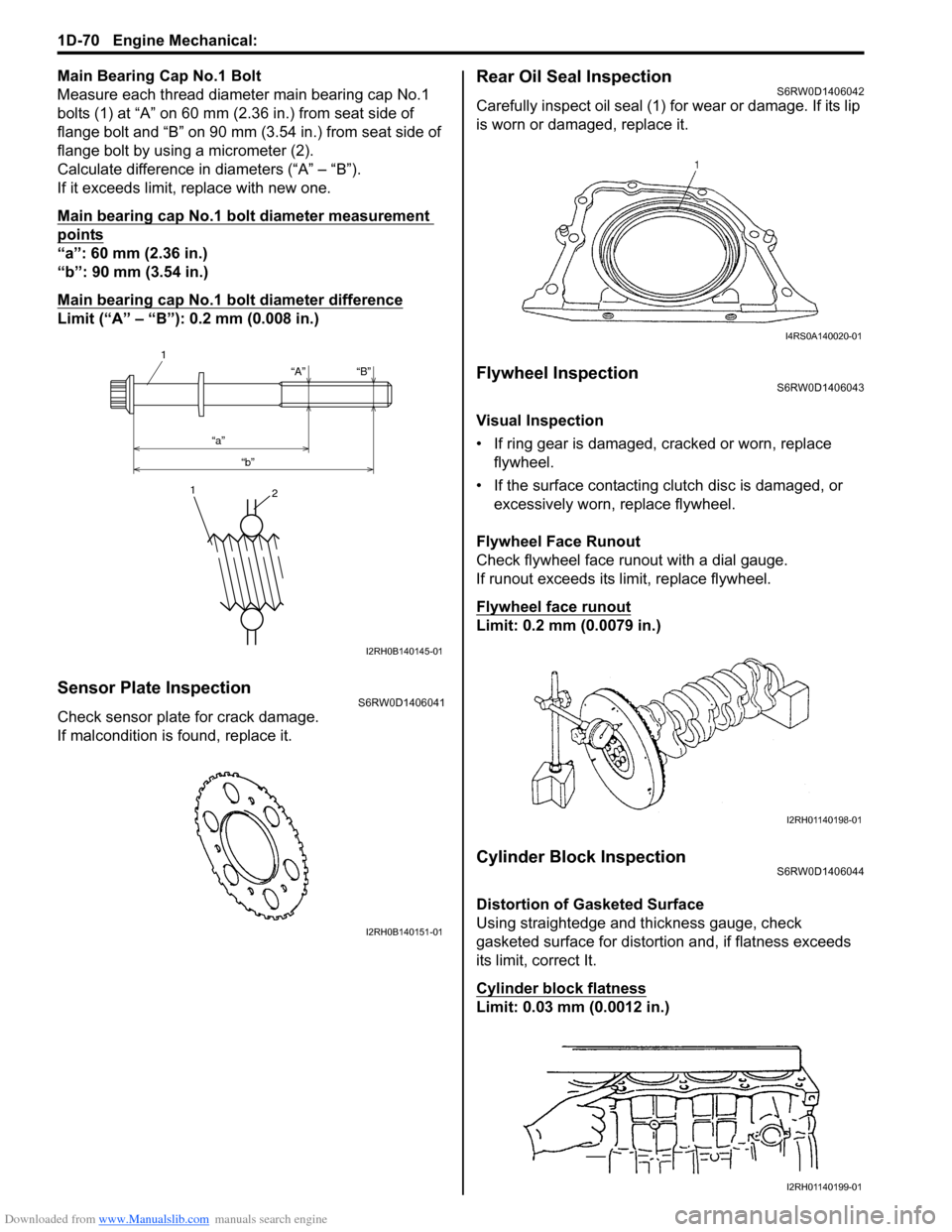

Main Bearing Cap No.1 Bolt

Measure each thread diameter main bearing cap No.1

bolts (1) at “A” on 60 mm (2.36 in.) from seat side of

flange bolt and “B” on 90 mm (3.54 in.) from seat side of

flange bolt by using a micrometer (2).

Calculate difference in diameters (“A” – “B”).

If it exceeds limit, replace with new one.

Main bearing cap No.1 bolt diameter measurement

points

“a”: 60 mm (2.36 in.)

“b”: 90 mm (3.54 in.)

Main bearing cap No.1 bolt diameter difference

Limit (“A” – “B”): 0.2 mm (0.008 in.)

Sensor Plate InspectionS6RW0D1406041

Check sensor plate for crack damage.

If malcondition is found, replace it.

Rear Oil Seal InspectionS6RW0D1406042

Carefully inspect oil seal (1) for wear or damage. If its lip

is worn or damaged, replace it.

Flywheel InspectionS6RW0D1406043

Visual Inspection

• If ring gear is damaged, cracked or worn, replace

flywheel.

• If the surface contacting clutch disc is damaged, or

excessively worn, replace flywheel.

Flywheel Face Runout

Check flywheel face runout with a dial gauge.

If runout exceeds its limit, replace flywheel.

Flywheel face runout

Limit: 0.2 mm (0.0079 in.)

Cylinder Block InspectionS6RW0D1406044

Distortion of Gasketed Surface

Using straightedge and thickness gauge, check

gasketed surface for distortion and, if flatness exceeds

its limit, correct It.

Cylinder block flatness

Limit: 0.03 mm (0.0012 in.)

“A”

“a”

“b”“B”

1

1

2

I2RH0B140145-01

I2RH0B140151-01

I4RS0A140020-01

I2RH01140198-01

I2RH01140199-01

Page 353 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-71

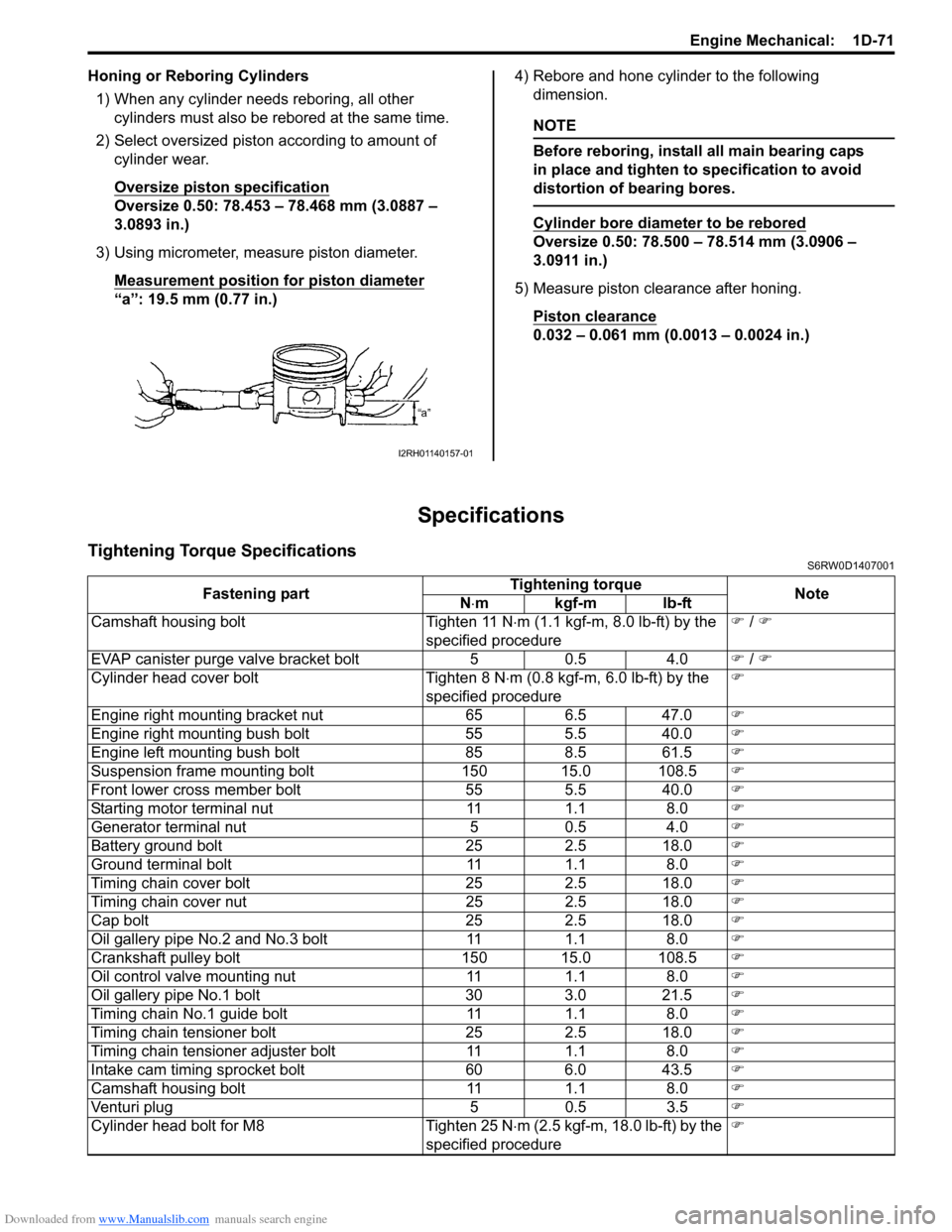

Honing or Reboring Cylinders

1) When any cylinder needs reboring, all other

cylinders must also be rebored at the same time.

2) Select oversized piston according to amount of

cylinder wear.

Oversize piston specification

Oversize 0.50: 78.453 – 78.468 mm (3.0887 –

3.0893 in.)

3) Using micrometer, measure piston diameter.

Measurement position for piston diameter

“a”: 19.5 mm (0.77 in.)4) Rebore and hone cylinder to the following

dimension.

NOTE

Before reboring, install all main bearing caps

in place and tighten to specification to avoid

distortion of bearing bores.

Cylinder bore diameter to be rebored

Oversize 0.50: 78.500 – 78.514 mm (3.0906 –

3.0911 in.)

5) Measure piston clearance after honing.

Piston clearance

0.032 – 0.061 mm (0.0013 – 0.0024 in.)

Specifications

Tightening Torque SpecificationsS6RW0D1407001

I2RH01140157-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Camshaft housing bolt Tighten 11 N⋅m (1.1 kgf-m, 8.0 lb-ft) by the

specified procedure�) / �)

EVAP canister purge valve bracket bolt 5 0.5 4.0�) / �)

Cylinder head cover bolt Tighten 8 N⋅m (0.8 kgf-m, 6.0 lb-ft) by the

specified procedure�)

Engine right mounting bracket nut 65 6.5 47.0�)

Engine right mounting bush bolt 55 5.5 40.0�)

Engine left mounting bush bolt 85 8.5 61.5�)

Suspension frame mounting bolt 150 15.0 108.5�)

Front lower cross member bolt 55 5.5 40.0�)

Starting motor terminal nut 11 1.1 8.0�)

Generator terminal nut 5 0.5 4.0�)

Battery ground bolt 25 2.5 18.0�)

Ground terminal bolt 11 1.1 8.0�)

Timing chain cover bolt 25 2.5 18.0�)

Timing chain cover nut 25 2.5 18.0�)

Cap bolt 25 2.5 18.0�)

Oil gallery pipe No.2 and No.3 bolt 11 1.1 8.0�)

Crankshaft pulley bolt 150 15.0 108.5�)

Oil control valve mounting nut 11 1.1 8.0�)

Oil gallery pipe No.1 bolt 30 3.0 21.5�)

Timing chain No.1 guide bolt 11 1.1 8.0�)

Timing chain tensioner bolt 25 2.5 18.0�)

Timing chain tensioner adjuster bolt 11 1.1 8.0�)

Intake cam timing sprocket bolt 60 6.0 43.5�)

Camshaft housing bolt 11 1.1 8.0�)

Venturi plug 5 0.5 3.5�)

Cylinder head bolt for M8 Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) by the

specified procedure�)

Page 372 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-7 Engine Cooling System:

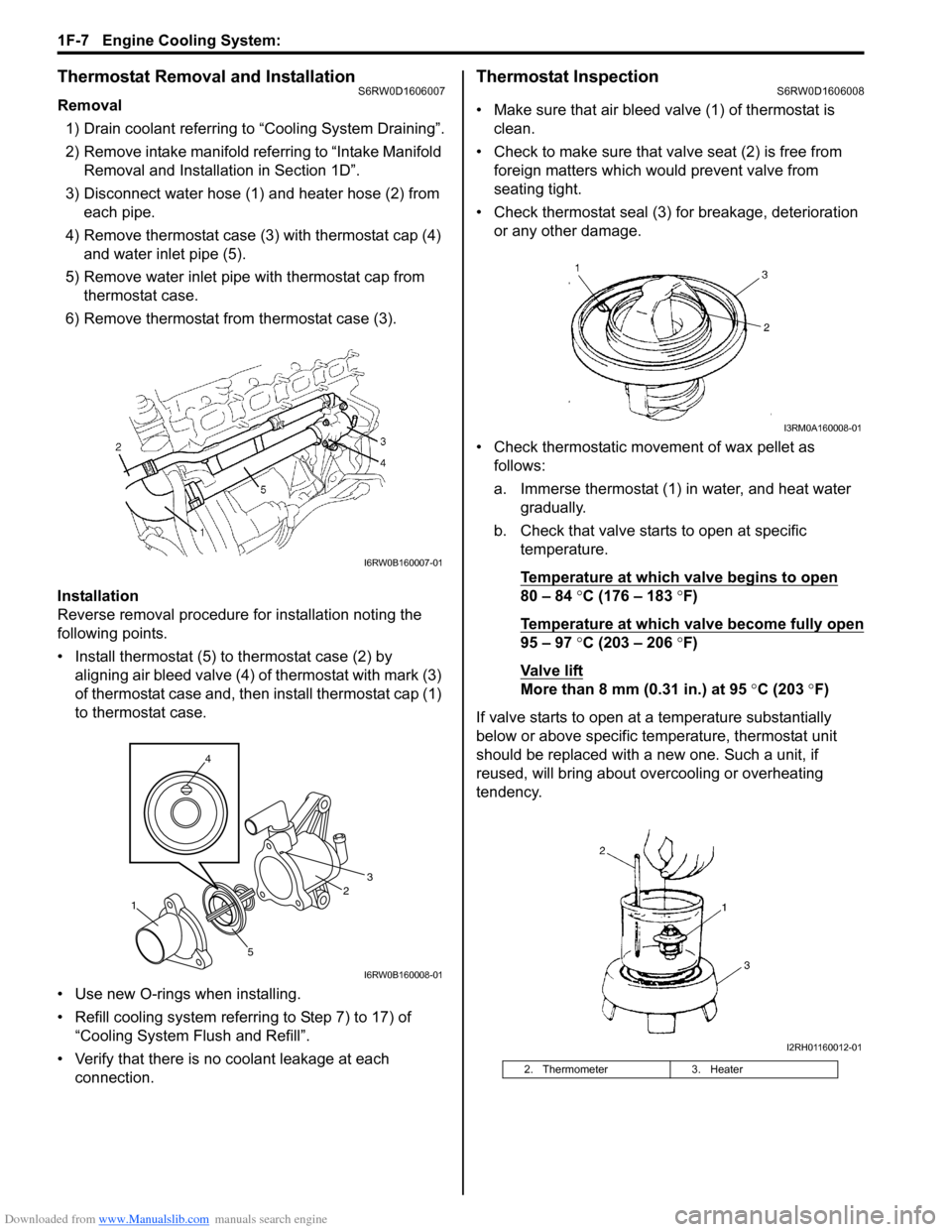

Thermostat Removal and InstallationS6RW0D1606007

Removal

1) Drain coolant referring to “Cooling System Draining”.

2) Remove intake manifold referring to “Intake Manifold

Removal and Installation in Section 1D”.

3) Disconnect water hose (1) and heater hose (2) from

each pipe.

4) Remove thermostat case (3) with thermostat cap (4)

and water inlet pipe (5).

5) Remove water inlet pipe with thermostat cap from

thermostat case.

6) Remove thermostat from thermostat case (3).

Installation

Reverse removal procedure for installation noting the

following points.

• Install thermostat (5) to thermostat case (2) by

aligning air bleed valve (4) of thermostat with mark (3)

of thermostat case and, then install thermostat cap (1)

to thermostat case.

• Use new O-rings when installing.

• Refill cooling system referring to Step 7) to 17) of

“Cooling System Flush and Refill”.

• Verify that there is no coolant leakage at each

connection.

Thermostat InspectionS6RW0D1606008

• Make sure that air bleed valve (1) of thermostat is

clean.

• Check to make sure that valve seat (2) is free from

foreign matters which would prevent valve from

seating tight.

• Check thermostat seal (3) for breakage, deterioration

or any other damage.

• Check thermostatic movement of wax pellet as

follows:

a. Immerse thermostat (1) in water, and heat water

gradually.

b. Check that valve starts to open at specific

temperature.

Temperature at which valve begins to open

80 – 84 °C (176 – 183 °F)

Temperature at which valve become fully open

95 – 97 °C (203 – 206 °F)

Va l v e l i ft

More than 8 mm (0.31 in.) at 95 °C (203 °F)

If valve starts to open at a temperature substantially

below or above specific temperature, thermostat unit

should be replaced with a new one. Such a unit, if

reused, will bring about overcooling or overheating

tendency.

I6RW0B160007-01

4

53

12

I6RW0B160008-01

2. Thermometer 3. Heater

I3RM0A160008-01

I2RH01160012-01

Page 386 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-9 Fuel System:

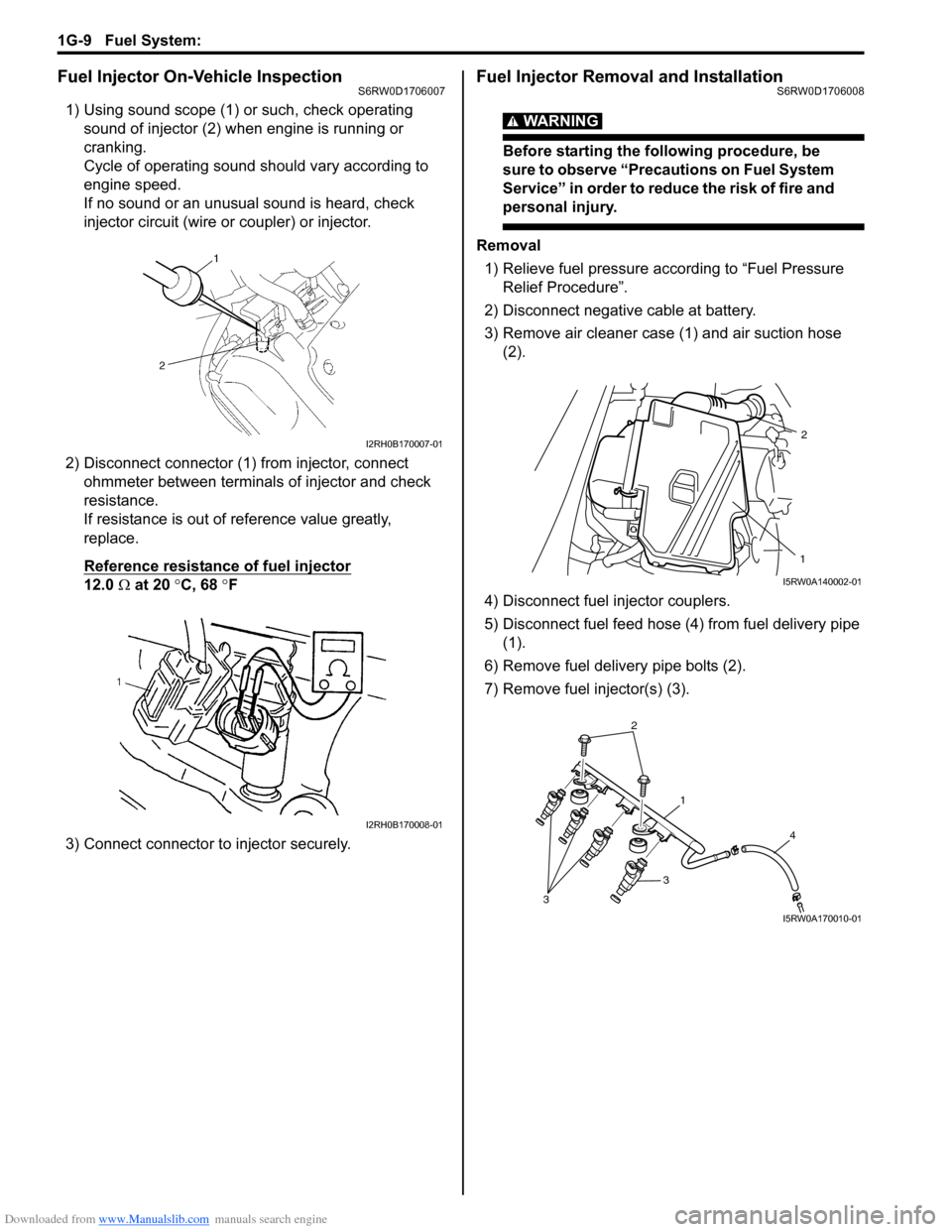

Fuel Injector On-Vehicle InspectionS6RW0D1706007

1) Using sound scope (1) or such, check operating

sound of injector (2) when engine is running or

cranking.

Cycle of operating sound should vary according to

engine speed.

If no sound or an unusual sound is heard, check

injector circuit (wire or coupler) or injector.

2) Disconnect connector (1) from injector, connect

ohmmeter between terminals of injector and check

resistance.

If resistance is out of reference value greatly,

replace.

Reference resistance of fuel injector

12.0 Ω at 20 °C, 68 °F

3) Connect connector to injector securely.

Fuel Injector Removal and InstallationS6RW0D1706008

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk of fire and

personal injury.

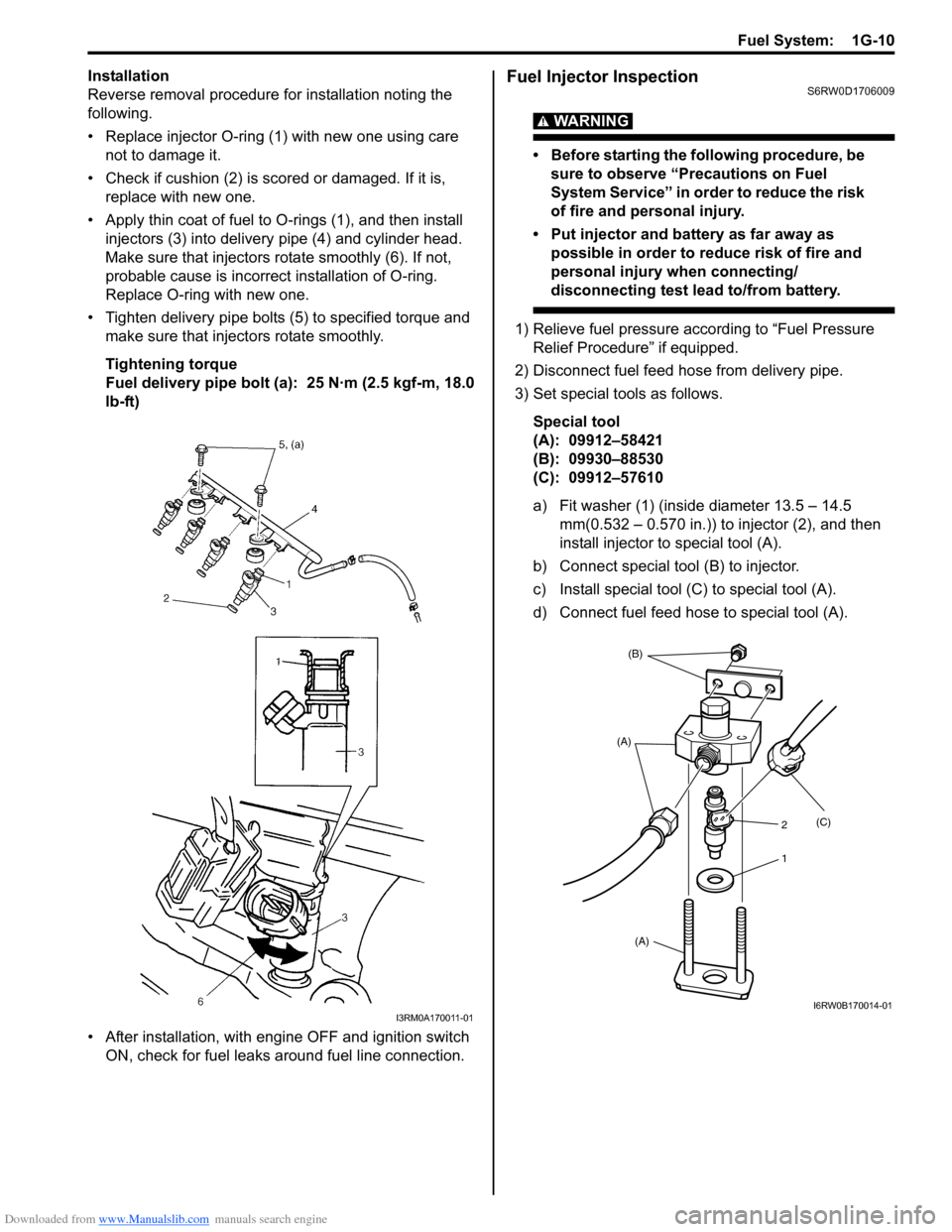

Removal

1) Relieve fuel pressure according to “Fuel Pressure

Relief Procedure”.

2) Disconnect negative cable at battery.

3) Remove air cleaner case (1) and air suction hose

(2).

4) Disconnect fuel injector couplers.

5) Disconnect fuel feed hose (4) from fuel delivery pipe

(1).

6) Remove fuel delivery pipe bolts (2).

7) Remove fuel injector(s) (3).

I2RH0B170007-01

I2RH0B170008-01

1

2

I5RW0A140002-01

2

1

4

3

3

I5RW0A170010-01

Page 387 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-10

Installation

Reverse removal procedure for installation noting the

following.

• Replace injector O-ring (1) with new one using care

not to damage it.

• Check if cushion (2) is scored or damaged. If it is,

replace with new one.

• Apply thin coat of fuel to O-rings (1), and then install

injectors (3) into delivery pipe (4) and cylinder head.

Make sure that injectors rotate smoothly (6). If not,

probable cause is incorrect installation of O-ring.

Replace O-ring with new one.

• Tighten delivery pipe bolts (5) to specified torque and

make sure that injectors rotate smoothly.

Tightening torque

Fuel delivery pipe bolt (a): 25 N·m (2.5 kgf-m, 18.0

lb-ft)

• After installation, with engine OFF and ignition switch

ON, check for fuel leaks around fuel line connection.Fuel Injector InspectionS6RW0D1706009

WARNING!

• Before starting the following procedure, be

sure to observe “Precautions on Fuel

System Service” in order to reduce the risk

of fire and personal injury.

• Put injector and battery as far away as

possible in order to reduce risk of fire and

personal injury when connecting/

disconnecting test lead to/from battery.

1) Relieve fuel pressure according to “Fuel Pressure

Relief Procedure” if equipped.

2) Disconnect fuel feed hose from delivery pipe.

3) Set special tools as follows.

Special tool

(A): 09912–58421

(B): 09930–88530

(C): 09912–57610

a) Fit washer (1) (inside diameter 13.5 – 14.5

mm(0.532 – 0.570 in.)) to injector (2), and then

install injector to special tool (A).

b) Connect special tool (B) to injector.

c) Install special tool (C) to special tool (A).

d) Connect fuel feed hose to special tool (A).

I3RM0A170011-01

(B)

(A)

(A)(C)

2

1

I6RW0B170014-01

Page 395 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-18

Special Tools and Equipment

Special ToolS6RW0D1708001

09912–57610 09912–58421

Injector checking tool plate Checking tool set

�)This kit includes the

following items. 1. Tool body

and washer, 2. Body plug, 3.

Body attachment-1, 4.

Holder, 5. Return hose and

clamp, 6. Body attachment-2

and washer, 7. Hose

attachment-1, 8. Hose

attachment-2 �)

09912–58432 09912–58442

Fuel pressure gauge hose Fuel pressure gauge

This tool is included in fuel

pressure gauge set (09912-

58413). �)This tool is included in fuel

pressure gauge set (09912-

58413). �)

09912–58490 09919–47020

3-way joint & hose Quick joint remover

�)�)

09930–88530 SUZUKI scan tool (SUZUKI-

SDT)

Injector test lead —

�)This kit includes following

items. 1. SUZUKI-SDT 2.

DLC3 cable 3. USB cable 4.

AC/DC power supply 5.

Voltage meter probe 6.

Storage case �)

1

2

34

56

Page 402 of 1556

Downloaded from www.Manualslib.com manuals search engine 1H-7 Ignition System:

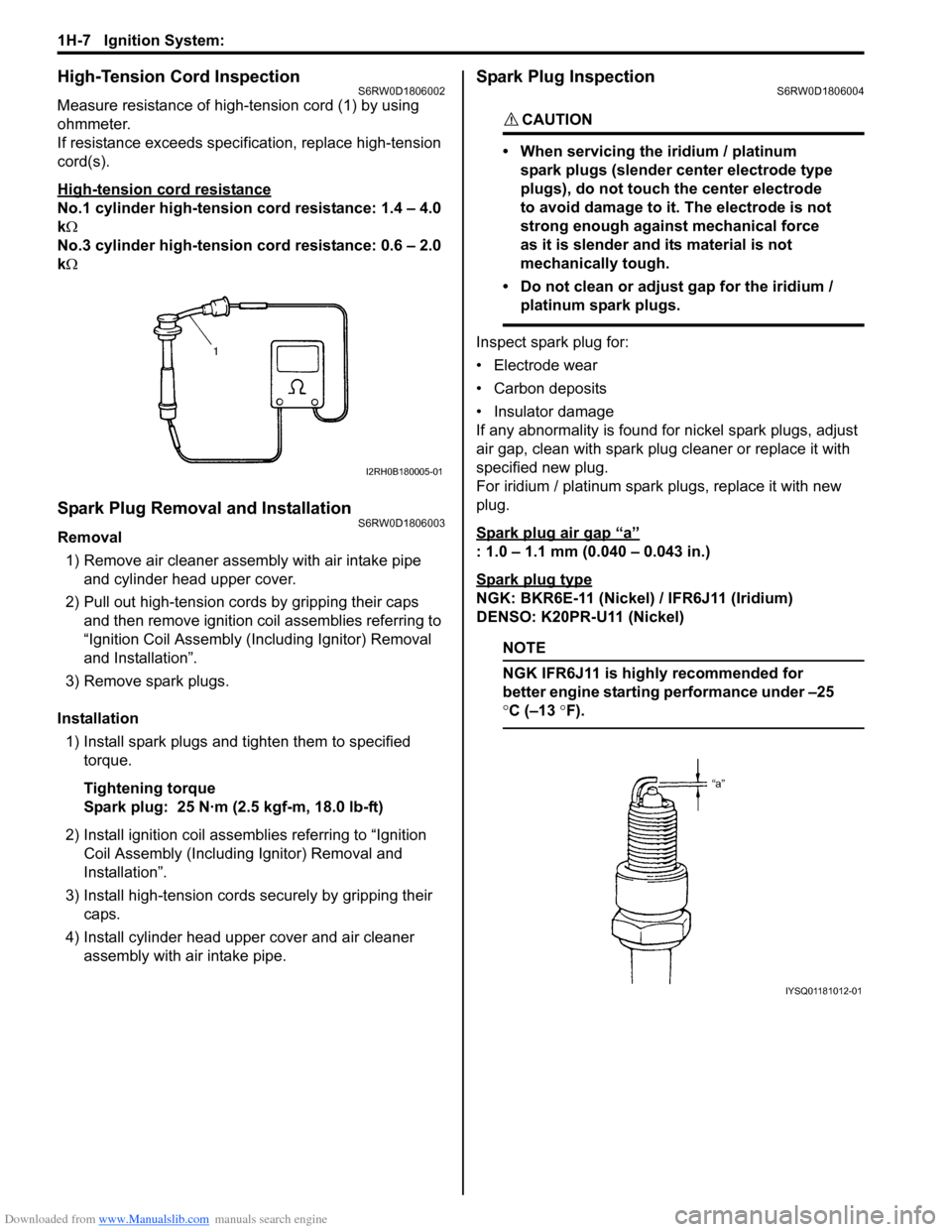

High-Tension Cord InspectionS6RW0D1806002

Measure resistance of high-tension cord (1) by using

ohmmeter.

If resistance exceeds specification, replace high-tension

cord(s).

High-tension cord resistance

No.1 cylinder high-tension cord resistance: 1.4 – 4.0

kΩ

No.3 cylinder high-tension cord resistance: 0.6 – 2.0

kΩ

Spark Plug Removal and InstallationS6RW0D1806003

Removal

1) Remove air cleaner assembly with air intake pipe

and cylinder head upper cover.

2) Pull out high-tension cords by gripping their caps

and then remove ignition coil assemblies referring to

“Ignition Coil Assembly (Including Ignitor) Removal

and Installation”.

3) Remove spark plugs.

Installation

1) Install spark plugs and tighten them to specified

torque.

Tightening torque

Spark plug: 25 N·m (2.5 kgf-m, 18.0 lb-ft)

2) Install ignition coil assemblies referring to “Ignition

Coil Assembly (Including Ignitor) Removal and

Installation”.

3) Install high-tension cords securely by gripping their

caps.

4) Install cylinder head upper cover and air cleaner

assembly with air intake pipe.

Spark Plug InspectionS6RW0D1806004

CAUTION!

• When servicing the iridium / platinum

spark plugs (slender center electrode type

plugs), do not touch the center electrode

to avoid damage to it. The electrode is not

strong enough against mechanical force

as it is slender and its material is not

mechanically tough.

• Do not clean or adjust gap for the iridium /

platinum spark plugs.

Inspect spark plug for:

• Electrode wear

• Carbon deposits

• Insulator damage

If any abnormality is found for nickel spark plugs, adjust

air gap, clean with spark plug cleaner or replace it with

specified new plug.

For iridium / platinum spark plugs, replace it with new

plug.

Spark plug air gap

“a”

: 1.0 – 1.1 mm (0.040 – 0.043 in.)

Spark plug type

NGK: BKR6E-11 (Nickel) / IFR6J11 (Iridium)

DENSO: K20PR-U11 (Nickel)

NOTE

NGK IFR6J11 is highly recommended for

better engine starting performance under –25

°C (–13 °F).

I2RH0B180005-01

IYSQ01181012-01

Page 405 of 1556

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-10

Specifications

Tightening Torque SpecificationsS6RW0D1807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS6RW0D1808001

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Spark plug 25 2.5 18.0�)

Ignition coil bolt 11 1.1 8.0�)

09930–76420 SUZUKI scan tool (SUZUKI-

SDT)

Timing-light (dry cell type) —

�)This kit includes following

items. 1. SUZUKI-SDT 2.

DLC3 cable 3. USB cable 4.

AC/DC power supply 5.

Voltage meter probe 6.

Storage case �)

1

2

34

56

Page 408 of 1556

Downloaded from www.Manualslib.com manuals search engine 1I-3 Starting System:

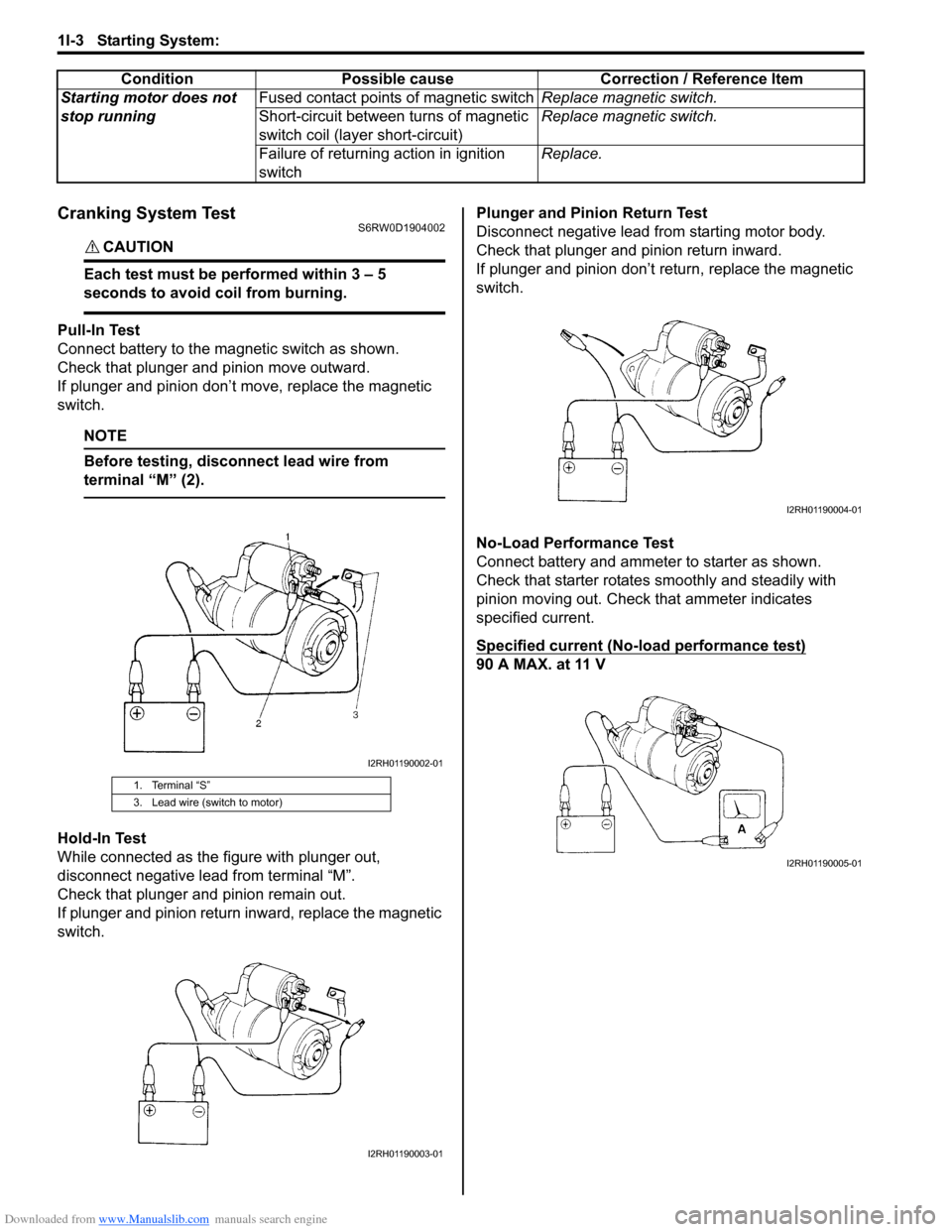

Cranking System TestS6RW0D1904002

CAUTION!

Each test must be performed within 3 – 5

seconds to avoid coil from burning.

Pull-In Test

Connect battery to the magnetic switch as shown.

Check that plunger and pinion move outward.

If plunger and pinion don’t move, replace the magnetic

switch.

NOTE

Before testing, disconnect lead wire from

terminal “M” (2).

Hold-In Test

While connected as the figure with plunger out,

disconnect negative lead from terminal “M”.

Check that plunger and pinion remain out.

If plunger and pinion return inward, replace the magnetic

switch.Plunger and Pinion Return Test

Disconnect negative lead from starting motor body.

Check that plunger and pinion return inward.

If plunger and pinion don’t return, replace the magnetic

switch.

No-Load Performance Test

Connect battery and ammeter to starter as shown.

Check that starter rotates smoothly and steadily with

pinion moving out. Check that ammeter indicates

specified current.

Specified current (No-load performance test)

90 A MAX. at 11 V Starting motor does not

stop runningFused contact points of magnetic switchReplace magnetic switch.

Short-circuit between turns of magnetic

switch coil (layer short-circuit)Replace magnetic switch.

Failure of returning action in ignition

switchReplace. Condition Possible cause Correction / Reference Item

1. Terminal “S”

3. Lead wire (switch to motor)

I2RH01190002-01

I2RH01190003-01

I2RH01190004-01

I2RH01190005-01