check engine SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1403 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-18

Rear Door Window Regulator Removal and

Installation

S6RW0D9506015

Removal

1) Remove door glass referring to “Rear Door Glass

Removal and Installation”.

2) Disconnect power window motor lead wire at

coupler.

3) Loosen regulator mounting screws, and then remove

rear window regulator (1).

Installation

Reverse removal procedure noting the following.

• Apply grease to sliding and rotating portions of

window regulator.

: Grease 99000–25011 (SUZUKI Super Grease A)

• Tighten rear door window regulator attaching screws.

Rear door window regulator screw tightening

order

(1) → (2)

Rear Door Window Regulator InspectionS6RW0D9506016

Check the following point:

• Check regulator sliding and rotating parts.

• Check rollers for wear and damage.

Rear End Door Window Defogger Switch

Inspection

S6RW0D9506017

1) Check rear end door window defogger switch for

operation as follows.

a) Rear end door window defogger switch is built in

HVAC control unit.

Remove HVAC control module (unit) referring to

“HVAC Control Unit Removal and Installation in

Section 7A” or “HVAC Control Module Removal

and Installation in Section 7B”.

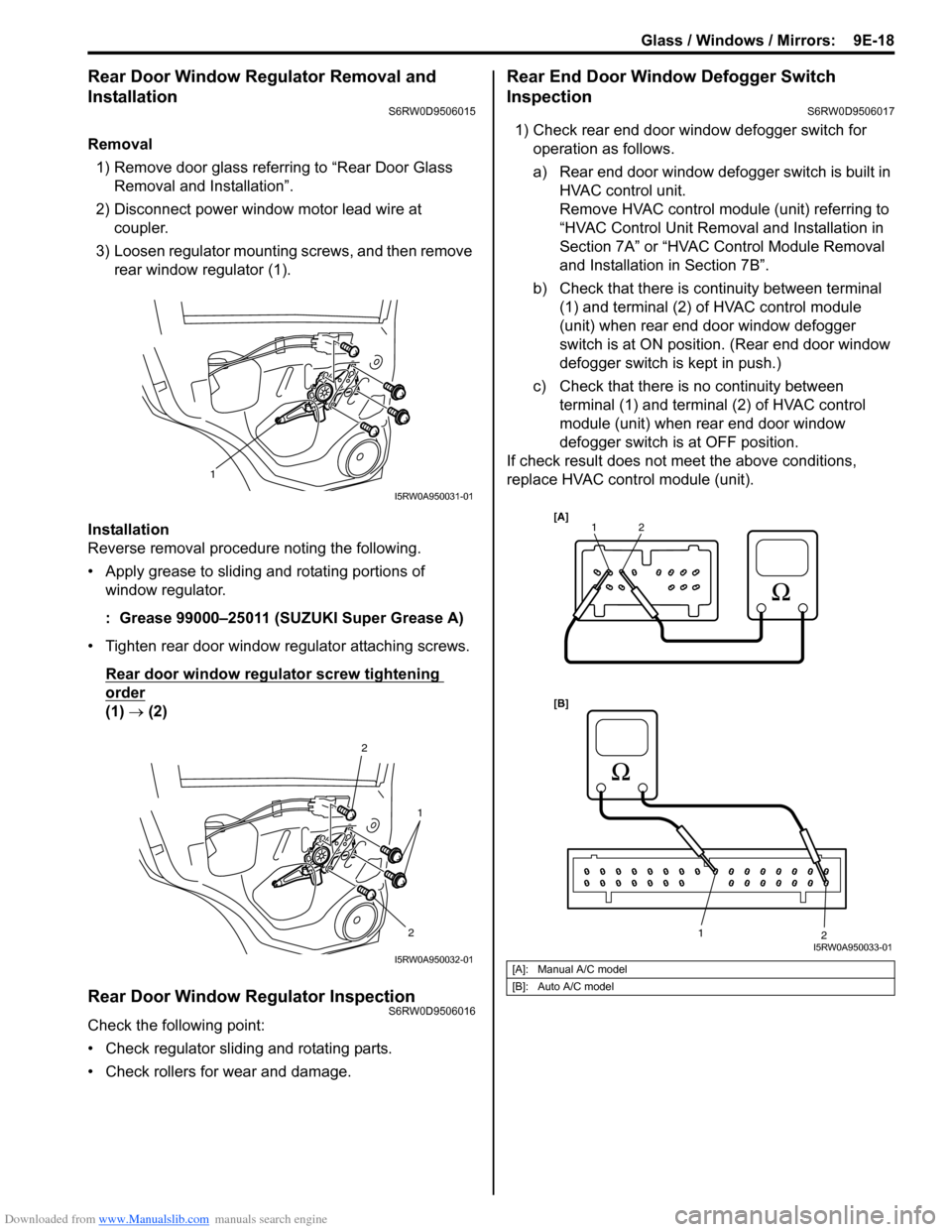

b) Check that there is continuity between terminal

(1) and terminal (2) of HVAC control module

(unit) when rear end door window defogger

switch is at ON position. (Rear end door window

defogger switch is kept in push.)

c) Check that there is no continuity between

terminal (1) and terminal (2) of HVAC control

module (unit) when rear end door window

defogger switch is at OFF position.

If check result does not meet the above conditions,

replace HVAC control module (unit).

1

I5RW0A950031-01

2

2

1

I5RW0A950032-01[A]: Manual A/C model

[B]: Auto A/C model

1

1 2

2[A]

[B]

I5RW0A950033-01

Page 1404 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-19 Glass / Windows / Mirrors:

Rear End Door Window Defogger Relay

Inspection

S6RW0D9506018

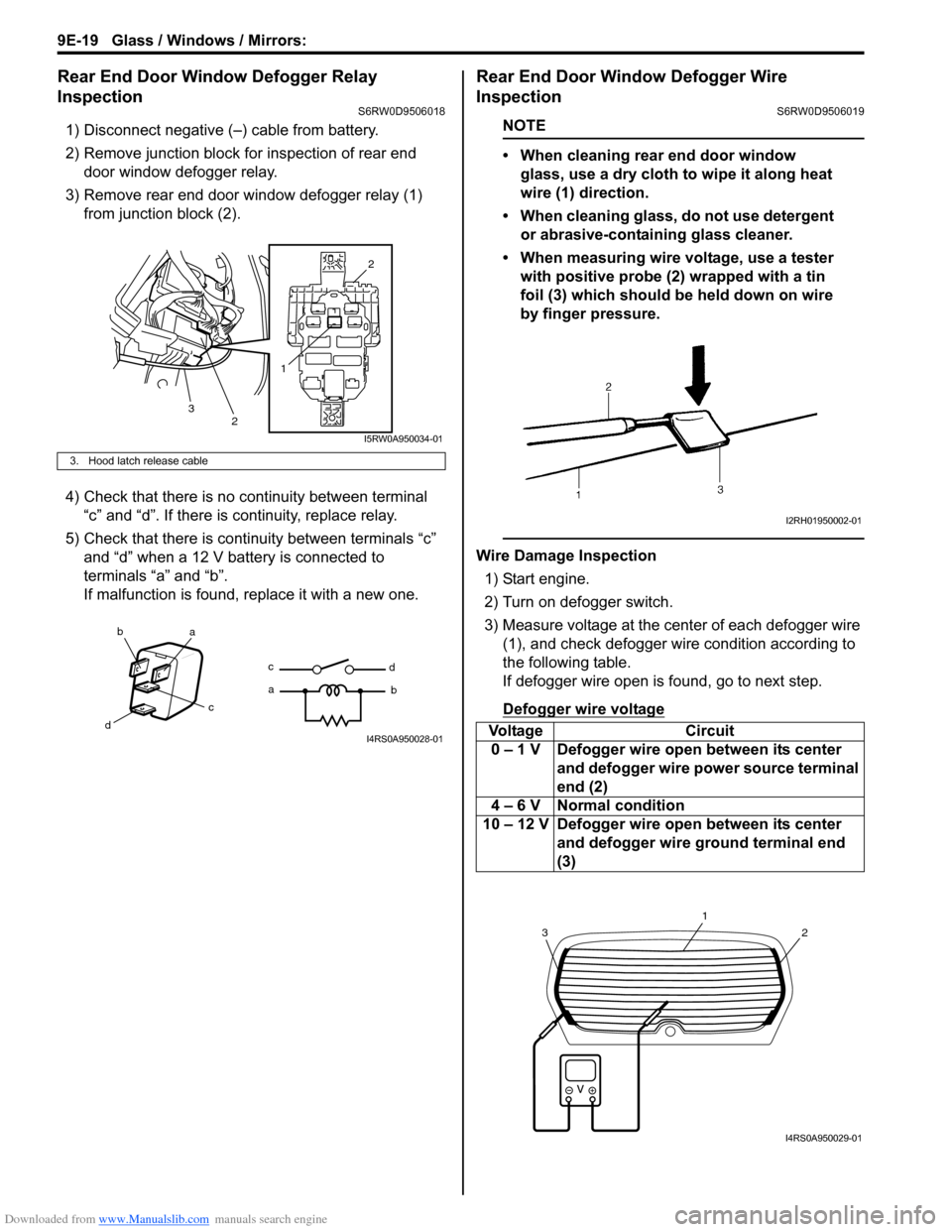

1) Disconnect negative (–) cable from battery.

2) Remove junction block for inspection of rear end

door window defogger relay.

3) Remove rear end door window defogger relay (1)

from junction block (2).

4) Check that there is no continuity between terminal

“c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c”

and “d” when a 12 V battery is connected to

terminals “a” and “b”.

If malfunction is found, replace it with a new one.

Rear End Door Window Defogger Wire

Inspection

S6RW0D9506019

NOTE

• When cleaning rear end door window

glass, use a dry cloth to wipe it along heat

wire (1) direction.

• When cleaning glass, do not use detergent

or abrasive-containing glass cleaner.

• When measuring wire voltage, use a tester

with positive probe (2) wrapped with a tin

foil (3) which should be held down on wire

by finger pressure.

Wire Damage Inspection

1) Start engine.

2) Turn on defogger switch.

3) Measure voltage at the center of each defogger wire

(1), and check defogger wire condition according to

the following table.

If defogger wire open is found, go to next step.

Defogger wire voltage

3. Hood latch release cable

12

2

3

I5RW0A950034-01

ba

c

dc

ad

bI4RS0A950028-01Voltage Circuit

0 – 1 V Defogger wire open between its center

and defogger wire power source terminal

end (2)

4 – 6 V Normal condition

10 – 12 V Defogger wire open between its center

and defogger wire ground terminal end

(3)

I2RH01950002-01

2

1

3

I4RS0A950029-01

Page 1405 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-20

4) Touch voltmeter negative (–) lead to defogger wire

ground terminal end (1).

5) Touch voltmeter positive (+) lead with a foil strip to

defogger wire power source terminal end (2), then

move it along wire to defogger wire ground terminal

end (1).

The place where voltmeter fluctuates from 10 – 12 V

to 0 – 1 V is where there is open.

If found defective, repair defogger wire referring to

“Rear End Door Window Defogger Wire Repair”.

Rear End Door Window Defogger Wire RepairS6RW0D9506020

1) Use white gasoline for cleaning.

2) Apply masking tape (1) at both upper and lower

sides of heat wire (2) to be repaired.

3) Apply commercially-available repair agent (3) with a

fine-tip brush (4).

4) 2 to 3 minutes later, remove masking tapes (1).

5) Leave repaired heat wire as it is for at least 24 hours

before operating the defogger again.

Power Window Main Switch InspectionS6RW0D9506021

Switch for Driver Side Window

Without Pinching Prevention Function Model

1) Remove driver side door trim referring to step 1) to

3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Connect 12 V battery positive (+) terminal to terminal

“IG” of power window main switch and its negative (–

) terminal to terminal “E” of power window main

switch.

4) Check for continuity between terminals as shown

below.

If check result is not as specified, replace power

window main switch.

21

I4RS0A950030-01

I2RH01950005-01

I7RW01950004-01

Page 1406 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-21 Glass / Windows / Mirrors:

With Pinching Prevention Function Model

NOTE

After replacing or disconnecting the power

window main switch, make sure to execute to

the initial setting, (to have the door glass

closed position learned) refer to “Power

Window Main Switch Initialization (Pinching

Prevention Function Model)”.

1) Remove driver side door trim referring to step 1) to

3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Connect 12 V battery positive (+) terminal to terminal

“IG” and “B” of power window main switch and its

negative (–) terminal to terminal “E” of power window

main switch.

4) Check for continuity between terminals as shown

below.

If check result is not as specified, replace power

window main switch.

[A]: Terminal

[B]: Driver side window switch position

1. UP

2. OFF

3. DOWN

DSB IG

E

SG SV

SB SA

DRU DRD

RLURLDRRURRDASUASD

[B][A]

1

2

3E DRU DRD B

E DRU DRD B

IG

[B]

I6RW0D950002-01

Page 1407 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-22

Switch for Other Window than Driver Side

1) Remove driver side door trim referring to step 1) to

3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Check for continuity between terminals as shown

below.

If check result is not as specified, replace power window

main switch.Power Window Sub Switch InspectionS6RW0D9506022

1) Remove front door trim from door panel, refer to Step

1) to 3) of “Front Door Glass Removal and

Installation”.

2) Remove power window sub switch from door trim.

3) Check for continuity between terminals at each

switch condition.

If check result is not as specified, replace switch.

[A]: Left-hand steering vehicle

[B]: Right-hand steering vehicle

I5RW0A950036-02

I5JB0A950037-01

Page 1408 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-23 Glass / Windows / Mirrors:

Pulse Sensor and Its Circuit Inspection

(Pinching Prevention Function Model)

S6RW0D9506029

NOTE

After replacing or disconnecting the driver

side power window regulator (motor), power

window main switch, battery and/or fuse,

make sure to execute the initial setting, (to

have the door glass closed position learned)

refer to “Power Window Main Switch

Initialization (Pinching Prevention Function

Model)”.

Pulse Sensor Circuit Diagram1) Remove driver side door trim referring to Step 1) to

3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from driver side

door trim, and them connect connector to power

window main switch.

3) Disconnect power window motor connector.

4) Turn ignition switch to ON position.

5) Check that “SV” wire terminal voltage of power

window motor connector is 10 – 14 V. If voltage is

not satisfied, check power window main switch

circuit for open, short and high resistance. If circuit is

OK, replace power window main switch.

6) Connect power window motor connector.

7) Connect oscilloscope to power window main switch

connector terminals.

8) Check pulse sensor signal by using oscilloscope. If

pulse sensor signal is not satisfied, check pulse

sensor 1 and 2 circuit. If circuit is OK, replace door

window regulator (motor).

Reference Waveform

[A]: Power window main switch connector

(viewed from harness side)

[B]: Driver side power window motor connector

(viewed from harness side)

1. Power window main switch

2. Driver side power window motor

3. Pulse sensor 1

4. Pulse sensor 2

SG

SV SB SA

SG SV SBSA

B IG

E

4 3

SG SV SBSA

SG SV SBSA

2 1

[A] [B]

I6RW0D950003-01

Measurement

terminalCH1: “SA” terminal to “SG” terminal

CH2: “SB” terminal to “SG” terminal

Oscilloscope

settingCH1: 5V/DIV, CH2: 5V/DIV

TIME: 10ms/DIV

Measurement

conditionIgnition switch is at ON position,

driver side power window operate

1. Normal operation

2. Something caught

I6RW0D950004-01

Page 1409 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-24

Power Window Main Switch Initialization

(Pinching Prevention Function Model)

S6RW0D9506030

CAUTION!

• After replacing or disconnecting the driver

side door window regulator (motor), power

window main switch, battery or fuse, be

sure to execute initial setting (to have door

glass completely closed position learned).

If initial setting is not executed, correct

automatic operation (including pinching

prevention operation) would not be

available.

• Make sure that no foreign matter is

pinched while executing initial setting.

1) Open driver side door glass fully.

2) Raise driver side door window switch (MANUAL UP

position) of power window main switch until door

glass is closed completely and hold the switch in that

state for 2 seconds or more.3) Use auto-down / auto-up function of power window

main switch and check that door glass opens fully /

closes completely.

4) Check pinching prevention function referring to

“Inspection of Pinching Prevention Function

(Pinching Prevention Function Model)”.

Door Mirror ComponentsS6RW0D9506023 1. AUTO UP position

2. MANUAL UP position

3. OFF position

1

2

3

I6RW0D950005-01

2

1

i

iiiii

3

I5RW0A950038-03

1. Door mirror

2. Door mirror mounting nut

:Tighten nuts in such order as indicated in the figure.

3. Door mirror trim

Page 1410 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-25 Glass / Windows / Mirrors:

Door Mirror Removal and InstallationS6RW0D9506024

When removing or installing door mirror, refer to the

figure in “Door Mirror Components”.

Power Door Mirror Switch InspectionS6RW0D9506025

1) Remove driver side door trim referring to step 1) to

3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Check for continuity between terminals at each

switch position.

If check result is not as specified, replace door mirror

switch.

Power Door Mirror Actuator InspectionS6RW0D9506026

1) Remove door trim referring to step 1) to 3) of “Front

Door Glass Removal and Installation”.

2) Disconnect door mirror coupler (1).

3) Check that door mirror operates properly when

battery voltage is applied to connector terminals.

4) Connect battery positive (+) and negative (–)

terminal to the door mirror terminals as shown.

If it does not follow the table’s operation, replace

door mirror assembly.

*: Vehicle with retractable mirror only

ABC

DEFG

A

BC

DE

FG

Up

Down

Left

Right

L

RH

I

*Set

*Retract

HII5RS0C950004-01

*: Vehicle with retractable mirror only

A

B

C1 Operation

Terminal

Up

Down

Left

Right

*Set

*RetractCDE B A

D

E

I6RW0D950007-01

Page 1411 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-26

Door Mirror Heater Inspection (If Equipped)S6RW0D9506027

1) Remove door trim referring to step 1) to 3) of “Front

Door Glass Removal and Installation”.

2) Disconnect door mirror connector (1).

3) Check for continuity between terminals “a” and “b”.

If no continuity, replace outside mirror.

Door Mirror Heater Switch Inspection (If

Equipped)

S6RW0D9506028

Door mirror heater is operated by rear end door window

defogger switch. Check rear end door window defogger

switch referring to “Rear End Door Window Defogger

Switch Inspection”.

Special Tools and Equipment

Recommended Service MaterialS6RW0D9508001

NOTE

Required service material is also described in the following.

“Front Door Window Components”

“Rear Door Window Components”

a

b1I7RW01950008-01

Material SUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25011�) / �)

Page 1414 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-3 Security and Locks:

Diagnostic Information and Procedures

Power Door Lock System Symptom Diagnosis (If Equipped)S6RW0D9604001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Door Lock System Operation Inspection (If Equipped)S6RW0D9604002

1) Check the following operation:

a) Turn the driver side key cylinder is turned LOCK once, check all doors lock.

b) Turn the driver side door key cylinder is turned UNLOCK position with door key twice, check all doors unlock.

c) With all doors unlocked, insert key in key cylinder of driver side door and turn it to lock side, turn it again to lock

side within 3 seconds and check that no door can be opened even when door lock knob is moved to unlock

side (dead lock function, if equipped).

If malfunction is found, go to “Power Door Lock System Symptom Diagnosis (If Equipped)”. Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by all of

switchesCircuit fuse blownReplace fuse and check for short circuit.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only power

door lock switchCircuit fuse blownReplace fuse and check for short circuit.

Power door lock switch faultyCheck power door lock switch referring to

“Power Door Lock Switch Inspection (If

Equipped)”.

Wiring harness connected to power door

lock switch faultyRepair.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only key

cylinder switchCircuit fuse blownReplace fuse and check for short circuit.

Key cylinder switch faultyCheck key cylinder switch referring to “Door

Key Cylinder Switch Inspection (If Equipped)”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Only one door can not be

locked / unlockedPower door lock actuator faultyCheck actuator referring to “Power Door Lock

Actuator Inspection (If Equipped)”.

Wiring harness connected to applicable

door lock actuator faultyRepair.

BCM faultyReplace after making sure that none of above

parts is faulty.