wheel SUZUKI SX4 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2010, Model line: SX4, Model: SUZUKI SX4 2010 1.GPages: 297, PDF Size: 4.51 MB

Page 235 of 297

7-30

INSPECTION AND MAINTENANCE

80J23-03E

Temperature – A, B, C

The temperature grades are A (the

highest), B and C, representing the

tire’s resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled condi-

tions on a specified indoor laboratory

test wheel. Sustained high tempera-

ture can cause the material of the tire

to degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. The grade C corre-

sponds to a level of performance

which all passenger car tires must

meet under the Federal Motor Vehicle

Safety Standard No. 109. Grades B

and A represent higher levels of per-

formance on the laboratory test wheel

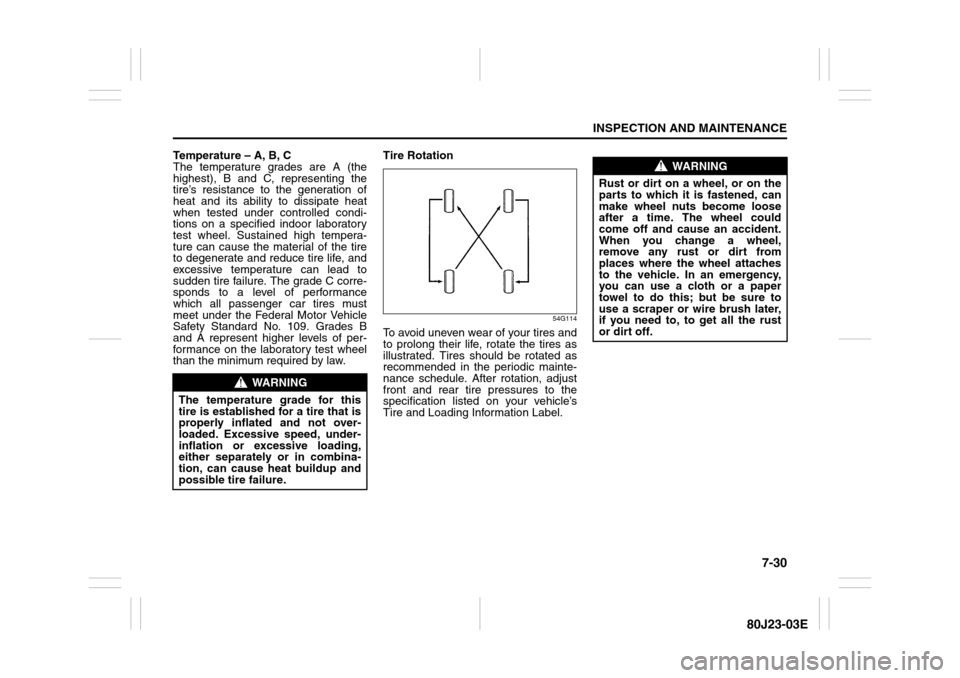

than the minimum required by law.Tire Rotation

54G114

To avoid uneven wear of your tires and

to prolong their life, rotate the tires as

illustrated. Tires should be rotated as

recommended in the periodic mainte-

nance schedule. After rotation, adjust

front and rear tire pressures to the

specification listed on your vehicle’s

Tire and Loading Information Label.

WARNING

The temperature grade for this

tire is established for a tire that is

properly inflated and not over-

loaded. Excessive speed, under-

inflation or excessive loading,

either separately or in combina-

tion, can cause heat buildup and

possible tire failure.

WARNING

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

make wheel nuts become loose

after a time. The wheel could

come off and cause an accident.

When you change a wheel,

remove any rust or dirt from

places where the wheel attaches

to the vehicle. In an emergency,

you can use a cloth or a paper

towel to do this; but be sure to

use a scraper or wire brush later,

if you need to, to get all the rust

or dirt off.

Page 236 of 297

7-31INSPECTION AND MAINTENANCE

80J23-03E

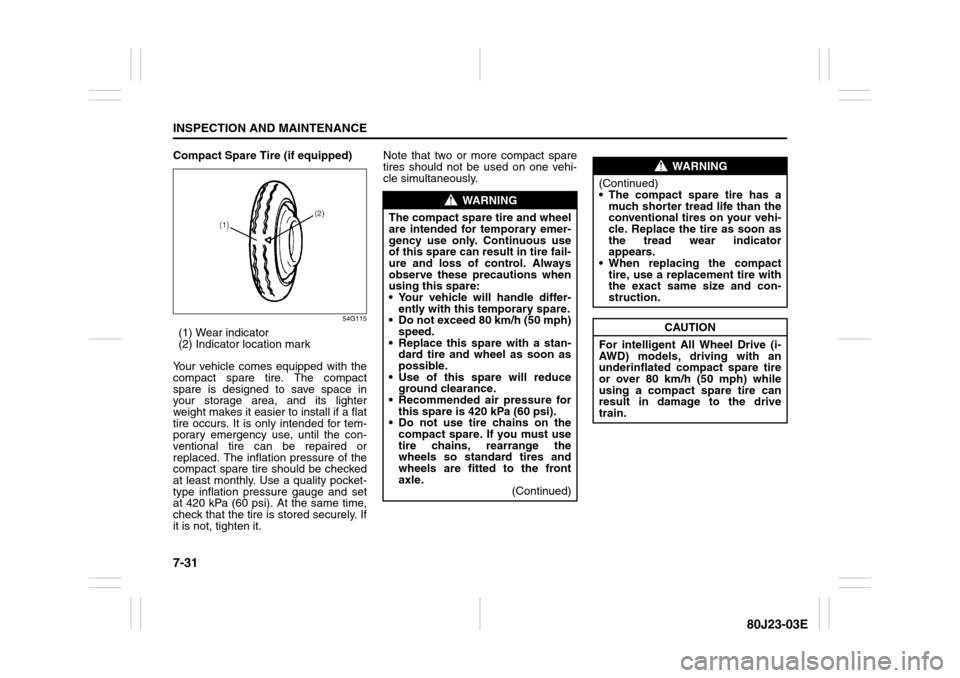

Compact Spare Tire (if equipped)

54G115

(1) Wear indicator

(2) Indicator location mark

Your vehicle comes equipped with the

compact spare tire. The compact

spare is designed to save space in

your storage area, and its lighter

weight makes it easier to install if a flat

tire occurs. It is only intended for tem-

porary emergency use, until the con-

ventional tire can be repaired or

replaced. The inflation pressure of the

compact spare tire should be checked

at least monthly. Use a quality pocket-

type inflation pressure gauge and set

at 420 kPa (60 psi). At the same time,

check that the tire is stored securely. If

it is not, tighten it.Note that two or more compact spare

tires should not be used on one vehi-

cle simultaneously.

WARNING

The compact spare tire and wheel

are intended for temporary emer-

gency use only. Continuous use

of this spare can result in tire fail-

ure and loss of control. Always

observe these precautions when

using this spare:

Your vehicle will handle differ-

ently with this temporary spare.

Do not exceed 80 km/h (50 mph)

speed.

Replace this spare with a stan-

dard tire and wheel as soon as

possible.

Use of this spare will reduce

ground clearance.

Recommended air pressure for

this spare is 420 kPa (60 psi).

Do not use tire chains on the

compact spare. If you must use

tire chains, rearrange the

wheels so standard tires and

wheels are fitted to the front

axle.

(Continued)

WARNING

(Continued)

The compact spare tire has a

much shorter tread life than the

conventional tires on your vehi-

cle. Replace the tire as soon as

the tread wear indicator

appears.

When replacing the compact

tire, use a replacement tire with

the exact same size and con-

struction.

CAUTION

For intelligent All Wheel Drive (i-

AWD) models, driving with an

underinflated compact spare tire

or over 80 km/h (50 mph) while

using a compact spare tire can

result in damage to the drive

train.

Page 237 of 297

7-32

INSPECTION AND MAINTENANCE

80J23-03E

Snow Tires

Your vehicle is equipped with all-sea-

son tires which are designed for use in

summer and most winter conditions.

For improved traction in severe winter

conditions, SUZUKI recommends

mounting radial snow tires on all four

wheels. Snow tires must be the same

size as the standard tires. Also be sure

to use the tires of the same type and

brand on all four wheels of your vehi-

cle.GLOSSARY OF TIRE TERMINOL-

OGY

Accessory Weight – the combined

weight (in excess of those standard

items which may be replaced) of CVT,

power steering, power brakes, power

windows, power seats, radio, and

heater, to the extent that these items

are available as factory-installed

equipment (whether installed or not).

Cold Tire Inflation Pressure – the pres-

sure in a tire that has been driven less

than 1 mile or has been standing for

three hours or more.

Curb Weight – the weight of a motor

vehicle with standard equipment

including the maximum capacity of

fuel, oil, and coolant, and, if so

equipped, air conditioning and addi-

tional weight optional engine.

Intended Outboard Sidewall – (1) the

sidewall that contains a whitewall,

bears white lettering or bears manu-

facturer, brand, and/or model name

molding that is higher or deeper than

the same molding on the other side-

wall of the tire, or (2) the outward fac-

ing sidewall of an asymmetrical tire

that has a particular side that must

always face outward when mounted

on a vehicle.Maximum Inflation Pressure – the max-

imum cold inflation pressure a tire is

designed to support in normal service.

Maximum Loaded Vehicle Weight –

the sum of curb weight, accessory

weight, vehicle capacity weight (total

load capacity), and production options

weight.

Normal Occupant Weight – 68 kilo-

grams times the number of occupants

specified in the second column of

Table 1 (shown below).

Occupant distribution – distribution of

occupants in a vehicle as specified in

the third column of Table 1 (shown

below).

Production Options Weight – the com-

bined weight of those installed regular

production options weighing over 2.3

kilograms in excess of those standard

items which they replace, not previ-

ously considered in curb weight or

accessory weight, including heavy

duty brakes, ride levelers, roof rack,

heavy duty battery, and special trim.

Recommended Inflation Pressure –

the cold tire inflation pressure recom-

mended by a manufacturer.

Rim – metal support for a tire or tire

and tube assembly upon which the tire

beads are seated.

Page 247 of 297

7-42

INSPECTION AND MAINTENANCE

80J23-03E

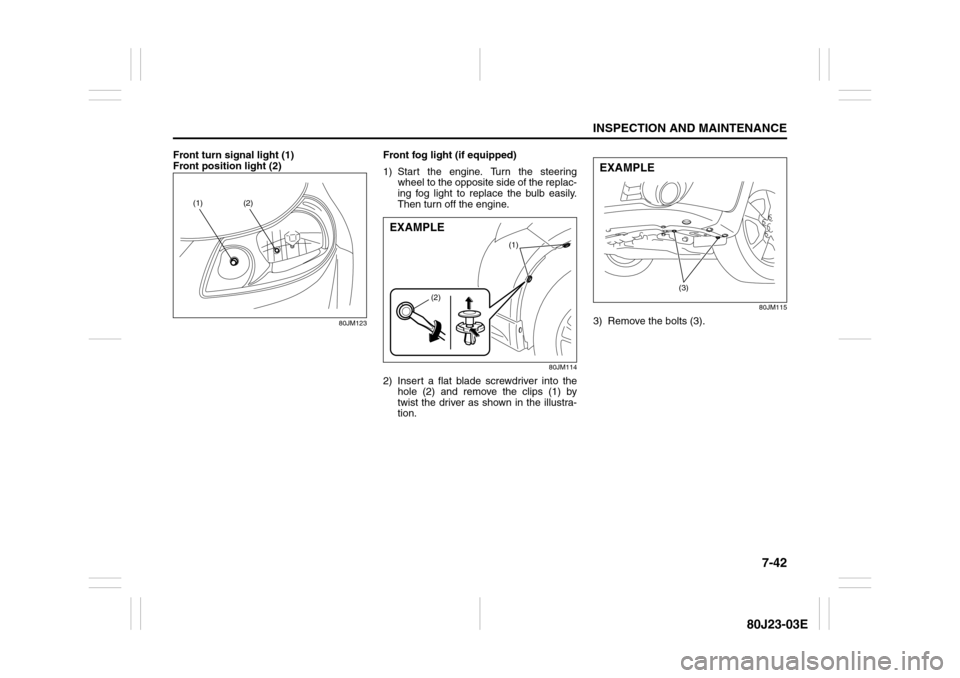

Front turn signal light (1)

Front position light (2)

80JM123

Front fog light (if equipped)

1) Start the engine. Turn the steering

wheel to the opposite side of the replac-

ing fog light to replace the bulb easily.

Then turn off the engine.

80JM114

2) Insert a flat blade screwdriver into the

hole (2) and remove the clips (1) by

twist the driver as shown in the illustra-

tion.

80JM115

3) Remove the bolts (3).

(1)

(2)

(1)

(2)

EXAMPLE

(3)

EXAMPLE

Page 257 of 297

EMERGENCY SERVICE

8

80J23-03E

60G411

EMERGENCY SERVICETire Changing Tool ............................................................. 8-1

Jacking Instructions ........................................................... 8-2

Changing Wheels ................................................................ 8-4

Jump Starting Instructions ................................................ 8-5

Towing a Disabled Vehicle ................................................. 8-6

If the Starter Does Not Operate .......................................... 8-6

If the Engine is Flooded ...................................................... 8-7

If the Engine Overheats ...................................................... 8-7

Page 258 of 297

8-1EMERGENCY SERVICE

80J23-03E

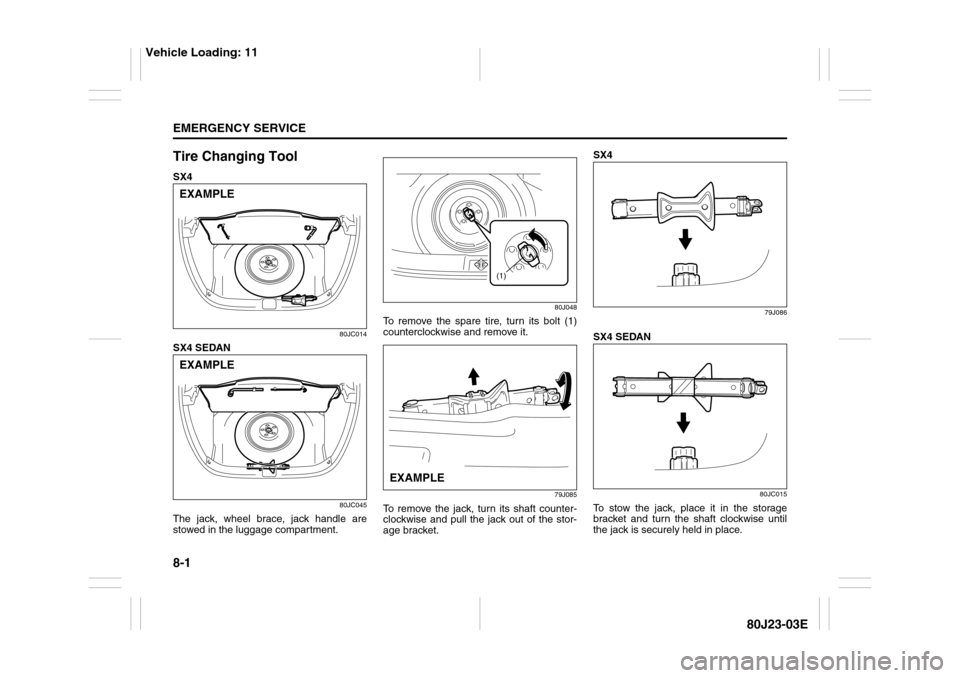

Tire Changing ToolSX4

80JC014

SX4 SEDAN

80JC045

The jack, wheel brace, jack handle are

stowed in the luggage compartment.

80J048

To remove the spare tire, turn its bolt (1)

counterclockwise and remove it.

79J085

To remove the jack, turn its shaft counter-

clockwise and pull the jack out of the stor-

age bracket.SX4

79J086

SX4 SEDAN

80JC015

To stow the jack, place it in the storage

bracket and turn the shaft clockwise until

the jack is securely held in place.

EXAMPLEEXAMPLE

(1)

EXAMPLE

Vehicle Loading: 11

Page 259 of 297

8-2

EMERGENCY SERVICE

80J23-03E

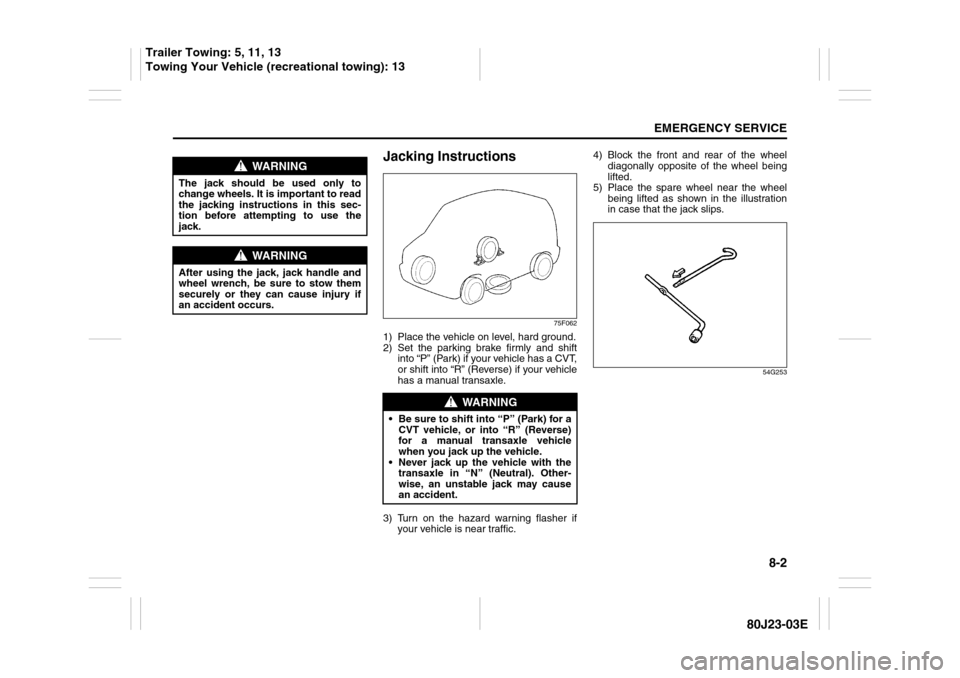

Jacking Instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift

into “P” (Park) if your vehicle has a CVT,

or shift into “R” (Reverse) if your vehicle

has a manual transaxle.

3) Turn on the hazard warning flasher if

your vehicle is near traffic.4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case that the jack slips.

54G253

WARNING

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

WARNING

After using the jack, jack handle and

wheel wrench, be sure to stow them

securely or they can cause injury if

an accident occurs.

WARNING

Be sure to shift into “P” (Park) for a

CVT vehicle, or into “R” (Reverse)

for a manual transaxle vehicle

when you jack up the vehicle.

Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, an unstable jack may cause

an accident.

Trailer Towing: 5, 11, 13

Towing Your Vehicle (recreational towing): 13

Page 260 of 297

8-3EMERGENCY SERVICE

80J23-03E

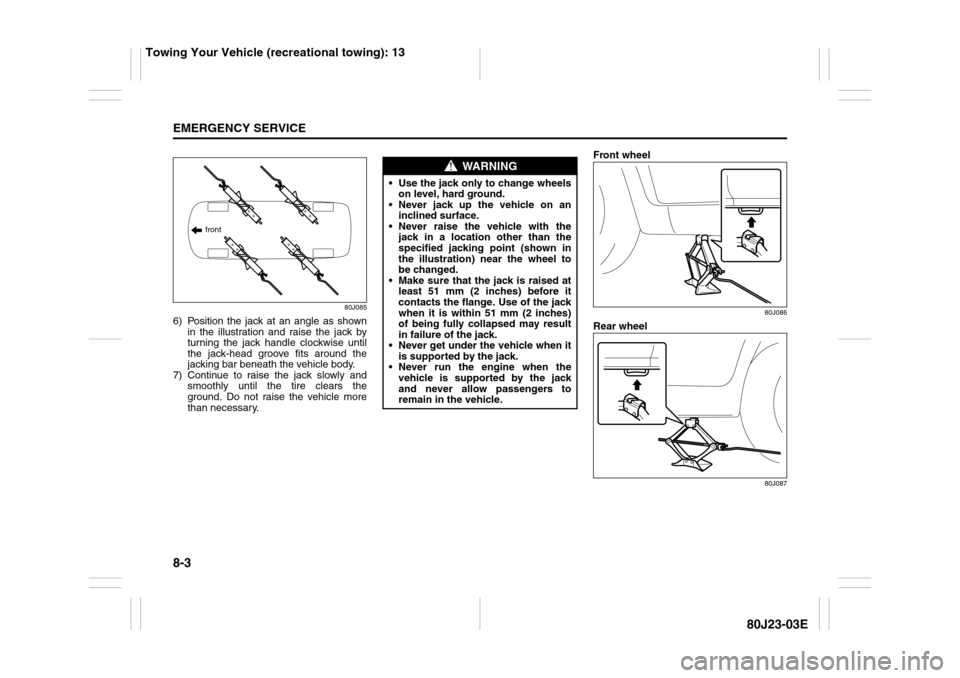

80J085

6) Position the jack at an angle as shown

in the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.

7) Continue to raise the jack slowly and

smoothly until the tire clears the

ground. Do not raise the vehicle more

than necessary.Front wheel

80J086

Rear wheel

80J087

front

WARNING

Use the jack only to change wheels

on level, hard ground.

Never jack up the vehicle on an

inclined surface.

Never raise the vehicle with the

jack in a location other than the

specified jacking point (shown in

the illustration) near the wheel to

be changed.

Make sure that the jack is raised at

least 51 mm (2 inches) before it

contacts the flange. Use of the jack

when it is within 51 mm (2 inches)

of being fully collapsed may result

in failure of the jack.

Never get under the vehicle when it

is supported by the jack.

Never run the engine when the

vehicle is supported by the jack

and never allow passengers to

remain in the vehicle.

Towing Your Vehicle (recreational towing): 13

Page 261 of 297

8-4

EMERGENCY SERVICE

80J23-03E

Changing WheelsTo change a wheel, use the following pro-

cedure:

1) Remove the jack, tools and spare wheel

from the vehicle.

2) Loosen, but do not remove the wheel

nuts.

3) Jack up the vehicle (follow the jacking

instructions in this section).

4) Remove the wheel nuts and wheel.

5) Before installing the new wheel, clean

any mud or dirt off from the surface of

the wheel and hub with a clean cloth.

Clean the hub carefully; it may be hot

from driving.

6) Install the new wheel and replace the

wheel nuts with their cone shaped end

facing the wheel. Tighten each nut

snugly by hand until the wheel is

securely seated on the hub.

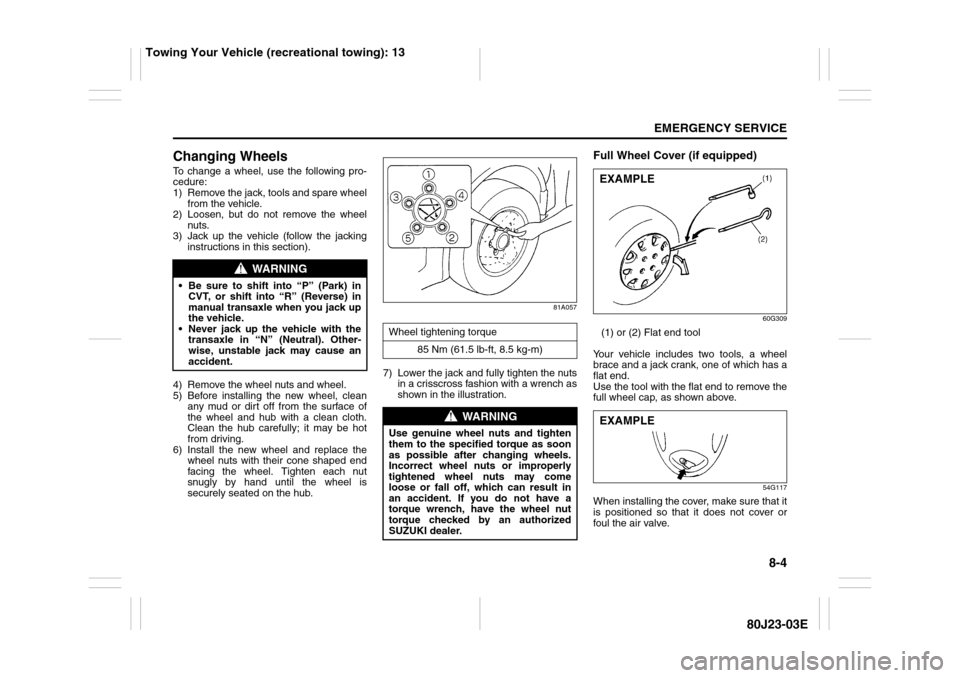

81A057

7) Lower the jack and fully tighten the nuts

in a crisscross fashion with a wrench as

shown in the illustration.

Full Wheel Cover (if equipped)

60G309

(1) or (2) Flat end tool

Your vehicle includes two tools, a wheel

brace and a jack crank, one of which has a

flat end.

Use the tool with the flat end to remove the

full wheel cap, as shown above.

54G117

When installing the cover, make sure that it

is positioned so that it does not cover or

foul the air valve.

WARNING

Be sure to shift into “P” (Park) in

CVT, or shift into “R” (Reverse) in

manual transaxle when you jack up

the vehicle.

Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, unstable jack may cause an

accident.

Wheel tightening torque

85 Nm (61.5 lb-ft, 8.5 kg-m)

WARNING

Use genuine wheel nuts and tighten

them to the specified torque as soon

as possible after changing wheels.

Incorrect wheel nuts or improperly

tightened wheel nuts may come

loose or fall off, which can result in

an accident. If you do not have a

torque wrench, have the wheel nut

torque checked by an authorized

SUZUKI dealer.

EXAMPLEEXAMPLE

Towing Your Vehicle (recreational towing): 13

Page 263 of 297

8-6

EMERGENCY SERVICE

80J23-03E

4) If the booster battery you are using is

installed on another vehicle, start the

engine of the vehicle with the booster

battery. Run the engine at moderate

speed.

5) Start the engine of the vehicle with the

discharged battery.

6) Remove the jumper cables in the exact

reverse order in which you connected

them.

Towing a Disabled VehicleEmergency TowingIf your vehicle is disabled, it may be towed

by a tow truck using one of the following

methods:

1) Tow the vehicle with two wheels lifted

by the tow truck and the other two

wheels on a towing dolly.

2) Use the appropriate towing method

specified for your vehicle in the “Towing

Your Vehicle (recreational towing)” sec-

tion, but with the wheels lifted by the

tow truck instead of on a towing dolly.

Be sure to carefully follow the specific

instructions provided in the “Towing

Your Vehicle (recreational towing)” sec-

tion.

If the Starter Does Not

Operate1) Try turning the ignition switch to the

“START” position with the headlights

turned on to determine the battery con-

dition. If the headlights go excessively

dim or go off, it usually means that

either the battery has run down or bat-

tery terminal contact is poor. Recharge

the battery or correct battery terminal

contact if necessary.

2) If the headlights remain bright, check

the fuses. If the reason for failure of the

starter is not obvious, there may be a

major electrical problem. Have the vehi-

cle inspected by your authorized

SUZUKI dealer.

WARNING

Never connect the jumper cable

directly to the negative (–) terminal of

the discharged battery, or an explo-

sion may occur.

CAUTION

If vehicle damage (such as steering

or drivetrain damage, etc.) prevents

normal use of the towing procedures

for your vehicle described in the

“Towing Your Vehicle (recreational

towing)” section, have your vehicle

towed with two wheels lifted by the

tow truck and the other two wheels

on a towing dolly.