ignition coil TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1994, Model line: CAMRY, Model: TOYOTA CAMRY 1994 XV10 / 4.GPages: 307, PDF Size: 5.48 MB

Page 254 of 307

254

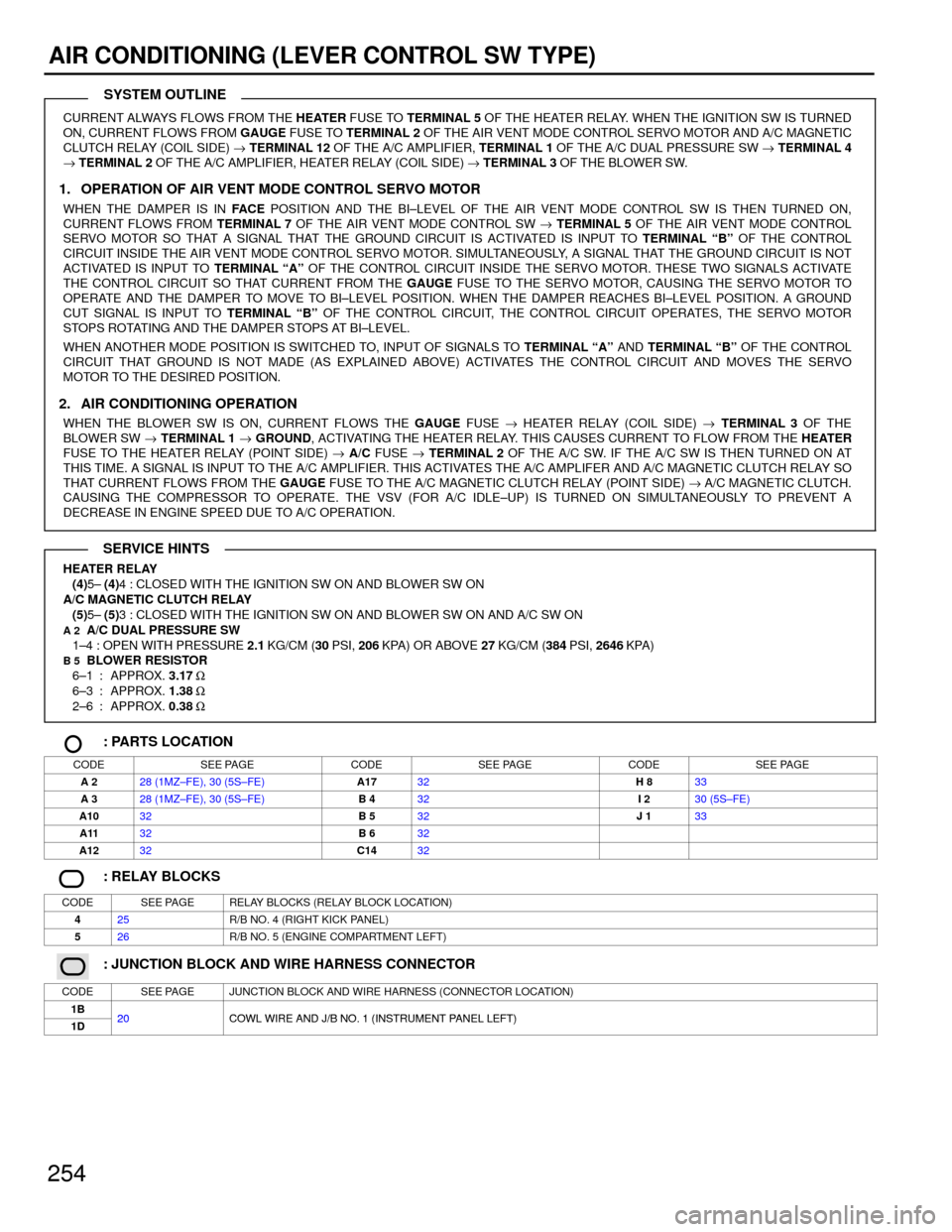

AIR CONDITIONING (LEVER CONTROL SW TYPE)

CURRENT ALWAYS FLOWS FROM THE HEATER FUSE TO TERMINAL 5 OF THE HEATER RELAY. WHEN THE IGNITION SW IS TURNED

ON, CURRENT FLOWS FROM GAUGE FUSE TO TERMINAL 2 OF THE AIR VENT MODE CONTROL SERVO MOTOR AND A/C MAGNETIC

CLUTCH RELAY (COIL SIDE) " TERMINAL 12 OF THE A/C AMPLIFIER, TERMINAL 1 OF THE A/C DUAL PRESSURE SW " TERMINAL 4

" TERMINAL 2 OF THE A/C AMPLIFIER, HEATER RELAY (COIL SIDE) " TERMINAL 3 OF THE BLOWER SW.

1. OPERATION OF AIR VENT MODE CONTROL SERVO MOTOR

WHEN THE DAMPER IS IN FACE POSITION AND THE BI±LEVEL OF THE AIR VENT MODE CONTROL SW IS THEN TURNED ON,

CURRENT FLOWS FROM TERMINAL 7 OF THE AIR VENT MODE CONTROL SW " TERMINAL 5 OF THE AIR VENT MODE CONTROL

SERVO MOTOR SO THAT A SIGNAL THAT THE GROUND CIRCUIT IS ACTIVATED IS INPUT TO TERMINAL ªBº OF THE CONTROL

CIRCUIT INSIDE THE AIR VENT MODE CONTROL SERVO MOTOR. SIMULTANEOUSLY, A SIGNAL THAT THE GROUND CIRCUIT IS NOT

ACTIVATED IS INPUT TO TERMINAL ªAº OF THE CONTROL CIRCUIT INSIDE THE SERVO MOTOR. THESE TWO SIGNALS ACTIVATE

THE CONTROL CIRCUIT SO THAT CURRENT FROM THE GAUGE FUSE TO THE SERVO MOTOR, CAUSING THE SERVO MOTOR TO

OPERATE AND THE DAMPER TO MOVE TO BI±LEVEL POSITION. WHEN THE DAMPER REACHES BI±LEVEL POSITION. A GROUND

CUT SIGNAL IS INPUT TO TERMINAL ªBº OF THE CONTROL CIRCUIT, THE CONTROL CIRCUIT OPERATES, THE SERVO MOTOR

STOPS ROTATING AND THE DAMPER STOPS AT BI±LEVEL.

WHEN ANOTHER MODE POSITION IS SWITCHED TO, INPUT OF SIGNALS TO TERMINAL ªAº AND TERMINAL ªBº OF THE CONTROL

CIRCUIT THAT GROUND IS NOT MADE (AS EXPLAINED ABOVE) ACTIVATES THE CONTROL CIRCUIT AND MOVES THE SERVO

MOTOR TO THE DESIRED POSITION.

2. AIR CONDITIONING OPERATION

WHEN THE BLOWER SW IS ON, CURRENT FLOWS THE GAUGE FUSE " HEATER RELAY (COIL SIDE) " TERMINAL 3 OF THE

BLOWER SW " TERMINAL 1 " GROUND, ACTIVATING THE HEATER RELAY. THIS CAUSES CURRENT TO FLOW FROM THE HEATER

FUSE TO THE HEATER RELAY (POINT SIDE) " A/C FUSE " TERMINAL 2 OF THE A/C SW. IF THE A/C SW IS THEN TURNED ON AT

THIS TIME. A SIGNAL IS INPUT TO THE A/C AMPLIFIER. THIS ACTIVATES THE A/C AMPLIFER AND A/C MAGNETIC CLUTCH RELAY SO

THAT CURRENT FLOWS FROM THE GAUGE FUSE TO THE A/C MAGNETIC CLUTCH RELAY (POINT SIDE) " A/C MAGNETIC CLUTCH.

CAUSING THE COMPRESSOR TO OPERATE. THE VSV (FOR A/C IDLE±UP) IS TURNED ON SIMULTANEOUSLY TO PREVENT A

DECREASE IN ENGINE SPEED DUE TO A/C OPERATION.

HEATER RELAY

(4)5± (4)4 : CLOSED WITH THE IGNITION SW ON AND BLOWER SW ON

A/C MAGNETIC CLUTCH RELAY

(5)5± (5)3 : CLOSED WITH THE IGNITION SW ON AND BLOWER SW ON AND A/C SW ON

A 2 A/C DUAL PRESSURE SW

1±4 : OPEN WITH PRESSURE 2.1 KG/CM (30 PSI, 206 KPA) OR ABOVE 27 KG/CM (384 PSI, 2646 KPA)

B 5 BLOWER RESISTOR

6±1 : APPROX. 3.17 W

6±3 : APPROX. 1.38 W

2±6 : APPROX. 0.38 W

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

A 228 (1MZ±FE), 30 (5S±FE)A1732H 833

A 328 (1MZ±FE), 30 (5S±FE)B 432I 230 (5S±FE)

A1032B 532J 133

A1132B 632

A1232C1432

: RELAY BLOCKS

CODESEE PAGERELAY BLOCKS (RELAY BLOCK LOCATION)

425R/B NO. 4 (RIGHT KICK PANEL)

526R/B NO. 5 (ENGINE COMPARTMENT LEFT)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1B20COWL WIRE AND J/B NO 1 (INSTRUMENT PANEL LEFT)1D20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

SYSTEM OUTLINE

SERVICE HINTS

Page 265 of 307

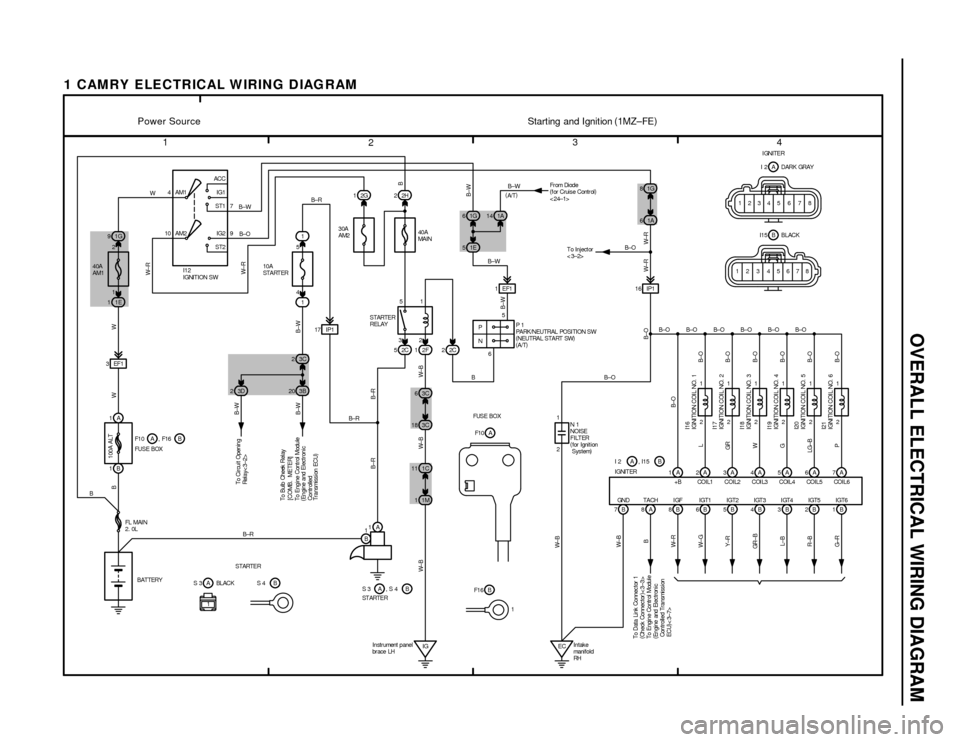

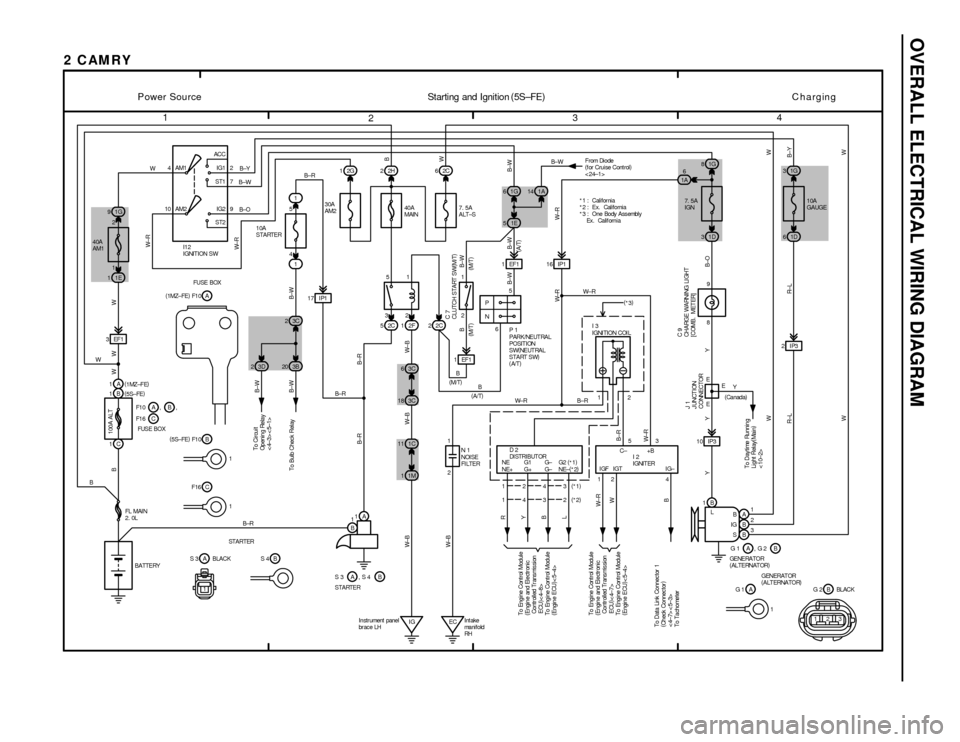

OVERALL ELECTRICAL WIRING DIAGRAM

1

234

1 CAMRY ELECTRICAL WIRING DIAGRAM

4ACC

IG1

ST1

IG2

ST2 AM1

7

9 10 AM2

2 2

1

5

1C 113C 6 2G 1

1G 912H 2

3C1A 14

1E 11

2C 2F

3C 182C

3EF117 IP11EF1 16 IP11A 6

1A

1

B1M 11G 8

3D 2

B±R B± O B±W W

W± R

B± RBB±W B± R

WW

B±W B±W

B±R B±R

W± B W± B

W±BB±WB

W± R W±B

IG

B±W

I12

IGNITION SW10A

START ER 40A

AM130A

AM2

FL MAI N

2. 0L

BATTERYIGNITER

To Circuit Opening

Relay< 3±2>

40A

MA I N

1

BBLACK

STARTER

B100A ALT

B±O

Instr ument panel

br ace LHB

EC 2 1

Intake

manifold

RH

W± B

B±O 5

6

W± R

P

N 61GB±W

(

A/ T)Fr om Diode

(

f or Cruis e Contr ol)

< 24±1>

B2

3B 201

3

251

B±W

51E

1A2 1

I16

IGNI TION COI L NO. 1

I21

IGNI TION COI L NO. 6

2 1

I20

IGNI TION COI L NO. 52 1

6A

I19

IGNI TION COI L NO. 42 1

5A

I18

IGNI TION COI L NO. 32 1

4A

I17

IGNI TION COI L NO. 22 1

3A 7A

1B 2B 3B 4B 5B 6B 8B 8A 7B2A

L

R±BL±B GR ± BY±R W± G

B± O B

IGT6 IGT5 IGT4 IGT3 IGT2 IGT1 IGF TACH GN DCOI L 6 COI L 5 COIL4 COI L3 COIL2 COI L1 +BG±R PLG±BG W GR W± R

B± O

B± O

B± O

B± O

B± O

B±OB±O B±O B±O B± O

To Injector

<3±2>

B±O

Starting and Ignition(

1MZ±FE)

Power Source

ST ARTERIGNITER

8 7 6 5 4 3 2 1

1 2 3 45678

ABLACKADARKGRAY

STARTER

RELAY

P1

PARK/ NEUTRAL POSI TI ON SW

(

NEUTRAL START SW)

(

A/T)

FUSE BOX

To Bulb Check Relay

To Engine Cont rol Module

(

Engine and Elect ronic

Co nt r ol le d

To Data Link Connec tor 1

(

Check Connec tor)

<3±3>

To Engine Contr ol Module

(

Engine and Elec tronic

Controlled Transmission

ECU)

<3±7>

B± O B± O 5

4

1A

1BF1 0 A , F16 B

1 S3 S4

S3 A , S4 BI2 A ,I15 BI2

I15

N1

NOISE

FILTER

(

for Ignit ion

System)

1 A F10

B F1 6 FUSE BOX

W±R Tra nsmi ss i on ECU) [COMB. METER]

Page 266 of 307

OVERALL ELECTRICAL WIRING DIAGRAM

1

234

2CAMRY

4ACC

IG1

ST1

IG2

ST2 AM1 2

7

9 10 AM2

21 4 5

2 1

E E

1C 113C 6 2G

2 1G 912C 6

1A 14

1E 11

2C 2F

3C 182C

3EF117 IP1

1EF116 IP1 1E 5

1A

1

B1M 1

1

L

A

B

B B

IG

S 10 IP38

31D 31D6 1G 8

1G 3

6

1A

3D 2 W

B±R B± O B±WB±Y W

W± R

B

B

B±W

B±R

B±RW± R

W WW

B±W

B±R B± R

W±B W±B

R

Y

B

L

W± R

W

B

YB±R

W±R

YB± WW

W± R

R± L W

R±L

WW± B

B±W

143212 4

IG

To Engine Cont rol Module

(

Engine and Electr onic

Contr olled Tr ans mis sion

ECU)

< 4±8>

To Engine Cont rol Module

(

Engine ECU)

< 5±4>

To Engine Cont rol Module

(

Engine and Electr onic

Contr olled Tr ans mis sion

ECU)

< 4±7>

To Engine Cont rol Module

(

Engine ECU)

< 5±4>

W

B±Y

W W±RB± W

Y I12

IGNITION SW10A

STARTER

40A

AM130A

AM2

FL MAI N

2. 0L

BATTERY

To Bulb Chec k Relay

C7

CLUTCH START SW(

M/T)

I3

IGNITION COIL

D2

DI STRI B UT OR

I2

IGNITER

C9

CHA RGE WA RNI NG LI GHT

[COMB. METER]7. 5A

IGN10A

GAUGE

To Day time Running

Light Relay(

Ma i n)

< 10±2> To Data Link Connec tor 1

(

Check Connec tor)

< 4±7> < 5±3>

To Ta cho me ter

B

1 A B BL ACKGENERATOR

(

ALTERNATOR) STARTER

B

(

Canada)

100A ALT

2IP3

B±O9

5 12

B

Instr ument panel

br ac e LHEC 2 1

Intake

ma n i f o l d

RH N1

NOI SE

FI LTER

W±B

W± R 5

6

Y

1

2

3

J1

JUNCTION

CONNECTORW± R

P

N61GB± WFrom Diode

(

f or Cruise Cont rol)

< 24±1>

123 BE (

M/T)

(

M/T)

(

A/T)(

A/T) 23C

B±W To Ci rcu i t

Opening Relay

<4±3><5±1>

B± R35 22H

7. 5A

ALT±S

EF 1 1 40A

MAIN

+B C±

IGF IGT IG± G2(

*1)

NE±(

*2) G±

G± G1

G+ NE

NE+ 5 1

1

B

P o w e r S o u r c e Starting and Ignition(

5S±FE)

Charging

P1

PARK/NEUTRAL

POSITION

SW(

NE UT RA L

START SW)

(

A/ T)

(

M/T) B

2

1

1B 1A

1C

1 A S 3 BLACKA (

1MZ± FE)

F1 0FUSE BOX

1

1 B (

5S±FE)

F1 0

C F16

S4

S3 A , S4 B

STARTER*1 : Califor nia

*2 : Ex. California

*3 : One Body Ass embly

Ex. California

G1 A , G2 B

GE NE RA TOR

(

AL TERNAT OR)

G1 G2 (

1MZ±FE)

(

5S±FE)

1243(

*1)

(

*2) FUSE BOXC F1 6 F1 0 A , B ,

B±W3B 20(

*3)