ignition coil TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1994, Model line: CAMRY, Model: TOYOTA CAMRY 1994 XV10 / 4.GPages: 307, PDF Size: 5.48 MB

Page 82 of 307

82

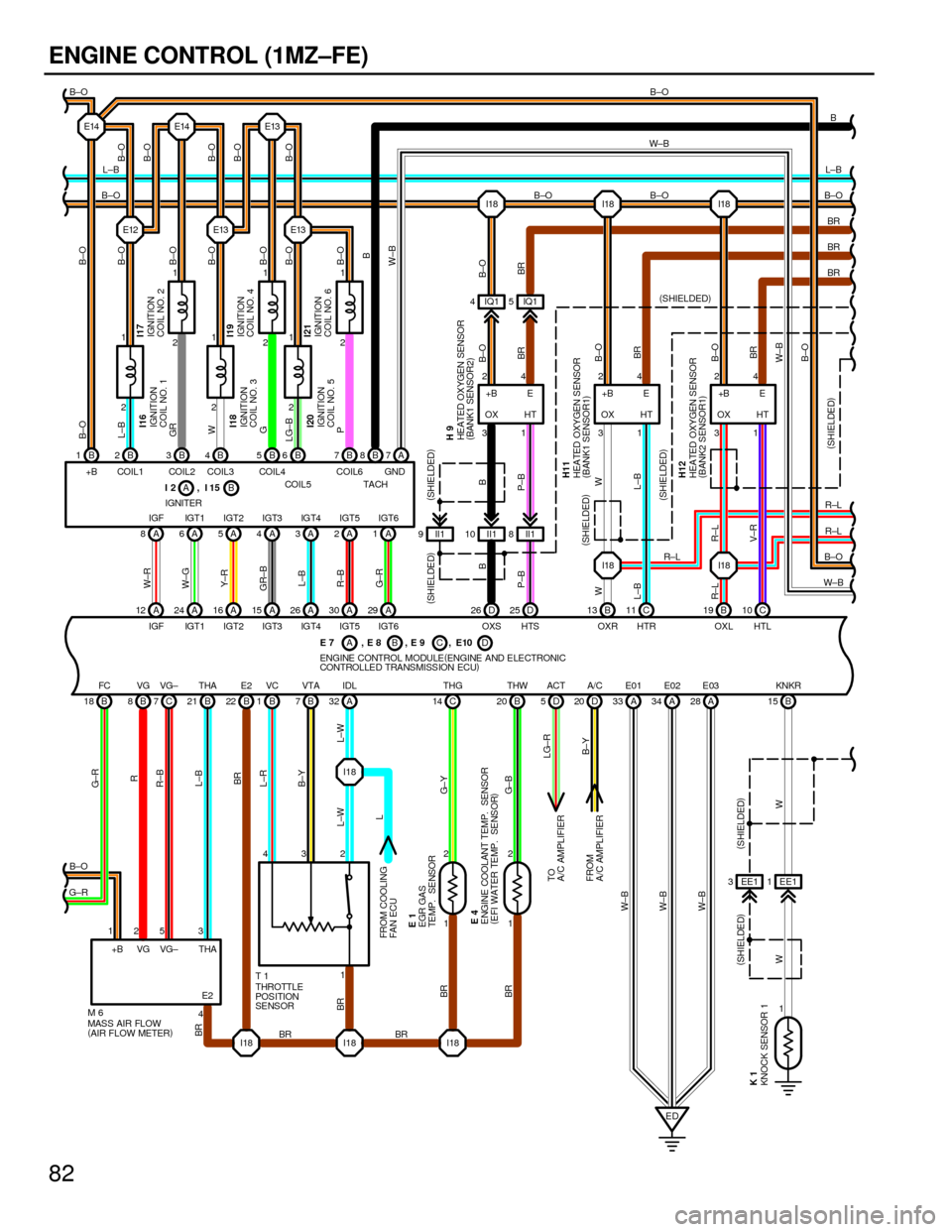

ENGINE CONTROL (1MZ±FE)

A A

I18 I18 I18

ED 1 2

4 53 1

1 432 7VG±

B 21THA

B 22E2

B 7VTA

A 32IDL

C 14THG

B 20THW

D 20A/C

A 34E02

A 28E03 B±O

B±OL±B

BR

G±R

BR BR

BRR±B

L±B

B±Y

L±W

B±Y

W±B

W±BG±B BR G±Y BR1B 15KNKR

EE1 3EE11

WWBR

ENGINE COOLANT TEMP. SENSOR

(

EFI WATER TEMP. SENSOR) E4 EGR GAS

TE MP. SE NSOR

THROTTLE

POSITION

SENSOR T1

MASS AIR FLOW

(

AIR FLOW METER) M6

FROM

A/C AMPLIFIER

KNOCK SENSOR 1 K1

D 5ACT

LG±R

TO

A/C AMPLIFIER E1

1 2D

ENGINE CONTROL MODULE(

ENGINE A ND E LE CTRONIC

CONTROLLED TRANSMISSION ECU) E7 ,E8 ,E9 , E10BC

(

SHIELDED) (

SHIELDED)

I18

L±W

W±BBR

BR

D 26

OXSD 25

HTS IQ1 4IQ15

II1 9 II110 II18

B±O

BR P±BB

P±B B

4 2

31+B E

OX HT

H9

HEATED OXYGEN SENSOR

(

BANK1 SENSOR2)

L±B

I18

B±O

BR (

SHIELDED)

(

SHIELDED)

(

SHIELDED)

+B VG± THA

E2 B 18FC

B 1VC

2

VGB 8VG

BR

B±O

L±RR G±R

L

FROM COOLING

FA N ECU

A 33E01

W±B

B±OR±L R±L 4 2

31+B E

OX HT

H12

HEATED OXYGEN SENSOR

(

BANK2 SENSOR1)

4 2

31+B E

OX HT

H11

HEATED OXYGEN SENSOR

(

BANK1 SENSOR1)

I18 I18

C 10 B 19 B 13 C11B±OB

I18 I18

A 7 B 7 B 6 B 5 B 4 B 3 B 2 B 1B8 E14 E14 E13

E13 E13 E12

A 29 A 30 A 26 A 15 A 16 A 24 A 12A 1 A 2 A 3 A 4 A 5 A 6 A 8 2 1

2 1

2 1

2 1

2 1

2 1

IGNITION

COIL NO. 1 I16

IGNITION

COIL NO. 2 I17

IGNITION

COIL NO. 3 I18

IGNITION

COIL NO. 4 I19

IGNITION

COIL NO. 5 I20

IGNITION

COIL NO. 6 I21

+B COIL1 COIL2 COIL3 COIL4

COIL5COIL6

TA CHGND

IGF IGT1 IGT2 IGT3 IGT4 IGT5 IGT6 IGF IGT1 IGT2 IGT3 IGT4 IGT5 IGT6

C IGNITER I2 , I15B

W±R

W±G

Y±R

GR±B

L±B

R±B

G±RL±B

GR

WB±O B±O

B±O

B±O

B±O

B

W±B G

LG±B

PB±O

B±O

B±O B±O B±O B±O B±O B±O

(

SHIELDED) (

SHIELDED)

(

SHIELDED) W W

L±B

R±LL±B

R±L

V±R

W±B

B±OBR B±OBR B±O

B±O B±O

R±L

OXR HTR OXL HTLW±BB±O

Page 88 of 307

88

ENGINE CONTROL (5S±FE)

THIS SYSTEM UTILIZES AN ENGINE CONTROL MODULE (ENGINE ECU (M/T), ENGINE AND ELECTRONIC CONTROLLED

TRANSMISSION ECU (A/T)) AND MAINTAINS OVERALL CONTROL OF THE ENGINE, TRANSMISSION AND SO ON. AN OUTLINE OF THE

ENGINE CONTROL IS EXPLAINED HERE.

1. INPUT SIGNALS

(1) ENGINE COOLANT TEMP. (WATER TEMP.) SIGNAL SYSTEM

THE ENGINE COOLANT TEMP. SENSOR (EFI WATER TEMP. SENSOR) DETECTS THE ENGINE COOLANT TEMP. AND HAS A

BUILT±IN THERMISTOR WITH A RESISTANCE WHICH VARIES ACCORDING TO THE ENGINE COOLANT TEMP. (WATER TEMP.)

THUS THE ENGINE COOLANT TEMP. (WATER TEMP.) IS INPUT IN THE FORM OF A CONTROL SIGNAL TO TERMINAL THW OF

THE ENGINE CONTROL MODULE (ECU).

(2) INTAKE AIR TEMP. SIGNAL SYSTEM

THE INTAKE AIR TEMP. SENSOR (IN±AIR TEMP. SENSOR) IS DETECTS THE INTAKE AIR TEMP., WHICH IS INPUT AS A

CONTROL SIGNAL TO TERMINAL THA OF THE ENGINE CONTROL MODULE (ECU).

(3) OXYGEN SENSOR SIGNAL SYSTEM

THE OXYGEN DENSITY IN THE EXHAUST GASES IS DETECTED AND INPUT AS A CONTROL SIGNAL TO TERMINAL OX1 AND

OX2 OF THE ENGINE CONTROL MODULE (ECU).

(4) RPM SIGNAL SYSTEM

CRANKSHAFT POSITION AND ENGINE RPM ARE DETECTED BY THE PICK±UP COIL INSTALLED INSIDE THE DISTRIBUTOR.

CRANKSHAFT POSITION IS INPUT AS A CONTROL SIGNAL TO TERMINALS G+ AND G2 (CALIFORNIA), OF THE ENGINE

CONTROL MODULE (ECU), AND RPM IS INPUT TO TERMINAL NE+.

(5) THROTTLE SIGNAL SYSTEM

THE THROTTLE POSITION SENSOR DETECTS THE THROTTLE VALVE OPENING ANGLE, WHICH IS INPUT AS A CONTROL

SIGNAL TO TERMINAL VTA OF THE ENGINE CONTROL MODULE (ECU), OR WHEN THE VALVE IS FULLY CLOSED, TO

TERMINAL IDL

(6) VEHICLE SPEED SIGNAL SYSTEM

THE VEHICLE SPEED SENSOR (SPEED SENSOR), INSTALLED INSIDE THE COMBINATION METER, DETECTS THE VEHICLE

SPEED AND INPUTS A CONTROL SIGNAL TO TERMINAL SPD OF THE ENGINE CONTROL MODULE (ECU).

(7) PARK/NEUTRAL POSITION SW (NEUTRAL START SW) SIGNAL SYSTEM (A/T)

THE PARK/NEUTRAL POSITION SW (NEUTRAL START SW) DETECTS WHETHER THE SHIFT POSITION ARE IN NEUTRAL AND

PARKING OR NOT, AND INPUTS A CONTROL SIGNAL TO TERMINAL NSW OF THE ENGINE CONTROL MODULE (ECU).

(8) A/C SW SIGNAL SYSTEM

THE A/C AMPLIFIER INPUTS THE A/C OPERATIONS TO TARMINAL ACA OF THE ENGINE CONTROL MODULE (ECU) AS A

CONTROL SIGNAL.

(9) BATTERY SIGNAL CIRCUIT

VOLTAGE IS CONSTANTLY APPLIED TO TERMINAL BATT OF THE ENGINE CONTROL MODULE (ECU). WHEN THE IGNITION SW

TURNED ON, THE VOLTAGE FOR ENGINE CONTROL MODULE (ECU) START±UP POWER SUPPLY IS APPLIED TO TERMINALS

+B AND +B1 OF ENGINE CONTROL MODULE (ECU) VIA EFI MAIN RELAY. THE CURRENT FLOWING THROUGH THE IGN FUSE

FLOWS TO TERMINAL IGSW OF THE ENGINE CONTROL MODULE (ECU).

(10) INTAKE AIR VOLUME SIGNAL SYSTEM

INTAKE AIR VOLUME IS DETECTED BY THE MANIFOLD ABSOLUTE PRESSURE SENSOR (VACUUM SENSOR) (FOR MANIFOLD

PRESSURE) AND IS INPUT AS A CONTROL SIGNAL TO TERMINAL PIM OF THE ENGINE CONTROL MODULE (ECU).

(11) STA SIGNAL CIRCUIT

TO CONFIRM WHETHER THE ENGINE IS CRANKING, THE VOLTAGE APPLIED TO THE STARTER MOTOR DURING CRANKING IS

DETECTED AND THE SIGNAL IS INPUT INTO TERMINAL STA OF THE ENGINE CONTROL MODULE (ECU) AS A CONTROL

SIGNAL.

(12) ENGINE KNOCK SIGNAL CIRCUIT

ENGINE KNOCKING IS DETECTED BY KNOCK SENSOR AND THE SIGNAL IS INPUT INTO TERMINAL KNK AS A CONTROL

SIGNAL.

(13) ELECTRICAL LOAD SIGNAL SYSTEM

THE SIGNAL WHEN SYSTEMS SUCH AS THE REAR WINDOW DEFOGGER, HEADLIGHTS, ETC. WHICH CAUSE A HIGH

ELECTRICAL BURDEN ARE ON IS INPUT TO TERMINAL ELS AS A CONTROL SIGNAL.

SYSTEM OUTLINE

Page 91 of 307

91

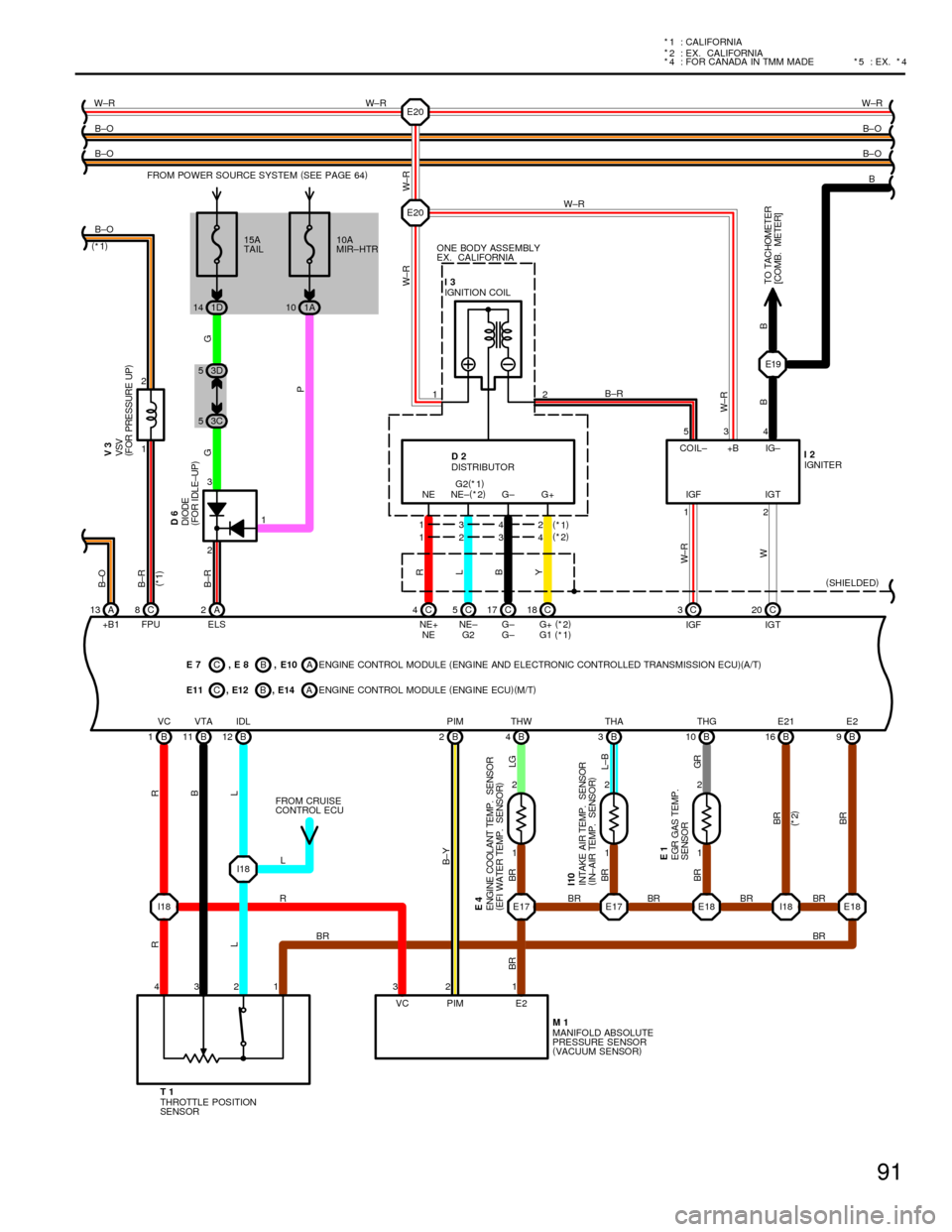

*

2 : EX. CALIFORNIA

* 4 : FOR CANADA IN TMM MADE * 1 : CALIFORNIA

* 5 : EX. * 4

B C

I18B 11 B 1B12

R

B

L R

VC VTA IDL

THROTTLE POSITION

SENSOR T11 2

1 2

1 2 E20

E20

E18 E17 E17 1234

2 3

32 112

A 13 A2C 18 C 17 C 5 C 4

B 2 A

4B3B10 B16 B9 PIM THW THA THG E21 E2 NE NE±(

*2)

G± G+B B± O W±R W±R

B±O

B± O

BR BR BR

B±Y

BR BR

BR

BR

BR

BRGR L±BLGB±R G G

W± R W±R

R

L

B

Y

B±O

D6

I3

D2

E7 ,E8 , E10 +B1 ELSW± R

NE+ NE± G± G+(

*2)

VC E2PIM

(

*2)

M1

E4

I10

E1

MANIFOLD ABSOLUTE

PRESSURE SENSOR

(

VACUUM SENSOR)

ENGINE COOLANT TEMP. SENSOR

(

EFI WATER TEMP. SENSOR)

INTAKE AIR TEMP. SENSOR

(

IN±AIR TEMP. SENSOR)

EGR GAS TEMP.

SENSOR

ENGINE CONTROL MODULE(

ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)(

A/T)

B

DIODE

(

FOR IDLE±UP)

IGNITION COIL

DISTRIBUTOR FROM

I18 E18

4321BR

BR I18

L

L FROM CRUISE

CONTROL ECU 1

P

E19

C 3C20 534

12

W± R

WBW±R

B

W±R

(

SHIELDED)

IGF IGT COIL± +B IG±

IGF IGTIGNITER I2

TO TACHOMETER

[COMB. METER]

C 8

FPU 1 2 B±O

(

*1)

B±O

(

*1) B±RV3

VSV

(

FOR PRESSURE UP)

1342G2(

*1)

(

*1)

(

*2)

NE G2 G± G1(

*1)

B E11 , E12CA,E14ENGINE CONTROL MODULE(

ENGINE ECU)(

M/T) ONE BODY ASSEMBLY

EX. CALIFORNIA

R

BRB±R

1D 1415A

TAIL

1A 1010A

MIR±HTR

3C 53D 5

POWER SOURCESYSTEM(

SEE PAGE 64)

Page 99 of 307

99

AB

1 2

1 2

1 2 E20

E20

E18 E17 E171234

32 112

C 1A 5 A 18 A 17 A 4

B 2C

4B3B13 B9 B 16 IP116

PIM THW THA THG E2E21 NE NE± G± G+

(

SHIELDED) B B±O W±R W± R

B±O

B±O

R

BRBR BR BR BR

B±Y

BR

BR

BR

BR

BRGR L±BLGW±R W±R

R

L

B

Y

B±O

D6

I3

D2

E11 , E12 , E14 +B1W±R

NE+ NE± G± G+

VC E2PIM

M1

E4

I10

E1

MANIFOLD ABSOLUTE

PRESSURE SENSOR

(

VACUUM SENSOR)

ENGINE COOLANT

TEMP. SENSOR

(

EFI WATER TEMP.

SENSOR)

INTAKE AIR

TEM P. SE NSOR

(

IN±AIR TEMP.

SENSOR)

EGR GAS TEMP.

SENSOR

ENGINE CONTROL MODULE(

ENGINE ECU)

B

DIODE

(

FOR IDLE±UP)

IGNITION COIL

DISTRIBUTOR

I18 E18

BR

BRBR 2 3

C 12

B±R G G

ELS FRO E 64)

1

P

E19

A 3A22

W±R

WB±R

W±R

BB

B

W± R

B± R

12 534

COIL± +B

IG F IGT

IG F IGTIGNITER I2

TO

TACHOMETER

[COMB. METER]

W±R

(

*

2)B±O

B±O

NE+

1D 1415A

TAIL

1A 1010A

MIR±HTR

3C 53D 5

M POWER SOURCE SYSTEM(

SEE PAG

Page 109 of 307

109

CURRENT FROM THE BATTERY IS ALWAYS FLOWING FROM THE FL MAIN " HEADLIGHT RELAY (COIL SIDE) " TERMINAL 5 OF THE

DAYTIME RUNNING LIGHT RELAY (MAIN) AND TERMINAL 14 OF THE DIMMER SW, HEADLIGHT RELAY (COIL SIDE) " TERMINAL 3 OF

THE INTEGRATION RELAY " TERMINAL 4 " TERMINAL 13 OF THE LIGHT CONTROL SW, FL MAIN " DAYTIME RUNNING LIGHT

RELAY NO. 2 (COIL SIDE) " TERMINAL 17 OF THE DAYTIME RUNNING LIGHT RELAY.

1. DAYTIME RUNNING LIGHT OPERATION

WHEN THE ENGINE IS STARTED, VOLTAGE GENERATED AT TERMINAL L OF THE GENERATOR (ALTERNATOR) IS APPLIED TO

TERMINAL 11 OF THE DAYTIME RUNNING LIGHT RELAY (MAIN).

IF THE PARKING BRAKE LEVER IS PULLED UP (PARKING BRAKE SW ON) AT THIS TIME, THE RELAY IS NOT ENERGIZED, SO THE

DAYTIME RUNNING LIGHT SYSTEM DOES NOT OPERATE. IF THE PARKING BRAKE LEVER IS RELEASED (PARKING BRAKE LEVER

SW OFF), THE SIGNAL IS INPUT TO TERMINAL 8 OF THE RELAY. THIS ACTIVATES THE RELAY ALSO, CURRENT FROM FL MAIN

FLOWES TO DAYTIME RUNNING LIGHT RELAY NO. 2 (POINT SIDE) " HEAD (UPR±LH) FUSE " TERMINAL 1 OF THE HEAD LH±HI "

TERMINAL 2 " TERMINAL 2 OF THE HEAD RH±HI " TERMINAL 1 " TERMINAL 4 OF THE DAYTIME RUNNING LIGHT RELAY NO. 3 "

TERMINAL 2 " TO GROUND, SO BOTH TAIL AND HEADLIGHT UP.

THIS IS HOW THE DAYTIME RUNNING LIGHT SYSTEM OPERATES. ONCE THE DAYTIME RUNNING LIGHT SYSTEM OPERATES AND

HEAD HAVE LIGHT UP, HEAD REMAIN ON EVEN IF THE PARKING BRAKE LEVER IS PULLED UP (PARKING BRAKE SW ON).

EVEN IF THE ENGINE STALLS WITH THE IGNITION SW ON AND THERE IS NO VOLTAGE FROM TERMINAL L OF THE GENERATOR

(ALTERNATOR), HEAD REMAIN ON. IF THE IGNITION SW IS THEN TURNED OFF, AND HEAD ARE TURNED OFF.

IF THE ENGINE IS STARTED WHILE THE PARKING BRAKE LEVER IS RELEASED (PARKING BRAKE SW OFF), THE DAYTIME RUNNING

LIGHT SYSTEM OPERATES AND TAIL, HEADLIGHT UP AS THE ENGINE STARTS.

2. HEADLIGHT OPERATION

*(WHEN THE LIGHT CONTROL SW AT THE HEAD POSITION)

WHEN THE LIGHT CONTROL SW IS SET TO HEAD POSITION, THE CURRENT FLOWING TO THE HEADLIGHT RELAY (COIL SIDE)

FLOWS TO TERMINAL 3 OF THE INTEGRATION RELAY " TERMINAL 4 " TERMINAL 13 OF THE LIGHT CONTROL SW " TERMINAL 11

" GROUND, TURNING THE HEADLIGHT RELAY ON.

THIS CAUSES THE CURRENT FLOWING TO THE HEADLIGHT RELAY (POINT SIDE) " DRL FUSE " DAYTIME RUNNING LIGHT RELAY

NO. 3 (COIL SIDE) AND DAYTIME RUNNING LIGHT RELAY NO. 4 (COIL SIDE) " GROUND, TURNING THE DAYTIME RUNNING LIGHT

RELAY NO. 3 AND NO. 4 ON. ALSO, CURRENT FROM THE HEADLIGHT RELAY (POINT SIDE) TO HEAD (LWR) FUSES " TERMINAL 1

OF THE HEADLIGHTS (LO) " TERMINAL 2 " GROUND, SO THE HEADLIGHTS (LO) LIGHT UP.

*(DIMMER SW AT FLASH POSITION)

WHEN THE DIMMER SW IS SET TO FLASH POSITION, CURRENT FLOWS FROM HEADLIGHT RELAY (COIL SIDE) " TERMINAL 14 OF

THE DIMMER SW " TERMINAL 9 " GROUND, TURNING THE HEADLIGHT RELAY ON. AT THE SAME TIME, SIGNALS ARE OUTPUT

FROM TERMINAL 12 AND TERMINAL 14 OF THE DIMMER SW TO TERMINAL 16 AND TERMINAL 5 OF THE DAYTIME RUNNING LIGHT

RELAY (MAIN), ACTIVATING THE DAYTIME RUNNING LIGHT RELAY (MAIN) AND ALSO THE DAYTIME RUNNING LIGHT RELAY NO. 2.

WHEN THE HEADLIGHT RELAY AND DAYTIME RUNNING LIGHT RELAY (MAIN) ARE ACTIVATED, THE HEADLIGHTS (LO AND HI) THEN

LIGHT UP.

*(DIMMER SW AT HIGH POSITION)

WHEN THE LIGHT CONTROL SW IS SET TO HEAD POSITION, A SIGNAL IS OUTPUT FROM TERMINAL 13 OF THE LIGHT CONTROL SW

" TERMINAL 4 OF THE INTEGRATION RELAY " TERMINAL 3 " TERMINAL 5 OF THE DAYTIME RUNNING LIGHT RELAY (MAIN).

WHEN THE DIMMER SW IS SET TO HIGH POSITION, A SIGNAL IS OUTPUT FROM TERMINAL 12 OF THE DIMMER SW TO TERMINAL 16

OF THE DAYTIME RUNNING LIGHT RELAY (MAIN). THESE SIGNALS ACTIVATE DAYTIME RUNNING LIGHT RELAY NO. 2, SO CURRENT

FLOWS FROM DAYTIME RUNNING LIGHT RELAY NO. 2 (POINT SIDE) " HEAD (UPR±LH) FUSE " TERMINAL 1 OF THE HEADLIGHT

LH±HI " TERMINAL 2 " DAYTIME RUNNING LIGHT RELAY NO. 4 (POINT SIDE) " GROUND, AND CURRENT ALSO SIMUTANEOUSLY

FLOWS FROM HEAD (UPR±RH) FUSE " DAYTIME RUNNING LIGHT RELAY NO. 3 (POINT SIDE) " TERMINAL 1 OF THE HEADLIGHT

RH±HI " TERMINAL 2 " DAYTIME RUNNING LIGHT RELAY NO. 4 (POINT SIDE), CAUSING THE HEADLIGHTS (HI SIDE) TO LIGHT UP.

D 4 DAYTIME RUNNING LIGHT RELAY (MAIN)

2±GROUND : APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION

15±GROUND : ALWAYS APPROX. 12 VOLTS

8±GROUND : CONTINUITY WITH THE PARKING BRAKE LEVER PULLED UP (PARKING BRAKE SW ON)

13±GROUND : ALWAYS CONTINUITY

SYSTEM OUTLINE

SERVICE HINTS

Page 113 of 307

11 3

WITH THE IGNITION SW TURNED ON, THE CURRENT FLOWS TO TERMINAL 7 OF THE INTEGRATION RELAY THROUGH GAUGE FUSE.

VOLTAGE IS APPLIED AT ALL TIMES TO TERMINAL (A) 2 OF THE INTEGRATION RELAY THROUGH THE TAILLIGHT RELAY (COIL SIDE),

AND TO TERMINAL (A) 3 THROUGH THE HEADLIGHT RELAY (COIL SIDE).

1. NORMAL LIGHTING OPERATION

(TURN TAILLIGHT ON)

WITH LIGHT CONTROL SW TURNED TO TAILLIGHT POSITION, A SIGNAL IS INPUT INTO TERMINAL (A) 1 OF THE INTEGRATION

RELAY. ACCORDING TO THIS SIGNAL, THE CURRENT FLOWING TO TERMINAL (A) 2 OF THE RELAY FLOWS FROM TERMINAL (A) 1 "

TERMINAL 2 OF THE LIGHT CONTROL SW " TERMINAL 11 " TO GROUND AND TAILLIGHT RELAY CAUSES TAILLIGHT TO TURN ON.

(TURN HEADLIGHT ON)

WITH LIGHT CONTROL SW TURNED TO HEADLIGHT POSITION, A SIGNAL IS INPUT INTO TERMINALS (A) 1 AND (A) 4 OF THE

INTEGRATION RELAY. ACCORDING TO THIS SIGNAL, THE CURRENT FLOWING TO TERMINAL (A) 3 OF THE RELAY FLOWS TO

TERMINAL (A) 4 " TERMINAL 13 OF THE LIGHT CONTROL SW " TERMINAL 11 " TO GROUND IN THE HEADLIGHT CIRCUIT, AND

CAUSES TAILLIGHT AND HEADLIGHT RELAY TO TURN THE LIGHT ON. THE TAILLIGHT CIRCUIT IS SAME AS ABOVE.

2. LIGHT AUTO TURN OFF OPERATION

WITH LIGHTS ON AND IGNITION SW TURNED OFF (INPUT SIGNAL GOES TO TERMINAL 7 OF THE RELAY), WHEN DOOR ON DRIVER'S

SIDE IS OPENED (INPUT SIGNAL GOES TO TERMINAL 6 OF THE RELAY), THE RELAY OPERATES AND THE CURRENT IS CUT OFF

WHICH FLOWS FROM TERMINAL (A) 2 OF THE RELAY TO TERMINAL (A) 1 IN TAILLIGHT CIRCUIT AND FROM TERMINAL (A) 3 TO

TERMINAL (A) 4 IN HEADLIGHT CIRCUIT. AS A RESULT, ALL LIGHTS ARE TURNED OFF AUTOMATICALLY.

I13 INTEGRATION RELAY

7±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

1±GROUND : ALWAYS APPROX. 12 VOLTS

(A)3±GROUND : APPROX. 12 VOLTS WITH LIGHT CONTROL SW AT OFF OR TAIL POSITION

(A)2±GROUND : APPROX. 12 VOLTS WITH LIGHT CONTROL SW AT OFF POSITION

6±GROUND : CONTINUITY WITH FRONT LH DOOR OPEN

(A)4±GROUND : CONTINUITY WITH LIGHT CONTROL SW AT HEAD POSITION

(A)1±GROUND : CONTINUITY WITH LIGHT CONTROL SW AT TAIL OR HEAD POSITION

10±GROUND : ALWAYS CONTINUITY

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C1232F10A28 (1MZ±FE), 30 (5S±FE)F16C28 (1MZ±FE), 30 (5S±FE)

D1234 (S/D), 35 (C/P), 36 (W/G)F10B28 (1MZ±FE), 30 (5S±FE)I13A33

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1B

1C20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1E

20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1H20FLOOR NO. 1 WIRE J/B NO. 1 (INSTRUMENT PANEL LEFT)

1M20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

2G22COWL WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

2H22ENGINE WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

EF138 (1MZ±FE)ENGINE WIRE AND COWL WIREEF140 (5S±FE)ENGINE WIRE AND COWL WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

IE42LEFT KICK PANEL

IG42INSTRUMENT PANEL BRACE LH

SYSTEM OUTLINE

SERVICE HINTS

Page 163 of 307

163

CURRENT ALWAYS FLOWS TO TERMINAL 8 OF THE DOOR LOCK CONTROL RELAY THROUGH THE POWER FUSE.

WHEN THE IGNITION SW IS TURNED ON, THE CURRENT FLOWING THROUGH THE GAUGE FUSE FLOWS THROUGH THE COIL SIDE

OF THE POWER MAIN RELAY TO GROUND, CAUSING THE RELAY TO OPERATE. THE CURRENT FLOWING THROUGH THE POWER

FUSE FLOWS TO THE LH DOOR LOCK CONTROL SW, CAUSING THE INDICATOR LIGHT TO LIGHT UP.

1. MANUAL LOCK OPERATION

WHEN THE DOOR LOCK CONTROL SW AND KEY SW ARE PUSHED TO LOCK POSITION, A LOCK SIGNAL IS INPUT TO TERMINAL 10,

12 OF THE DOOR LOCK CONTROL RELAY AND CAUSES THE RELAY TO FUNCTION. CURRENT FLOWS FROM TERMINAL 8 OF THE

RELAY " TERMINAL 4 " TERMINAL 4 OF THE DOOR LOCK MOTORS, (EX. C/P FRONT DOOR) OR TERMINAL 7 (C/P FRONT DOOR),

OF THE DOOR LOCK MOTOR TERMINAL 2 OF THE BACK DOOR LOCK MOTOR " TERMINAL 2 OF THE DOOR LOCK MOTORS, (EX.

C/P FRONT DOOR) OR TERMINAL 5 (C/P FRONT DOOR) OF THE DOOR LOCK MOTOR TERMINAL 1 OF THE BACK DOOR LOCK

MOTOR " TERMINAL 3 OF THE RELAY " TERMINAL 16 " TO GROUND AND THE DOOR LOCK MOTOR CAUSES THE DOOR TO

LOCK.

2. MANUAL UNLOCK OPERATION

WHEN THE DOOR LOCK CONTROL SW AND KEY SW RH TO UNLOCK POSITION, AN UNLOCK SIGNAL IS INPUT TO TERMINAL 11, 13

OF THE DOOR LOCK RELAY AND CAUSES THE RELAY TO FUNCTION. CURRENT FLOWS FROM TERMINAL 8 OF THE RELAY "

TERMINAL 3 " TERMINAL 2 OF THE DOOR LOCK MOTORS, (EX. C/P FRONT DOOR) OR TERMINAL 5 (C/P FRONT DOOR) OF THE

DOOR LOCK MOTOR TERMINAL 1 OF THE BACK DOOR LOCK MOTOR " TERMINAL 4 OF THE DOOR LOCK MOTORS, (EX. C/P

FRONT DOOR) OR TERMINAL 7 (C/P FRONT DOOR), OF THE DOOR LOCK MOTOR TERMINAL 2 OF THE BACK DOOR LOCK MOTOR "

TERMINAL 4 OF THE RELAY " TERMINAL 16 " TO GROUND AND DOOR LOCK MOTORS CAUSES DOOR TO UNLOCK.

3. DOUBLE OPERATION UNLOCK OPERATION

WHEN THE DOOR LOCK KEY SW (DRIVER'S) IS TURNED TO THE UNLOCK SIDE, ONLY THE DRIVER'S DOOR IS MECHANICALLY

UNLOCKED. TURNING THE DOOR LOCK KEY SW (DRIVER'S) TO THE UNLOCK SIDE CAUSES A SIGNAL TO BE INPUT TO TERMINAL 9

OF THE RELAY, AND IF THE SIGNAL IS INPUT AGAIN WITHIN 3 SECONDS BY TURNING THE SW TO THE UNLOCK SIDE AGAIN,

CURRENT FLOWS TERMINAL 3 " TERMINAL 2 OF DOOR LOCK MOTORS, (EX. C/P FRONT DOOR) OR TERMINAL 5 (C/P FRONT

DOOR) OF THE DOOR LOCK MOTOR TERMINAL 1 OF THE BACK DOOR LOCK MOTOR " TERMINAL 4 OF THE DOOR LOCK MOTORS,

(EX. C/P FRONT DOOR) OR TERMINAL 7 (C/P FRONT DOOR), OF THE DOOR LOCK MOTOR TERMINAL 2 OF THE BACK DOOR LOCK

MOTOR " TERMINAL 4 OF THE RELAY " TERMINAL 16 " GROUND, CAUSING THE DOOR LOCK MOTORS TO OPERATE AND

UNLOCK THE DOORS.

4. IGNITION KEY REMINDER OPERATION

*OPERATING DOOR LOCK KNOB (OPERATION OF DOOR LOCK MOTORS)

WITH IGNITION KEY IN CYLINDER (UNLOCK WARNING SW ON), WHEN THE DOOR IS OPENED AND LOCKED USING DOOR LOCK

KNOB (DOOR LOCK MOTOR), THE DOOR IS LOCKED ONCE BUT EACH DOOR IS UNLOCKED SOON BY THE FUNCTION OF RELAY.

AS A RESULT, THE CURRENT FLOWS FROM TERMINAL 8 OF THE RELAY " TERMINAL 3 " TERMINAL 2 OF THE DOOR LOCK

MOTORS, (EX. C/P FRONT DOOR) OR TERMINAL 5 (C/P FRONT DOOR) OF THE DOOR LOCK MOTOR TERMINAL 2 OF THE BACK

DOOR LOCK MOTOR " TERMINAL 4 OF THE DOOR LOCK MOTORS, (EX. C/P FRONT DOOR) OR TERMINAL 7 (C/P FRONT DOOR),

OF THE DOOR LOCK MOTOR TERMINAL 1 OF THE BACK DOOR LOCK MOTOR " TERMINAL 4 OF THE RELAY " TERMINAL 16 "

TO GROUND AND CAUSES ALL THE DOORS TO UNLOCK.

*OPERATING DOOR LOCK CONTROL SW OR DOOR LOCK KEY SW

WITH IGNITION KEY IN CYLINDER (UNLOCK WARNING SW ON), WHEN THE DOOR IS OPENED AND LOCKED USING DOOR LOCK

CONTROL SW OR KEY SW, THE DOOR IS LOCKED ONCE BUT EACH DOOR IS UNLOCK BY THE FUNCTION OF SW CONTAINED IN

MOTORS, WHICH THE SIGNAL IS INPUT TO TERMINAL 6 (DRIVER'S) OR 5 (PASSENGER'S) OF THE RELAY. ACCORDING TO THIS

INPUT SIGNAL, THE CURRENT IN ECU FLOWS FROM TERMINAL 8 OF THE RELAY " TERMINAL 3 " TERMINAL 2 OF THE DOOR

LOCK MOTORS, (EX. C/P FRONT DOOR) OR TERMINAL 5 (C/P FRONT DOOR) OF THE DOOR LOCK MOTOR TERMINAL 2 OF THE

BACK DOOR LOCK MOTOR " TERMINAL 4 OF THE DOOR LOCK MOTORS, TERMINAL 1 OF THE BACK DOOR LOCK MOTOR "

TERMINAL 4 OF THE RELAY " TERMINAL 16 " TO GROUND AND CAUSES ALL THE DOOR TO UNLOCK.

*IN CASE OF KEY LESS LOCK

WITH IGNITION KEY IN CYLINDER (UNLOCK WARNING SW ON), WHEN THE UNLOCK FUNCTION IS DISTURBED MORE THAN 0.2

SECONDS, FOR EXAMPLE PUSHING THE DOOR LOCK KNOB ETC., THE DOOR HOLDS ON LOCK CONDITION. CLOSING THE DOOR

AFTER, DOOR COURTESY SW INPUTS THE SIGNAL INTO TERMINAL 2 OR 14 OF THE RELAY. BY THIS INPUT SIGNAL, THE ECU

WORKS AND CURRENT FLOWS FROM TERMINAL 8 OF THE RELAY " TERMINAL 3 " TERMINAL 2 OF THE DOOR LOCK MOTORS,

(EX. C/P FRONT DOOR) OR TERMINAL 5 (C/P FRONT DOOR) OF THE DOOR LOCK MOTOR TERMINAL 1 OF THE BACK DOOR LOCK

MOTOR " TERMINAL 4 OF THE DOOR LOCK MOTORS, (EX. C/P FRONT DOOR) OR TERMINAL 7 (C/P FRONT DOOR), OF THE

DOOR LOCK MOTOR TERMINAL 2 OF THE BACK DOOR LOCK MOTOR " TERMINAL 4 OF THE RELAY " TERMINAL 16 " TO

GROUND AND CAUSES ALL THE DOORS TO UNLOCK.

SYSTEM OUTLINE

Page 187 of 307

187

WHEN THE IGNITION SW IS TURNED ON, CURRENT FLOWS TO TERMINAL 2 OF WASHER MOTOR, TERMINAL 4 OF REAR WIPER

RELAY AND TERMINAL 1 OF REAR WIPER MOTOR THROUGH THE WIPER FUSE.

1. REAR WIPER NORMAL OPERATION

WITH THE IGNITION SW TURNED ON AND REAR WIPER AND WASHER SW TURNED ON, THE CURRENT FLOWING TO TERMINAL 4

OF REAR WIPER RELAY FLOWS TO TERMINAL 6 OF RELAY " TERMINAL 1 OF REAR WIPER AND WASHER SW " TERMINAL 16 "

TO GROUND. THUS, THE RELAY COIL IS ACTIVATED AND THE CURRENT TO TERMINAL 4 OF RELAY FLOWS TO TERMINAL 1 "

TERMINAL 4 OF REAR WIPER MOTOR " MOTOR " TERMINAL 2 " TO GROUND AND CAUSES THE MOTOR TO OPERATE THE

WIPER.

2. REAR WIPER INTERMITTENT OPERATION

WITH THE IGNITION SW TURNED ON AND REAR WIPER AND WASHER SW TURNED TO INT POSITION, THE CURRENT FLOWING TO

TERMINAL 4 OF REAR WIPER RELAY FLOWS TO TERMINAL 3 OF RELAY " TERMINAL 10 OF WIPER SW " TERMINAL 16 " TO

GROUND. AS A RESULT, THE RELAY OPERATES AND CURRENT FLOWS FROM TERMINAL 4 OF RELAY " TERMINAL 1 " TERMINAL

4 OF REAR WIPER MOTOR " MOTOR " TERMINAL 2 " TO GROUND, CAUSING THE MOTOR TO ROTATE TO OPERATE THE WIPER.

AT THIS TIME THE CONTACT IN THE WIPER MOTOR CLOSED AND THE CURRENT FLOWS FROM TERMINAL 1 OF REAR WIPER

MOTOR " TERMINAL 3 " TERMINAL 2 OF REAR WIPER RELAY " TERMINAL 1 " TERMINAL 4 OF REAR WIPER MOTOR "

TERMINAL 2 " TO GROUND.

THUS, THE INTERMITTENT±STOP CIRCUIT OPERATES, THE CONDENOR IN THE CIRCUIT CHARGES AND THE WIPER CONTINUES TO

OPERATE UNTIL REACHING THE STOP POSITION. AFTER THE WIPER STOPS, CURRENT DOES NOT FLOW TO THE

INTERMITTENT±STOP CIRCUIT FROM TERMINAL 2 OF RELAY, BUT THE CONDENSER DISCHARGES CURRENT INTO THE

INTERMITTENT CIRCUIT AND THE CIRCUIT OPERATES UNTIL THE CONDENSER DISCHARGE ENDS. AS A RESULT, THIS DISCHARGE

INTERVAL BECOMES THE INTERMITTENT TIME.

WHEN THE CURRENT IS DISCHARGED COMPLETELY, THE CURRENT FLOWING TO TERMINAL 4 OF RELAY FLOWS TO TERMINAL 3

" TERMINAL 10 OF REAR WIPER AND WASHER SW " TERMINAL 16 " TO GROUND.

THEN, THE CURRENT IN TERMINAL 4 OF RELAY FLOWS FROM TERMINAL 1 " TERMINAL 4 OF MOTOR " MOTOR " TERMINAL 2 "

TO GROUND AND ROTATES THE MOTOR. THROUGH REPEITION OF THIS PROCESS, INTERMITTENT OPERATION OF THE REAR

WIPER OCCURS.

3. WASHER OPERATION

WITH THE IGNITION SW ON AND THE REAR WIPER AND WASHER SW IS TURNED STRONGLY (WASHER SW ON), CURRENT FLOWS

FROM TERMINAL 2 OF WASHER MOTOR " TERMINAL 3 " TERMINAL 2 OF REAR WIPER AND WASHER SW " TERMINAL 16 " TO

GROUND SO THAT THE WASHER MOTOR ROTATES AND WINDOW WASHER EJECTS THE SPRAY, ONLY THE WHILE THE REAR

WASHER SW IS TURNED, WHEN THE REAR WIPER SW IS OFF, AND THE REAR WIPER AND WASHER SW IS THEN TURNED IN THE

OFF DIRECTION, WASHER LIQUID WILL ALSO SPLAY.

R19 REAR WIPER RELAY

4±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

7±GROUND : ALWAYS CONTINUITY

1±4 : POINTS CHANGES EVERY APPROX. 9±15 SECONDS INTERMITTENTLY WITH IGNITION SW ON AND WIPER SW AT

INT POSITION

W 1 WASHER MOTOR

2±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

3±GROUND : CONTINUITY WITH WASHER SW TURNED ON

SYSTEM OUTLINE

SERVICE HINTS

Page 243 of 307

243

FAN MOTOR OPERATION

WITH THE IGNITION SW IS TURNED ON, CURRENT FLOWS FROM ECU±IG FUSE TO RADIATOR FAN RELAY NO. 1 (COIL SIDE) AND

RADIATOR FAN RELAY NO. 2 (COIL SIDE) " TERMINAL 2 OF THE A/C SINGLE PRESSURE SW " TERMINAL 3 " TERMINAL 2 OF THE

WATER TEMP. SW " TERMINAL 1 " GROUND, AND RADIATOR FAN RELAY NO. 1 AND NO. 2 ARE TURNED ON.

*RADIATOR FAN MOTOR OPERATION

WHEN THE IGNITION SW IS TURNED ON, RADIATOR FAN RELAY NO. 1 IS TURNED ON. IF AT THIS TIME THE ENGINE COOLANT

TEMPERATURE IS APPROX. 90°C (194°F) OR HIGHER, THE WATER TEMP. SW IS TURNED OFF, RADIATOR FAN RELAY NO. 1 IS

TURNED OFF.

AS A RESULT, CURRENT FROM THE RDI FAN FUSE TO RADIATOR FAN RELAY NO. 1 (POINT SIDE) " TERMINAL 2 OF THE

RADIATOR FAN MOTOR " TERMINAL 1 " GROUND, THUS ACTIVATING THE ROTATION OF THE RADIATOR FAN MOTOR.

*LOW SPEED OPERATION

WHEN THE IGNITION SW IS TURNED ON AND THE A/C ACTIVATED, RADIATOR FAN RELAY NO. 1 AND RADIATOR FAN RELAY NO. 2

ARE TURNED ON, CURRENT FLOWS FROM A/C MAGNETIC CLUTCH RELAY (POINT SIDE) TO RADIATOR FAN RELAY NO. 3 (COIL

SIDE) " GROUND, AND RADIATOR FAN RELAY NO. 3 IS TURNED ON.

AS A RESULT, CURRENT FLOWS FROM CDS FAN FUSE TO TERMINAL 2 OF THE A/C CONDENSER FAN MOTOR " TERMINAL 1 "

RADIAOTR FAN RELAY NO. 2 (POINT SIDE) " RADIATOR FAN RELAY NO. 3 (POINT SIDE) " TERMINAL 2 OF THE RADIATOR FAN

MOTOR " TERMINAL 1 " GROUND, FLOWING TO EACH FAN MOTOR IN SERIES, CAUSING THE FAN TO AT LOW SPEED.

*HIGH SPEED OPERATION OF THE FAN MOTOR DUARING A/C OPERATION

WHEN THE A/C OPERATION, THE REFRIGERRANT PRESSURE BECOME HIGHER THAN OR DINARY LEVEL (APPROX. 15.58 KG/CM

2

(221.2 PSI, 1527 KPA)) THE A/C SINGLE PRESSURE SW IS TURNED OFF. AS A RESULT, RADIATOR FAN RELAY NO. 1 AND RADIATOR

FAN RELAY NO. 2 ARE TURNED OFF, AND CURRENT FLOWS FROM RDI FUSE TO RADIATOR FAN RELAY NO. 1 (POINT SIDE) "

TERMINAL 2 OF THE RADIATOR FAN MOTOR " TERMINAL 1 " GROUND, AND CURRENT FLOWS FROM CDS FAN FUSE TO

TERMINAL 2 OF THE A/C CONDENSER FAN MOTOR " TERMINAL 1 " RADIATOR FAN RELAY NO. 2 (POINT SIDE) " GROUND, AND

TO EACH FAN MOTOR IN PARALLEL, THUS CAUSING THE FAN MOTORS OPERATE HIGH SPEED.

NOTE THAT, BECAUSE THE CURRENT FLOWS IN THE SAME MENNER EVEN IF THE ENGINE COOLANT TEMPERATURE IS APPROX.

90°C (194°F) OR HIGHER, THE FAN MOTOR OPERATE AT HIGH SPEED.

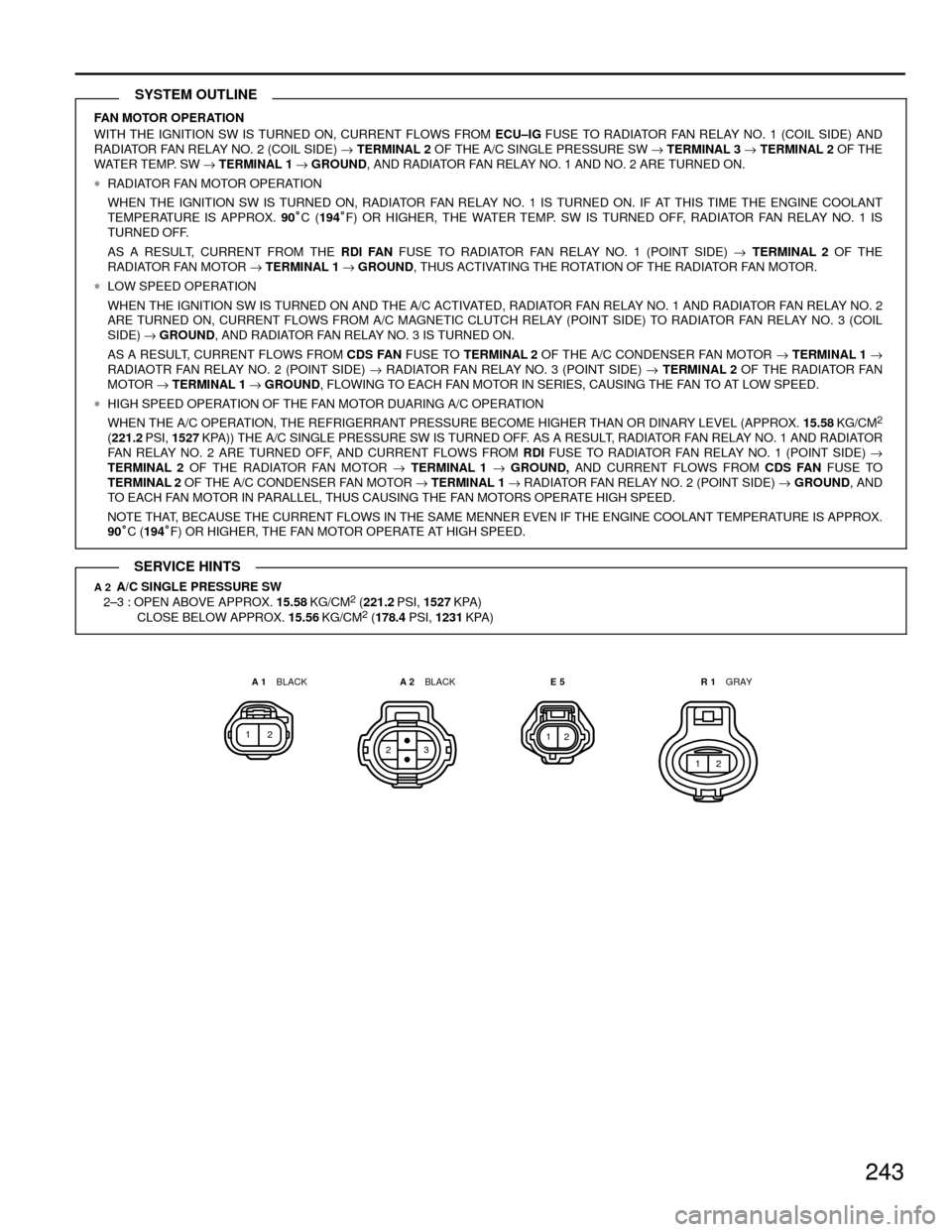

A 2 A/C SINGLE PRESSURE SW

2±3 : OPEN ABOVE APPROX. 15.58 KG/CM2 (221.2 PSI, 1527 KPA)

CLOSE BELOW APPROX. 15.56 KG/CM2 (178.4 PSI, 1231 KPA)

2 1

2 1 A1R1 BLACKGRAY

12E5 A2BLACK

23

SYSTEM OUTLINE

SERVICE HINTS

Page 249 of 307

249

1. AIR INLET CONTROL SERVO MOTOR OPERATION (FOR PUSH SW TYPE)

(SWITCHING FROM FRESH TO RECIRC)

WITH THE IGNITION SW ON, CURRENT FROM THE GAUGE FUSE FLOWS TO TERMINAL 1 OF THE SERVO MOTOR. WHEN THE

RECIRC SW IS TURNED ON, THE CURRENT FLOWS FROM SERVO MOTOR " TERMINAL 3 " TERMINAL 5 OF THE HEATER

CONTROL SW " TERMINAL 1 " GROUND, THE MOTOR ROTATES AND THE DAMPER MOVES TO THE RECIRC SIDE. WHEN IT IS IN

THE RECIRC POSITION, THE CIRCUIT IS CUT INSIDE THE SERVO MOTOR AND THE DAMPER STOPS IN THAT POSITION.

WHEN THE CIRCUIT FOR THE INDICATOR LIGHT, CURRENT FLOWS FROM THE GAUGE FUSE " TERMINAL 12 OF THE HEATER

CONTROL SW " INDICATOR LIGHT " TERMINAL 1 " GROUND AND THE INDICATOR LIGHT CONTINUES TO LIGHT UP WHILE THE

RECIRC SW IS ON.

(SWITCHING FROM RECIRC TO FRESH)

WHEN THE IGNITION IS ON AND THE FRESH SW IS TURNED ON, CURRENT FLOWS FROM TERMINAL 2 OF THE SERVO MOTOR "

TERMINAL 6 OF THE HEATER CONTROL SW " TERMINAL 1 " GROUND, THE MOTOR ROTATES AND THE DAMPER MOVES TO THE

FRESH SIDE. WHEN THE DAMPER IS IN THE FRESH POSITION, THE CIRCUIT IS CUT INSIDE THE SERVO MOTOR AND THE DAMPER

STOPS IN THAT POSITION.

2. OPERATION OF AIR VENT MODE CONTROL SERVO MOTOR

WHEN THE IGNITION SW ON, CURRENT FLOWS FROM THE GAUGE FUSE TO TERMINAL 12 OF THE HEATER CONTROL SW,

TERMINAL 6 OF THE AIR VENT MODE CONTROL SERVO MOTOR.

WHEN THE DAMPER IS IN FACE POSITION AND THE BI±LEVEL OF THE HEATER CONTROL SW IS THEN TURNED ON, CURRENT

FLOWS FROM TERMINAL 3 OF THE HEATER CONTROL SW " TERMINAL 4 OF THE AIR VENT MODE CONTROL SERVO MOTOR SO

THAT A SINGAL THAT THE GROUND CIRCUIT IS ACTIVATED IS INPUT TO TERMINAL ªBº OF THE CONTROL CIRCUIT INSIDE THE AIR

VENT MODE CONTROL SERVO MOTOR.

SIMULTANEOUSLY, A SIGNAL THAT THE GROUND CIRCUIT IS NOT ACTIVATED IS INPUT TO TERMINAL ªAº OF THE CONTROL

CIRCUIT INSIDE THE SERVO MOTOR. THESE TWO SIGNALS ACTIVATE THE CONTROL CIRCUIT SO THAT CURRENT FROM THE

GAUGE FUSE TO THE SERVO MOTOR, CAUSING THE SERVO MOTOR TO OPERATE AND THE DAMPER TO MOVE TO BI±LEVEL

POSITION. WHEN THE DAMPER REACHES BI±LEVEL POSITION, A GROUND CUT SIGNAL IS INPUT TO TERMINAL ªBº OF THE

CONTROL CIRCUIT, THE CONTROL CIRCUIT OPERATES, THE SERVO MOTOR STOPS ROTATING AND THE DAMPER STOPS AT

BI±LEVEL.

WHEN ANOTHER MODE POSITION IS SWITCHED TO, INPUT OF SIGNALS TO TERMINAL ªAº AND TERMINAL ªBº OF THE CONTROL

CIRCUIT THAT GROUND IS MADE OR GROUND IS NOT MADE (AS EXPLAINED ABOVE) ACTIAVTES THE CONTROL CIRCUIT AND

MOVES THE SERVO MOTOR TO THE DESIRED POSITION.

3. AIR CONDITIONING OPERATION

WHEN THE IGNITION SW ON, CURRENT FLOWS FROM GAUGE FUSE TO TERMINAL 12 OF THE HEATER CONTROL SW, TERMINAL 6

OF THE AIR VENT MODE CONTROL SERVO MOTOR.

WHEN THE BLOWER SW IS ON, CURRENT FLOWS FROM THE GAUGE FUSE " HEATER RELAY (COIL SIDE) " TERMINAL 7 OF THE

BLOWER SW " TERMINAL 5 " GROUND, ACTIVATING THE HEATER RELAY. THIS CAUSES CURRENT TO FLOW FROM THE HEATER

FUSE TO THE HEATER RELAY (POINT SIDE) " A/C FUSE " TERMINAL 7 OF THE HEATER CONTROL SW (A/C SW). IF THE HEATER

CONTROL (A/C SW) IS THEN TURNED ON AT THIS TIME, A SIGNAL IS INPUT TO THE A/C AMPLIFIRE. THIS ACTIVATES THE A/C

AMPLIFIER AND A/C MAGNETIC CLUTCH RELAY SO THAT CURRENT FLOWS FROM THE GAUGE FUSE TO THE A/C MAGNETIC

CLUTCH RELAY (POINT SIDE) " A/C MAGNETIC CLUTCH, CAUSING THE COMPRESSOR TO OPERATE. THE VSV (FOR A/C IDLE±UP)

IS TURNED ON SIMULTANEOUSLY TO PREVENT A DECREASE IN ENGINE SPEED DUE TO A/C OPERATION.

HEATER RELAY

(4)5± (4)4 : CLOSED WITH THE IGNITION SW ON AND BLOWER SW ON

A/C MAGNETIC CLUTCH RELAY

(4)5± (4)3 : CLOSED WITH THE IGNITION SW ON AND BLOWER SW ON AND A/C SW ON

A 2 A/C DUAL PRESSURE SW

1±4 : OPEN WITH PRESSURE 2.1 KG/CM (30 PSI, 206 KPA) OR ABOVE 27 KG/CM (384 PSI, 2646 KPA)

B 5 BLOWER RESISTOR

6±2 : APPROX. 1.12 W

2±3 : APPROX. 0.5 W

3±1 : APPROX. 0.2 W

SYSTEM OUTLINE

SERVICE HINTS