sensor TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1994, Model line: CAMRY, Model: TOYOTA CAMRY 1994 XV10 / 4.GPages: 307, PDF Size: 5.48 MB

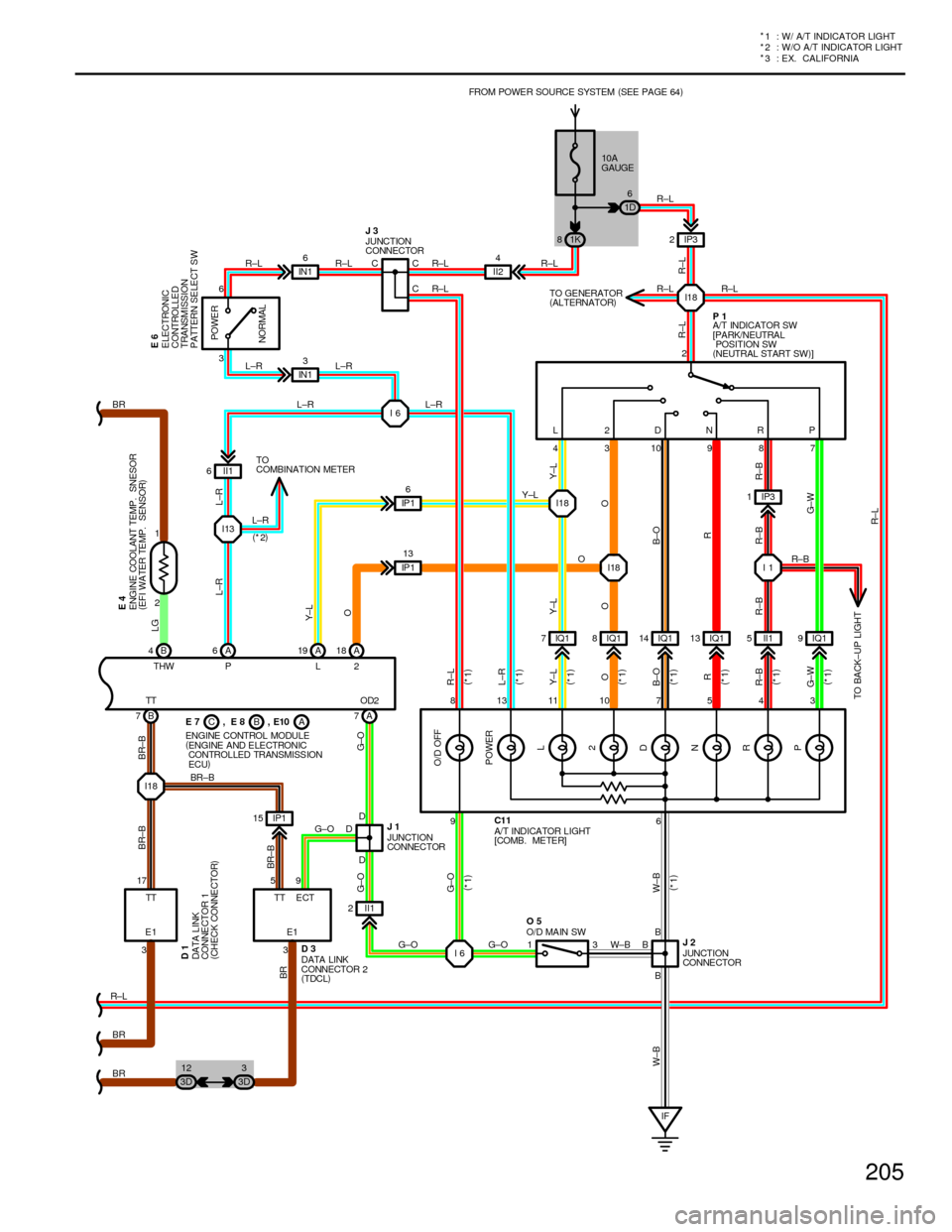

Page 205 of 307

205

* 2 : W/O A/T INDICATOR LIGHT *

1 : W/ A/T INDICATOR LIGHT

*

3 : EX. CALIFORNIA

CB

II1 6

IQ1 7IQ18IQ114 IQ113 II15IQ19 IP3 1 L2DNRP

43109872

I18

I6 I6

I13

I18 II24

B 7TT

A 7OD2 B 4

THWA 6

PA 19

LA 18

2

IF 96 3

3

B DC

B 17 5 9DD 6C

8131110 7 5 4 3 C

2 1R±L R±L R±L

L±R

BR

BR±B

G±O

BRW±B G±OR±L

L±R

L±R

L±R LG

L±R

Y±L

O

R±L

L±R

Y±L

O

B±O

R

R±B

G±W G±WR±BR B±OOY±L Y±L

O

R±L W±BG±O BR±B BR±B

G±O

G±O

BR

W±B

FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

POWER

NORMAL ENGINE COOLANT TEMP. SNESOR

(

EFI WATER TEMP. SENSOR)

JUNCTION

CONNECTOR

JUNCTION

CONNE CTOR O/D MAIN SW A/T INDICATOR LIGHT

[COMB. METER]A/T INDICATOR SW

[PA RK/NEUTRA L

POSITION SW

(

NEUTRAL START SW)

] JUNCTION

CONNECTOR

DA TA LINK

CONNE CTOR 1

(

CHECK CONNE CTOR)DATA LINK

CONNECTOR 2

(

TDCL) TT ECT

E1 TT

ELECTRONIC

CONTROLLE D

TRANSMISSION

PATTERN SELECT SW

R±B

ENGINE CONTROL MODULE

(

ENGINE A ND E LE CTRONIC

CONTROLLED TRANSMISSION

ECU)

C11

O5

J2

D1D3J1 E7 , E8 ,E10

E4

P1

E6

J3

A

3 1 IP1 15

BR±B

I18 IP3 2

R±LR±L

R±L

R±L

R±L

O Y±L

P R

N

D2 L POWER O/D OFF

B

BR3E1II1 2

G±O

(

*1)

(

*1)(

*1)

(

*1)

(

*1)

(

*1)

(

*1)

(

*1)

(

*1)

(

*1)

I1

R±B

R±B

TO BA CK± UP LI GHT

I18 TO

COMBINATION METER

L±RIN16

R±L

IN13

L±R

(

*2)TO GENERATOR

(

ALTERNATOR)R±L

IP 16

IP 113

1K 8GE

1D6

10A

GAU

3D12

3D3

Page 206 of 307

206

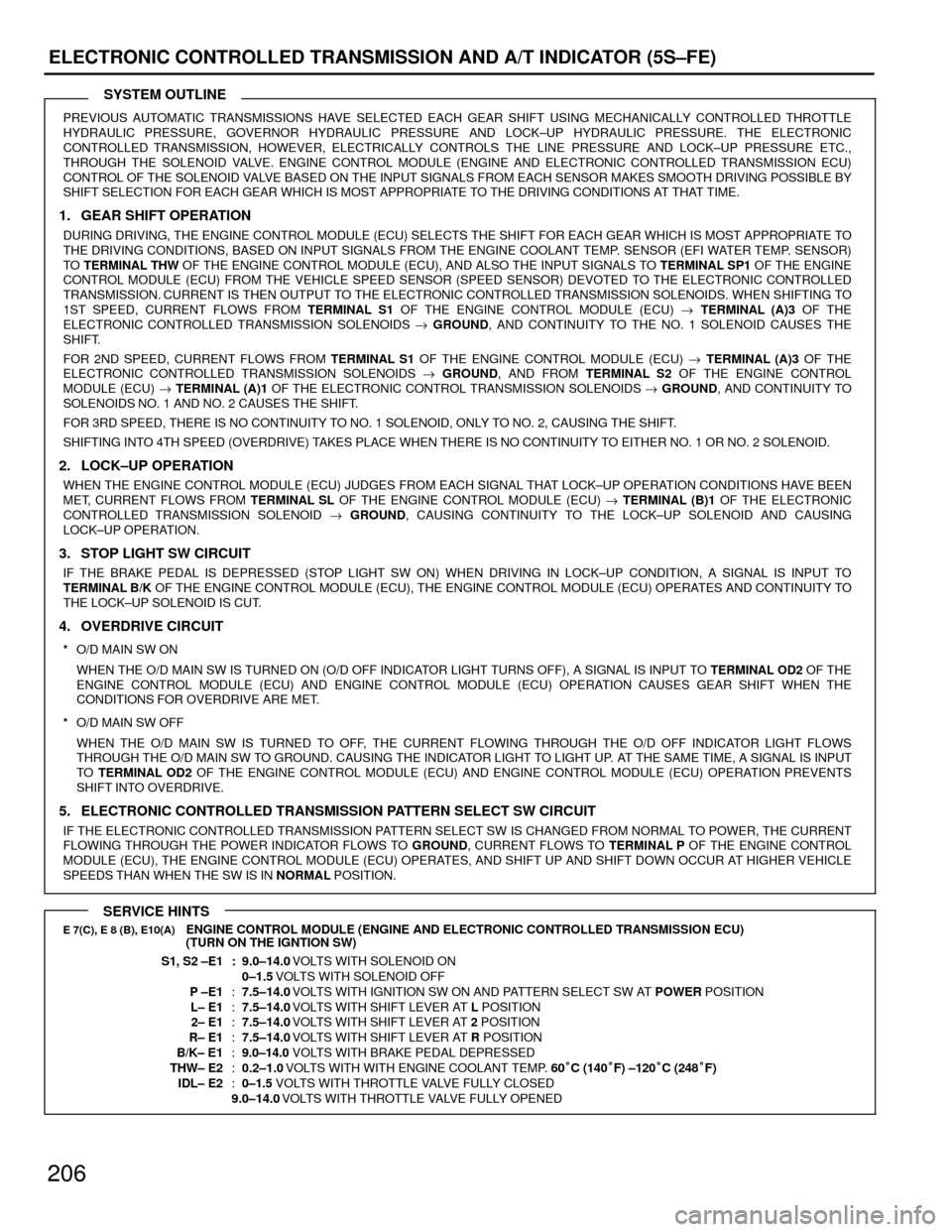

ELECTRONIC CONTROLLED TRANSMISSION AND A/T INDICATOR (5S±FE)

PREVIOUS AUTOMATIC TRANSMISSIONS HAVE SELECTED EACH GEAR SHIFT USING MECHANICALLY CONTROLLED THROTTLE

HYDRAULIC PRESSURE, GOVERNOR HYDRAULIC PRESSURE AND LOCK±UP HYDRAULIC PRESSURE. THE ELECTRONIC

CONTROLLED TRANSMISSION, HOWEVER, ELECTRICALLY CONTROLS THE LINE PRESSURE AND LOCK±UP PRESSURE ETC.,

THROUGH THE SOLENOID VALVE. ENGINE CONTROL MODULE (ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)

CONTROL OF THE SOLENOID VALVE BASED ON THE INPUT SIGNALS FROM EACH SENSOR MAKES SMOOTH DRIVING POSSIBLE BY

SHIFT SELECTION FOR EACH GEAR WHICH IS MOST APPROPRIATE TO THE DRIVING CONDITIONS AT THAT TIME.

1. GEAR SHIFT OPERATION

DURING DRIVING, THE ENGINE CONTROL MODULE (ECU) SELECTS THE SHIFT FOR EACH GEAR WHICH IS MOST APPROPRIATE TO

THE DRIVING CONDITIONS, BASED ON INPUT SIGNALS FROM THE ENGINE COOLANT TEMP. SENSOR (EFI WATER TEMP. SENSOR)

TO TERMINAL THW OF THE ENGINE CONTROL MODULE (ECU), AND ALSO THE INPUT SIGNALS TO TERMINAL SP1 OF THE ENGINE

CONTROL MODULE (ECU) FROM THE VEHICLE SPEED SENSOR (SPEED SENSOR) DEVOTED TO THE ELECTRONIC CONTROLLED

TRANSMISSION. CURRENT IS THEN OUTPUT TO THE ELECTRONIC CONTROLLED TRANSMISSION SOLENOIDS. WHEN SHIFTING TO

1ST SPEED, CURRENT FLOWS FROM TERMINAL S1 OF THE ENGINE CONTROL MODULE (ECU) " TERMINAL (A)3 OF THE

ELECTRONIC CONTROLLED TRANSMISSION SOLENOIDS " GROUND, AND CONTINUITY TO THE NO. 1 SOLENOID CAUSES THE

SHIFT.

FOR 2ND SPEED, CURRENT FLOWS FROM TERMINAL S1 OF THE ENGINE CONTROL MODULE (ECU) " TERMINAL (A)3 OF THE

ELECTRONIC CONTROLLED TRANSMISSION SOLENOIDS " GROUND, AND FROM TERMINAL S2 OF THE ENGINE CONTROL

MODULE (ECU) " TERMINAL (A)1 OF THE ELECTRONIC CONTROL TRANSMISSION SOLENOIDS " GROUND, AND CONTINUITY TO

SOLENOIDS NO. 1 AND NO. 2 CAUSES THE SHIFT.

FOR 3RD SPEED, THERE IS NO CONTINUITY TO NO. 1 SOLENOID, ONLY TO NO. 2, CAUSING THE SHIFT.

SHIFTING INTO 4TH SPEED (OVERDRIVE) TAKES PLACE WHEN THERE IS NO CONTINUITY TO EITHER NO. 1 OR NO. 2 SOLENOID.

2. LOCK±UP OPERATION

WHEN THE ENGINE CONTROL MODULE (ECU) JUDGES FROM EACH SIGNAL THAT LOCK±UP OPERATION CONDITIONS HAVE BEEN

MET, CURRENT FLOWS FROM TERMINAL SL OF THE ENGINE CONTROL MODULE (ECU) " TERMINAL (B)1 OF THE ELECTRONIC

CONTROLLED TRANSMISSION SOLENOID " GROUND, CAUSING CONTINUITY TO THE LOCK±UP SOLENOID AND CAUSING

LOCK±UP OPERATION.

3. STOP LIGHT SW CIRCUIT

IF THE BRAKE PEDAL IS DEPRESSED (STOP LIGHT SW ON) WHEN DRIVING IN LOCK±UP CONDITION, A SIGNAL IS INPUT TO

TERMINAL B/K OF THE ENGINE CONTROL MODULE (ECU), THE ENGINE CONTROL MODULE (ECU) OPERATES AND CONTINUITY TO

THE LOCK±UP SOLENOID IS CUT.

4. OVERDRIVE CIRCUIT

*O/D MAIN SW ON

WHEN THE O/D MAIN SW IS TURNED ON (O/D OFF INDICATOR LIGHT TURNS OFF), A SIGNAL IS INPUT TO TERMINAL OD2 OF THE

ENGINE CONTROL MODULE (ECU) AND ENGINE CONTROL MODULE (ECU) OPERATION CAUSES GEAR SHIFT WHEN THE

CONDITIONS FOR OVERDRIVE ARE MET.

*O/D MAIN SW OFF

WHEN THE O/D MAIN SW IS TURNED TO OFF, THE CURRENT FLOWING THROUGH THE O/D OFF INDICATOR LIGHT FLOWS

THROUGH THE O/D MAIN SW TO GROUND. CAUSING THE INDICATOR LIGHT TO LIGHT UP. AT THE SAME TIME, A SIGNAL IS INPUT

TO TERMINAL OD2 OF THE ENGINE CONTROL MODULE (ECU) AND ENGINE CONTROL MODULE (ECU) OPERATION PREVENTS

SHIFT INTO OVERDRIVE.

5. ELECTRONIC CONTROLLED TRANSMISSION PATTERN SELECT SW CIRCUIT

IF THE ELECTRONIC CONTROLLED TRANSMISSION PATTERN SELECT SW IS CHANGED FROM NORMAL TO POWER, THE CURRENT

FLOWING THROUGH THE POWER INDICATOR FLOWS TO GROUND, CURRENT FLOWS TO TERMINAL P OF THE ENGINE CONTROL

MODULE (ECU), THE ENGINE CONTROL MODULE (ECU) OPERATES, AND SHIFT UP AND SHIFT DOWN OCCUR AT HIGHER VEHICLE

SPEEDS THAN WHEN THE SW IS IN NORMAL POSITION.

E 7(C), E 8 (B), E10(A)ENGINE CONTROL MODULE (ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)

(TURN ON THE IGNTION SW)

S1, S2 ±E1 :9.0±14.0 VOLTS WITH SOLENOID ON

0±1.5 VOLTS WITH SOLENOID OFF

P ±E1:7.5±14.0 VOLTS WITH IGNITION SW ON AND PATTERN SELECT SW AT POWER POSITION

L± E1:7.5±14.0 VOLTS WITH SHIFT LEVER AT L POSITION

2± E1:7.5±14.0 VOLTS WITH SHIFT LEVER AT 2 POSITION

R± E1:7.5±14.0 VOLTS WITH SHIFT LEVER AT R POSITION

B/K± E1:9.0±14.0 VOLTS WITH BRAKE PEDAL DEPRESSED

THW± E2:0.2±1.0 VOLTS WITH WITH ENGINE COOLANT TEMP. 60°C (140°F) ±120°C (248°F)

IDL± E2:0±1.5 VOLTS WITH THROTTLE VALVE FULLY CLOSED

9.0±14.0 VOLTS WITH THROTTLE VALVE FULLY OPENED

SYSTEM OUTLINE

SERVICE HINTS

Page 210 of 307

210

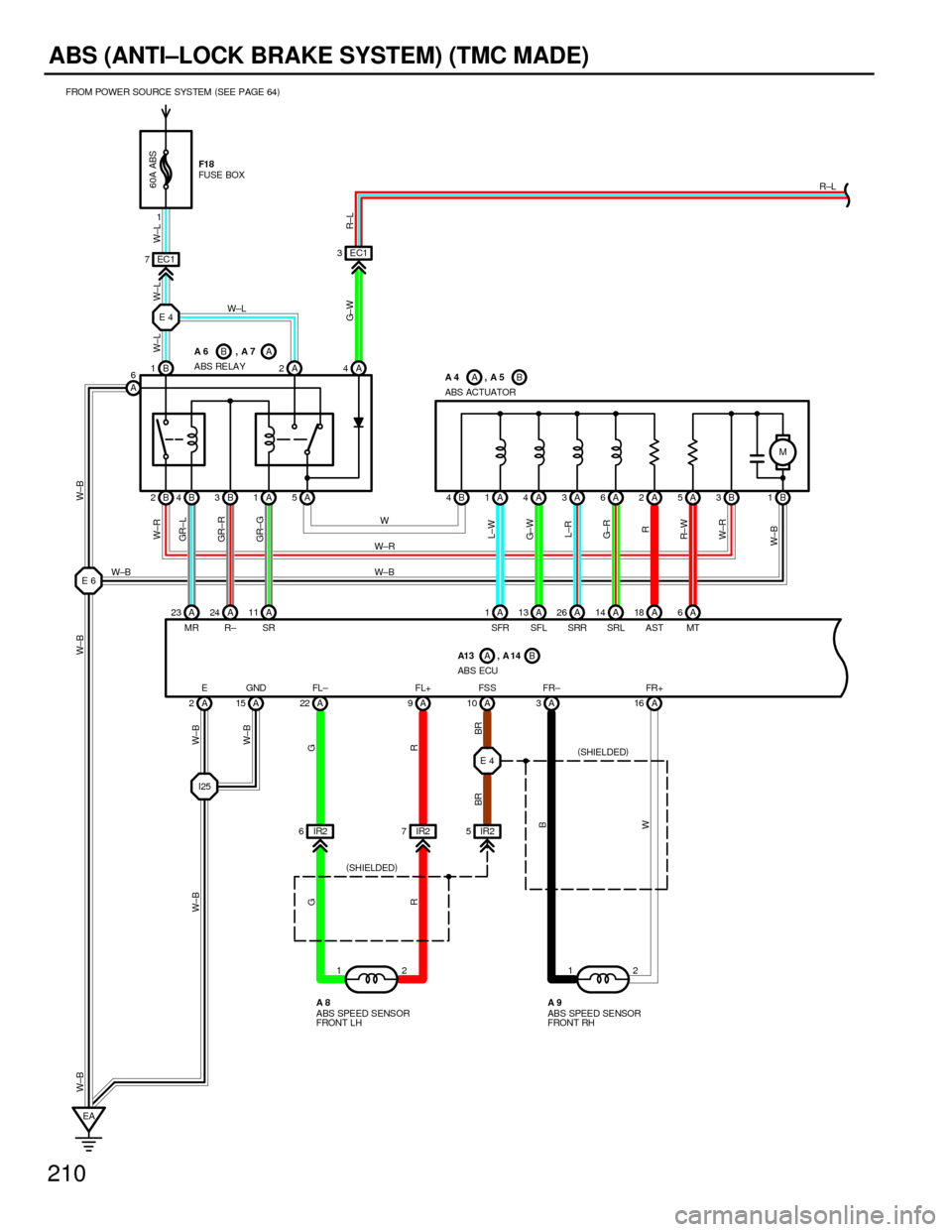

ABS (ANTI±LOCK BRAKE SYSTEM) (TMC MADE)

A B

A

E4

E6

I25E4 EC1 7EC1 3

IR2 6IR27IR25M

2 1 A 23 A24 A11 A1A13 A26 A14 A18 A6 B 4A1A4A3A6A2A5B1 A 5 A 1 B 4 B 2B3

A 2A15 A22 A10 A3A16B 3

B 1A2A4

A6

A 9

2 1

EAR±L

FR+ FR± FS S FL+ FL ± GND E

W±L W±L W±L

W±LG± W W±R

GR±L

GR±R

GR±G

L±W

G±W

L±R

G±R

R

R±W

W±R

W±BW±B

W±B W±B

W±B

BR BR R G W±B

B

W

W

W±B1FUSE BOX

60A ABS

ABS RELAY

ABS ACTUATOR

R±L

R± SR MR SFR SFL SRR SRL AST MT

ABS SPEED SENSOR

FRONT LHABS SPEED SENSOR

FRONT RH

W±B

(

SHIELDED)(

SHIELDED) ABS ECU FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

A1 3 , A 1 4 BA A6 , A7

B A4 , A5

A8 A9 F1 8

W±R

W±B

G

R

Page 211 of 307

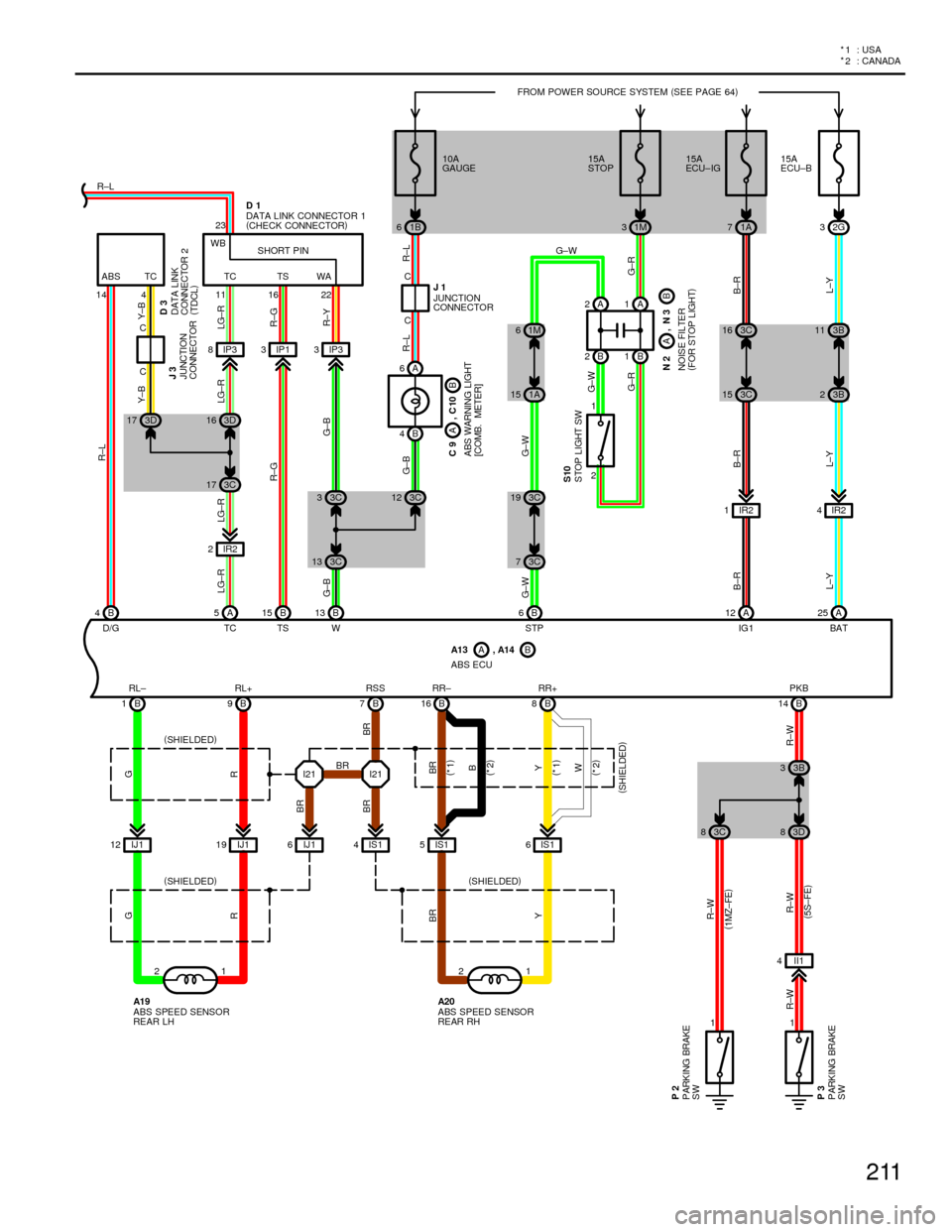

211

*

2 : CANADA *1 : USA

A

A

A

2G

II1 4 IR2 2IR2 1IR24

IS1 6 IS1 5 IS1 4 IJ1 6 IJ1 19 IJ1 12

1 2 1 2I21 I21 B 1B9B7B

16 B8B14A 25 A 12 B 6 B 13 A 5 B 4A 6

B

4

11 IP3 8IP33

B 15

RL± RL+ RSS RR± RR+ PKB

BR ABS TC TC TS WA R±LFROM POWER SOURCE SYSTEM(

SEE PAGE 64)

R±L

B±R

L±Y B±R

L±Y B±R

L±Y G±W G±WG±BR±G LG±RR±L

LG±R

G±BG±BY±B

LG±R LG±R

R±G

R±YY±B G

R R G

BR

YBR

Y

R±W R±W R±WR±W

11 16 22 4 1423

D/G TC TS W STP IG1 BATWB

DATA LINK

CONNECTOR 2

(

TDCL)

DATA LINK CONNECTOR 1

(

CHECK CONNECTOR)

C C

ABS WARNING LIGHT

[COMB. METER]

ABS SPEED SENSOR

REAR LH(

SHIELDED)

(

SHIELDED)

ABS SPEED SENSOR

REAR RH

PARKING BRAKE

SW

PARKING BRAKE

SW(

1MZ±FE)

ABS ECU

JUNCTION

CONNECTOR

R±LC CJ1

JUNCTION

CONNECTORJ3

C9 ,C10

B

A13 , A14

B

BR BR

BR

A19 A20

P2

P3(

5S±FE)

D1

D3

SHORT PIN

STOP LIGHT SW

G±R

G±W

2 1

S10

B

1 A 2

B 2B1

NOISE FILTER

(

FOR STOP LIGHT) N2 , N3

A

G±W

G±R

IP1 3

(

*1)

(

*

1) B

(

*2)

W

(

*2)

(

SHIELDED)

(

SHIELDED)

1A 151M 6

1B 61M31A73 10A

GAUGE15A

ECU±B 15A

ECU±IG 15A

STOP

3C 73C 19

3D 17

3C 173D 16

3C 133C 33C12

3C 15 3B23B 11 3C 16

3B 3

3D 8 3C 8

Page 212 of 307

212

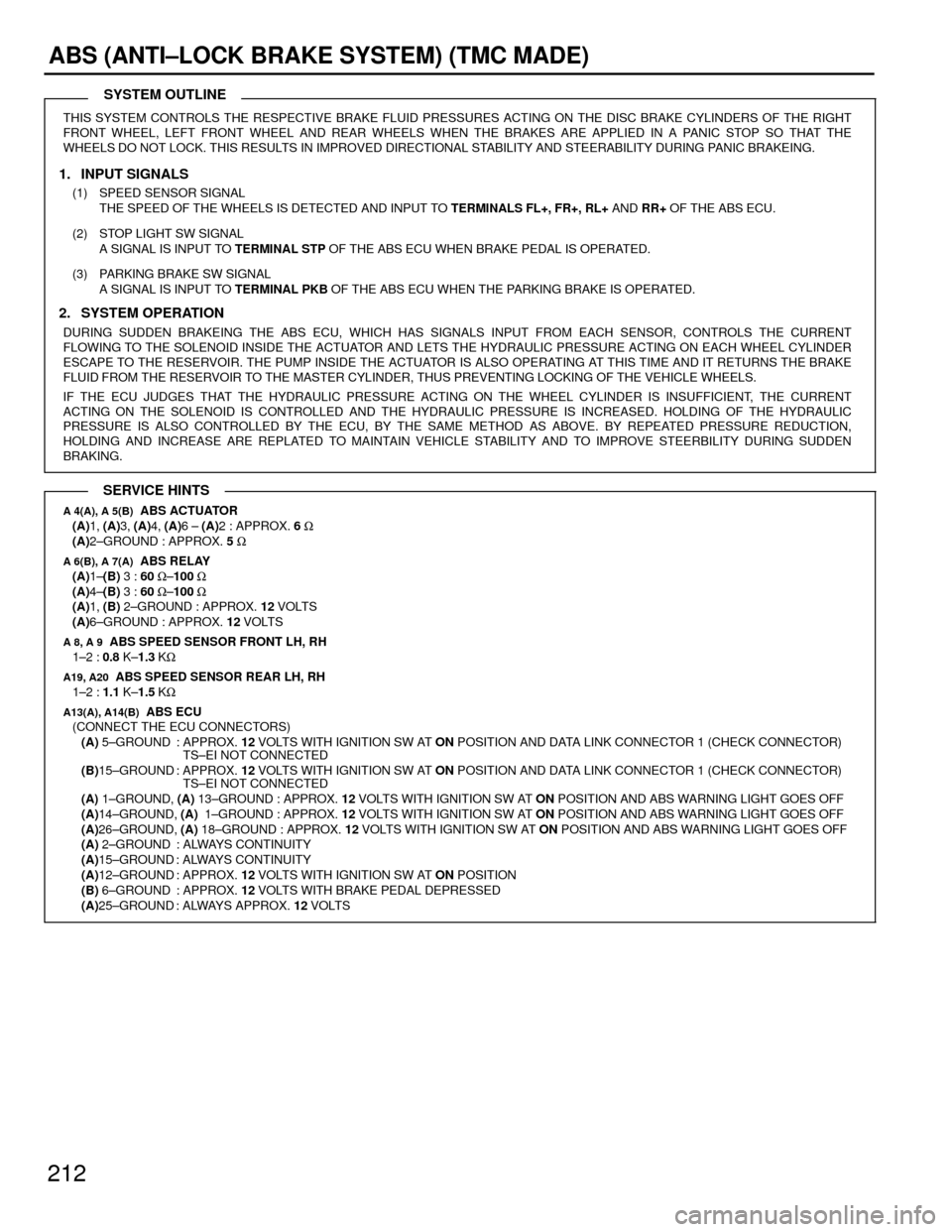

ABS (ANTI±LOCK BRAKE SYSTEM) (TMC MADE)

THIS SYSTEM CONTROLS THE RESPECTIVE BRAKE FLUID PRESSURES ACTING ON THE DISC BRAKE CYLINDERS OF THE RIGHT

FRONT WHEEL, LEFT FRONT WHEEL AND REAR WHEELS WHEN THE BRAKES ARE APPLIED IN A PANIC STOP SO THAT THE

WHEELS DO NOT LOCK. THIS RESULTS IN IMPROVED DIRECTIONAL STABILITY AND STEERABILITY DURING PANIC BRAKEING.

1. INPUT SIGNALS

(1) SPEED SENSOR SIGNAL

THE SPEED OF THE WHEELS IS DETECTED AND INPUT TO TERMINALS FL+, FR+, RL+ AND RR+ OF THE ABS ECU.

(2) STOP LIGHT SW SIGNAL

A SIGNAL IS INPUT TO TERMINAL STP OF THE ABS ECU WHEN BRAKE PEDAL IS OPERATED.

(3) PARKING BRAKE SW SIGNAL

A SIGNAL IS INPUT TO TERMINAL PKB OF THE ABS ECU WHEN THE PARKING BRAKE IS OPERATED.

2. SYSTEM OPERATION

DURING SUDDEN BRAKEING THE ABS ECU, WHICH HAS SIGNALS INPUT FROM EACH SENSOR, CONTROLS THE CURRENT

FLOWING TO THE SOLENOID INSIDE THE ACTUATOR AND LETS THE HYDRAULIC PRESSURE ACTING ON EACH WHEEL CYLINDER

ESCAPE TO THE RESERVOIR. THE PUMP INSIDE THE ACTUATOR IS ALSO OPERATING AT THIS TIME AND IT RETURNS THE BRAKE

FLUID FROM THE RESERVOIR TO THE MASTER CYLINDER, THUS PREVENTING LOCKING OF THE VEHICLE WHEELS.

IF THE ECU JUDGES THAT THE HYDRAULIC PRESSURE ACTING ON THE WHEEL CYLINDER IS INSUFFICIENT, THE CURRENT

ACTING ON THE SOLENOID IS CONTROLLED AND THE HYDRAULIC PRESSURE IS INCREASED. HOLDING OF THE HYDRAULIC

PRESSURE IS ALSO CONTROLLED BY THE ECU, BY THE SAME METHOD AS ABOVE. BY REPEATED PRESSURE REDUCTION,

HOLDING AND INCREASE ARE REPLATED TO MAINTAIN VEHICLE STABILITY AND TO IMPROVE STEERBILITY DURING SUDDEN

BRAKING.

A 4(A), A 5(B) ABS ACTUATOR

(A)1, (A)3, (A)4, (A)6 ± (A)2 : APPROX. 6 W

(A)2±GROUND : APPROX. 5 W

A 6(B), A 7(A) ABS RELAY

(A)1±(B) 3 : 60 W±100 W

(A)4±(B) 3 : 60 W±100 W

(A)1, (B) 2±GROUND : APPROX. 12 VOLTS

(A)6±GROUND : APPROX. 12 VOLTS

A 8, A 9 ABS SPEED SENSOR FRONT LH, RH

1±2 : 0.8 K±1.3 KW

A19, A20 ABS SPEED SENSOR REAR LH, RH

1±2 : 1.1 K±1.5 KW

A13(A), A14(B) ABS ECU

(CONNECT THE ECU CONNECTORS)

(A) 5±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND DATA LINK CONNECTOR 1 (CHECK CONNECTOR)

TS±EI NOT CONNECTED

(B)15±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND DATA LINK CONNECTOR 1 (CHECK CONNECTOR)

TS±EI NOT CONNECTED

(A) 1±GROUND, (A) 13±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND ABS WARNING LIGHT GOES OFF

(A)14±GROUND, (A) 1±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND ABS WARNING LIGHT GOES OFF

(A)26±GROUND, (A) 18±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND ABS WARNING LIGHT GOES OFF

(A) 2±GROUND : ALWAYS CONTINUITY

(A)15±GROUND : ALWAYS CONTINUITY

(A)12±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

(B) 6±GROUND : APPROX. 12 VOLTS WITH BRAKE PEDAL DEPRESSED

(A)25±GROUND : ALWAYS APPROX. 12 VOLTS

SYSTEM OUTLINE

SERVICE HINTS

Page 214 of 307

214

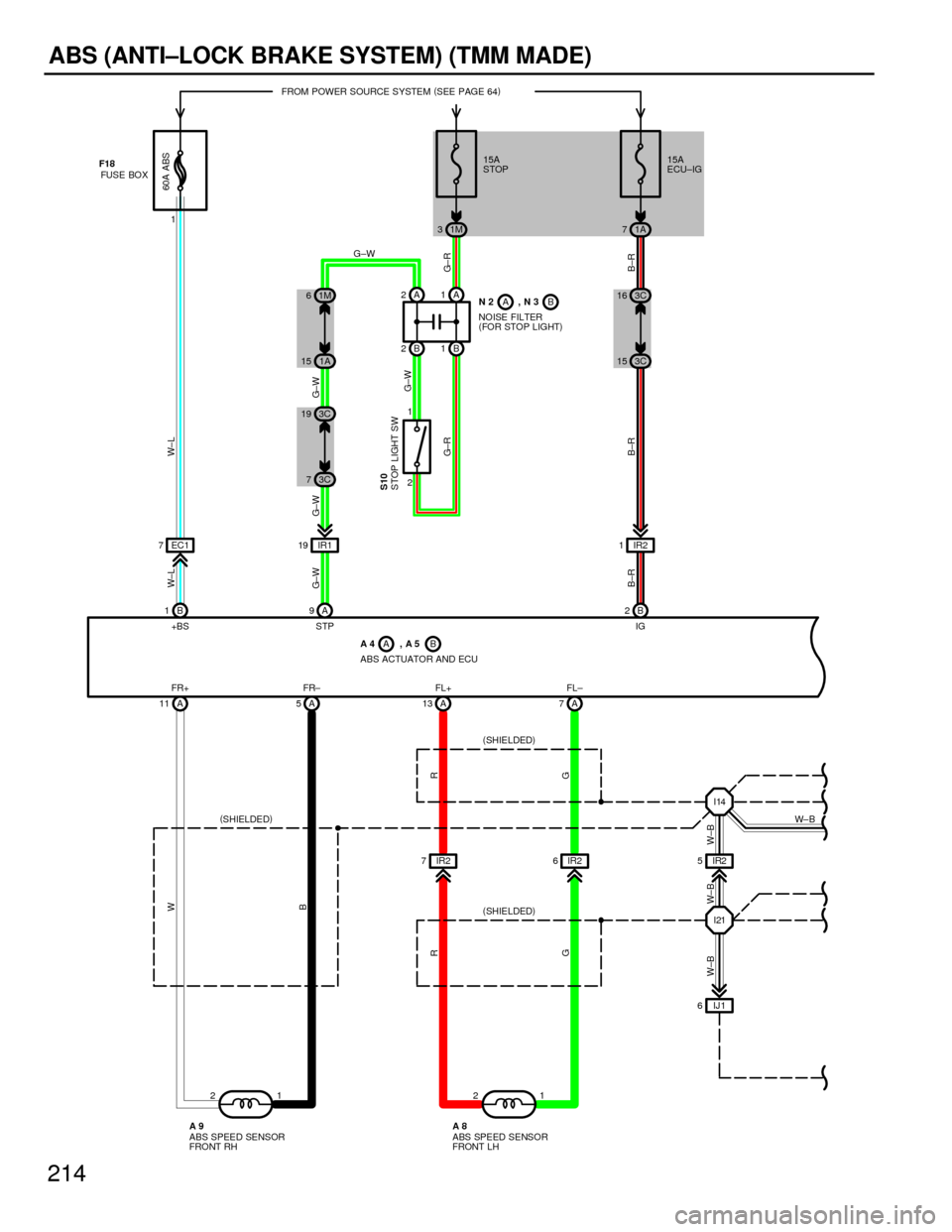

ABS (ANTI±LOCK BRAKE SYSTEM) (TMM MADE)

EC1 7

IR2 7IR26IR2 1 IR1 19

B 1A9B 2

A 11 A5A13 A7

IJ1 6IR2 5

I21 I14

1 21 2 B 2B1 A 2A1

2 1

FR+ FR± FL+ FL± +BS STPIG

W

B

R

GR

G

W±B W± B W±BB±R G±WW±L

G±W

G±R

B±R W± L

G±W

G±W

G± R

B±R

G±W

(

SHIELDED) (

SHIELDED)

(

SHIELDED)B A4 ,A5A

ABS ACTUATOR AND ECU FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

B N2 ,N3A

NOISE FILTER

(

FO R STO P L I G HT)

STOP LIGHT SW S10

W± B

A9 A8

ABS SPEED SENSOR

FRONT RHABS SPEED SENSOR

FRONT LH FUS E BO X F18

60A ABS

11M 31A7 15A

STOP15A

ECU±IG

1A 151M 6

3C 19

3C 7

3C 153C 16

Page 215 of 307

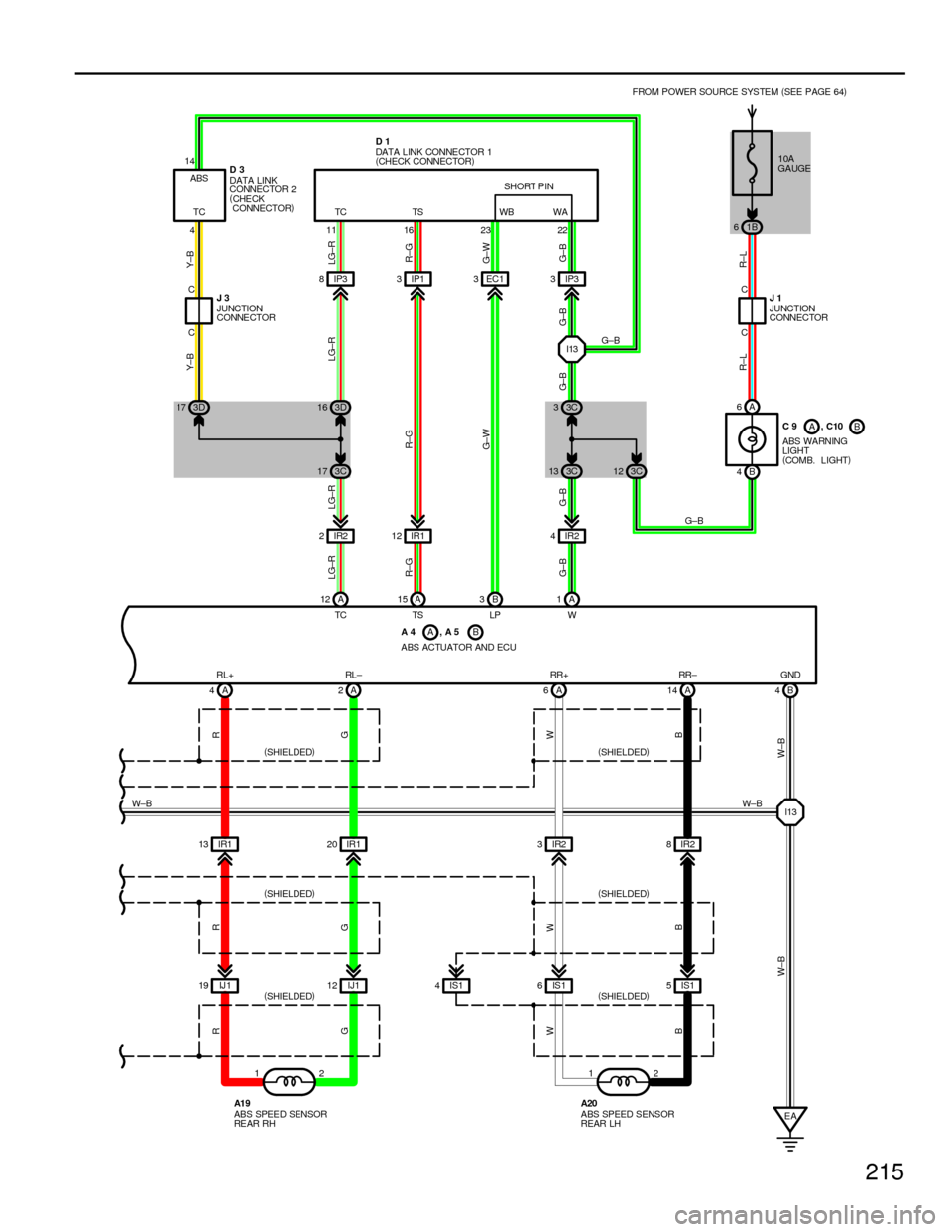

215

C C IP3 8IP13EC13IP33

IR1 20 IR23IR28

IJ 1 19 IJ112 IS14IS16IS15 IR1 13A 12 A15 B3A1

A 4A2A6A14 B4 I13

B 4A 6

2 12 1

EA C C

RL+ RL± RR+ RR± GNDTC TS TC ABS

IR2 2IR112 IR24 11 16 23 22WA WB

I13 G±B G±B

TC TS LP W

R

G

W

B R

G R

G

W

BW

B

W±B W±B

W±BW±B

LG±R

R±G

G±B G±BLG±R

R±G

G±WLG±R

G±B G± B

R±L R±LY±B Y±B

R±G

G±W

G±B LG±R

4 14

A1 9A20 J3D3

J1 DATA LINK

CONNECTOR 2

(

CHE CK

CONNECTOR)

JUNCTION

CONNE CTORJUNCTION

CONNECTOR SHORT PIN

ABS SPEED SENSOR

RE AR RHABS SPEED SENSOR

REAR LH DATA LINK CONNE CTOR 1

(

CHECK CONNECTOR) D1

(

SHIELDED) (

SHIELDED) (

SHIELDED)(

SHIELDED)

(

SHIELDED)

(

SHIELDED)B C9 ,C10

A

B A4 ,A5AABS WARNING

LIGHT

(

COMB. LIGHT)

ABS ACTUATOR AND ECUFROM POWER SOURCE SYSTEM(

SEE PAGE 64)

3C 17 3D 17 3D163C 13 3C12 3C 3

10A

GAUGE

1B 6

Page 218 of 307

218

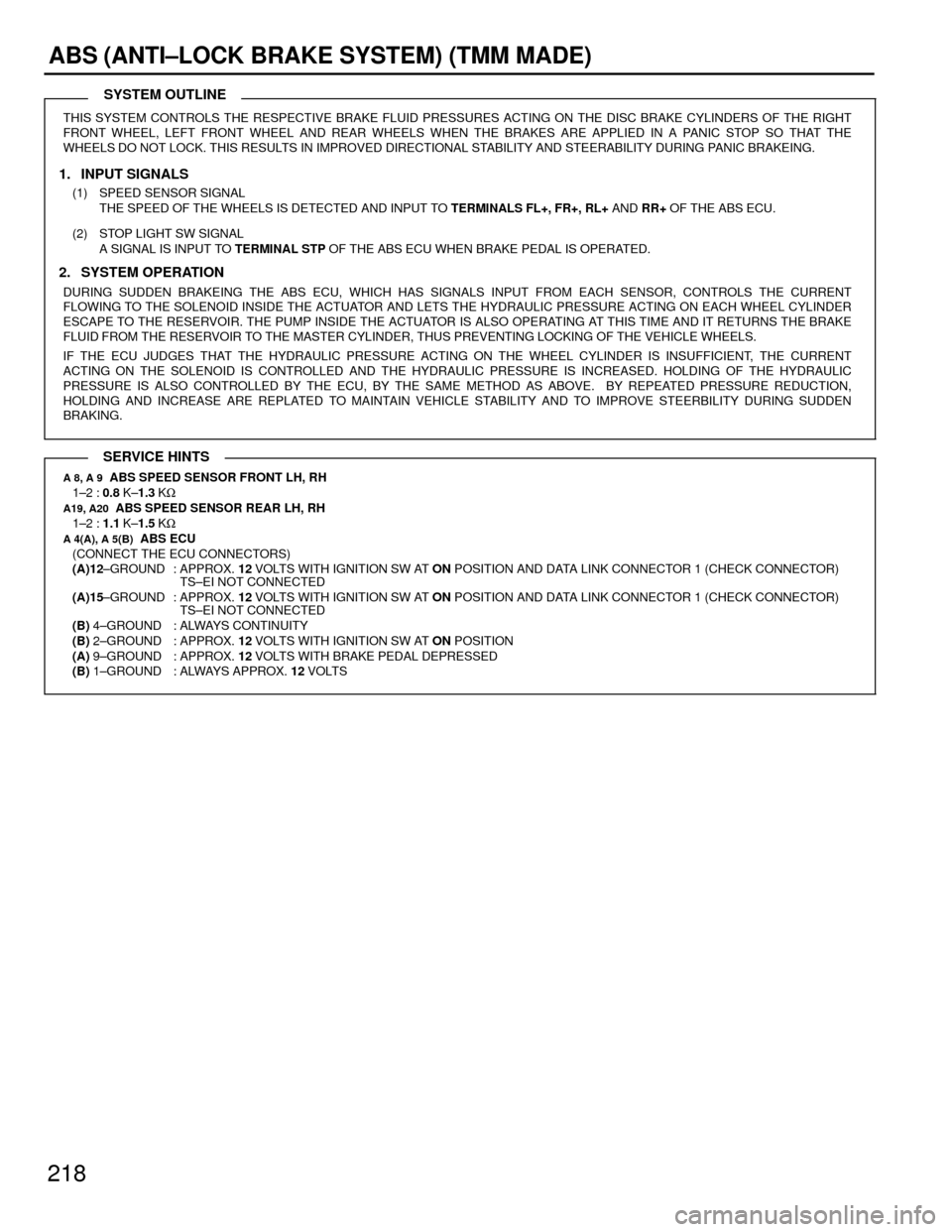

ABS (ANTI±LOCK BRAKE SYSTEM) (TMM MADE)

THIS SYSTEM CONTROLS THE RESPECTIVE BRAKE FLUID PRESSURES ACTING ON THE DISC BRAKE CYLINDERS OF THE RIGHT

FRONT WHEEL, LEFT FRONT WHEEL AND REAR WHEELS WHEN THE BRAKES ARE APPLIED IN A PANIC STOP SO THAT THE

WHEELS DO NOT LOCK. THIS RESULTS IN IMPROVED DIRECTIONAL STABILITY AND STEERABILITY DURING PANIC BRAKEING.

1. INPUT SIGNALS

(1) SPEED SENSOR SIGNAL

THE SPEED OF THE WHEELS IS DETECTED AND INPUT TO TERMINALS FL+, FR+, RL+ AND RR+ OF THE ABS ECU.

(2) STOP LIGHT SW SIGNAL

A SIGNAL IS INPUT TO TERMINAL STP OF THE ABS ECU WHEN BRAKE PEDAL IS OPERATED.

2. SYSTEM OPERATION

DURING SUDDEN BRAKEING THE ABS ECU, WHICH HAS SIGNALS INPUT FROM EACH SENSOR, CONTROLS THE CURRENT

FLOWING TO THE SOLENOID INSIDE THE ACTUATOR AND LETS THE HYDRAULIC PRESSURE ACTING ON EACH WHEEL CYLINDER

ESCAPE TO THE RESERVOIR. THE PUMP INSIDE THE ACTUATOR IS ALSO OPERATING AT THIS TIME AND IT RETURNS THE BRAKE

FLUID FROM THE RESERVOIR TO THE MASTER CYLINDER, THUS PREVENTING LOCKING OF THE VEHICLE WHEELS.

IF THE ECU JUDGES THAT THE HYDRAULIC PRESSURE ACTING ON THE WHEEL CYLINDER IS INSUFFICIENT, THE CURRENT

ACTING ON THE SOLENOID IS CONTROLLED AND THE HYDRAULIC PRESSURE IS INCREASED. HOLDING OF THE HYDRAULIC

PRESSURE IS ALSO CONTROLLED BY THE ECU, BY THE SAME METHOD AS ABOVE. BY REPEATED PRESSURE REDUCTION,

HOLDING AND INCREASE ARE REPLATED TO MAINTAIN VEHICLE STABILITY AND TO IMPROVE STEERBILITY DURING SUDDEN

BRAKING.

A 8, A 9 ABS SPEED SENSOR FRONT LH, RH

1±2 : 0.8 K±1.3 KW

A19, A20 ABS SPEED SENSOR REAR LH, RH

1±2 : 1.1 K±1.5 KW

A 4(A), A 5(B) ABS ECU

(CONNECT THE ECU CONNECTORS)

(A)12±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND DATA LINK CONNECTOR 1 (CHECK CONNECTOR)

TS±EI NOT CONNECTED

(A)15±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND DATA LINK CONNECTOR 1 (CHECK CONNECTOR)

TS±EI NOT CONNECTED

(B) 4±GROUND : ALWAYS CONTINUITY

(B) 2±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

(A) 9±GROUND : APPROX. 12 VOLTS WITH BRAKE PEDAL DEPRESSED

(B) 1±GROUND : ALWAYS APPROX. 12 VOLTS

SYSTEM OUTLINE

SERVICE HINTS

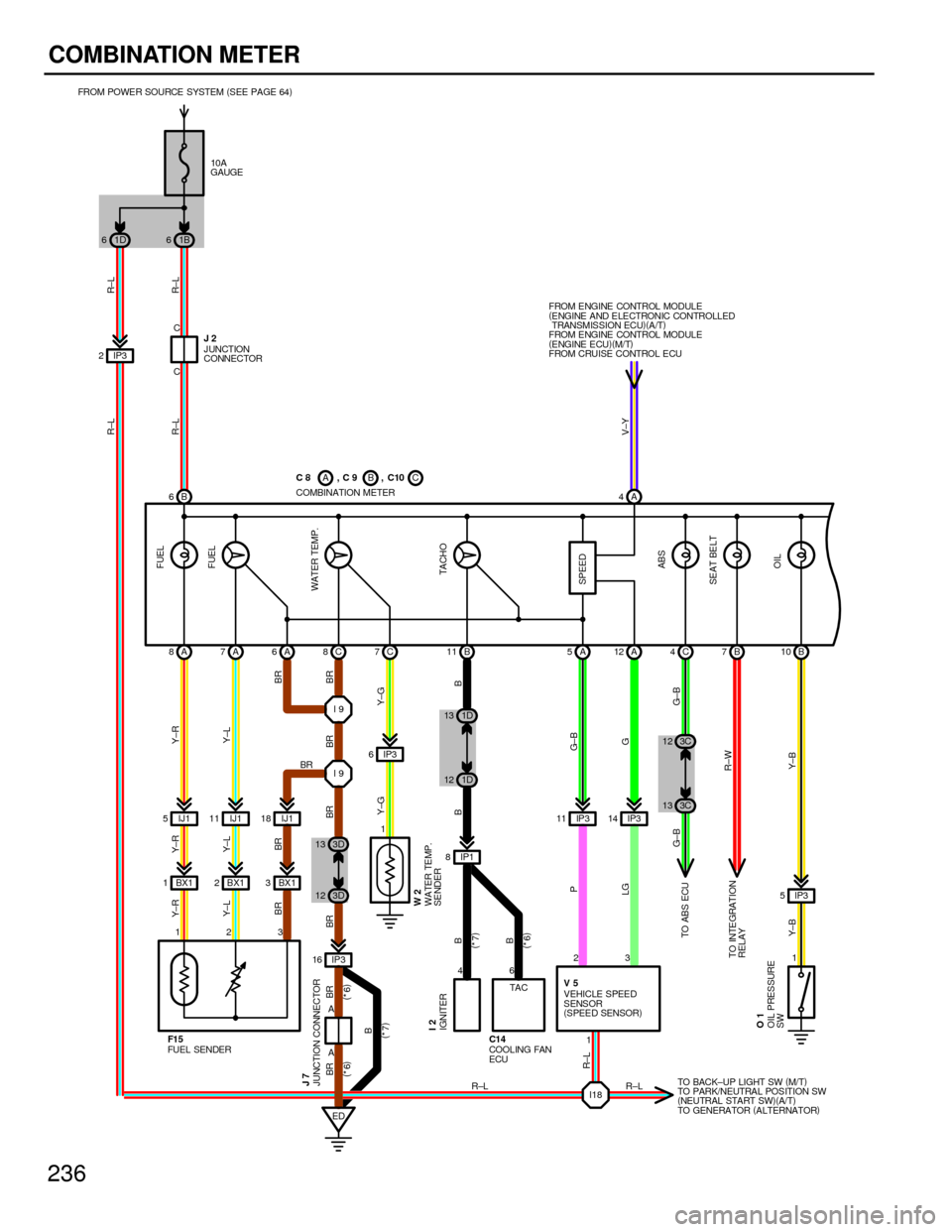

Page 236 of 307

236

COMBINATION METER

AB

IJ1 5IJ111 IJ118

BX1 3 BX1 2 BX1 1 IP3 2

IP3 6

IP1 8IP 3 11 IP314

IP3 5

IP3 161

ED1 A 4

A 8A7A6A 5A12 B 11 B7B10 C 8C7C 4

123

23

4

1 I9

I9 C C

6 FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

R±L

R±L R±L R±L

BRY±L Y±R

BR BR BR Y±L Y±R Y±R

Y±L

BR

BR BR

B Y±G

BY±G

B

P

LG GG±B

G±B G±B

R±W

Y±B Y±BV±Y

R±L JUNCTION

CONNECTOR

BR

BR

FROM E NGINE CONTROL MODULE

(

E NGINE A ND E LE CTRONIC CONTROLLED

TRANSMISSION ECU)(

A/T)

FROM E NGINE CONTROL MODULE

(

ENGINE ECU)(

M/T)

FROM CRUISE CONTROL ECU

SPEEDFUEL

FUEL

WATER TEMP.

TA CHO

ABS

SEAT BELT

OIL

FUEL SENDER

WATER TEMP.

SENDER

IGNITER

VEHICLE SPEED

SENSOR

(

SPEED SENSOR)

TO AB S ECU

TO INTEGRATION

RELAY

OIL P RES SURE

SW

J2

B

W2

I2

V5

O1F1 5C

COMBINATION METER C8 ,C9 , C10

TO BACK±UP LIGHT SW(

M/T)

TO PARK/NEUTRAL POSITION SW

(

NEUTRAL START SW)(

A/T)

TO GENERA TOR(

ALTERNATOR) R±L

R±L

I18 6

TA C

COOLING FAN

ECU C14

BR

B

B JUNCTION CONNECTOR J7

(

*6) (

*6)

(

*7)A

A

(

*7)

(

*6)

1B 6 1D 610A

GAUGE

3D 13

3D 12

1D 121D 13

3C 133C 12

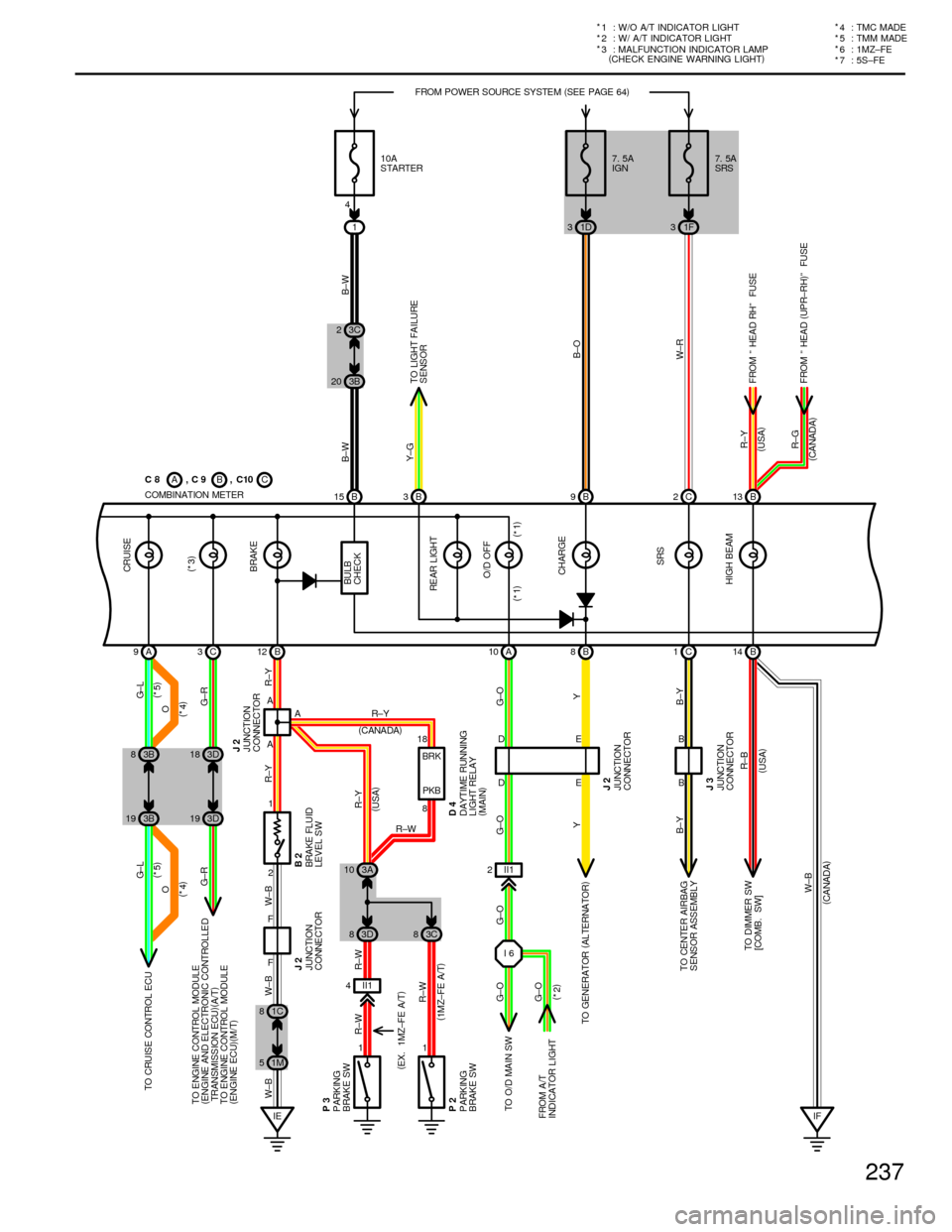

Page 237 of 307

237

*

1 : W/O A/T INDICATOR LIGHT

* 2 : W/ A/T INDICATOR LIGHT

*

3 : MALFUNCTION INDICATOR LAMP

(

CHECK ENGINE WARNING LIGHT)

*7 : 5S±FE *

6 : 1MZ±FE * 5 : TMM MADE

*

4:TMCMADE

AB

C

COMBINATION METER1

IEIF 2 1B 15 B3B9B13

B 12B 8B14 C 1 C 3 A 9A 10C 2

II1 4

11B DE 18 A

FB E D

8 A

FAFROM POWER SOURCE SYSTEM(

SEE PAGE 64)

B±W

R±Y

R±GW±R Y±G B±W

B±O G± L

G±R

R±Y R±Y W±BG±RG± L

±B W±B

R±W R±W

R±W

G±O

Y

B±Y

R±BB±YY G±O R±Y

R±Y

R±W 10A

STARTER

TO LIGHT FAILURE

SENSOR

FROM º HEAD RHº FUSE

FROM º HEAD(

UP R±RH)

ºFUSE

(

CA NADA) (

USA) CRUISE

(

*3)

BRAKE

BULB

CHECK

RE AR LIGHT

O/D OFF

CHARGE

SRS

HIGH BEAM

PKB BRK

TOO/DMAINSW

TO GENERATOR(

ALTERNATOR)

TO CENTER AIRBAG

SENSOR ASSEMBLY

TO DIMMER SW

[COMB. SW] TO CRUISE CONTROL ECU

TO E NGINE CONTROL MODULE

(

ENGINE AND ELECTRONIC CONTROLLED

TRANSMISSION ECU)(

A/T)

TO E NGINE CONTROL MODULE

(

ENGINE ECU)(

M/T)

BRAKE FLUID

LEVEL SWJUNCTION

CONNECTOR

JUNCTION

CONNE CTOR

DAYTIME RUNNING

LIGHT RELAY

(

MAIN) PARKING

BRAKE SW

PARKING

BRAKE SW(

EX. 1MZ±FE A/T)

(

1MZ±FE A/T)

JUNCTION

CONNECTOR

JUNCTION

CONNECTOR (

USA)

(

CANA DA) C8 ,C9 , C10

J2

J2 B2

P3

P2 D4

J2

J3(

*1) (

*1)

(

USA)

II1 2

I6

G±O

G±O G±O

(

*2) FROM A/T

INDICATOR LIGHT

W±B

(

CA NADA)(

*5) (

*5)

O

(

*4)O

(

*4)

4

3B 203C 2

1D 31F3 7. 5A

IGN7. 5A

SRS

3B 19 3D19 3B 83D18

3D 83C8 3A 10

1M 51C 8

W