TOYOTA CAMRY 1999 Service Repair Manual

CAMRY 1999

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57448/w960_57448-0.png

TOYOTA CAMRY 1999 Service Repair Manual

Trending: OBD port, manual transmission, oil change, trailer, center console, low oil pressure, wheel

Page 521 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±72

HINT: Turn the counter drive gear right and left several

times before measuring the preload.

(c) Lock the adjusting nut with one locking washer tab. Bend

the locking washer tab until it is flat with the adjusting nut

groove.

9. INSTALL NO.3 OVERDRIVE PLANETARY THRUST

WASHER

10. INSTALL PINION SHAFT PLUGS

Install the 4 plugs into the pinion shaft.

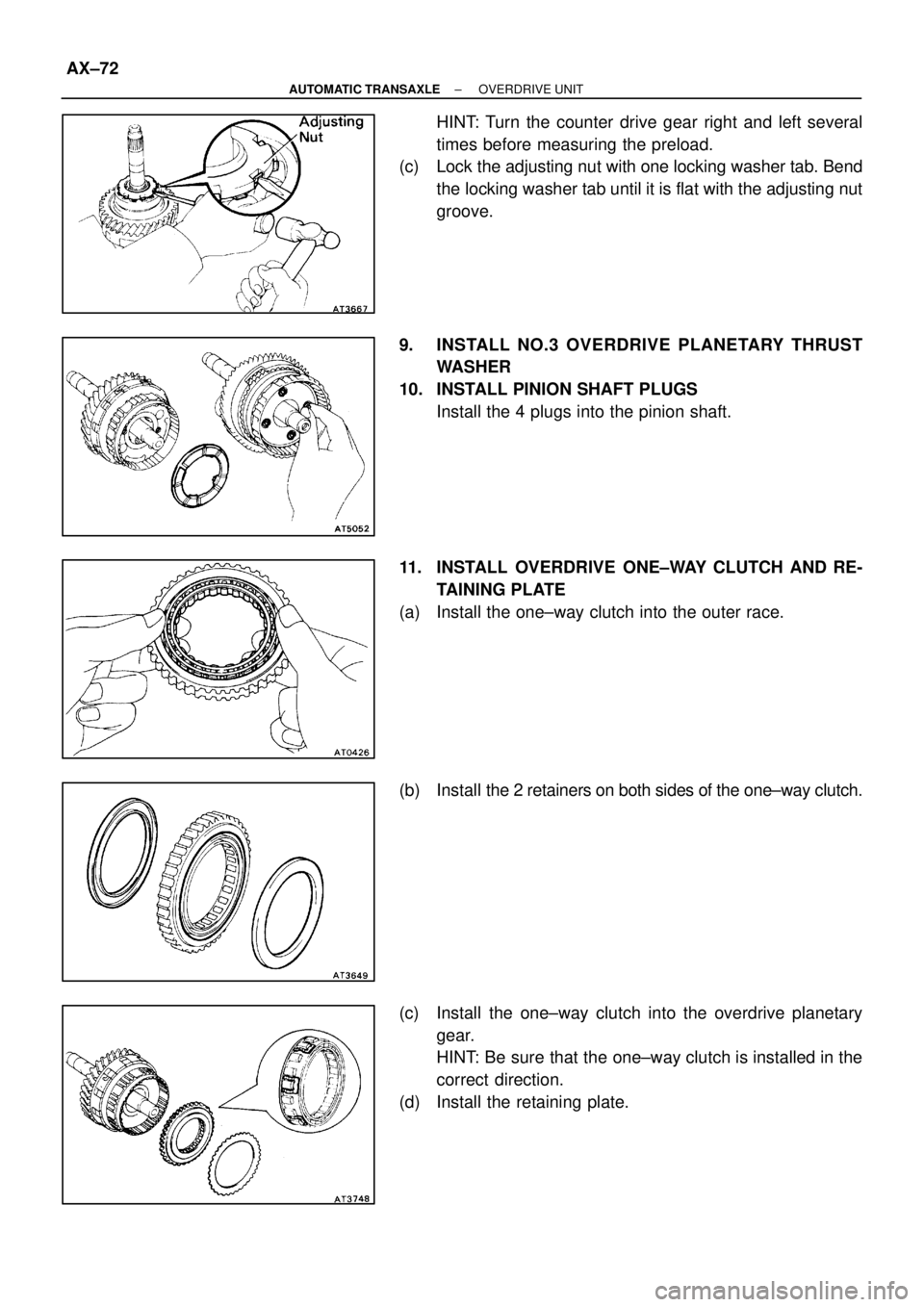

11. INSTALL OVERDRIVE ONE±WAY CLUTCH AND RE-

TAINING PLATE

(a) Install the one±way clutch into the outer race.

(b) Install the 2 retainers on both sides of the one±way clutch.

(c) Install the one±way clutch into the overdrive planetary

gear.

HINT: Be sure that the one±way clutch is installed in the

correct direction.

(d) Install the retaining plate.

Page 522 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±73

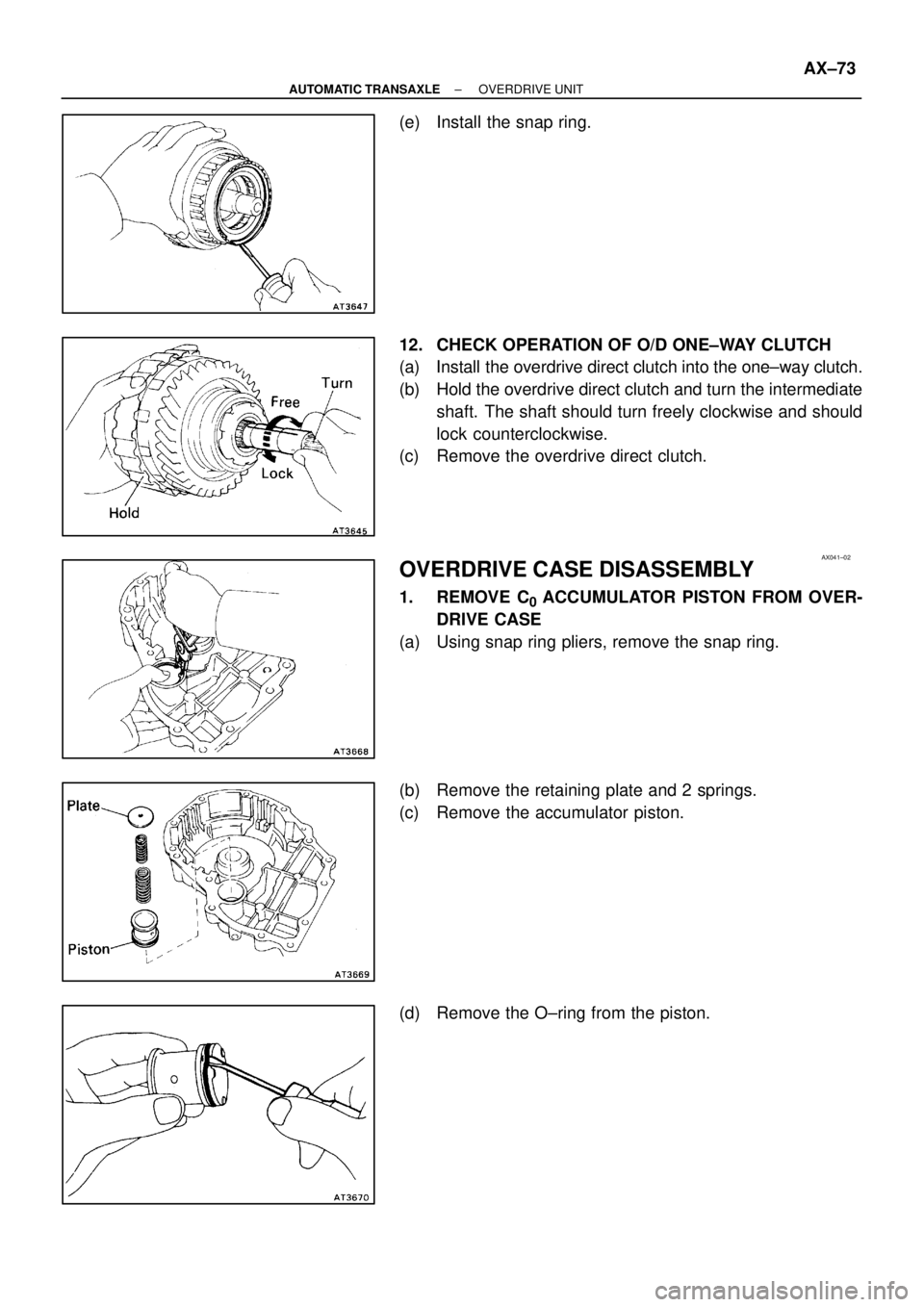

(e) Install the snap ring.

12. CHECK OPERATION OF O/D ONE±WAY CLUTCH

(a) Install the overdrive direct clutch into the one±way clutch.

(b) Hold the overdrive direct clutch and turn the intermediate

shaft. The shaft should turn freely clockwise and should

lock counterclockwise.

(c) Remove the overdrive direct clutch.

OVERDRIVE CASE DISASSEMBLY

1. REMOVE C0 ACCUMULATOR PISTON FROM OVER-

DRIVE CASE

(a) Using snap ring pliers, remove the snap ring.

(b) Remove the retaining plate and 2 springs.

(c) Remove the accumulator piston.

(d) Remove the O±ring from the piston.

AX041±02

Page 523 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±74

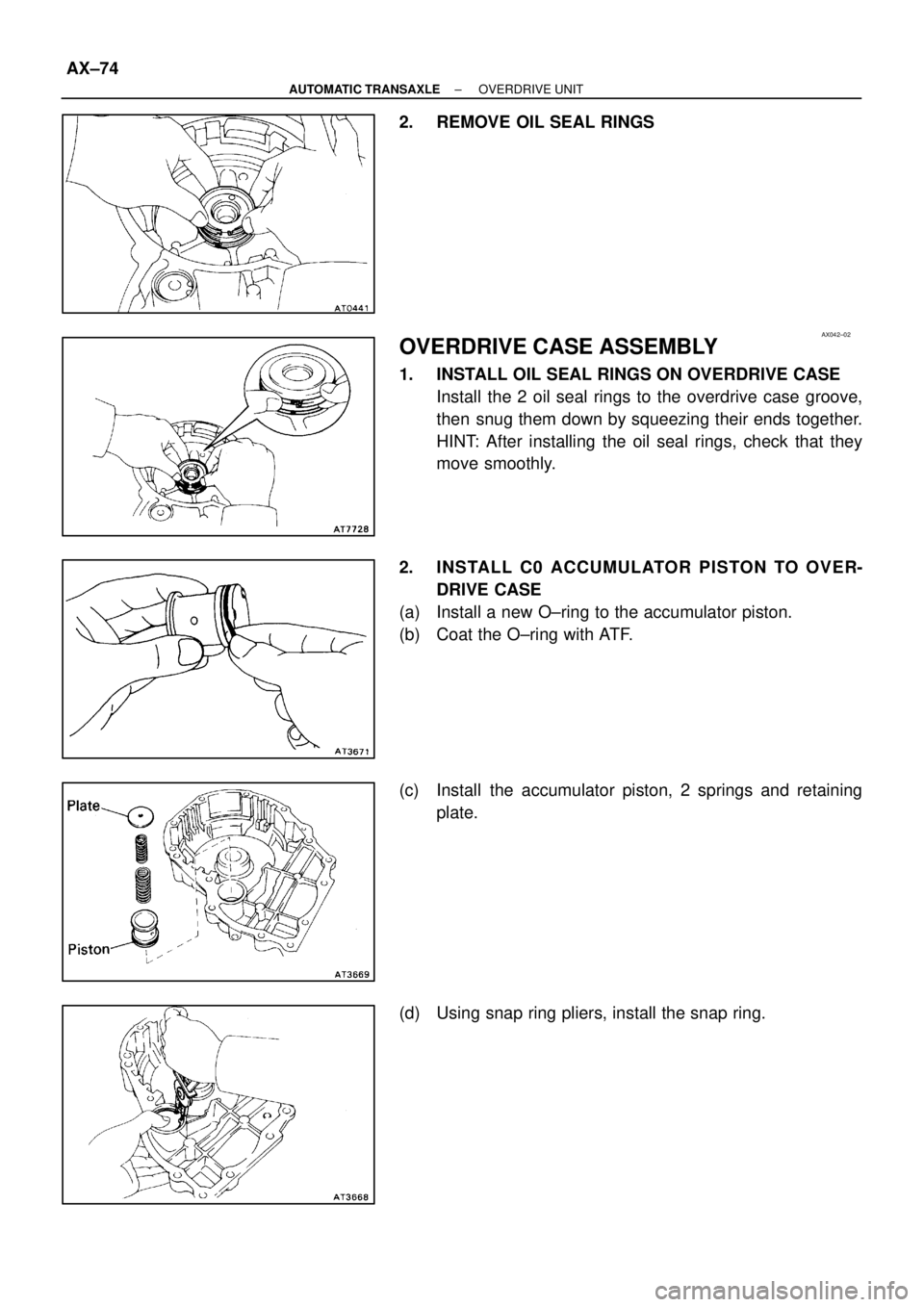

2. REMOVE OIL SEAL RINGS

OVERDRIVE CASE ASSEMBLY

1. INSTALL OIL SEAL RINGS ON OVERDRIVE CASE

Install the 2 oil seal rings to the overdrive case groove,

then snug them down by squeezing their ends together.

HINT: After installing the oil seal rings, check that they

move smoothly.

2. INSTALL C0 ACCUMULATOR PISTON TO OVER-

DRIVE CASE

(a) Install a new O±ring to the accumulator piston.

(b) Coat the O±ring with ATF.

(c) Install the accumulator piston, 2 springs and retaining

plate.

(d) Using snap ring pliers, install the snap ring.

AX042±02

Page 524 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±75

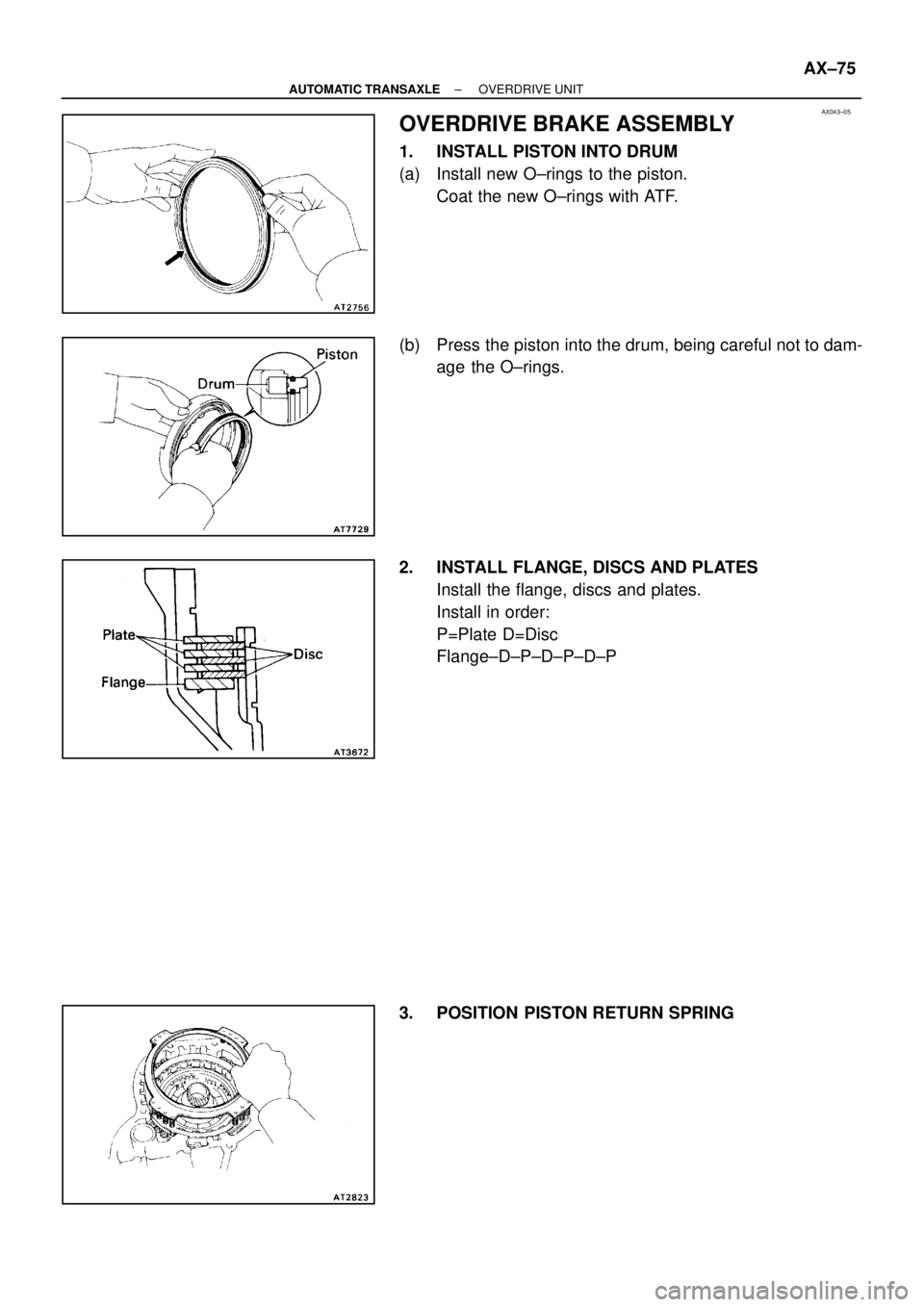

OVERDRIVE BRAKE ASSEMBLY

1. INSTALL PISTON INTO DRUM

(a) Install new O±rings to the piston.

Coat the new O±rings with ATF.

(b) Press the piston into the drum, being careful not to dam-

age the O±rings.

2. INSTALL FLANGE, DISCS AND PLATES

Install the flange, discs and plates.

Install in order:

P=Plate D=Disc

Flange±D±P±D±P±D±P

3. POSITION PISTON RETURN SPRING

AX043±05

Page 525 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±76

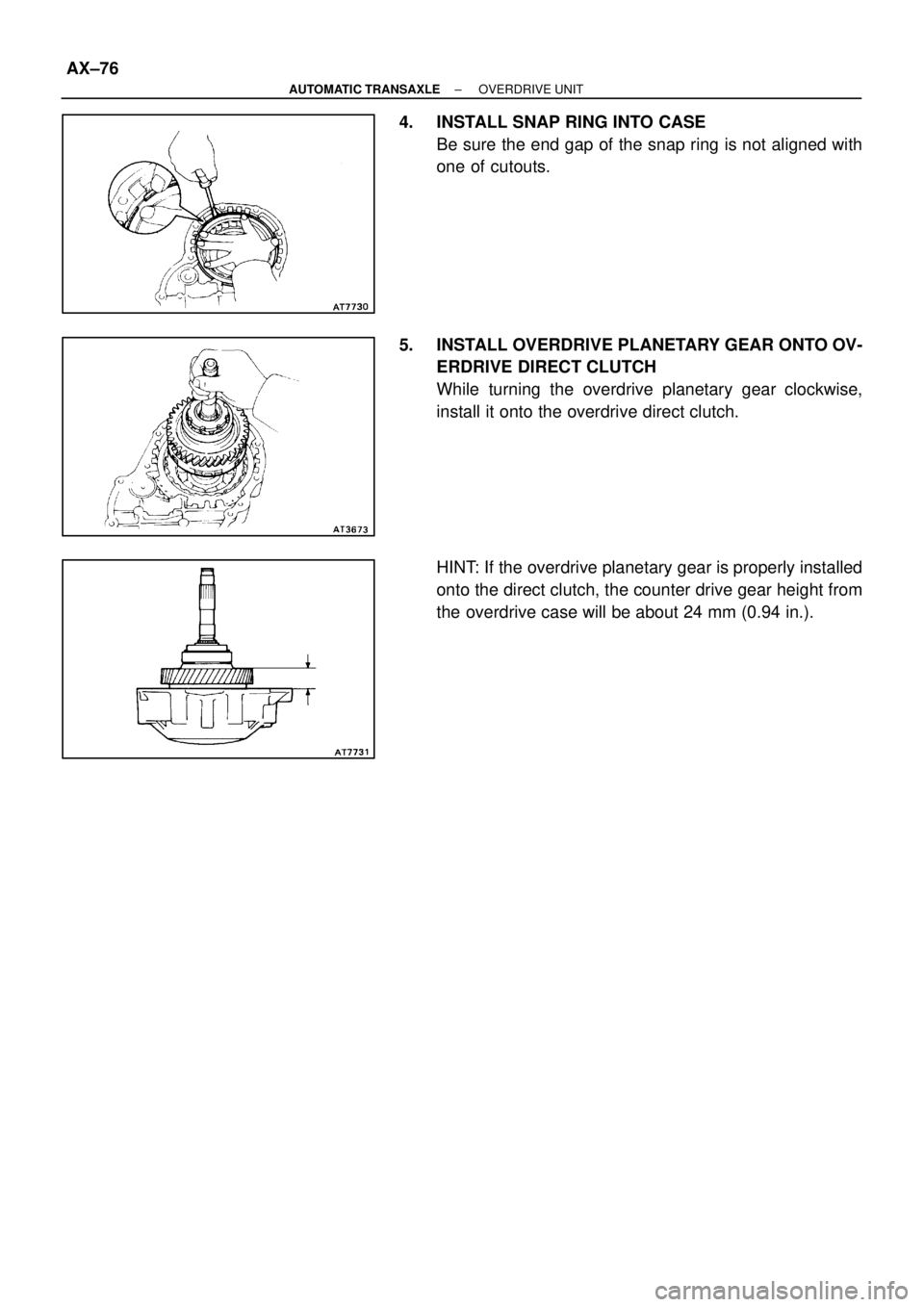

4. INSTALL SNAP RING INTO CASE

Be sure the end gap of the snap ring is not aligned with

one of cutouts.

5. INSTALL OVERDRIVE PLANETARY GEAR ONTO OV-

ERDRIVE DIRECT CLUTCH

While turning the overdrive planetary gear clockwise,

install it onto the overdrive direct clutch.

HINT: If the overdrive planetary gear is properly installed

onto the direct clutch, the counter drive gear height from

the overdrive case will be about 24 mm (0.94 in.).

Page 526 of 4592

AUTOMATIC TRANSAXLEVALVE BODY ±

AX±77

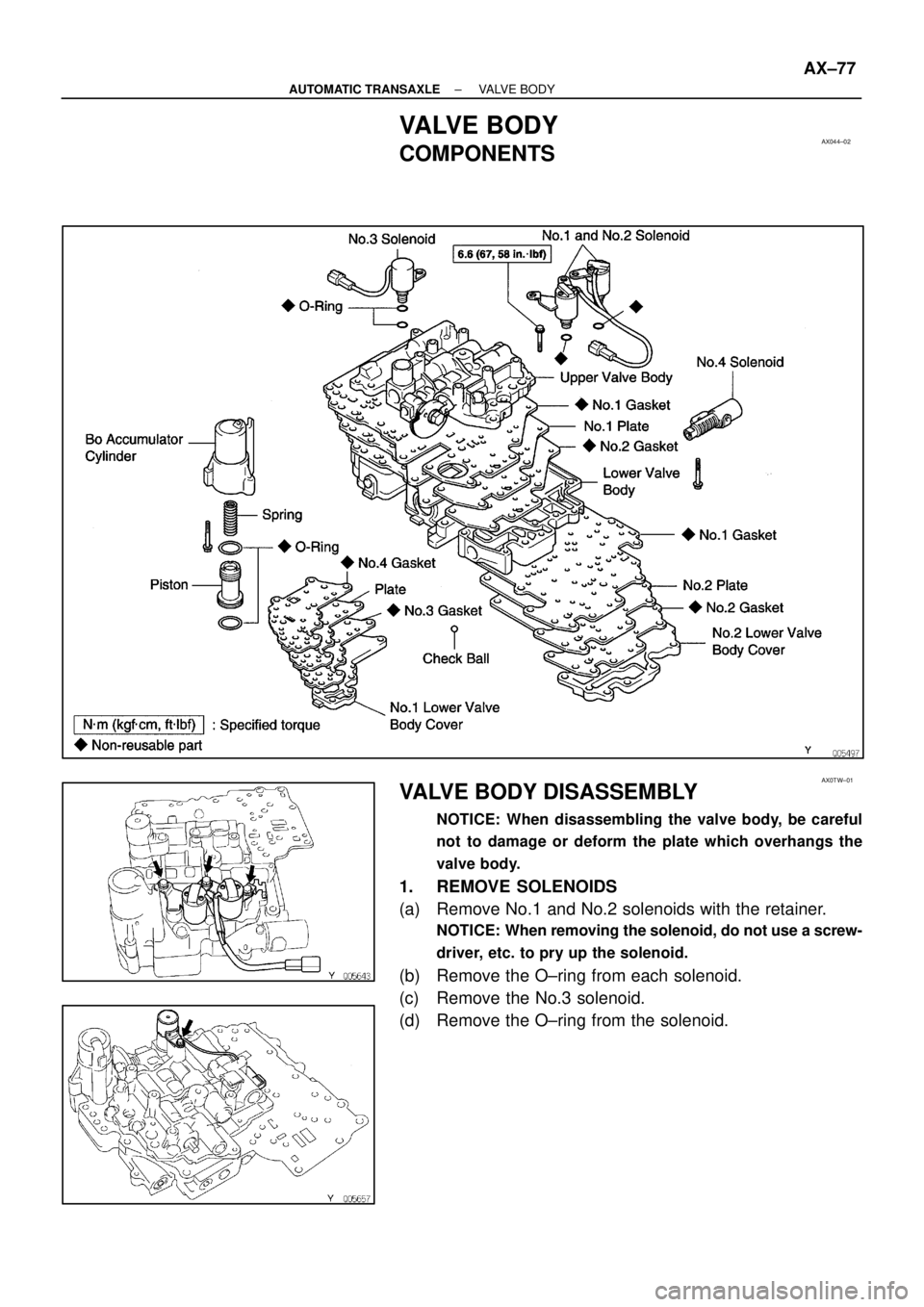

VALVE BODY

COMPONENTS

VALVE BODY DISASSEMBLY

NOTICE: When disassembling the valve body, be careful

not to damage or deform the plate which overhangs the

valve body.

1. REMOVE SOLENOIDS

(a) Remove No.1 and No.2 solenoids with the retainer.

NOTICE: When removing the solenoid, do not use a screw-

driver, etc. to pry up the solenoid.

(b) Remove the O±ring from each solenoid.

(c) Remove the No.3 solenoid.

(d) Remove the O±ring from the solenoid.

AX044±02

AX0TW±01

Page 527 of 4592

AUTOMATIC TRANSAXLEVALVE BODY ±

AX±78

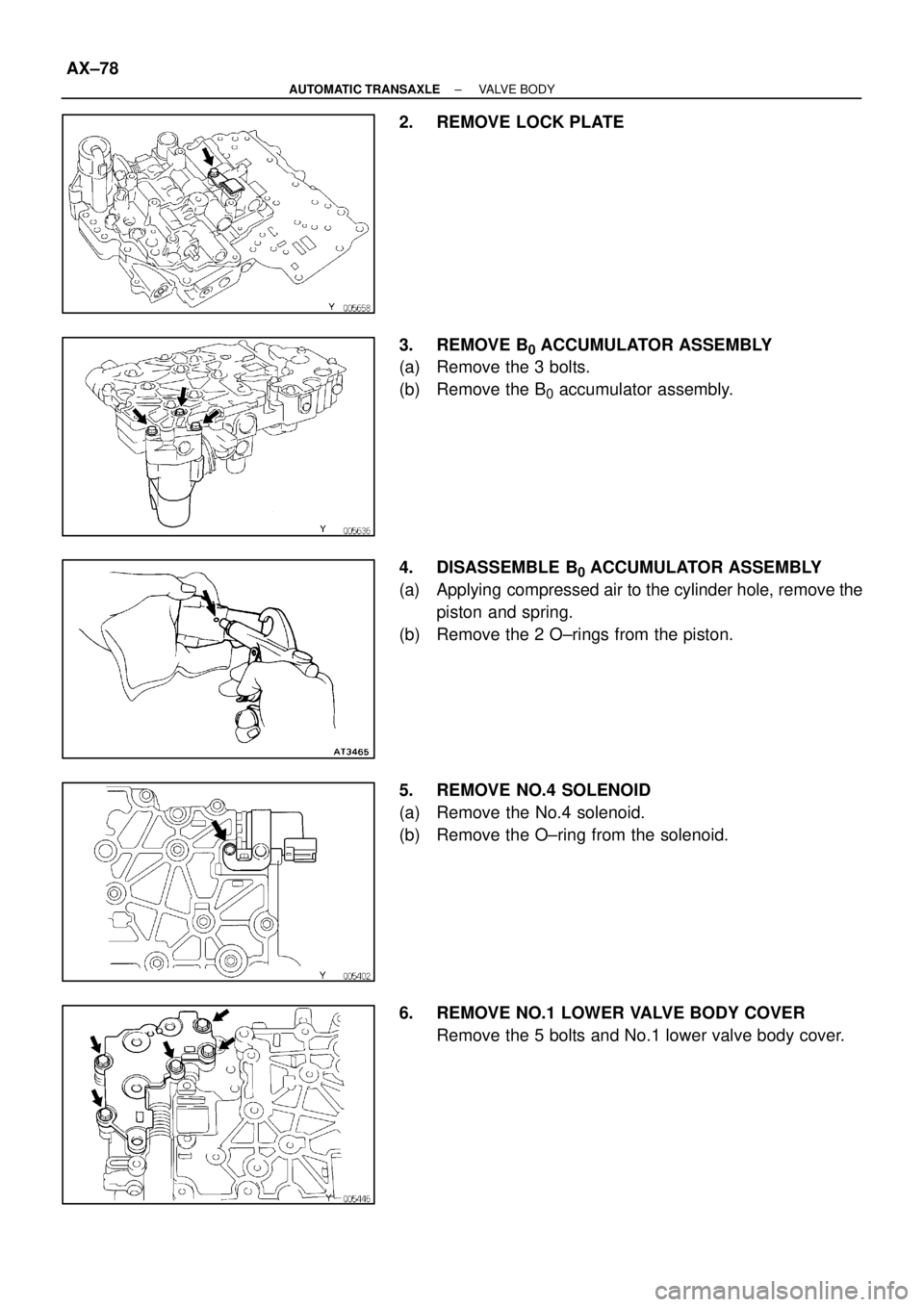

2. REMOVE LOCK PLATE

3. REMOVE B

0 ACCUMULATOR ASSEMBLY

(a) Remove the 3 bolts.

(b) Remove the B

0 accumulator assembly.

4. DISASSEMBLE B

0 ACCUMULATOR ASSEMBLY

(a) Applying compressed air to the cylinder hole, remove the

piston and spring.

(b) Remove the 2 O±rings from the piston.

5. REMOVE NO.4 SOLENOID

(a) Remove the No.4 solenoid.

(b) Remove the O±ring from the solenoid.

6. REMOVE NO.1 LOWER VALVE BODY COVER

Remove the 5 bolts and No.1 lower valve body cover.

Page 528 of 4592

AUTOMATIC TRANSAXLEVALVE BODY ±

AX±79

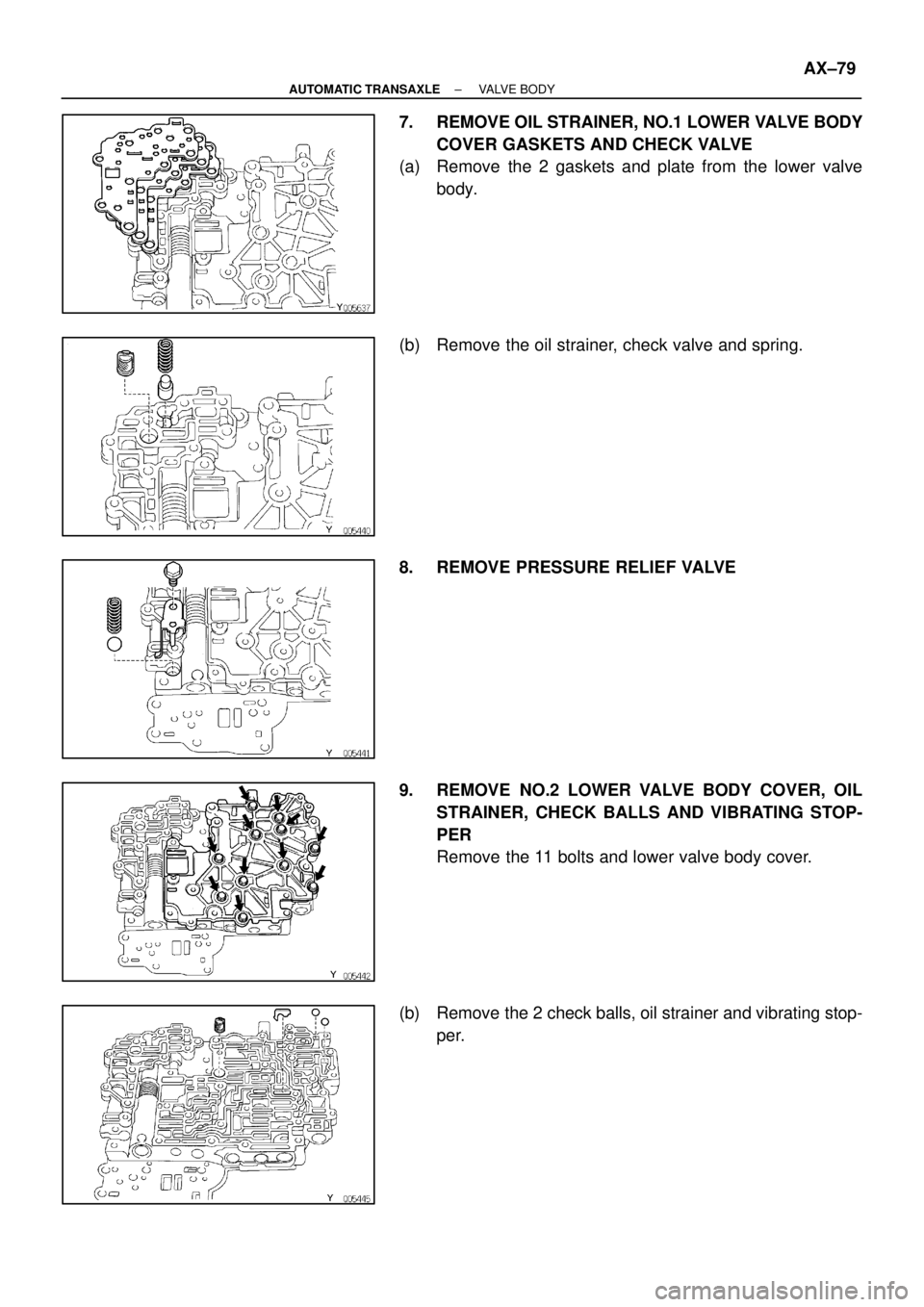

7. REMOVE OIL STRAINER, NO.1 LOWER VALVE BODY

COVER GASKETS AND CHECK VALVE

(a) Remove the 2 gaskets and plate from the lower valve

body.

(b) Remove the oil strainer, check valve and spring.

8. REMOVE PRESSURE RELIEF VALVE

9. REMOVE NO.2 LOWER VALVE BODY COVER, OIL

STRAINER, CHECK BALLS AND VIBRATING STOP-

PER

Remove the 11 bolts and lower valve body cover.

(b) Remove the 2 check balls, oil strainer and vibrating stop-

per.

Page 529 of 4592

AUTOMATIC TRANSAXLEVALVE BODY ±

AX±80

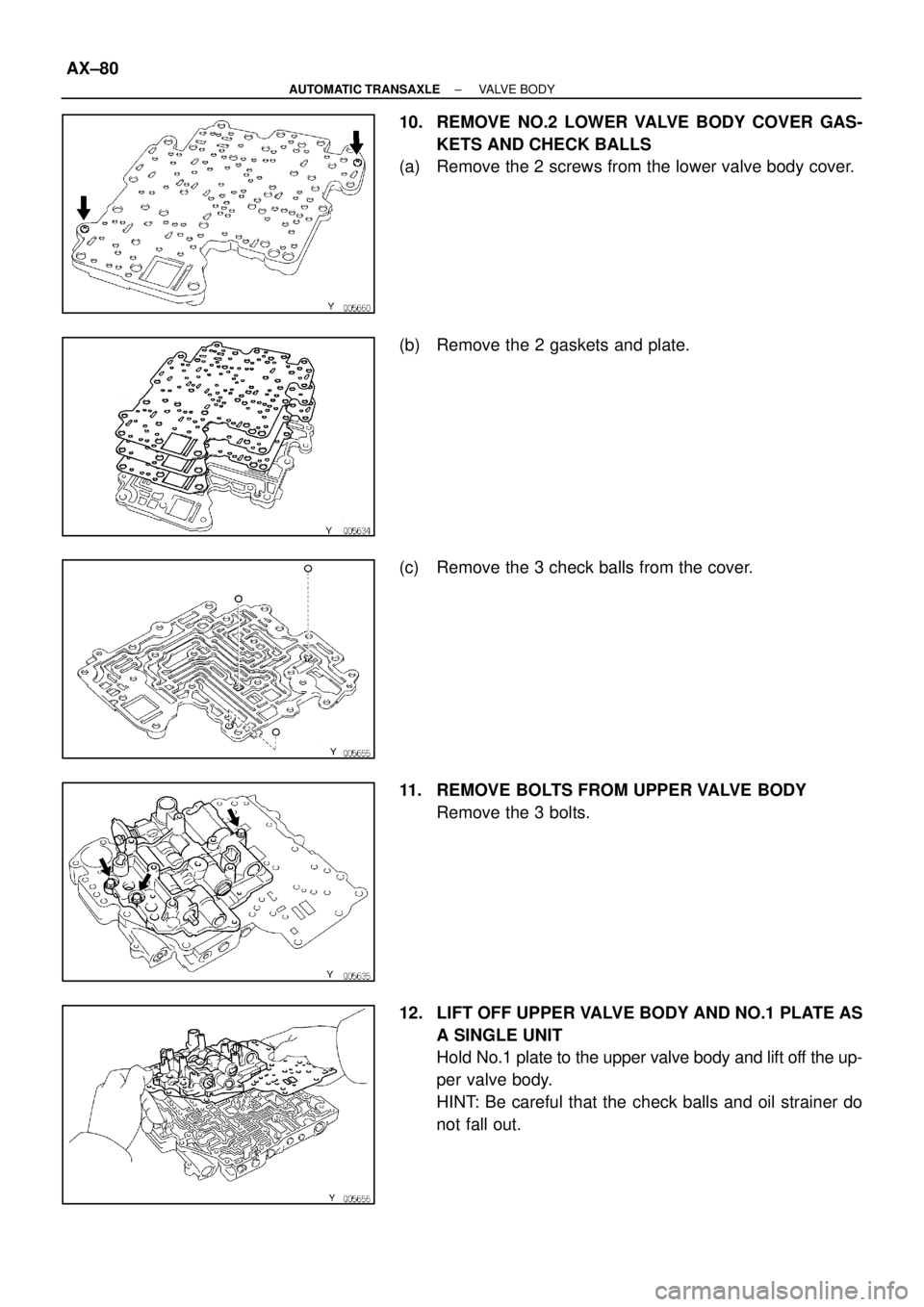

10. REMOVE NO.2 LOWER VALVE BODY COVER GAS-

KETS AND CHECK BALLS

(a) Remove the 2 screws from the lower valve body cover.

(b) Remove the 2 gaskets and plate.

(c) Remove the 3 check balls from the cover.

11. REMOVE BOLTS FROM UPPER VALVE BODY

Remove the 3 bolts.

12. LIFT OFF UPPER VALVE BODY AND NO.1 PLATE AS

A SINGLE UNIT

Hold No.1 plate to the upper valve body and lift off the up-

per valve body.

HINT: Be careful that the check balls and oil strainer do

not fall out.

Page 530 of 4592

AUTOMATIC TRANSAXLEVALVE BODY ±

AX±81

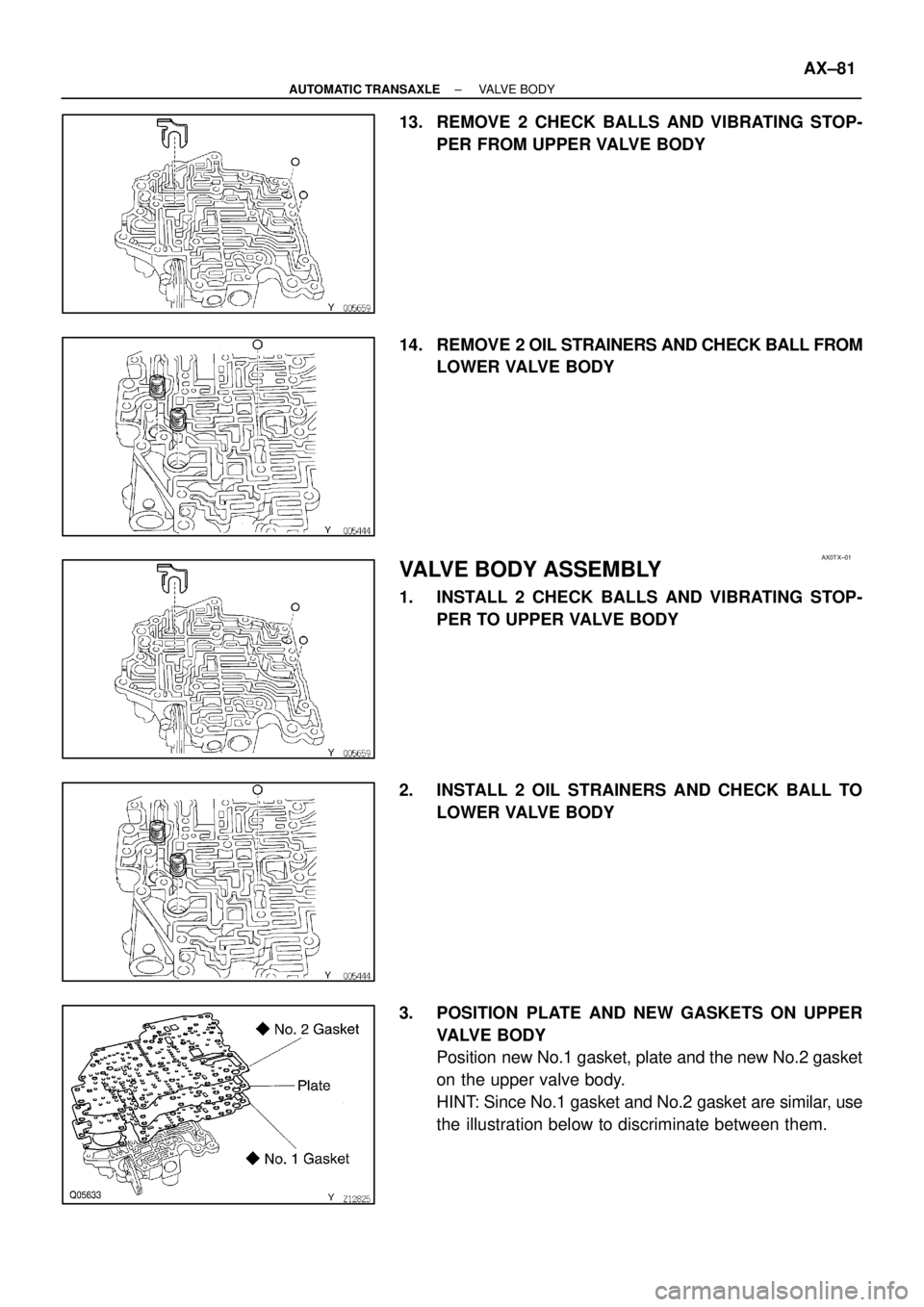

13. REMOVE 2 CHECK BALLS AND VIBRATING STOP-

PER FROM UPPER VALVE BODY

14. REMOVE 2 OIL STRAINERS AND CHECK BALL FROM

LOWER VALVE BODY

VALVE BODY ASSEMBLY

1. INSTALL 2 CHECK BALLS AND VIBRATING STOP-

PER TO UPPER VALVE BODY

2. INSTALL 2 OIL STRAINERS AND CHECK BALL TO

LOWER VALVE BODY

3. POSITION PLATE AND NEW GASKETS ON UPPER

VALVE BODY

Position new No.1 gasket, plate and the new No.2 gasket

on the upper valve body.

HINT: Since No.1 gasket and No.2 gasket are similar, use

the illustration below to discriminate between them.

AX0TX±01

Trending: warning, glove box, transmission, Transmission service, trailer, radiator sensor, manual transmission