sensor TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1114 of 2389

16. CONNECT ACCELERATOR CABLE AND BRACKET TO

THROTTLE BODY AND AIR INTAKE CHAMBER

17. (A/T)

CONNECT THROTTLE CABLE TO THROTTLE BODY

AND BRACKET, AND ADJUST IT

18. FILL WITH COOLANT (See page CO±5)

19. CONNECT CABLE TO NEGATIVE TERMINAL OF

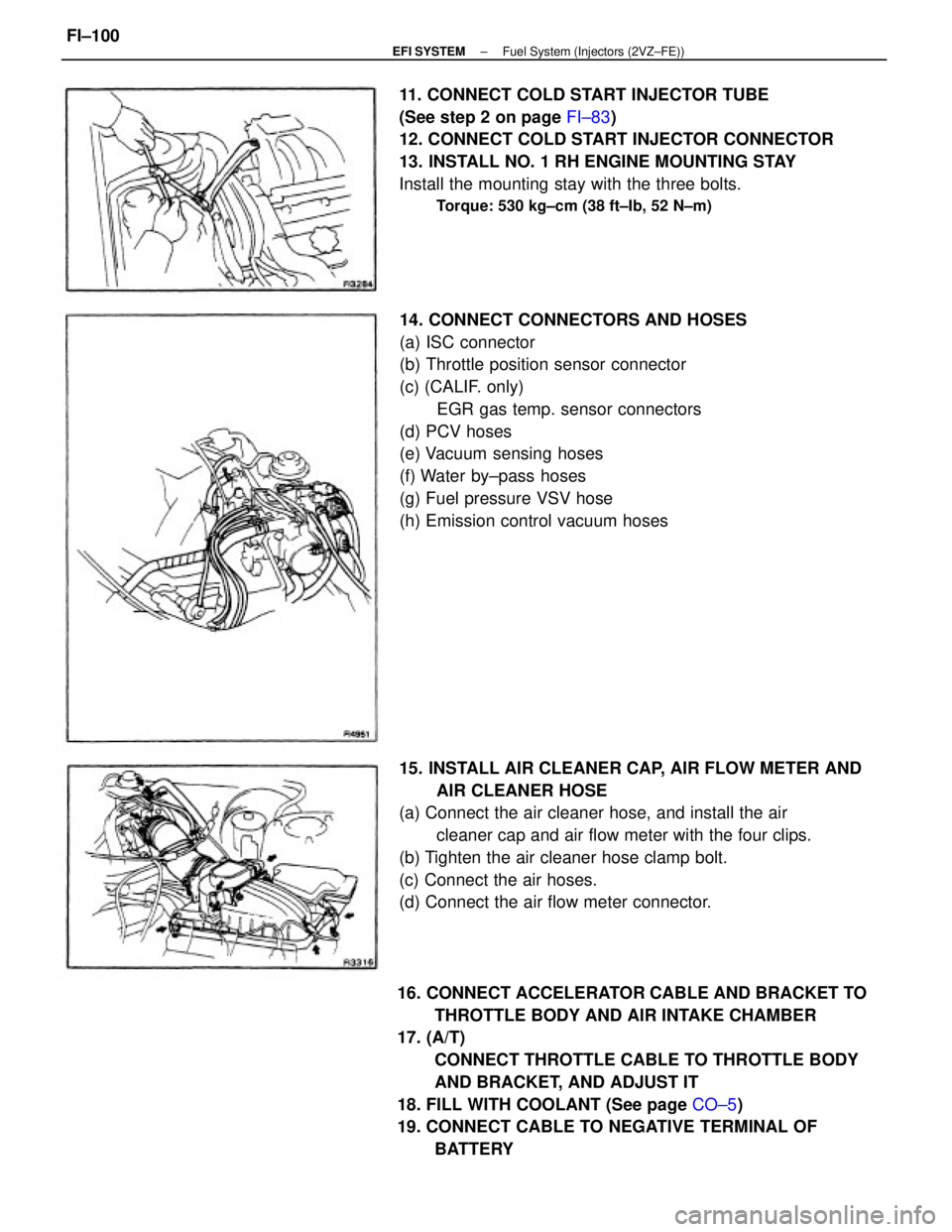

BATTERY 14. CONNECT CONNECTORS AND HOSES

(a) ISC connector

(b) Throttle position sensor connector

(c) (CALIF. only)

EGR gas temp. sensor connectors

(d) PCV hoses

(e) Vacuum sensing hoses

(f) Water by±pass hoses

(g) Fuel pressure VSV hose

(h) Emission control vacuum hoses

15. INSTALL AIR CLEANER CAP, AIR FLOW METER AND

AIR CLEANER HOSE

(a) Connect the air cleaner hose, and install the air

cleaner cap and air flow meter with the four clips.

(b) Tighten the air cleaner hose clamp bolt.

(c) Connect the air hoses.

(d) Connect the air flow meter connector. 11. CONNECT COLD START INJECTOR TUBE

(See step 2 on page FI±83)

12. CONNECT COLD START INJECTOR CONNECTOR

13. INSTALL NO. 1 RH ENGINE MOUNTING STAY

Install the mounting stay with the three bolts.

Torque: 530 kg±cm (38 ft±Ib, 52 N±m)

± EFI SYSTEMFuel System (Injectors (2VZ±FE))FI±100

Page 1120 of 2389

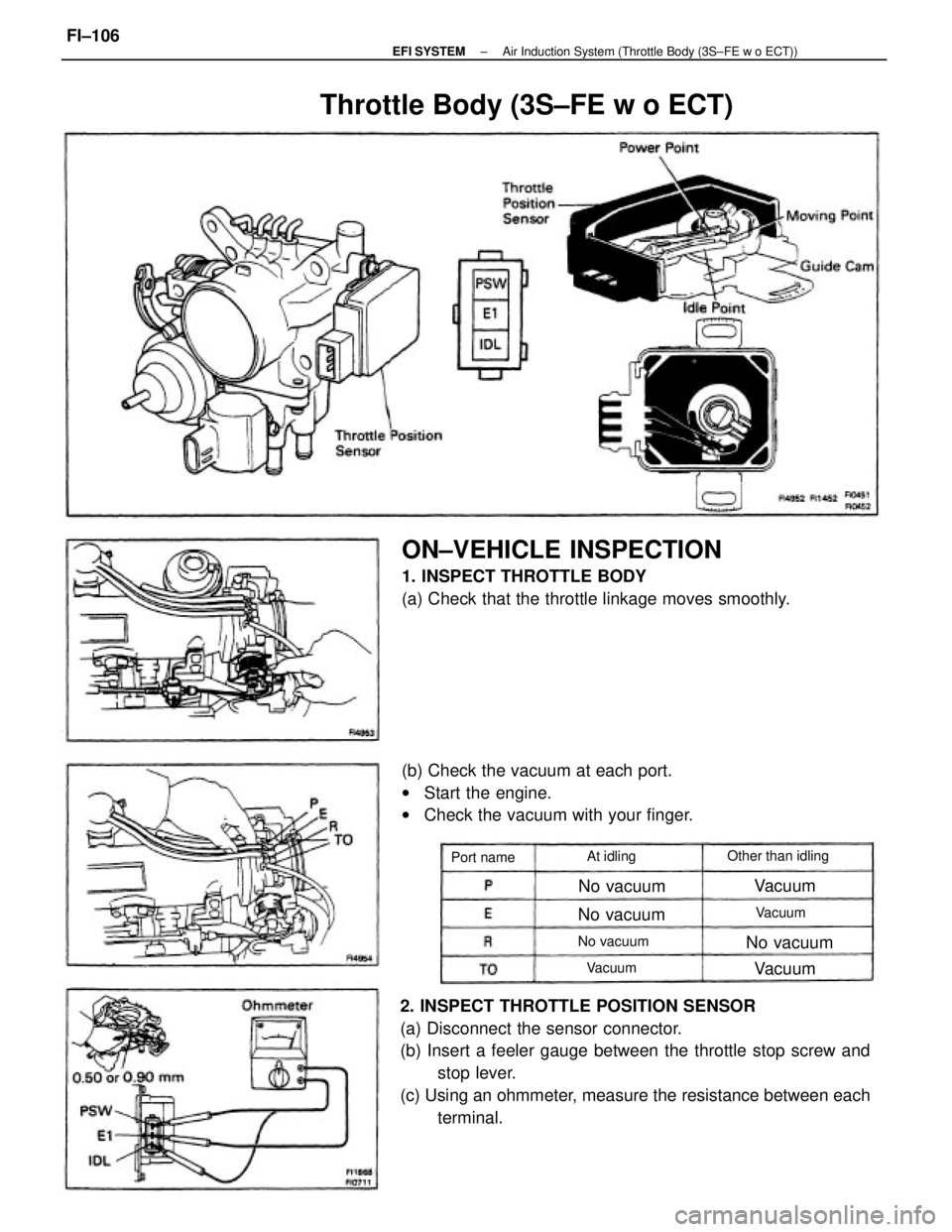

2. INSPECT THROTTLE POSITION SENSOR

(a) Disconnect the sensor connector.

(b) Insert a feeler gauge between the throttle stop screw and

stop lever.

(c) Using an ohmmeter, measure the resistance between each

terminal.

ON±VEHICLE INSPECTION

1. INSPECT THROTTLE BODY

(a) Check that the throttle linkage moves smoothly.

(b) Check the vacuum at each port.

wStart the engine.

wCheck the vacuum with your finger.

Throttle Body (3S±FE w o ECT)

Other than idling

No vacuum

No vacuum No vacuum

No vacuum Port nameAt idling

Vacuum

Vacuum

VacuumVacuum

± EFI SYSTEMAir Induction System (Throttle Body (3S±FE w o ECT))FI±106

Page 1121 of 2389

(d) Reconnect the sensor connector.

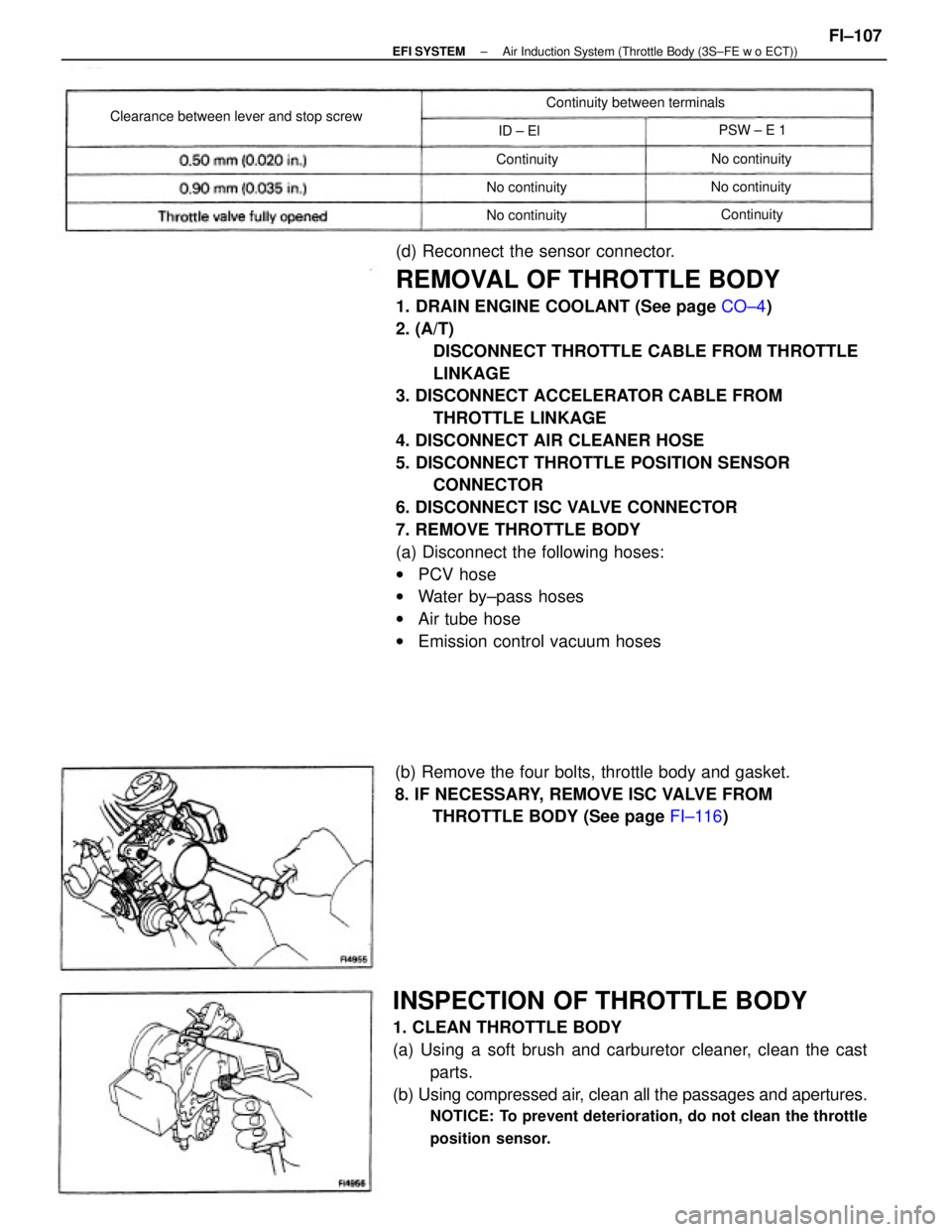

REMOVAL OF THROTTLE BODY

1. DRAIN ENGINE COOLANT (See page CO±4)

2. (A/T)

DISCONNECT THROTTLE CABLE FROM THROTTLE

LINKAGE

3. DISCONNECT ACCELERATOR CABLE FROM

THROTTLE LINKAGE

4. DISCONNECT AIR CLEANER HOSE

5. DISCONNECT THROTTLE POSITION SENSOR

CONNECTOR

6. DISCONNECT ISC VALVE CONNECTOR

7. REMOVE THROTTLE BODY

(a) Disconnect the following hoses:

wPCV hose

wWater by±pass hoses

wAir tube hose

wEmission control vacuum hoses

INSPECTION OF THROTTLE BODY

1. CLEAN THROTTLE BODY

(a) Using a soft brush and carburetor cleaner, clean the cast

parts.

(b) Using compressed air, clean all the passages and apertures.

NOTICE: To prevent deterioration, do not clean the throttle

position sensor.

(b) Remove the four bolts, throttle body and gasket.

8. IF NECESSARY, REMOVE ISC VALVE FROM

THROTTLE BODY (See page FI±116)

Clearance between lever and stop screwContinuity between terminals

No continuity

No continuity

No continuity

No continuityPSW ± E 1

Continuity

Continuity ID ± El

± EFI SYSTEMAir Induction System (Throttle Body (3S±FE w o ECT))FI±107

Page 1122 of 2389

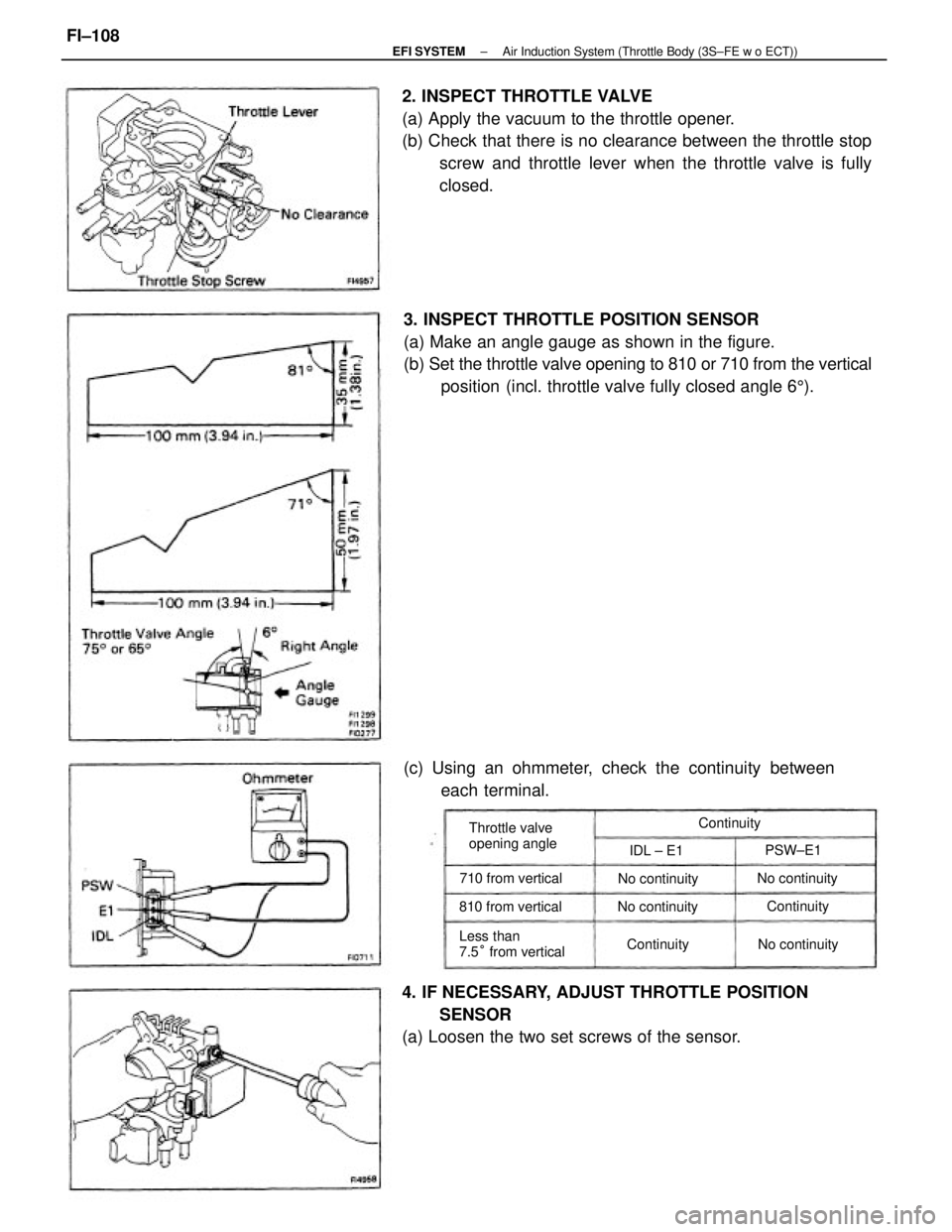

3. INSPECT THROTTLE POSITION SENSOR

(a) Make an angle gauge as shown in the figure.

(b) Set the throttle valve opening to 810 or 710 from the vertical

position (incl. throttle valve fully closed angle 65). 2. INSPECT THROTTLE VALVE

(a) Apply the vacuum to the throttle opener.

(b) Check that there is no clearance between the throttle stop

screw and throttle lever when the throttle valve is fully

closed.

4. IF NECESSARY, ADJUST THROTTLE POSITION

SENSOR

(a) Loosen the two set screws of the sensor.(c) Using an ohmmeter, check the continuity between

each terminal.

Less than

7.5° from vertical Throttle valve

opening angle

710 from vertical

810 from verticalNo continuity

No continuity

No continuity

No continuityContinuity

ContinuityPSW±E1 Continuity

IDL ± E1

± EFI SYSTEMAir Induction System (Throttle Body (3S±FE w o ECT))FI±108

Page 1123 of 2389

(b) Connect the following hoses:

wPCV hose

wWater by±pass hoses

wAir tube hose

wEmission control vacuum hoses

3. CONNECT ISC VALVE CONNECTOR

4. CONNECT THROTTLE POSITION SENSOR

CONNECTOR

5. CONNECT AIR CLEANER HOSE

6. CONNECT ACCELERATOR CABLE, AND ADJUST IT

7. (A/T)

CONNECT THROTTLE CABLE, AND ADJUST IT

8. FILL WITH ENGINE COOLANT (See page CO±5)

INSTALLATION OF THROTTLE BODY

1. INSTALL ISC VALVE TO THROTTLE BODY

(See page FI±117)

2. INSTALL THROTTLE BODY

(a) Install a new gasket and the throttle body with the four bolts.

Torque: 195 kg±cm (14 ft±Ib, 19 N±m)

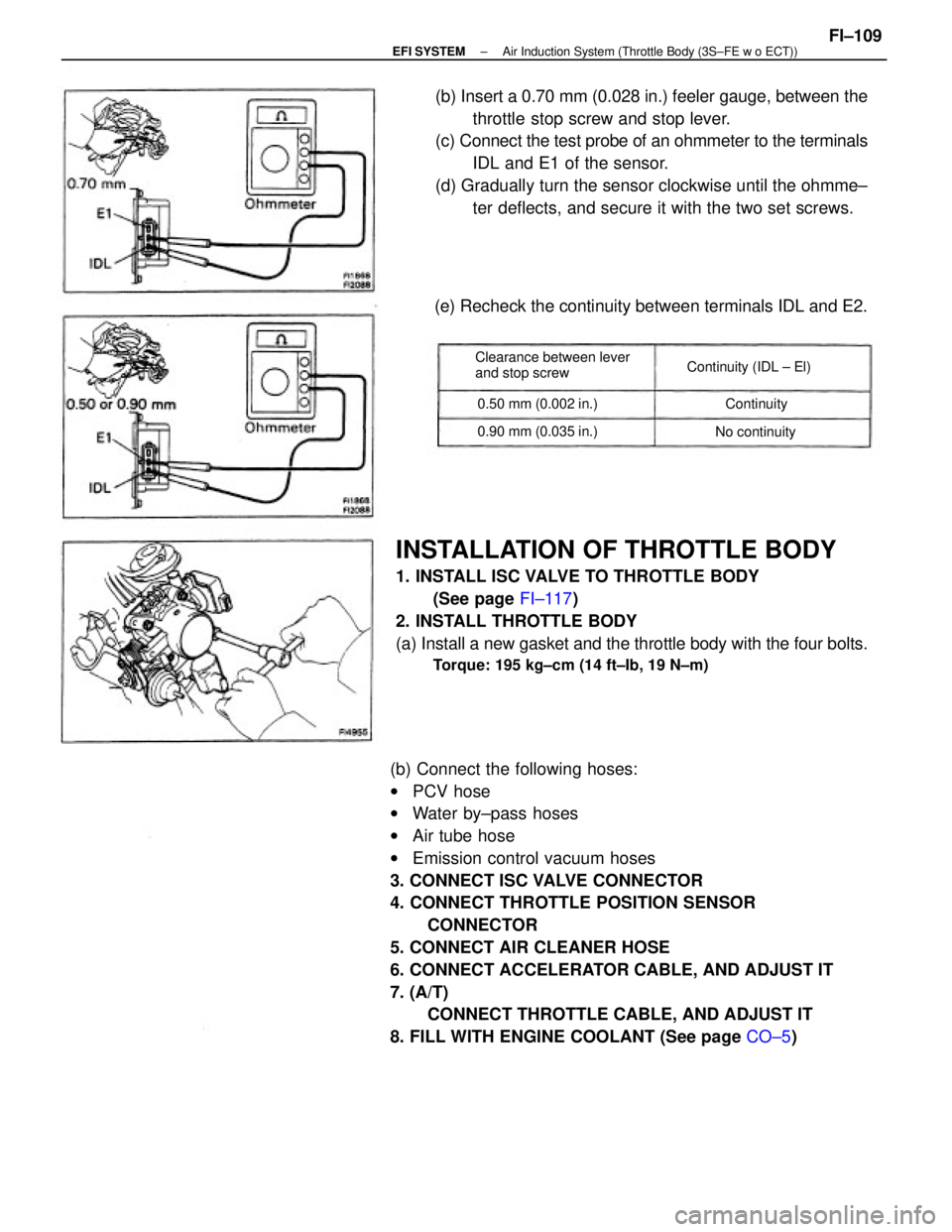

(b) Insert a 0.70 mm (0.028 in.) feeler gauge, between the

throttle stop screw and stop lever.

(c) Connect the test probe of an ohmmeter to the terminals

IDL and E1 of the sensor.

(d) Gradually turn the sensor clockwise until the ohmme±

ter deflects, and secure it with the two set screws.

(e) Recheck the continuity between terminals IDL and E2.

Clearance between lever

and stop screwContinuity (IDL ± El)

0.90 mm (0.035 in.) 0.50 mm (0.002 in.)

No continuityContinuity

± EFI SYSTEMAir Induction System (Throttle Body (3S±FE w o ECT))FI±109

Page 1124 of 2389

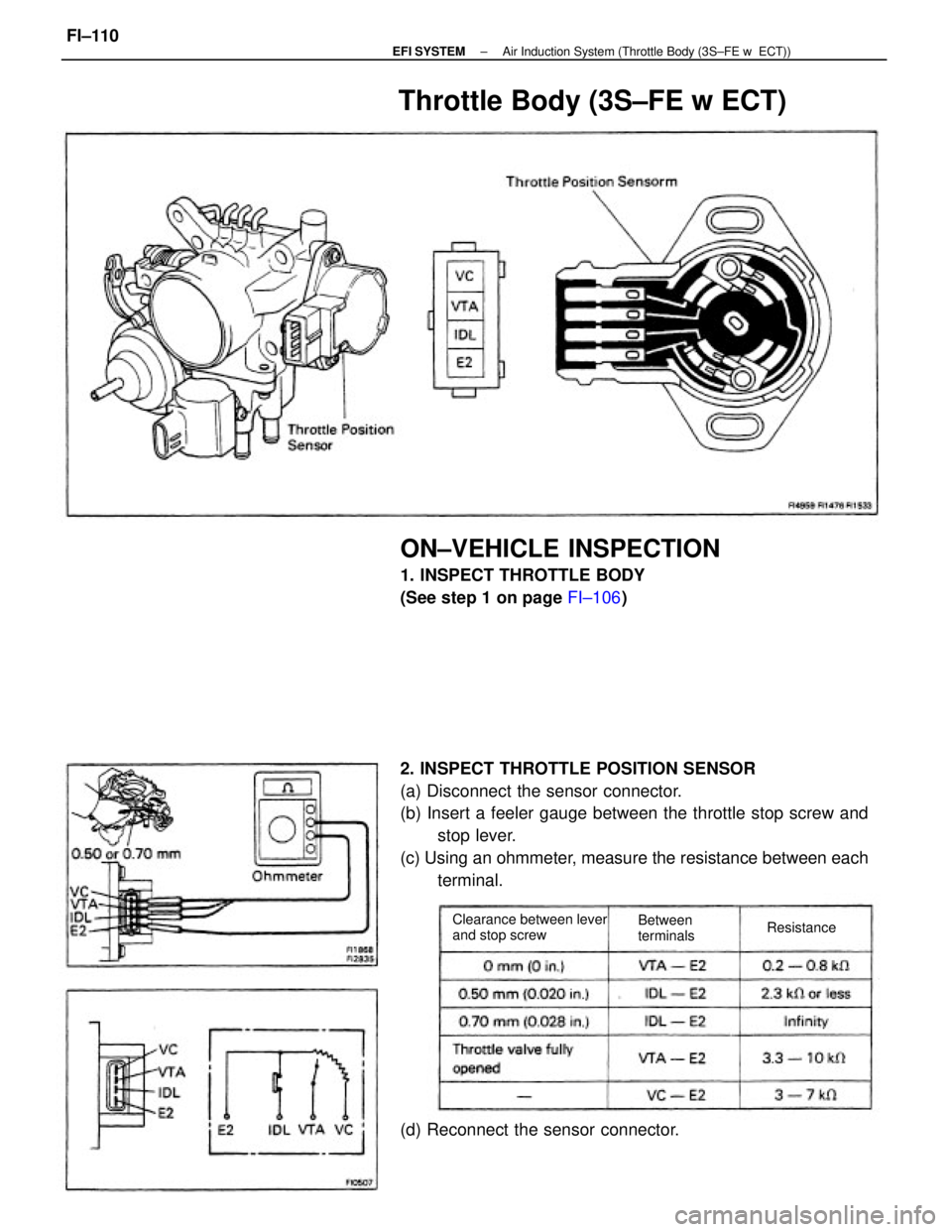

2. INSPECT THROTTLE POSITION SENSOR

(a) Disconnect the sensor connector.

(b) Insert a feeler gauge between the throttle stop screw and

stop lever.

(c) Using an ohmmeter, measure the resistance between each

terminal.

ON±VEHICLE INSPECTION

1. INSPECT THROTTLE BODY

(See step 1 on page FI±106)

Throttle Body (3S±FE w ECT)

(d) Reconnect the sensor connector.

Clearance between lever

and stop screwBetween

terminalsResistance

± EFI SYSTEMAir Induction System (Throttle Body (3S±FE w ECT))FI±110

Page 1125 of 2389

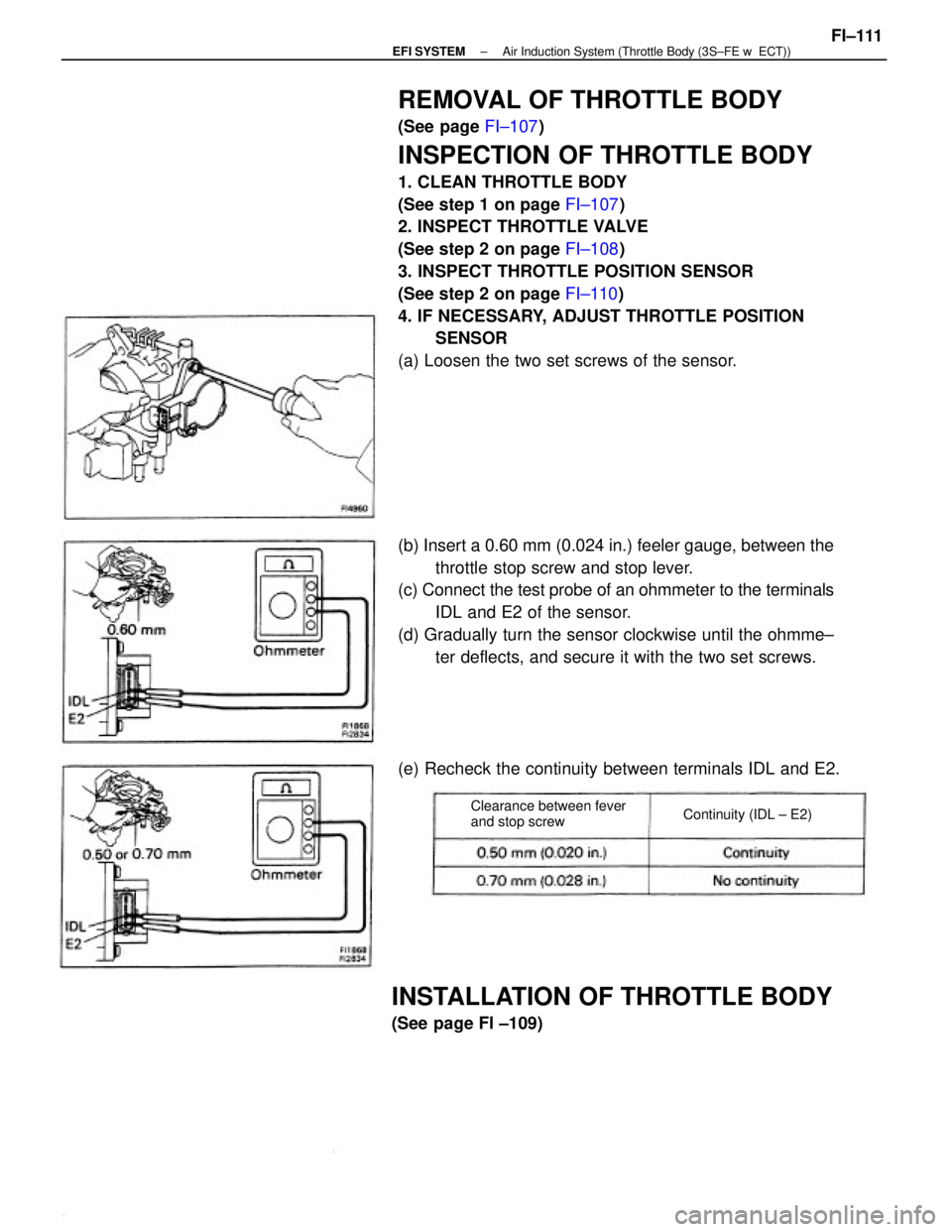

REMOVAL OF THROTTLE BODY

(See page FI±107)

INSPECTION OF THROTTLE BODY

1. CLEAN THROTTLE BODY

(See step 1 on page FI±107)

2. INSPECT THROTTLE VALVE

(See step 2 on page FI±108)

3. INSPECT THROTTLE POSITION SENSOR

(See step 2 on page FI±110)

4. IF NECESSARY, ADJUST THROTTLE POSITION

SENSOR

(a) Loosen the two set screws of the sensor.

(b) Insert a 0.60 mm (0.024 in.) feeler gauge, between the

throttle stop screw and stop lever.

(c) Connect the test probe of an ohmmeter to the terminals

IDL and E2 of the sensor.

(d) Gradually turn the sensor clockwise until the ohmme±

ter deflects, and secure it with the two set screws.

INSTALLATION OF THROTTLE BODY

(See page Fl ±109)(e) Recheck the continuity between terminals IDL and E2.

Clearance between fever

and stop screwContinuity (IDL ± E2)

± EFI SYSTEMAir Induction System (Throttle Body (3S±FE w ECT))FI±111

Page 1126 of 2389

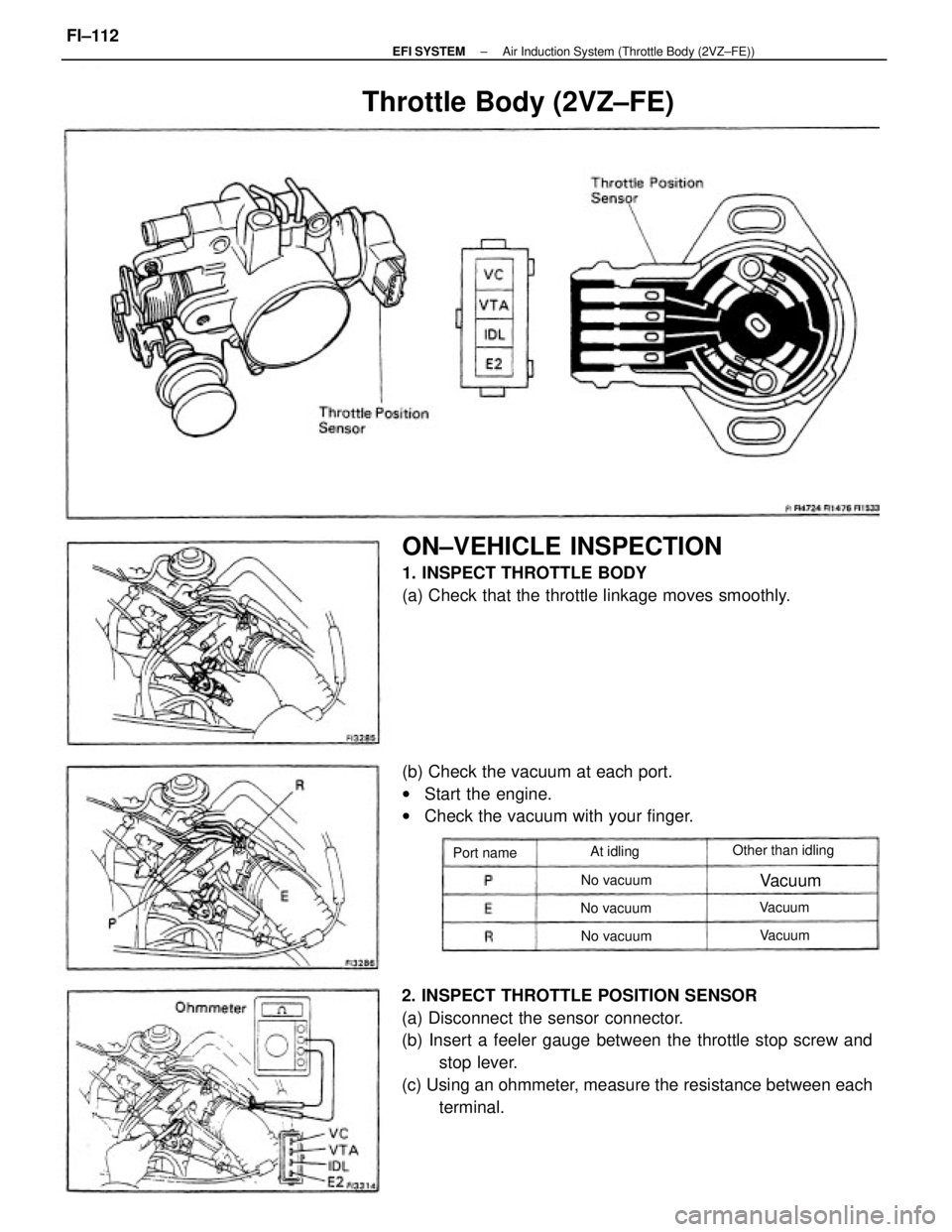

2. INSPECT THROTTLE POSITION SENSOR

(a) Disconnect the sensor connector.

(b) Insert a feeler gauge between the throttle stop screw and

stop lever.

(c) Using an ohmmeter, measure the resistance between each

terminal.

ON±VEHICLE INSPECTION

1. INSPECT THROTTLE BODY

(a) Check that the throttle linkage moves smoothly.

(b) Check the vacuum at each port.

wStart the engine.

wCheck the vacuum with your finger.

Throttle Body (2VZ±FE)

Other than idling

No vacuum No vacuum

No vacuum Port nameAt idling

Vacuum

Vacuum

Vacuum

± EFI SYSTEMAir Induction System (Throttle Body (2VZ±FE))FI±112

Page 1127 of 2389

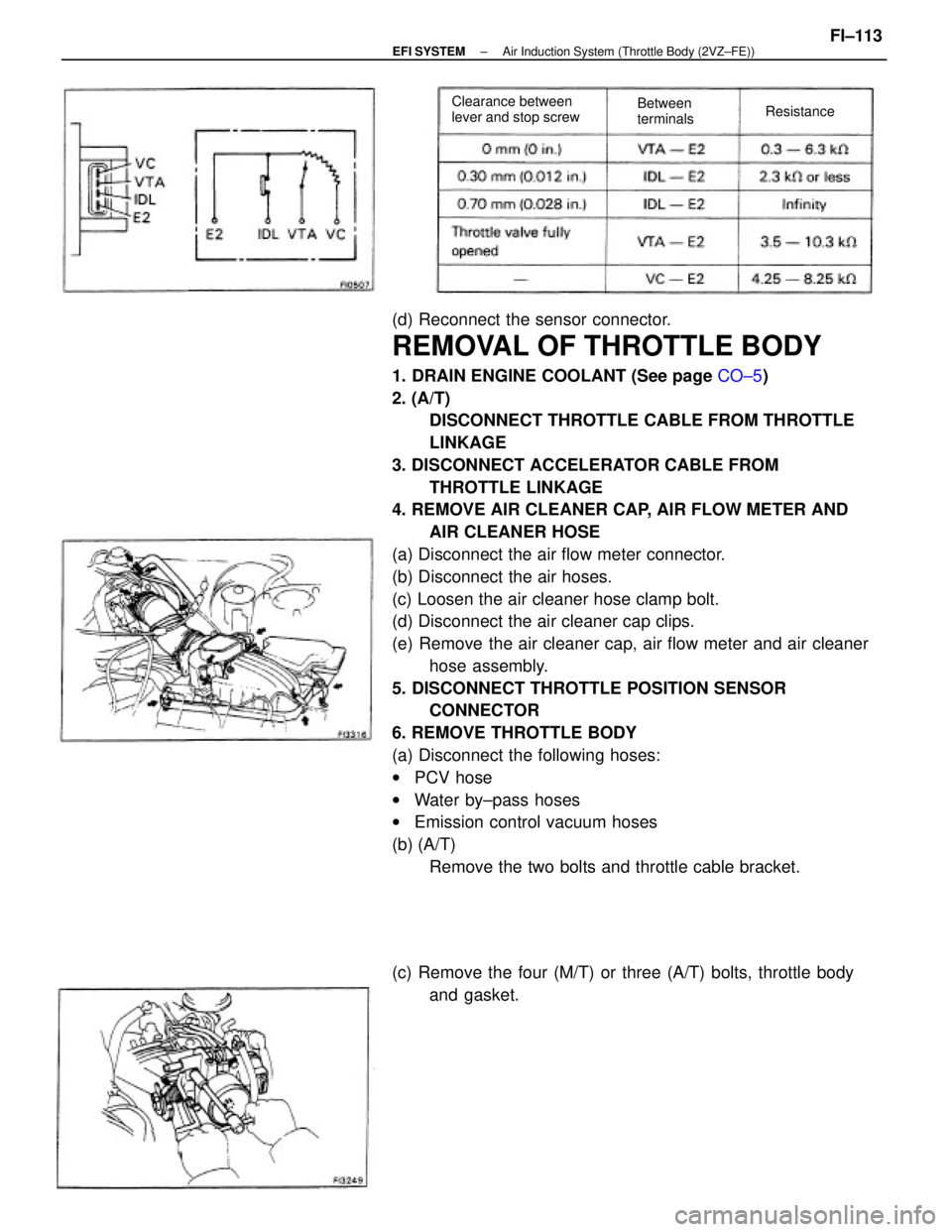

(d) Reconnect the sensor connector.

REMOVAL OF THROTTLE BODY

1. DRAIN ENGINE COOLANT (See page CO±5)

2. (A/T)

DISCONNECT THROTTLE CABLE FROM THROTTLE

LINKAGE

3. DISCONNECT ACCELERATOR CABLE FROM

THROTTLE LINKAGE

4. REMOVE AIR CLEANER CAP, AIR FLOW METER AND

AIR CLEANER HOSE

(a) Disconnect the air flow meter connector.

(b) Disconnect the air hoses.

(c) Loosen the air cleaner hose clamp bolt.

(d) Disconnect the air cleaner cap clips.

(e) Remove the air cleaner cap, air flow meter and air cleaner

hose assembly.

5. DISCONNECT THROTTLE POSITION SENSOR

CONNECTOR

6. REMOVE THROTTLE BODY

(a) Disconnect the following hoses:

wPCV hose

wWater by±pass hoses

wEmission control vacuum hoses

(b) (A/T)

Remove the two bolts and throttle cable bracket.

(c) Remove the four (M/T) or three (A/T) bolts, throttle body

and gasket.

Clearance between

lever and stop screwBetween

terminalsResistance

± EFI SYSTEMAir Induction System (Throttle Body (2VZ±FE))FI±113

Page 1128 of 2389

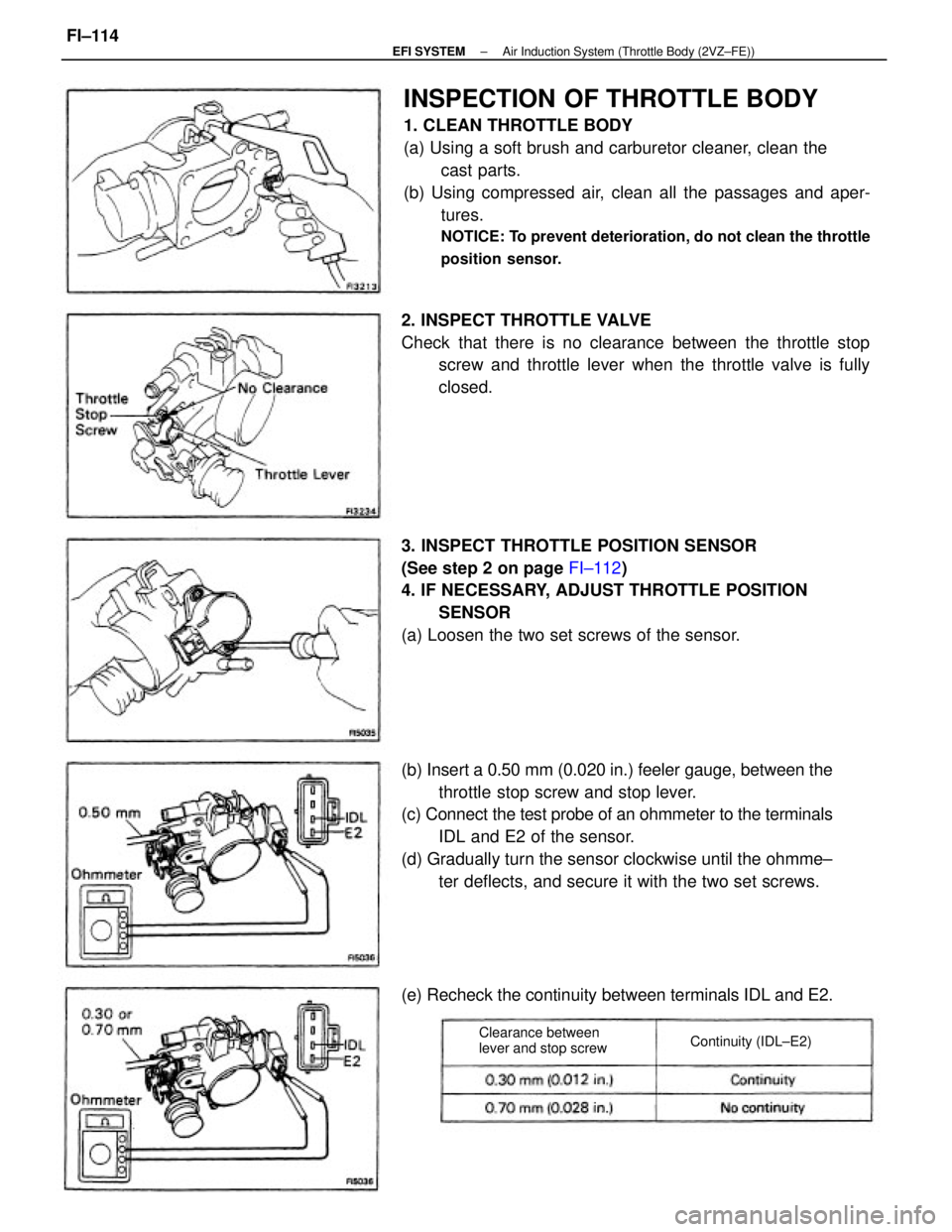

INSPECTION OF THROTTLE BODY

1. CLEAN THROTTLE BODY

(a) Using a soft brush and carburetor cleaner, clean the

cast parts.

(b) Using compressed air, clean all the passages and aper-

tures.

NOTICE: To prevent deterioration, do not clean the throttle

position sensor.

(b) Insert a 0.50 mm (0.020 in.) feeler gauge, between the

throttle stop screw and stop lever.

(c) Connect the test probe of an ohmmeter to the terminals

IDL and E2 of the sensor.

(d) Gradually turn the sensor clockwise until the ohmme±

ter deflects, and secure it with the two set screws. 3. INSPECT THROTTLE POSITION SENSOR

(See step 2 on page FI±112)

4. IF NECESSARY, ADJUST THROTTLE POSITION

SENSOR

(a) Loosen the two set screws of the sensor. 2. INSPECT THROTTLE VALVE

Check that there is no clearance between the throttle stop

screw and throttle lever when the throttle valve is fully

closed.

(e) Recheck the continuity between terminals IDL and E2.

Clearance between

lever and stop screwContinuity (IDL±E2)

± EFI SYSTEMAir Induction System (Throttle Body (2VZ±FE))FI±114