ECU TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1932 of 2389

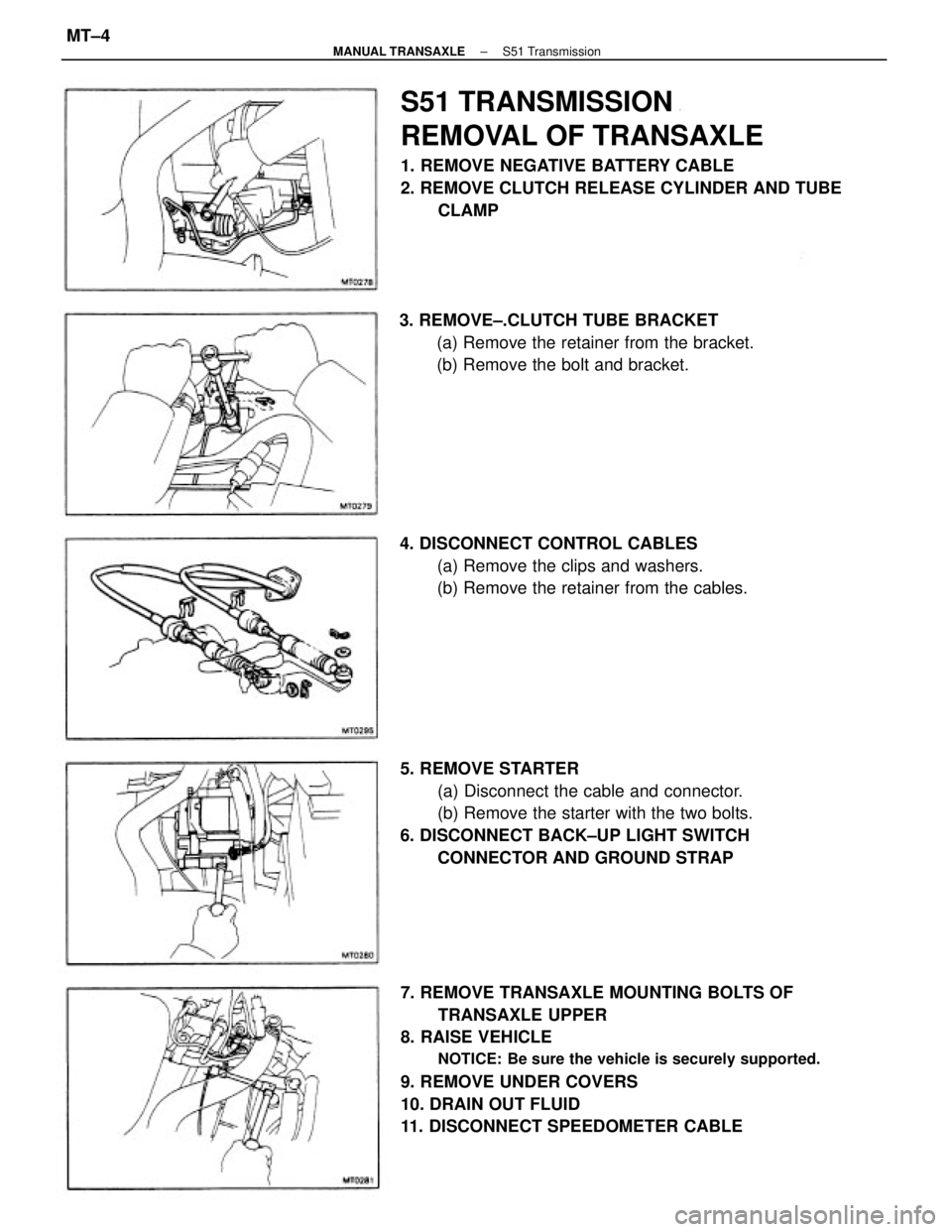

7. REMOVE TRANSAXLE MOUNTING BOLTS OF

TRANSAXLE UPPER

8. RAISE VEHICLE

NOTICE: Be sure the vehicle is securely supported.

9. REMOVE UNDER COVERS

10. DRAIN OUT FLUID

11. DISCONNECT SPEEDOMETER CABLE

S51 TRANSMISSION

REMOVAL OF TRANSAXLE

1. REMOVE NEGATIVE BATTERY CABLE

2. REMOVE CLUTCH RELEASE CYLINDER AND TUBE

CLAMP

5. REMOVE STARTER

(a) Disconnect the cable and connector.

(b) Remove the starter with the two bolts.

6. DISCONNECT BACK±UP LIGHT SWITCH

CONNECTOR AND GROUND STRAP 3. REMOVE±.CLUTCH TUBE BRACKET

(a) Remove the retainer from the bracket.

(b) Remove the bolt and bracket.

4. DISCONNECT CONTROL CABLES

(a) Remove the clips and washers.

(b) Remove the retainer from the cables.

± MANUAL TRANSAXLES51 TransmissionMT±4

Page 1938 of 2389

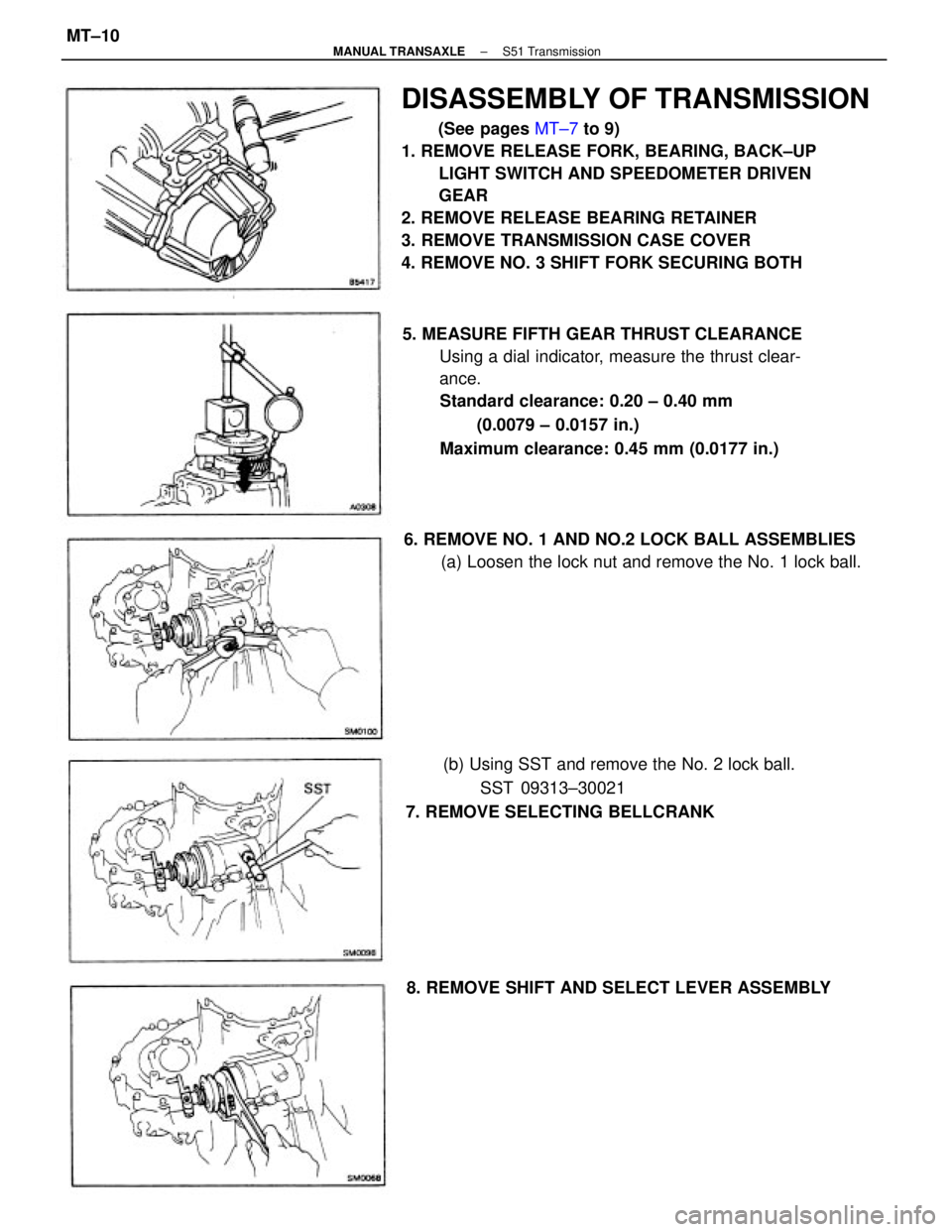

DISASSEMBLY OF TRANSMISSION

(See pages MT±7 to 9)

1. REMOVE RELEASE FORK, BEARING, BACK±UP

LIGHT SWITCH AND SPEEDOMETER DRIVEN

GEAR

2. REMOVE RELEASE BEARING RETAINER

3. REMOVE TRANSMISSION CASE COVER

4. REMOVE NO. 3 SHIFT FORK SECURING BOTH

5. MEASURE FIFTH GEAR THRUST CLEARANCE

Using a dial indicator, measure the thrust clear-

ance.

Standard clearance: 0.20 ± 0.40 mm

(0.0079 ± 0.0157 in.)

Maximum clearance: 0.45 mm (0.0177 in.)

(b) Using SST and remove the No. 2 lock ball.

SST 09313±30021

7. REMOVE SELECTING BELLCRANK 6. REMOVE NO. 1 AND NO.2 LOCK BALL ASSEMBLIES

(a) Loosen the lock nut and remove the No. 1 lock ball.

8. REMOVE SHIFT AND SELECT LEVER ASSEMBLY

± MANUAL TRANSAXLES51 TransmissionMT±10

Page 1952 of 2389

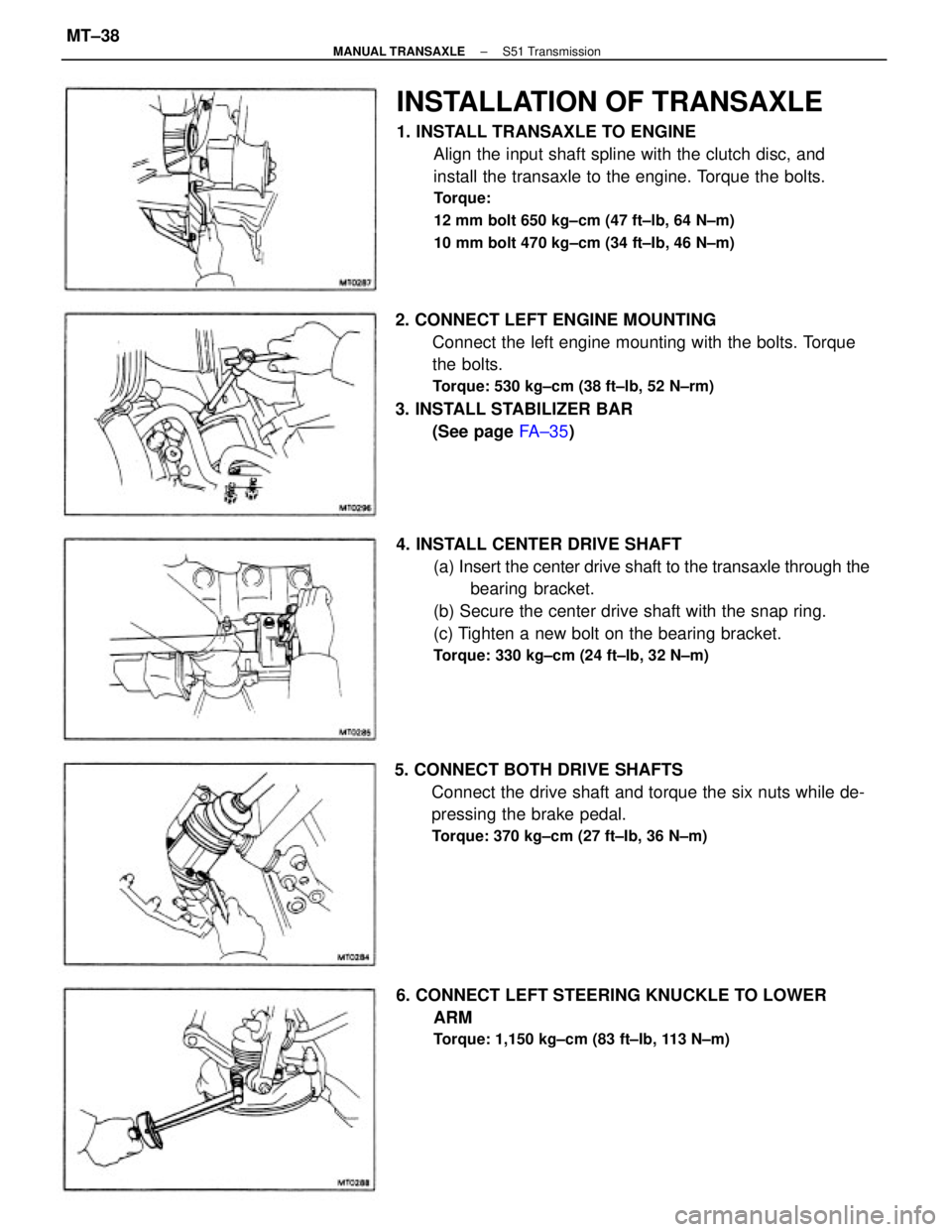

INSTALLATION OF TRANSAXLE

1. INSTALL TRANSAXLE TO ENGINE

Align the input shaft spline with the clutch disc, and

install the transaxle to the engine. Torque the bolts.

Torque:

12 mm bolt 650 kg±cm (47 ft±lb, 64 N±m)

10 mm bolt 470 kg±cm (34 ft±Ib, 46 N±m)

2. CONNECT LEFT ENGINE MOUNTING

Connect the left engine mounting with the bolts. Torque

the bolts.

Torque: 530 kg±cm (38 ft±lb, 52 N±rm)

3. INSTALL STABILIZER BAR

(See page FA±35)

4. INSTALL CENTER DRIVE SHAFT

(a) Insert the center drive shaft to the transaxle through the

bearing bracket.

(b) Secure the center drive shaft with the snap ring.

(c) Tighten a new bolt on the bearing bracket.

Torque: 330 kg±cm (24 ft±lb, 32 N±m)

5. CONNECT BOTH DRIVE SHAFTS

Connect the drive shaft and torque the six nuts while de-

pressing the brake pedal.

Torque: 370 kg±cm (27 ft±Ib, 36 N±m)

6. CONNECT LEFT STEERING KNUCKLE TO LOWER

ARM

Torque: 1,150 kg±cm (83 ft±Ib, 113 N±m)

± MANUAL TRANSAXLES51 TransmissionMT±38

Page 1967 of 2389

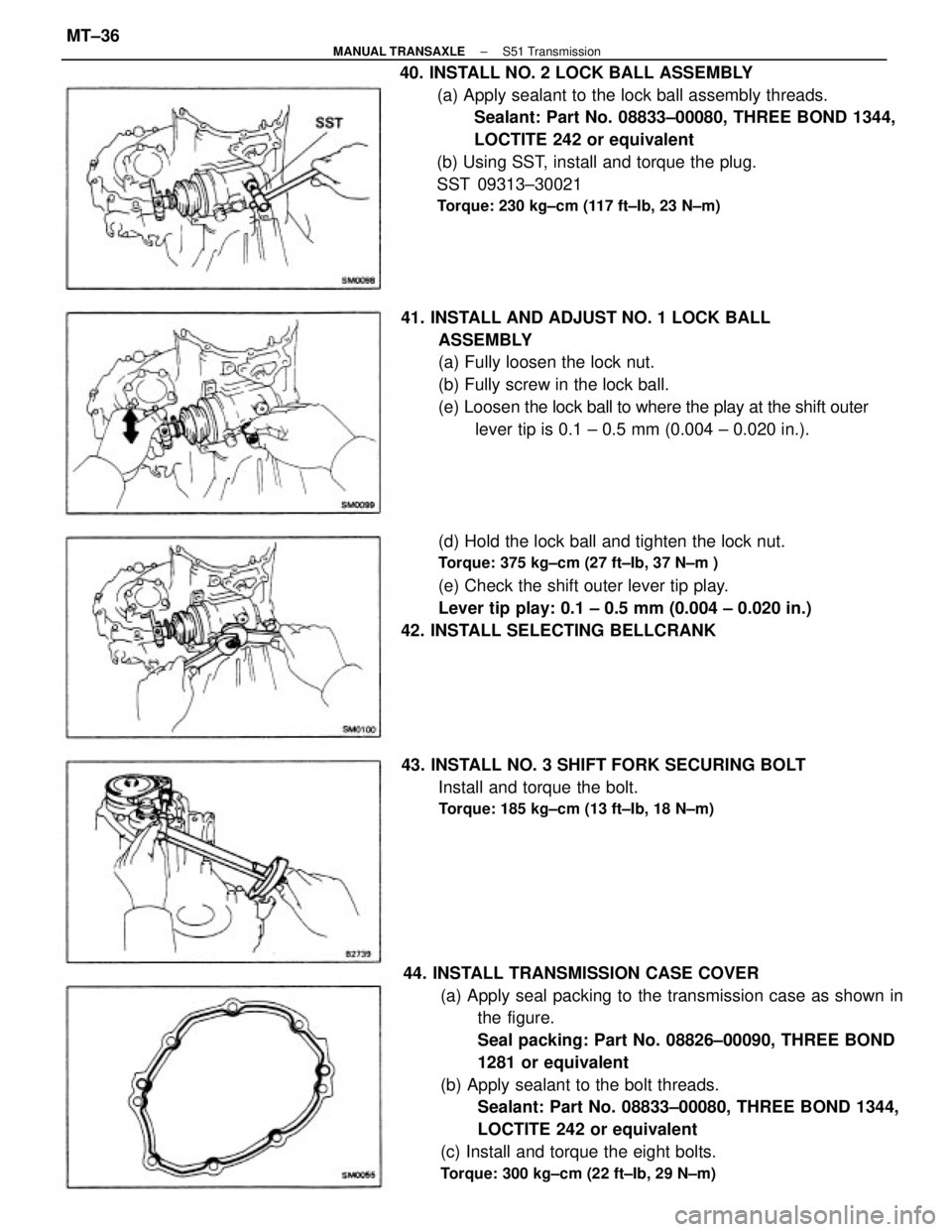

44. INSTALL TRANSMISSION CASE COVER

(a) Apply seal packing to the transmission case as shown in

the figure.

Seal packing: Part No. 08826±00090, THREE BOND

1281 or equivalent

(b) Apply sealant to the bolt threads.

Sealant: Part No. 08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(c) Install and torque the eight bolts.

Torque: 300 kg±cm (22 ft±Ib, 29 N±m)

40. INSTALL NO. 2 LOCK BALL ASSEMBLY

(a) Apply sealant to the lock ball assembly threads.

Sealant: Part No. 08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(b) Using SST, install and torque the plug.

SST 09313±30021

Torque: 230 kg±cm (117 ft±Ib, 23 N±m)

41. INSTALL AND ADJUST NO. 1 LOCK BALL

ASSEMBLY

(a) Fully loosen the lock nut.

(b) Fully screw in the lock ball.

(e) Loosen the lock ball to where the play at the shift outer

lever tip is 0.1 ± 0.5 mm (0.004 ± 0.020 in.).

(d) Hold the lock ball and tighten the lock nut.

Torque: 375 kg±cm (27 ft±Ib, 37 N±m )

(e) Check the shift outer lever tip play.

Lever tip play: 0.1 ± 0.5 mm (0.004 ± 0.020 in.)

42. INSTALL SELECTING BELLCRANK

43. INSTALL NO. 3 SHIFT FORK SECURING BOLT

Install and torque the bolt.

Torque: 185 kg±cm (13 ft±Ib, 18 N±m)

± MANUAL TRANSAXLES51 TransmissionMT±36

Page 2016 of 2389

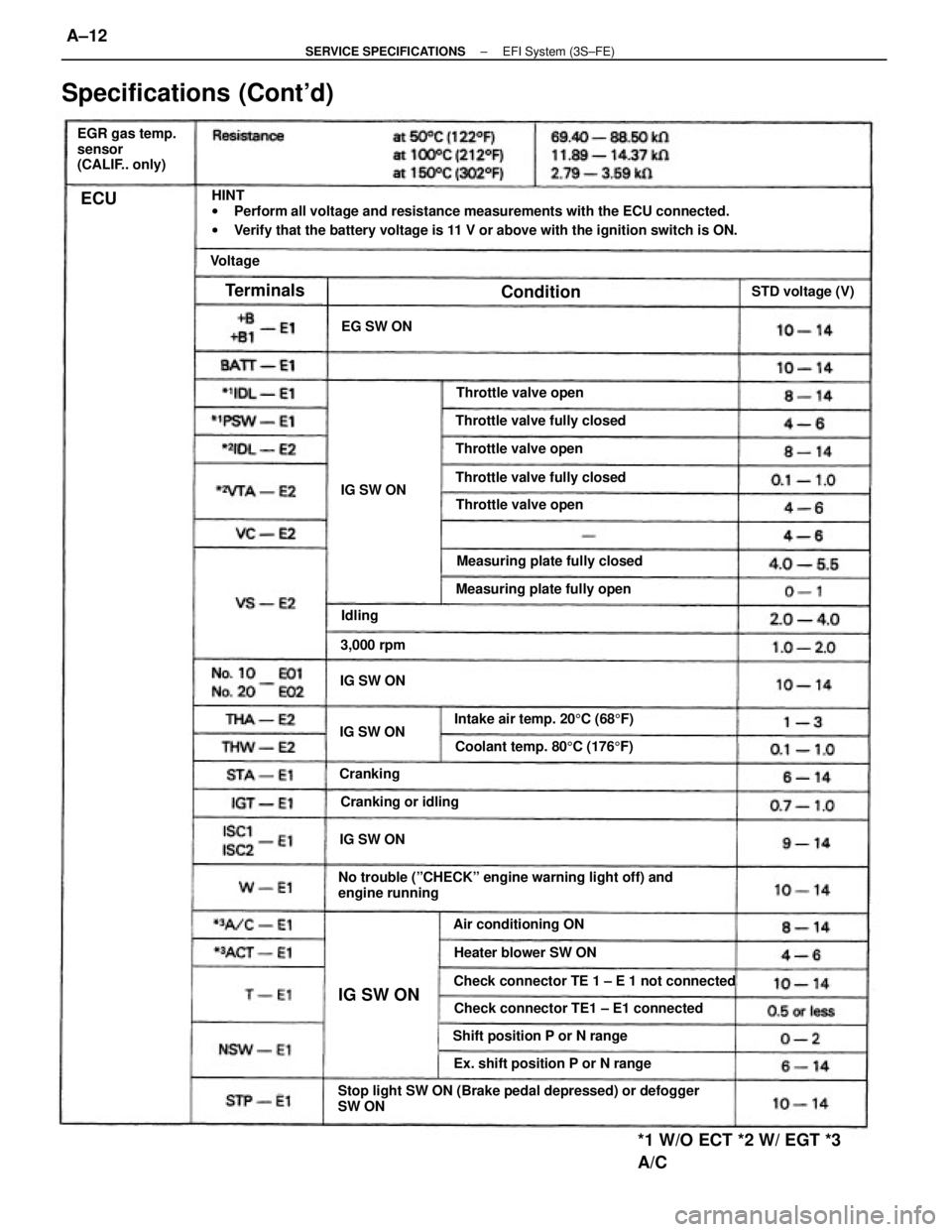

KEY±LESS TYPE SYNCHROMESH

FUNCTION

* HUB SLEEVE

There are three protrusions on the inside of the hub sleeve to

push the key spring.

* CLUTCH HUB

Three apertures are located around the clutch hub to secure the

synchronizer ring and key spring in place.

* KEY SPRING

The key spring has four claws. One claw is to secure the key spring

in place. Three claws also act as shifting keys as well as key

springs.

SYNCHRONIZER RING

A chamfered ledge is provided at three points along the outer pe-

riphery and a bolt is provided in each to secure a key spring. wThe oil used in each transaxle is as follows:

Transaxle oil E50 (08885±80206)

Recommended oil

Oil grade: AN GL±5

Viscosity: SAE 75W±90 or 80W±90

Above ±18

°C (0°F) SAE 90

Above ± 1 8°C (0°F) SAE 84W

wOil capacity: 5.0 Liters (s.3 Us qts, 4.4 Imp. qts)

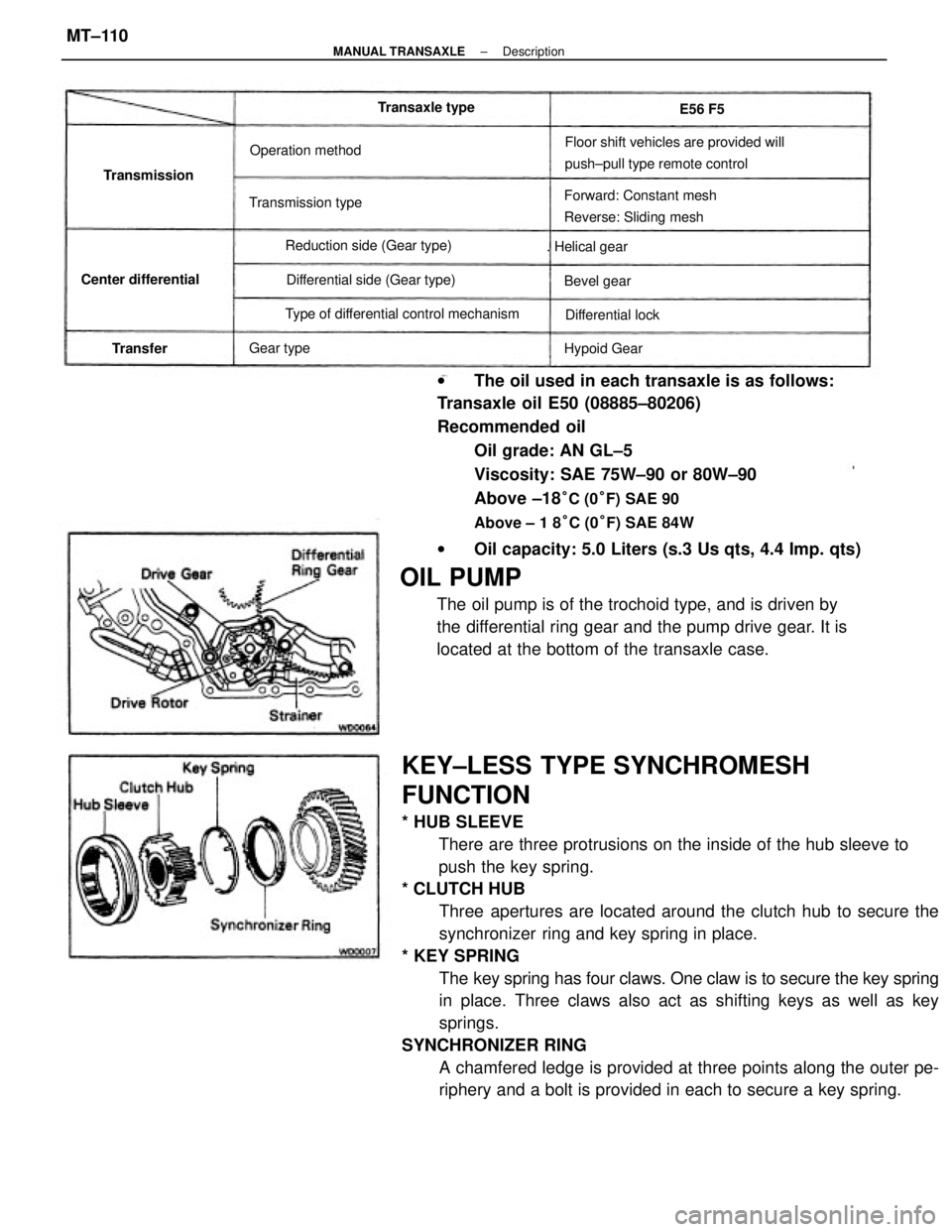

OIL PUMP

The oil pump is of the trochoid type, and is driven by

the differential ring gear and the pump drive gear. It is

located at the bottom of the transaxle case.

Floor shift vehicles are provided will

push±pull type remote control

Forward: Constant mesh

Reverse: Sliding mesh

Type of differential control mechanismDifferential side (Gear type) Reduction side (Gear type) Transmission typeOperation method

Center differential. Helical gear

Differential lock Transaxle type

Hypoid Gear Transmission

Bevel gear

Gear type

TransferE56 F5

± MANUAL TRANSAXLEDescriptionMT±110

Page 2223 of 2389

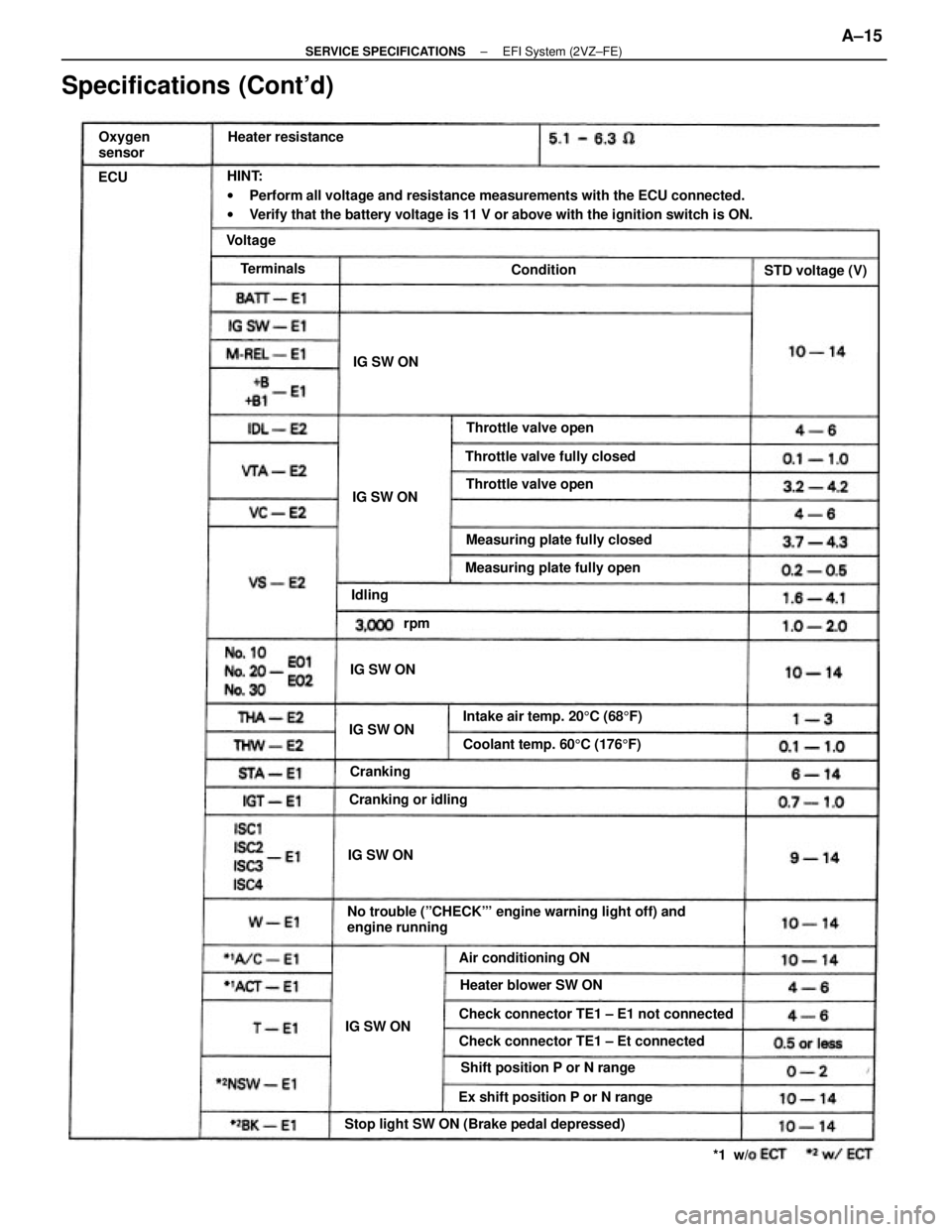

HINT

wPerform all voltage and resistance measurements with the ECU connected.

wVerify that the battery voltage is 11 V or above with the ignition switch is ON.

Stop light SW ON (Brake pedal depressed) or defogger

SW ONNo trouble (ºCHECKº engine warning light off) and

engine running

Check connector TE 1 ± E 1 not connected

Specifications (Cont'd)

Check connector TE1 ± E1 connected

*1 W/O ECT *2 W/ EGT *3

A/C

EGR gas temp.

sensor

(CALIF.. only)

Ex. shift position P or N rangeIntake air temp. 205C (685F) Measuring plate fully closed

Coolant temp. 805C (1765F)

Shift position P or N rangeMeasuring plate fully open Throttle valve fully closed

Throttle valve fully closed

Heater blower SW ON Air conditioning ONThrottle valve open

Throttle valve open

Throttle valve open

Cranking or idlingSTD voltage (V)

3,000 rpmEG SW ON

IG SW ON IG SW ONIG SW ONIG SW ON

IG SW ON

Cranking

Terminals

Condition

Voltage

Idling

ECU

± SERVICE SPECIFICATIONSEFI System (3S±FE)A±12

Page 2224 of 2389

Fuel tank band x Body

Cold start injector x Air intake chamber

Cold start injector pipe x Cold start injector

Cold start injector pipe x Delivery pipe

Fuel pressure regulator X Delivery pipe

Fuel return pipe x Fuel pressure regulator

Delivery pipe x Cylinder head

Throttle body x Air intake chamberFuel evaporation vent tube x Fuel tank 4WD

Fuel inlet pipe x Fuel tankFuel sender gauge

Fuel pump X Fuel tank

Specifications (Cont'd)

Torque Specifications

Coolant temp. 805C (1765F) Intake air temp. 205C (685F) Measuring plate fully closed

Measuring plate fully openThrottle valve fully closed

Throttle valve fully closedThrottle valve fully closedThrottle valve fully closed

Throttle valve fully openThrottle valve fully open

* 1 w/o ECT *2 w/ ECT Throttle valve openThrottle valve open

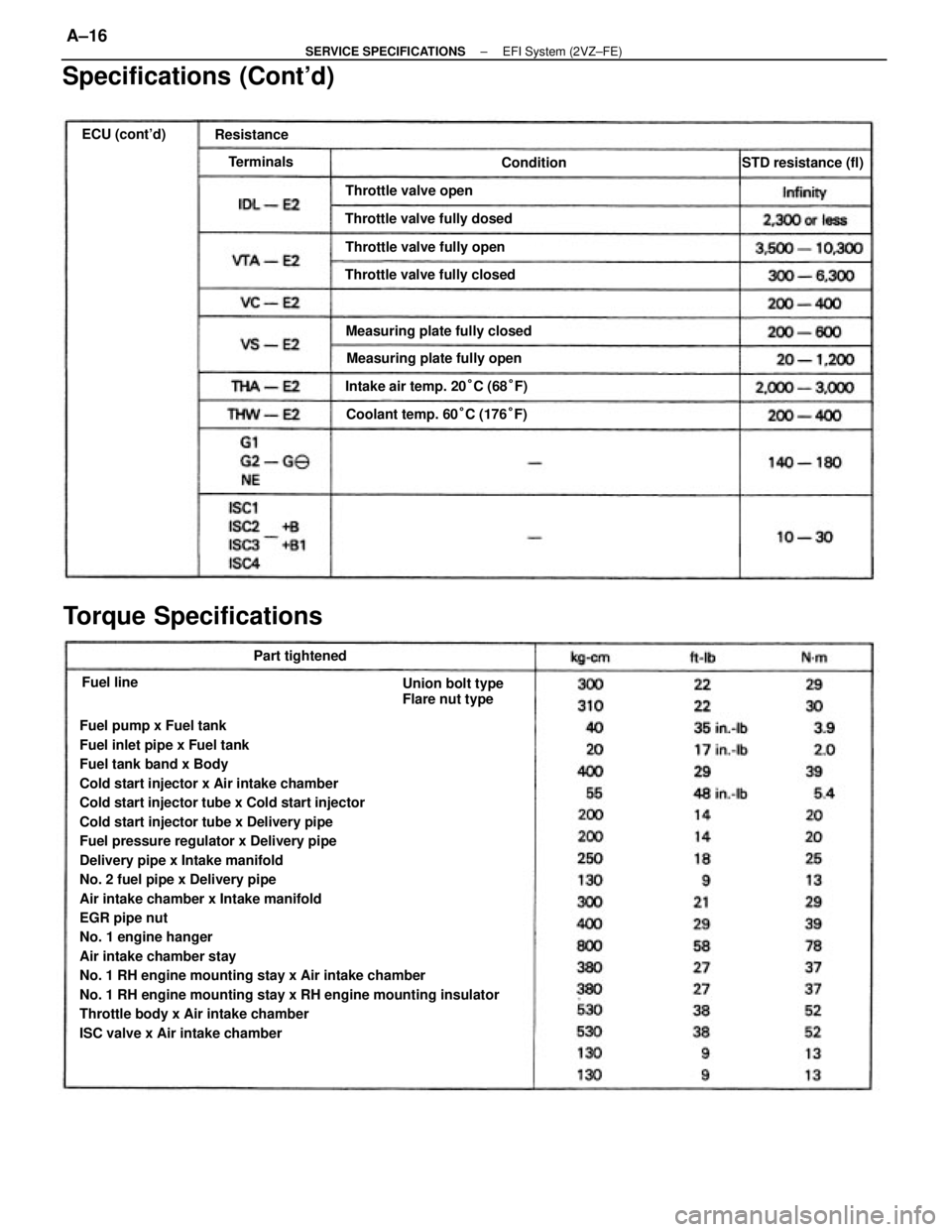

Part tightened ECU (cont'd) Resistance

Condition

Fuel line

± SERVICE SPECIFICATIONSEFI System (3S±FE)A±13

Page 2227 of 2389

HINT:

wPerform all voltage and resistance measurements with the ECU connected.

wVerify that the battery voltage is 11 V or above with the ignition switch is ON.

No trouble (ºCHECKº' engine warning light off) and

engine running

Specifications (Cont'd)

Stop light SW ON (Brake pedal depressed)Check connector TE1 ± E1 not connected

Check connector TE1 ± Et connected

Shift position P or N range

Ex shift position P or N rangeIntake air temp. 205C (685F) Measuring plate fully closed

Coolant temp. 605C (1765F) Measuring plate fully open Throttle valve fully closed

Heater blower SW ON Air conditioning ONThrottle valve open

Throttle valve open

Cranking or idling Heater resistance

STD voltage (V) Oxygen

sensor

IG SW ON

IG SW ONIG SW ON

IG SW ONIG SW ON

IG SW ONCranking Terminals

Condition Voltage

Idling

*1 w/ rpm ECU

± SERVICE SPECIFICATIONSEFI System (2VZ±FE)A±15

Page 2228 of 2389

Fuel pump x Fuel tank

Fuel inlet pipe x Fuel tank

Fuel tank band x Body

Cold start injector x Air intake chamber

Cold start injector tube x Cold start injector

Cold start injector tube x Delivery pipe

Fuel pressure regulator x Delivery pipe

Delivery pipe x Intake manifold

No. 2 fuel pipe x Delivery pipe

Air intake chamber x Intake manifold

EGR pipe nut

No. 1 engine hanger

Air intake chamber stay

No. 1 RH engine mounting stay x Air intake chamber

No. 1 RH engine mounting stay x RH engine mounting insulator

Throttle body x Air intake chamber

ISC valve x Air intake chamber

Specifications (Cont'd)

Torque Specifications

Intake air temp. 20°C (68°F) Measuring plate fully closed

Coolant temp. 60°C (176°F)

Union bolt type

Flare nut type Measuring plate fully open Throttle valve fully dosed

Throttle valve fully closedThrottle valve fully open Throttle valve openSTD resistance (fl)

Part tightened ECU (cont'd)

Resistance

Terminals

Condition

Fuel line

± SERVICE SPECIFICATIONSEFI System (2VZ±FE)A±16

Page 2337 of 2389

The oil seals on both sides of the power cylinder

are for the prevention of leakage of the high

pressure fluid which acts on the piston. Always

use new oil seals when reassembling and be

very careful not to scratch or damage them.

Because of the high pressure, even the slightest

scratch will cause fluid leakage, resulting in an

inoperative power steering system.

Also, be very careful not to scratch the sliding

portion of the rack which makes contact with the

oil seals. When removing the rack ends from the

rack, it is very easy to cause a burr when hold-

ing the tip of the rack with a wrench. Therefore,

before assembling the rack, first check the tip for

burrs and remove any with an oil stone.

Teflon rings are used for the piston and control

valve. These teflon rings are highly durable

against wear, but if it is necessary to replace

them, be careful not to stretch the new ones.

After installing a teflon ring into its groove, snug

it down into the groove before assembly of the

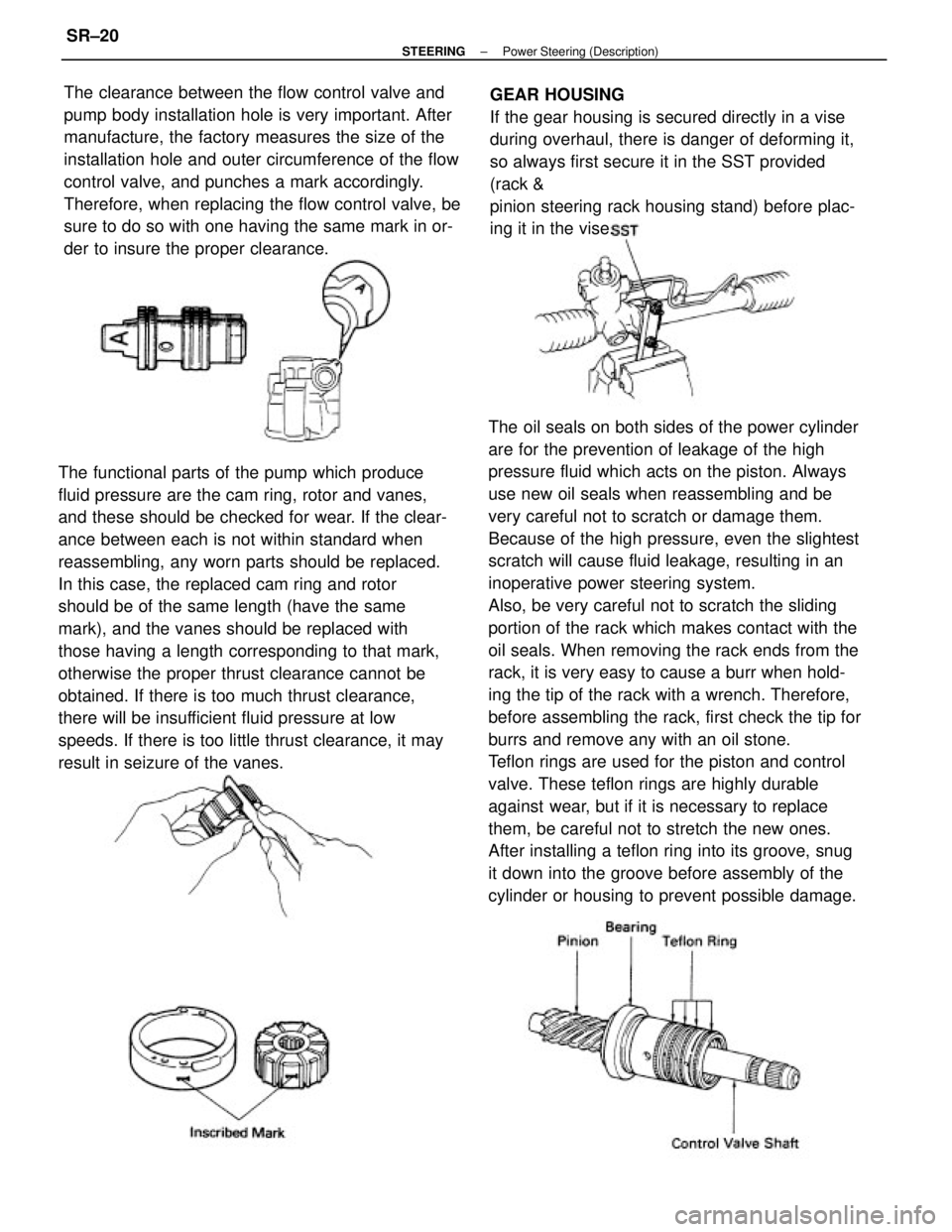

cylinder or housing to prevent possible damage. The functional parts of the pump which produce

fluid pressure are the cam ring, rotor and vanes,

and these should be checked for wear. If the clear-

ance between each is not within standard when

reassembling, any worn parts should be replaced.

In this case, the replaced cam ring and rotor

should be of the same length (have the same

mark), and the vanes should be replaced with

those having a length corresponding to that mark,

otherwise the proper thrust clearance cannot be

obtained. If there is too much thrust clearance,

there will be insufficient fluid pressure at low

speeds. If there is too little thrust clearance, it may

result in seizure of the vanes.The clearance between the flow control valve and

pump body installation hole is very important. After

manufacture, the factory measures the size of the

installation hole and outer circumference of the flow

control valve, and punches a mark accordingly.

Therefore, when replacing the flow control valve, be

sure to do so with one having the same mark in or-

der to insure the proper clearance.GEAR HOUSING

If the gear housing is secured directly in a vise

during overhaul, there is danger of deforming it,

so always first secure it in the SST provided

(rack &

pinion steering rack housing stand) before plac-

ing it in the vise.

± STEERINGPower Steering (Description)SR±20