alternator TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 968 of 2389

Rectifiers (Rectifier Holder)

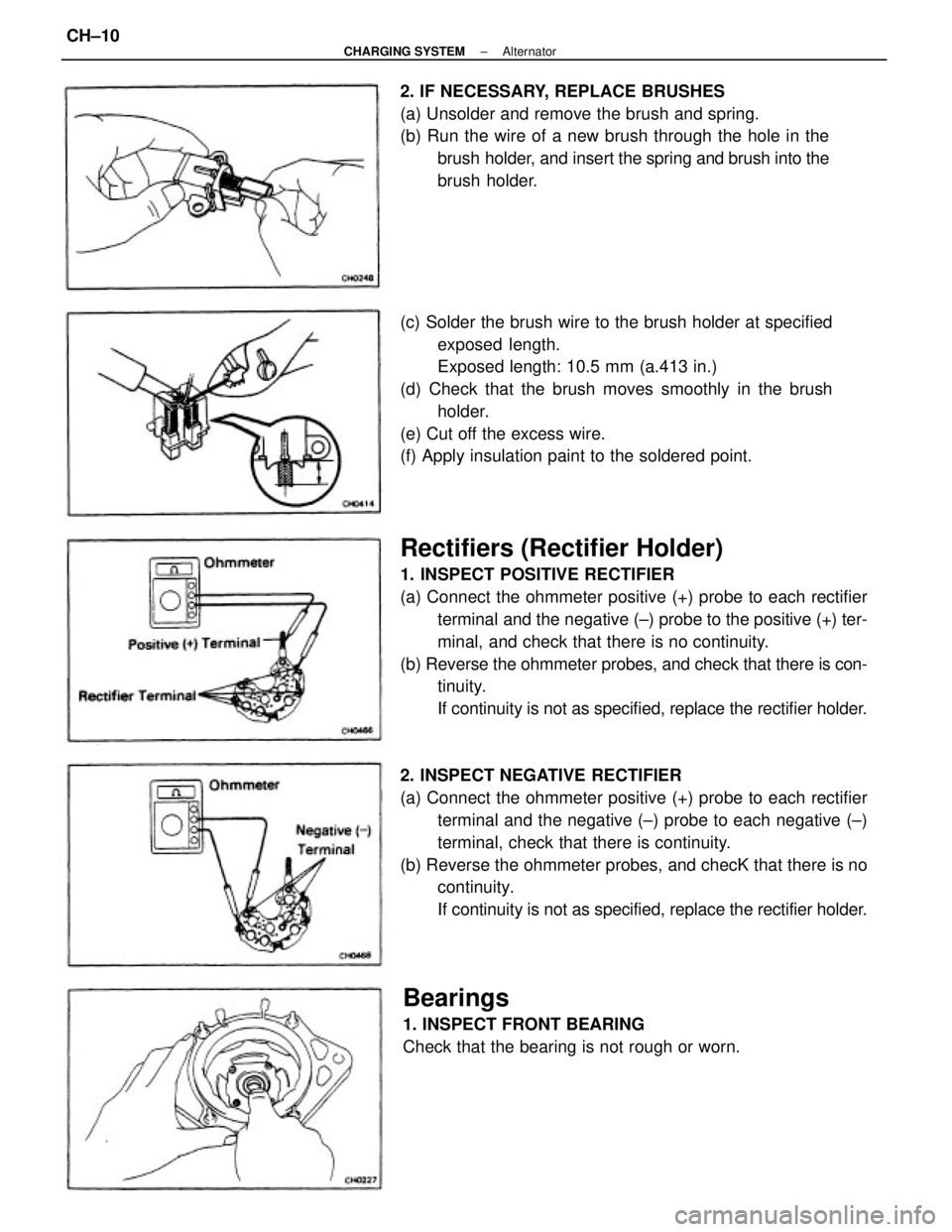

1. INSPECT POSITIVE RECTIFIER

(a) Connect the ohmmeter positive (+) probe to each rectifier

terminal and the negative (±) probe to the positive (+) ter-

minal, and check that there is no continuity.

(b) Reverse the ohmmeter probes, and check that there is con-

tinuity.

If continuity is not as specified, replace the rectifier holder.

2. INSPECT NEGATIVE RECTIFIER

(a) Connect the ohmmeter positive (+) probe to each rectifier

terminal and the negative (±) probe to each negative (±)

terminal, check that there is continuity.

(b) Reverse the ohmmeter probes, and checK that there is no

continuity.

If continuity is not as specified, replace the rectifier holder. (c) Solder the brush wire to the brush holder at specified

exposed length.

Exposed length: 10.5 mm (a.413 in.)

(d) Check that the brush moves smoothly in the brush

holder.

(e) Cut off the excess wire.

(f) Apply insulation paint to the soldered point. 2. IF NECESSARY, REPLACE BRUSHES

(a) Unsolder and remove the brush and spring.

(b) Run the wire of a new brush through the hole in the

brush holder, and insert the spring and brush into the

brush holder.

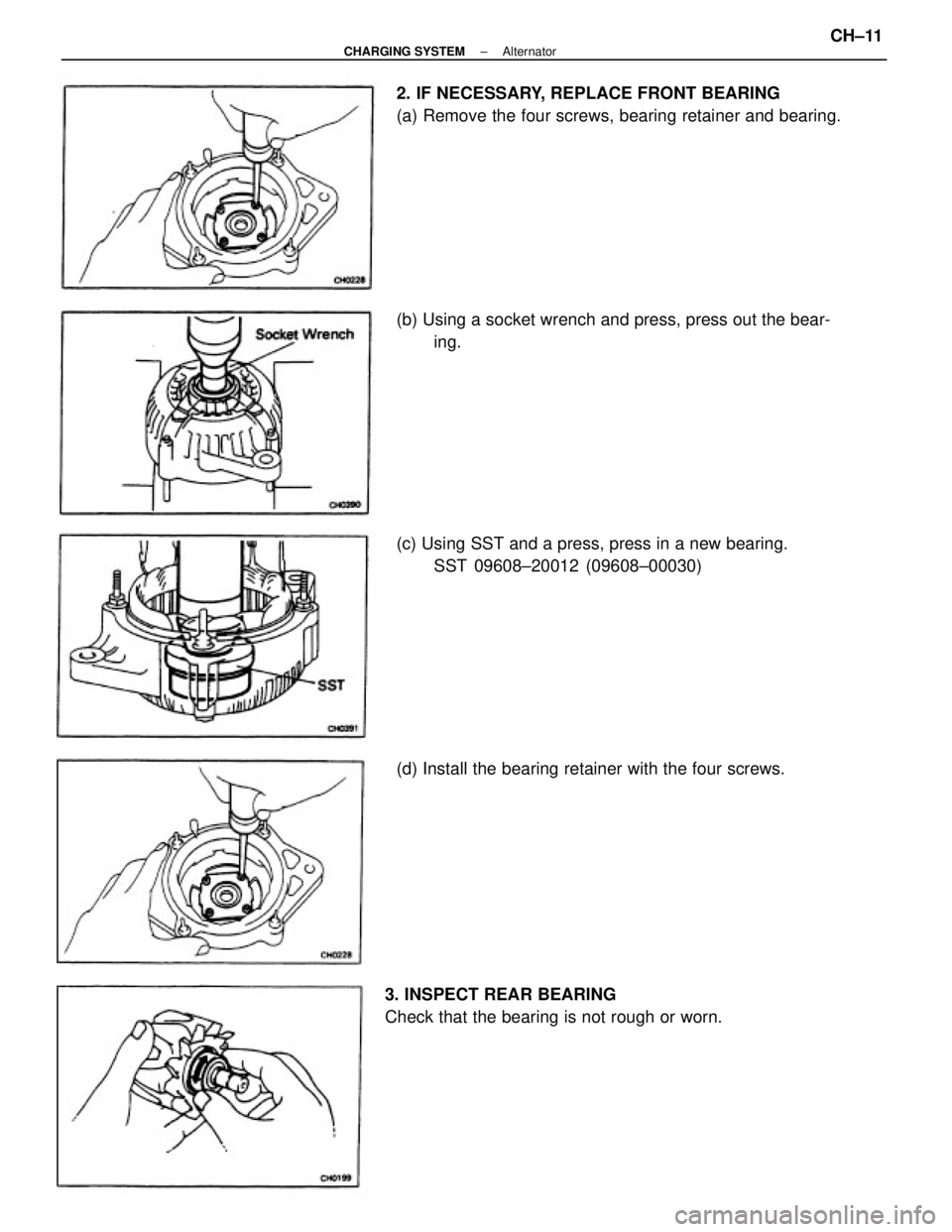

Bearings

1. INSPECT FRONT BEARING

Check that the bearing is not rough or worn.

± CHARGING SYSTEMAlternatorCH±10

Page 969 of 2389

2. IF NECESSARY, REPLACE FRONT BEARING

(a) Remove the four screws, bearing retainer and bearing.

(c) Using SST and a press, press in a new bearing.

SST 09608±20012 (09608±00030)

3. INSPECT REAR BEARING

Check that the bearing is not rough or worn.(b) Using a socket wrench and press, press out the bear-

ing.

(d) Install the bearing retainer with the four screws.

± CHARGING SYSTEMAlternatorCH±11

Page 970 of 2389

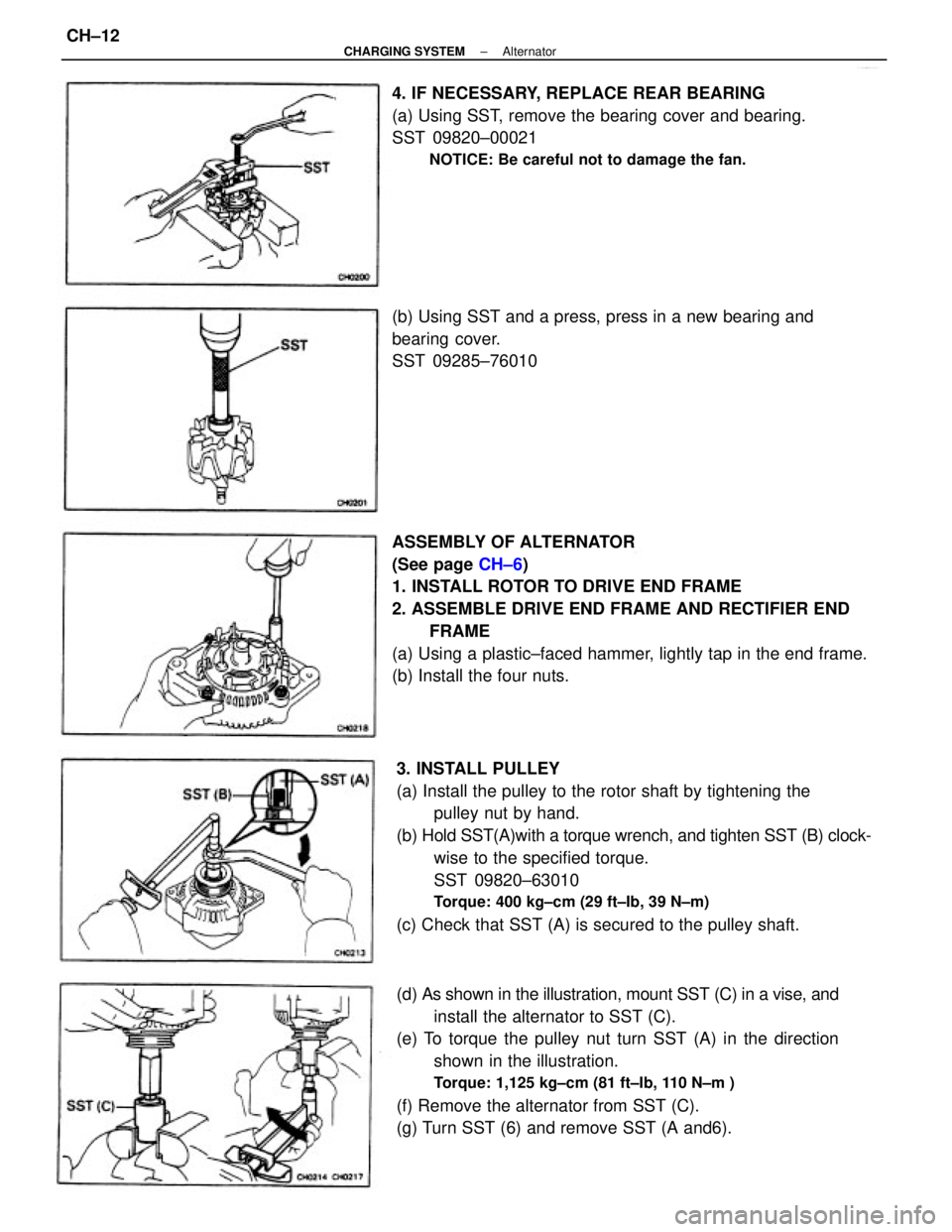

ASSEMBLY OF ALTERNATOR

(See page CH±6)

1. INSTALL ROTOR TO DRIVE END FRAME

2. ASSEMBLE DRIVE END FRAME AND RECTIFIER END

FRAME

(a) Using a plastic±faced hammer, lightly tap in the end frame.

(b) Install the four nuts.

3. INSTALL PULLEY

(a) Install the pulley to the rotor shaft by tightening the

pulley nut by hand.

(b) Hold SST(A)with a torque wrench, and tighten SST (B) clock-

wise to the specified torque.

SST 09820±63010

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

(c) Check that SST (A) is secured to the pulley shaft.

(d) As shown in the illustration, mount SST (C) in a vise, and

install the alternator to SST (C).

(e) To torque the pulley nut turn SST (A) in the direction

shown in the illustration.

Torque: 1,125 kg±cm (81 ft±Ib, 110 N±m )

(f) Remove the alternator from SST (C).

(g) Turn SST (6) and remove SST (A and6). 4. IF NECESSARY, REPLACE REAR BEARING

(a) Using SST, remove the bearing cover and bearing.

SST 09820±00021

NOTICE: Be careful not to damage the fan.

(b) Using SST and a press, press in a new bearing and

bearing cover.

SST 09285±76010

± CHARGING SYSTEMAlternatorCH±12

Page 971 of 2389

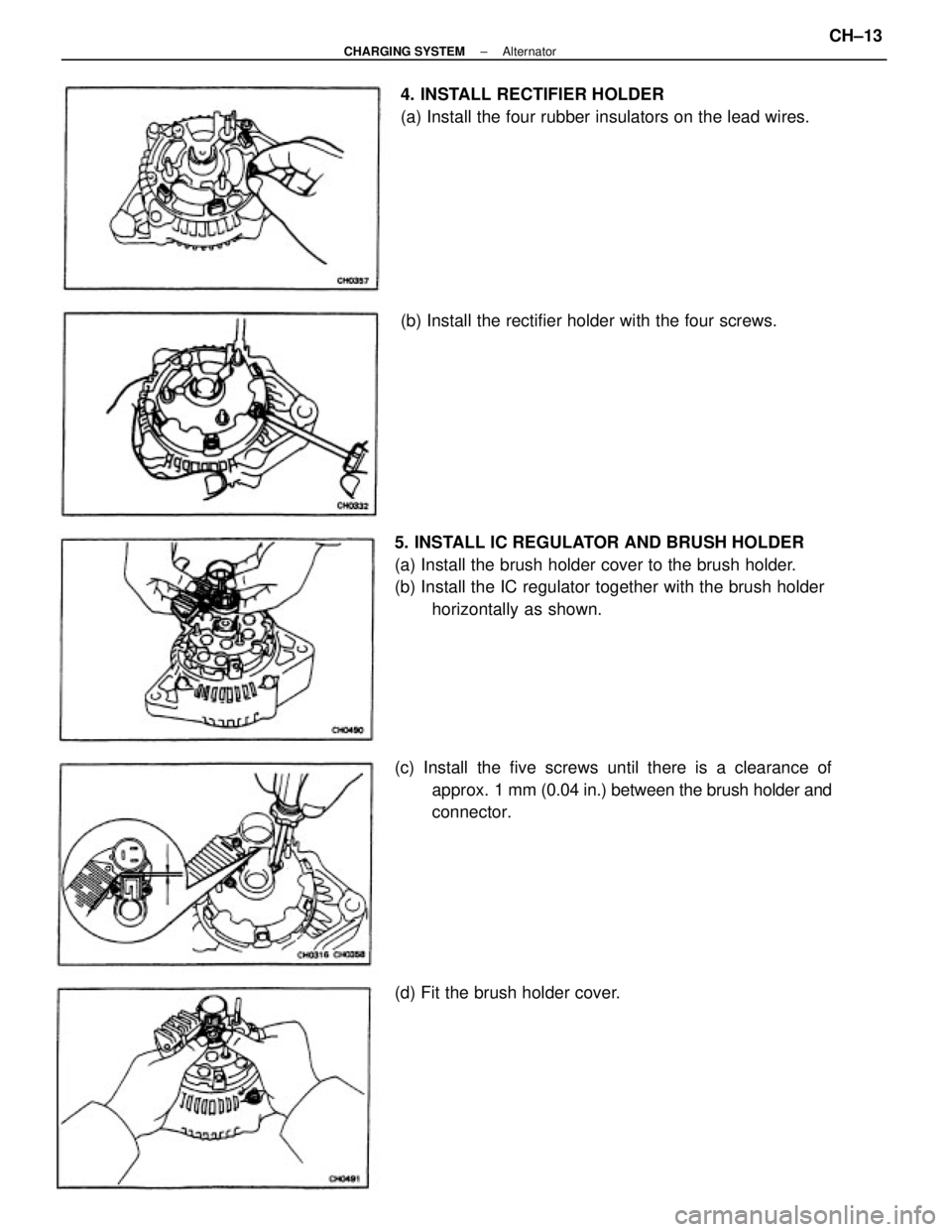

5. INSTALL IC REGULATOR AND BRUSH HOLDER

(a) Install the brush holder cover to the brush holder.

(b) Install the IC regulator together with the brush holder

horizontally as shown.

(c) Install the five screws until there is a clearance of

approx. 1 mm (0.04 in.) between the brush holder and

connector. 4. INSTALL RECTIFIER HOLDER

(a) Install the four rubber insulators on the lead wires.

(b) Install the rectifier holder with the four screws.

(d) Fit the brush holder cover.

± CHARGING SYSTEMAlternatorCH±13

Page 972 of 2389

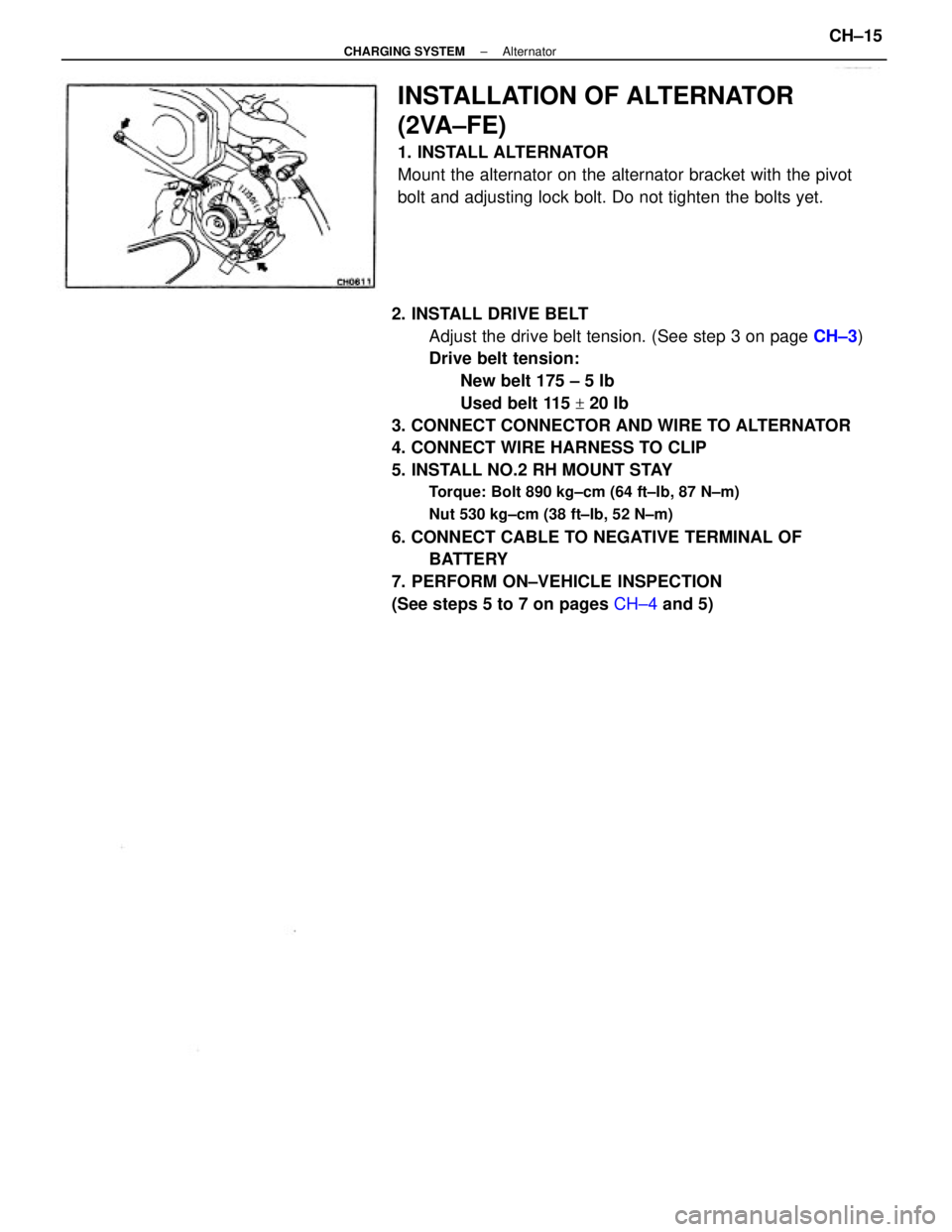

2. INSTALL DRIVE BELT

Adjust the drive belt tension. (See step 3 on page CH±3)

Drive belt tension:

w/ A/C New belt 175 + 5 lb

Used belt 130+ 10 lb

w/o A/C New belt 125 t 25 Ib

Used belt 95 + 20 Ib

3. CONNECT CONNECTOR AND WIRE TO ALTERNATOR

4. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY

5. PERFORM ON±VEHICLE INSPECTION

(See steps 5 to 7 on pages CH±4 and 5)

INSTALLATION OF ALTERNATOR

(3S±FE)

1. INSTALL ALTERNATOR

Mount the alternator on the alternator brackets with the

pivot bolt and adjusting lock bolt. Do not tighten the bolts

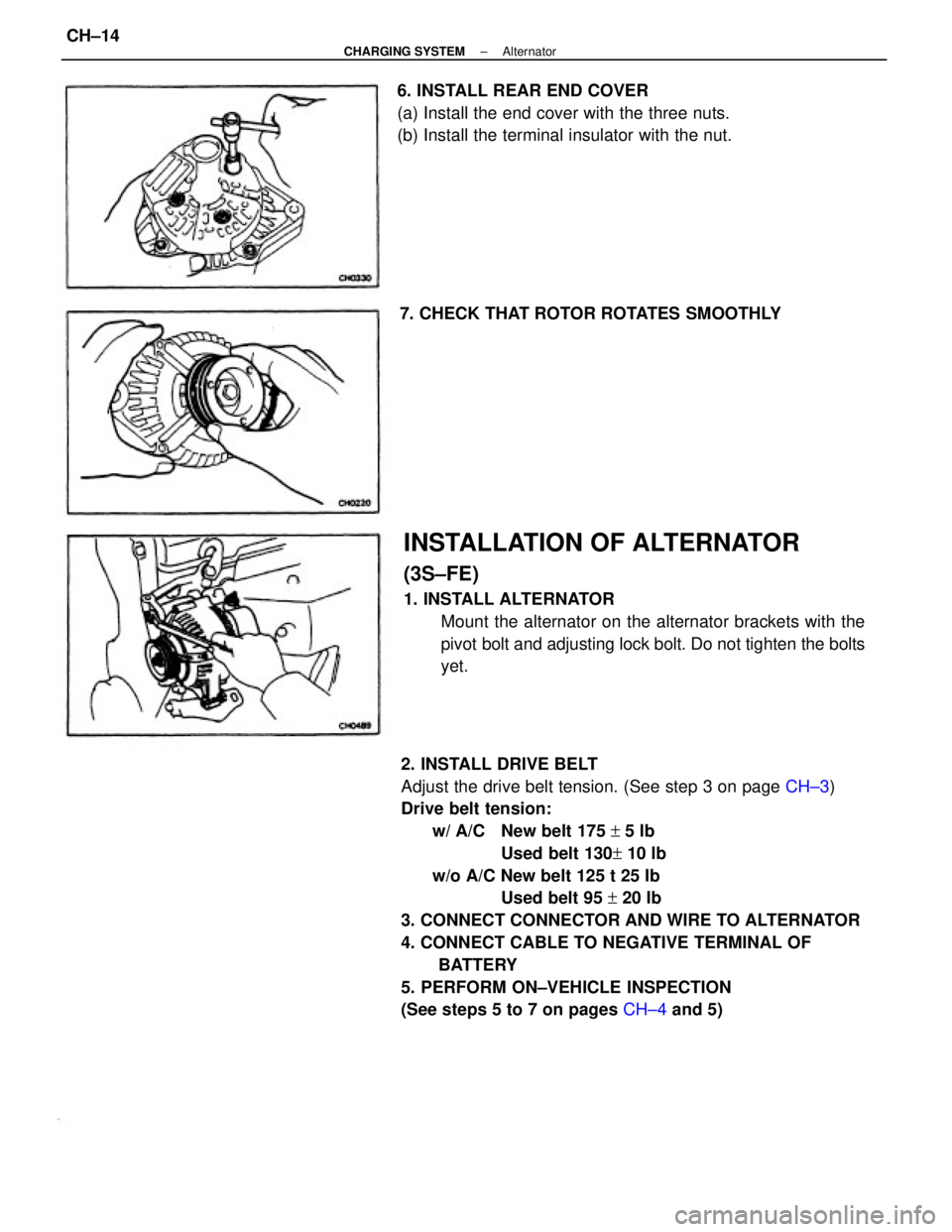

yet. 6. INSTALL REAR END COVER

(a) Install the end cover with the three nuts.

(b) Install the terminal insulator with the nut.

7. CHECK THAT ROTOR ROTATES SMOOTHLY

± CHARGING SYSTEMAlternatorCH±14

Page 973 of 2389

2. INSTALL DRIVE BELT

Adjust the drive belt tension. (See step 3 on page CH±3)

Drive belt tension:

New belt 175 ± 5 Ib

Used belt 115

+ 20 Ib

3. CONNECT CONNECTOR AND WIRE TO ALTERNATOR

4. CONNECT WIRE HARNESS TO CLIP

5. INSTALL NO.2 RH MOUNT STAY

Torque: Bolt 890 kg±cm (64 ft±Ib, 87 N±m)

Nut 530 kg±cm (38 ft±Ib, 52 N±m)

6. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY

7. PERFORM ON±VEHICLE INSPECTION

(See steps 5 to 7 on pages CH±4 and 5)

INSTALLATION OF ALTERNATOR

(2VA±FE)

1. INSTALL ALTERNATOR

Mount the alternator on the alternator bracket with the pivot

bolt and adjusting lock bolt. Do not tighten the bolts yet.

± CHARGING SYSTEMAlternatorCH±15

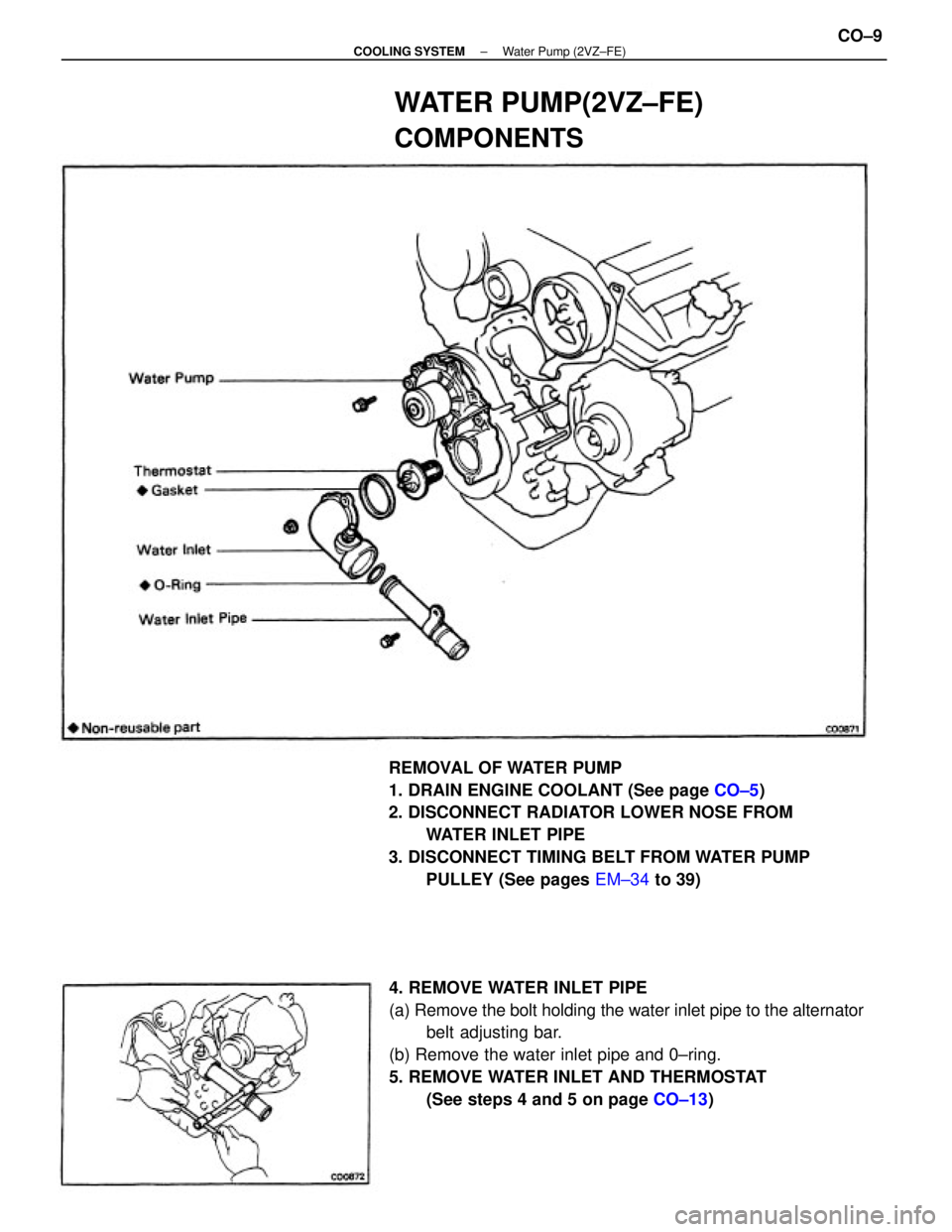

Page 996 of 2389

REMOVAL OF WATER PUMP

1. DRAIN ENGINE COOLANT (See page CO±5)

2. DISCONNECT RADIATOR LOWER NOSE FROM

WATER INLET PIPE

3. DISCONNECT TIMING BELT FROM WATER PUMP

PULLEY (See pages EM±34 to 39)

4. REMOVE WATER INLET PIPE

(a) Remove the bolt holding the water inlet pipe to the alternator

belt adjusting bar.

(b) Remove the water inlet pipe and 0±ring.

5. REMOVE WATER INLET AND THERMOSTAT

(See steps 4 and 5 on page CO±13)

WATER PUMP(2VZ±FE)

COMPONENTS

± COOLING SYSTEMWater Pump (2VZ±FE)CO±9

Page 998 of 2389

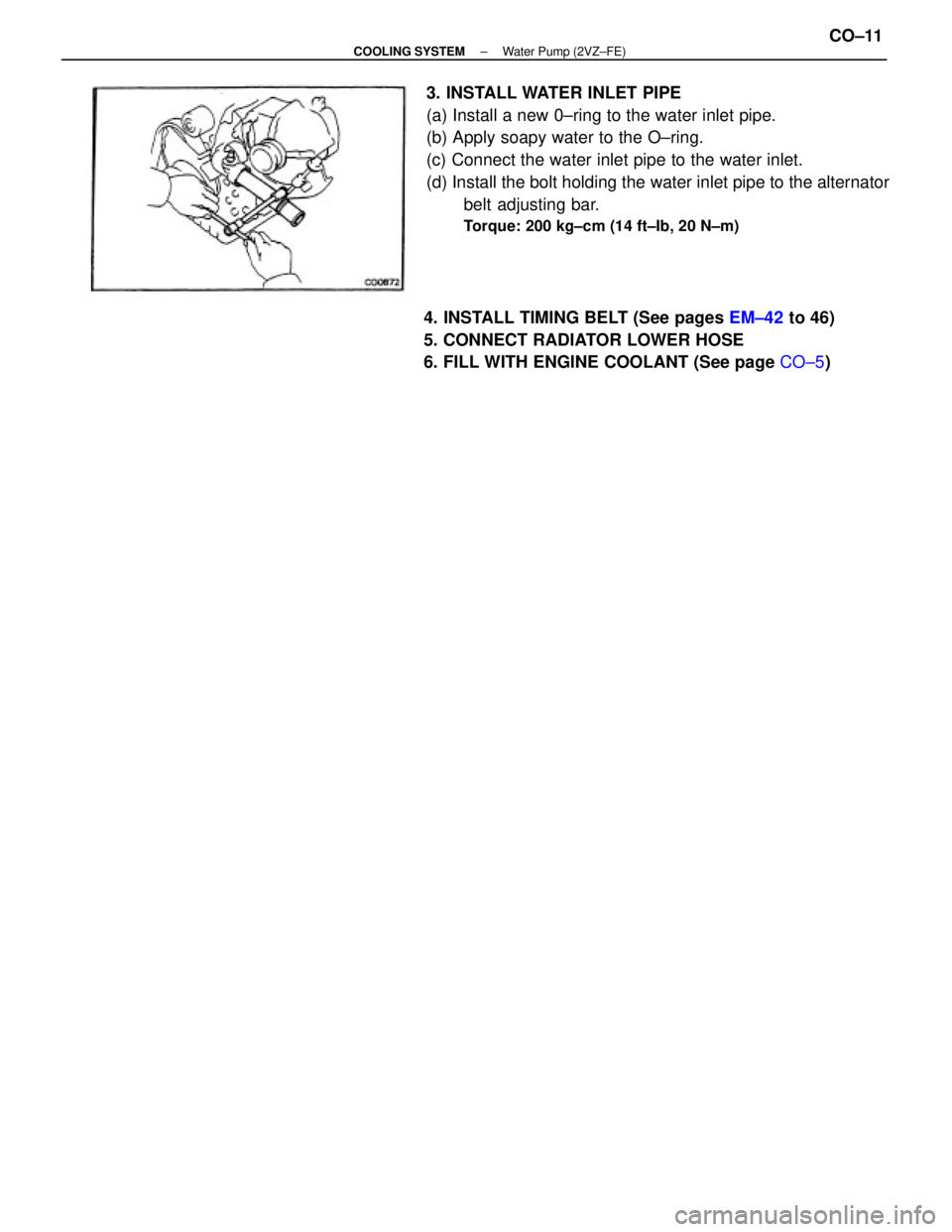

3. INSTALL WATER INLET PIPE

(a) Install a new 0±ring to the water inlet pipe.

(b) Apply soapy water to the O±ring.

(c) Connect the water inlet pipe to the water inlet.

(d) Install the bolt holding the water inlet pipe to the alternator

belt adjusting bar.

Torque: 200 kg±cm (14 ft±Ib, 20 N±m)

4. INSTALL TIMING BELT (See pages EM±42 to 46)

5. CONNECT RADIATOR LOWER HOSE

6. FILL WITH ENGINE COOLANT (See page CO±5)

± COOLING SYSTEMWater Pump (2VZ±FE)CO±11

Page 1187 of 2389

ENGINE TUNE±UP

INSPECTION OF ENGINE COOLANT

(See steps 1 and 2 on page CO±4)

INSPECTION OF ENGINE OIL

(See steps 1 and 2 on page LU±6)

INSPECTION OF BATTERY

(See steps 1 and 2 on page CH±3)

Standard specific gravity:

1.25 ±1.27 when fully charged at 2O°C (68°F)

INSPECTION OF AIR FILTER

(See step 3 on page MA±5)

INSPECTION OF HIGH±TENSION CORDS

(See page IG±6 or 10)

Maximum resistance: 25 kW per cord

INSPECTION OF SPARK PLUGS (3S±FE)

(See page IG±6)

Correct electrode gap: 1.1 mm (0.043 in.)

Recommended spark plugs:

ND Q16R±U11

NGK BCPR5EY11

INSPECTION OF SPARK PLUGS (2VZ±FE)

(See page IG±10)

Correct electrode gap of new plug:

1.1 mm (0.043 in.)

Maximum electrode gap: 1.3 mm (0.051 in.)

Recommended spark plugs:

ND P020R

NGK BCPR6EP11

INSPECTION OF ALTERNATOR DRIVE BELT

(See step 3 on page CH±3)

Drive belt tension:

3S±FE w/ A/C New belt 175 +5 Ib

Used belt 130 +10 Ib

w/o A/C New belt 125 +25 Ib

Used belt 95 +20 Ib

2VZ±FE New belt 175 +5 Ib

Used belt 115 +20 Ib

± ENGINE MECHANICALEngine Tune±UpEM±10

Page 1200 of 2389

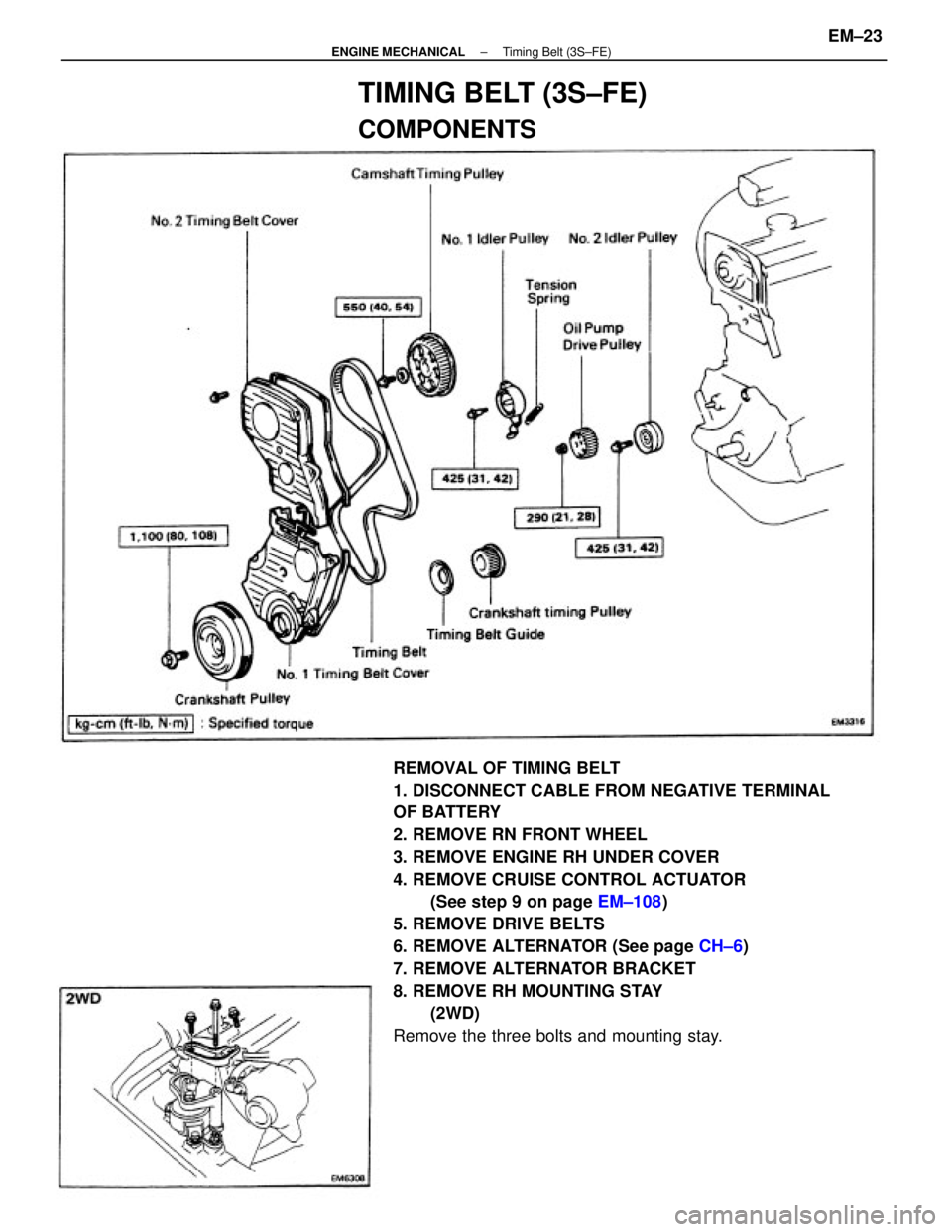

REMOVAL OF TIMING BELT

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

2. REMOVE RN FRONT WHEEL

3. REMOVE ENGINE RH UNDER COVER

4. REMOVE CRUISE CONTROL ACTUATOR

(See step 9 on page EM±108)

5. REMOVE DRIVE BELTS

6. REMOVE ALTERNATOR (See page CH±6)

7. REMOVE ALTERNATOR BRACKET

8. REMOVE RH MOUNTING STAY

(2WD)

Remove the three bolts and mounting stay.

TIMING BELT (3S±FE)

COMPONENTS

± ENGINE MECHANICALTiming Belt (3S±FE)EM±23