automatic transmission TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 265 of 2389

A140E Automatic Transaxle (ECT)

WHAT IS THE ECT?

ECT means Electronic Controlled Transaxle. The hydraulic control system of the previous automatic

transaxle has been changed, the throttle and governor pressure have been replaced by electronic

signals and a micro computer has been used to give precise control of shift timing and lock±up tim-

ing.

FEATURES OF THE ECT

(a) The shift pattern can be chosen.

In the ECT ECU micro computer used in the A140E, two types of shift pattern, Power and Normal,

are recorded in the memory. By operating the pattern select switch, the driver can select the pre-

ferred shift pattern.

(b) Reduced fuel consumption and reduced shock during shifting is made possible.

Precise control of the shift timing by the ECT ECU, operation of the lock±up clutch from low speeds,

and decreased fuel consumption are made possible. Also, shock during Shifting is reduced.

(e) Self±Diagnostic System

When a malfunction occurs in the electronic control system, the driver is informed of this fact. Also,

there is a Self±Diagnostic System which displays the location of the malfunction when the service

connector is shorted.

(d) Fail±Safe System

A fail±Safe System is included so that, even if a malfunction occurs in the electronic control system,

the vehicle will be able to operate.

CONSTRUCTION AND OPERATION

When the A140E (ECT) is compared with the A140L, the automatic transaxle body has the same

construction and operation, with the exception of the hydraulic control system, as the A140L.

The electronic control system, which controls the shift timing and lock±up timing, has been added.

1. Hydraulic Control System (Comparison with the A140L)

VALVE BODY ± Additions or changes to solenoid valve

In the A140E there are three solenoid valves, the No. 1, the No. 2 and the lock±up solenoid valves.

Shifting occurs according to whether the No. 1 and No. 2 solenoid valves are ON or OFF, and the

lock±up solenoid valve controls the lock±up clutch.

GOVERNOR VALVE ± Removed

With the A140E, the governor valve has been replaced with a speed sensor, so that instead of the

governor pressure, a speed sensor signal is sent to the ECT ECU.

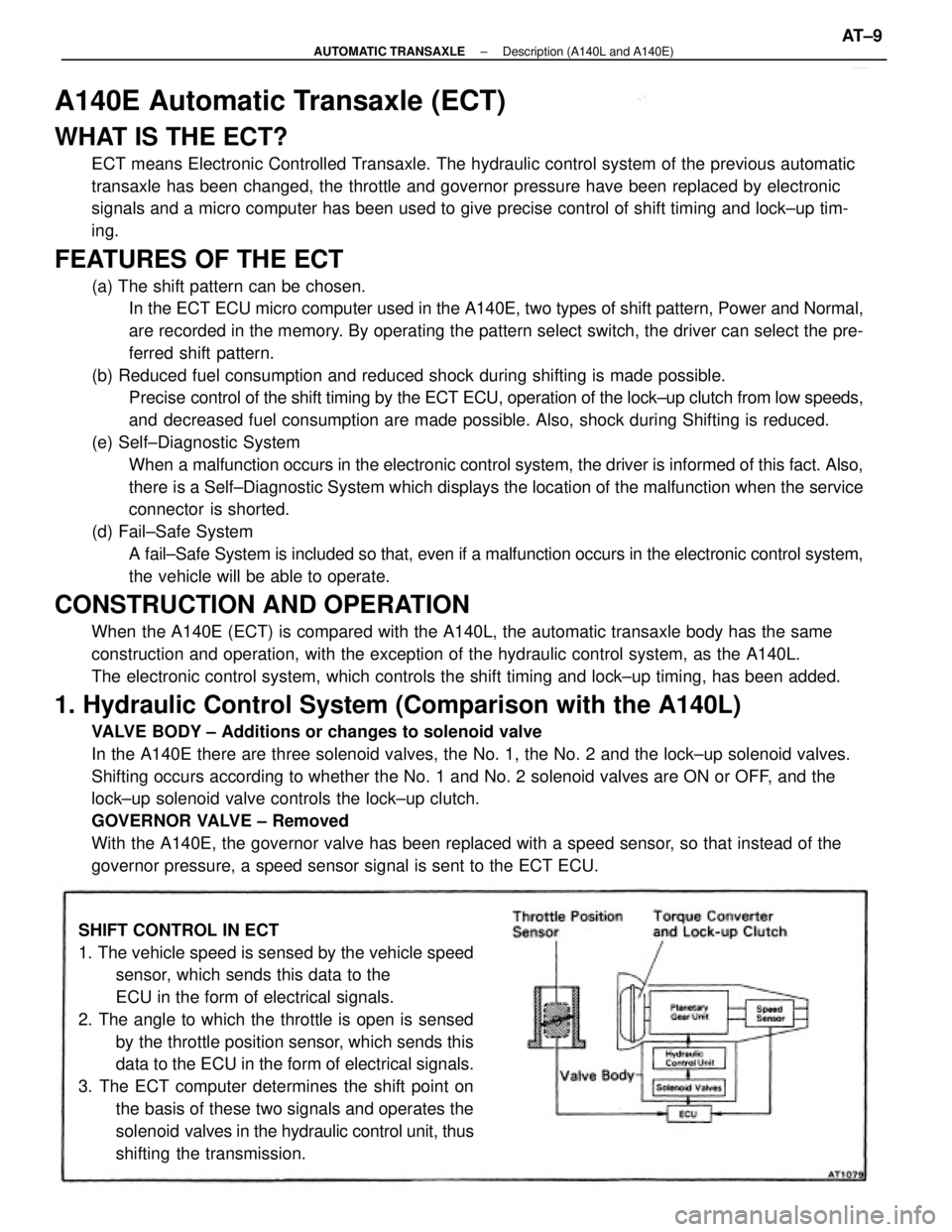

SHIFT CONTROL IN ECT

1. The vehicle speed is sensed by the vehicle speed

sensor, which sends this data to the

ECU in the form of electrical signals.

2. The angle to which the throttle is open is sensed

by the throttle position sensor, which sends this

data to the ECU in the form of electrical signals.

3. The ECT computer determines the shift point on

the basis of these two signals and operates the

solenoid valves in the hydraulic control unit, thus

shifting the transmission.

± AUTOMATIC TRANSAXLEDescription (A140L and A140E)AT±9

Page 276 of 2389

Preliminary Check

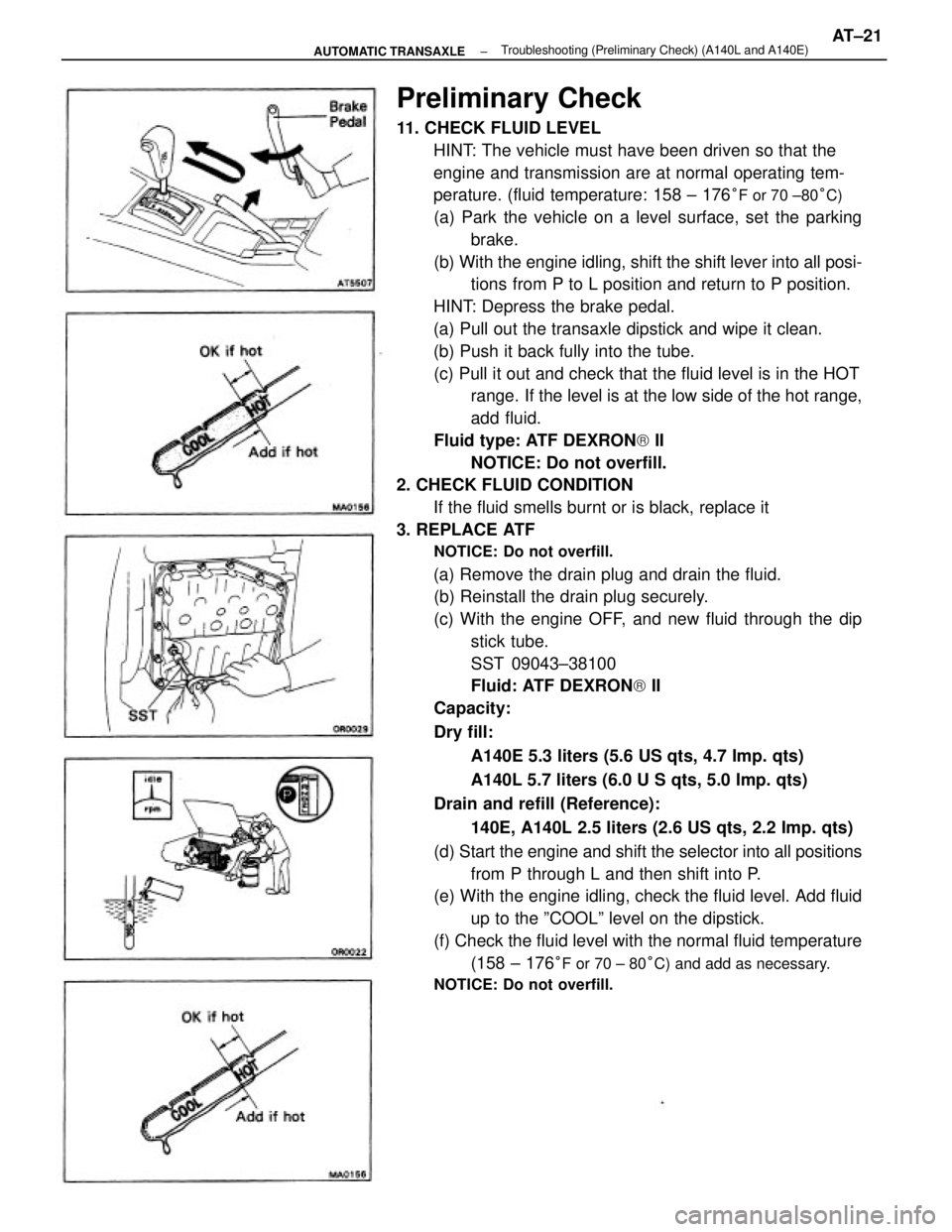

11. CHECK FLUID LEVEL

HINT: The vehicle must have been driven so that the

engine and transmission are at normal operating tem-

perature. (fluid temperature: 158 ± 176

°F or 70 ±80°C)

(a) Park the vehicle on a level surface, set the parking

brake.

(b) With the engine idling, shift the shift lever into all posi-

tions from P to L position and return to P position.

HINT: Depress the brake pedal.

(a) Pull out the transaxle dipstick and wipe it clean.

(b) Push it back fully into the tube.

(c) Pull it out and check that the fluid level is in the HOT

range. If the level is at the low side of the hot range,

add fluid.

Fluid type: ATF DEXRON) II

NOTICE: Do not overfill.

2. CHECK FLUID CONDITION

If the fluid smells burnt or is black, replace it

3. REPLACE ATF

NOTICE: Do not overfill.

(a) Remove the drain plug and drain the fluid.

(b) Reinstall the drain plug securely.

(c) With the engine OFF, and new fluid through the dip

stick tube.

SST 09043±38100

Fluid: ATF DEXRON) II

Capacity:

Dry fill:

A140E 5.3 liters (5.6 US qts, 4.7 Imp. qts)

A140L 5.7 liters (6.0 U S qts, 5.0 Imp. qts)

Drain and refill (Reference):

140E, A140L 2.5 liters (2.6 US qts, 2.2 Imp. qts)

(d) Start the engine and shift the selector into all positions

from P through L and then shift into P.

(e) With the engine idling, check the fluid level. Add fluid

up to the ºCOOLº level on the dipstick.

(f) Check the fluid level with the normal fluid temperature

(158 ± 176

°F or 70 ± 80°C) and add as necessary.

NOTICE: Do not overfill.

± AUTOMATIC TRANSAXLETroubleshooting (Preliminary Check) (A140L and A140E)AT±21

Page 287 of 2389

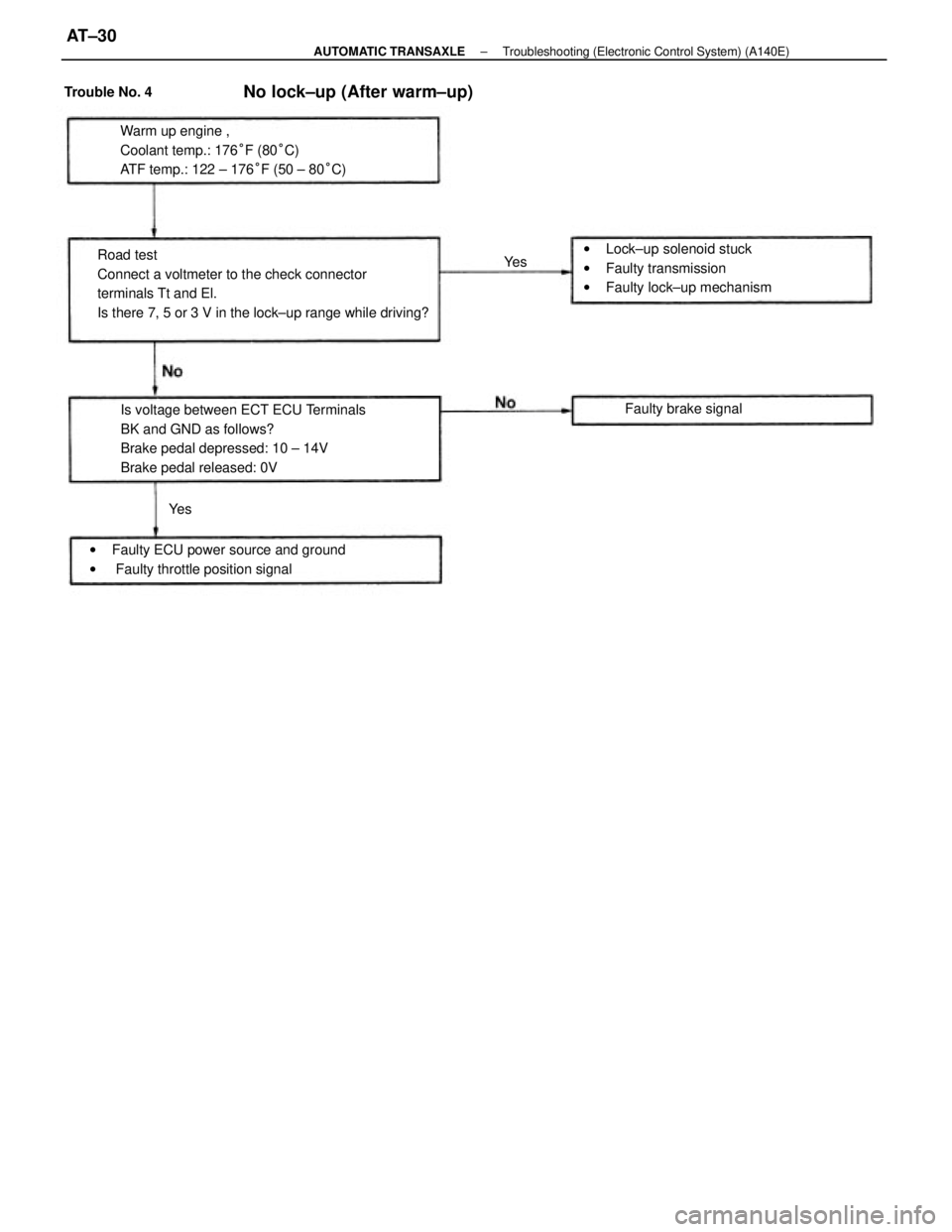

Road test

Connect a voltmeter to the check connector

terminals Tt and El.

Is there 7, 5 or 3 V in the lock±up range while driving?

Is voltage between ECT ECU Terminals

BK and GND as follows?

Brake pedal depressed: 10 ± 14V

Brake pedal released: 0V Warm up engine ,

Coolant temp.: 176°F (80°C)

ATF temp.: 122 ± 176°F (50 ± 80°C)

wLock±up solenoid stuck

wFaulty transmission

wFaulty lock±up mechanism

wFaulty ECU power source and ground

w Faulty throttle position signal

No lock±up (After warm±up)

Faulty brake signal Trouble No. 4

Ye s

Ye s

± AUTOMATIC TRANSAXLETroubleshooting (Electronic Control System) (A140E)AT±30

Page 305 of 2389

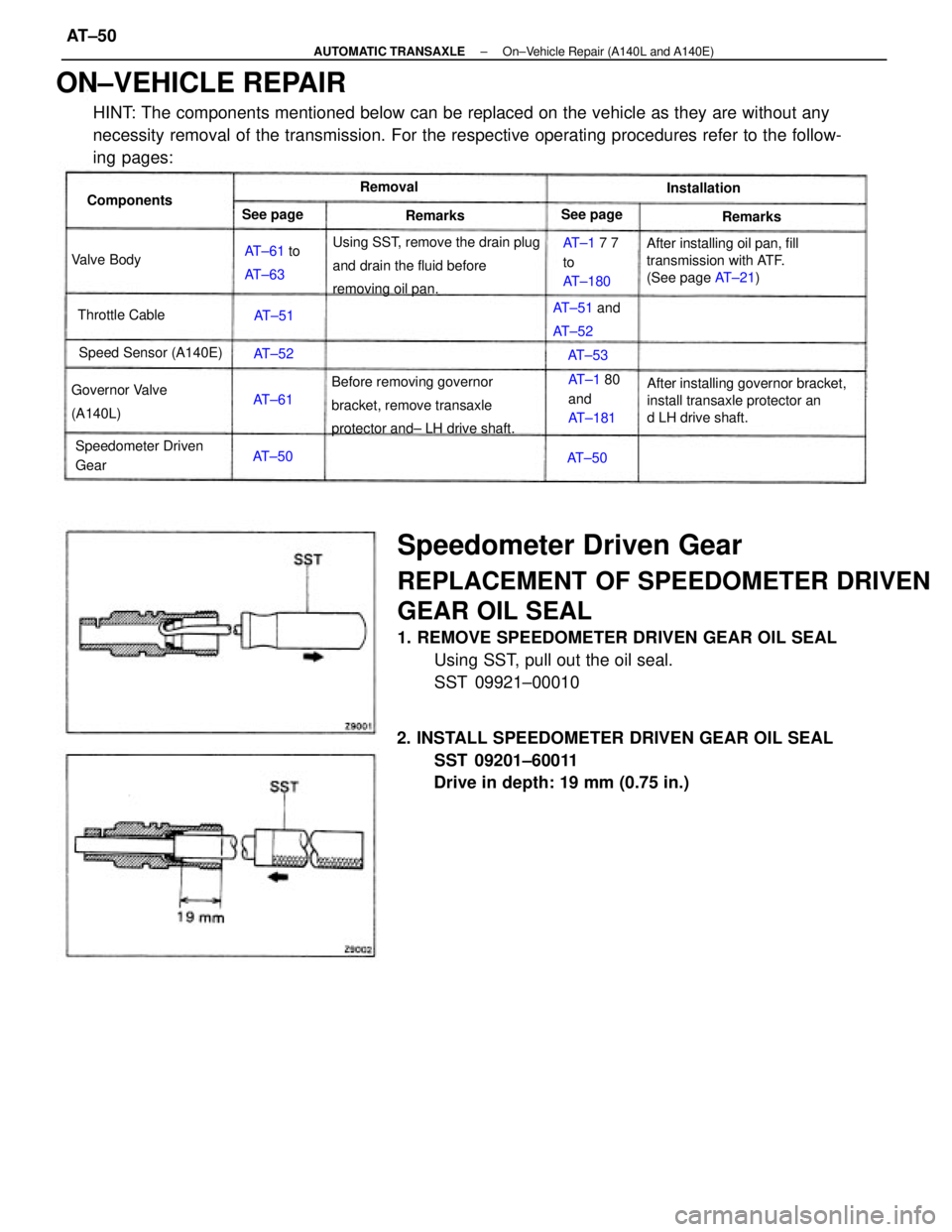

Speedometer Driven Gear

REPLACEMENT OF SPEEDOMETER DRIVEN

GEAR OIL SEAL

1. REMOVE SPEEDOMETER DRIVEN GEAR OIL SEAL

Using SST, pull out the oil seal.

SST 09921±00010

ON±VEHICLE REPAIR

HINT: The components mentioned below can be replaced on the vehicle as they are without any

necessity removal of the transmission. For the respective operating procedures refer to the follow-

ing pages:

2. INSTALL SPEEDOMETER DRIVEN GEAR OIL SEAL

SST 09201±60011

Drive in depth: 19 mm (0.75 in.)

After installing governor bracket,

install transaxle protector an

d LH drive shaft. Using SST, remove the drain plug

and drain the fluid before

removing oil pan.

Before removing governor

bracket, remove transaxle

protector and± LH drive shaft.After installing oil pan, fill

transmission with ATF.

(See page AT±21)

Speedometer Driven

Gear Governor Valve

(A140L)AT±1 7 7

to

AT±180

Speed Sensor (A140E)

AT±1 80

and

AT±181 AT±51 and

AT±52 AT±61 to

AT±63

Throttle CableComponents

Valve BodyInstallation

See page See pageRemoval

Remarks Remarks

AT±50 AT±61AT±51

AT±50AT±52

AT±53

± AUTOMATIC TRANSAXLEOn±Vehicle Repair (A140L and A140E)AT±50

Page 306 of 2389

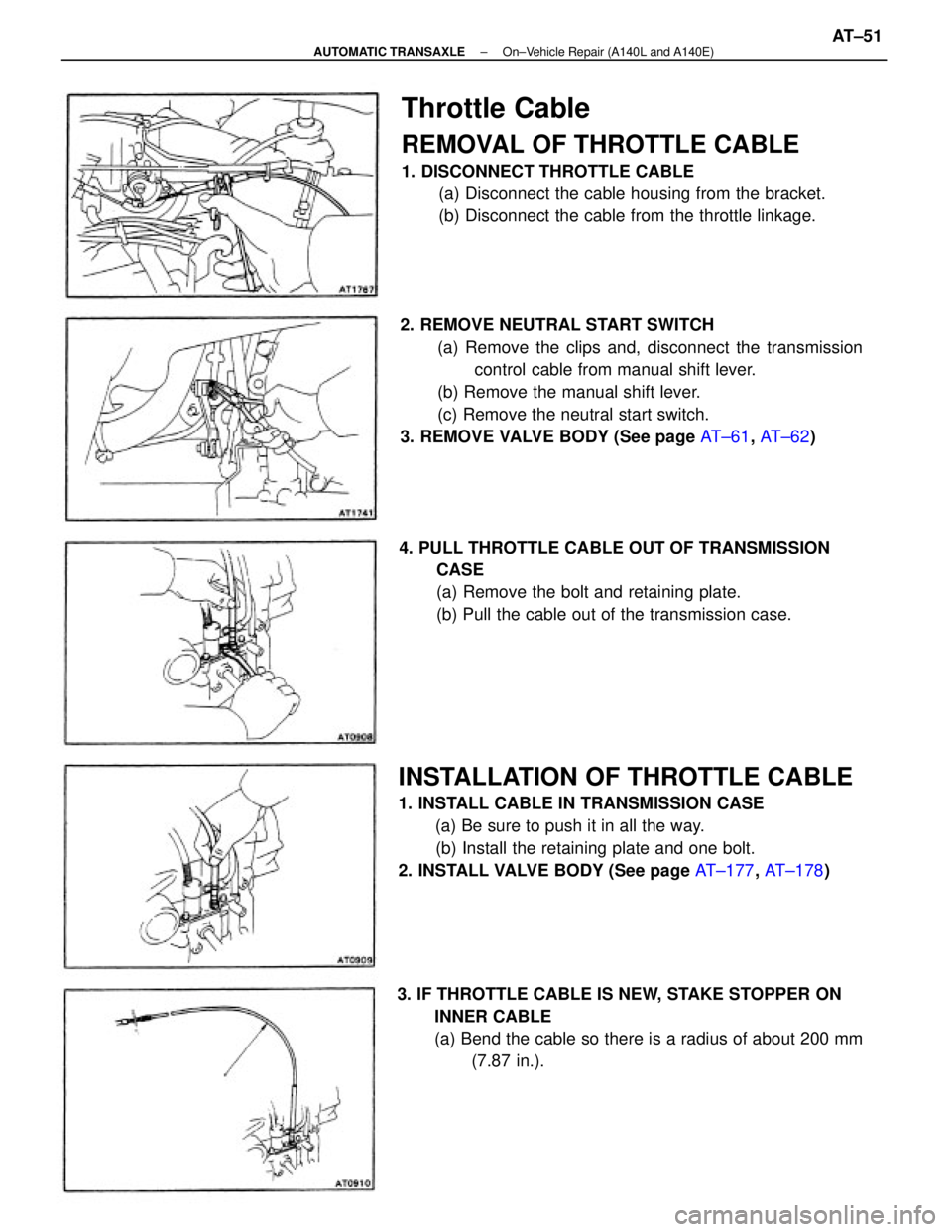

2. REMOVE NEUTRAL START SWITCH

(a) Remove the clips and, disconnect the transmission

control cable from manual shift lever.

(b) Remove the manual shift lever.

(c) Remove the neutral start switch.

3. REMOVE VALVE BODY (See page AT±61, AT±62)

INSTALLATION OF THROTTLE CABLE

1. INSTALL CABLE IN TRANSMISSION CASE

(a) Be sure to push it in all the way.

(b) Install the retaining plate and one bolt.

2. INSTALL VALVE BODY (See page AT±177, AT±178)

Throttle Cable

REMOVAL OF THROTTLE CABLE

1. DISCONNECT THROTTLE CABLE

(a) Disconnect the cable housing from the bracket.

(b) Disconnect the cable from the throttle linkage.

4. PULL THROTTLE CABLE OUT OF TRANSMISSION

CASE

(a) Remove the bolt and retaining plate.

(b) Pull the cable out of the transmission case.

3. IF THROTTLE CABLE IS NEW, STAKE STOPPER ON

INNER CABLE

(a) Bend the cable so there is a radius of about 200 mm

(7.87 in.).

± AUTOMATIC TRANSAXLEOn±Vehicle Repair (A140L and A140E)AT±51

Page 307 of 2389

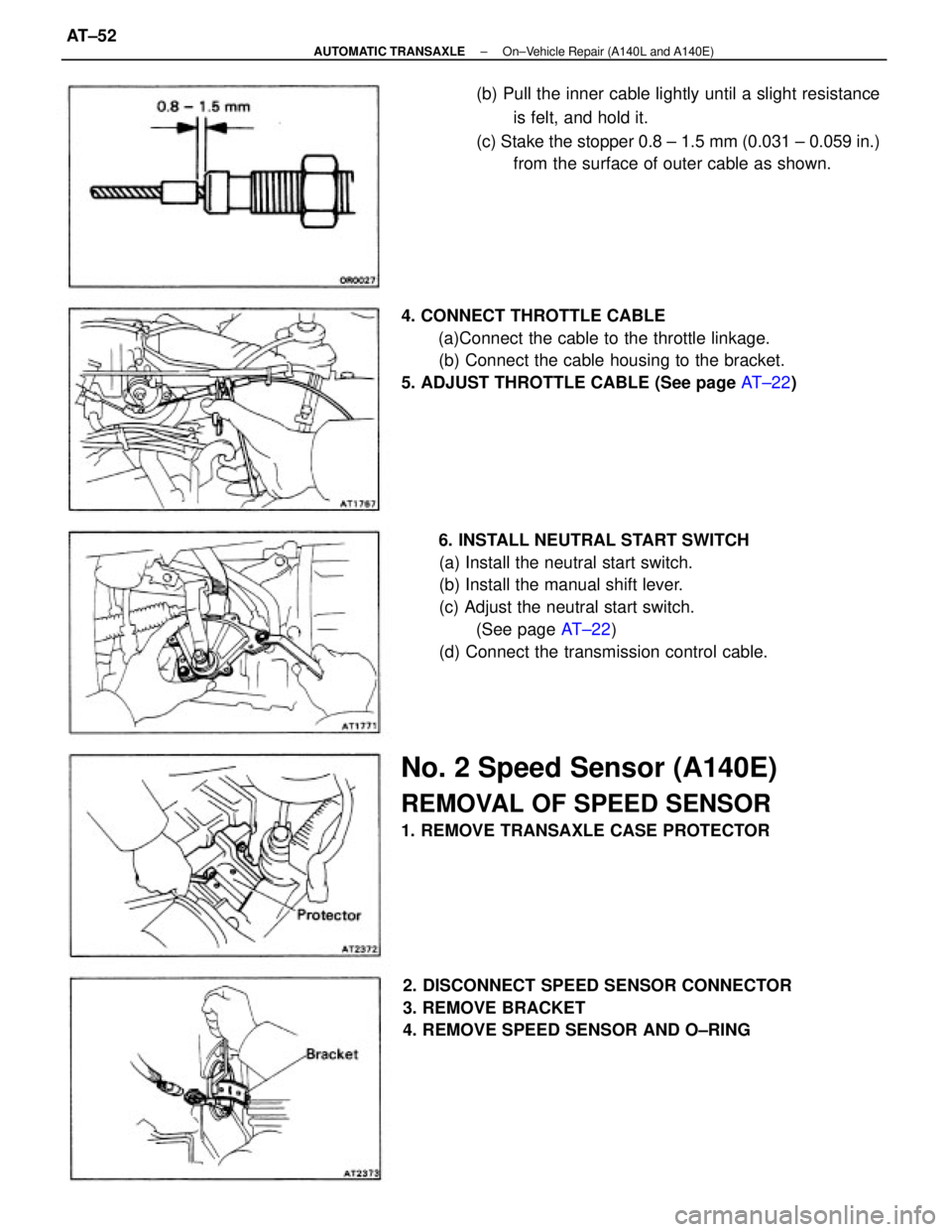

6. INSTALL NEUTRAL START SWITCH

(a) Install the neutral start switch.

(b) Install the manual shift lever.

(c) Adjust the neutral start switch.

(See page AT±22)

(d) Connect the transmission control cable. 4. CONNECT THROTTLE CABLE

(a)Connect the cable to the throttle linkage.

(b) Connect the cable housing to the bracket.

5. ADJUST THROTTLE CABLE (See page AT±22) (b) Pull the inner cable lightly until a slight resistance

is felt, and hold it.

(c) Stake the stopper 0.8 ± 1.5 mm (0.031 ± 0.059 in.)

from the surface of outer cable as shown.

No. 2 Speed Sensor (A140E)

REMOVAL OF SPEED SENSOR

1. REMOVE TRANSAXLE CASE PROTECTOR

2. DISCONNECT SPEED SENSOR CONNECTOR

3. REMOVE BRACKET

4. REMOVE SPEED SENSOR AND O±RING

± AUTOMATIC TRANSAXLEOn±Vehicle Repair (A140L and A140E)AT±52

Page 311 of 2389

COMPONENT PARTS

General Notes

The instructions here are organized so that you work on only one component group at a time.

This will help avoid confusion from similar±looking parts of different subassemblies being on

your work bench at the same time.

The component groups are inspected and repaired from the converter housing side.

As much as possible, complete the inspection, repair and assembly before proceeding to the

next component group. If a component group can not be assembled because parts are being or-

dered, be sure tc keep all parts of that group in a separate container while proceeding with dis-

assembly, inspection, repair and assembly of other component groups.

Recommended fluid for the automatic transaxle is ATF type DEXRON) ll.

GENERAL CLEANING NOTES:

1. All disassembled parts should be washed clean with any fluid passages and holes blown trough wit com-

pressed air.

2. When using compressed air to dry parts, always aim away from yourself to prevent accidentally spraying,

automatic transmission fluid or kerosene in your face.

3. The recommended automatic transaxle fluid or kerosene should be used for cleaning.

PARTS ARRANGEMENT:

1. After cleaning, the parts should be arranged in proper order to allow efficient inspection, repairs, an(

reassembly.

2. When disassembling a valve body, be sure to keep each valve together with the corresponding spring

3. New brakes and clutches that are to be used for replacement must be soaked in transaxle fluid for a least

fifteen minutes before assembly.

GENERAL ASSEMBLY:

1. All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with

transmission fluid prior to reassembly.

2. All gaskets and rubber O±rings should be replaced.

3. Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed in the

groove correctly.

4. If a worn bushing is to be replaced, the subassembly containing that bushing must be replaced.

5. Check thrust bearings and races for wear or damage. Replace if necessary.

6. Use petroleum jelly to keep parts in place.

± AUTOMATIC TRANSAXLEComponent Parts (General Notes) (A140L and A140E)AT±78

Page 324 of 2389

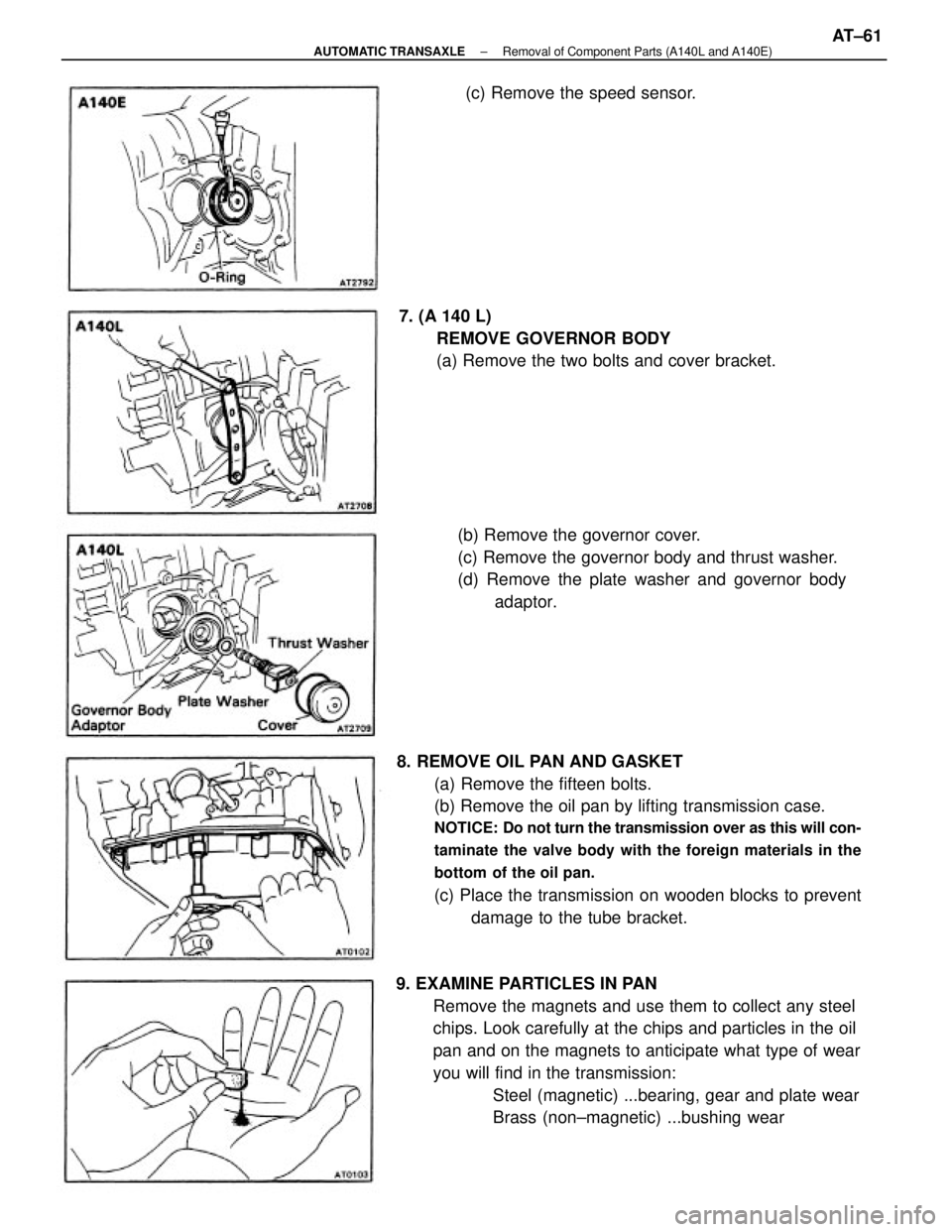

8. REMOVE OIL PAN AND GASKET

(a) Remove the fifteen bolts.

(b) Remove the oil pan by lifting transmission case.

NOTICE: Do not turn the transmission over as this will con-

taminate the valve body with the foreign materials in the

bottom of the oil pan.

(c) Place the transmission on wooden blocks to prevent

damage to the tube bracket.

9. EXAMINE PARTICLES IN PAN

Remove the magnets and use them to collect any steel

chips. Look carefully at the chips and particles in the oil

pan and on the magnets to anticipate what type of wear

you will find in the transmission:

Steel (magnetic) ...bearing, gear and plate wear

Brass (non±magnetic) ...bushing wear (b) Remove the governor cover.

(c) Remove the governor body and thrust washer.

(d) Remove the plate washer and governor body

adaptor. 7. (A 140 L)

REMOVE GOVERNOR BODY

(a) Remove the two bolts and cover bracket.(c) Remove the speed sensor.

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±61

Page 328 of 2389

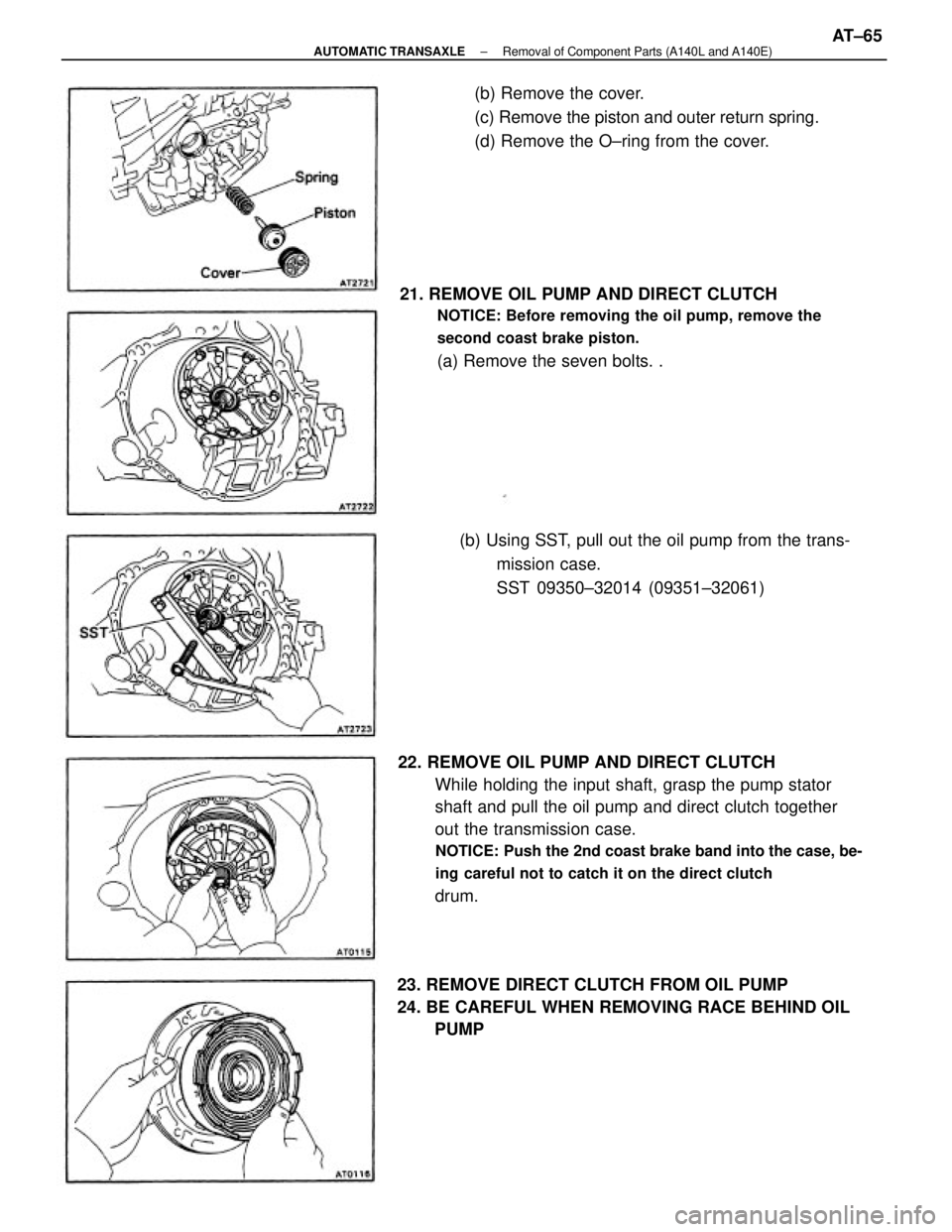

22. REMOVE OIL PUMP AND DIRECT CLUTCH

While holding the input shaft, grasp the pump stator

shaft and pull the oil pump and direct clutch together

out the transmission case.

NOTICE: Push the 2nd coast brake band into the case, be-

ing careful not to catch it on the direct clutch

drum. 21. REMOVE OIL PUMP AND DIRECT CLUTCH

NOTICE: Before removing the oil pump, remove the

second coast brake piston.

(a) Remove the seven bolts. .

23. REMOVE DIRECT CLUTCH FROM OIL PUMP

24. BE CAREFUL WHEN REMOVING RACE BEHIND OIL

PUMP(b) Using SST, pull out the oil pump from the trans-

mission case.

SST 09350±32014 (09351±32061) (b) Remove the cover.

(c) Remove the piston and outer return spring.

(d) Remove the O±ring from the cover.

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±65

Page 330 of 2389

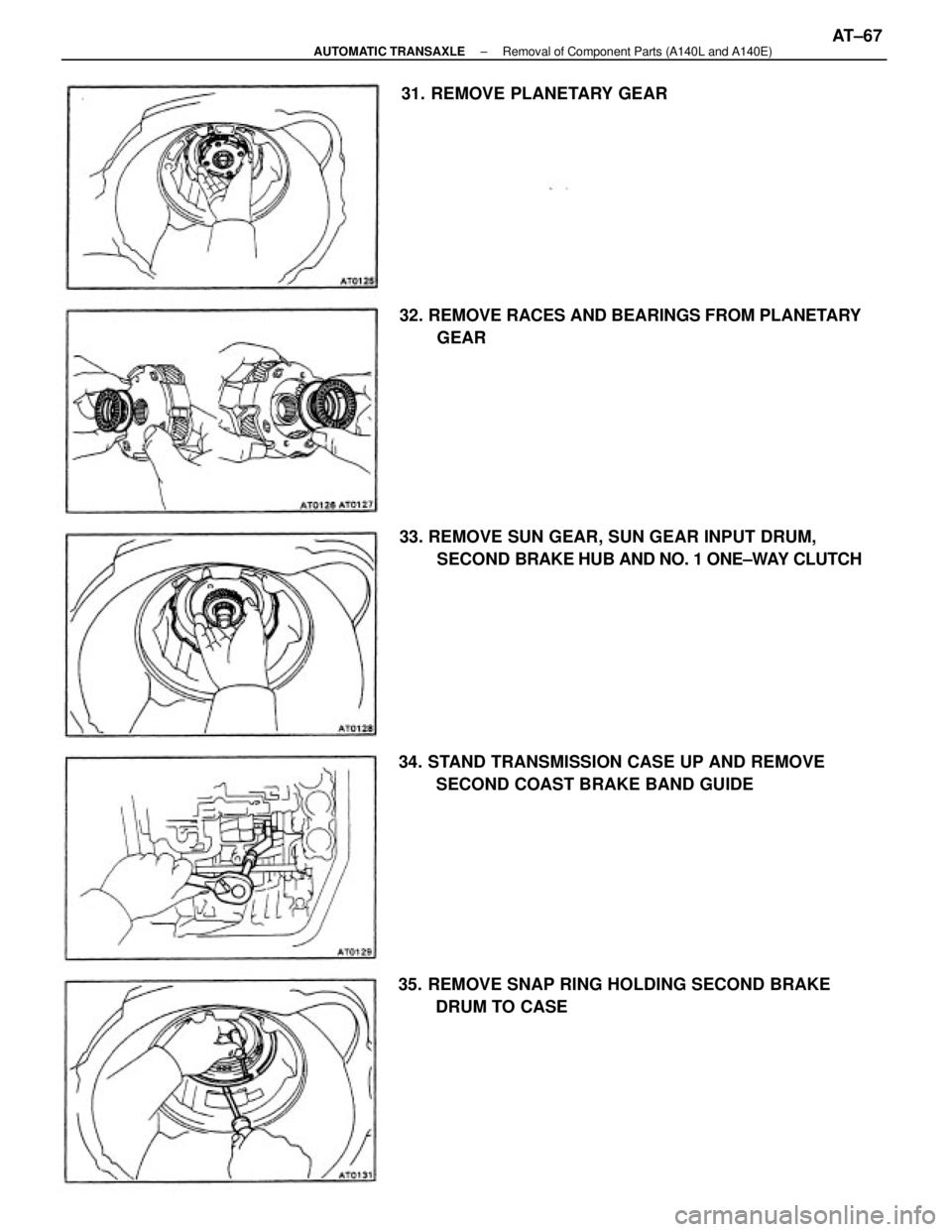

34. STAND TRANSMISSION CASE UP AND REMOVE

SECOND COAST BRAKE BAND GUIDE 33. REMOVE SUN GEAR, SUN GEAR INPUT DRUM,

SECOND BRAKE HUB AND NO. 1 ONE±WAY CLUTCH

35. REMOVE SNAP RING HOLDING SECOND BRAKE

DRUM TO CASE 32. REMOVE RACES AND BEARINGS FROM PLANETARY

GEAR 31. REMOVE PLANETARY GEAR

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±67