fuel pump TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1046 of 2389

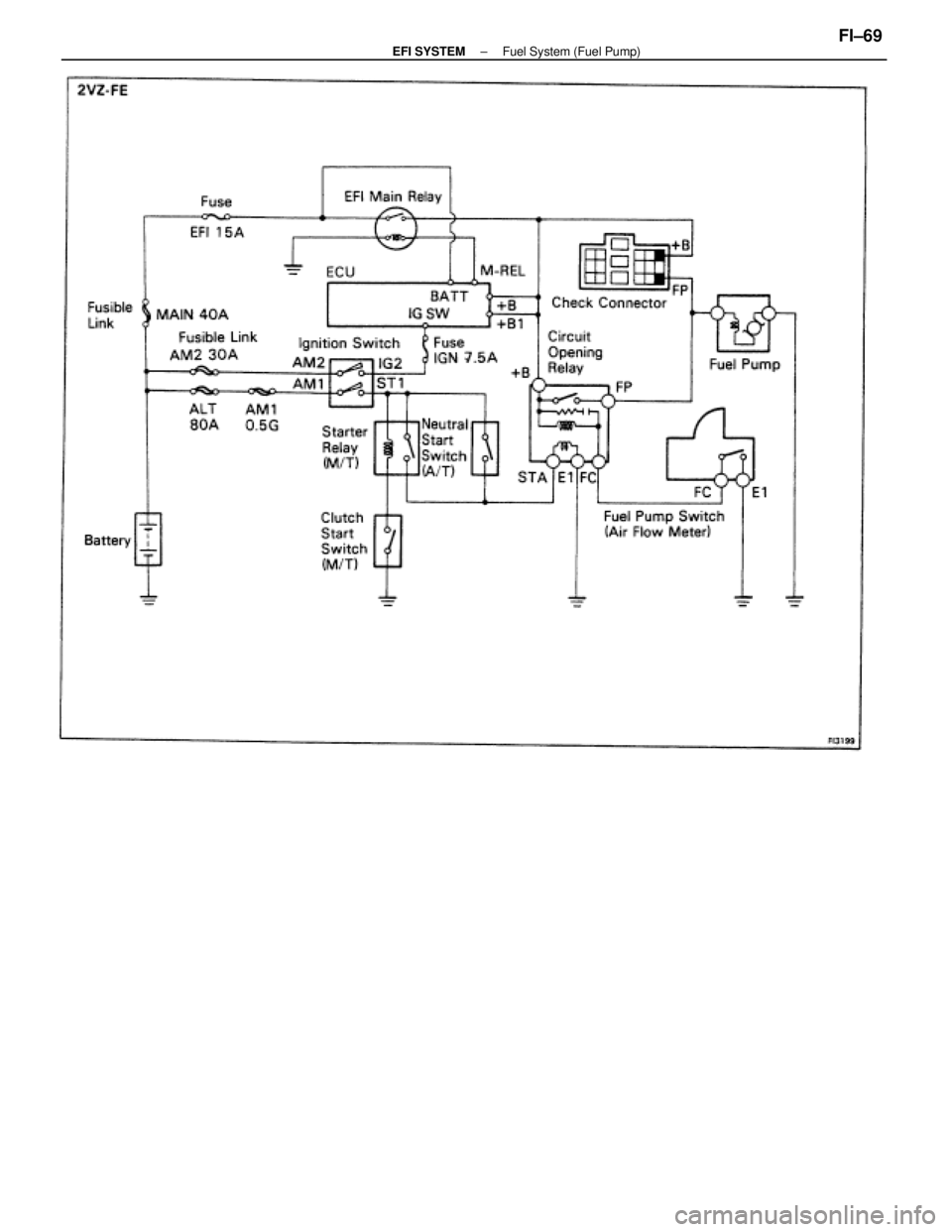

± EFI SYSTEMFuel System (Fuel Pump)FI±69

Page 1047 of 2389

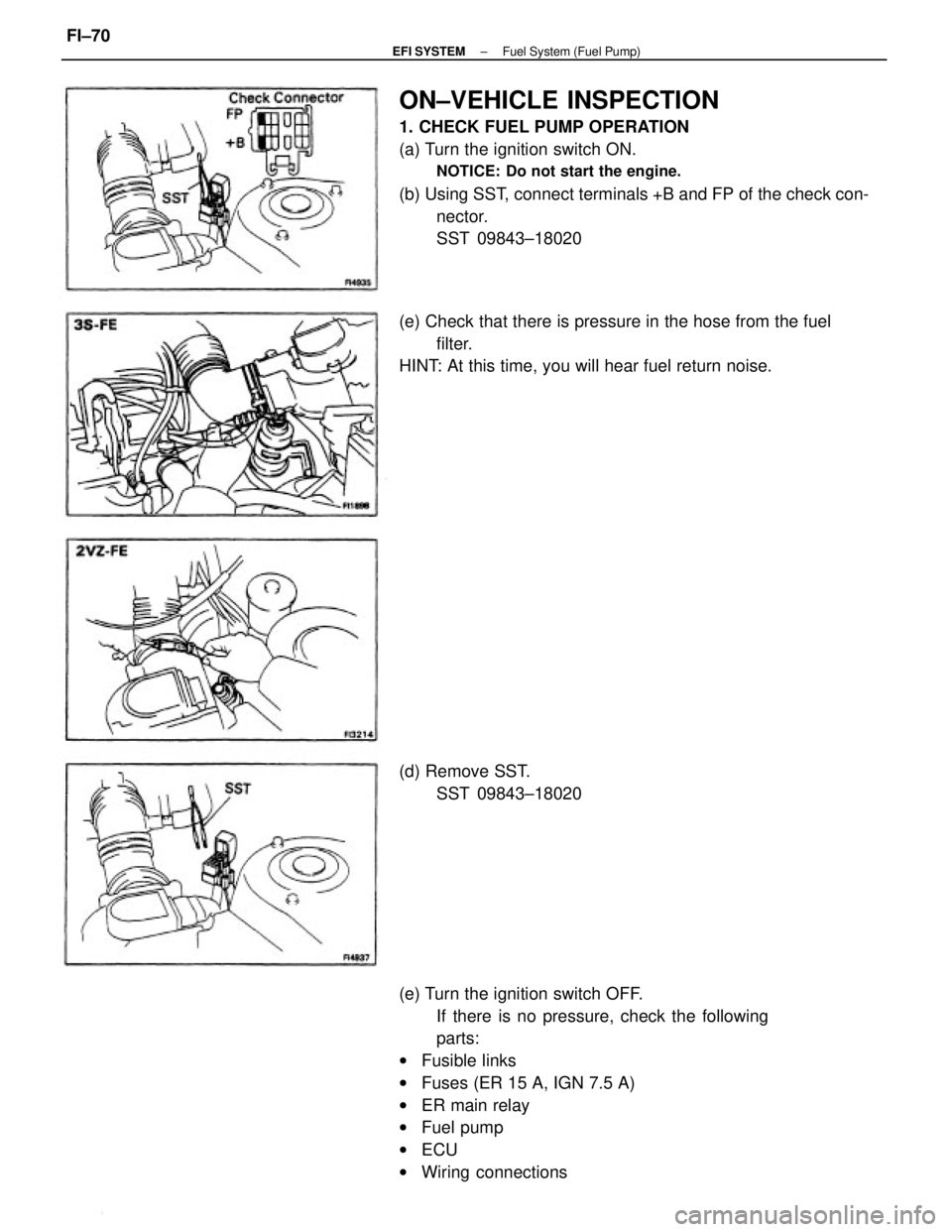

ON±VEHICLE INSPECTION

1. CHECK FUEL PUMP OPERATION

(a) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(b) Using SST, connect terminals +B and FP of the check con-

nector.

SST 09843±18020

(e) Turn the ignition switch OFF.

If there is no pressure, check the following

parts:

wFusible links

wFuses (ER 15 A, IGN 7.5 A)

wER main relay

wFuel pump

wECU

wWiring connections (e) Check that there is pressure in the hose from the fuel

filter.

HINT: At this time, you will hear fuel return noise.

(d) Remove SST.

SST 09843±18020

± EFI SYSTEMFuel System (Fuel Pump)FI±70

Page 1048 of 2389

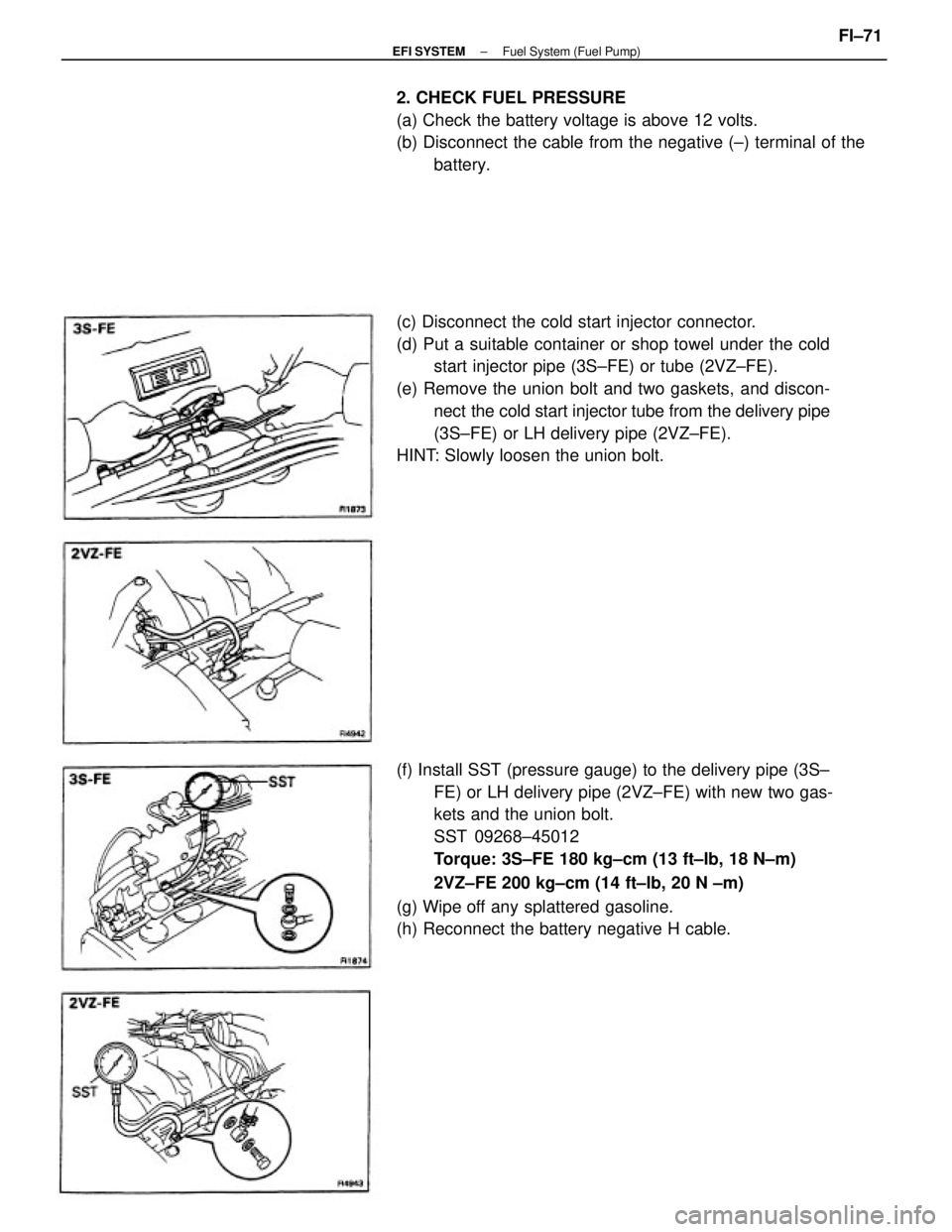

(f) Install SST (pressure gauge) to the delivery pipe (3S±

FE) or LH delivery pipe (2VZ±FE) with new two gas-

kets and the union bolt.

SST 09268±45012

Torque: 3S±FE 180 kg±cm (13 ft±Ib, 18 N±m)

2VZ±FE 200 kg±cm (14 ft±lb, 20 N ±m)

(g) Wipe off any splattered gasoline.

(h) Reconnect the battery negative H cable. (c) Disconnect the cold start injector connector.

(d) Put a suitable container or shop towel under the cold

start injector pipe (3S±FE) or tube (2VZ±FE).

(e) Remove the union bolt and two gaskets, and discon-

nect the cold start injector tube from the delivery pipe

(3S±FE) or LH delivery pipe (2VZ±FE).

HINT: Slowly loosen the union bolt. 2. CHECK FUEL PRESSURE

(a) Check the battery voltage is above 12 volts.

(b) Disconnect the cable from the negative (±) terminal of the

battery.

± EFI SYSTEMFuel System (Fuel Pump)FI±71

Page 1049 of 2389

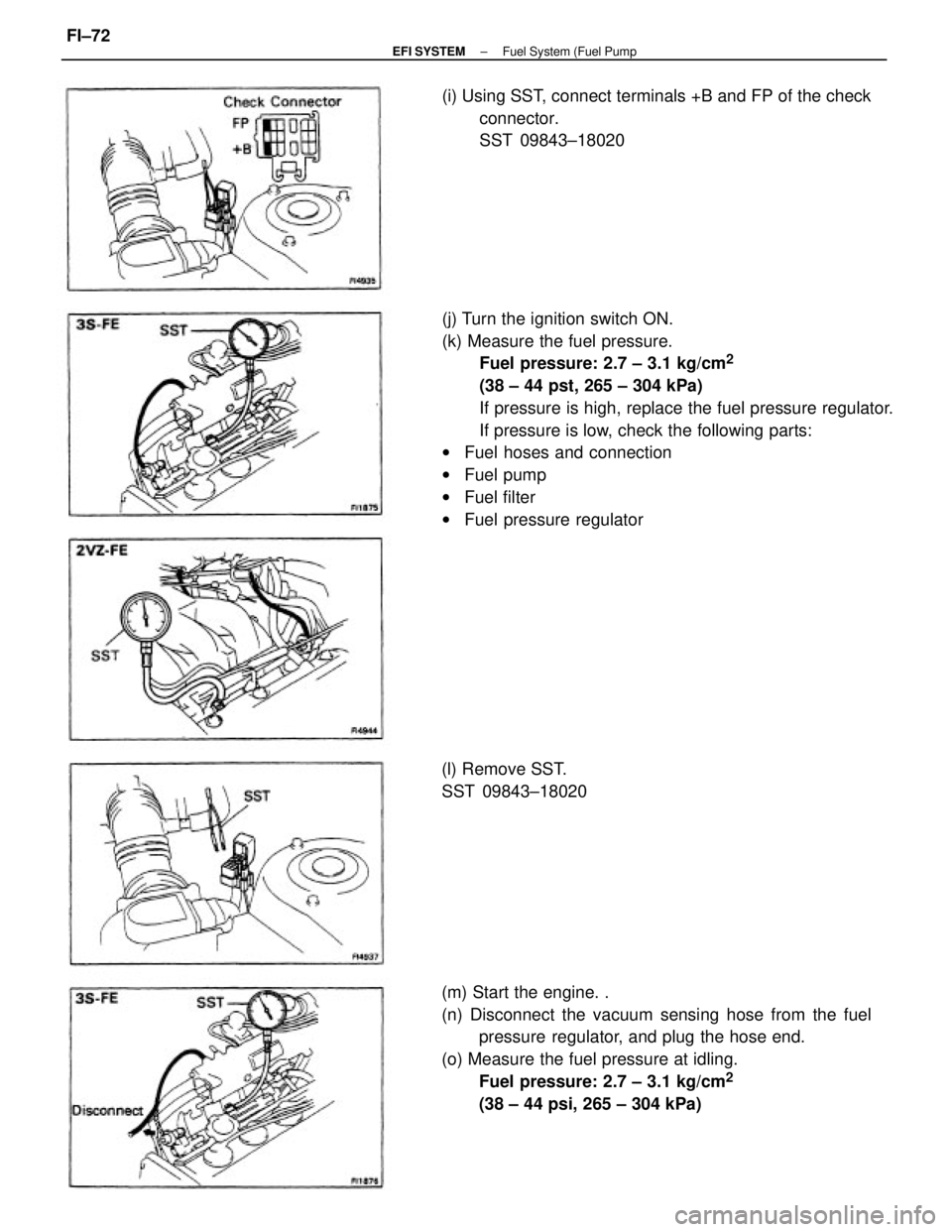

(j) Turn the ignition switch ON.

(k) Measure the fuel pressure.

Fuel pressure: 2.7 ± 3.1 kg/cm

2

(38 ± 44 pst, 265 ± 304 kPa)

If pressure is high, replace the fuel pressure regulator.

If pressure is low, check the following parts:

wFuel hoses and connection

wFuel pump

wFuel filter

wFuel pressure regulator

(m) Start the engine. .

(n) Disconnect the vacuum sensing hose from the fuel

pressure regulator, and plug the hose end.

(o) Measure the fuel pressure at idling.

Fuel pressure: 2.7 ± 3.1 kg/cm

2

(38 ± 44 psi, 265 ± 304 kPa) (i) Using SST, connect terminals +B and FP of the check

connector.

SST 09843±18020

(l) Remove SST.

SST 09843±18020

± EFI SYSTEMFuel System (Fuel PumpFI±72

Page 1050 of 2389

(s) After checking fuel pressure, disconnect the battery

negative (±) cable and carefully remove the SST to

prevent gasoline from splashing.

SST 09268±45012

(t) Install the cold start injector pipe (3S±FE) or tube (2VZ±

FE) with two new gaskets and the. union bolt.

Torque: 3S±FE 180 kg±cm (113 ft±lb, 18 N±m)

2VZ±FE 204 kg±cm (14 ft±Ib, 20 N±m)

(u) Reconnect the cold start injector connector.

(v) Reconnect the cable to the negative (±) terminal of the

battery.

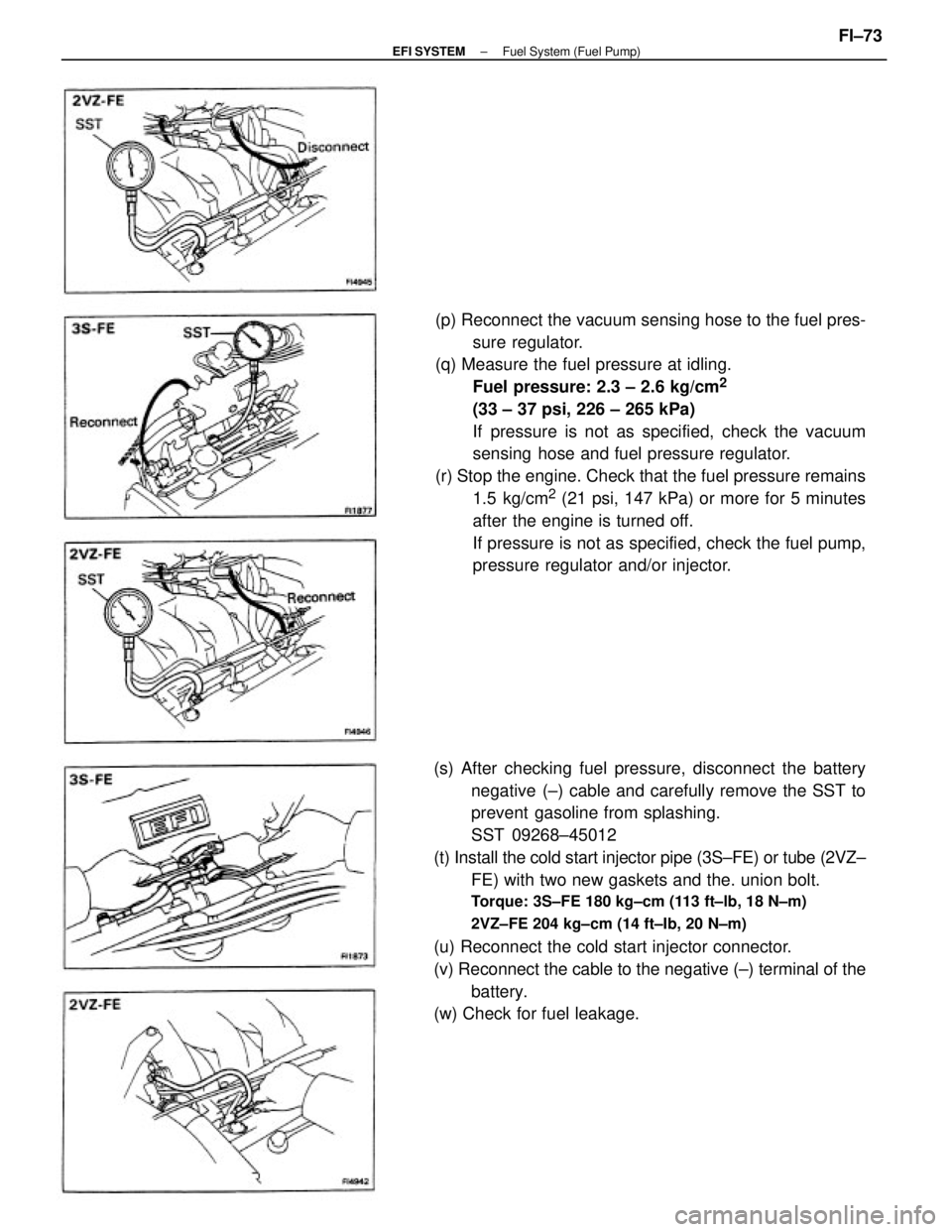

(w) Check for fuel leakage.(p) Reconnect the vacuum sensing hose to the fuel pres-

sure regulator.

(q) Measure the fuel pressure at idling.

Fuel pressure: 2.3 ± 2.6 kg/cm

2

(33 ± 37 psi, 226 ± 265 kPa)

If pressure is not as specified, check the vacuum

sensing hose and fuel pressure regulator.

(r) Stop the engine. Check that the fuel pressure remains

1.5 kg/cm

2 (21 psi, 147 kPa) or more for 5 minutes

after the engine is turned off.

If pressure is not as specified, check the fuel pump,

pressure regulator and/or injector.

± EFI SYSTEMFuel System (Fuel Pump)FI±73

Page 1051 of 2389

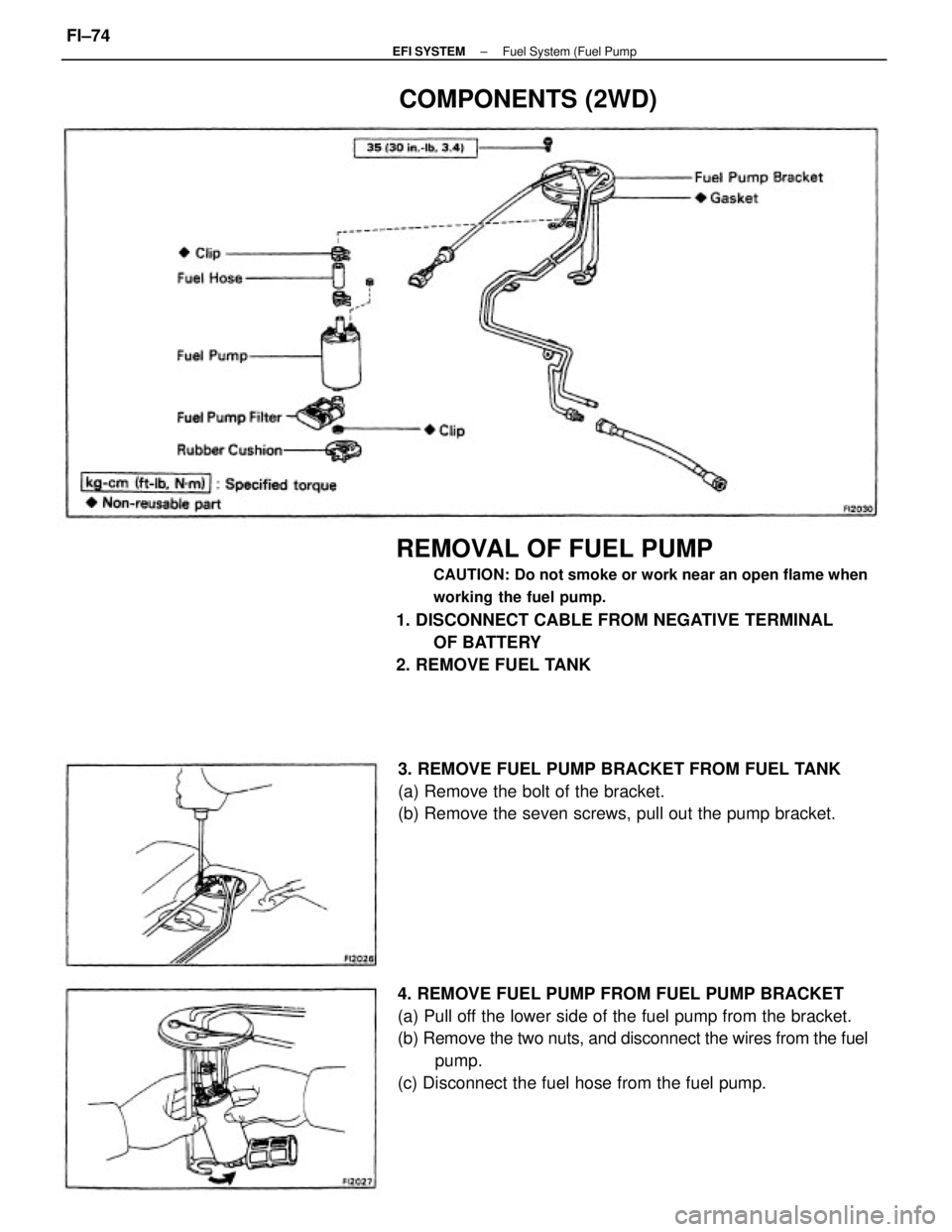

REMOVAL OF FUEL PUMP

CAUTION: Do not smoke or work near an open flame when

working the fuel pump.

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

2. REMOVE FUEL TANK

4. REMOVE FUEL PUMP FROM FUEL PUMP BRACKET

(a) Pull off the lower side of the fuel pump from the bracket.

(b) Remove the two nuts, and disconnect the wires from the fuel

pump.

(c) Disconnect the fuel hose from the fuel pump.3. REMOVE FUEL PUMP BRACKET FROM FUEL TANK

(a) Remove the bolt of the bracket.

(b) Remove the seven screws, pull out the pump bracket.

COMPONENTS (2WD)

± EFI SYSTEMFuel System (Fuel PumpFI±74

Page 1052 of 2389

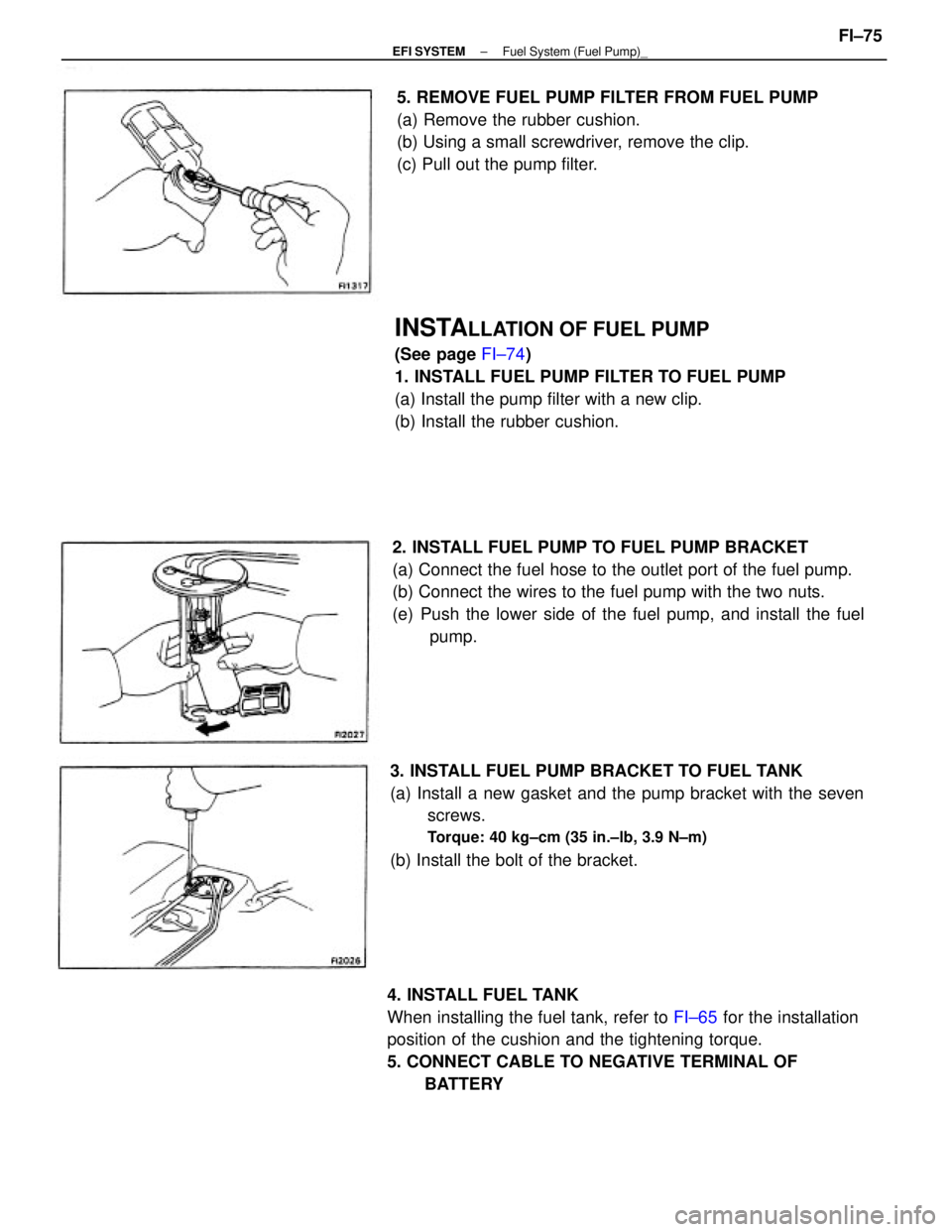

4. INSTALL FUEL TANK

When installing the fuel tank, refer to FI±65 for the installation

position of the cushion and the tightening torque.

5. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY 2. INSTALL FUEL PUMP TO FUEL PUMP BRACKET

(a) Connect the fuel hose to the outlet port of the fuel pump.

(b) Connect the wires to the fuel pump with the two nuts.

(e) Push the lower side of the fuel pump, and install the fuel

pump.

3. INSTALL FUEL PUMP BRACKET TO FUEL TANK

(a) Install a new gasket and the pump bracket with the seven

screws.

Torque: 40 kg±cm (35 in.±lb, 3.9 N±m)

(b) Install the bolt of the bracket.

INSTALLATION OF FUEL PUMP

(See page FI±74)

1. INSTALL FUEL PUMP FILTER TO FUEL PUMP

(a) Install the pump filter with a new clip.

(b) Install the rubber cushion.5. REMOVE FUEL PUMP FILTER FROM FUEL PUMP

(a) Remove the rubber cushion.

(b) Using a small screwdriver, remove the clip.

(c) Pull out the pump filter.

± EFI SYSTEMFuel System (Fuel Pump)_FI±75

Page 1053 of 2389

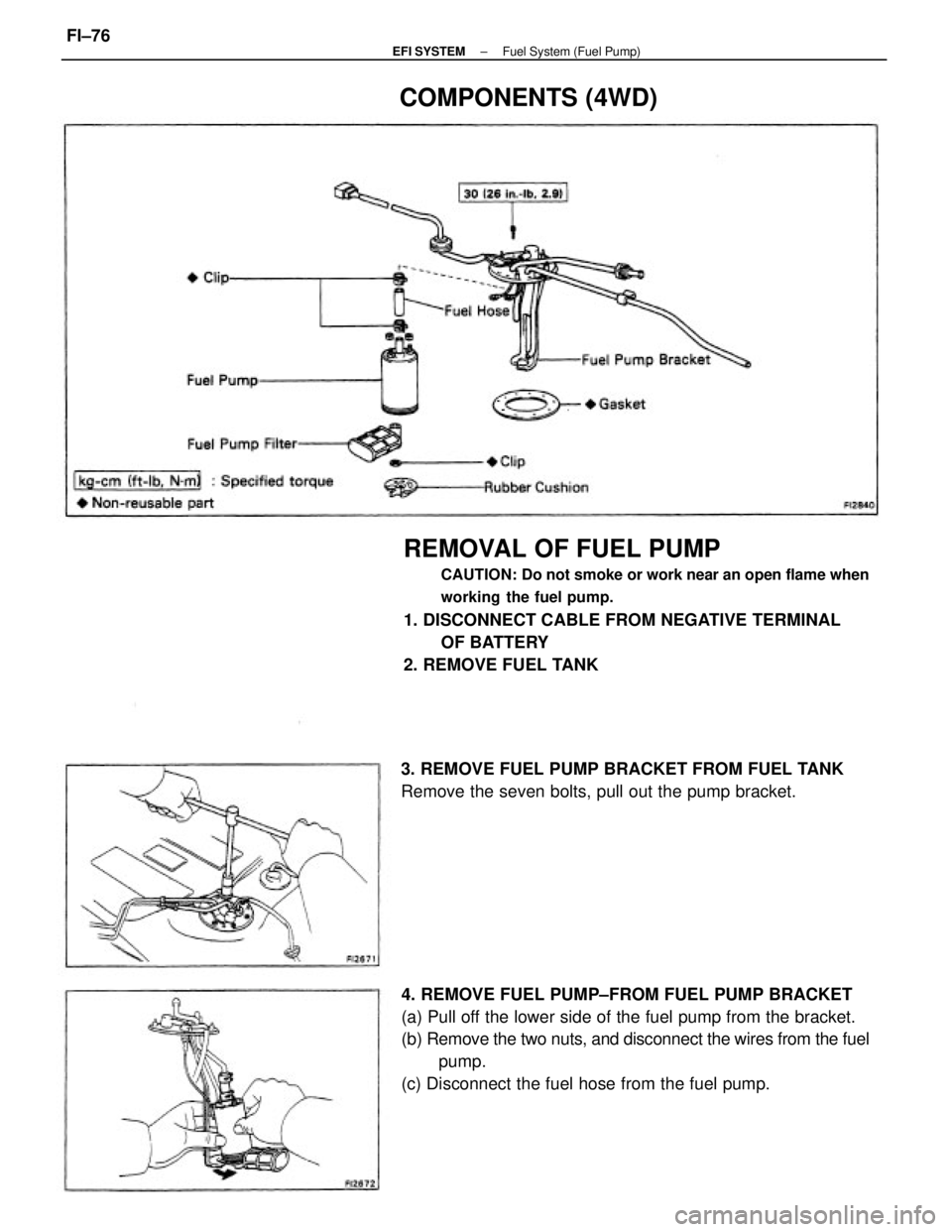

REMOVAL OF FUEL PUMP

CAUTION: Do not smoke or work near an open flame when

working the fuel pump.

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

2. REMOVE FUEL TANK

4. REMOVE FUEL PUMP±FROM FUEL PUMP BRACKET

(a) Pull off the lower side of the fuel pump from the bracket.

(b) Remove the two nuts, and disconnect the wires from the fuel

pump.

(c) Disconnect the fuel hose from the fuel pump. 3. REMOVE FUEL PUMP BRACKET FROM FUEL TANK

Remove the seven bolts, pull out the pump bracket.

COMPONENTS (4WD)

± EFI SYSTEMFuel System (Fuel Pump)FI±76

Page 1054 of 2389

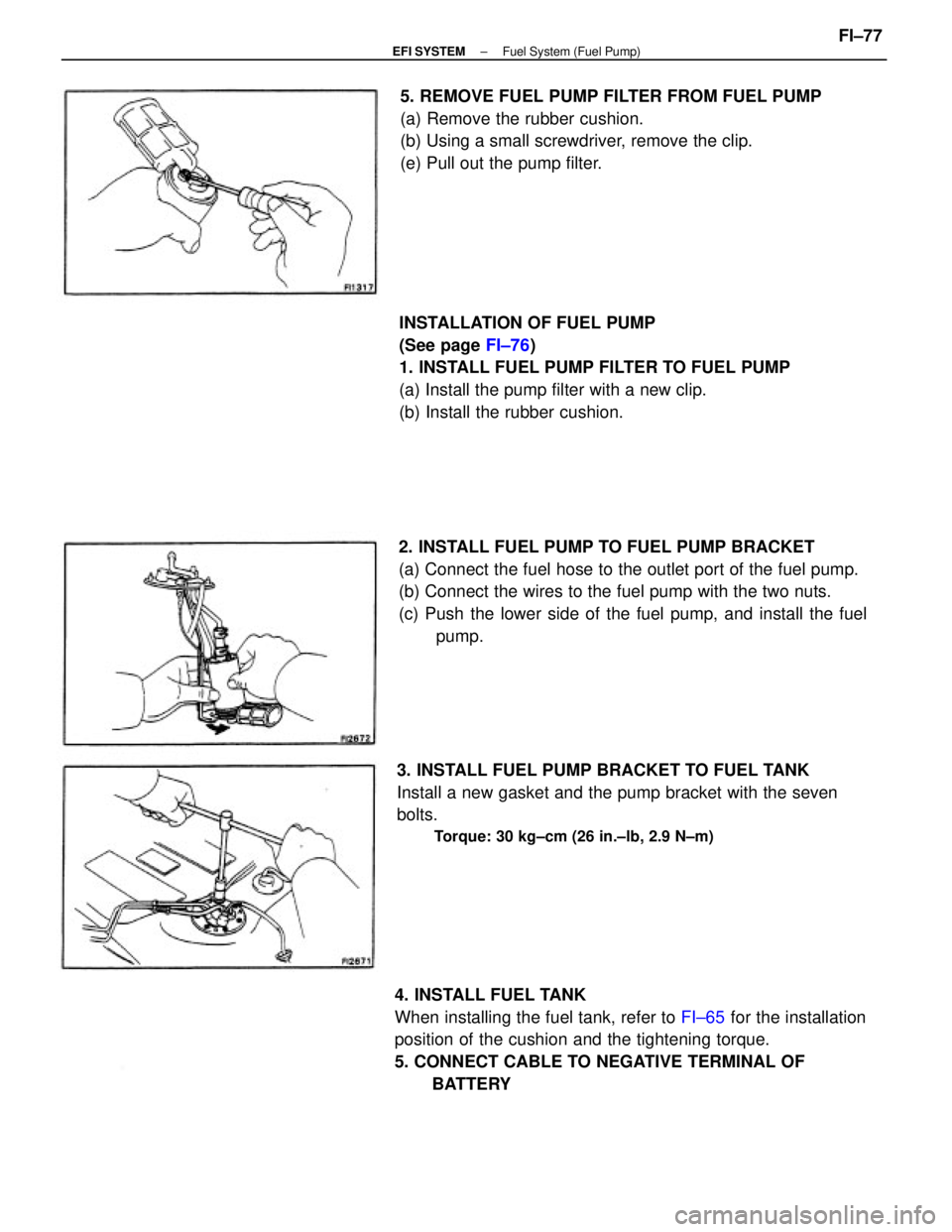

2. INSTALL FUEL PUMP TO FUEL PUMP BRACKET

(a) Connect the fuel hose to the outlet port of the fuel pump.

(b) Connect the wires to the fuel pump with the two nuts.

(c) Push the lower side of the fuel pump, and install the fuel

pump.

4. INSTALL FUEL TANK

When installing the fuel tank, refer to FI±65 for the installation

position of the cushion and the tightening torque.

5. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY INSTALLATION OF FUEL PUMP

(See page FI±76)

1. INSTALL FUEL PUMP FILTER TO FUEL PUMP

(a) Install the pump filter with a new clip.

(b) Install the rubber cushion.

3. INSTALL FUEL PUMP BRACKET TO FUEL TANK

Install a new gasket and the pump bracket with the seven

bolts.

Torque: 30 kg±cm (26 in.±lb, 2.9 N±m)

5. REMOVE FUEL PUMP FILTER FROM FUEL PUMP

(a) Remove the rubber cushion.

(b) Using a small screwdriver, remove the clip.

(e) Pull out the pump filter.

± EFI SYSTEMFuel System (Fuel Pump)FI±77

Page 1183 of 2389

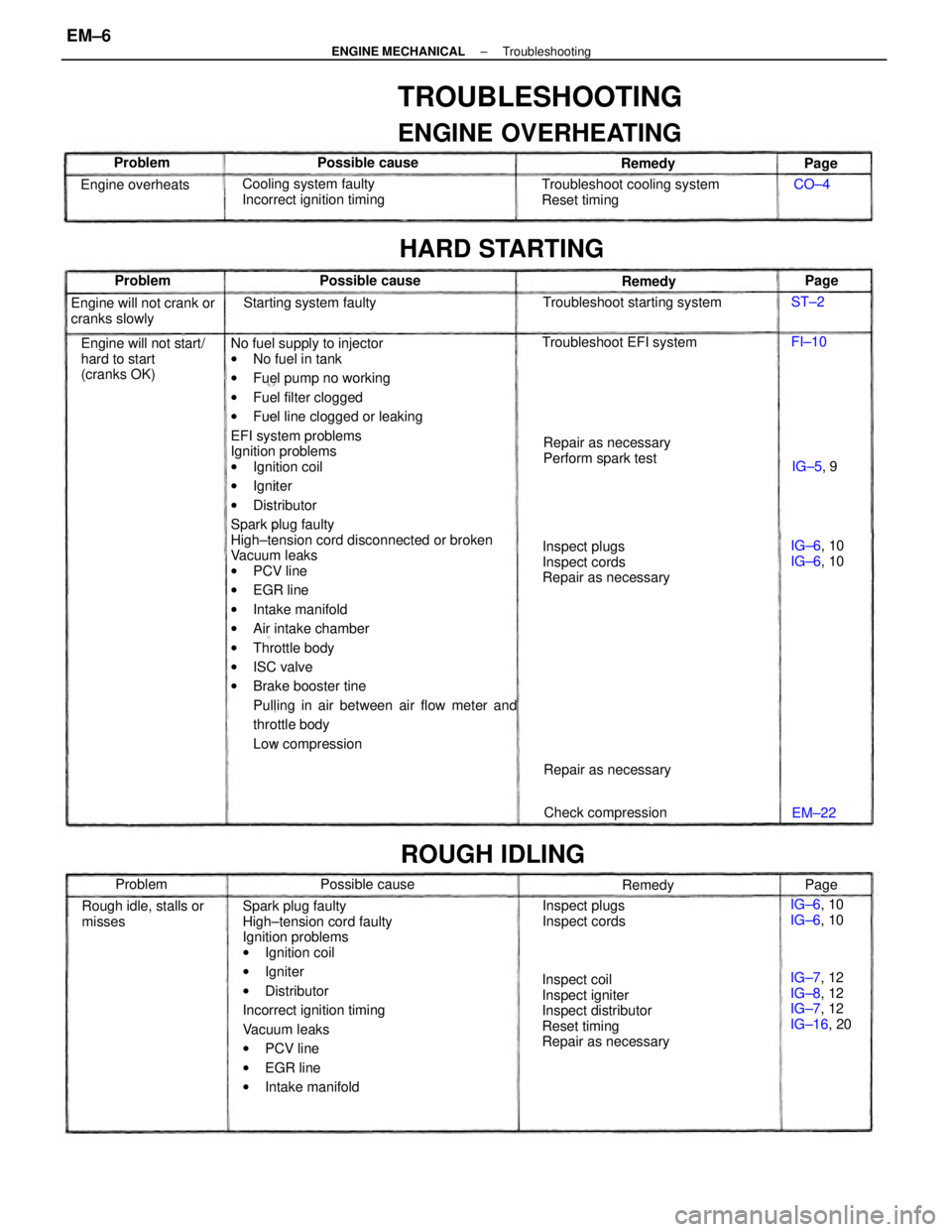

No fuel supply to injector

wNo fuel in tank

wFuel pump no working

wFuel filter clogged

wFuel line clogged or leaking

EFI system problems

Ignition problems

wIgnition coil

wIgniter

wDistributor

Spark plug faulty

High±tension cord disconnected or broken

Vacuum leaks

wPCV line

wEGR line

wIntake manifold

wAir intake chamber

wThrottle body

wISC valve

wBrake booster tine

Pulling in air between air flow meter and

throttle body

Low compression

Spark plug faulty

High±tension cord faulty

Ignition problems

wIgnition coil

wIgniter

wDistributor

Incorrect ignition timing

Vacuum leaks

wPCV line

wEGR line

wIntake manifold

TROUBLESHOOTING

ENGINE OVERHEATING

Inspect coil

Inspect igniter

Inspect distributor

Reset timing

Repair as necessaryInspect plugs

Inspect cords

Repair as necessary Troubleshoot cooling system

Reset timing

Engine will not start/

hard to start

(cranks OK)Cooling system faulty

Incorrect ignition timing

Repair as necessary

Perform spark test Engine will not crank or

cranks slowly

IG±7, 12

IG±8, 12

IG±7, 12

IG±16, 20 Rough idle, stalls or

misses

HARD STARTING

Troubleshoot starting system

Inspect plugs

Inspect cords Troubleshoot EFI system

ROUGH IDLING

Starting system faulty

Check compression Repair as necessary Engine overheats

IG±6, 10

IG±6, 10 IG±6, 10

IG±6, 10 Possible cause

Possible cause Possible cause

Remedy Remedy

Problem

Remedy Problem Problem

IG±5, 9

EM±22Page

Page

Page CO±4

FI±10 ST±2

± ENGINE MECHANICALTroubleshootingEM±6