fuel pump TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1286 of 2389

15. DISCONNECT HOSES

(a) Two heater water by±pass hoses

(b) Two fuel hoses

NOTICE: Catch leaking fuel in a container.

(c) Brake booster vacuum hose

(d) A/C control valve vacuum hoses

(e) Charcoal canister vacuum hose

16. DISCONNECT WIRES AND CONNECTORS

(a) Check connector

(b) Ground straps from LH fender apron

(e) Connectors from relay box

(d) Engine room wire connector

17. RAISE VEHICLE

NOTICE: Be sure the vehicle is securely supported.

18. REMOVE ENGINE UNDER COVERS

19. DRAIN ENGINE OIL (See page LU±7)

20. REMOVE SUSPENSION LOWER CROSSMEMBER

Remove the four bolts, two nuts and crossmember.

21. REMOVE DRIVE SHAFTS

22. (4WD) .

REMOVE PROPELLER SHAFT

23. (4WD)

REMOVE DEFECTOR FROM TRANSFER EXTENSION

HOUSING

24. REMOVE PS PUMP WITHOUT DISCONNECTING

HOSES

HINT: Put aside the pump and suspend it to the cowl with a

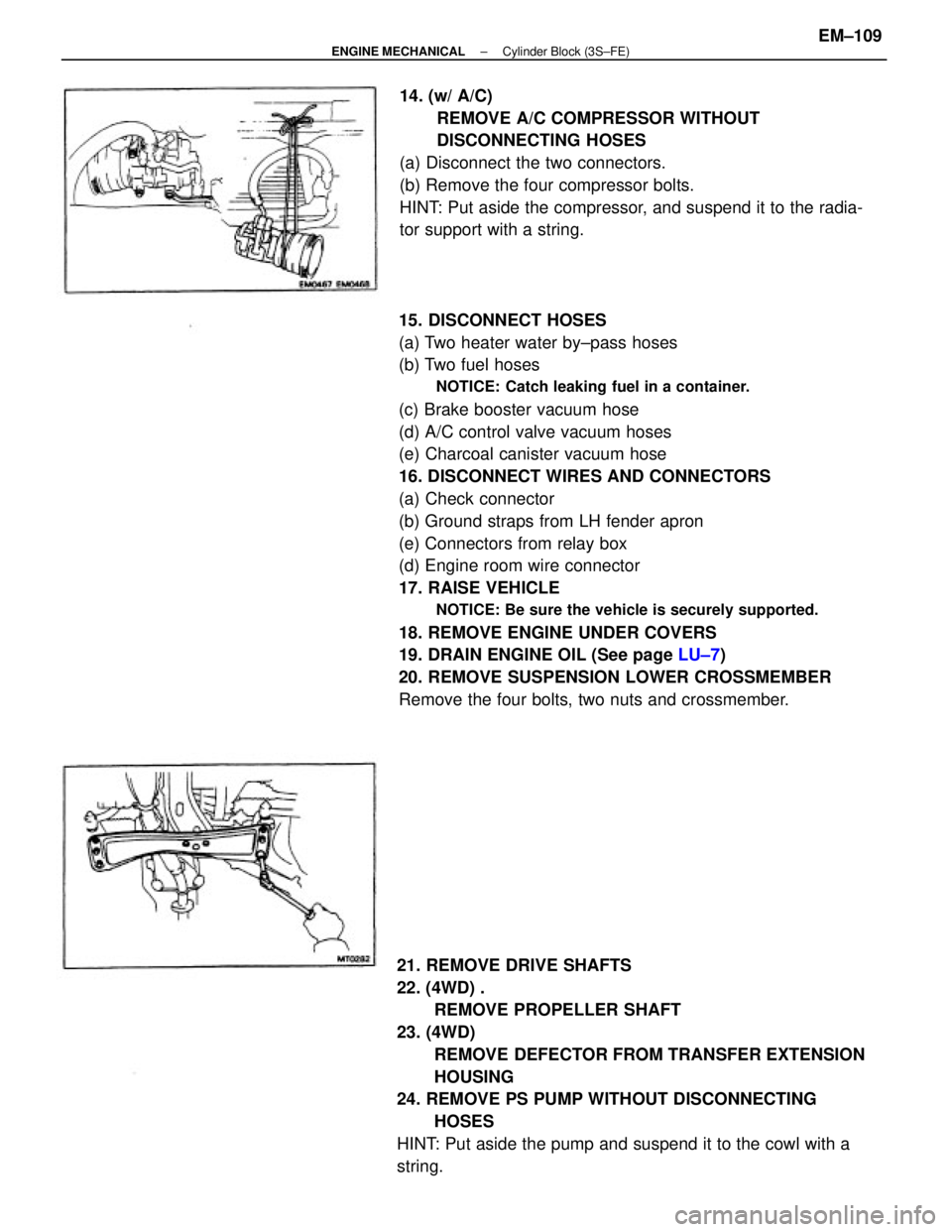

string.14. (w/ A/C)

REMOVE A/C COMPRESSOR WITHOUT

DISCONNECTING HOSES

(a) Disconnect the two connectors.

(b) Remove the four compressor bolts.

HINT: Put aside the compressor, and suspend it to the radia-

tor support with a string.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±109

Page 1313 of 2389

(c) Install the clamp with the bolt.

13. INSTALL PS PUMP

14. (4WD)

INSTALL DEFLECTOR TO TRANSFER EXTENSION

HOUSING

15. (411VD)

INSTALL PROPELLER SHAFT

16. INSTALL DRIVE SHAFTS

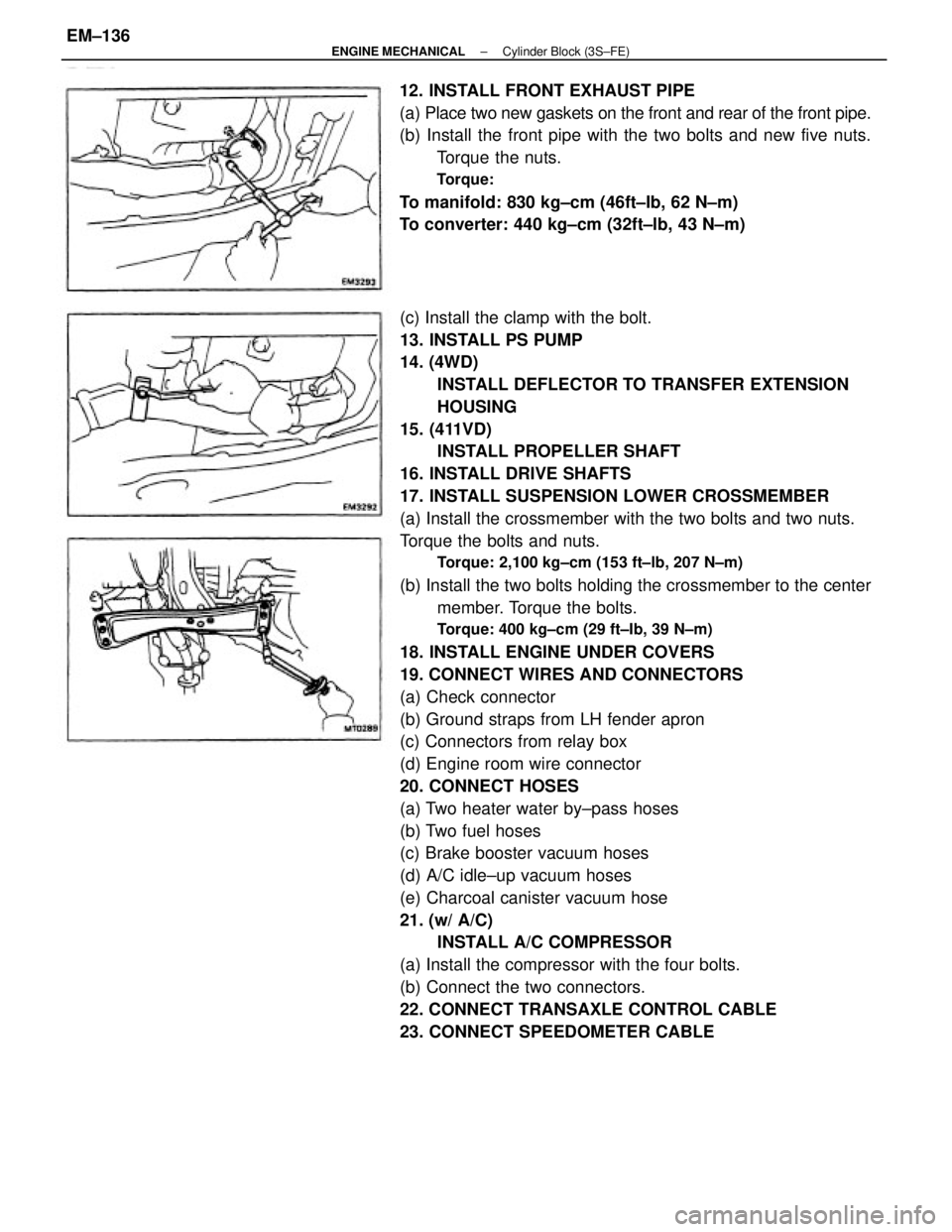

17. INSTALL SUSPENSION LOWER CROSSMEMBER

(a) Install the crossmember with the two bolts and two nuts.

Torque the bolts and nuts.

Torque: 2,100 kg±cm (153 ft±lb, 207 N±m)

(b) Install the two bolts holding the crossmember to the center

member. Torque the bolts.

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

18. INSTALL ENGINE UNDER COVERS

19. CONNECT WIRES AND CONNECTORS

(a) Check connector

(b) Ground straps from LH fender apron

(c) Connectors from relay box

(d) Engine room wire connector

20. CONNECT HOSES

(a) Two heater water by±pass hoses

(b) Two fuel hoses

(c) Brake booster vacuum hoses

(d) A/C idle±up vacuum hoses

(e) Charcoal canister vacuum hose

21. (w/ A/C)

INSTALL A/C COMPRESSOR

(a) Install the compressor with the four bolts.

(b) Connect the two connectors.

22. CONNECT TRANSAXLE CONTROL CABLE

23. CONNECT SPEEDOMETER CABLE 12. INSTALL FRONT EXHAUST PIPE

(a) Place two new gaskets on the front and rear of the front pipe.

(b) Install the front pipe with the two bolts and new five nuts.

Torque the nuts.

Torque:

To manifold: 830 kg±cm (46ft±Ib, 62 N±m)

To converter: 440 kg±cm (32ft±lb, 43 N±m)

± ENGINE MECHANICALCylinder Block (3S±FE)EM±136

Page 1318 of 2389

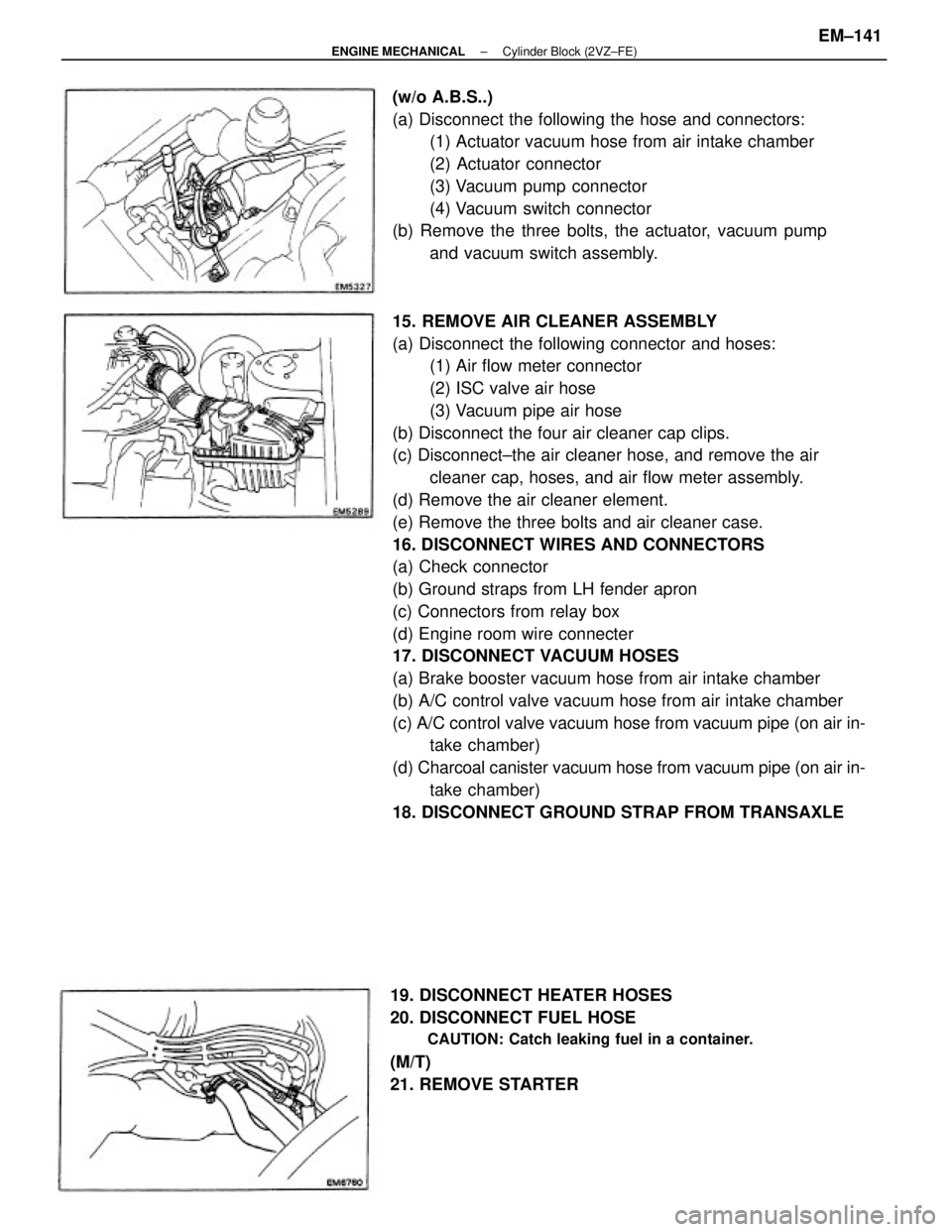

15. REMOVE AIR CLEANER ASSEMBLY

(a) Disconnect the following connector and hoses:

(1) Air flow meter connector

(2) ISC valve air hose

(3) Vacuum pipe air hose

(b) Disconnect the four air cleaner cap clips.

(c) Disconnect±the air cleaner hose, and remove the air

cleaner cap, hoses, and air flow meter assembly.

(d) Remove the air cleaner element.

(e) Remove the three bolts and air cleaner case.

16. DISCONNECT WIRES AND CONNECTORS

(a) Check connector

(b) Ground straps from LH fender apron

(c) Connectors from relay box

(d) Engine room wire connecter

17. DISCONNECT VACUUM HOSES

(a) Brake booster vacuum hose from air intake chamber

(b) A/C control valve vacuum hose from air intake chamber

(c) A/C control valve vacuum hose from vacuum pipe (on air in-

take chamber)

(d) Charcoal canister vacuum hose from vacuum pipe (on air in-

take chamber)

18. DISCONNECT GROUND STRAP FROM TRANSAXLE (w/o A.B.S..)

(a) Disconnect the following the hose and connectors:

(1) Actuator vacuum hose from air intake chamber

(2) Actuator connector

(3) Vacuum pump connector

(4) Vacuum switch connector

(b) Remove the three bolts, the actuator, vacuum pump

and vacuum switch assembly.

19. DISCONNECT HEATER HOSES

20. DISCONNECT FUEL HOSE

CAUTION: Catch leaking fuel in a container.

(M/T)

21. REMOVE STARTER

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±141

Page 2224 of 2389

Fuel tank band x Body

Cold start injector x Air intake chamber

Cold start injector pipe x Cold start injector

Cold start injector pipe x Delivery pipe

Fuel pressure regulator X Delivery pipe

Fuel return pipe x Fuel pressure regulator

Delivery pipe x Cylinder head

Throttle body x Air intake chamberFuel evaporation vent tube x Fuel tank 4WD

Fuel inlet pipe x Fuel tankFuel sender gauge

Fuel pump X Fuel tank

Specifications (Cont'd)

Torque Specifications

Coolant temp. 805C (1765F) Intake air temp. 205C (685F) Measuring plate fully closed

Measuring plate fully openThrottle valve fully closed

Throttle valve fully closedThrottle valve fully closedThrottle valve fully closed

Throttle valve fully openThrottle valve fully open

* 1 w/o ECT *2 w/ ECT Throttle valve openThrottle valve open

Part tightened ECU (cont'd) Resistance

Condition

Fuel line

± SERVICE SPECIFICATIONSEFI System (3S±FE)A±13

Page 2228 of 2389

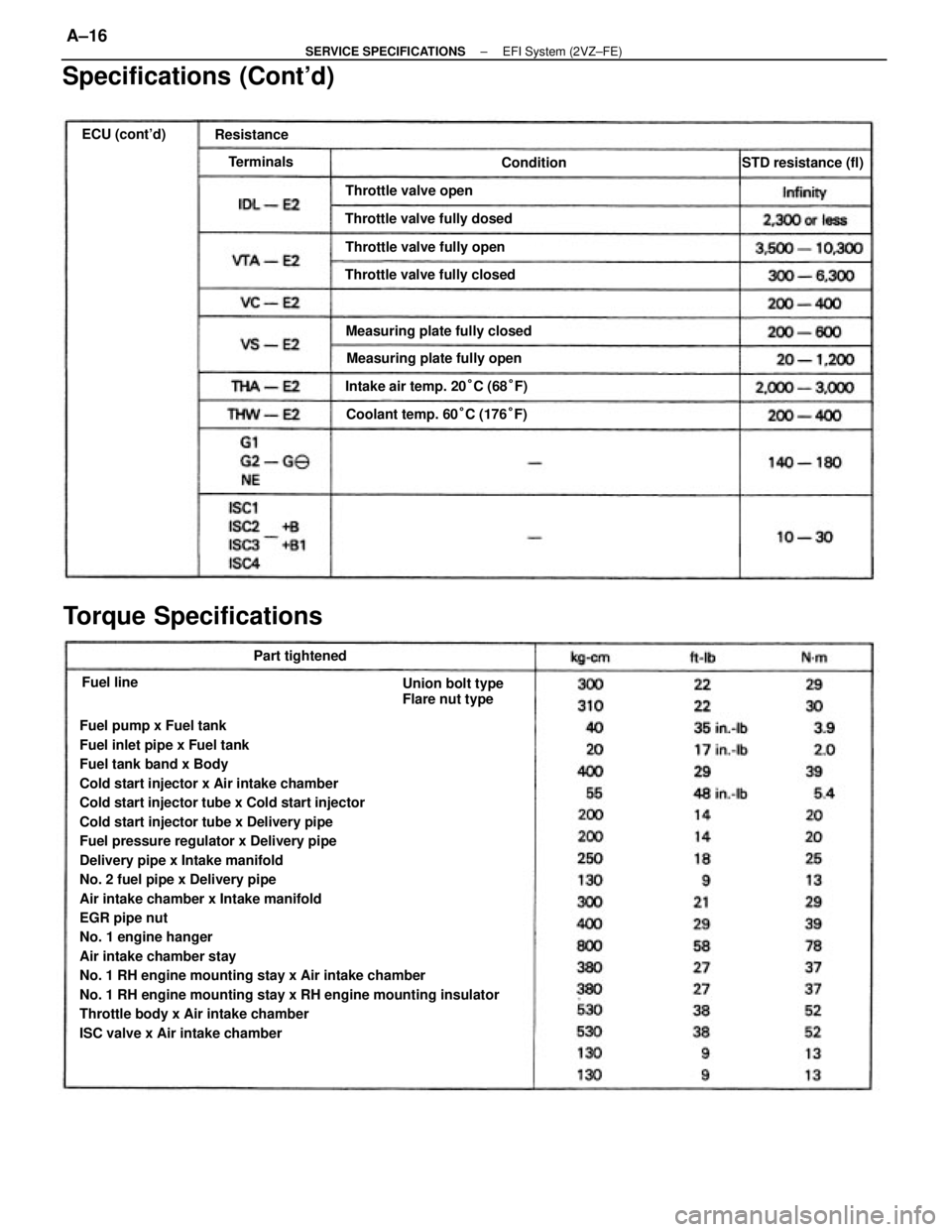

Fuel pump x Fuel tank

Fuel inlet pipe x Fuel tank

Fuel tank band x Body

Cold start injector x Air intake chamber

Cold start injector tube x Cold start injector

Cold start injector tube x Delivery pipe

Fuel pressure regulator x Delivery pipe

Delivery pipe x Intake manifold

No. 2 fuel pipe x Delivery pipe

Air intake chamber x Intake manifold

EGR pipe nut

No. 1 engine hanger

Air intake chamber stay

No. 1 RH engine mounting stay x Air intake chamber

No. 1 RH engine mounting stay x RH engine mounting insulator

Throttle body x Air intake chamber

ISC valve x Air intake chamber

Specifications (Cont'd)

Torque Specifications

Intake air temp. 20°C (68°F) Measuring plate fully closed

Coolant temp. 60°C (176°F)

Union bolt type

Flare nut type Measuring plate fully open Throttle valve fully dosed

Throttle valve fully closedThrottle valve fully open Throttle valve openSTD resistance (fl)

Part tightened ECU (cont'd)

Resistance

Terminals

Condition

Fuel line

± SERVICE SPECIFICATIONSEFI System (2VZ±FE)A±16

Page 2285 of 2389

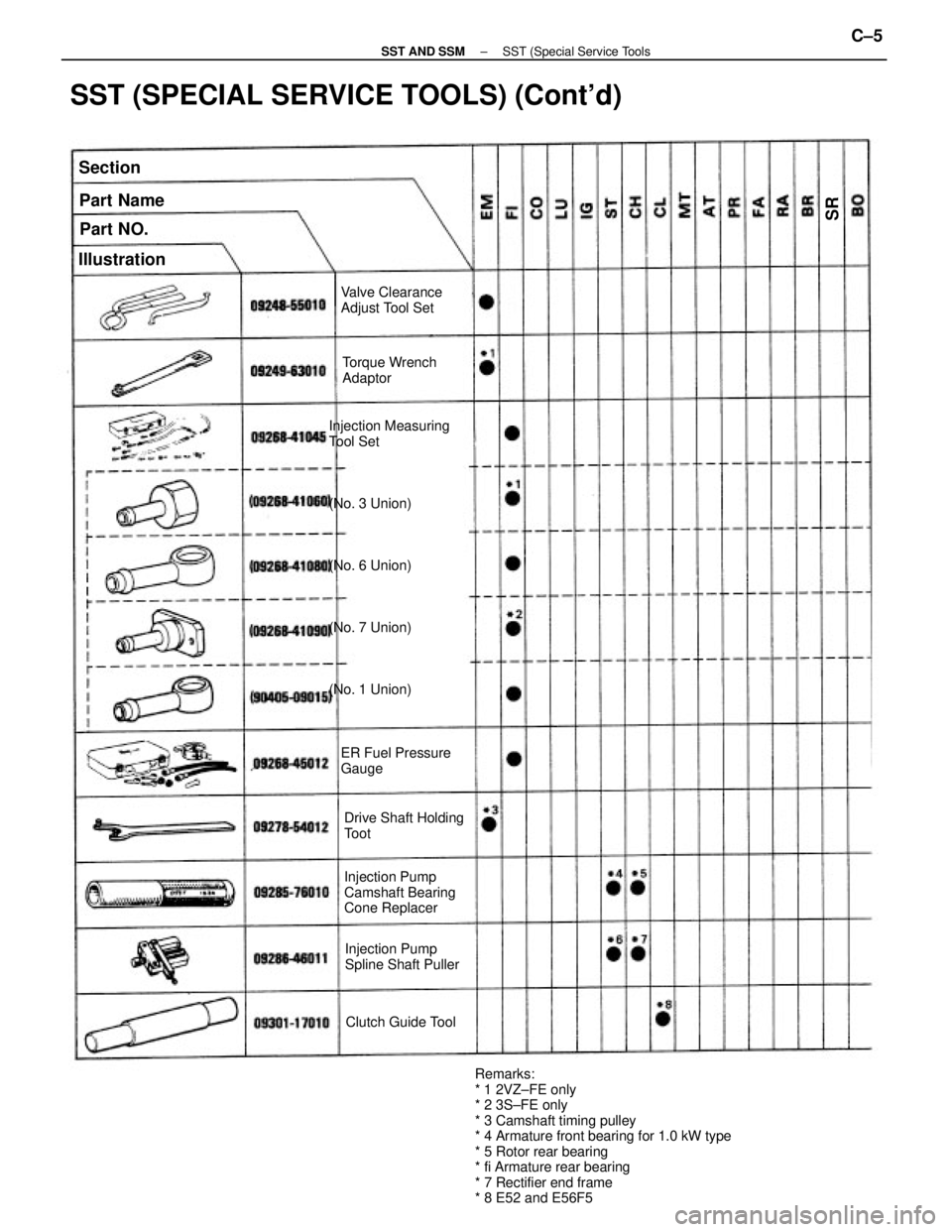

Remarks:

* 1 2VZ±FE only

* 2 3S±FE only

* 3 Camshaft timing pulley

* 4 Armature front bearing for 1.0 kW type

* 5 Rotor rear bearing

* fi Armature rear bearing

* 7 Rectifier end frame

* 8 E52 and E56F5 Injection Measuring

Tool Set

(No. 3 Union)

(No. 6 Union)

(No. 7 Union)

(No. 1 Union)

SST (SPECIAL SERVICE TOOLS) (Cont'd)

Injection Pump

Camshaft Bearing

Cone Replacer ER Fuel Pressure

Gauge

Injection Pump

Spline Shaft Puller Drive Shaft Holding

Toot Valve Clearance

Adjust Tool Set

Torque Wrench

Adaptor

Illustration

Clutch Guide Tool

Part Name

Part NO. SectionSR

± SST AND SSMSST (Special Service ToolsC±5