relay TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 242 of 2389

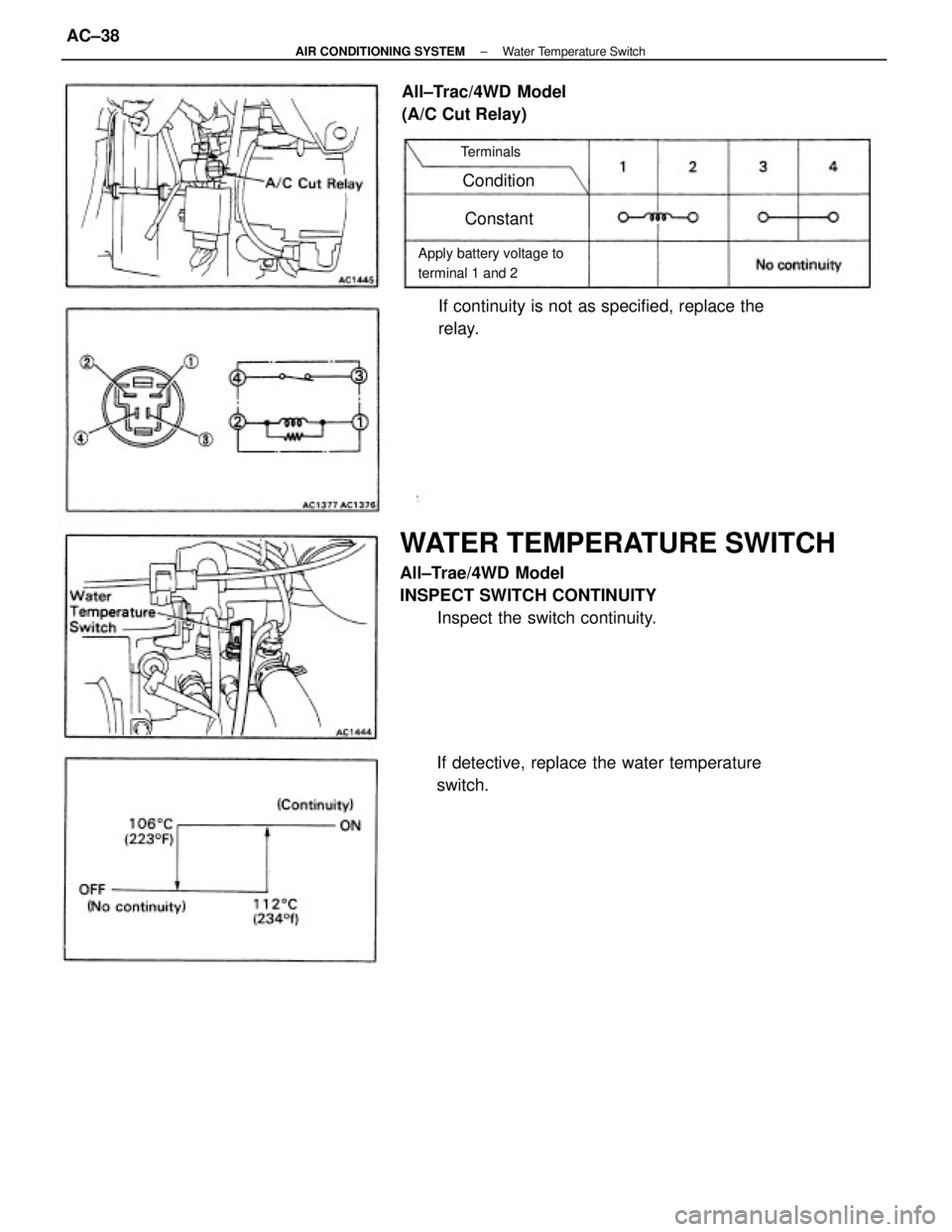

WATER TEMPERATURE SWITCH

All±Trae/4WD Model

INSPECT SWITCH CONTINUITY

Inspect the switch continuity.

If detective, replace the water temperature

switch.If continuity is not as specified, replace the

relay. All±Trac/4WD Model

(A/C Cut Relay)

Apply battery voltage to

terminal 1 and 2Terminals

Condition

Constant

± AIR CONDITIONING SYSTEMWater Temperature SwitchAC±38

Page 244 of 2389

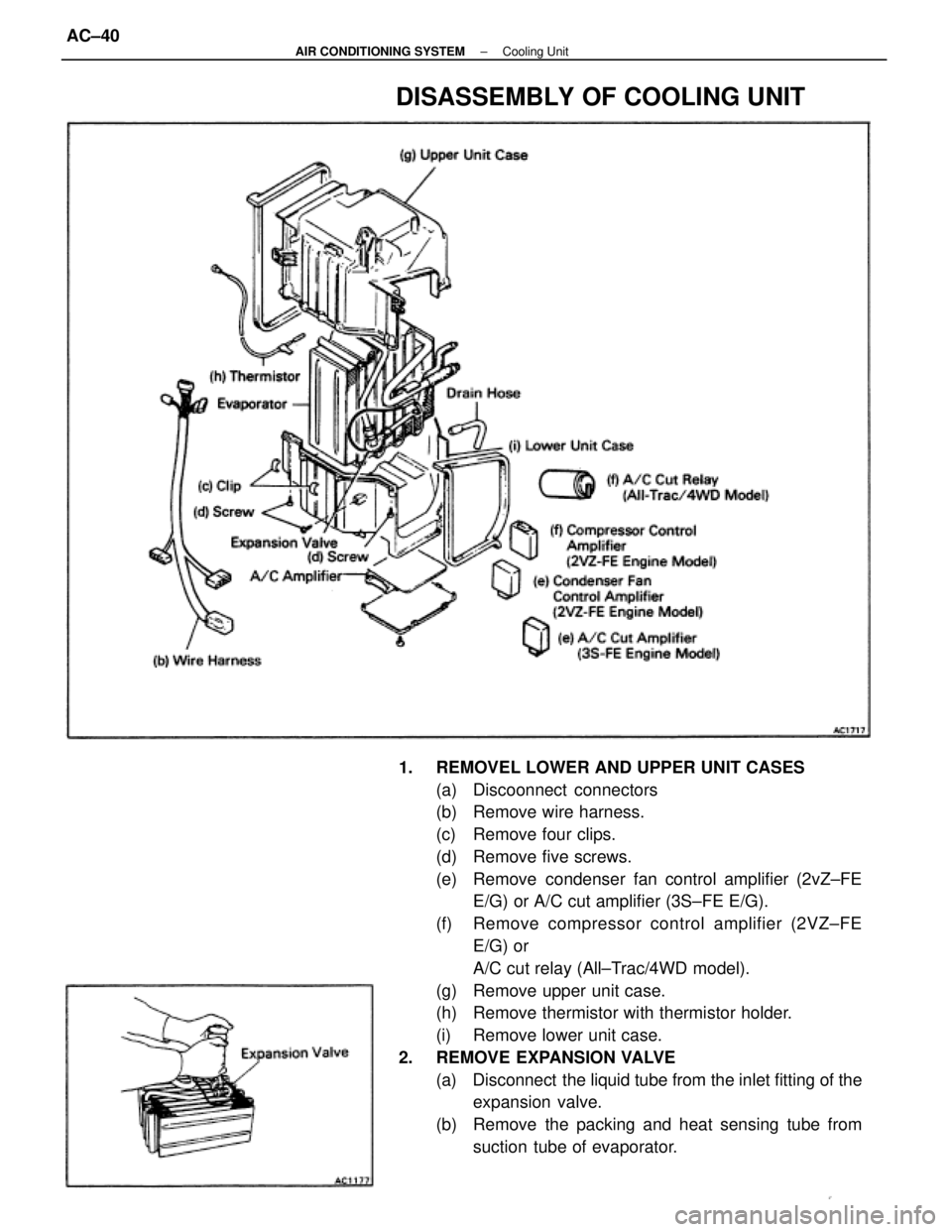

1. REMOVEL LOWER AND UPPER UNIT CASES

(a) Discoonnect connectors

(b) Remove wire harness.

(c) Remove four clips.

(d) Remove five screws.

(e) Remove condenser fan control amplifier (2vZ±FE

E/G) or A/C cut amplifier (3S±FE E/G).

(f) Remove compressor control amplifier (2VZ±FE

E/G) or

A/C cut relay (All±Trac/4WD model).

(g) Remove upper unit case.

(h) Remove thermistor with thermistor holder.

(i) Remove lower unit case.

2. REMOVE EXPANSION VALVE

(a) Disconnect the liquid tube from the inlet fitting of the

expansion valve.

(b) Remove the packing and heat sensing tube from

suction tube of evaporator.

DISASSEMBLY OF COOLING UNIT

± AIR CONDITIONING SYSTEMCooling UnitAC±40

Page 298 of 2389

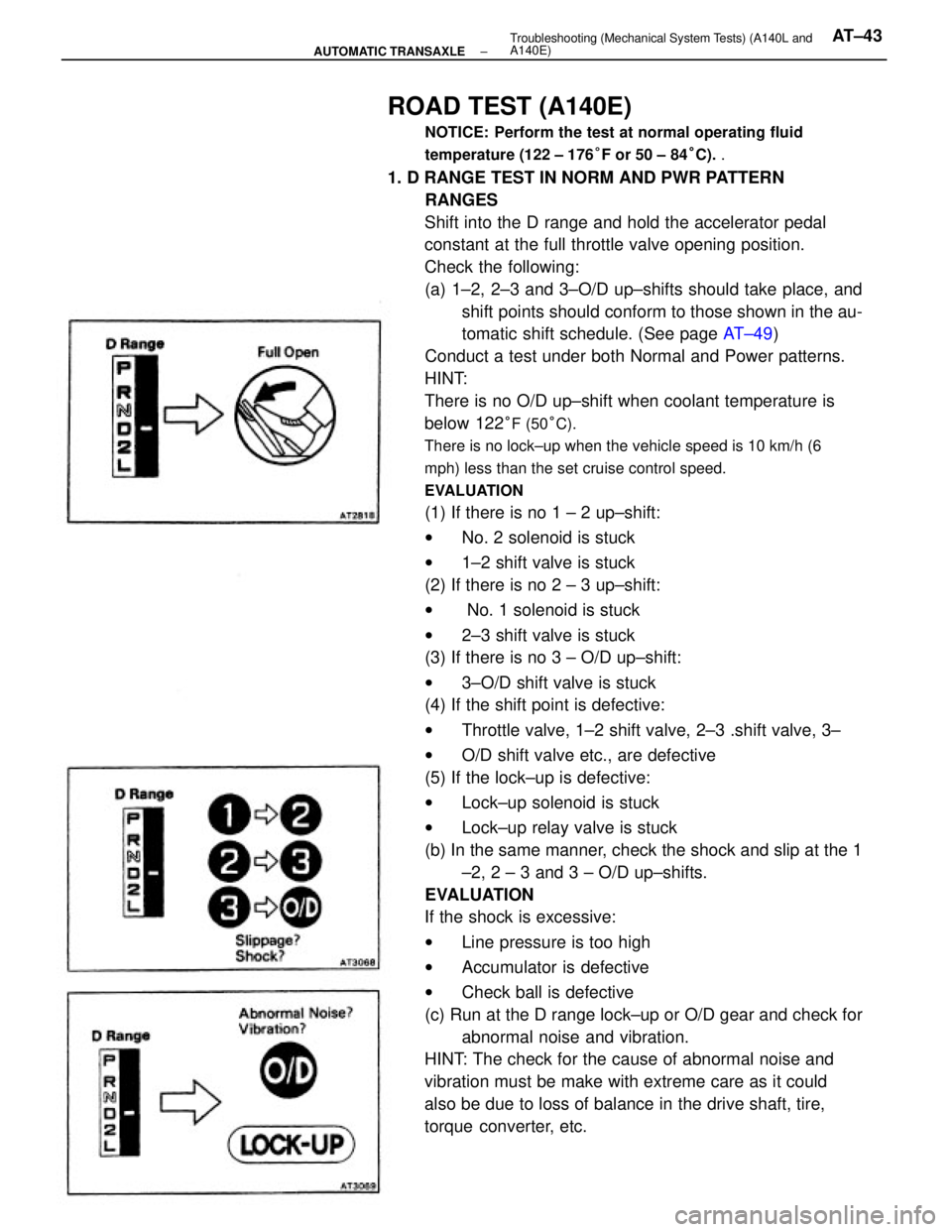

ROAD TEST (A140E)

NOTICE: Perform the test at normal operating fluid

temperature (122 ± 176°F or 50 ± 84°C). .

1. D RANGE TEST IN NORM AND PWR PATTERN

RANGES

Shift into the D range and hold the accelerator pedal

constant at the full throttle valve opening position.

Check the following:

(a) 1±2, 2±3 and 3±O/D up±shifts should take place, and

shift points should conform to those shown in the au-

tomatic shift schedule. (See page AT±49)

Conduct a test under both Normal and Power patterns.

HINT:

There is no O/D up±shift when coolant temperature is

below 122

°F (50°C).

There is no lock±up when the vehicle speed is 10 km/h (6

mph) less than the set cruise control speed.

EVALUATION

(1) If there is no 1 ± 2 up±shift:

wNo. 2 solenoid is stuck

w1±2 shift valve is stuck

(2) If there is no 2 ± 3 up±shift:

w No. 1 solenoid is stuck

w2±3 shift valve is stuck

(3) If there is no 3 ± O/D up±shift:

w3±O/D shift valve is stuck

(4) If the shift point is defective:

wThrottle valve, 1±2 shift valve, 2±3 .shift valve, 3±

wO/D shift valve etc., are defective

(5) If the lock±up is defective:

wLock±up solenoid is stuck

wLock±up relay valve is stuck

(b) In the same manner, check the shock and slip at the 1

±2, 2 ± 3 and 3 ± O/D up±shifts.

EVALUATION

If the shock is excessive:

wLine pressure is too high

wAccumulator is defective

wCheck ball is defective

(c) Run at the D range lock±up or O/D gear and check for

abnormal noise and vibration.

HINT: The check for the cause of abnormal noise and

vibration must be make with extreme care as it could

also be due to loss of balance in the drive shaft, tire,

torque converter, etc.

± AUTOMATIC TRANSAXLETroubleshooting (Mechanical System Tests) (A140L and

A140E)AT±43

Page 380 of 2389

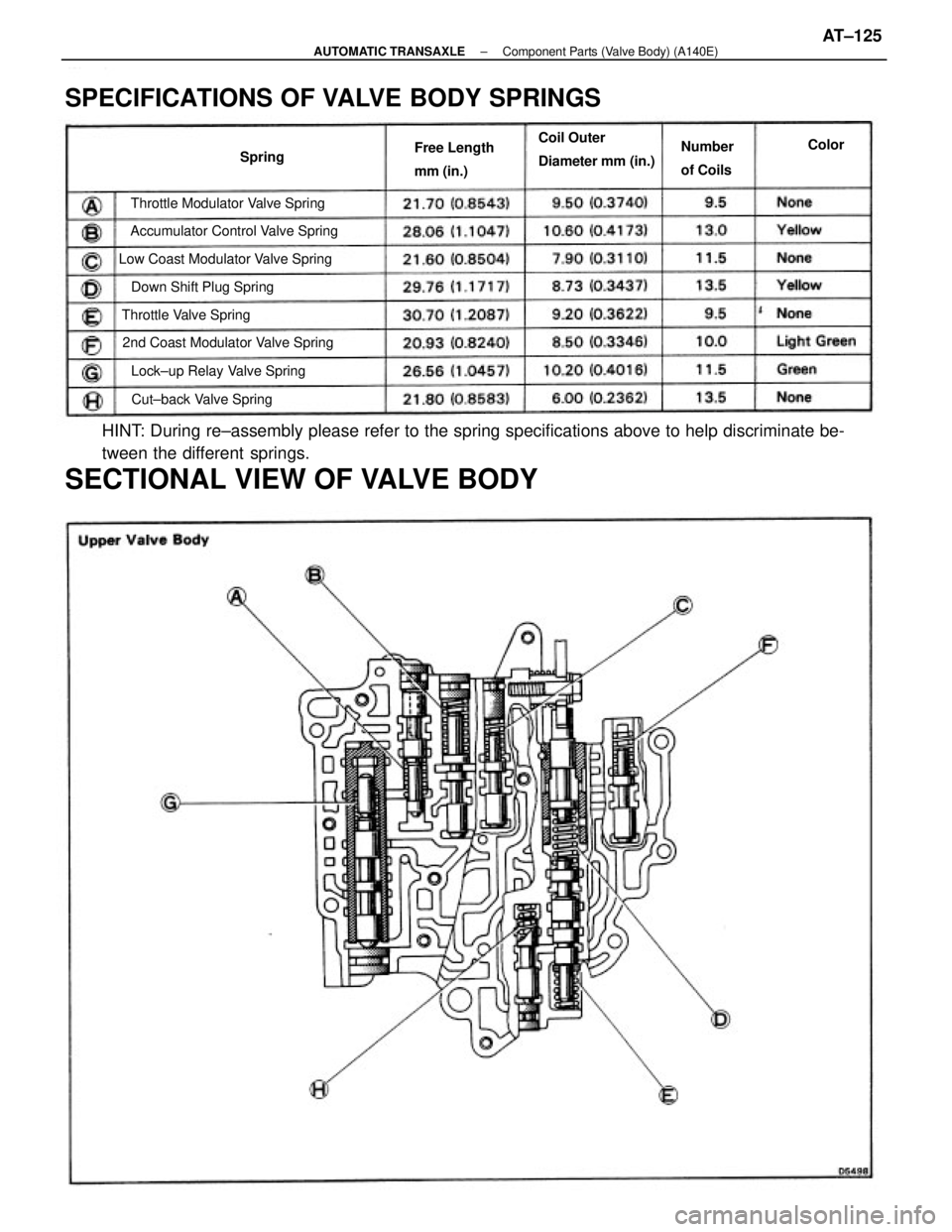

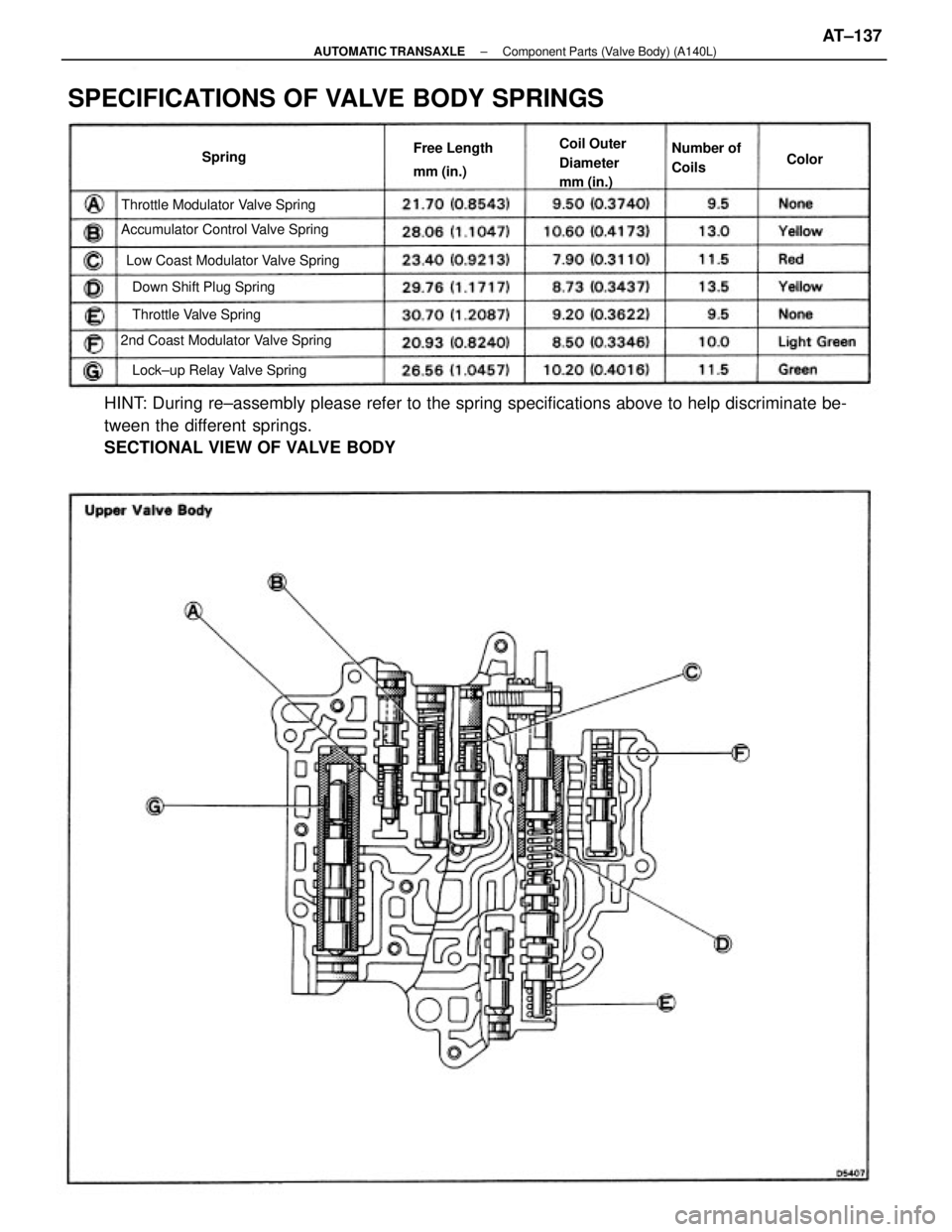

HINT: During re±assembly please refer to the spring specifications above to help discriminate be-

tween the different springs.

SECTIONAL VIEW OF VALVE BODY

SPECIFICATIONS OF VALVE BODY SPRINGS

Low Coast Modulator Valve Spring

2nd Coast Modulator Valve SpringAccumulator Control Valve SpringThrottle Modulator Valve Spring

Lock±up Relay Valve SpringCoil Outer

Diameter mm (in.)

Down Shift Plug Spring

Cut±back Valve Spring Throttle Valve SpringFree Length

mm (in.)Number

of Coils SpringColor

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body) (A140E)AT±125

Page 392 of 2389

HINT: During re±assembly please refer to the spring specifications above to help discriminate be-

tween the different springs.

SECTIONAL VIEW OF VALVE BODY

SPECIFICATIONS OF VALVE BODY SPRINGS

Low Coast Modulator Valve Spring

2nd Coast Modulator Valve SpringAccumulator Control Valve SpringThrottle Modulator Valve Spring

Lock±up Relay Valve SpringCoil Outer

Diameter

mm (in.)

Down Shift Plug Spring

Throttle Valve SpringFree Length

mm (in.)Number of

Coils Spring

Color

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body) (A140L)AT±137

Page 463 of 2389

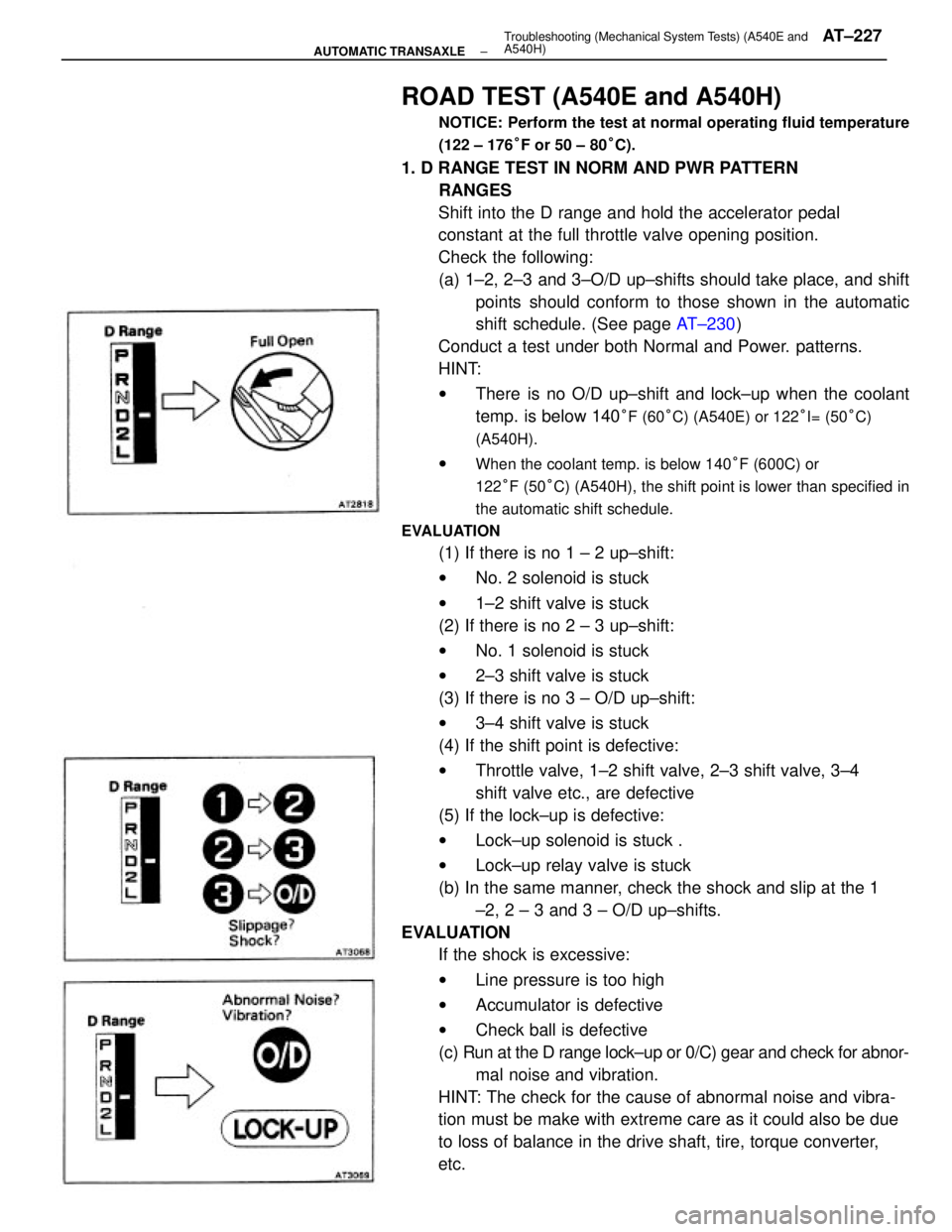

ROAD TEST (A540E and A540H)

NOTICE: Perform the test at normal operating fluid temperature

(122 ± 176°F or 50 ± 80°C).

1. D RANGE TEST IN NORM AND PWR PATTERN

RANGES

Shift into the D range and hold the accelerator pedal

constant at the full throttle valve opening position.

Check the following:

(a) 1±2, 2±3 and 3±O/D up±shifts should take place, and shift

points should conform to those shown in the automatic

shift schedule. (See page AT±230)

Conduct a test under both Normal and Power. patterns.

HINT:

wThere is no O/D up±shift and lock±up when the coolant

temp. is below 140

°F (60°C) (A540E) or 122°I= (50°C)

(A540H).

wWhen the coolant temp. is below 140°F (600C) or

122°F (50°C) (A540H), the shift point is lower than specified in

the automatic shift schedule.

EVALUATION

(1) If there is no 1 ± 2 up±shift:

wNo. 2 solenoid is stuck

w1±2 shift valve is stuck

(2) If there is no 2 ± 3 up±shift:

wNo. 1 solenoid is stuck

w2±3 shift valve is stuck

(3) If there is no 3 ± O/D up±shift:

w3±4 shift valve is stuck

(4) If the shift point is defective:

wThrottle valve, 1±2 shift valve, 2±3 shift valve, 3±4

shift valve etc., are defective

(5) If the lock±up is defective:

wLock±up solenoid is stuck .

wLock±up relay valve is stuck

(b) In the same manner, check the shock and slip at the 1

±2, 2 ± 3 and 3 ± O/D up±shifts.

EVALUATION

If the shock is excessive:

wLine pressure is too high

wAccumulator is defective

wCheck ball is defective

(c) Run at the D range lock±up or 0/C) gear and check for abnor-

mal noise and vibration.

HINT: The check for the cause of abnormal noise and vibra-

tion must be make with extreme care as it could also be due

to loss of balance in the drive shaft, tire, torque converter,

etc.

± AUTOMATIC TRANSAXLETroubleshooting (Mechanical System Tests) (A540E and

A540H)AT±227

Page 571 of 2389

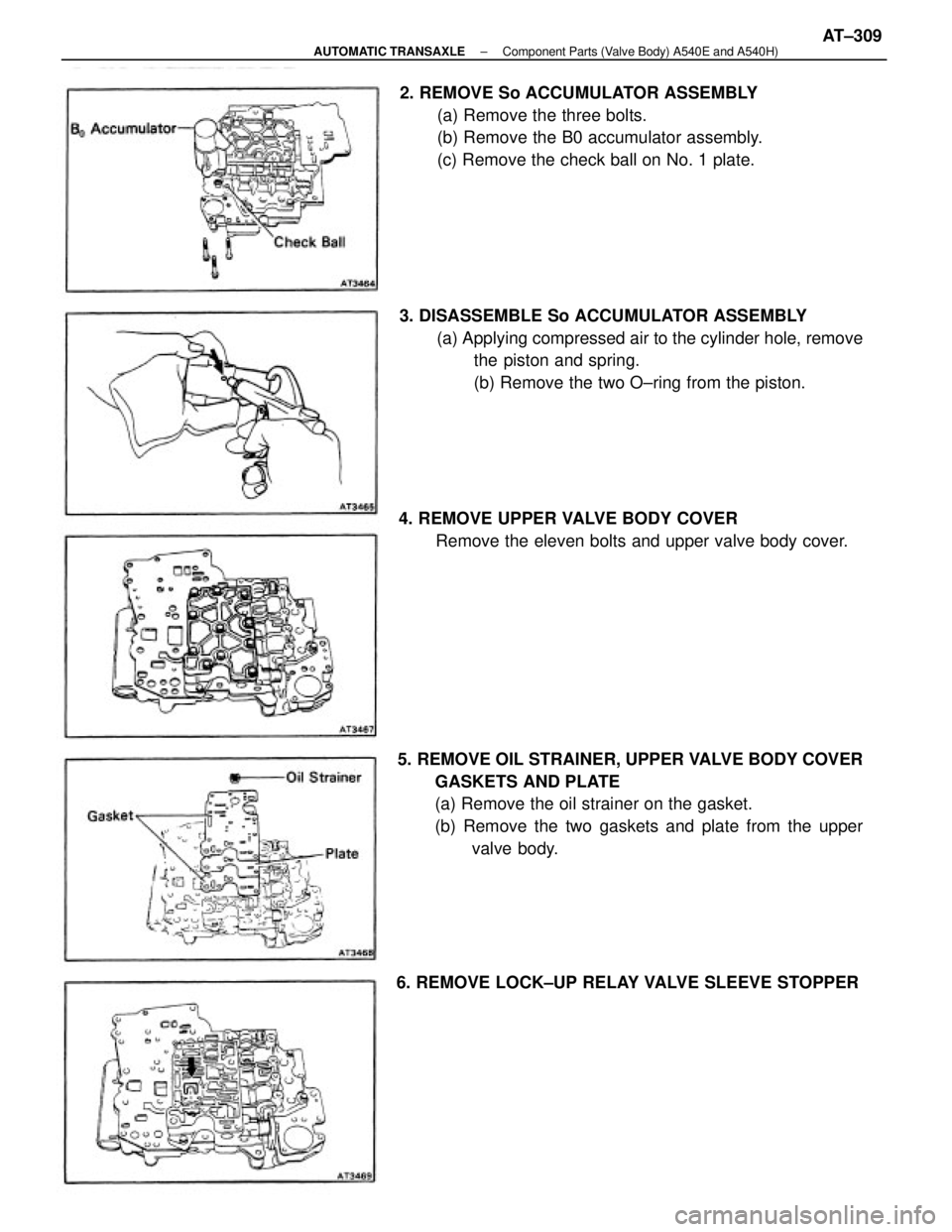

5. REMOVE OIL STRAINER, UPPER VALVE BODY COVER

GASKETS AND PLATE

(a) Remove the oil strainer on the gasket.

(b) Remove the two gaskets and plate from the upper

valve body. 3. DISASSEMBLE So ACCUMULATOR ASSEMBLY

(a) Applying compressed air to the cylinder hole, remove

the piston and spring.

(b) Remove the two O±ring from the piston. 2. REMOVE So ACCUMULATOR ASSEMBLY

(a) Remove the three bolts.

(b) Remove the B0 accumulator assembly.

(c) Remove the check ball on No. 1 plate.

4. REMOVE UPPER VALVE BODY COVER

Remove the eleven bolts and upper valve body cover.

6. REMOVE LOCK±UP RELAY VALVE SLEEVE STOPPER

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body) A540E and A540H)AT±309

Page 575 of 2389

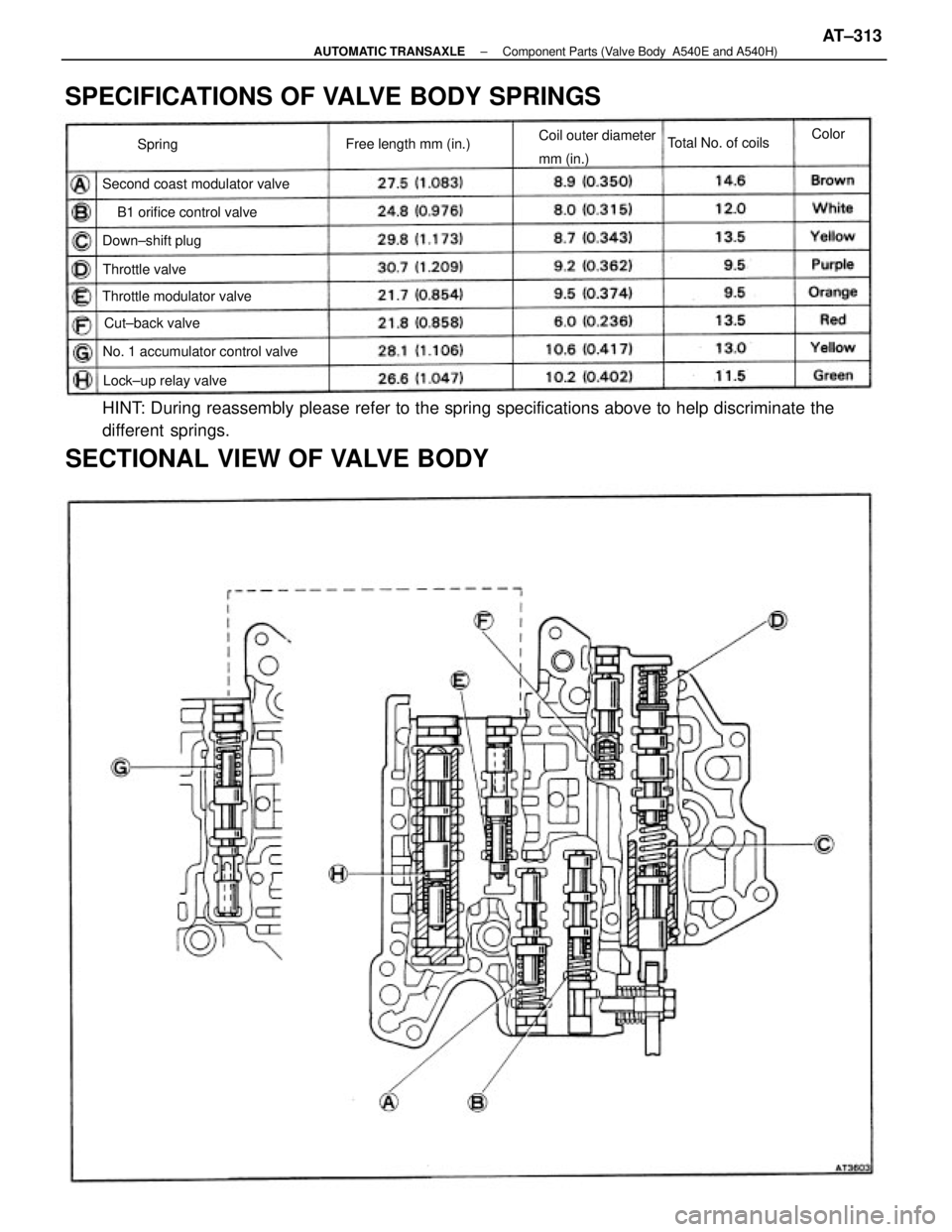

HINT: During reassembly please refer to the spring specifications above to help discriminate the

different springs.

SECTIONAL VIEW OF VALVE BODY SPECIFICATIONS OF VALVE BODY SPRINGS

No. 1 accumulator control valveCoil outer diameter

mm (in.)

Second coast modulator valve

B1 orifice control valve

Throttle modulator valveFree length mm (in.)

Lock±up relay valveTotal No. of coils

Down±shift plug

Cut±back valve Throttle valveColor

Spring

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body A540E and A540H)AT±313

Page 581 of 2389

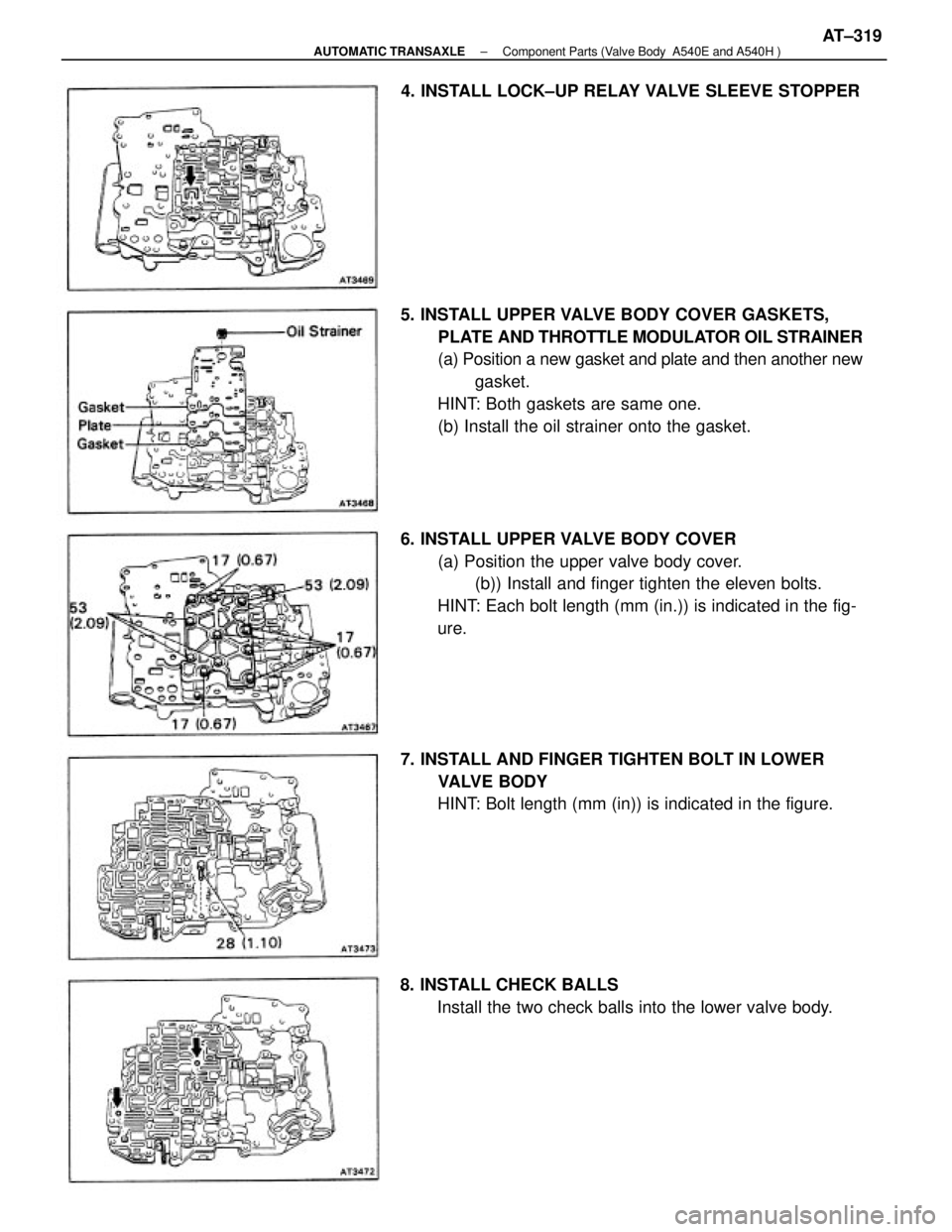

5. INSTALL UPPER VALVE BODY COVER GASKETS,

PLATE AND THROTTLE MODULATOR OIL STRAINER

(a) Position a new gasket and plate and then another new

gasket.

HINT: Both gaskets are same one.

(b) Install the oil strainer onto the gasket.

6. INSTALL UPPER VALVE BODY COVER

(a) Position the upper valve body cover.

(b)) Install and finger tighten the eleven bolts.

HINT: Each bolt length (mm (in.)) is indicated in the fig-

ure.

7. INSTALL AND FINGER TIGHTEN BOLT IN LOWER

VALVE BODY

HINT: Bolt length (mm (in)) is indicated in the figure.

8. INSTALL CHECK BALLS

Install the two check balls into the lower valve body. 4. INSTALL LOCK±UP RELAY VALVE SLEEVE STOPPER

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body A540E and A540H )AT±319

Page 751 of 2389

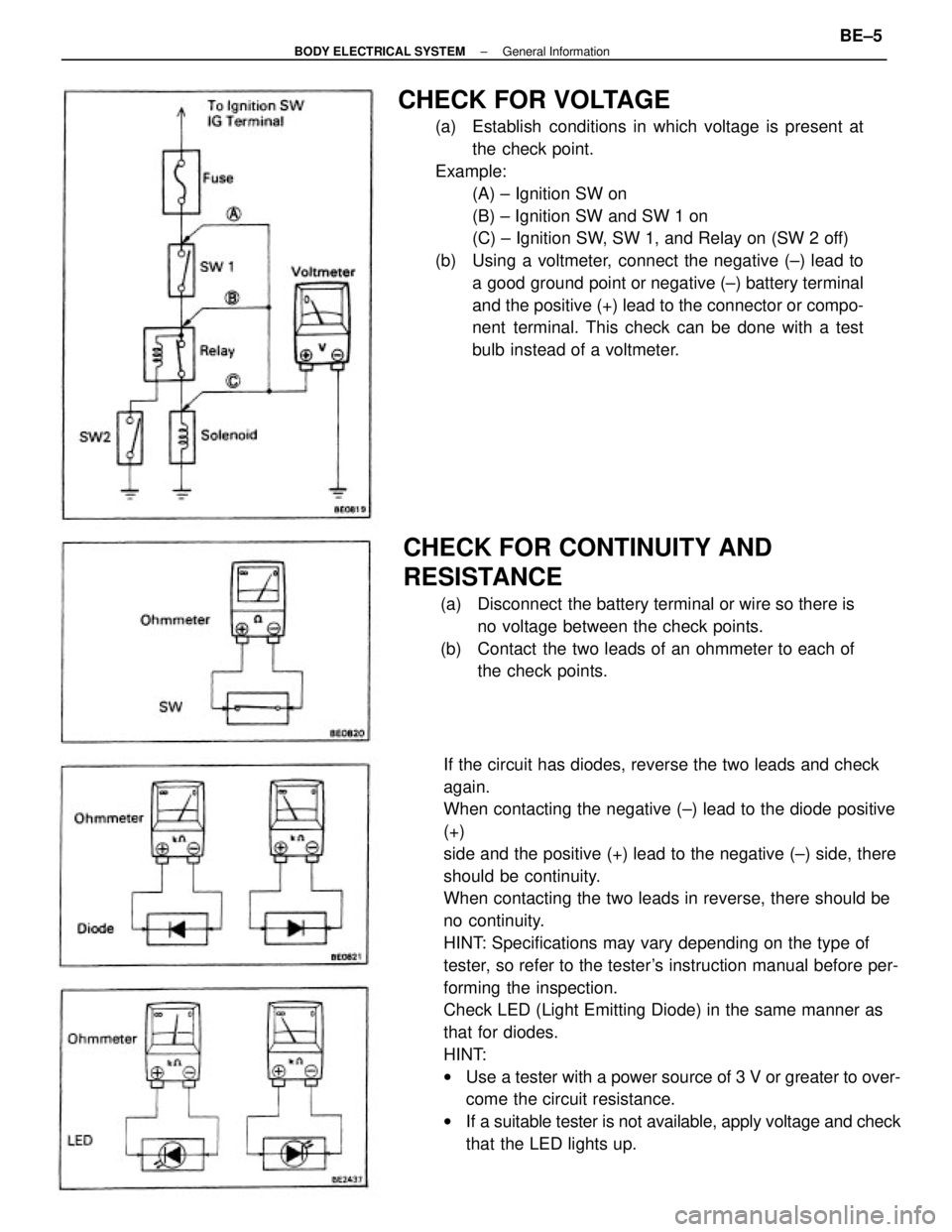

If the circuit has diodes, reverse the two leads and check

again.

When contacting the negative (±) lead to the diode positive

(+)

side and the positive (+) lead to the negative (±) side, there

should be continuity.

When contacting the two leads in reverse, there should be

no continuity.

HINT: Specifications may vary depending on the type of

tester, so refer to the tester's instruction manual before per-

forming the inspection.

Check LED (Light Emitting Diode) in the same manner as

that for diodes.

HINT:

wUse a tester with a power source of 3 V or greater to over-

come the circuit resistance.

wIf a suitable tester is not available, apply voltage and check

that the LED lights up.

CHECK FOR VOLTAGE

(a) Establish conditions in which voltage is present at

the check point.

Example:

(A) ± Ignition SW on

(B) ± Ignition SW and SW 1 on

(C) ± Ignition SW, SW 1, and Relay on (SW 2 off)

(b) Using a voltmeter, connect the negative (±) lead to

a good ground point or negative (±) battery terminal

and the positive (+) lead to the connector or compo-

nent terminal. This check can be done with a test

bulb instead of a voltmeter.

CHECK FOR CONTINUITY AND

RESISTANCE

(a) Disconnect the battery terminal or wire so there is

no voltage between the check points.

(b) Contact the two leads of an ohmmeter to each of

the check points.

± BODY ELECTRICAL SYSTEMGeneral InformationBE±5