engine TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 261 of 2389

A140L Automatic Transaxle

CONSTRUCTION AND OPERATION

The A140L automatic transaxle can be roughly divided into the automatic transmission section and the

differential section. The automatic transmission section is composed of the torque converter, planetary

gear unit and the hydraulic control system.

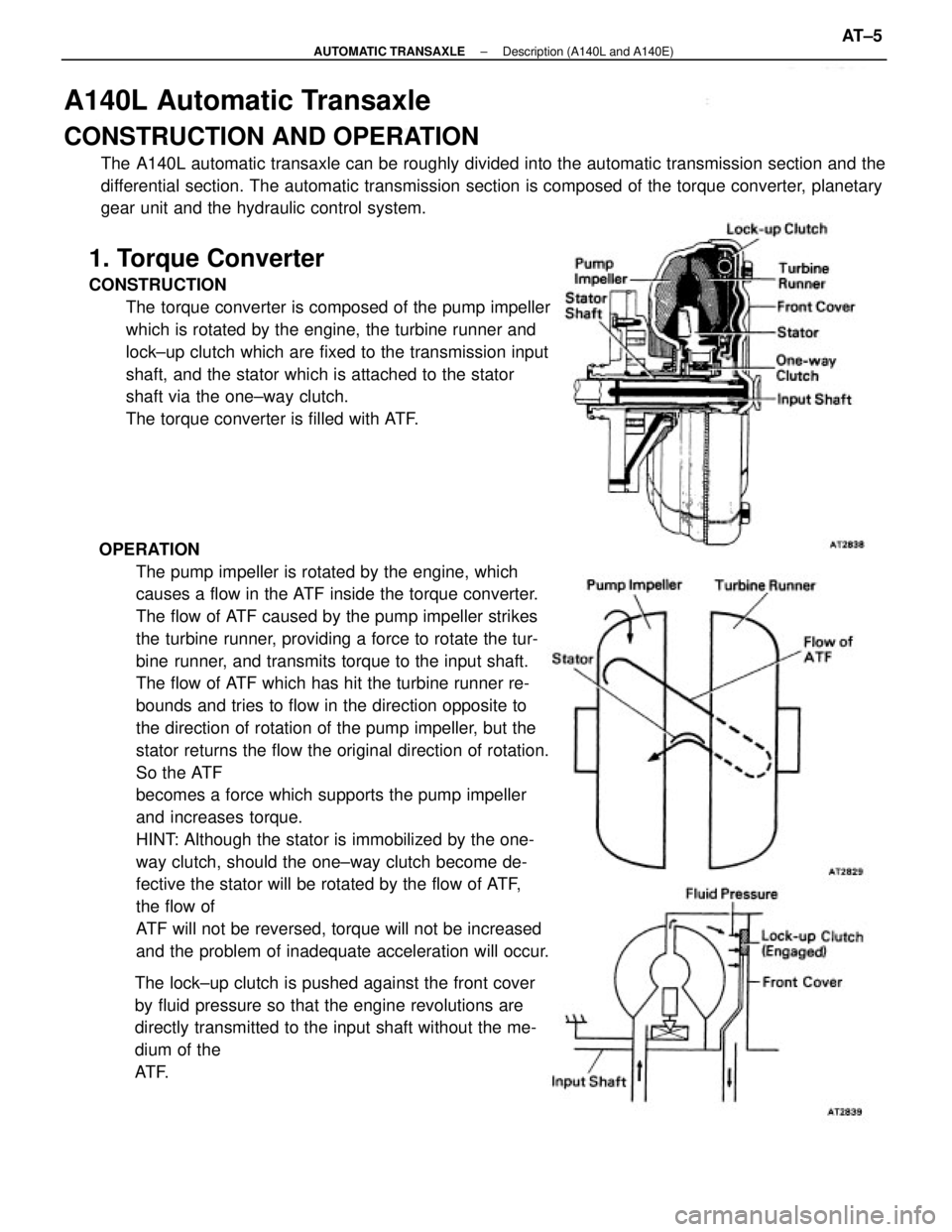

OPERATION

The pump impeller is rotated by the engine, which

causes a flow in the ATF inside the torque converter.

The flow of ATF caused by the pump impeller strikes

the turbine runner, providing a force to rotate the tur-

bine runner, and transmits torque to the input shaft.

The flow of ATF which has hit the turbine runner re-

bounds and tries to flow in the direction opposite to

the direction of rotation of the pump impeller, but the

stator returns the flow the original direction of rotation.

So the ATF

becomes a force which supports the pump impeller

and increases torque.

HINT: Although the stator is immobilized by the one-

way clutch, should the one±way clutch become de-

fective the stator will be rotated by the flow of ATF,

the flow of

ATF will not be reversed, torque will not be increased

and the problem of inadequate acceleration will occur.

The lock±up clutch is pushed against the front cover

by fluid pressure so that the engine revolutions are

directly transmitted to the input shaft without the me-

dium of the

AT F.

1. Torque Converter

CONSTRUCTION

The torque converter is composed of the pump impeller

which is rotated by the engine, the turbine runner and

lock±up clutch which are fixed to the transmission input

shaft, and the stator which is attached to the stator

shaft via the one±way clutch.

The torque converter is filled with ATF.

± AUTOMATIC TRANSAXLEDescription (A140L and A140E)AT±5

Page 263 of 2389

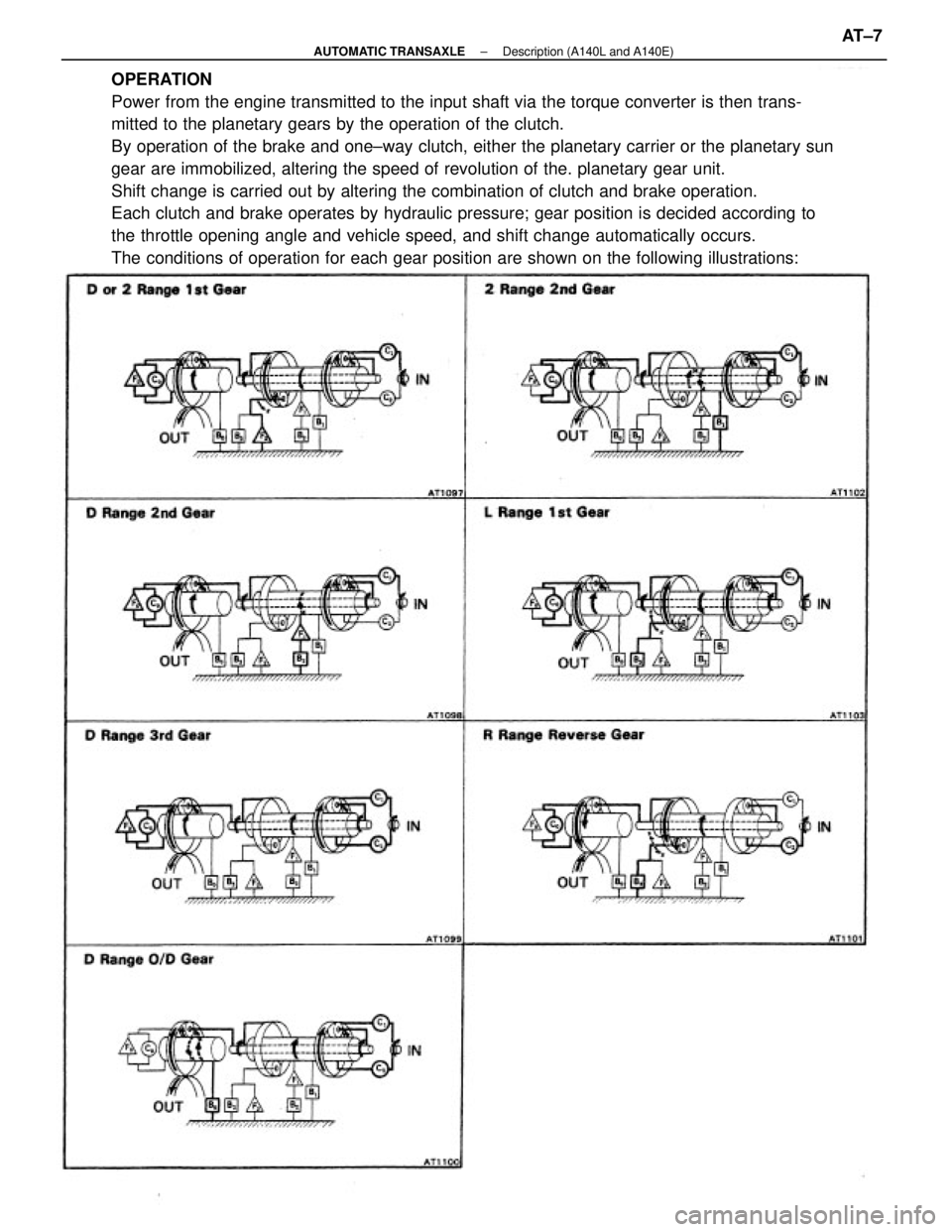

OPERATION

Power from the engine transmitted to the input shaft via the torque converter is then trans-

mitted to the planetary gears by the operation of the clutch.

By operation of the brake and one±way clutch, either the planetary carrier or the planetary sun

gear are immobilized, altering the speed of revolution of the. planetary gear unit.

Shift change is carried out by altering the combination of clutch and brake operation.

Each clutch and brake operates by hydraulic pressure; gear position is decided according to

the throttle opening angle and vehicle speed, and shift change automatically occurs.

The conditions of operation for each gear position are shown on the following illustrations:

± AUTOMATIC TRANSAXLEDescription (A140L and A140E)AT±7

Page 264 of 2389

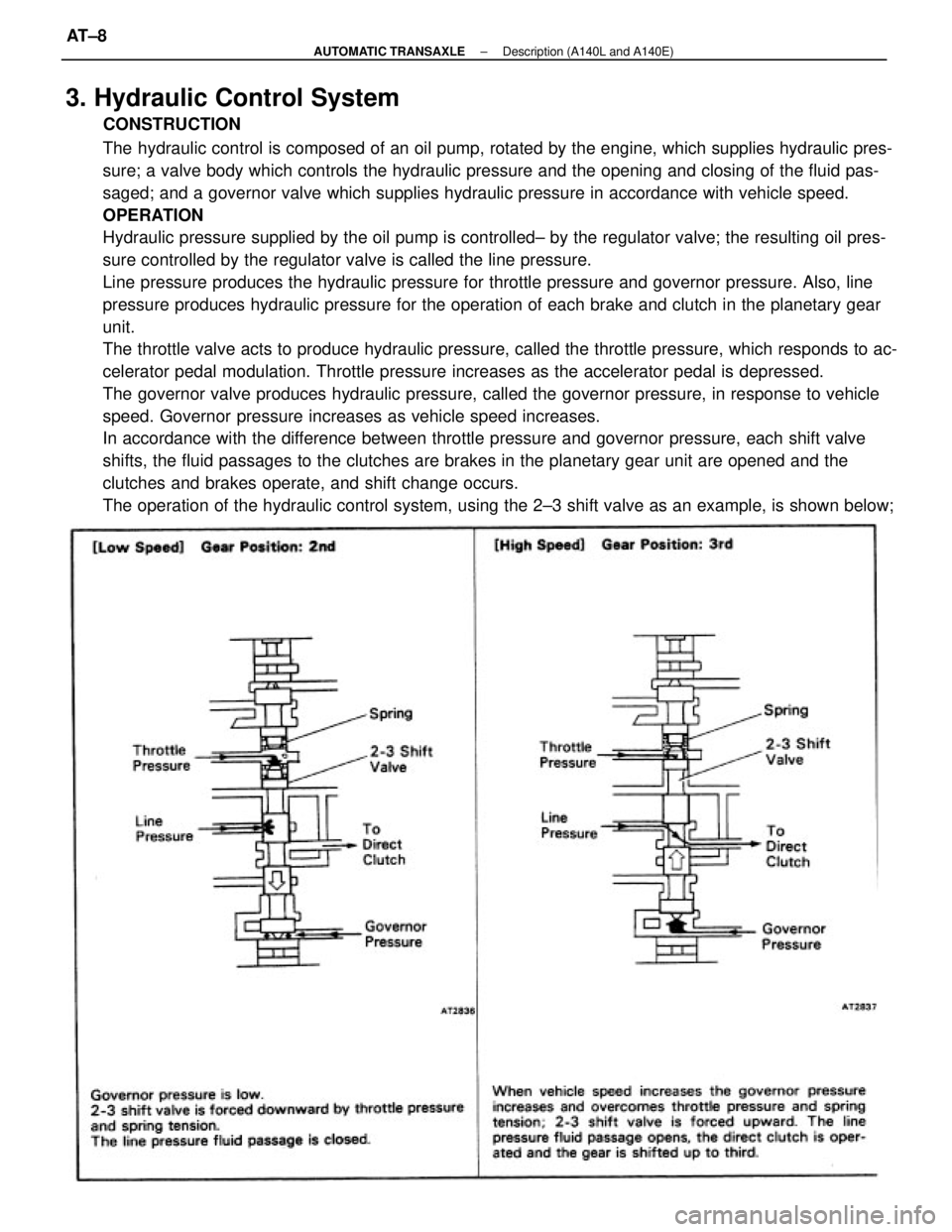

3. Hydraulic Control System

CONSTRUCTION

The hydraulic control is composed of an oil pump, rotated by the engine, which supplies hydraulic pres-

sure; a valve body which controls the hydraulic pressure and the opening and closing of the fluid pas-

saged; and a governor valve which supplies hydraulic pressure in accordance with vehicle speed.

OPERATION

Hydraulic pressure supplied by the oil pump is controlled± by the regulator valve; the resulting oil pres-

sure controlled by the regulator valve is called the line pressure.

Line pressure produces the hydraulic pressure for throttle pressure and governor pressure. Also, line

pressure produces hydraulic pressure for the operation of each brake and clutch in the planetary gear

unit.

The throttle valve acts to produce hydraulic pressure, called the throttle pressure, which responds to ac-

celerator pedal modulation. Throttle pressure increases as the accelerator pedal is depressed.

The governor valve produces hydraulic pressure, called the governor pressure, in response to vehicle

speed. Governor pressure increases as vehicle speed increases.

In accordance with the difference between throttle pressure and governor pressure, each shift valve

shifts, the fluid passages to the clutches are brakes in the planetary gear unit are opened and the

clutches and brakes operate, and shift change occurs.

The operation of the hydraulic control system, using the 2±3 shift valve as an example, is shown below;

± AUTOMATIC TRANSAXLEDescription (A140L and A140E)AT±8

Page 266 of 2389

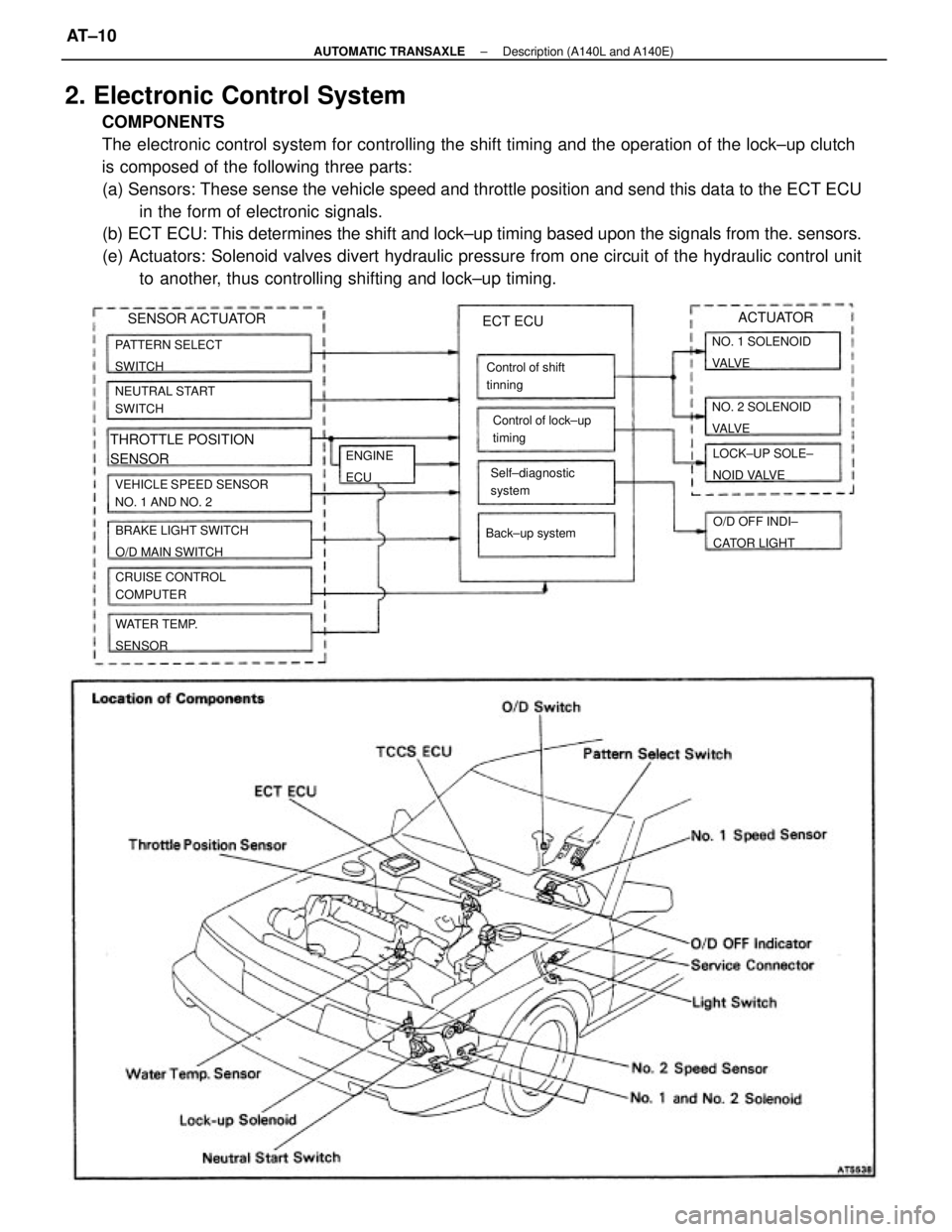

2. Electronic Control System

COMPONENTS

The electronic control system for controlling the shift timing and the operation of the lock±up clutch

is composed of the following three parts:

(a) Sensors: These sense the vehicle speed and throttle position and send this data to the ECT ECU

in the form of electronic signals.

(b) ECT ECU: This determines the shift and lock±up timing based upon the signals from the. sensors.

(e) Actuators: Solenoid valves divert hydraulic pressure from one circuit of the hydraulic control unit

to another, thus controlling shifting and lock±up timing.

VEHICLE SPEED SENSOR

NO. 1 AND NO. 2

BRAKE LIGHT SWITCH

O/D MAIN SWITCH

THROTTLE POSITION

SENSOR

CRUISE CONTROL

COMPUTER PATTERN SELECT

SWITCH

NEUTRAL START

SWITCH

LOCK±UP SOLE±

NOID VALVE NO. 2 SOLENOID

VA LV E NO. 1 SOLENOID

VA LV E

Control of shift

tinning

Self±diagnostic

systemControl of lock±up

timing

WATER TEMP.

SENSORO/D OFF INDI±

CATOR LIGHT Back±up system

ECT ECU

ENGINE

ECU

ACTUATOR

SENSOR ACTUATOR

± AUTOMATIC TRANSAXLEDescription (A140L and A140E)AT±10

Page 268 of 2389

Adjust throttle cable

Inspect throttle cable and cam

Inspect accumulator pistons

Inspect valve body

Disassemble and inspect

transaxle

Inspect throttle cable

Inspect valve body

Disassemble and inspect

transaxle

Inspect solenoid valve

Inspect electronic control

Inspect solenoid valve

Inspect electronic control

Inspect valve body

Disassemble and inspect

transaxleInspect electronic control

Inspect valve body

Inspect solenoid valve

Disassemble and inspect

transaxle

Solenoid valve faulty

Electronic control faulty

Valve body faulty

Transaxle faultyElectronic control faulty

Valve body faulty

Solenoid valve faulty

Transaxle faulty

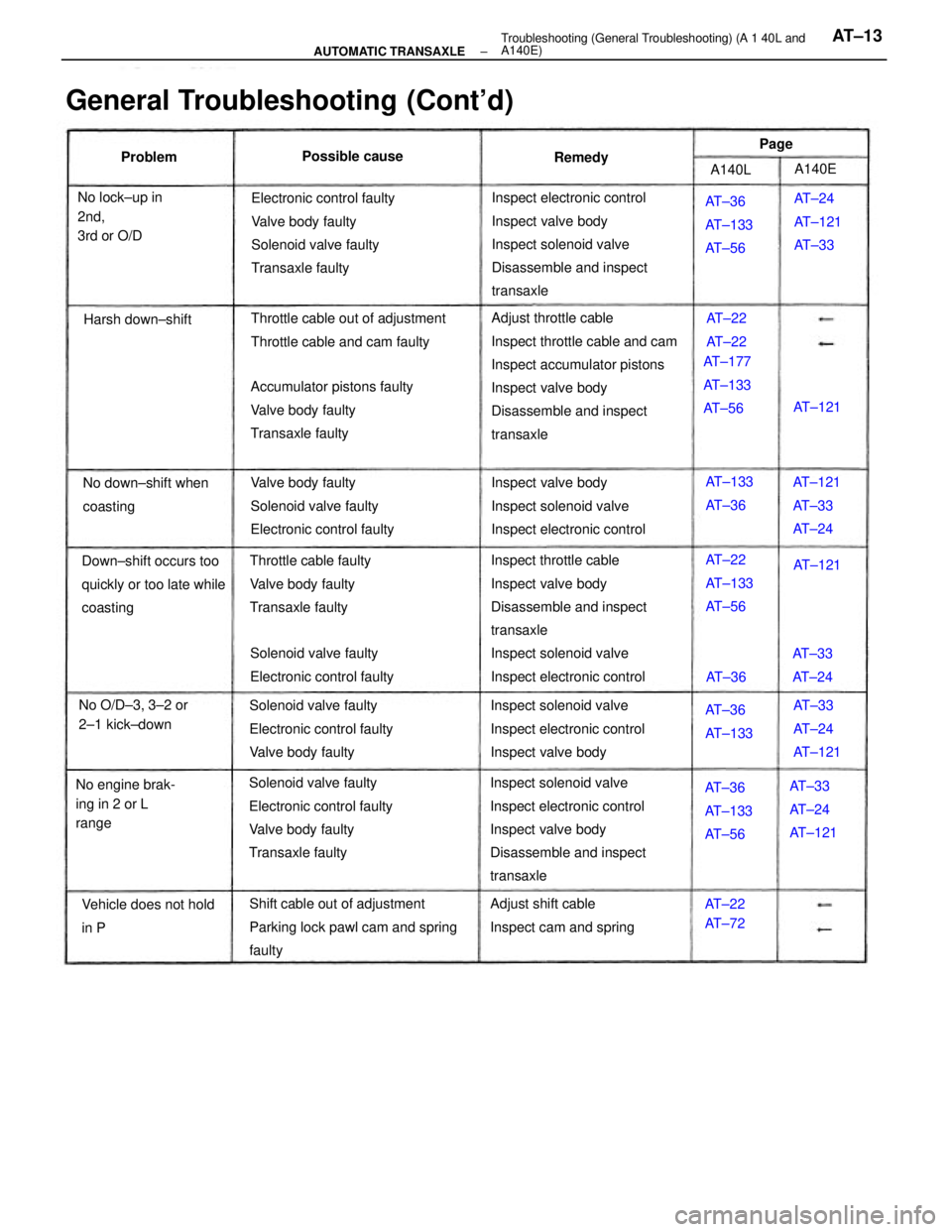

General Troubleshooting (Cont'd)

Shift cable out of adjustment

Parking lock pawl cam and spring

faultyAccumulator pistons faulty

Valve body faulty

Transaxle faulty

Inspect valve body

Inspect solenoid valve

Inspect electronic control

Inspect solenoid valve

Inspect electronic control

Inspect valve body Solenoid valve faulty

Electronic control faulty

Valve body faultyValve body faulty

Solenoid valve faulty

Electronic control faultyThrottle cable out of adjustment

Throttle cable and cam faulty

Throttle cable faulty

Valve body faulty

Transaxle faulty Down±shift occurs too

quickly or too late while

coasting

Solenoid valve faulty

Electronic control faulty

Adjust shift cable

Inspect cam and spring No down±shift when

coastingAT±36

AT±133

AT±56

AT±33

AT±24

AT±121 No engine brak-

ing in 2 or L

rangeAT±24

AT±121

AT±33

AT±36

AT±133

AT±56 No lock±up in

2nd,

3rd or O/D

No O/D±3, 3±2 or

2±1 kick±down

Vehicle does not hold

in PAT±177

AT±133

AT±56

AT±121

AT±33

AT±24 AT±133

AT±36

AT±22

AT±133

AT±56

AT±33

AT±24

AT±121 AT±36

AT±133AT±121 AT±121 Harsh down±shiftPossible cause

AT±33

AT±24

AT±22

AT±72AT±22

AT±22

AT±36A140E Problem

Remedy

A140LPage

± AUTOMATIC TRANSAXLETroubleshooting (General Troubleshooting) (A 1 40L and

A140E)AT±13

Page 271 of 2389

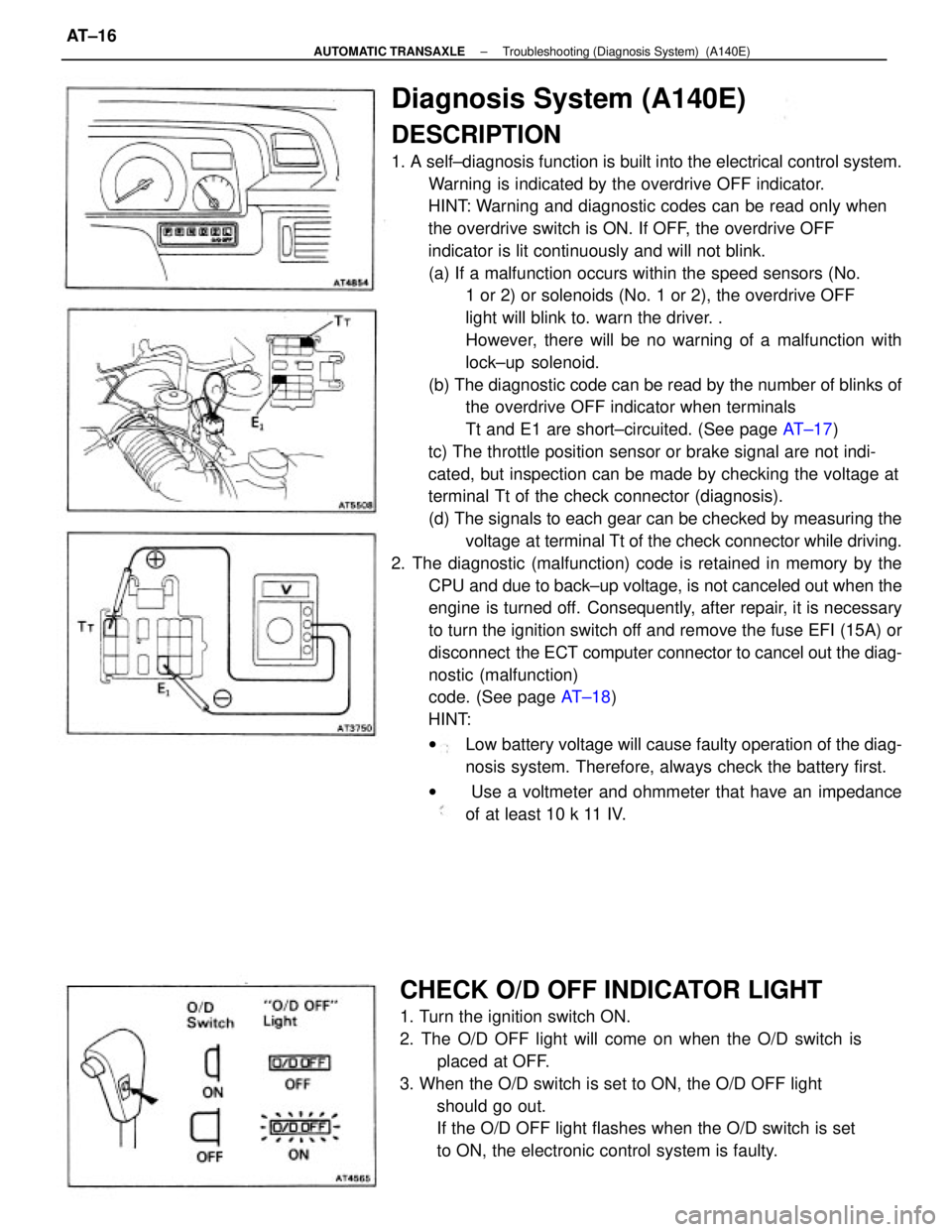

Diagnosis System (A140E)

DESCRIPTION

1. A self±diagnosis function is built into the electrical control system.

Warning is indicated by the overdrive OFF indicator.

HINT: Warning and diagnostic codes can be read only when

the overdrive switch is ON. If OFF, the overdrive OFF

indicator is lit continuously and will not blink.

(a) If a malfunction occurs within the speed sensors (No.

1 or 2) or solenoids (No. 1 or 2), the overdrive OFF

light will blink to. warn the driver. .

However, there will be no warning of a malfunction with

lock±up solenoid.

(b) The diagnostic code can be read by the number of blinks of

the overdrive OFF indicator when terminals

Tt and E1 are short±circuited. (See page AT±17)

tc) The throttle position sensor or brake signal are not indi-

cated, but inspection can be made by checking the voltage at

terminal Tt of the check connector (diagnosis).

(d) The signals to each gear can be checked by measuring the

voltage at terminal Tt of the check connector while driving.

2. The diagnostic (malfunction) code is retained in memory by the

CPU and due to back±up voltage, is not canceled out when the

engine is turned off. Consequently, after repair, it is necessary

to turn the ignition switch off and remove the fuse EFI (15A) or

disconnect the ECT computer connector to cancel out the diag-

nostic (malfunction)

code. (See page AT±18)

HINT:

wLow battery voltage will cause faulty operation of the diag-

nosis system. Therefore, always check the battery first.

w Use a voltmeter and ohmmeter that have an impedance

of at least 10 k 11 IV.

CHECK O/D OFF INDICATOR LIGHT

1. Turn the ignition switch ON.

2. The O/D OFF light will come on when the O/D switch is

placed at OFF.

3. When the O/D switch is set to ON, the O/D OFF light

should go out.

If the O/D OFF light flashes when the O/D switch is set

to ON, the electronic control system is faulty.

± AUTOMATIC TRANSAXLETroubleshooting (Diagnosis System) (A140E)AT±16

Page 272 of 2389

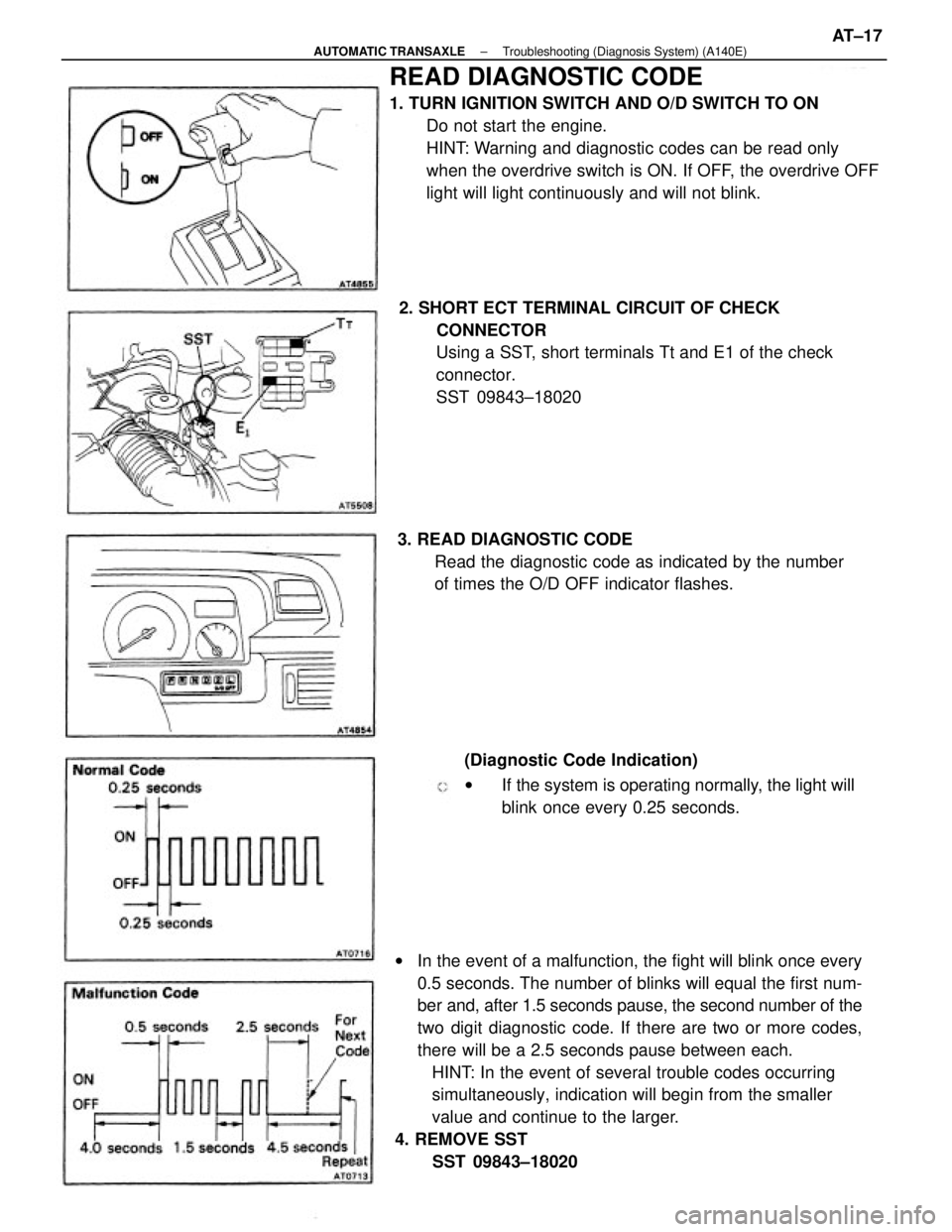

wIn the event of a malfunction, the fight will blink once every

0.5 seconds. The number of blinks will equal the first num-

ber and, after 1.5 seconds pause, the second number of the

two digit diagnostic code. If there are two or more codes,

there will be a 2.5 seconds pause between each.

HINT: In the event of several trouble codes occurring

simultaneously, indication will begin from the smaller

value and continue to the larger.

4. REMOVE SST

SST 09843±18020

READ DIAGNOSTIC CODE

1. TURN IGNITION SWITCH AND O/D SWITCH TO ON

Do not start the engine.

HINT: Warning and diagnostic codes can be read only

when the overdrive switch is ON. If OFF, the overdrive OFF

light will light continuously and will not blink.

2. SHORT ECT TERMINAL CIRCUIT OF CHECK

CONNECTOR

Using a SST, short terminals Tt and E1 of the check

connector.

SST 09843±18020

(Diagnostic Code Indication)

wIf the system is operating normally, the light will

blink once every 0.25 seconds. 3. READ DIAGNOSTIC CODE

Read the diagnostic code as indicated by the number

of times the O/D OFF indicator flashes.

± AUTOMATIC TRANSAXLETroubleshooting (Diagnosis System) (A140E)AT±17

Page 276 of 2389

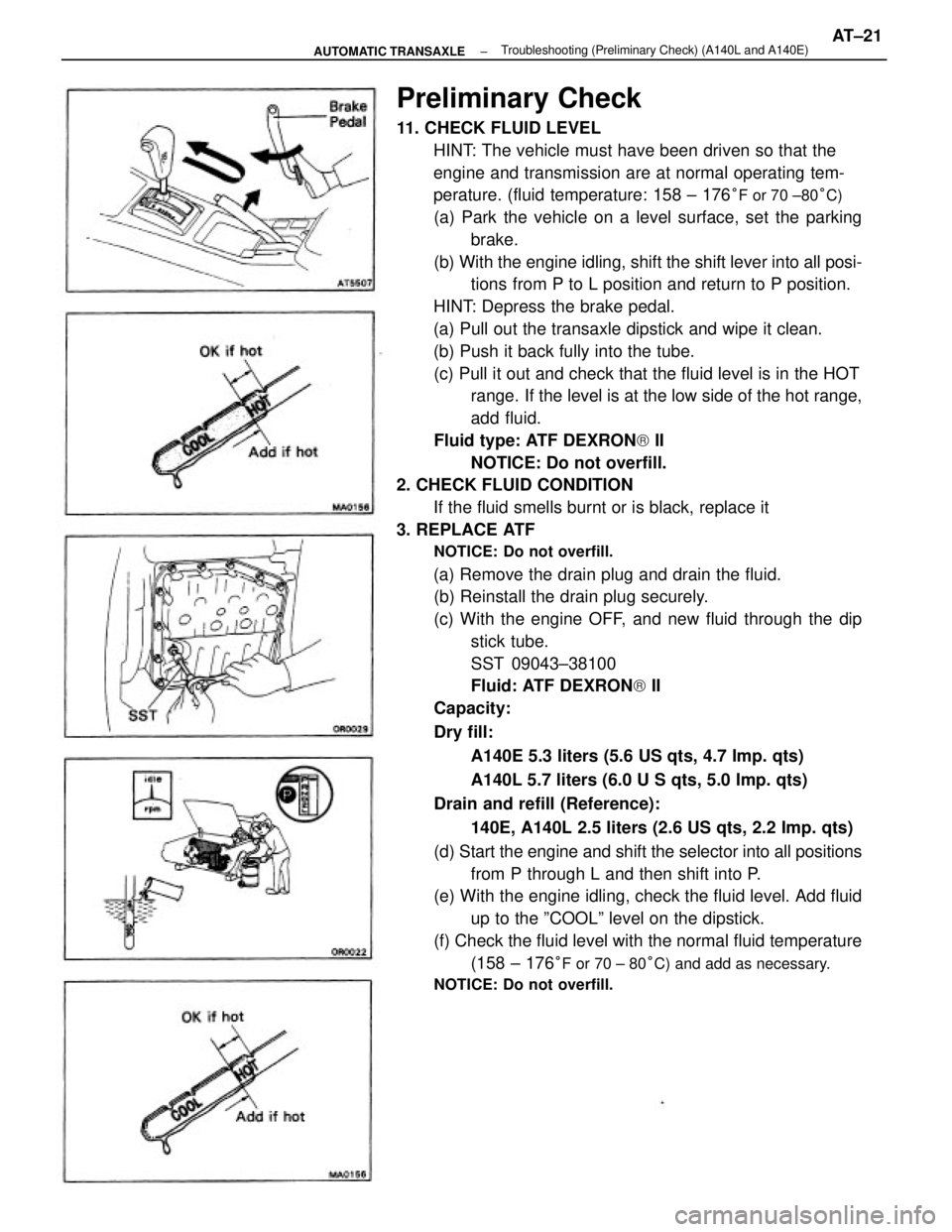

Preliminary Check

11. CHECK FLUID LEVEL

HINT: The vehicle must have been driven so that the

engine and transmission are at normal operating tem-

perature. (fluid temperature: 158 ± 176

°F or 70 ±80°C)

(a) Park the vehicle on a level surface, set the parking

brake.

(b) With the engine idling, shift the shift lever into all posi-

tions from P to L position and return to P position.

HINT: Depress the brake pedal.

(a) Pull out the transaxle dipstick and wipe it clean.

(b) Push it back fully into the tube.

(c) Pull it out and check that the fluid level is in the HOT

range. If the level is at the low side of the hot range,

add fluid.

Fluid type: ATF DEXRON) II

NOTICE: Do not overfill.

2. CHECK FLUID CONDITION

If the fluid smells burnt or is black, replace it

3. REPLACE ATF

NOTICE: Do not overfill.

(a) Remove the drain plug and drain the fluid.

(b) Reinstall the drain plug securely.

(c) With the engine OFF, and new fluid through the dip

stick tube.

SST 09043±38100

Fluid: ATF DEXRON) II

Capacity:

Dry fill:

A140E 5.3 liters (5.6 US qts, 4.7 Imp. qts)

A140L 5.7 liters (6.0 U S qts, 5.0 Imp. qts)

Drain and refill (Reference):

140E, A140L 2.5 liters (2.6 US qts, 2.2 Imp. qts)

(d) Start the engine and shift the selector into all positions

from P through L and then shift into P.

(e) With the engine idling, check the fluid level. Add fluid

up to the ºCOOLº level on the dipstick.

(f) Check the fluid level with the normal fluid temperature

(158 ± 176

°F or 70 ± 80°C) and add as necessary.

NOTICE: Do not overfill.

± AUTOMATIC TRANSAXLETroubleshooting (Preliminary Check) (A140L and A140E)AT±21

Page 277 of 2389

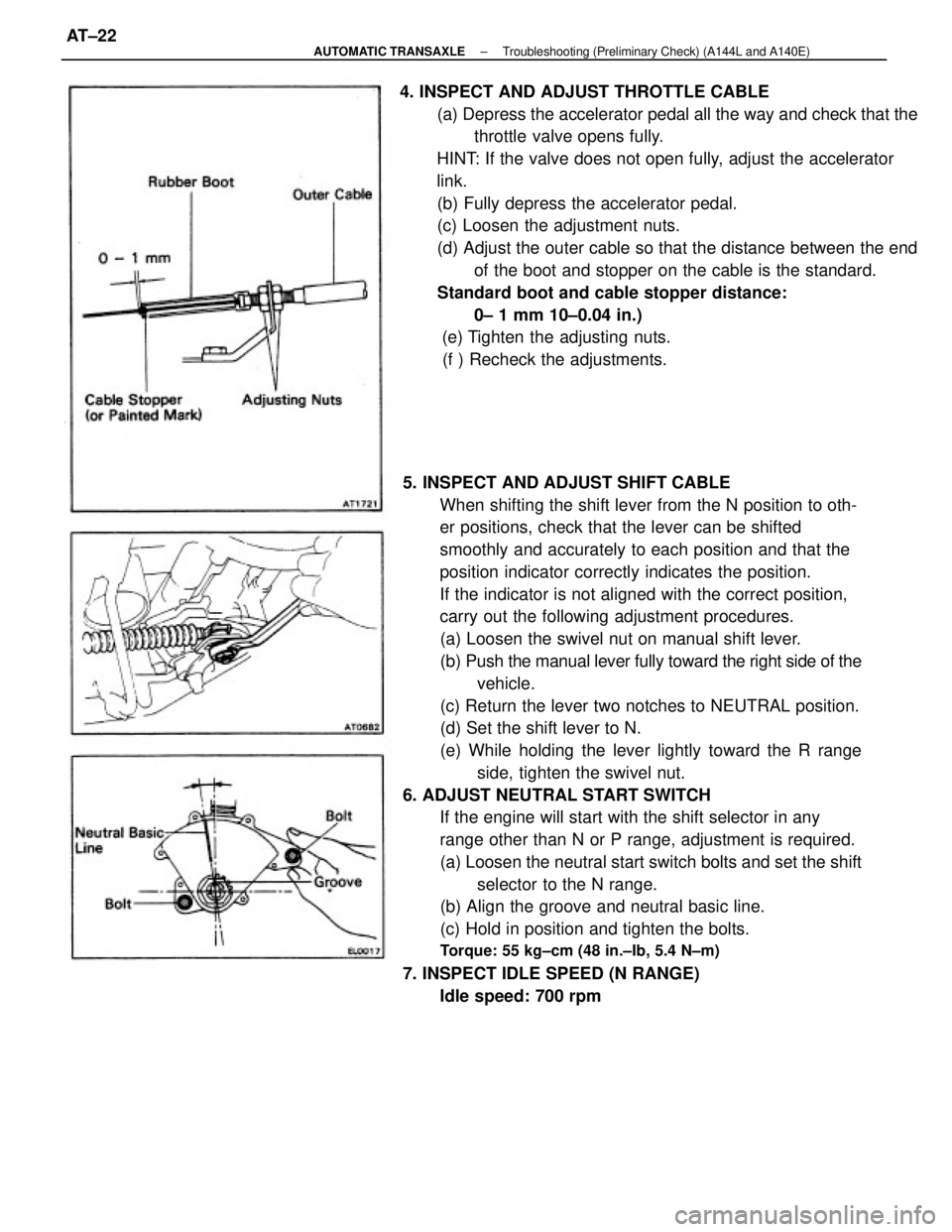

5. INSPECT AND ADJUST SHIFT CABLE

When shifting the shift lever from the N position to oth-

er positions, check that the lever can be shifted

smoothly and accurately to each position and that the

position indicator correctly indicates the position.

If the indicator is not aligned with the correct position,

carry out the following adjustment procedures.

(a) Loosen the swivel nut on manual shift lever.

(b) Push the manual lever fully toward the right side of the

vehicle.

(c) Return the lever two notches to NEUTRAL position.

(d) Set the shift lever to N.

(e) While holding the lever lightly toward the R range

side, tighten the swivel nut.

6. ADJUST NEUTRAL START SWITCH

If the engine will start with the shift selector in any

range other than N or P range, adjustment is required.

(a) Loosen the neutral start switch bolts and set the shift

selector to the N range.

(b) Align the groove and neutral basic line.

(c) Hold in position and tighten the bolts.

Torque: 55 kg±cm (48 in.±Ib, 5.4 N±m)

7. INSPECT IDLE SPEED (N RANGE)

Idle speed: 700 rpm 4. INSPECT AND ADJUST THROTTLE CABLE

(a) Depress the accelerator pedal all the way and check that the

throttle valve opens fully.

HINT: If the valve does not open fully, adjust the accelerator

link.

(b) Fully depress the accelerator pedal.

(c) Loosen the adjustment nuts.

(d) Adjust the outer cable so that the distance between the end

of the boot and stopper on the cable is the standard.

Standard boot and cable stopper distance:

0± 1 mm 10±0.04 in.)

(e) Tighten the adjusting nuts.

(f ) Recheck the adjustments.

± AUTOMATIC TRANSAXLETroubleshooting (Preliminary Check) (A144L and A140E)AT±22

Page 278 of 2389

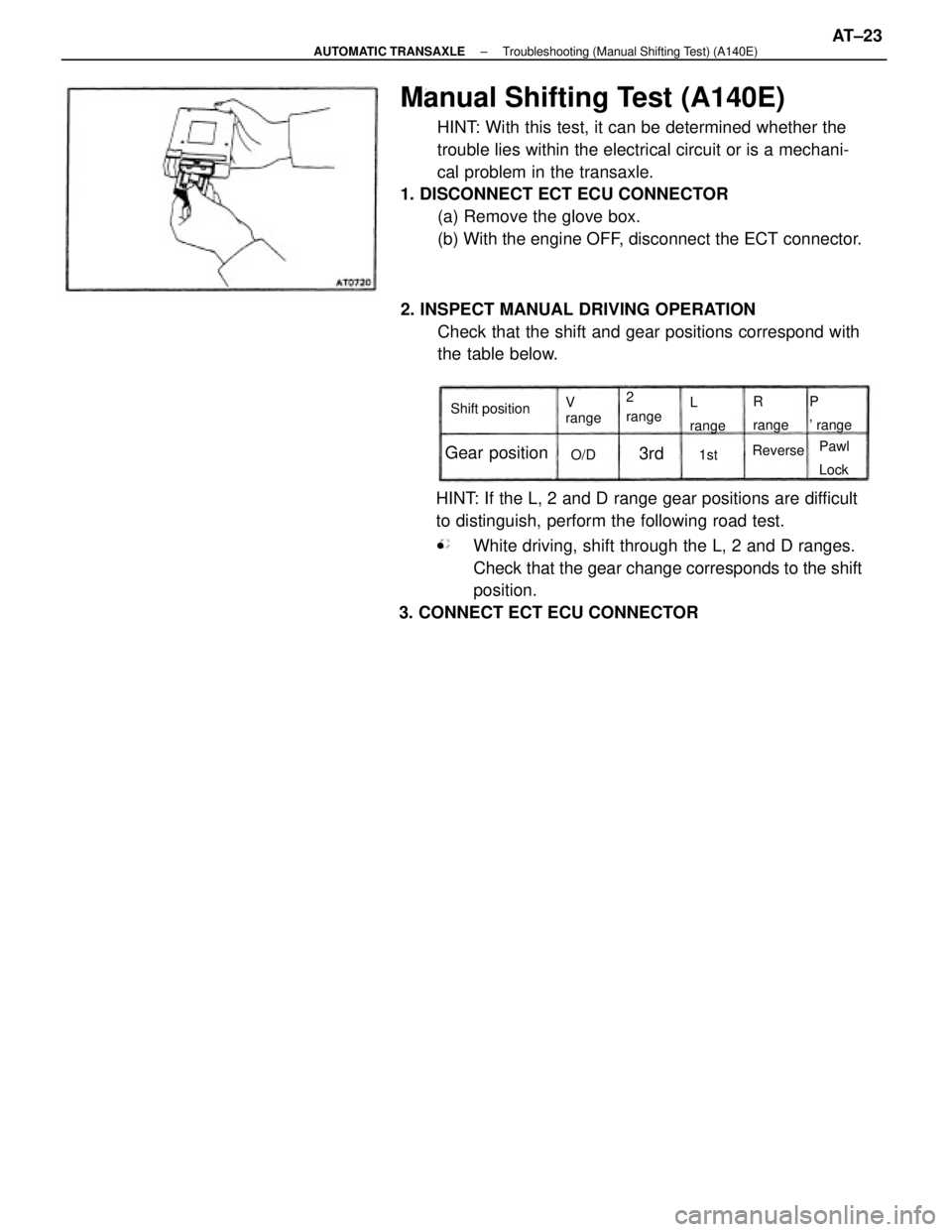

Manual Shifting Test (A140E)

HINT: With this test, it can be determined whether the

trouble lies within the electrical circuit or is a mechani-

cal problem in the transaxle.

1. DISCONNECT ECT ECU CONNECTOR

(a) Remove the glove box.

(b) With the engine OFF, disconnect the ECT connector.

HINT: If the L, 2 and D range gear positions are difficult

to distinguish, perform the following road test.

wWhite driving, shift through the L, 2 and D ranges.

Check that the gear change corresponds to the shift

position.

3. CONNECT ECT ECU CONNECTOR2. INSPECT MANUAL DRIVING OPERATION

Check that the shift and gear positions correspond with

the table below.

Gear position

Shift positionP

' range R

range 2

range V

rangeL

range

Pawl

Lock Reverse

O/D 1st

3rd

± AUTOMATIC TRANSAXLETroubleshooting (Manual Shifting Test) (A140E)AT±23