service TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1245 of 2389

.

(d) Insert a service bolt (A) into the service hole of the camshaft

sub±gear.

(e) Using a screwdriver, align the holes of the camshaft main

gear and sub±gear by turning camshaft sub±gear clock-

wise, and install a service bolt (B).

NOTICE: Be careful not damage the camshaft.

4. INSTALL CAMSHAFTS

HINT: Since the thrust clearance of the camshaft is small,

the camshaft must be held level while it is being installed.

If the camshaft is not kept level, the portion of the cylinder

head receiving the shaft thrust may crack or be damaged,

causing the camshaft to seize or break. To avoid this, the

following steps should be carried out.

A. Install intake camshaft

(a) Apply MP grease to the thrust portion of the camshaft.

(b) Place the intake camshaft at 80° BTDC of camshaft angle

on the cylinder head. 2. INSTALL SPARK PLUG TUBES

(a) Clean the cylinder head tube holes of any residual adhesive, oil

foreign particles. Remove any oil with kerosene or gasoline.

(b) Screw the threads of the spark plug tube coated with adhesive

into the cylinder head.

(c) Install the spark plug tube nut and using a 30 mm socket

wrench, torque the nuts.

Torque: 400 kg±cm (29 ft±lb, 39 N±m)

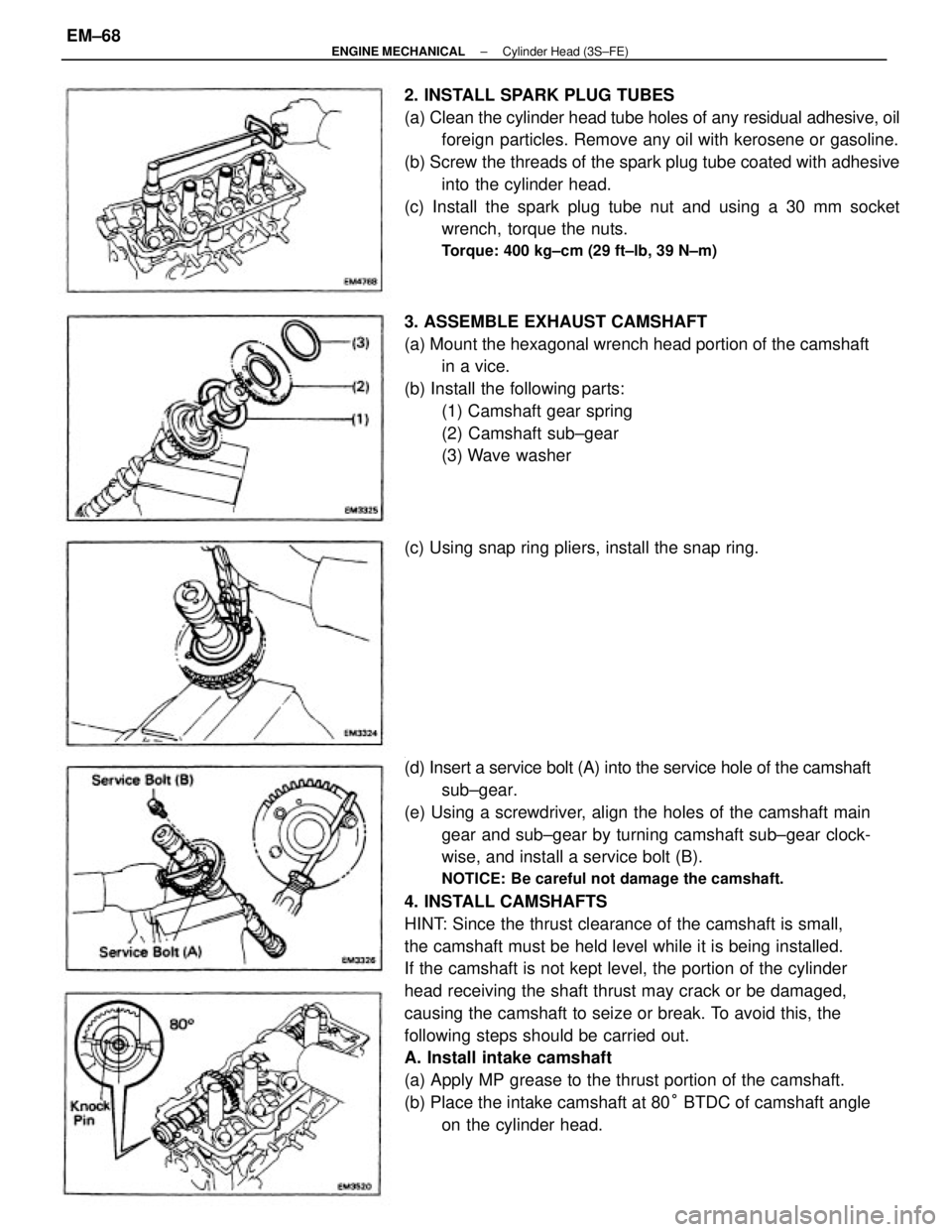

3. ASSEMBLE EXHAUST CAMSHAFT

(a) Mount the hexagonal wrench head portion of the camshaft

in a vice.

(b) Install the following parts:

(1) Camshaft gear spring

(2) Camshaft sub±gear

(3) Wave washer

(c) Using snap ring pliers, install the snap ring.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±68

Page 1247 of 2389

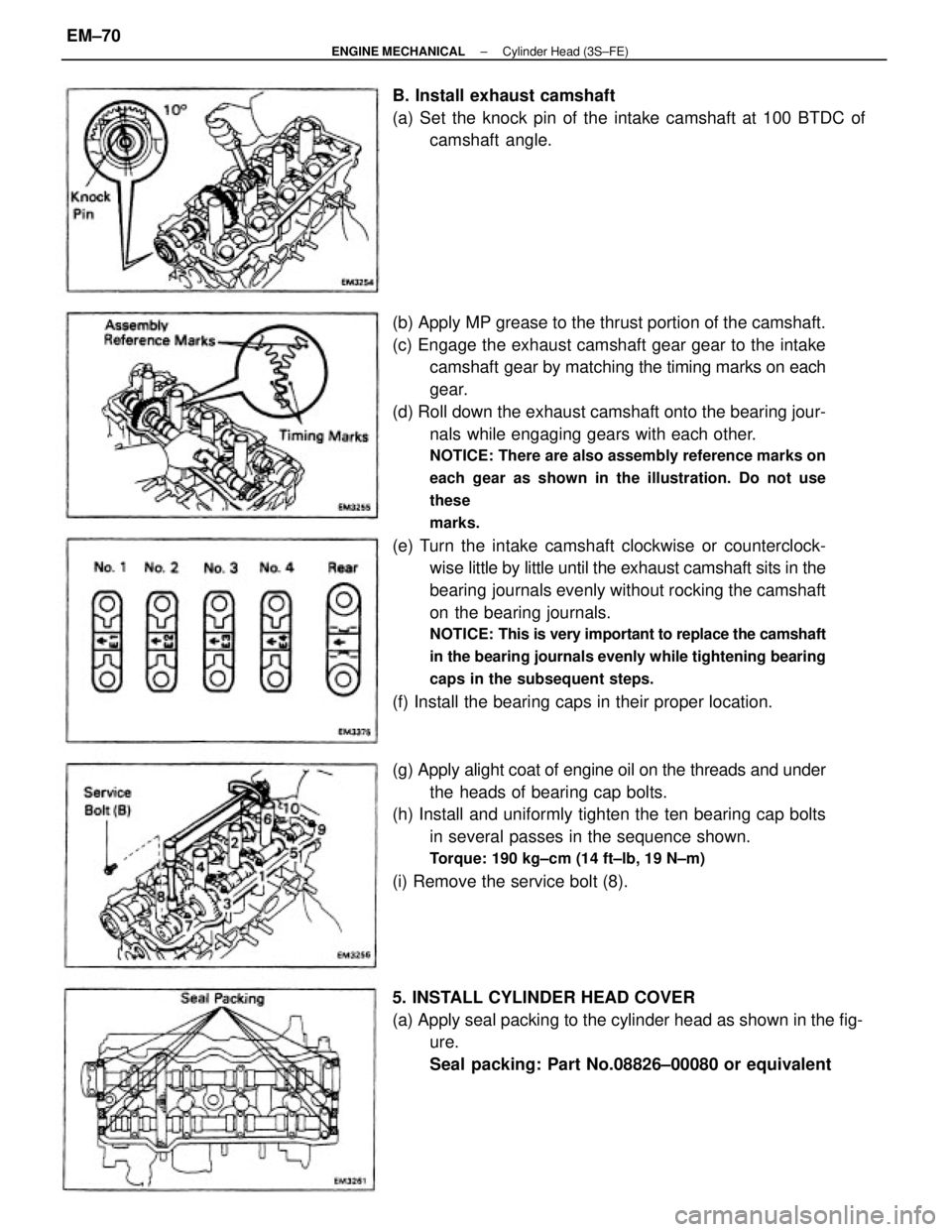

(b) Apply MP grease to the thrust portion of the camshaft.

(c) Engage the exhaust camshaft gear gear to the intake

camshaft gear by matching the timing marks on each

gear.

(d) Roll down the exhaust camshaft onto the bearing jour-

nals while engaging gears with each other.

NOTICE: There are also assembly reference marks on

each gear as shown in the illustration. Do not use

these

marks.

(e) Turn the intake camshaft clockwise or counterclock-

wise little by little until the exhaust camshaft sits in the

bearing journals evenly without rocking the camshaft

on the bearing journals.

NOTICE: This is very important to replace the camshaft

in the bearing journals evenly while tightening bearing

caps in the subsequent steps.

(f) Install the bearing caps in their proper location.

(g) Apply alight coat of engine oil on the threads and under

the heads of bearing cap bolts.

(h) Install and uniformly tighten the ten bearing cap bolts

in several passes in the sequence shown.

Torque: 190 kg±cm (14 ft±lb, 19 N±m)

(i) Remove the service bolt (8).

5. INSTALL CYLINDER HEAD COVER

(a) Apply seal packing to the cylinder head as shown in the fig-

ure.

Seal packing: Part No.08826±00080 or equivalent B. Install exhaust camshaft

(a) Set the knock pin of the intake camshaft at 100 BTDC of

camshaft angle.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±70

Page 1257 of 2389

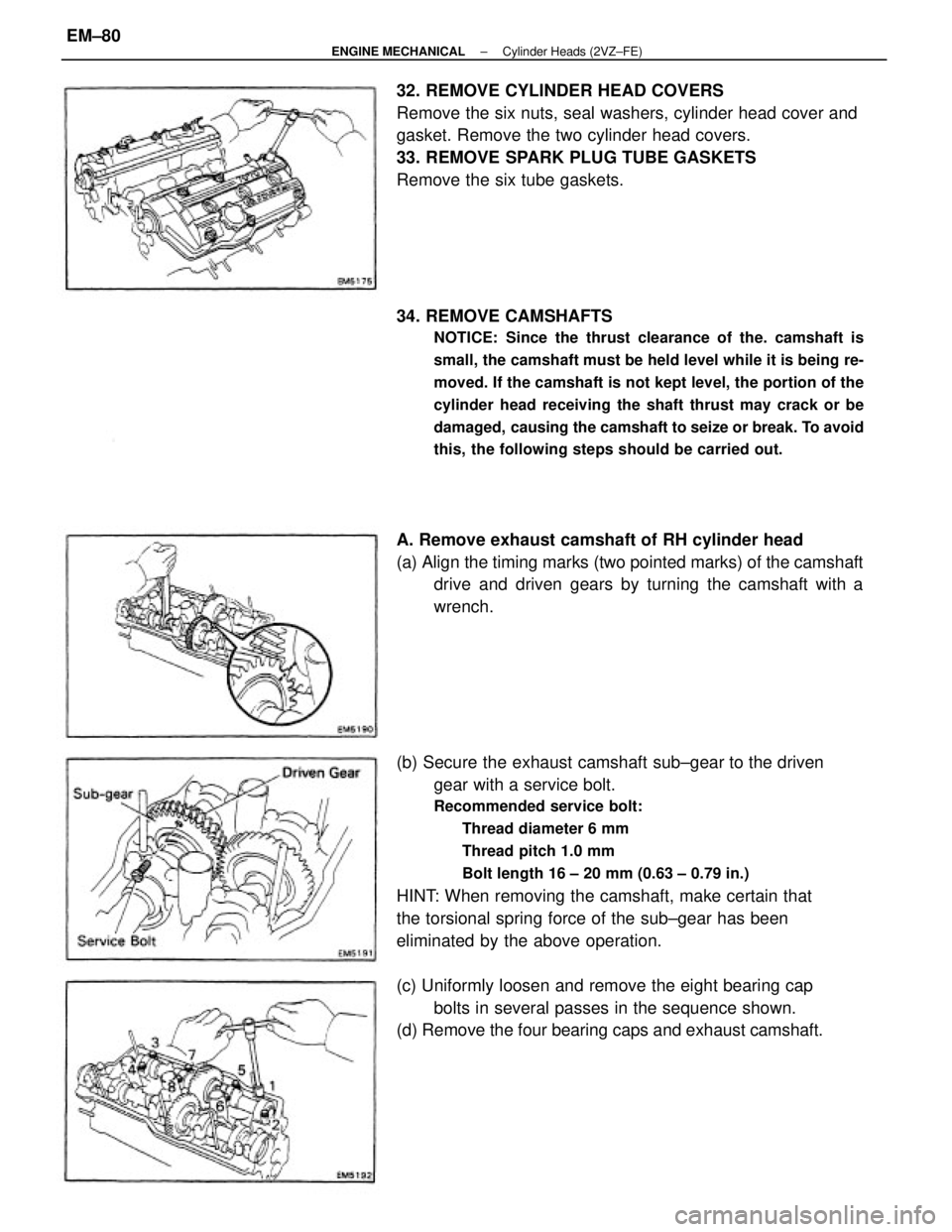

(b) Secure the exhaust camshaft sub±gear to the driven

gear with a service bolt.

Recommended service bolt:

Thread diameter 6 mm

Thread pitch 1.0 mm

Bolt length 16 ± 20 mm (0.63 ± 0.79 in.)

HINT: When removing the camshaft, make certain that

the torsional spring force of the sub±gear has been

eliminated by the above operation. 32. REMOVE CYLINDER HEAD COVERS

Remove the six nuts, seal washers, cylinder head cover and

gasket. Remove the two cylinder head covers.

33. REMOVE SPARK PLUG TUBE GASKETS

Remove the six tube gaskets.

34. REMOVE CAMSHAFTS

NOTICE: Since the thrust clearance of the. camshaft is

small, the camshaft must be held level while it is being re-

moved. If the camshaft is not kept level, the portion of the

cylinder head receiving the shaft thrust may crack or be

damaged, causing the camshaft to seize or break. To avoid

this, the following steps should be carried out.

A. Remove exhaust camshaft of RH cylinder head

(a) Align the timing marks (two pointed marks) of the camshaft

drive and driven gears by turning the camshaft with a

wrench.

(c) Uniformly loosen and remove the eight bearing cap

bolts in several passes in the sequence shown.

(d) Remove the four bearing caps and exhaust camshaft.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±80

Page 1258 of 2389

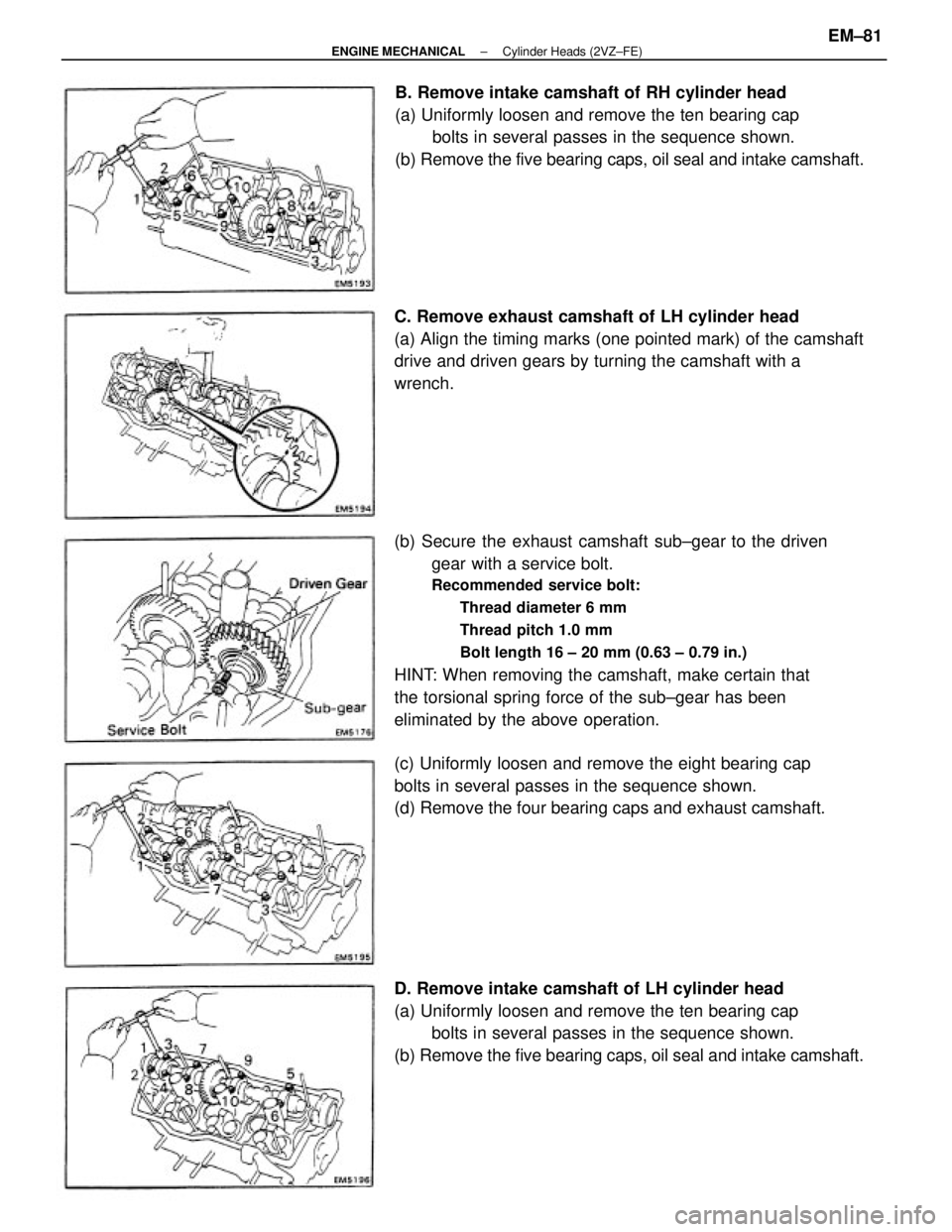

(b) Secure the exhaust camshaft sub±gear to the driven

gear with a service bolt.

Recommended service bolt:

Thread diameter 6 mm

Thread pitch 1.0 mm

Bolt length 16 ± 20 mm (0.63 ± 0.79 in.)

HINT: When removing the camshaft, make certain that

the torsional spring force of the sub±gear has been

eliminated by the above operation.

D. Remove intake camshaft of LH cylinder head

(a) Uniformly loosen and remove the ten bearing cap

bolts in several passes in the sequence shown.

(b) Remove the five bearing caps, oil seal and intake camshaft.B. Remove intake camshaft of RH cylinder head

(a) Uniformly loosen and remove the ten bearing cap

bolts in several passes in the sequence shown.

(b) Remove the five bearing caps, oil seal and intake camshaft.

C. Remove exhaust camshaft of LH cylinder head

(a) Align the timing marks (one pointed mark) of the camshaft

drive and driven gears by turning the camshaft with a

wrench.

(c) Uniformly loosen and remove the eight bearing cap

bolts in several passes in the sequence shown.

(d) Remove the four bearing caps and exhaust camshaft.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±81

Page 1259 of 2389

(e) Remove the following parts:

(1) Wave washer

(2) Camshaft sub±gear

(3) Camshaft gear spring

HINT: Arrange the camshaft sub±gears and gear

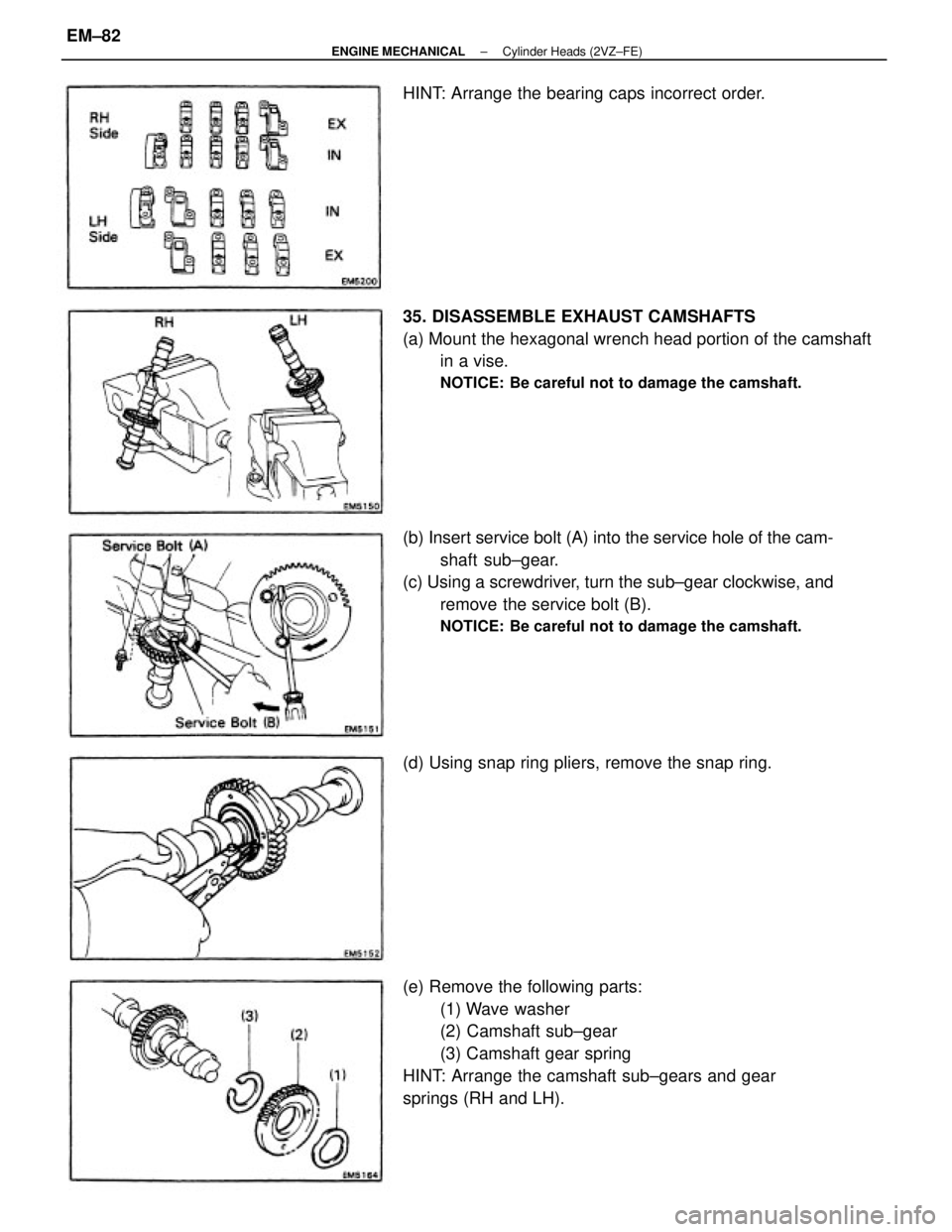

springs (RH and LH). (b) Insert service bolt (A) into the service hole of the cam-

shaft sub±gear.

(c) Using a screwdriver, turn the sub±gear clockwise, and

remove the service bolt (B).

NOTICE: Be careful not to damage the camshaft.

35. DISASSEMBLE EXHAUST CAMSHAFTS

(a) Mount the hexagonal wrench head portion of the camshaft

in a vise.

NOTICE: Be careful not to damage the camshaft.

(d) Using snap ring pliers, remove the snap ring. HINT: Arrange the bearing caps incorrect order.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±82

Page 1275 of 2389

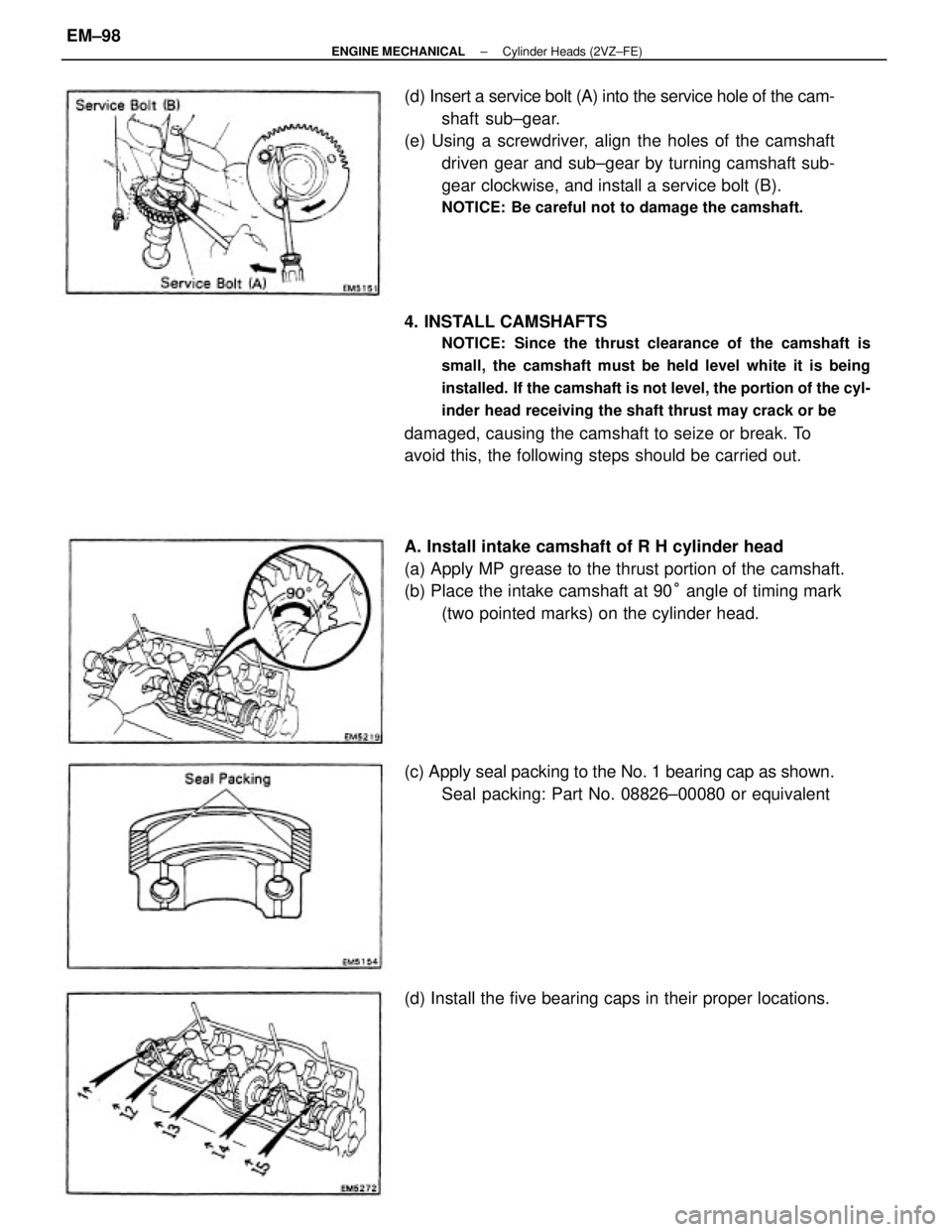

4. INSTALL CAMSHAFTS

NOTICE: Since the thrust clearance of the camshaft is

small, the camshaft must be held level white it is being

installed. If the camshaft is not level, the portion of the cyl-

inder head receiving the shaft thrust may crack or be

damaged, causing the camshaft to seize or break. To

avoid this, the following steps should be carried out. (d) Insert a service bolt (A) into the service hole of the cam-

shaft sub±gear.

(e) Using a screwdriver, align the holes of the camshaft

driven gear and sub±gear by turning camshaft sub-

gear clockwise, and install a service bolt (B).

NOTICE: Be careful not to damage the camshaft.

A. Install intake camshaft of R H cylinder head

(a) Apply MP grease to the thrust portion of the camshaft.

(b) Place the intake camshaft at 90° angle of timing mark

(two pointed marks) on the cylinder head.

(c) Apply seal packing to the No. 1 bearing cap as shown.

Seal packing: Part No. 08826±00080 or equivalent

(d) Install the five bearing caps in their proper locations.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±98

Page 1276 of 2389

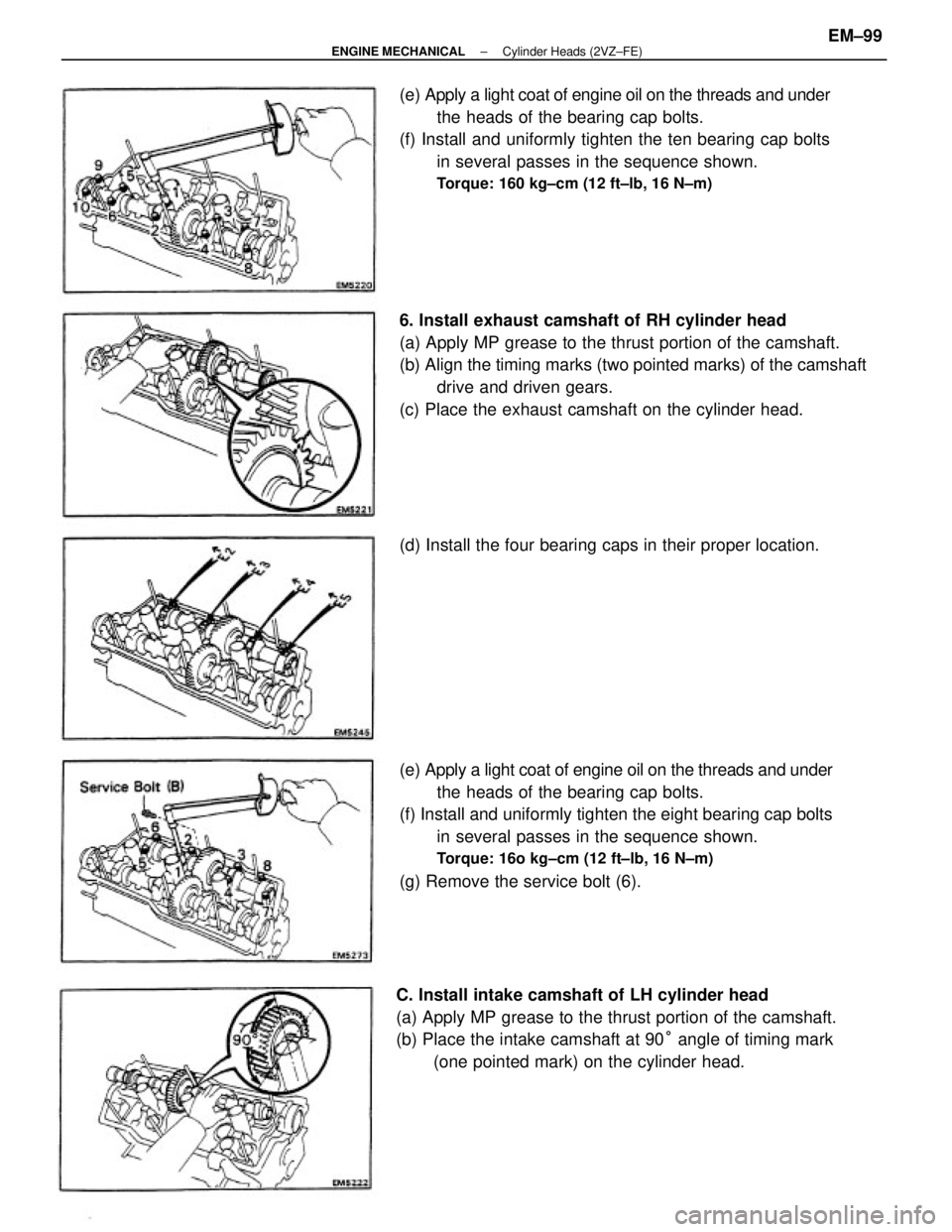

(e) Apply a light coat of engine oil on the threads and under

the heads of the bearing cap bolts.

(f) Install and uniformly tighten the eight bearing cap bolts

in several passes in the sequence shown.

Torque: 16o kg±cm (12 ft±lb, 16 N±m)

(g) Remove the service bolt (6). 6. Install exhaust camshaft of RH cylinder head

(a) Apply MP grease to the thrust portion of the camshaft.

(b) Align the timing marks (two pointed marks) of the camshaft

drive and driven gears.

(c) Place the exhaust camshaft on the cylinder head. (e) Apply a light coat of engine oil on the threads and under

the heads of the bearing cap bolts.

(f) Install and uniformly tighten the ten bearing cap bolts

in several passes in the sequence shown.

Torque: 160 kg±cm (12 ft±lb, 16 N±m)

C. Install intake camshaft of LH cylinder head

(a) Apply MP grease to the thrust portion of the camshaft.

(b) Place the intake camshaft at 90° angle of timing mark

(one pointed mark) on the cylinder head. (d) Install the four bearing caps in their proper location.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±99

Page 1278 of 2389

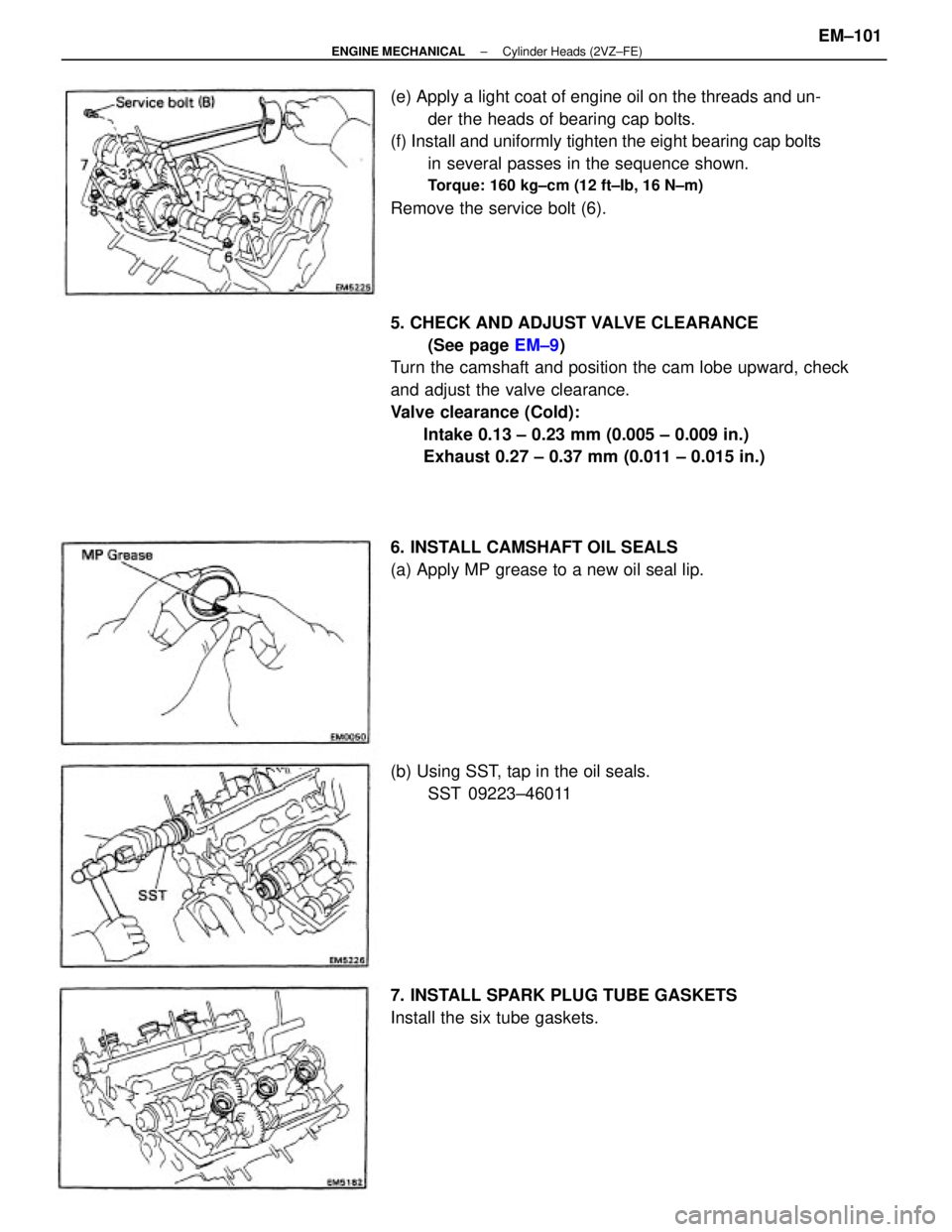

5. CHECK AND ADJUST VALVE CLEARANCE

(See page EM±9)

Turn the camshaft and position the cam lobe upward, check

and adjust the valve clearance.

Valve clearance (Cold):

Intake 0.13 ± 0.23 mm (0.005 ± 0.009 in.)

Exhaust 0.27 ± 0.37 mm (0.011 ± 0.015 in.) (e) Apply a light coat of engine oil on the threads and un-

der the heads of bearing cap bolts.

(f) Install and uniformly tighten the eight bearing cap bolts

in several passes in the sequence shown.

Torque: 160 kg±cm (12 ft±Ib, 16 N±m)

Remove the service bolt (6).

6. INSTALL CAMSHAFT OIL SEALS

(a) Apply MP grease to a new oil seal lip.

7. INSTALL SPARK PLUG TUBE GASKETS

Install the six tube gaskets. (b) Using SST, tap in the oil seals.

SST 09223±46011

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±101

Page 1441 of 2389

![TOYOTA CAMRY V20 1986 Service Information Special ToolSpecial Tool Locking

Lug

Locking

Lug

Terminal

Retainer

[Retainer at Full Lock Position] [Retainer at Temporary Lock Position]

Terminal Retainer

[Retainer at Full Lock Position]

Stopper

[Re TOYOTA CAMRY V20 1986 Service Information Special ToolSpecial Tool Locking

Lug

Locking

Lug

Terminal

Retainer

[Retainer at Full Lock Position] [Retainer at Temporary Lock Position]

Terminal Retainer

[Retainer at Full Lock Position]

Stopper

[Re](/img/14/57449/w960_57449-1440.png)

Special ToolSpecial Tool Locking

Lug

Locking

Lug

Terminal

Retainer

[Retainer at Full Lock Position] [Retainer at Temporary Lock Position]

Terminal Retainer

[Retainer at Full Lock Position]

Stopper

[Retainer at Temporary Lock Position]Terminal

Retainer Special

Tool

Service hole

TERMINAL AND CONNECTOR REPAIR±TERMINAL REPLACEMENT

B±12

22

Wire Harness Repair Manual (RM1022E)

[Case 2]

(1)Using the special tool, push the terminal retainer

locking lug (clip) and pull the terminal retainer up to

the temporary lock position.

[Case 3]

(1)Using the special tool, raise the retainer up to the

temporary lock position.

[Case 4]

Page 1442 of 2389

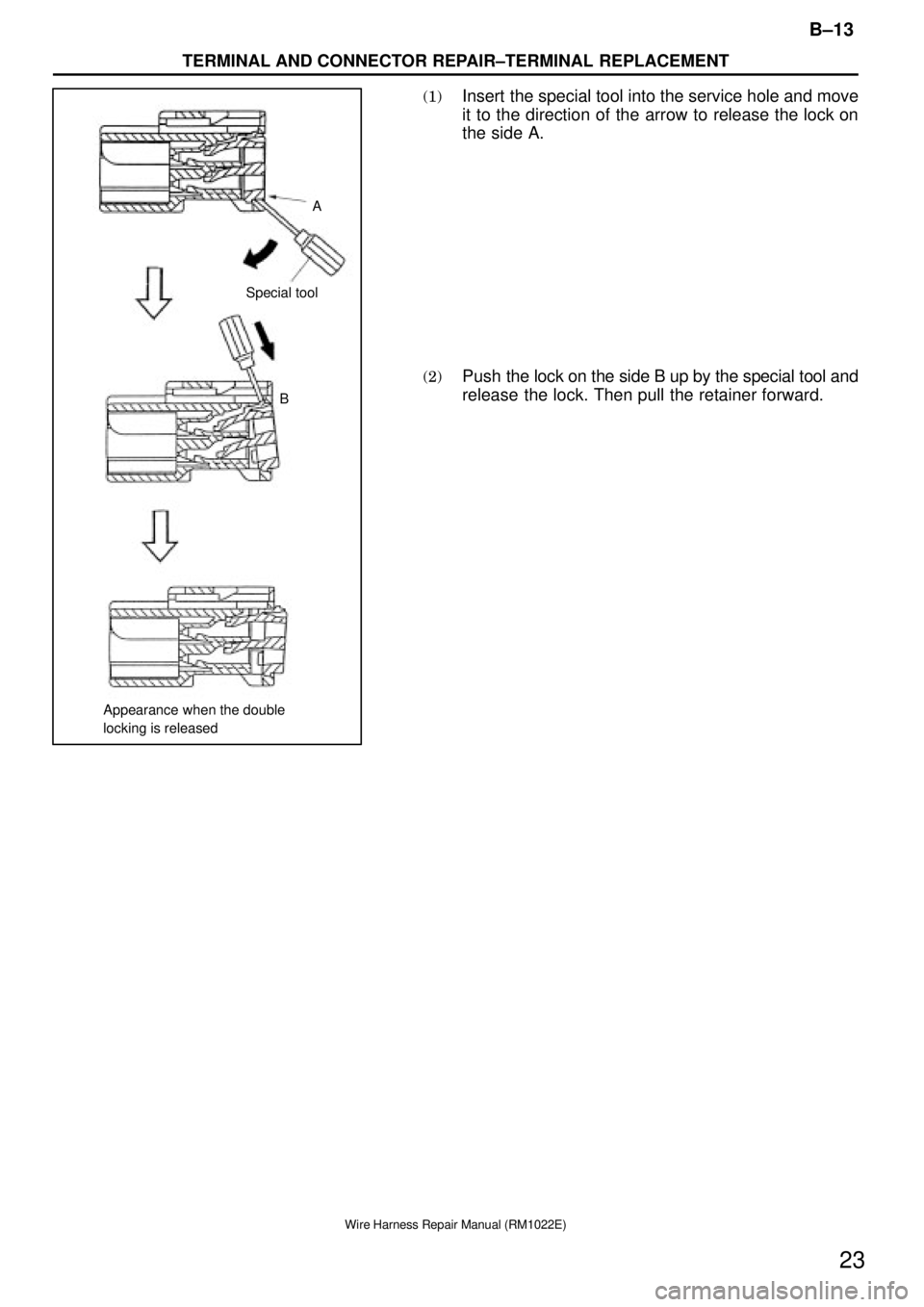

Appearance when the double

locking is releasedA

Special tool

B

B±13

TERMINAL AND CONNECTOR REPAIR±TERMINAL REPLACEMENT

23

Wire Harness Repair Manual (RM1022E)

(1)Insert the special tool into the service hole and move

it to the direction of the arrow to release the lock on

the side A.

(2)Push the lock on the side B up by the special tool and

release the lock. Then pull the retainer forward.