clock TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 63 of 346

EFI SYSTEM - Diagnosis System FI-29

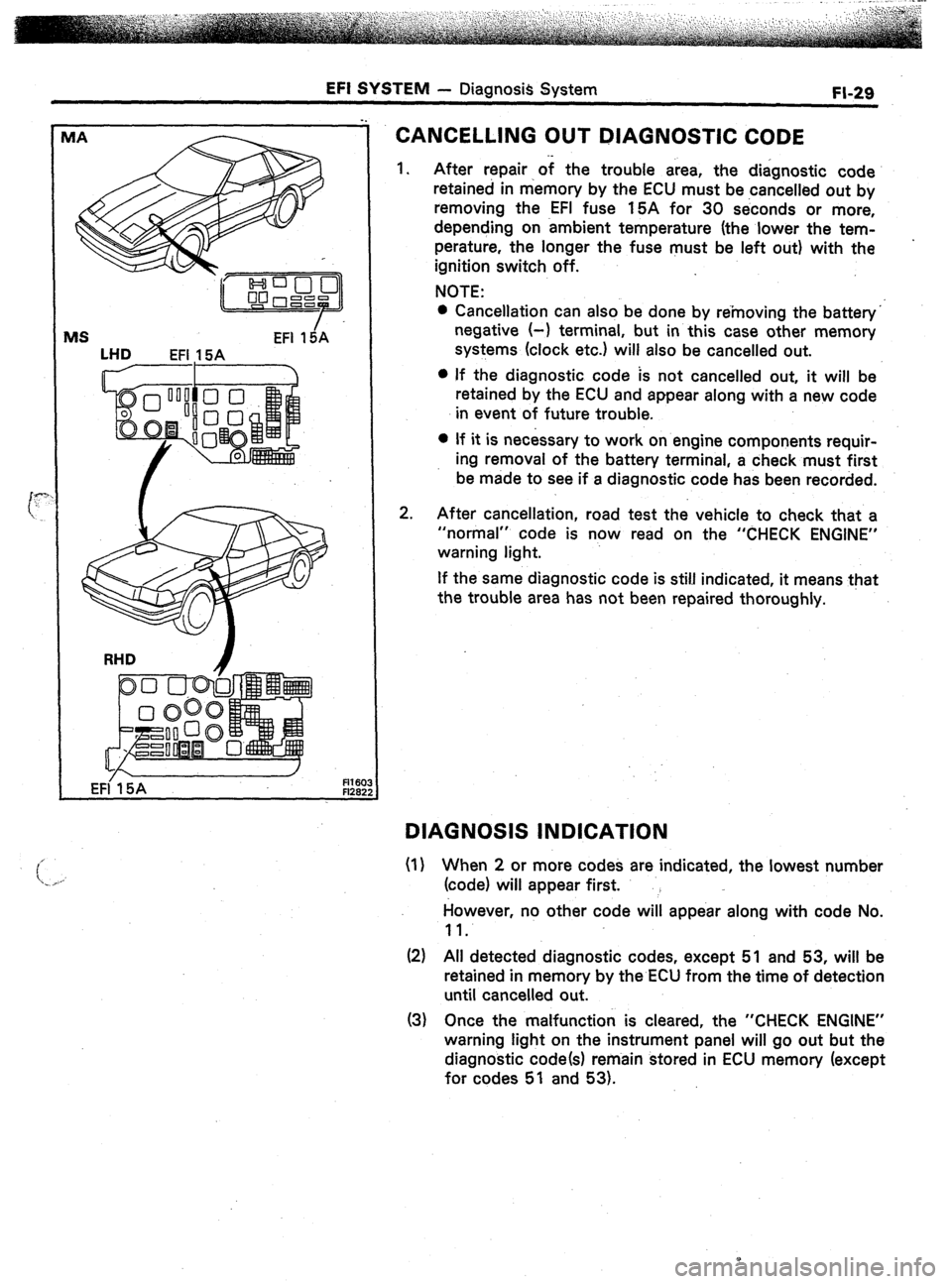

MS EFI 15iA

LHD

EFI 15A

EFI 15A

R16C

FI26:

CANCELLING OUT DIAGNOSTIC CODE

1.

2. After repair of the trouble area, the diagnostic code

retained in memory by the ECU must be cancelled out by

removing the EFI fuse 15A for 30 seconds or more,

depending on ambient temperature (the lower the tem-

perature, the longer the fuse must be left out) with the

ignition switch off.

NOTE:

l Cancellation can also be done by removing the battery”

negative (-1 terminal, but in this case other memory

systems (clock etc.) will also be cancelled out.

l If the diagnostic code is not cancelled out, it will be

retained by the ECU and appear along with a new code

in event of future trouble.

l If it is necessary to work on engine components requir-

ing removal of the battery terminal, a check must first

be made to see if a diagnostic code has been recorded.

After cancellation, road test the vehicle to check that a

“normal” code is now read on the “CHECK ENGINE”

warning light.

If the same diagnostic code is still indicated, it means that

the trouble area has not been repaired thoroughly.

DIAGNOSIS INDICATION

(I) When 2 or more codes are indicated, the lowest number

(code) will appear first.

However, no other code will appear along with code No.

11.

(2) All detected diagnostic codes, except 51 and 53, will be

retained in memory by the ECU from the time of detection

until cancelled out.

(3) Once the malfunction is cleared, the “CHECK ENGINE”

warning light on the instrument panel will go out but the

diagnostic code(s) remain stored in ECU memory (except

for codes 51 and 53).

Page 119 of 346

EFI SYSTEM - Fuel Svstem

FI-85

Pressure Regulator

Front 4

Delivery Pipe

fl1m:

FI166:

INSTALLATION OF PRESSURE REGULATOR

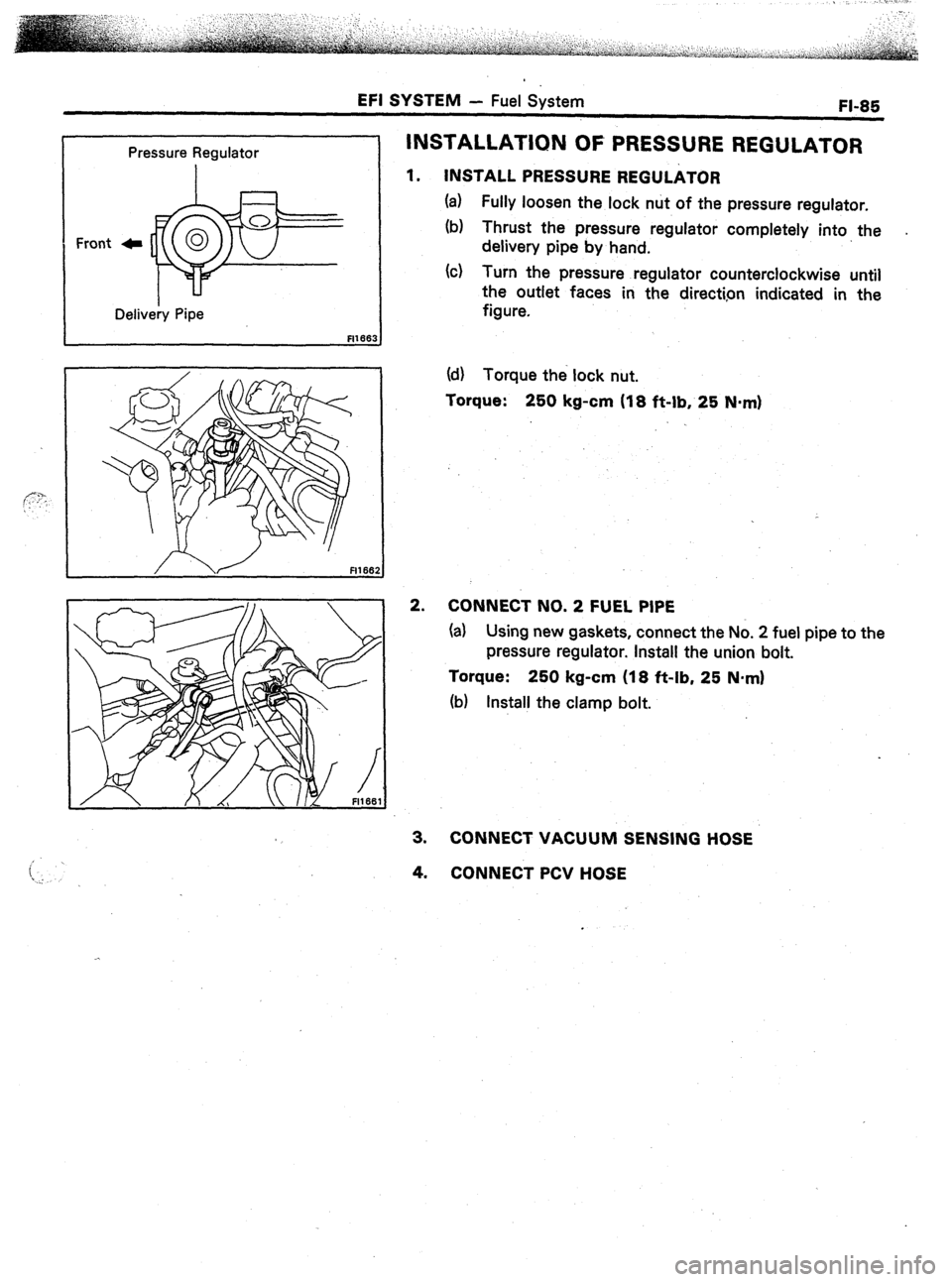

1. INSTALL PRESSURE REGULATOR

(a) Fully loosen the lock nut of the pressure regulator.

(b) Thrust the pressure regulator completely into, the

delivery pipe by hand.

(c) Turn the pressure regulator counterclockwise until

the outlet faces in the directi,on indicated in the

figure.

(d) Torque the lock nut.

Torque:

250 kg-cm (18 ft-lb, 25 N-m)

2.

CONNECT NO. 2 FUEL PIPE

(a) Using new gaskets, connect the No. 2 fuel pipe to the

pressure regulator. Install the union bolt.

Torque: 250 kg-cm (18 ft-lb, 25 N*mI

(b) Install the clamp bolt.

3. CONNECT VACUUM SENSING HOSE

4.

CONNECT PCV HOSE

Page 127 of 346

EFI SYSTEM - Fuel System

FI-93

-_

Pressure Requlator

Deb/Try Pipe

Front C

(e) Install the three spacers and bolts.

Torque the bolts.

Torque:

180 kg-cm (13 ft-lb, 18 N-m)

1.

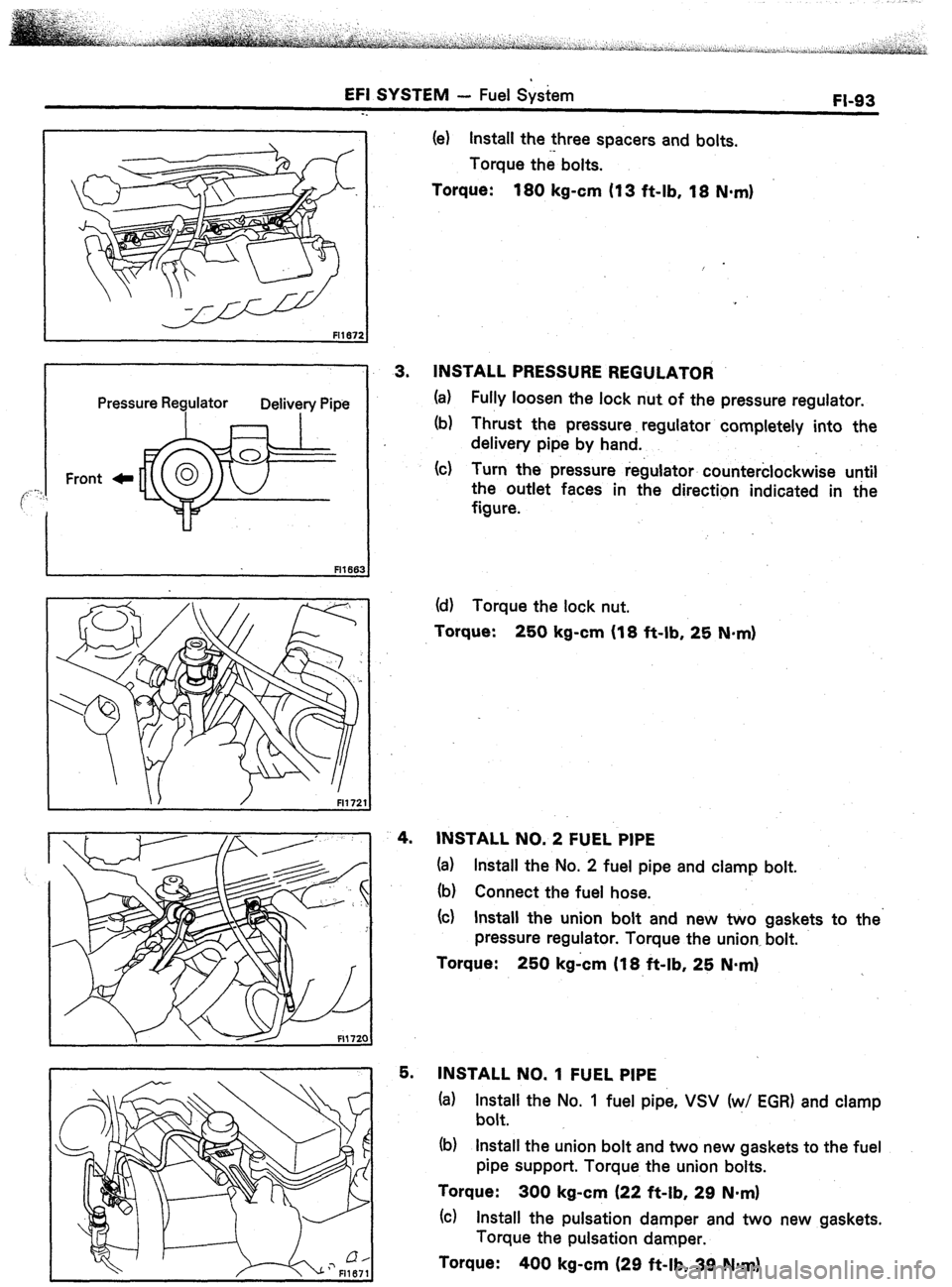

3. INSTALL PRESSURE REGULATOR

(a) Fully loosen the lock nut of the pressure regulator.

(b) Thrust the pressure. regulator completely into the

delivery pipe by hand.

(c) Turn the pressure regulator counterclockwise until

the outlet faces in the direction indicated in the

figure.

/ FI172

4.

5. (d) Torque the lock

nut.

Torque:

250 kg-cm (18 ft-lb, 25 N-m)

INSTALL NO. 2 FUEL PIPE

(a) Install the No. 2 fuel pipe and clamp bolt.

(b) Connect the fuel hose.

(cl Install the union bolt and new two gaskets to

pressure regulator. Torque the union, bolt.

Torque:

250 kgicm (18 ft-lb, 25 N*m) the’

INSTALL NO. 1 FUEL PIPE

(a) Install the No. 1 fuel pipe, VSV (w/ EGR) and clamp

bolt.

(b) Install the union bolt and two new gaskets to the fuel

pipe support. Torque the union bolts.

Torque: 300 kg-cm (22 ft-lb, 29 N.m)

(cl Install the pulsation damper and two new gaskets.

Torque the pulsation damper.

Torque:

400 kg-cm (29 ft-lb, 39 Nmrn)

Page 139 of 346

,_ ,.A< ,..,.

EFI SYSTEM - Air Induction System

FI-105

FI188

Ft162!

FHE

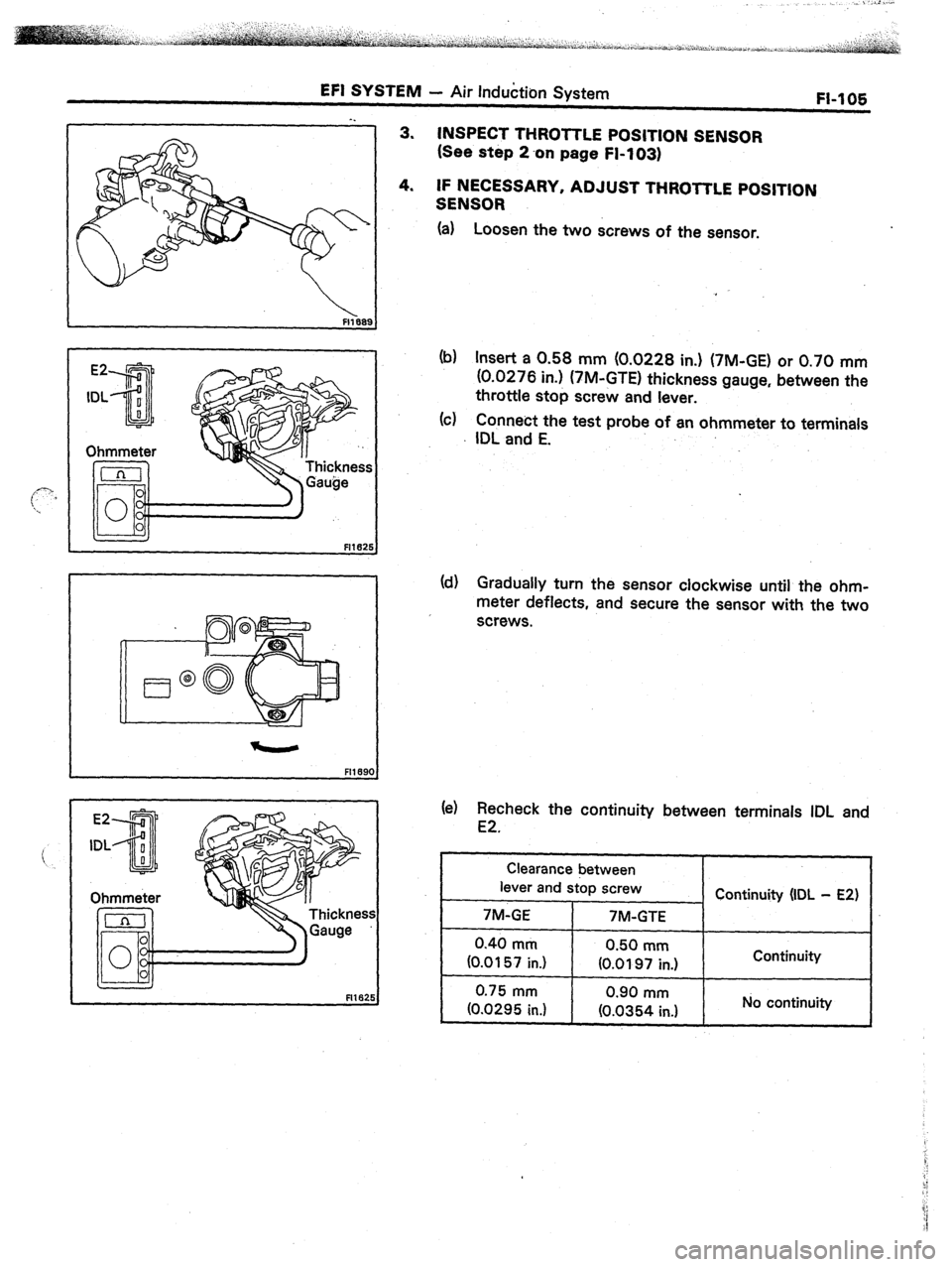

3. INSPECT THROTTLE POSITION SENSOR

(See step 2 -on page Fl-103)

4. IF NECESSARY, ADJUST THROTTLE POSITION

SENSOR

(a) Loosen the two screws of the sensor.

fll6i

(b) Insert a 0.58 mm (0.0228 in.) (7M-GE) or 0.70 mm

(0.0276 in.) (XVI-GTE) thickness gauge, between the

throttle stop screw and lever.

(c) Connect the test probe of an ohmmeter to terminals

IDL and E.

(dd) Gradually turn the sensor clockwise until the ohm-

meter deflects, and secure the sensor with the two

screws.

(e) Recheck the continuity between terminals IDL and

E2.

I Clearance between

I

I lever and stop screw

I Continuity (IDL - E2)

I 7M-GE

! 7M-GTE

I

0.40 mm

I 0.50 mm

(0.0157 in.) (0.0197 in.) Continuity

0.75 mm 0.90 mm

(0.0295 in.1 lo.0354 in.) No continuity

Page 197 of 346

.

ENGINE MECHANICAL - Timing Belt

EM-35

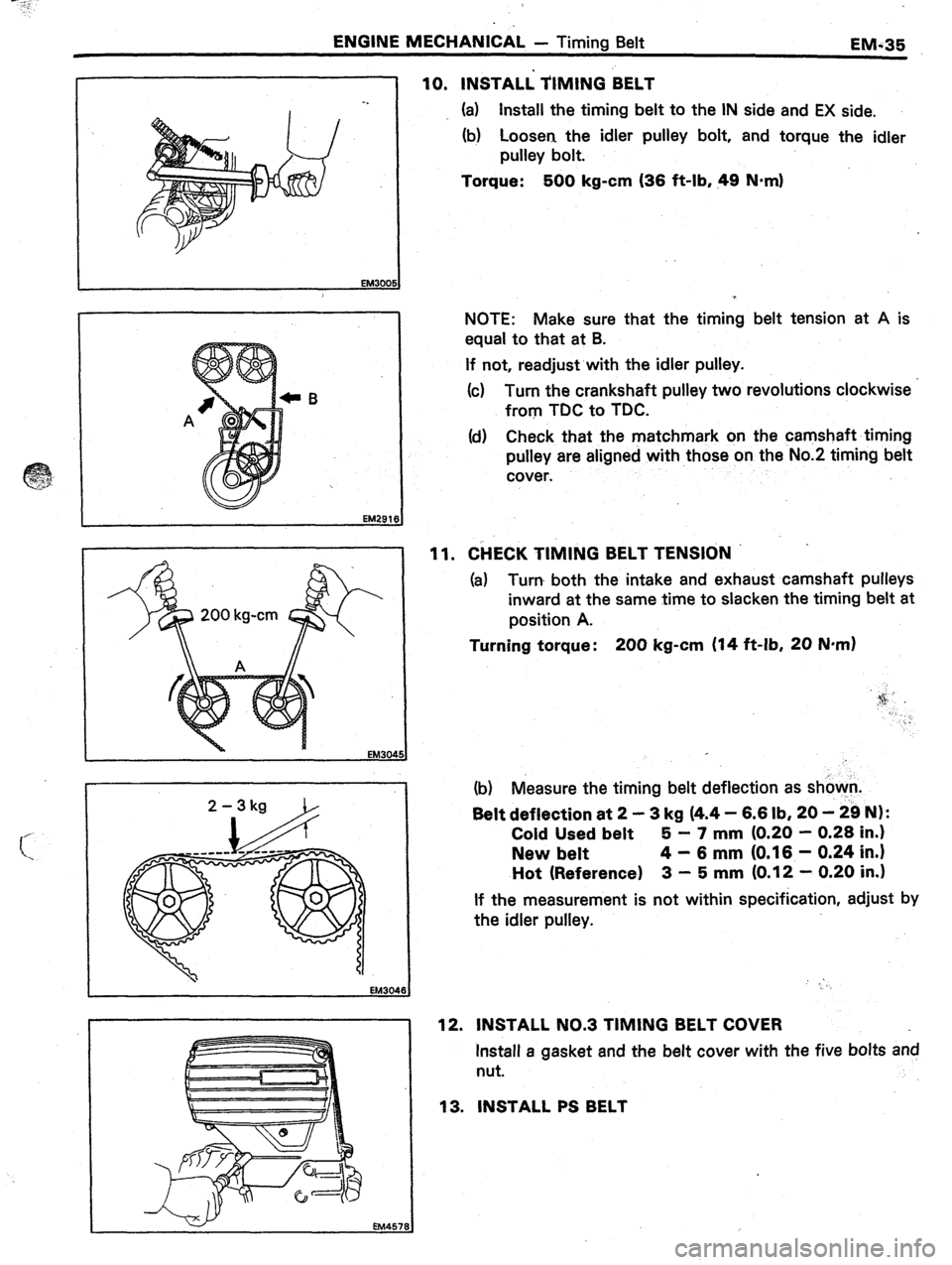

10. INSTALi TIMING BELT

B

EM304

EM457

(a) Install the timing belt to the IN side and EX side.

(b) Loosen the idler pulley bolt, and torque the idler

pulley bolt.

Torque: 500 kg-cm (36 ft-lb, 49 N.m)

7

NOTE: Make sure that the timing belt tension at A is

equal to that at B.

If not, readjust with the idler pulley.

(c) Turn the crankshaft pulley two revolutions clockwise

from TDC to TDC.

(d) Check that the matchmark on the camshaft timing

pulley are aligned with those on the No.2 timing belt

cover.

11. CHECK TIMING BELT TENSION

(a) Turn both the intake and exhaust camshaft pulleys

inward at the same time to slacken the timing belt at

position A.

Turning torque : 200 kg-cm (14 ft-lb, 20 N*m)

(b) Measure the timing belt deflection as shown.

Belt deflection at 2 - 3 kg (4.4 - 6.6 lb, 20 - 29 N):

Cold Used belt 5 - 7 mm (0.20 - 0.28 in.)

New belt 4 - 6 mm (0.16 - 0.24 in.1

Hot (Reference) 3 - 5 mm (0.12 - 0.20 in.)

If the measurement is not within specification, adjust by

the idler pulley.

12. INSTALL NO.3 TIMING BELT COVER

Install a gasket and the belt cover with the five bolts and

nut.

13. INSTALL PS BELT

Page 273 of 346

IGNITION SYSTEM - Distributor (7M-GE)

D&bbR,B”T& (TM-GE) IO:19

‘_:- ‘-. -I.. ..~ . -..

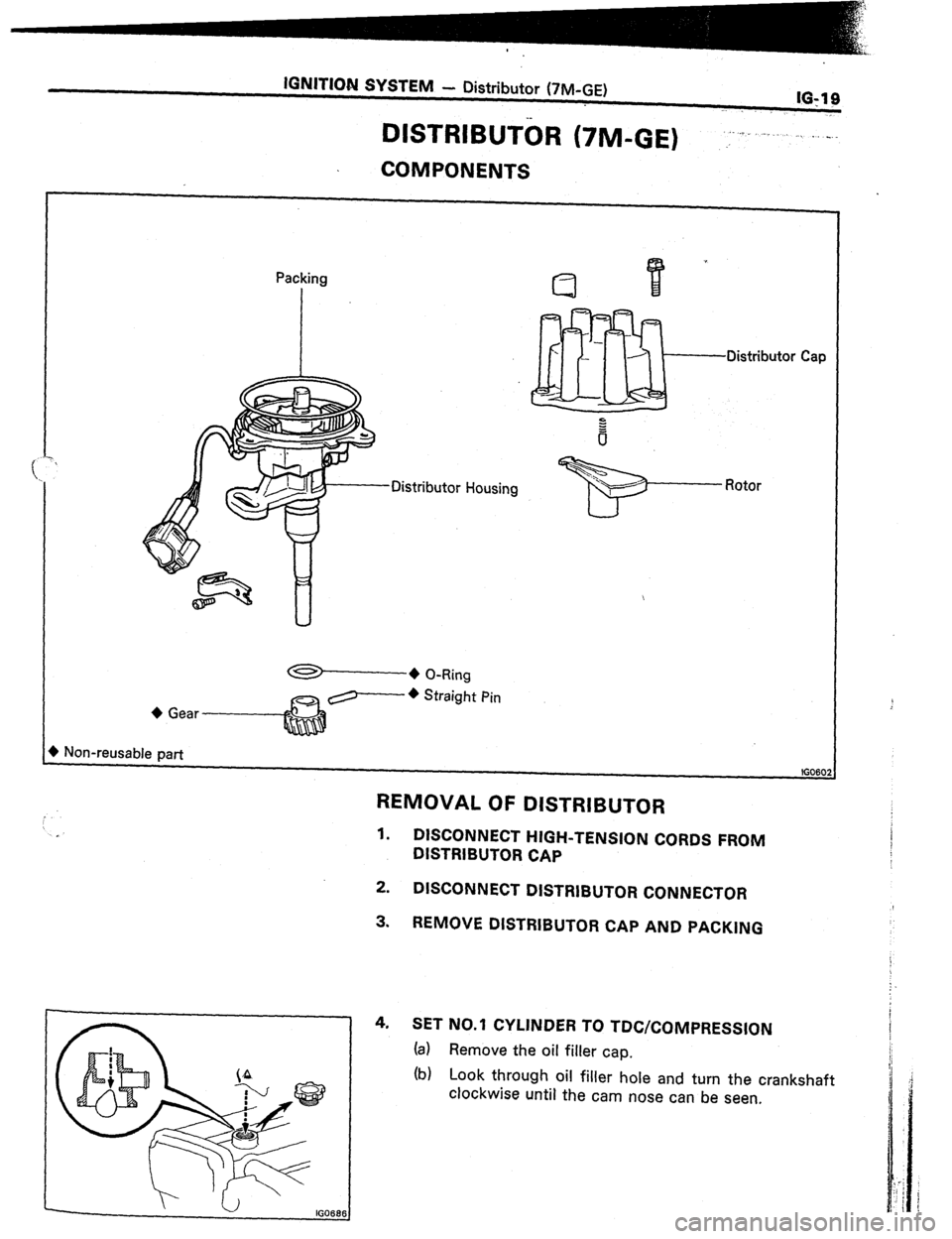

COMPONENTS

Packing

Distributor Cap

+ O-Ring

Q- l Straight Pin

+ Gear 8

Distributor Housing w- Rotor

+ Non-reusable part

I REMOVAL OF DISTRIBUTOR

1. DISCONNECT HIGH-TENSION CORDS FROM

DISTRIBUTOR CAP

2.

DISCONNECT DISTRIBUTOR CONNECTOR

3. REMOVE DISTRIBUTOR CAP AND PACKING

ffiO60

4. SET NO.1 CYLINDER TO TOWCOMPRESSION

(a) Remove the oil filler cap.

(b) Look through oil filler hole and turn the crankshaft

clockwise until the cam nose can be seen.

Page 274 of 346

16-20

ION ITION SYSTEM

- Distiibtitor ‘(7M-GE)

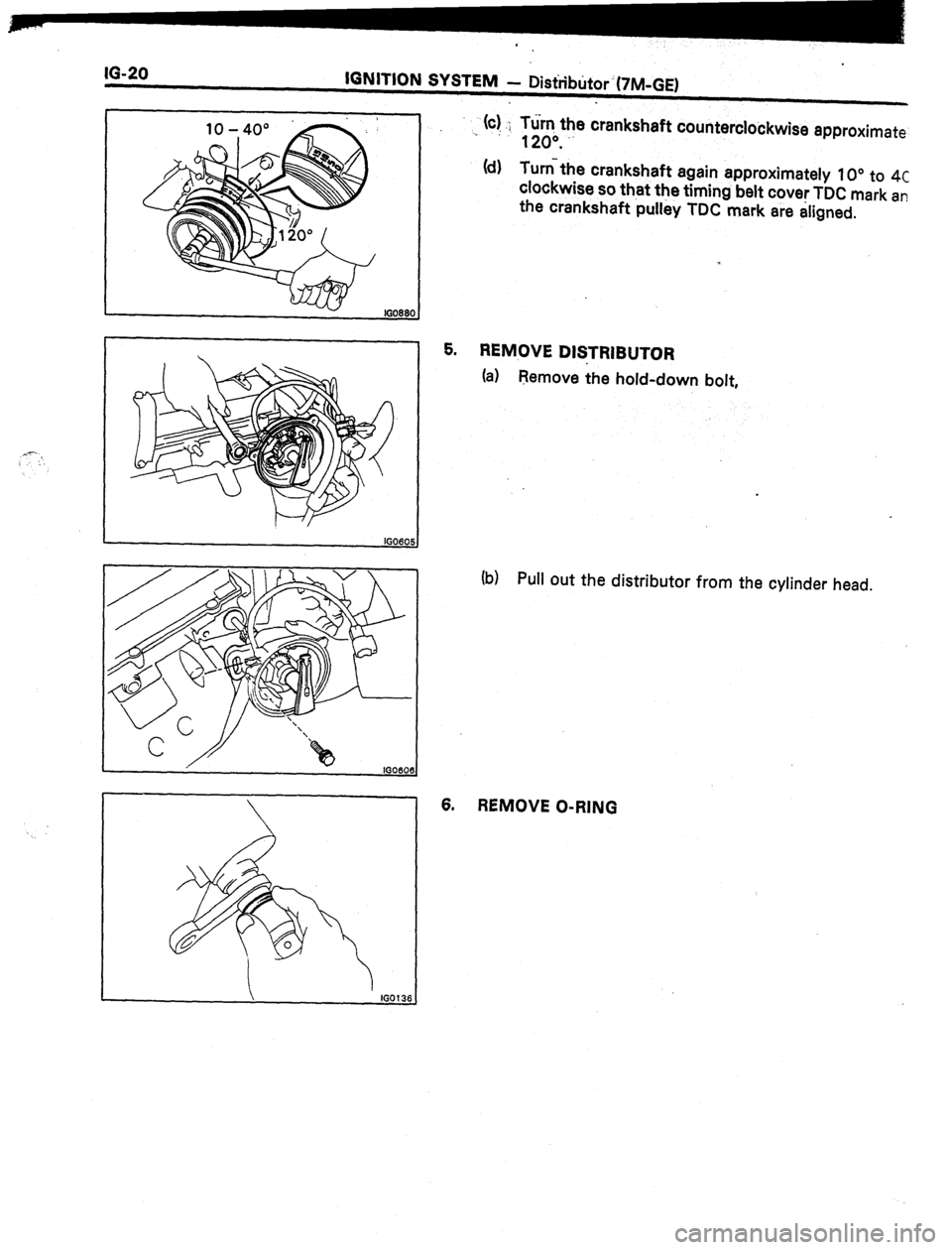

(c) .; Ttirq the crankshaft counterclockwise approximate

1 :

1 2o”.

Id) Turn-the crankshaft again approximately 10” to

4~

clockwise so that the timing belt cover TDC mark ar!

the crankshaft pull&y TDC mark are aligned.

/

IG06C

5. REMOVE DISTRIBUTOR

(a) Remove

;he hold-down bolt,

(b) Pull out the distributor from the cylinder head.

6. REMOVE O-RING

Page 277 of 346

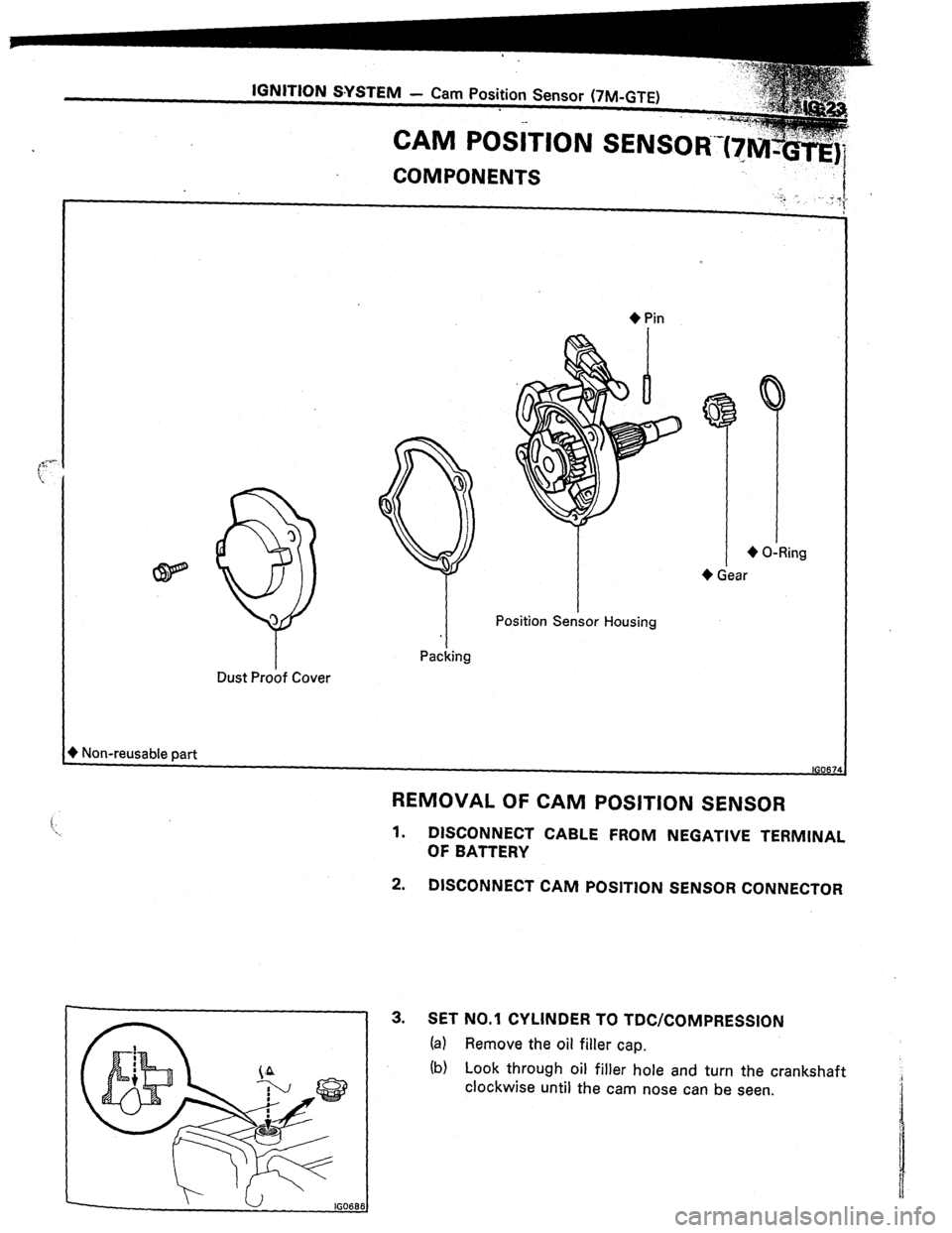

CAM POSiTION SENSOR-(7

COMPONENTS

* Non-reusable part

3

9 3

Dust Proof Cover Packing + Pin

Position Sensor Housing + Gear

-

~~-

REMOVAL OF CAM POSITION SENSOR

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL

Oi- BATTERY

2.

DISCONNECT CAM POSITION SENSOR CONNECTOR

3.

SET NO.1 CYLINDER TO TDWCOMPRESSION

(a) Remove the oil filler cap.

(b) Look through oil filler hole and turn the crankshaft

clockwise until the cam nose can be seen. :I

it

Page 278 of 346

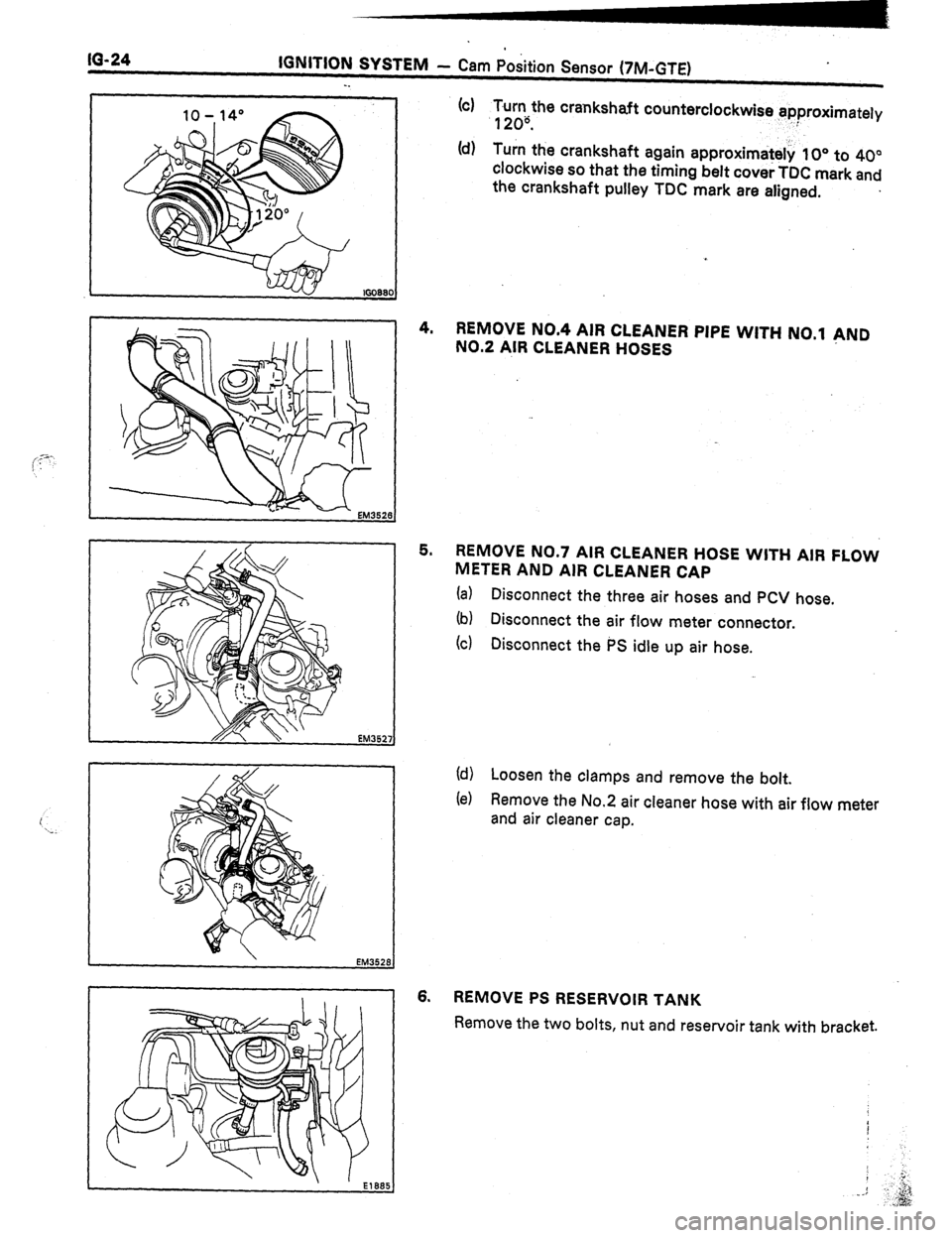

IQ-24 IGNITION SYSTEM - Cam Position Sensor (7M-GTE)

(cl y2;dthe crankshaft counterclockwise arjproximately

(d) Turn the crankshaft again approximtiteli 10” to 40”

clockwise so that the timing belt cove; TDC mark and

the crankshaft pulley TDC mark are aligned.

.

4. REMOVE NO.4 AIR CLEANER PIPE WITH NO.1 PND

NO.2 AIR CLEANER HOSES

5.

REMOVE NO.7 AIR CLEANER HOSE WITH AIR FLOW

METER AND AIR CLEANER CAP

(a) Disconnect the three air hoses and PCV hose.

(b) Disconnect the air flow meter connector.

(c) Disconnect the PS idle up air hose.

(d) Loosen the clamps and remove the bolt.

(e) Remove the No.2 air cleaner hose with air flow meter

and air cleaner cap.

6.

REMOVE PS RESERVOIR TANK

Remove the two bolts, nut and reservoir tank with bracket.

Page 294 of 346

LU-12

-.

LUBRICATION SYSTEM - Oij Pump

LUOJS

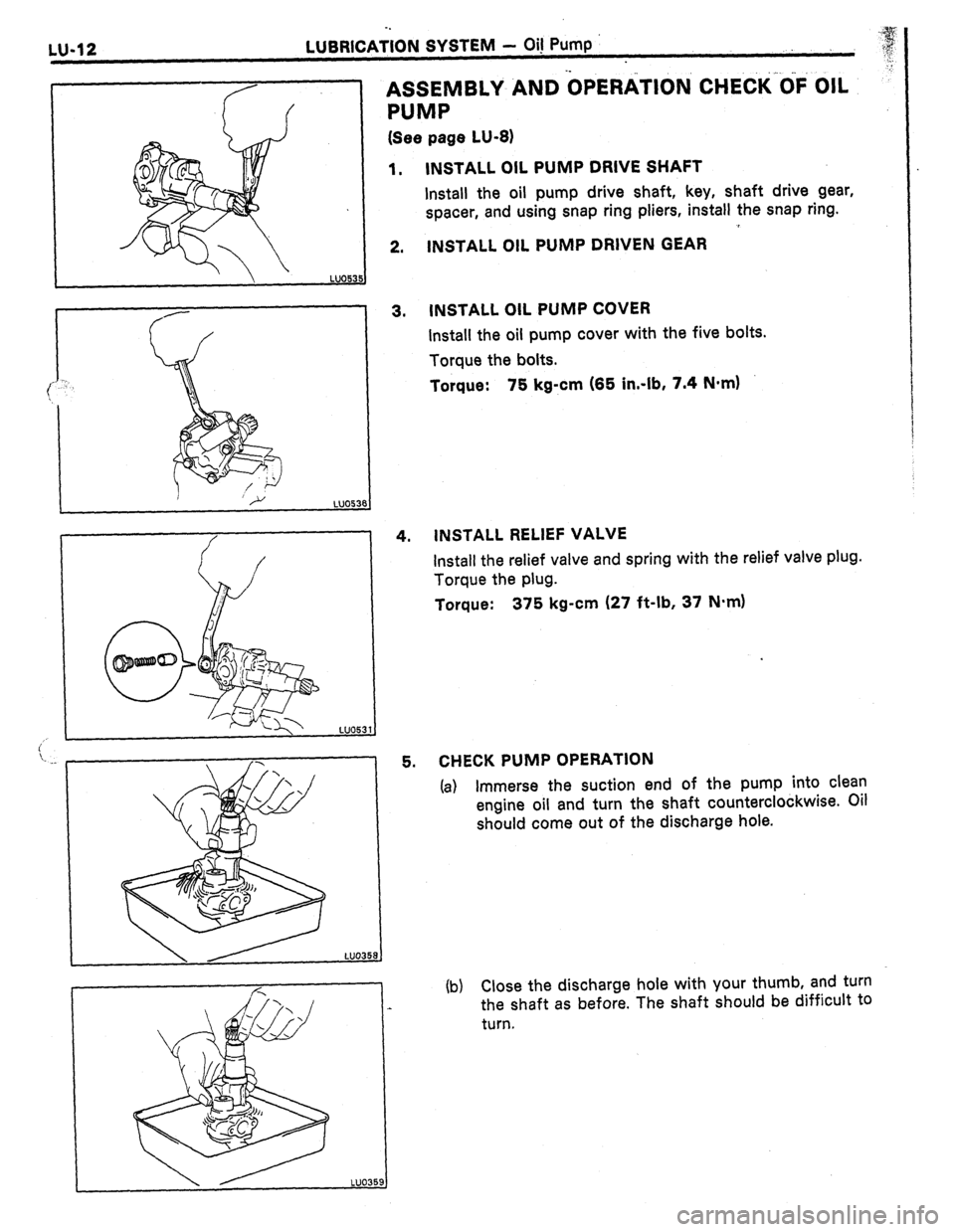

ASSEMBLY AND OPERATION CHECK OF OIL

”

PUMP

(See page LU-8)

5. INSTALL OIL PUMP DRIVE SHAFT

Install the oil pump drive shaft, key, shaft drive gear,

spacer, and using snap ring pliers, install the snap ring.

INSTALL OIL PUMP DRIVEN GEAR

INSTALL OIL PUMP COVER

Install the oil pump cover with the five bolts.

Torque the bolts.

Torque: 75 kg-cm (65 in.-lb, 7.4 N-m)

INSTALL RELIEF VALVE

Install the relief valve and spring with the relief valve plug.

Torque the plug.

Torque:

375 kg-cm (27 ft-lb, 37 N.m)

CHECK PUMP OPERATION

(a) Immerse the suction end of the pump into clean

engine oil and turn the shaft counterclockwise. Oil

should come out of the discharge hole.

(b) Close the discharge hole with your thumb, and turn

the shaft as before. The shaft should be difficult to

turn.