engine coolant TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 23 of 346

. COOLING SYSTEM - Description

co;3

RESERVOIR TANK

The reservoir tank is used to catch coolant

which overflows the cooling systein as a result of

volumetric expansion when the coolant is heated.

The coolant in the reservoir tank returns to the

radiator when the coolant temperature drops, thus

keeping the radiator full at all times and avoiding

needless coolant loss. Check the reservoir tank

level to learn if the coolant needs to be rep-

lenished.

WATER PUMP

The water pump is used for forced circulation of

coolant through the cooling system. It is mounted

on the front of the cylinder block and driven by a

V-ribbed belt,

THERMOSTAT I The cooling system is composed of the water

jacket (inside the cylinder block and cylinder head),

radiator, water pump, thermostat, cooling fan,

hoses and other components.

Coolant which is heated in the water

jacket is

pumped to the radiator, through which a cooling

fan blows air to cool the coolant as it passes

through. Coolant which has been cooled is then

sent back to the engine by the water pump, where

it cools the engine.

The water jacket is a network of channels in the

shell of the cylinder block and cylinder head

through which coolant passes. It is designed to

provide adequate cooling of the cylinders are com-

bustion chambers which become the hottest dur-

ing engine operation.

F(/ “ IATOR

The radiator performs the function of cooling

the coolant which has passed through the water

jacket and become hot, and is mounted in the front

of the vehicle. The radiator consists of an upper

tank and ‘lower tank, and a core which connects

the two tanks. The upper tank contains the inlet for

coolant from the water jacket and the filter inlet. It

also has a hose attached through which excess

coolant or steam can flow. The lower tank contains

the outlet for coolant and the drain cock. The core

contains many tubes through which coolant flows

from the upper tank to the lower tank as well as

cooling fins which radiate heat away from the coo-

lant in the tubes. The air sucked through the radia-

tor by cooling fan, as well as the wind generated

by the vehicle’s travel, passes through the radia-

tor, cooling it. Models with automatic transmission

incrl*-le an automatic transmission fluid cooler built

in:.

.le lower tank of the radiator.

RADIATOR CAP

The radiator cap is a pressure type can which

seals the radiator, resulting in pressurization of the

radiator as the coolant expands. The pressuriza-

tion prevents the coolant from boiling even when

the coolant temperature exceeds 100°C. A relief

valve (pressurization valve) and a vacuum valve

(negative pressure valve) are built into the radiator

zap. The relief valve opens and lets steam escape

:hrough the overflow pipe when the pressure

3enerated inside the cooling system exceeds the

imit (coolant temperature:

110 - 1 20°C, (230

- 248”F), pressure; 0.3 - 1 .O kg/cmz, (4.3 - 14.2

)si, 29.4 - 98.1 kPa). The vacuum valve opens to

3ljeviate the vacuum which develops in the coolant

system after the engine is stopped and the coolant

emperature drops. The valve’s opening allows the

)ressure in the cooling system to return to the

Qclant in the reservoir tank. The thermostat has a wax type and is mounted

in the. water outlet housing. The thermostat

includes a type of automatic valve operated by

fluctuations in the coolant temperature. This valve

closes when the coolant temperature drops, pre-

venting the circulation of coolant through the

engine and thus permitting the engine to warm up

rapidly. The valve opens when the coolant tem-

perature has risen, allowing the circulation of coo-

lant. Wax inside the thermostat expands when

heated and contracts when cooled. Heating the

wax thus generates pressure which overpowers

the force of the spring which keeps the valve

closed, thus opening the valve. When the wax

cools, its contraction causes the force of the

spring to take effect once more, closing the valve.

The thermostat in this engine operates at a tem-

perature of 88”C(19O”F).

I

I

Page 25 of 346

COOLING SYSTEM i Check and Replacement of Engine Coolant

co-5

._

CHECK AND REPLACEMENT OF

ENGINE COOLANT

1. CHECK ENGINE COOLANT LEVEL AT RESERVE TANK

The coolant level should be between the “LOW” and

“FULL” lines.

If low, check for leaks and add coolant up to the “FULL”

line. .,>‘

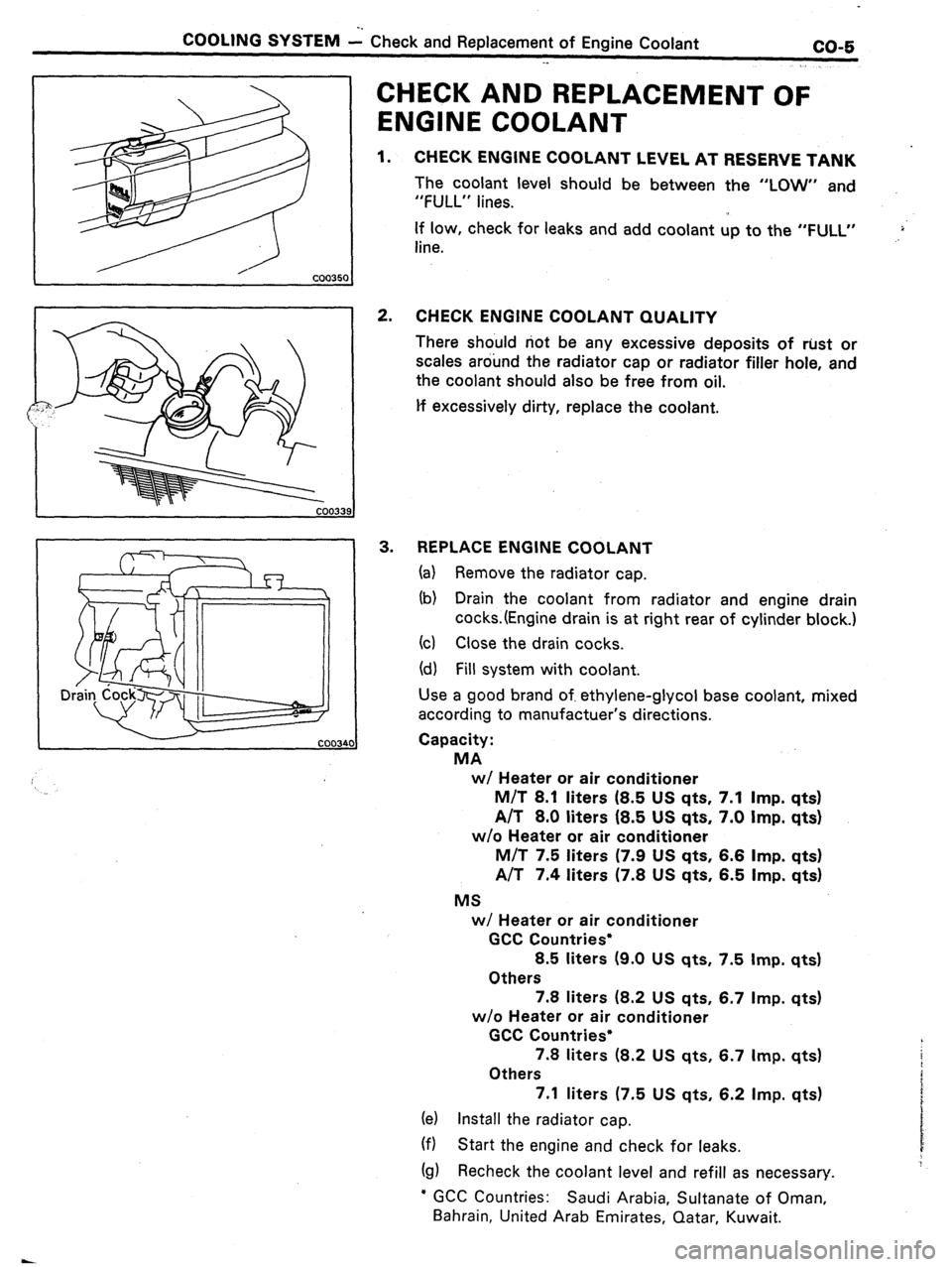

2. CHECK ENGINE COOLANT QUALITY

There should not be any excessive deposits of rust or

scales around the radiator cap or radiator filler hole, and

the coolant should also be free from oil.

lf excessively dirty, replace the coolant.

3. REPLACE ENGINE COOLANT

(a) Remove the radiator cap.

(b) Drain the coolant from radiator and engine drain

cocks.(Engine drain is at right rear of cylinder block.)

(cl Close the drain cocks.

(d) Fill system with coolant.

Use a good brand of. ethylene-glycol base coolant, mixed

according to manufactuer’s directions.

Capacity:

MA

w/ Heater or air conditioner

M/T 8.1 liters (8.5 US qts. 7.1 Imp. qts)

A/T 8.0 liters (8.5 US qts, 7.0 Imp. qts)

w/o Heater or air conditioner

M/T 7.5 liters (7.9 US qts, 6.6

Imp. qts)

A/T 7.4 liters (7.8 US qts, 6.5 Imp. qts)

MS

w/ Heater or air conditioner

GCC Countries*

8.5 liters (9.0 US qts, 7.5 Imp. qts)

Others

7.8 liters (8.2 US qts, 6.7 Imp. qts)

w/o Heater or air conditioner

GCC Countries*

7.8 liters (8.2 US qts, 6.7 Imp. qts)

Others

7.1 liters (7.5 US qts, 6.2 Imp. qts)

(e) Install the radiator cap.

(f) Start the engine and check for leaks.

(g) Recheck the coolant level and refill as necessary.

l GCC Countries: Saudi Arabia, Sultanate of Oman,

Bahrain, United Arab Emirates, Qatar, Kuwait.

Page 29 of 346

COOLING SYSTEM - Radiator

-,... ~‘e:,.,,’ _,

CLEANING OF RADIATOR _ ---w..w- -...,.

Using water or steam cleaner, remove mud and dirt from

the radiator core.

CAUTION: If using’ high-pressure, type cleaner, be

careful not to deform the fins of the radiator core. Keep

a distance of more than 40 - 50 cm (15.75 - 19.69 in.)

between the radiator core and cleaner nozzle when

the cleaner nozzle pressure is 30 - 35 kg/cm2 (427 -

1

498 psi, 2,942 - 3,432 kPa1.

I lNSPECTlON.OF RADIATOR

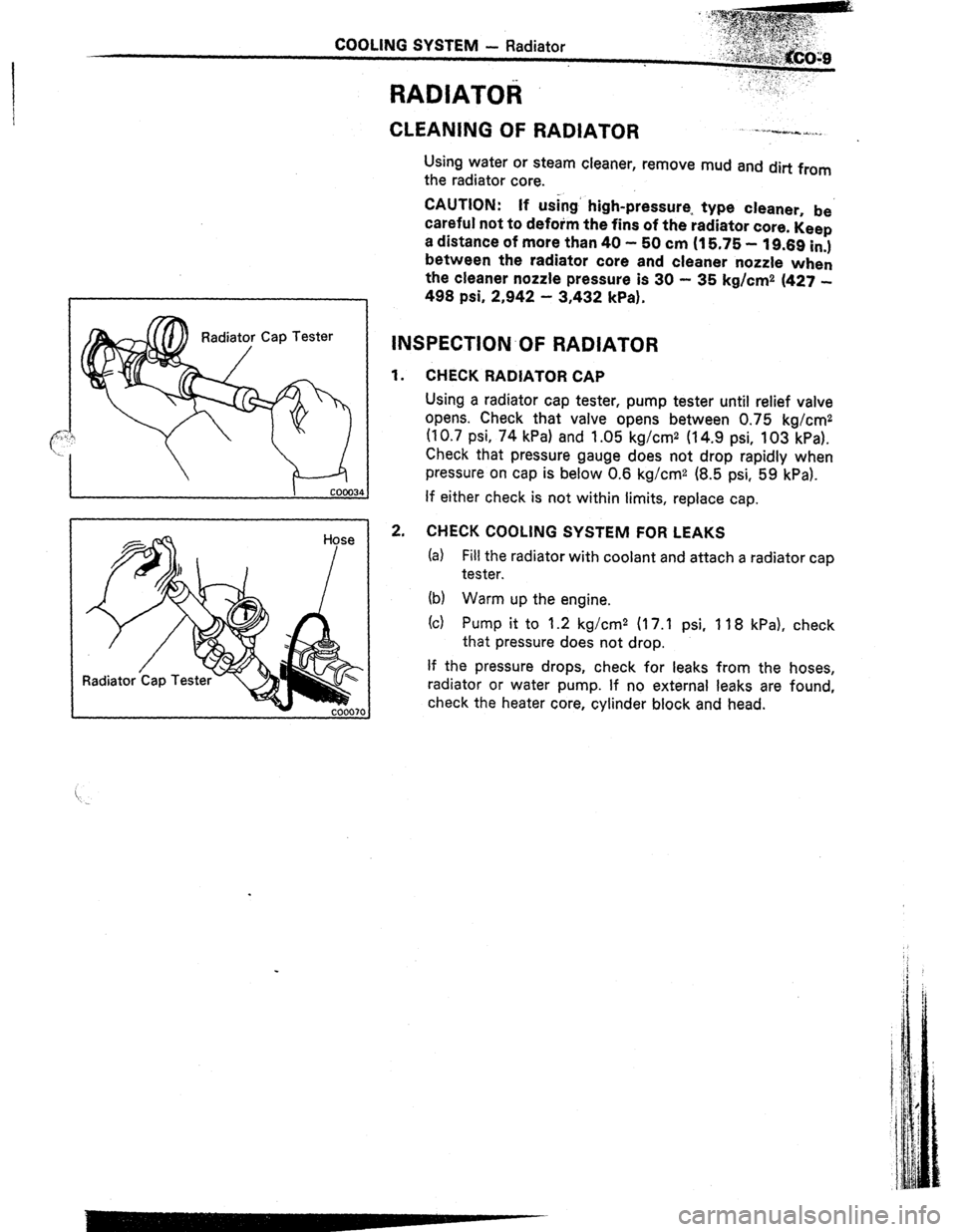

t 1. CHECK RADIATOR CAP

Using a radiator cap tester, pump tester until relief valve

opens. Check that valve opens between 0.75 kg/cm2

(10.7 psi, 74 kPa) and 1.05 kg/cm2 (14.9 psi, 103 kPa).

Check that pressure gauge does not drop rapidly when

pressure on cap is below 0.6 kg/cm2 (8.5 psi, 59 kPa).

!J If either check is not within limits, replace cap.

1 2. CHECK COOLING SYSTEM FOR LEAKS

(a) Fill the radiator with coolant and attach a radiator cap

tester.

(b) Warm up the engine.

(c) Pump it to 1.2 kg/cm2 117.1 psi, 118 kPa), check

that pressure does not drop.

If the pressure drops, check for leaks from the hoses,

radiator or water pump. If no external

leaks are found,

check the heater core, cylinder block

and head.

Page 40 of 346

1-6 EFI SYSTEM - System Description

‘he .EFI system is composed of 3 basic sub

;ystems; Fuel Induction, Air Induction and

Ziectronic Control.

FUEL SYSTEM

An electric fuel pump supplies sufficient fuel,

under a constant pressure, to the injectors. These

injectors inject a metered quantity of fuel into the

intake manifold in accordance with signals from

the ECU (Electronic Control Unit).

AIR INDUCTION SYSTEM

The air induction system provides sufficient air for

engine operation.

[3: ‘I

i&TRONIC CONTROL SYSTEM

The 7M-GE, 7M-GTE engines are equipped wifh a

Toyota Computer Control System (TCCS) which

centrally controls the EFI, ESA, Diagnosis systems,

etc. by means of an Electronic Control Unit (ECU -

for-merly EFI computer) employing a microcom-

puter.

By means of the ECU, the TCCS controls the

following functions:

1. Electronic Fuel injection (EFI)

The ECU receivers signals from,various sen-

sors indicating changing engine operating

conditions such as:

Exhaust oxygen content (w/ TWC)

Intake air volume

i Intake air temperature

Coolant temperature

Engine rpm

Vehicle speed

Acceleration/deceleration etc.

These signals are utilized by the ECU to

determine the injection duration necessary for

an optimum air-fuel ratio.

2. Electronic Spark Advance (ESA)

The ECU is programmed with data for

optimum ignition timing under any and all

operating conditions. Using data provided by

sensors which monitor various engine func-

tions (rpm, A/C signal, coolant temperature,

etc.), the microcomputer (ECU) triggers the

spark at precisely the right instant. (See IG

section) 3. Idle Speed Control (IX)

The ECU is programmed with, target idling

speed values to respond to different engine

conditions (coolant temperature, air condi-

tioner on/off, etc.). Sensors transmit signals

to the ECU which control the flow of air

through the bypass of the throttle valve and

adjust idle speed to the target value.

(See pages FI-53, 7 1, 108) ’

4. Diagnosis

The ECU detects any malfunctions or abnor-

malities in the sensor network and tights the

“CHECK ENGINE” warning light on the instru-

ment panel. At the same time, the trouble is

identified and a diagnostic code is recorded

by the ECU.

5. Fail-Safe Function ’

In the event of computer malfunction, a back-

up circuit will take over to provide minimal

drivability. Simultaneously, the “CHECK

ENGINE” warning light will come on.

Page 65 of 346

EFI SYSTEM

- Diagnosis System

FI-31

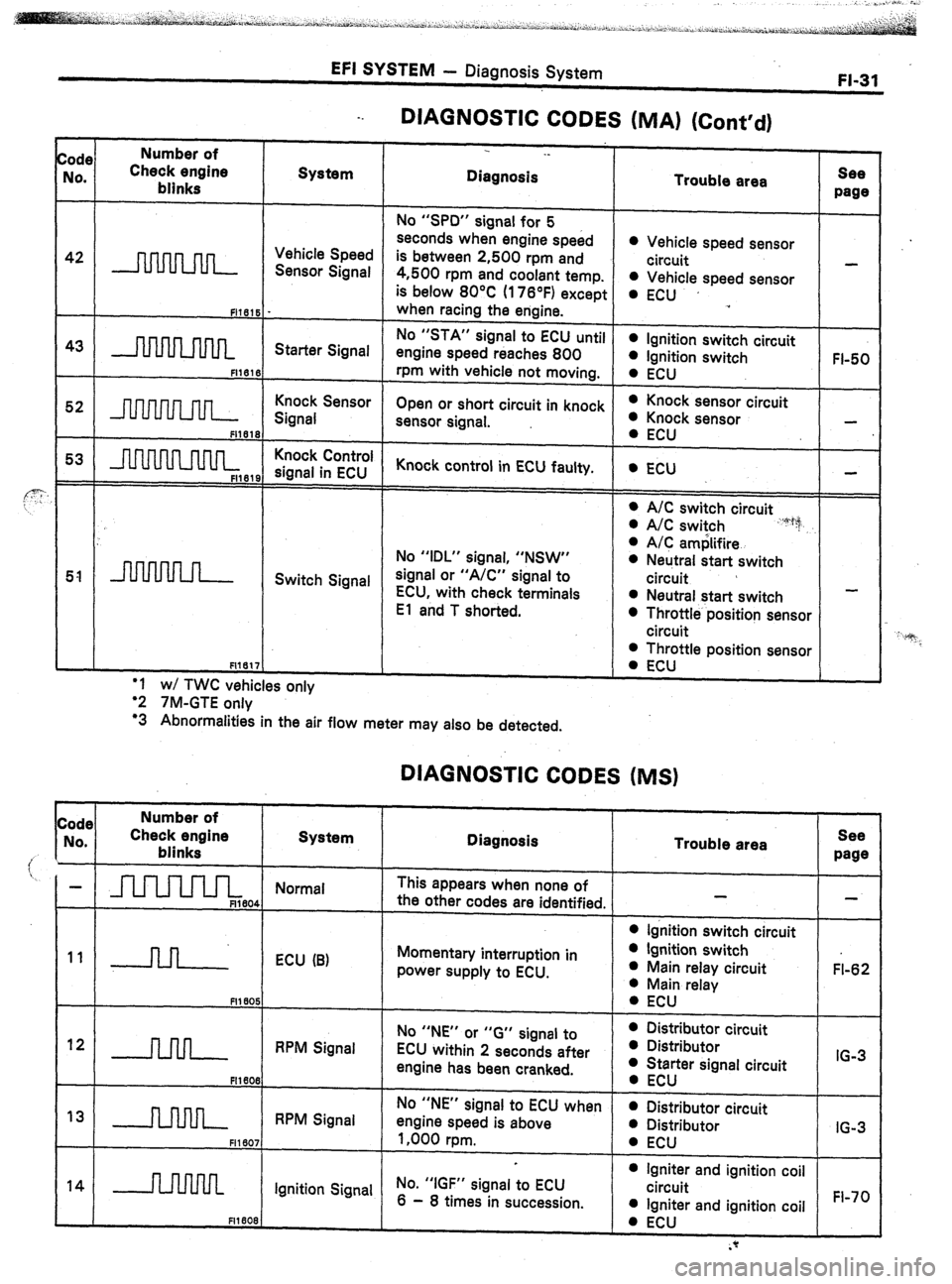

DIAGNOSTIC CODES (MA) (Cont’d) __

:odc

No. Number of

Check engine

blinks Diagnosis System See

page

FL50 Trouble area

l Vehicle speed sensor

circuit

l Vehicle speed sensor

. ECU ’

I

l Ignition switch circuit

l Ignition switch

l ECU

l Knock sensor circuit

l Knock sensor

l ECU

. ECU

l A/C switch circuit

l A/C switch ‘“q

l A/C am&fire

l Neutral start switch

circuit ’

l Neutral start switch

0 Throttle position sensor

circuit

l Throttle position sensor

l ECU Vehicle Speed

Sensor Signal

Starter Signal No “SPD” signal for 5

seconds when engine speed

is between 2,500 rpm and

4,500 rpm and coolant temp.

is below 80°C (176’F) except

when racing the engine.

No “STA” signal to ECU until

engine speed reaches 800

rpm with vehicle not moving.

Knock Sensor

Signal Open or short circuit in knock

sensor signal. 42

FI161

FHBl

Fl181

FIlei

52

Knock control in ECU faulty. Knock Control

signal in ECU

No “IDL” signal, “NSW”

signal or “A/C” signal to

ECU, with check terminals

El and T shorted. Switch Signal

‘1 WI TWC vehicles only

‘2 7M-GTE only

“3 Abnormalities in the air flow meter may also be detected.

DIAGNOSTIC CODES (MS)

Number of

Check engine

System

blinks

m Normal

fl1604

nn ECU (B) Diagnosis

This appears when none of

the other codes are identified.

Momentary interruption in

power supply to ECU. Trouble area See

page

l Ignition switch circuit

l Ignition switch

l Main relay circuit

l Main relay

l ECU FI-62

l Distributor circuit

0 Distributor

l Starter signal circuit

. ECU IG-3

l Distributor circuit

l Distributor

. ECU IG-3

l Igniter and ignition coil 11

FI1605

n nn RPM Signal No “NE” or “G” signal to

ECU within 2 seconds after

engine has been cranked.

FHBOB

nnnn, RPM Signal No “NE” signal to ECU when

engine speed is above

Fl1807 1,000 rpm. 12

-

13

-

14

-LJUlJUL 1 Ignition Signal 1 * No. “IGF” signal to ECU

6 - 8 times in succession. circuit

0 Igniter and ignition coil

. ECU

.t Fl-70

Page 71 of 346

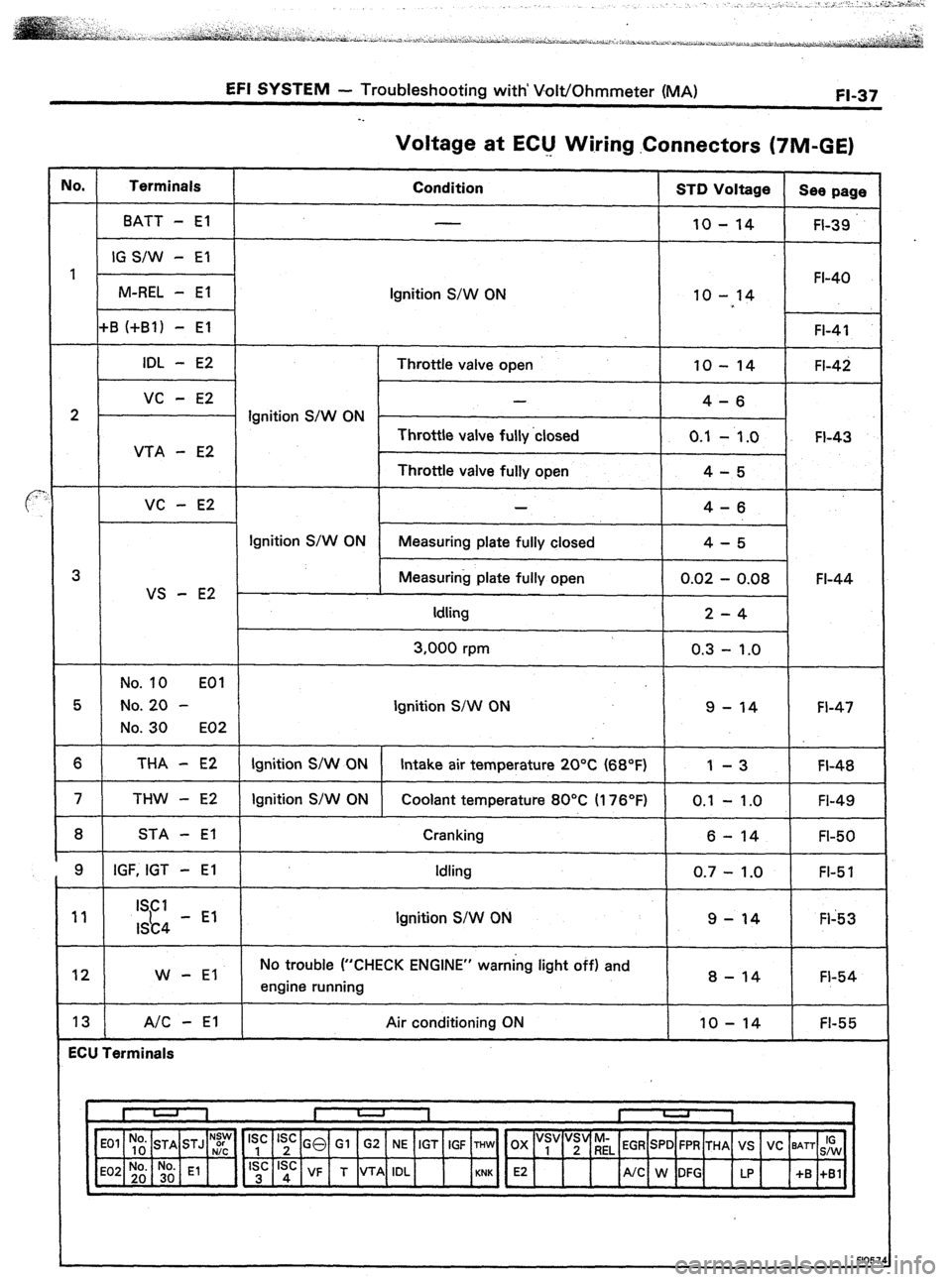

EFI SYSTEM - Troubleshooting with’ Volt/Ohmmeter (MA) FI-37

Voltage at EClJ Wiring .Connectors (TIM-GE)

IO. Terminals

Condition STD Voltage

See page

BATT - El

10 - 14 FI-39

IG S/W - El

1 FI-40

M-REL - El

Ignition S/W ON 10 - 14

+B (+Bl) - El FI-41

IDL - E2 Throttle valve open 10 - 14 FI-42

vc - E2 -

4-6

2 Ignition S/W ON -

Throttle valve fully ‘closed 0.1

- 1.0 FI-43

VTA - E2

Throttle valve fully open 4-5

VC - E2 4-6

Ignition S/W ON

Measuring plate fully closed 4-5

3 Measuring plate fully open 0.02 - 0.08 FI-44

VS - E2

Idling 2-4

3,000 rpm 0.3 - 1.0

No. 10 EOI

5 No. 20 - Ignition S/W ON 9 - 14 FI-47

No. 30 E02

6 THA - E2 Ignition S/W ON Intake air temperature 20°C (68°F) 1 -3 FI-48

7 THW - E2 Ignition S/W ON Coolant temperature 80°C II 76’F) 0.1 - 1 .O

FI-49

8 STA - El Cranking

6 - 14 FI-50

9 IGF, IGT - El Idling

0.7 - 1.0 FI-5 1

11 ISCI

I&4 - El Ignition S/W ON 9-14 Fl-53

12 W - El No trouble (“CHECK ENGINE” warning light off) and

engine running 8 - 14 FI-54

13 A/C - El Air conditioning ON IO - 14 FI-55

ECU Terminals

‘~,~] E2 4

/UC W:G up +S :,:I

N:y Is’ Is’ GO Gl G2 NE IGT IGF THW OX “s, “;“riL EGR SPD FPR THA VS VC BATT IG

F1057

Page 72 of 346

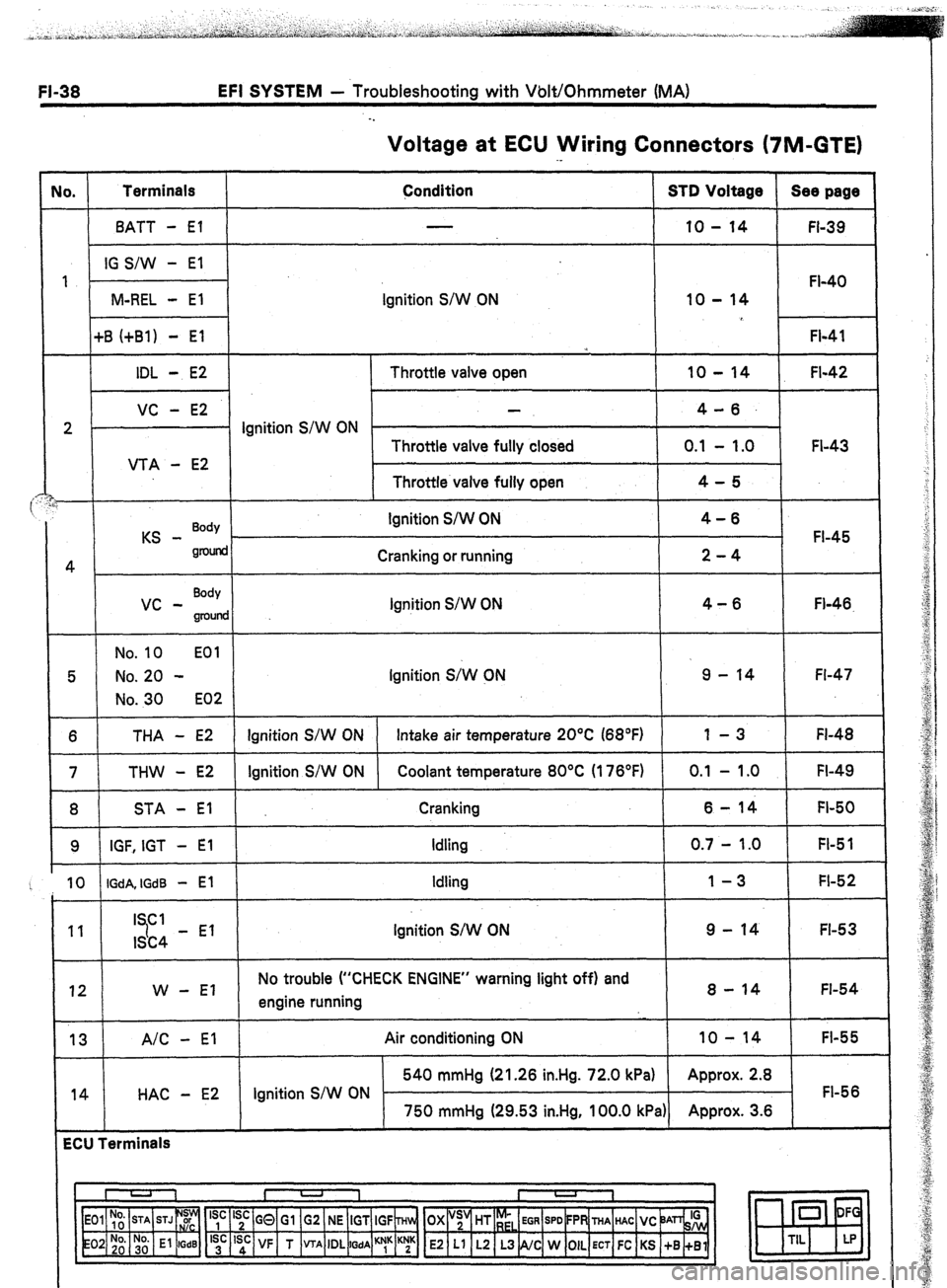

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MA)

. .

Voltage at ECU Wiring Connectors (7M-GTE)

No. Terminals

Condition STD Voltage Sea page

BATT - El 10 - 14

FI-39

IG S/W - El

1

FI-40

M-REL - El Ignition S/W ON 10 - 14

+B (+Bl) - El

FI-41

*

IDL - E2 Throttle valve open 10 - 14 FI-42

VC - E2 4-6.

2 . Ignition S/W ON

Throttle valve fully closed 0.1 - 1.0 FI-43

VTA - E2

Throttle valve fully open 4-5

i

KS - Body Ignition S/W ON 4-6

FI-45

gnMid

4 Cranking or running 2-4

vc - Body

Ignition S/W ON 4-6

groulld Fl-46.

No. 10 EOl

5 No. 20 - Ignition S;W CN 9 - 14 Fl-47

No. 30 E02

6 THA - E2 Ignition S/W ON Intake air temperature 20°C (68°F) 1 -3 FI-48

7 THW - E2 Ignition S/W ON Coolant temperature 80°C (176°F) 0.1 - 1 .O FI-49

8 STA - El Cranking 6-14 FI-50

9 IGF, IGT - El Idling 0.7 - 1.0 FI-5 1

10 IGdA, IGdB - El Idling 1-3 FI-52

11 I Cl

7 9 - 14 FI-53

ISC4 - El Ignition S/W ON

12 W - El No trouble (“CHECK ENGINE” warning light off) and

engine running 8 - 14 FI-54

13 A/C - El

14 HAC - E2 Air conditioning ON 10 - 14

FI-55

540 mmHg (21.26 in.Hg. 72.0 kPa) Approx. 2.8

Ignition S/W ON FI-56

750 mmHg (29.53 in.Hg, 100.0 kPa) Approx. 3.6

ECU Terminals

I U 1 I -

I

1

‘yc ‘;c GQ Gl G2 NE IGT IGF ~Hln, OX “;’ HT r;,

EGR SPD FPR THA HAC VC ‘JAn& 0 DF

‘;’ ‘sd: VF T VTA IDL

WA ““1” K;K E2 Ll L2 L3 NC W OIL ECT FC KS +B +Bl m

TIL LP

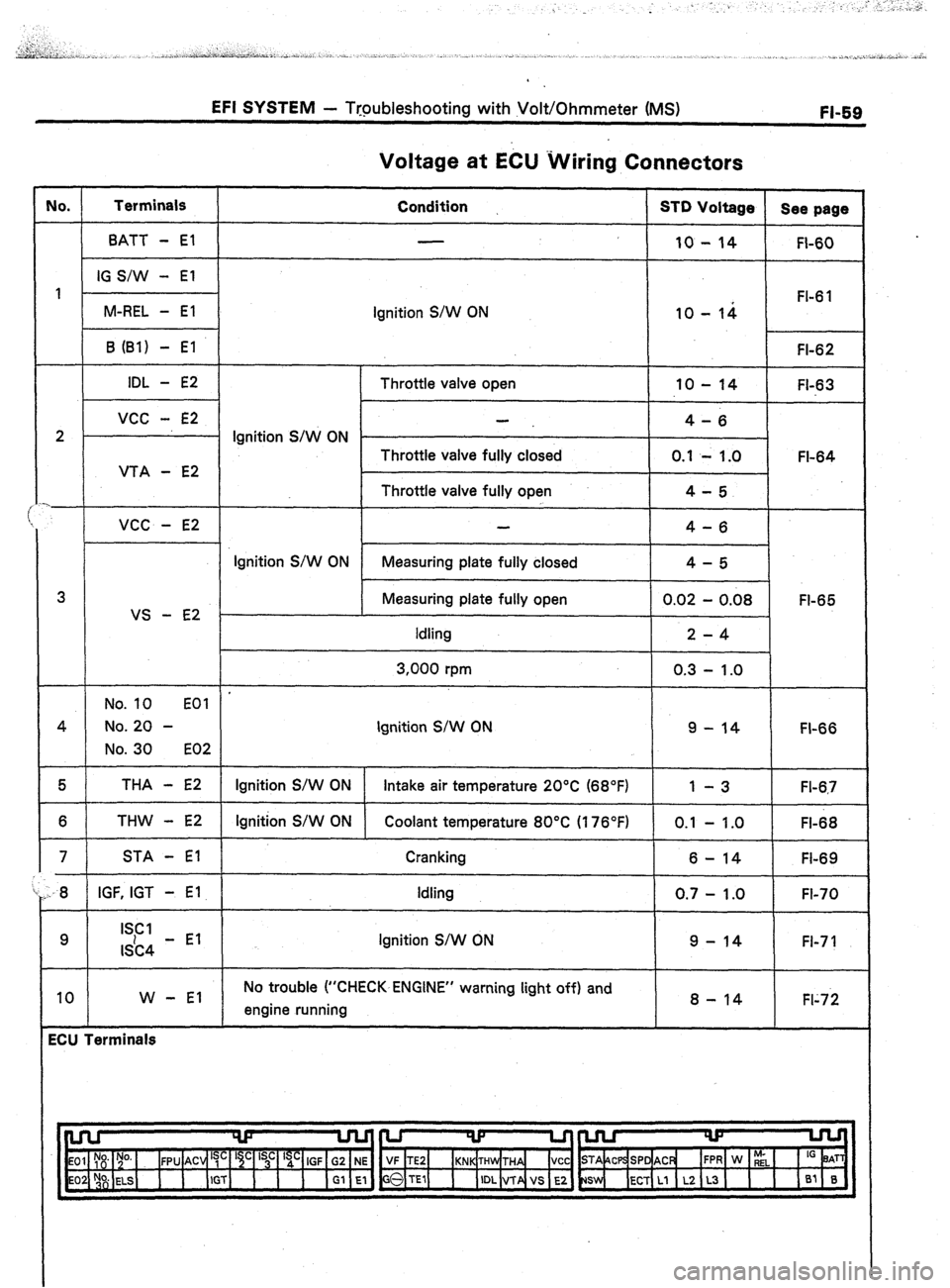

Page 93 of 346

EFI SYSTEM - Ttpbleshooting with Volt/Ohmmeter (MS)

FL59

IO.

I Terminals

BATT - El

IG S/W - El

M-REL - El

2P-

I UTA - E2

3

US - E2

THA - E2

THW - E2

.B / IGF, IGT - El

9 ISCI

lSC4 - El

10

I W - El

ECU Terminals

Voltage at ECU Wiring Connectors

Condition STD Voltage ’

10 - 14

ignition S/W ON

10 - 14

Throttle valve open 10 - 14

4-6

Ignition S/W ON .

Throttle valve fully closed 0.1 - 1.0

Throttle valve fully open

4-5

4-6

Ignition S/W ON Measuring plate fully closed

4-5

Measuring plate fully open

0.02 - 0.08

Idling 2-4

3,000 rpm 0.3 - 1 .o

Ignition S/W ON 9

- 14 FI-66

Ignition S/W ON Intake air temperature 20°C (68°F) 1

-3

Ignition S/W ON

Coolant temperature 80°C (176°F) 0.1 - 1.0

Cranking

6 - 14

Idling 0.7 - 1.0

Ignition S/W ON

9 - 14

No trouble (“CHECK-ENGINE” warning light off) and

engine running 8 - 14 See page

FI-60

FI-6 1

FI-62

FI-63

FI-64

Fl-65

Fl-6.7

FI-68

FI-69

Fl-70

FI-7 1

Fl;72

Page 142 of 346

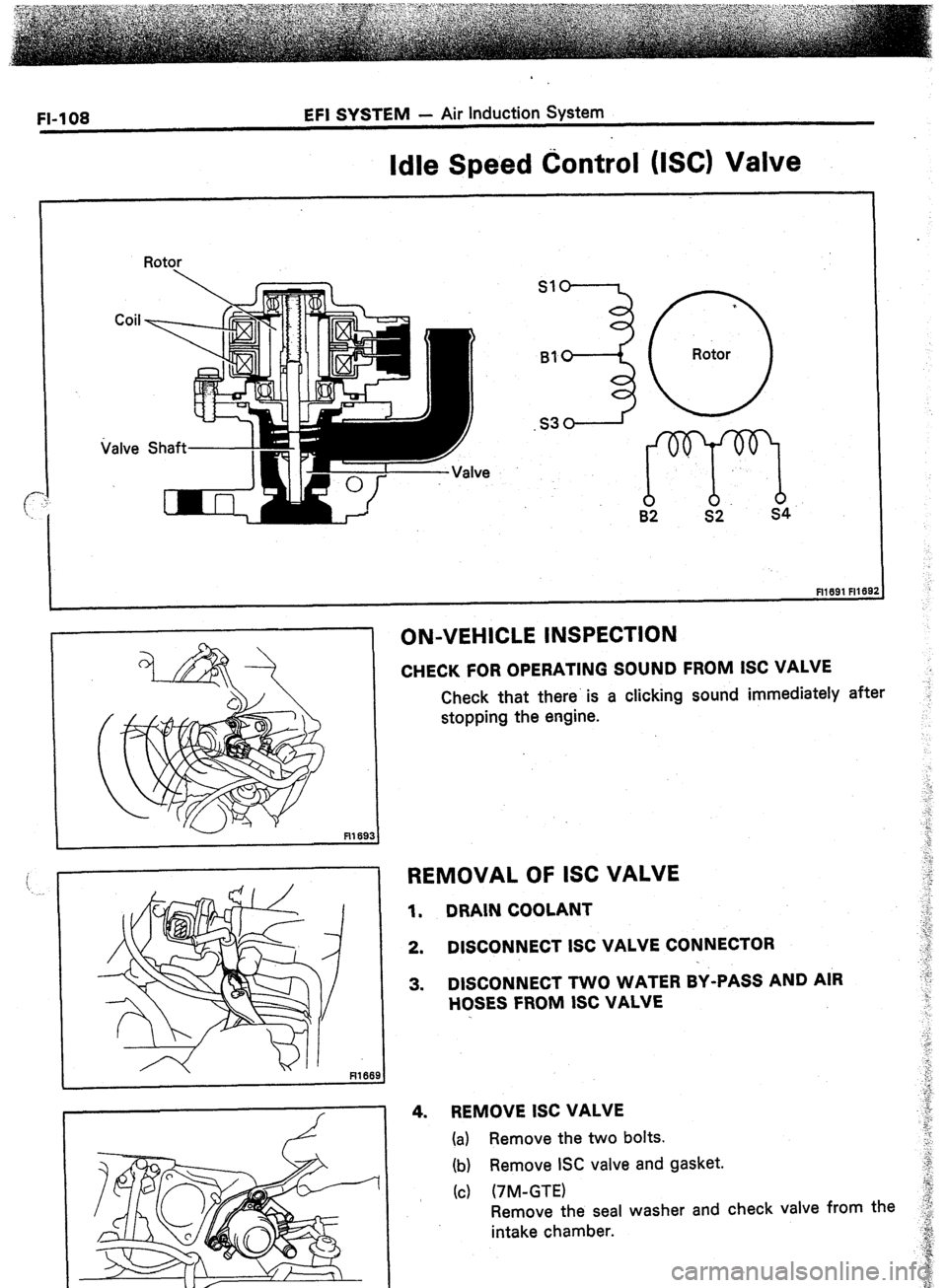

FI-108 EFI SYSTEM - Air Induction System

Idle Speed Control (EC) Valve

Rotor

Bl

Q-4

*

0

Rotor

m B2 s2. s4

Fll99lFH6.

,

ON-VEHICLE INSPECTION

CHECK FOR OPERATING SOUND FROM ISC VALVE

Check that there’ is a clicking sound immediately after

stopping the engine.

REMOVAL OF ISC VALVE

1. DRAIN COOLANT

2. DISCONNECT ISC VALVE CONNECTOR

3. DISCONNECT TWO WATER BY-PASS AND AIR

HOSES FROM ISC VALVE

4. REMOVE ISC VALVE

(a) Remove the two bolts.

(b)

Remove ISC valve and gasket.

(cd (7M-GTE)

Remove the seal washer and check valve from the

intake chamber.

Page 165 of 346

ENGINE MECHANICAL -, Description

EM-3

The 7M-GE, 7M-GTE engines are an in-line 6-

cylinder engine with the cylinders numbered l-2-

3-4-5-6 from the front. The crankshaft is sup-

ported by 7 bearings specified by the inside of the

crankcase. These bearings are made of kelmet.

.The crankshaft is integrated with 8 weights

which are cast along with it for balancing. Oil holes

‘are built into the crankshaft for supplying oil to the

connecting rods, pistons and other components.

These engine’s ignition order is l-5-3-6-2-4 .

The cylinder head is made of aluminum alloy, with

a cross flow type intake and exhaust layout and

with pent roof type combustion chambers. The

spark plugs are located in the center of the com-

bustion chambers.

Exhaust and intake valves are equipped with

irregular pitch springs with symmetrical ends

made of oil tempered silicon chrome steel wire

which are capable of following the valves even at

,high engine speeds.

Both the exhaust side cam shaft and the. intake

side cam shaft are driven by a single timing belt.

The cam journal is supported at 7 places between

the valve lifters of each cylinder and on the

cylinder head of front end. Lubrication of the cam

journal and cam is accomplished by oil being sup-

plied through the oiler port in the center of the

camshaft.

Adjustment of the valve clearance is done by

means of an outer shim type system, in which

valve adjusting shims are located above the valve

lifters. This permits replacement of the shims

without removal of the camshafts.

The resin timing belt cover is made in 2 pieces.

Pistons are made of highly temperature-resis-

tant aluminum alloy, and depressions are built into

the piston head to prevent interference with

valves.

Piston pins are the full-floating type, with the

pins fastened to neither the piston boss nor the

connecting rods. Instead, snap rings are fitted on

both ends of the pins, preventing the pins from

falling out.

The No. 1 compression ring is made of stainless

steel and the No. 2 compression ring is made of

cast iron. The oil ring is made of a combination of

stainless steel. The outer diameter of each piston

ring is slightly larger than the diameter of the

piston

and the flexibility of the rings allows them

to hug the cylinder walls when they are mounted

on the piston. Compression rings No. 1 and No. 2

work to prevent the leakage of gas from the

cylinder and the oil ring works to scrape oil off the

cylinder walls to prevent it from entering the com-

bustion chamber.

The cylinder block is made of cast iron. It has 6

cylinders which are approximately 1.6 times the

length of the piston stroke. The top of the cylin- ders is closed off by the cylinder head and the

lower end of the cylinders becomes the crankcase,

in which the crankshaft is installed. In addition,- the

cylinder block contains a water jacket, through

which coolant is pumped to cool the cylinders.

The .oil pan is bolted onto the botiom of the

cylinder block. The oil pan is an oil reservoir made .

of pressed steel sheet. A dividing plate’is included

-inside the oil pan to keep sufficient oil in the bot-

tom of the pan even when the vehicle is tilted. This

dividing plate also prevent5 the oil from making

waves when the vehicle is stopped suddenly and

thus shifting the oil away from the oil pump suc-

tion pipe.