inflation pressure TOYOTA COROLLA HATCHBACK 2021 (in English) Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2021, Model line: COROLLA HATCHBACK, Model: TOYOTA COROLLA HATCHBACK 2021Pages: 576, PDF Size: 12.73 MB

Page 490 of 576

4908-2. Steps to take in an emergency

COROLLA H/B_U

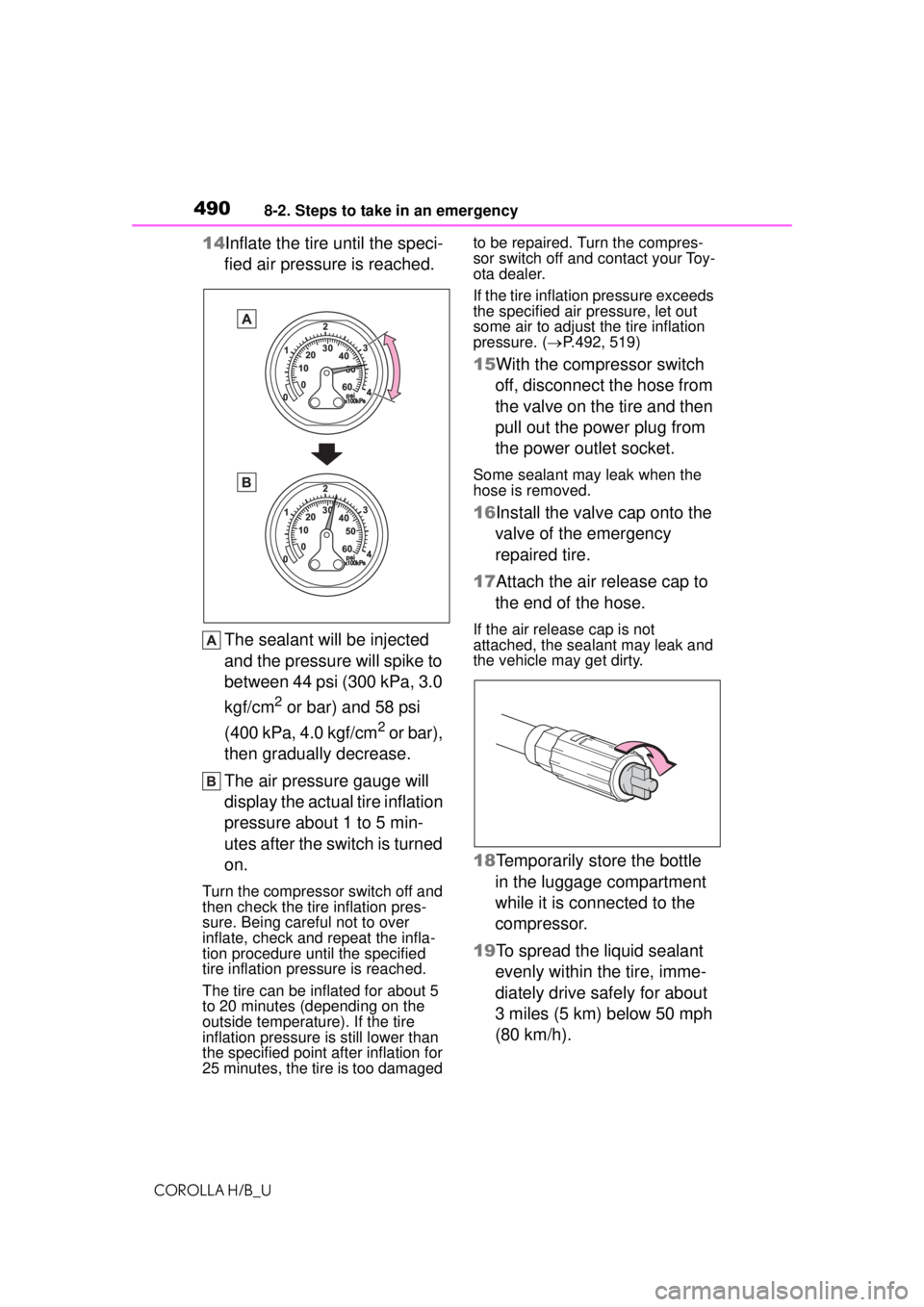

14Inflate the tire until the speci-

fied air pressure is reached.

The sealant will be injected

and the pressure will spike to

between 44 psi (300 kPa, 3.0

kgf/cm

2 or bar) and 58 psi

(400 kPa, 4.0 kgf/cm

2 or bar),

then gradually decrease.

The air pressure gauge will

display the actual tire inflation

pressure about 1 to 5 min-

utes after the switch is turned

on.

Turn the compressor switch off and

then check the tire inflation pres-

sure. Being careful not to over

inflate, check and repeat the infla-

tion procedure until the specified

tire inflation pressure is reached.

The tire can be inflated for about 5

to 20 minutes (depending on the

outside temperature). If the tire

inflation pressure is still lower than

the specified point after inflation for

25 minutes, the tire is too damaged to be repaired. Turn the compres-

sor switch off and contact your Toy-

ota dealer.

If the tire inflation pressure exceeds

the specified air pressure, let out

some air to adjust the tire inflation

pressure. (

P.492, 519)

15With the compressor switch

off, disconnect the hose from

the valve on the tire and then

pull out the power plug from

the power outlet socket.

Some sealant may leak when the

hose is removed.

16Install the valve cap onto the valve of the emergency

repaired tire.

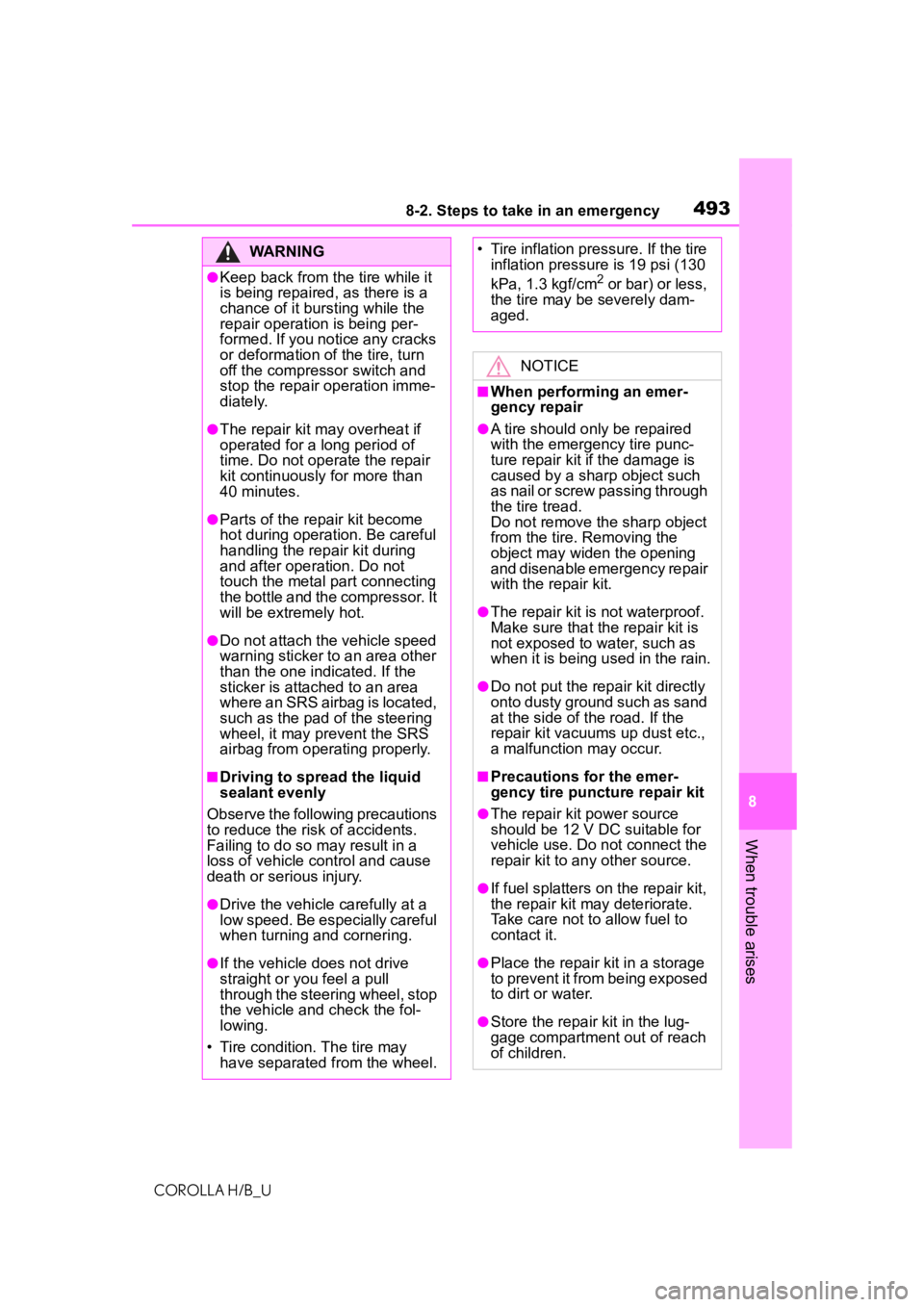

17Attach the air release cap to the end of the hose.

If the air release cap is not

attached, the sealant may leak and

the vehicle may get dirty.

18Temporarily store the bottle in the luggage compartment

while it is connected to the

compressor.

19To spread the liquid sealant evenly within the tire, imme-

diately drive safely for about

3 miles (5 km) below 50 mph

(80 km/h).

Page 491 of 576

4918-2. Steps to take in an emergency

COROLLA H/B_U

8

When trouble arises

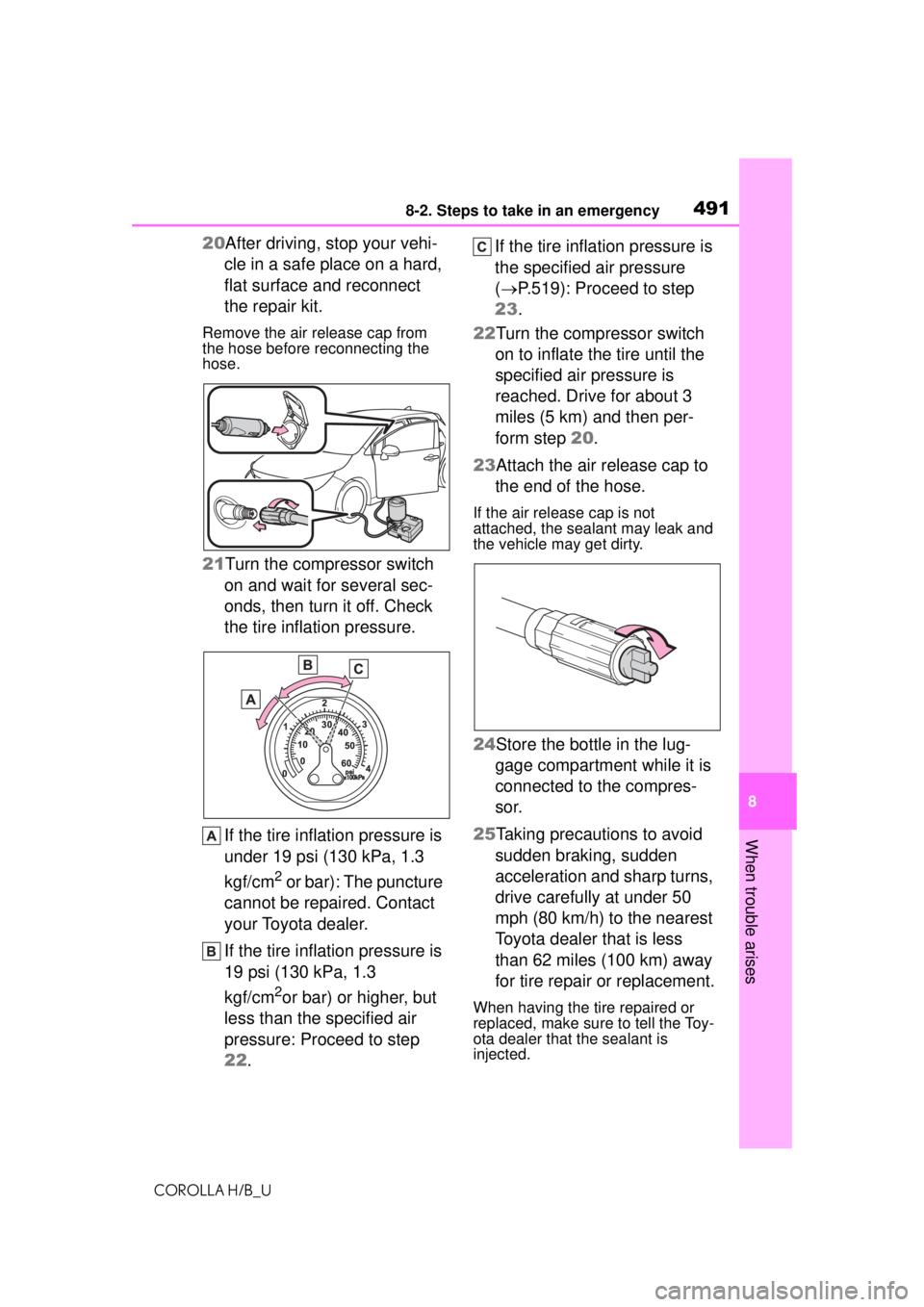

20 After driving, stop your vehi-

cle in a safe place on a hard,

flat surface and reconnect

the repair kit.

Remove the air release cap from

the hose before reconnecting the

hose.

21 Turn the compressor switch

on and wait for several sec-

onds, then turn it off. Check

the tire inflation pressure.

If the tire inflation pressure is

under 19 psi (130 kPa, 1.3

kgf/cm

2 or bar): The puncture

cannot be repaired. Contact

your Toyota dealer.

If the tire inflation pressure is

19 psi (130 kPa, 1.3

kgf/cm

2or bar) or higher, but

less than the specified air

pressure: Proceed to step

22. If the tire inflation pressure is

the specified air pressure

(

P.519): Proceed to step

23 .

22Turn the compressor switch on to inflate the tire until the

specified air pressure is

reached. Drive for about 3

miles (5 km) and then per-

form step 20 .

23Attach the air release cap to the end of the hose.

If the air release cap is not

attached, the sealant may leak and

the vehicle may get dirty.

24Store the bottle in the lug-gage compartment while it is

connected to the compres-

sor.

25Taking precautions to avoid sudden braking, sudden

acceleration and sharp turns,

drive carefully at under 50

mph (80 km/h) to the nearest

Toyota dealer that is less

than 62 miles (100 km) away

for tire repair or replacement.

When having the tire repaired or

replaced, make sure to tell the Toy-

ota dealer that the sealant is

injected.

Page 492 of 576

4928-2. Steps to take in an emergency

COROLLA H/B_U

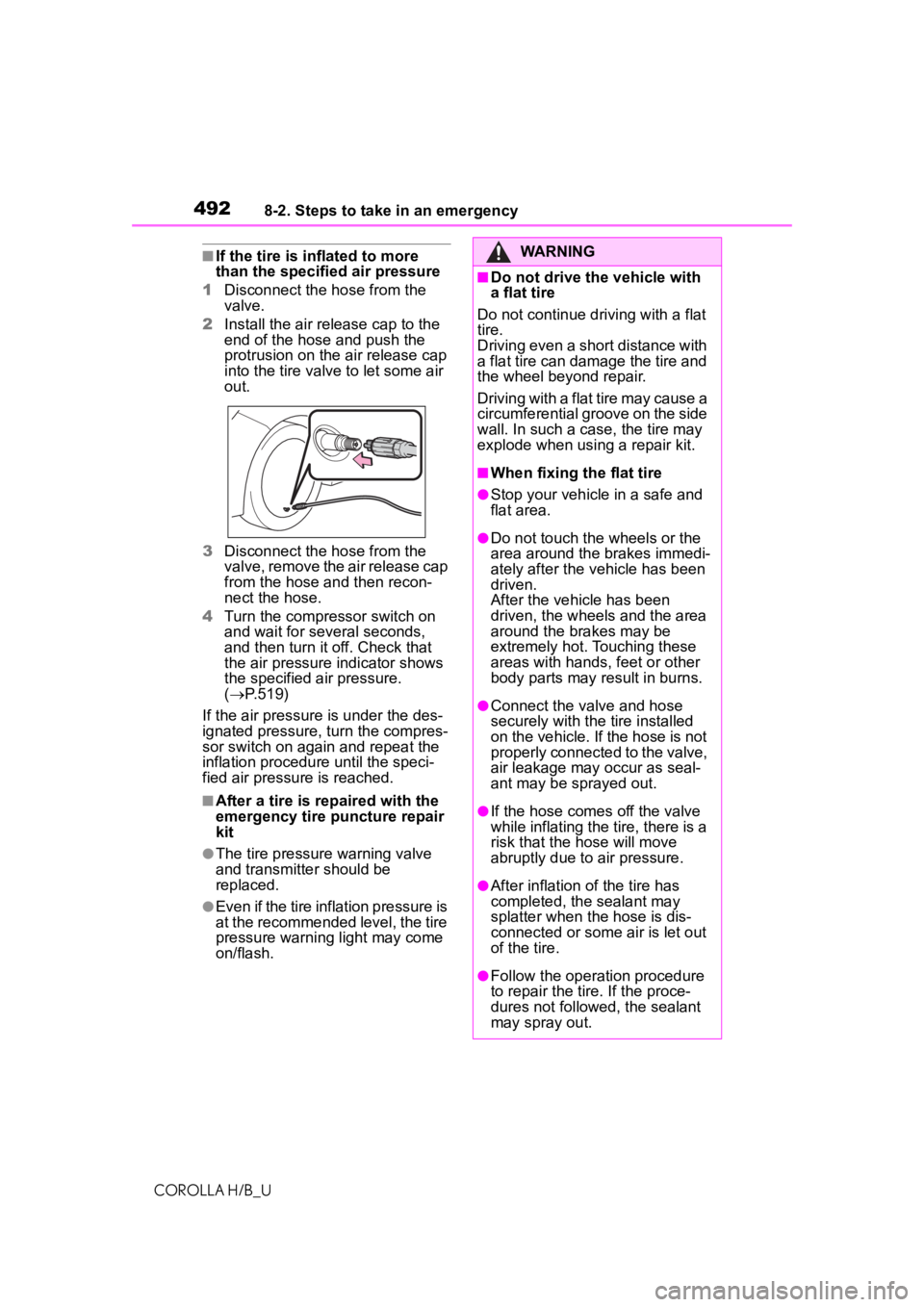

■If the tire is inflated to more

than the specified air pressure

1 Disconnect the hose from the

valve.

2 Install the air release cap to the

end of the hose and push the

protrusion on the air release cap

into the tire valve to let some air

out.

3 Disconnect the hose from the

valve, remove the air release cap

from the hose and then recon-

nect the hose.

4 Turn the compressor switch on

and wait for several seconds,

and then turn it off. Check that

the air pressure indicator shows

the specified air pressure.

( P.519)

If the air pressure is under the des-

ignated pressure, turn the compres-

sor switch on again and repeat the

inflation procedure until the speci-

fied air pressure is reached.

■After a tire is repaired with the

emergency tire puncture repair

kit

●The tire pressure warning valve

and transmitter should be

replaced.

●Even if the tire inflation pressure is

at the recommended level, the tire

pressure warning light may come

on/flash.

WARNING

■Do not drive the vehicle with

a flat tire

Do not continue driving with a flat

tire.

Driving even a short distance with

a flat tire can damage the tire and

the wheel beyond repair.

Driving with a flat tire may cause a

circumferential groove on the side

wall. In such a case, the tire may

explode when using a repair kit.

■When fixing the flat tire

●Stop your vehicle in a safe and

flat area.

●Do not touch the wheels or the

area around the brakes immedi-

ately after the vehicle has been

driven.

After the vehicle has been

driven, the wheels and the area

around the brakes may be

extremely hot. Touching these

areas with hands, feet or other

body parts may result in burns.

●Connect the valve and hose

securely with the tire installed

on the vehicle. If the hose is not

properly connected to the valve,

air leakage may occur as seal-

ant may be sprayed out.

●If the hose comes off the valve

while inflating the tire, there is a

risk that the hose will move

abruptly due to air pressure.

●After inflation of the tire has

completed, the sealant may

splatter when the hose is dis-

connected or some air is let out

of the tire.

●Follow the operation procedure

to repair the tire. If the proce-

dures not followed, the sealant

may spray out.

Page 493 of 576

4938-2. Steps to take in an emergency

COROLLA H/B_U

8

When trouble arises

WARNING

●Keep back from the tire while it

is being repaired, as there is a

chance of it bursting while the

repair operation is being per-

formed. If you notice any cracks

or deformation of the tire, turn

off the compressor switch and

stop the repair operation imme-

diately.

●The repair kit may overheat if

operated for a long period of

time. Do not operate the repair

kit continuously for more than

40 minutes.

●Parts of the repair kit become

hot during operation. Be careful

handling the repair kit during

and after operation. Do not

touch the metal part connecting

the bottle and the compressor. It

will be extremely hot.

●Do not attach the vehicle speed

warning sticker to an area other

than the one indicated. If the

sticker is attached to an area

where an SRS airbag is located,

such as the pad of the steering

wheel, it may prevent the SRS

airbag from operating properly.

■Driving to spread the liquid

sealant evenly

Observe the following precautions

to reduce the risk of accidents.

Failing to do so may result in a

loss of vehicle control and cause

death or serious injury.

●Drive the vehicle carefully at a

low speed. Be especially careful

when turning and cornering.

●If the vehicle does not drive

straight or you feel a pull

through the steering wheel, stop

the vehicle and check the fol-

lowing.

• Tire condition. The tire may have separated from the wheel.

• Tire inflation pressure. If the tire inflation pressure is 19 psi (130

kPa, 1.3 kgf/cm

2 or bar) or less,

the tire may be severely dam-

aged.

NOTICE

■When performing an emer-

gency repair

●A tire should only be repaired

with the emergency tire punc-

ture repair kit if the damage is

caused by a sharp object such

as nail or screw passing through

the tire tread.

Do not remove the sharp object

from the tire. Removing the

object may widen the opening

and disenable emergency repair

with the repair kit.

●The repair kit is not waterproof.

Make sure that the repair kit is

not exposed to water, such as

when it is being used in the rain.

●Do not put the repair kit directly

onto dusty ground such as sand

at the side of the road. If the

repair kit vacuums up dust etc.,

a malfunction may occur.

■Precautions for the emer-

gency tire puncture repair kit

●The repair kit power source

should be 12 V DC suitable for

vehicle use. Do not connect the

repair kit to any other source.

●If fuel splatters on the repair kit,

the repair kit may deteriorate.

Take care not to allow fuel to

contact it.

●Place the repair kit in a storage

to prevent it from being exposed

to dirt or water.

●Store the repair kit in the lug-

gage compartment out of reach

of children.

Page 519 of 576

5199-1. Specifications

COROLLA H/B_U

9

Vehicle specifications

*1: Minimum pedal clearance when depressed with a force of 67.4 lbf (300 N, 30.6 kgf) while the engine is running.

When performing the brake pedal inspection, also be sure to check that

the brake system warning light is no t illuminated when the engine is run-

ning. (If the brake system warning li ght is illuminated, refer to P.472.)

*2: Make sure to confirm that the brake warning light (yellow) does not illumi-

nate. (If the brake warning light illuminates, refer to P.472.)

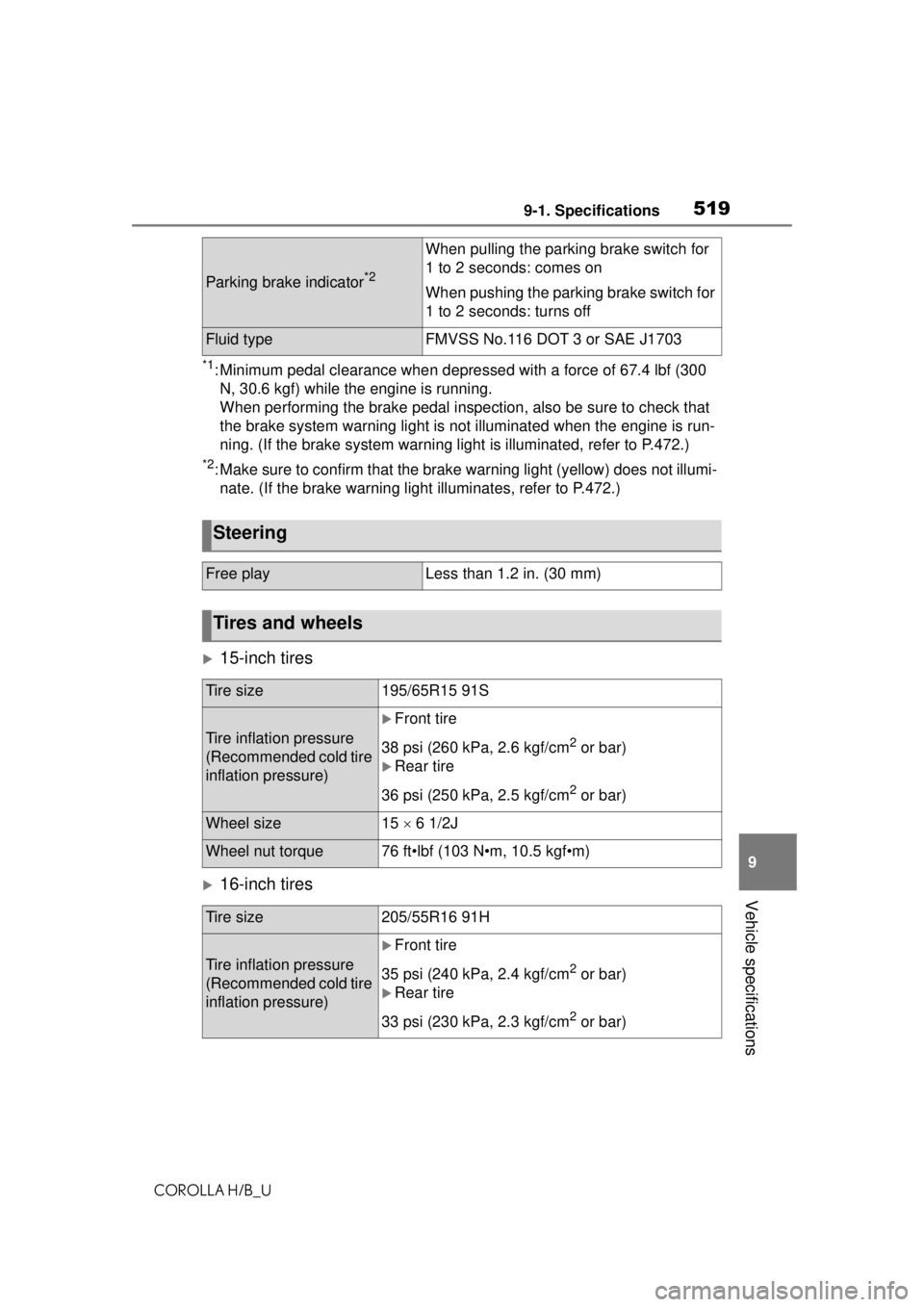

15-inch tires

16-inch tires

Parking brake indicator*2

When pulling the parking brake switch for

1 to 2 seconds: comes on

When pushing the parking brake switch for

1 to 2 seconds: turns off

Fluid typeFMVSS No.116 DOT 3 or SAE J1703

Steering

Free playLess than 1.2 in. (30 mm)

Tires and wheels

Tire size195/65R15 91S

Tire inflation pressure

(Recommended cold tire

inflation pressure)

Front tire

38 psi (260 kPa, 2.6 kgf/cm

2 or bar)

Rear tire

36 psi (250 kPa, 2.5 kgf/cm

2 or bar)

Wheel size15 6 1/2J

Wheel nut torque76 ft•lbf (103 N•m, 10.5 kgf•m)

Tire size205/55R16 91H

Tire inflation pressure

(Recommended cold tire

inflation pressure)

Front tire

35 psi (240 kPa, 2.4 kgf/cm

2 or bar)

Rear tire

33 psi (230 kPa, 2.3 kgf/cm

2 or bar)

Page 520 of 576

5209-1. Specifications

COROLLA H/B_U

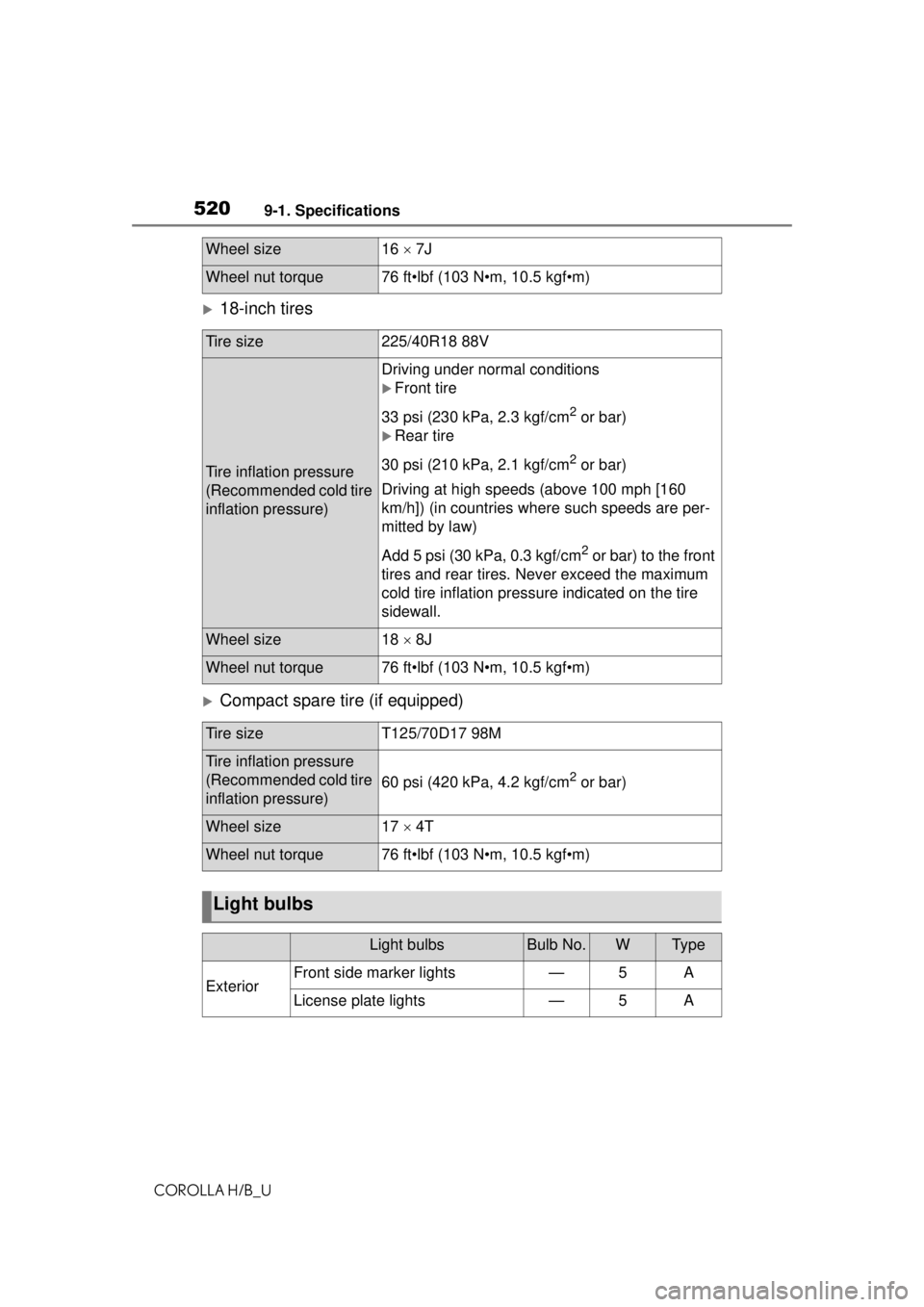

18-inch tires

Compact spare tire (if equipped)

Wheel size16 7J

Wheel nut torque76 ft•lbf (103 N•m, 10.5 kgf•m)

Tire size225/40R18 88V

Tire inflation pressure

(Recommended cold tire

inflation pressure)

Driving under normal conditions

Front tire

33 psi (230 kPa, 2.3 kgf/cm

2 or bar)

Rear tire

30 psi (210 kPa, 2.1 kgf/cm

2 or bar)

Driving at high speeds (above 100 mph [160

km/h]) (in countries where such speeds are per-

mitted by law)

Add 5 psi (30 kPa, 0.3 kgf/cm

2 or bar) to the front

tires and rear tires. Ne ver exceed the maximum

cold tire inflation pressu re indicated on the tire

sidewall.

Wheel size18 8J

Wheel nut torque76 ft•lbf (103 N•m, 10.5 kgf•m)

Tire sizeT125/70D17 98M

Tire inflation pressure

(Recommended cold tire

inflation pressure)

60 psi (420 kPa, 4.2 kgf/cm2 or bar)

Wheel size17 4T

Wheel nut torque76 ft•lbf (103 N•m, 10.5 kgf•m)

Light bulbs

Light bulbsBulb No.WTy p e

ExteriorFront side marker lights—5A

License plate lights—5A

Page 524 of 576

5249-1. Specifications

COROLLA H/B_U

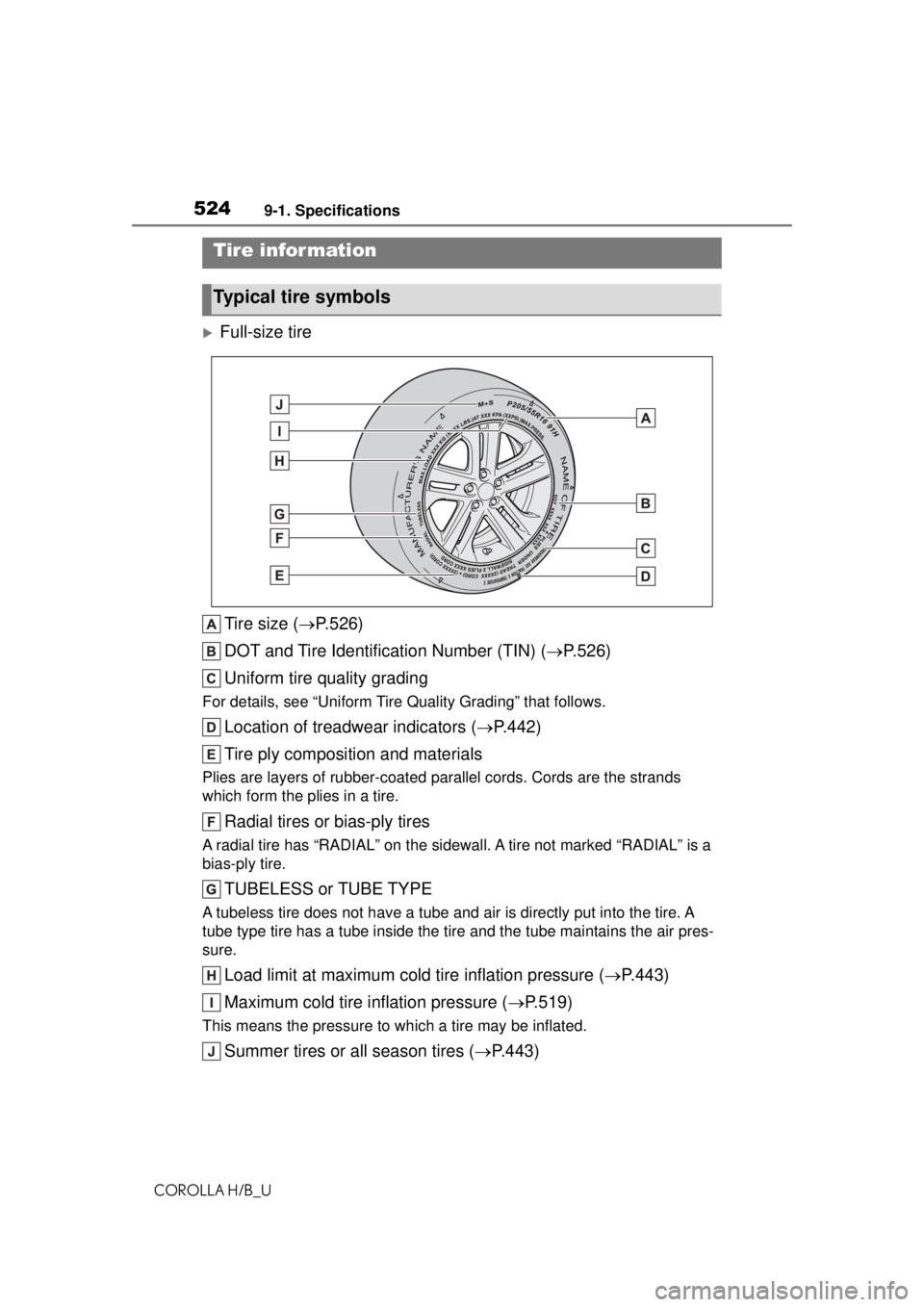

Full-size tireTire size ( P.526)

DOT and Tire Identification Number (TIN) ( P.526)

Uniform tire quality grading

For details, see “Uniform Tire Quality Grading” that follows.

Location of treadwear indicators ( P.442)

Tire ply composition and materials

Plies are layers of rubber-coated parallel cords. Cords are the strands

which form the plies in a tire.

Radial tires or bias-ply tires

A radial tire has “RADIAL” on the sidewall. A tire not marked “RADIAL” is a

bias-ply tire.

TUBELESS or TUBE TYPE

A tubeless tire does not have a tube and air is directly put into the tire. A

tube type tire has a tube inside the tire and the tube maintains the air pres-

sure.

Load limit at maximum cold tire inflation pressure ( P.443)

Maximum cold tire inflation pressure ( P.519)

This means the pressure to wh ich a tire may be inflated.

Summer tires or all season tires ( P.443)

Tire information

Typical tire symbols

Page 525 of 576

5259-1. Specifications

COROLLA H/B_U

9

Vehicle specifications

An all season tire has “M+S” on the sidewall. A tire not marked “M+S” is a

summer tire.

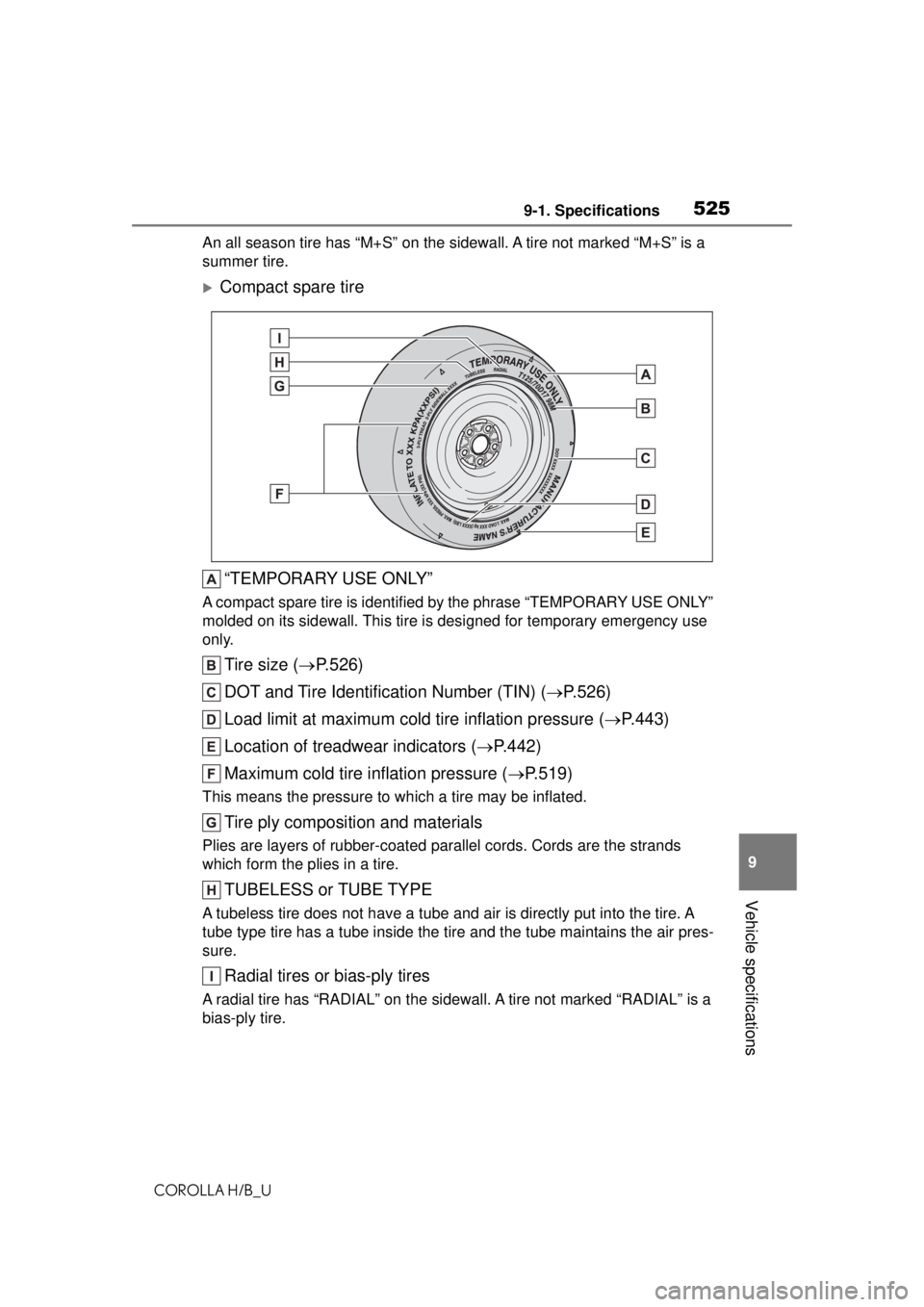

Compact spare tire “TEMPORARY USE ONLY”

A compact spare tire is identified by the phrase “TEMPORARY USE ONLY”

molded on its sidewall. This tire is designed for temporary emergency use

only.

Tire size ( P.526)

DOT and Tire Identification Number (TIN) ( P.526)

Load limit at maximum cold tire inflation pressure ( P.443)

Location of treadwear indicators ( P.442)

Maximum cold tire inflation pressure ( P.519)

This means the pressure to wh ich a tire may be inflated.

Tire ply composition and materials

Plies are layers of rubber-coated parallel cords. Cords are the strands

which form the plies in a tire.

TUBELESS or TUBE TYPE

A tubeless tire does not have a tube and air is directly put into the tire. A

tube type tire has a tube inside the tire and the tube maintains the air pres-

sure.

Radial tires or bias-ply tires

A radial tire has “RADIAL” on the sidewall. A tire not marked “RADIAL” is a

bias-ply tire.

Page 528 of 576

5289-1. Specifications

COROLLA H/B_Uwould wear one and a half (1 - 1/2)

times as well on the government

course as a tire graded 100.

The relative performance of tires

depends upon the actual conditions

of their use. Performance may differ

significantly from the norm due to

variations in driv

ing habits, service

practices and differences in road

characteristics and climate.

■Traction AA, A, B, C

The traction grades, from high-

est to lowest, are AA, A, B and

C, and they represent the tire’s

ability to stop on wet pavement

as measured under controlled

conditions on specified govern-

ment test surfaces of asphalt

and concrete.

A tire marked C may have poor

traction performance.

Warning: The traction grade

assigned to this tire is based on

braking (straight ahead) traction

tests and does not include corner-

ing (turning) traction.

■Temperature A, B, C

The temperature grades are A (the highest), B, and C, repre-

senting the tire’s resistance to

the generation of heat and its

ability to dissipate heat when

tested under controlled condi-

tions on a specified indoor labo-

ratory test wheel.

Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure.

Grade C corresponds to a level of

performance which all passenger

car tires must meet under the Fed-

eral Motor Vehicle Safety Standard

No. 109.

Grades B and A represent higher

levels of performance on the labo-

ratory test wheel than the minimum

required by law.

Warning: The temperature grades

of a tire assume that it is properly

inflated and not overloaded.

Excessive speed, underinflation, or

excessive loading, either sepa-

rately or in combination, can cause

heat buildup and possible tire fail-

ure.

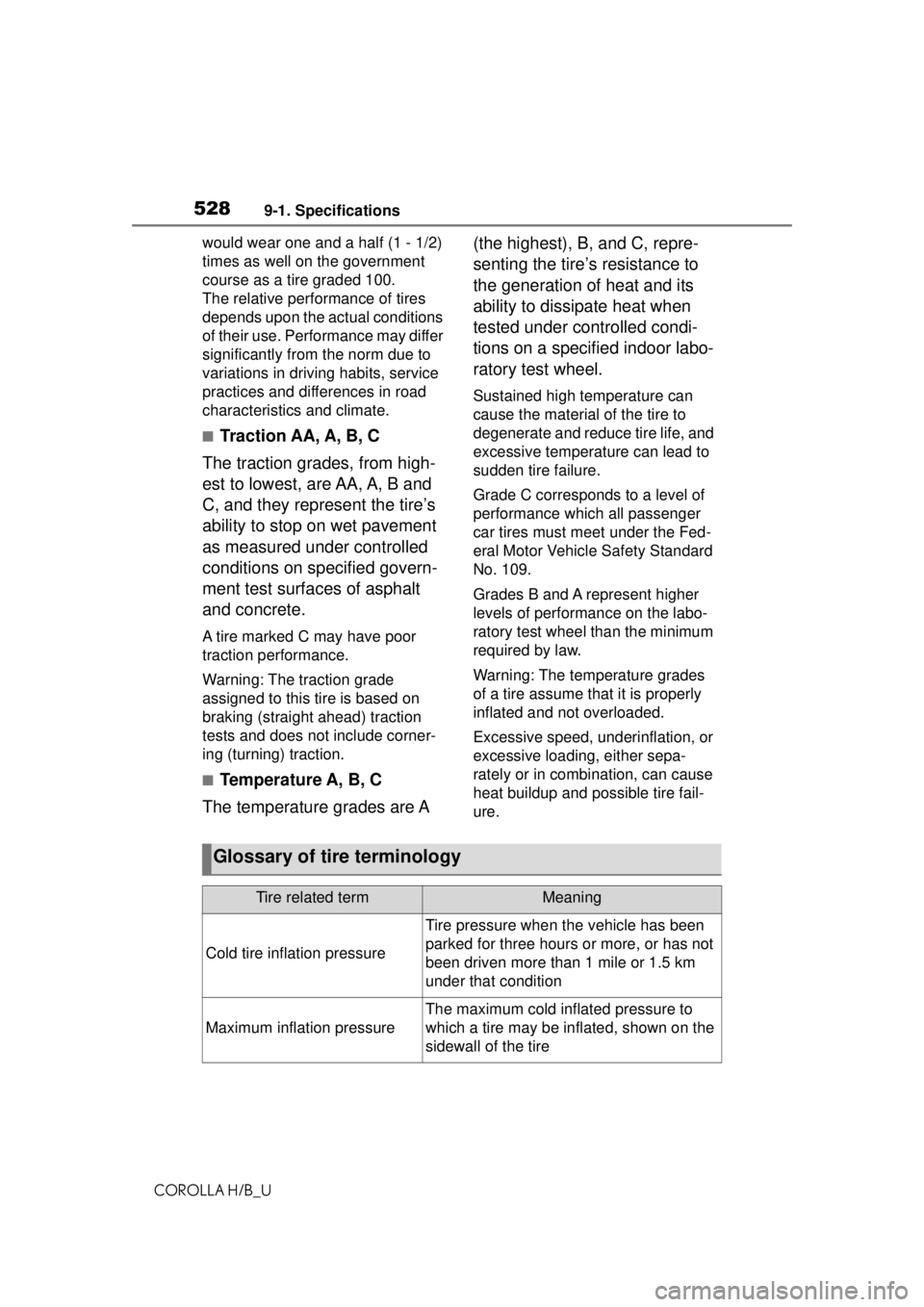

Glossary of tire terminology

Tire related termMeaning

Cold tire infl

ation pressure

Tire pressure when the vehicle has been

parked for three hours or more, or has not

been driven more than 1 mile or 1.5 km

under that condition

Maximum inflation pressure

The maximum cold inflated pressure to

which a tire may be inflated, shown on the

sidewall of the tire

Page 529 of 576

5299-1. Specifications

COROLLA H/B_U

9

Vehicle specifications

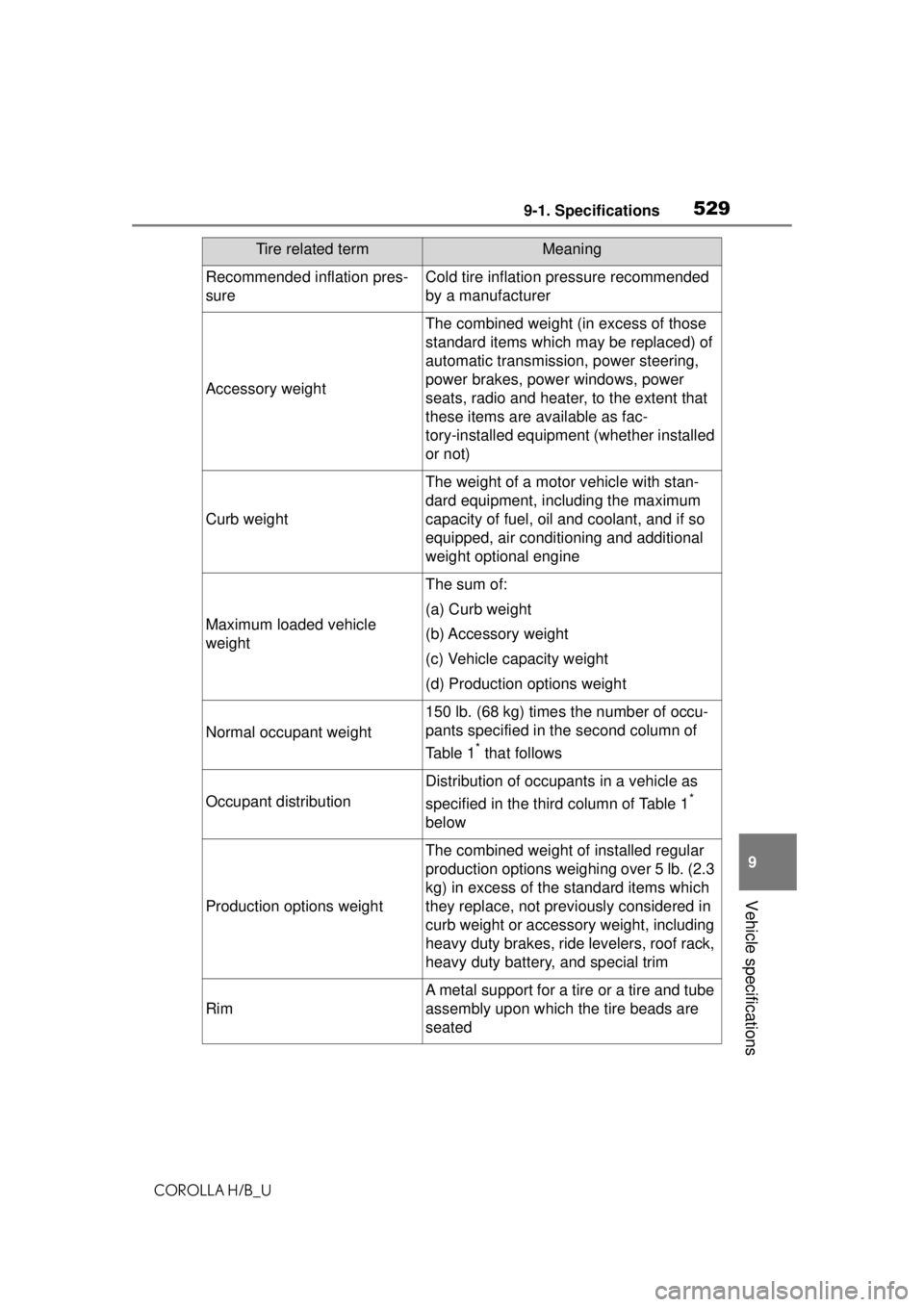

Recommended inflation pres-

sureCold tire inflation pressure recommended

by a manufacturer

Accessory weight

The combined weight (in excess of those

standard items which may be replaced) of

automatic transmission, power steering,

power brakes, power windows, power

seats, radio and heater, to the extent that

these items are available as fac-

tory-installed equipment (whether installed

or not)

Curb weight

The weight of a motor vehicle with stan-

dard equipment, including the maximum

capacity of fuel, oil and coolant, and if so

equipped, air conditioning and additional

weight optional engine

Maximum loaded vehicle

weight

The sum of:

(a) Curb weight

(b) Accessory weight

(c) Vehicle capacity weight

(d) Production options weight

Normal occupant weight

150 lb. (68 kg) times the number of occu-

pants specified in the second column of

Table 1

* that follows

Occupant distribution

Distribution of occupants in a vehicle as

specified in the third column of Table 1

*

below

Production options weight

The combined weight of installed regular

production options weighing over 5 lb. (2.3

kg) in excess of the standard items which

they replace, not previously considered in

curb weight or accessory weight, including

heavy duty brakes, ride levelers, roof rack,

heavy duty battery, and special trim

Rim

A metal support for a tire or a tire and tube

assembly upon which the tire beads are

seated

Tire related termMeaning