ECU TOYOTA LAND CRUISER 2012 Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2012, Model line: LAND CRUISER, Model: TOYOTA LAND CRUISER 2012Pages: 692, PDF Size: 29.3 MB

Page 592 of 692

592 5-2. Steps to take in an emergency

L/C200_EE (OM60G38E)

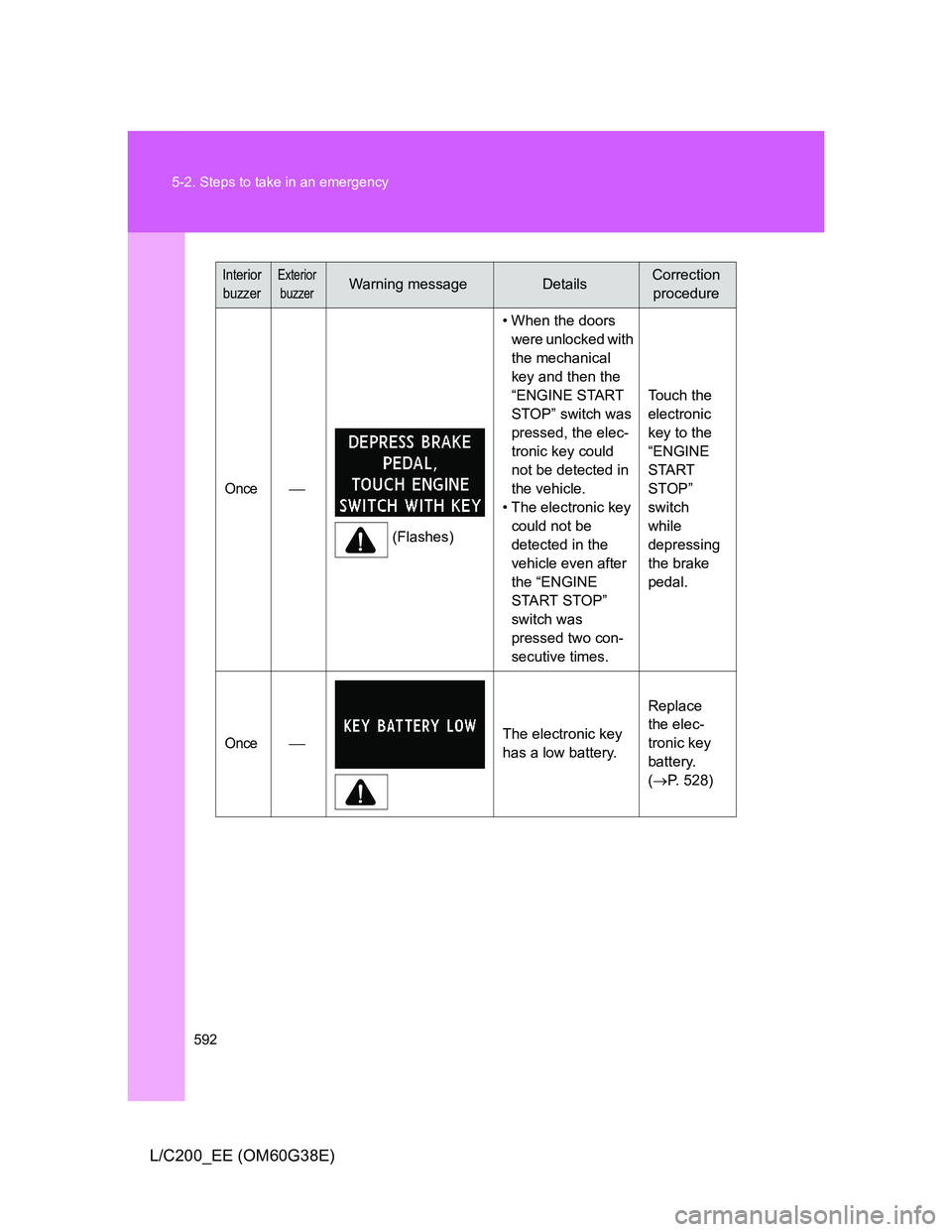

Interior

buzzerExterior

buzzerWarning messageDetailsCorrection

procedure

Once

(Flashes)• When the doors

were unlocked with

the mechanical

key and then the

“ENGINE START

STOP” switch was

pressed, the elec-

tronic key could

not be detected in

the vehicle.

• The electronic key

could not be

detected in the

vehicle even after

the “ENGINE

START STOP”

switch was

pressed two con-

secutive times. Touch the

electronic

key to the

“ENGINE

START

STOP”

switch

while

depressing

the brake

pedal.

OnceThe electronic key

has a low battery.Replace

the elec-

tronic key

battery.

(P. 528)

Page 605 of 692

5

605 5-2. Steps to take in an emergency

When trouble arises

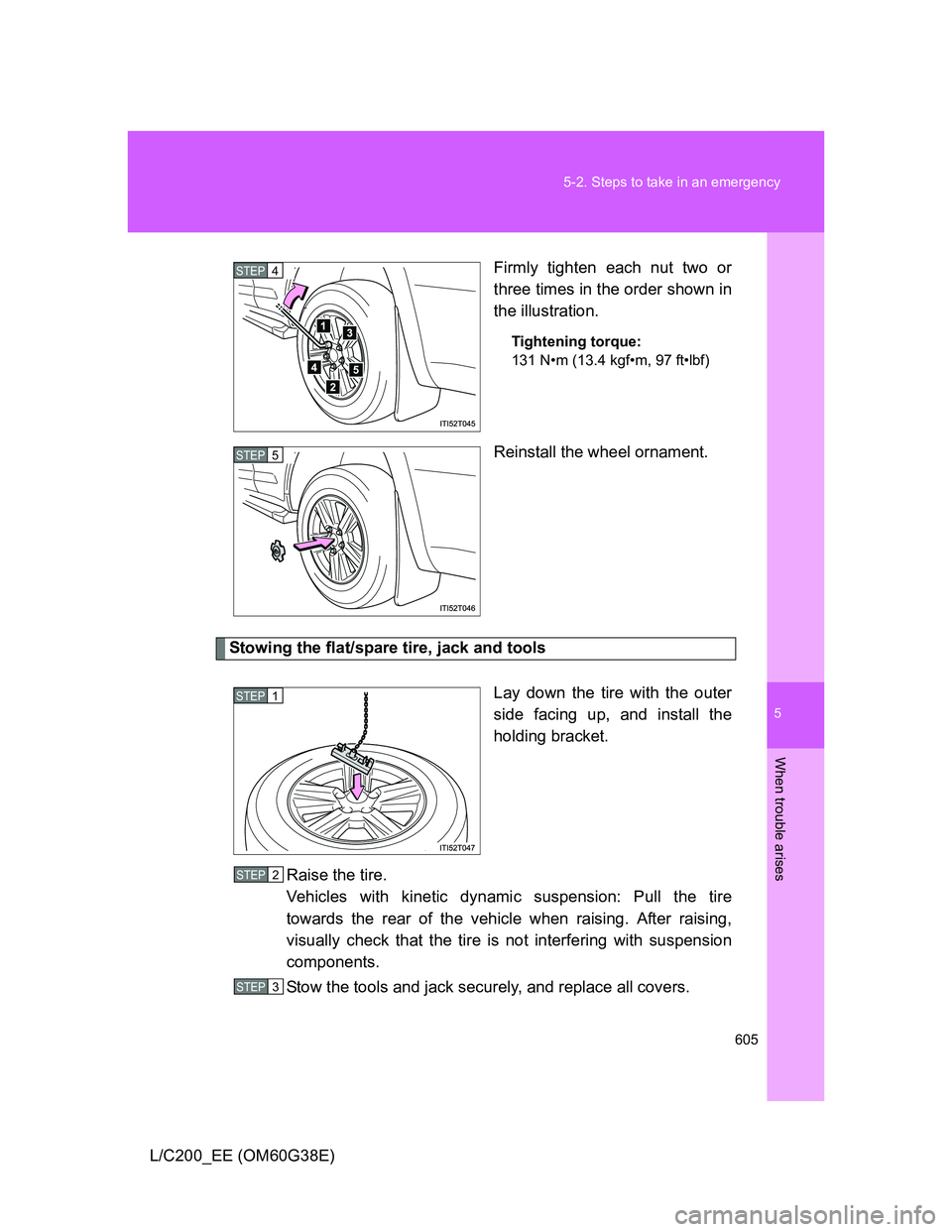

L/C200_EE (OM60G38E)Firmly tighten each nut two or

three times in the order shown in

the illustration.

Tightening torque:

131 N•m (13.4 kgf•m, 97 ft•lbf)

Reinstall the wheel ornament.

Stowing the flat/spare tire, jack and tools

Lay down the tire with the outer

side facing up, and install the

holding bracket.

Raise the tire.

Vehicles with kinetic dynamic suspension: Pull the tire

towards the rear of the vehicle when raising. After raising,

visually check that the tire is not interfering with suspension

components.

Stow the tools and jack securely, and replace all covers.

STEP4

STEP5

STEP1

STEP2

STEP3

Page 607 of 692

5

607 5-2. Steps to take in an emergency

When trouble arises

L/C200_EE (OM60G38E)

CAUTION

Using the tire jack

Improper use of the tire jack may lead to death or serious injuries due to the

vehicle suddenly falling off the jack.

Do not use the tire jack for any purpose other than replacing tires or install-

ing and removing tire chains.

Only use the tire jack that comes with this vehicle for replacing a flat tire.

Do not use it on other vehicles, and do not use other tire jacks for replac-

ing tires on this vehicle.

Always check that the tire jack is securely set to the jack point.

Be sure to turn off the 4-Wheel AHC and stop the engine. (Vehicles with 4-

Wheel AHC)

Do not put any part of your body under the vehicle supported by a jack.

Do not start or run the engine while your vehicle is supported by the jack.

Do not raise the vehicle while someone is in it.

When raising the vehicle, do not put an object on or under the jack.

Do not raise the vehicle to a height greater than that required to replace

the tire.

Use a jack stand if it is necessary to get under the vehicle.

Take particular care when lowering the vehicle to ensure that no one working

on or near the vehicle will be injured.

Using the jack handle

Tighten all the jack handle bolts securely using a Phillips-head screwdriver,

to prevent the extension parts from coming apart unexpectedly.

Page 615 of 692

5

615 5-2. Steps to take in an emergency

When trouble arises

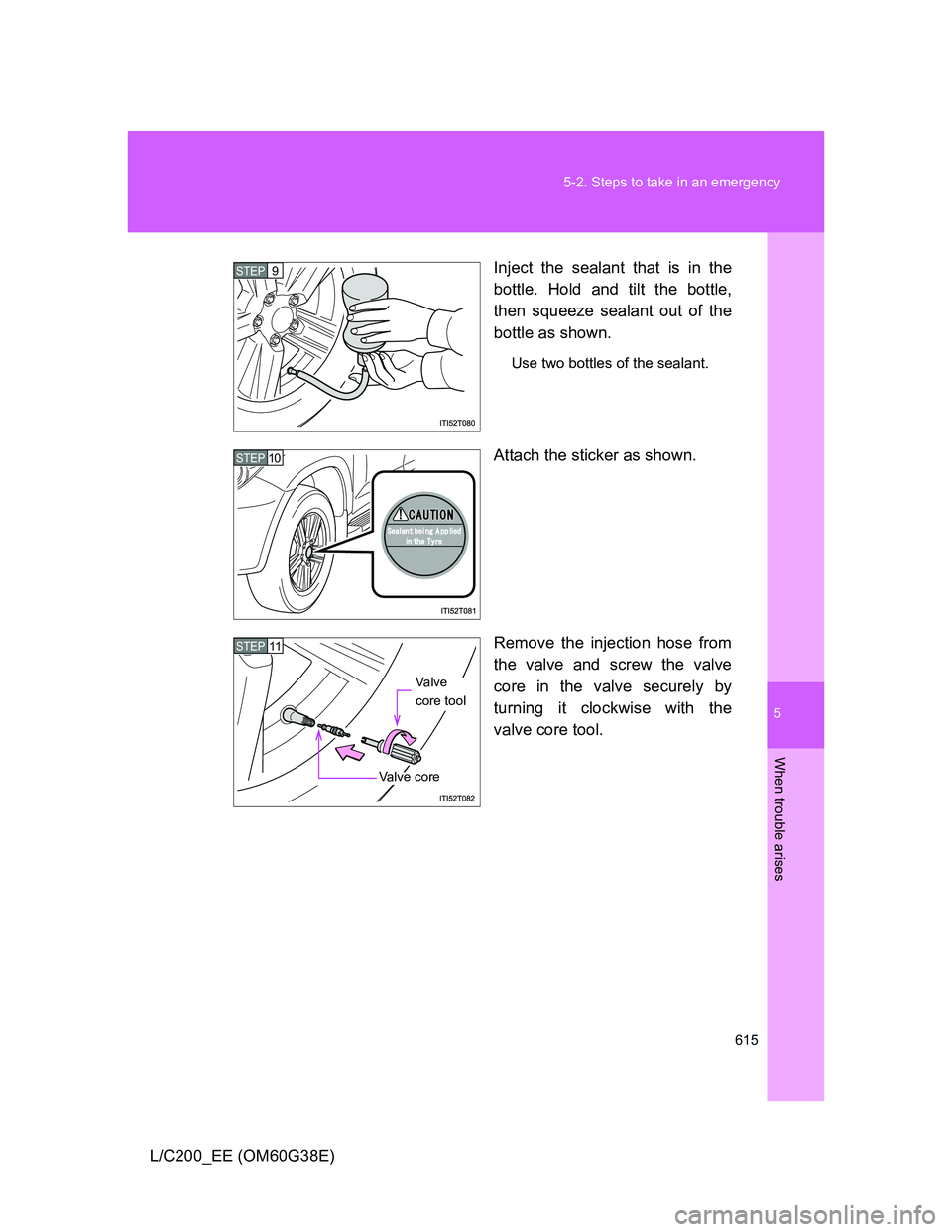

L/C200_EE (OM60G38E)Inject the sealant that is in the

bottle. Hold and tilt the bottle,

then squeeze sealant out of the

bottle as shown.

Use two bottles of the sealant.

Attach the sticker as shown.

Remove the injection hose from

the valve and screw the valve

core in the valve securely by

turning it clockwise with the

valve core tool.

STEP9

STEP10

STEP11

Va l v e

core tool

Va l v e c o r e

Page 621 of 692

5

621 5-2. Steps to take in an emergency

When trouble arises

L/C200_EE (OM60G38E)

CAUTION

Precaution for children

Keep the emergency tire puncture repair kit out of the reach of children and

store it properly.

Sealant precautions

The sealant in the emergency tire puncture repair kit is not for human con-

sumption.

If the sealant is consumed inadvertently, drink a large quantity of water

and get medical attention immediately.

If sealant gets in your eyes or on your skin, thoroughly wash with a large

quantity of water. If necessary, get medical attention.

When fixing the flat tire

Stop your vehicle in a safe and flat area.

If force is used to turn the valve core tool while air remains in the tire, spe-

cial care should be taken because the valve core could fly out.

Be careful, as sealant may fly out if you shake the bottle with the hose

installed.

If the hose is not securely installed, sealant may leak out when filling.

Connect the valve and hose securely with the tire installed on the vehicle.

Be careful handling the compressor, as parts of the compressor get hot

during operation. Some parts of the compressor may remain hot after use.

Driving to spread the liquid sealant evenly

Drive your vehicle with due care. Be especially careful when turning and cor-

nering.

Page 640 of 692

640

5-2. Steps to take in an emergency

L/C200_EE (OM60G38E)

If your vehicle has to be stopped in an emergency

Only in an emergency, such as if it becomes impossible to stop the

vehicle in the normal way, stop the vehicle using the following pro-

cedure:

Steadily step on the brake pedal with both feet and firmly

depress it.

Do not pump the brake pedal repeatedly as this will increase the

effort required to slow the vehicle.

Shift the shift lever to “N”.

If the shift lever is shifted to “N”

After slowing down, stop the vehicle in a safe place by the

road.

Stop the engine.

If the shift lever cannot be shifted to “N”

Keep depressing the brake pedal with both feet to reduce

vehicle speed as much as possible.

To stop the engine, press and

hold the “ENGINE START

STOP” switch for 3 consecu-

tive seconds or more, or press

it briefly 3 times or more in

succession.

Stop the vehicle in a safe place by the road.

STEP1

STEP2

STEP3

STEP4

STEP3

STEP4

Press and hold for 3 seconds or

more, or press briefly 3 times or more

STEP5

Page 676 of 692

676

L/C200_EE (OM60G38E)

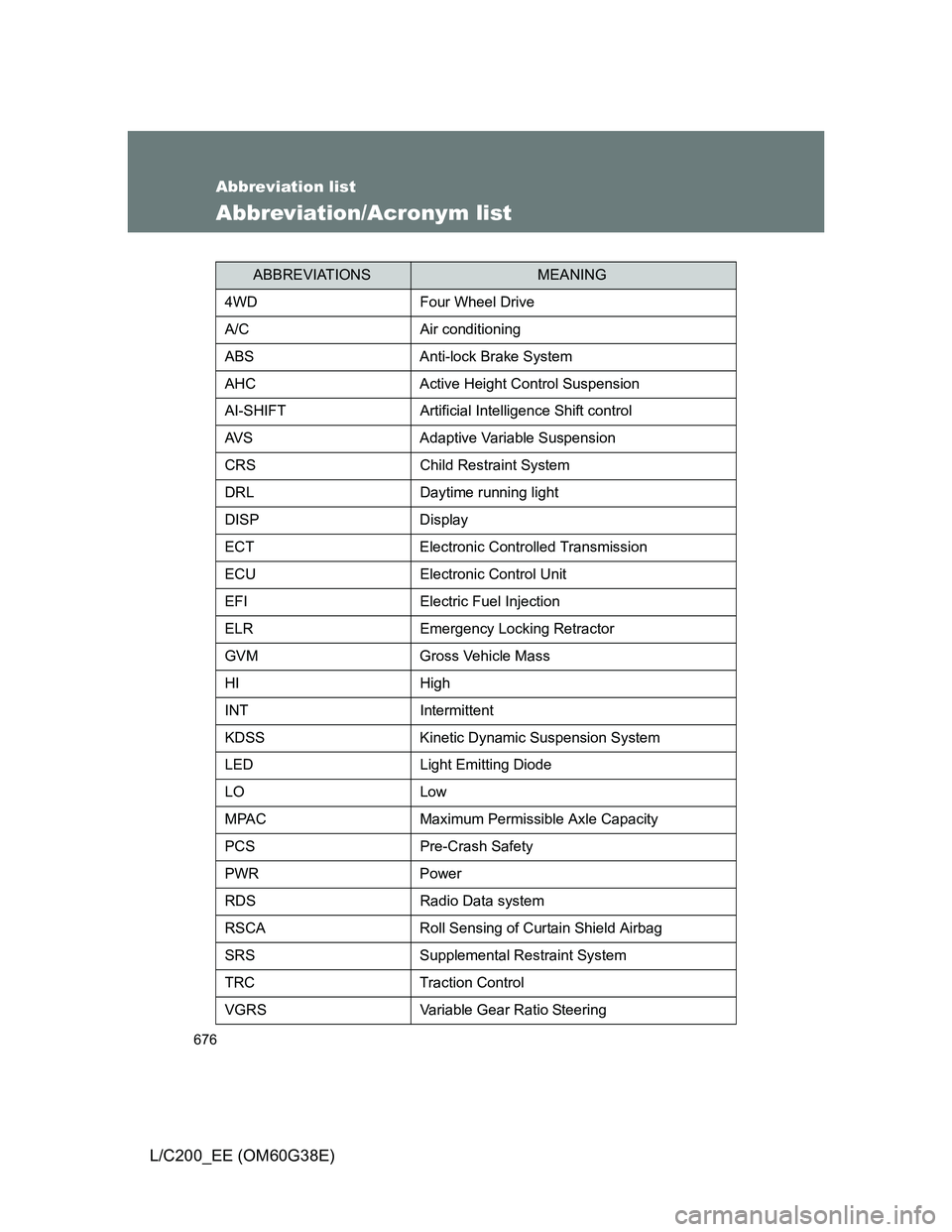

Abbreviation list

Abbreviation/Acronym list

ABBREVIATIONSMEANING

4WD Four Wheel Drive

A/C Air conditioning

ABS Anti-lock Brake System

AHC Active Height Control Suspension

AI-SHIFT Artificial Intelligence Shift control

AVS Adaptive Variable Suspension

CRS Child Restraint System

DRL Daytime running light

DISP Display

ECT Electronic Controlled Transmission

ECU Electronic Control Unit

EFI Electric Fuel Injection

ELR Emergency Locking Retractor

GVM Gross Vehicle Mass

HI High

INT Intermittent

KDSS Kinetic Dynamic Suspension System

LED Light Emitting Diode

LO Low

MPAC Maximum Permissible Axle Capacity

PCS Pre-Crash Safety

PWR Power

RDS Radio Data system

RSCA Roll Sensing of Curtain Shield Airbag

SRS Supplemental Restraint System

TRC Traction Control

VGRS Variable Gear Ratio Steering