sensor TOYOTA RAV4 1996 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 17 of 1632

DTC Detecting Condition

Detection of the following condition may set DTC 41:

At vehicle speed of about 2 MPH or more, if voltage at ABS ECU terminal IG1 is less than 9.5 volts for

10 seconds or more, DTC 41 may set.

Diagnostic Procedure

1. Check charging system voltage. If voltage is 10-14 volts, system is okay. Go to next step. If voltage is not

10-14 volts, repair charging system. Ensure system fuses are okay.

2. Turn ignition off. Remove ABS ECU. Do not disconnect electrical connectors. Turn ignition switch to

ON position. Measure voltage between terminals IG1 and GND at ABS ECU harness connector. See Fig.

3 . If voltage is 10-14 volts, turn ignition off. Condition may be intermittent. Check ABS ECU connectors

for poor connection or damage. Repair as necessary. If connectors are okay, replace ABS ECU. If voltage

is not as specified, go to next step.

3. Measure resistance between ground and GND terminals at ABS ECU harness connector. See Fig. 3

. If

resistance is one ohm or less, go to next step. If resistance is more than one ohm, repair ground circuit

wiring. See WIRING DIAGRAMS

.

4. Remove ECU-IG fuse from instrument panel junction block. If fuse is blown, check for short circuit in all

wiring harnesses and components connected to ECU-IG fuse (ECM, A/C, cruise control, deceleration

sensor, combination meter, sun roof, shift lock, transmission pattern select switch). See WIRING

DIAGRAMS . Repair as necessary. If fuse is not blown, check for open circuit in wiring harness between

battery and ABS ECU. Repair as necessary.

DTC 43 & DTC 45: DECELERATION SENSOR MALFUNCTION (4WD MODELS ONLY)

DTC Detecting Conditions

Detection of the following conditions may set DTCs 43 or 45:

On 2-door models, if output voltage from deceleration sensor does not change for 16 consecutive times or

more when vehicle speed is decreased from 19 MPH to zero MPH, DTC 43 will set.

On 4-door models, after battery cables are connected, if input from deceleration sensor does not change at

one cycle (zero MPH to 19 MPH or more, then back to zero) for 16 consecutive times, DTC 43 will set.

When brake pedal is not depressed at vehicle speed of 3 MPH or more, and forward and backward force

(force of more than 0.4 "G") is detected for 30 seconds or more, DTC 43 will set.

On 2-door models, at vehicle speed of 19 MPH or more, if deceleration sensor output and vehicle

acceleration from wheel speed remains abnormally different for one minute or more, DTC 45 will set.

Diagnostic Procedure

1. Check deceleration sensor. See DECELERATION SENSOR CHECK under COMPONENT TESTS.

Replace sensor as necessary. If sensor is okay, go to next step.

2. Check for open or short circuit in wiring harness between deceleration sensor and ABS ECU. See

WIRING DIAGRAMS

. Repair as necessary. If wiring harness is okay, replace ABS ECU.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 18 of 1632

DTC 44: DECELERATION SENSOR CIRCUIT (4WD MODELS ONLY)

Circuit Description

Deceleration sensor detects vehicle deceleration. Sensor signal is used in ABS control. If sensor functions

abnormally, ABS warning light will illuminate, but ABS will still operate.

DTC Detecting Conditions

Detection of the following conditions may set DTC 44:

On 2-door models, with ignition switch in ON position, and output voltage of terminals GL1 or GL2

remains 0.5 volts or less or 4.5 volts or more for more than one minute, DTC 44 will set.

On 2-door models, at vehicle speed of zero MPH, if outputs of terminals GL1 and GL2 remain

abnormally different for one minute or more, DTC 44 will set.

On 2-door models, if after ignition switch is turned to ON position, voltage at terminal VGS is 4.4 volts

or less, or 5.5 volts or more, and voltage continues for 1.2 seconds or more, DTC 44 will set.

On 4-door models, if an open or short circuit is detected in circuits GS1 or GS2 for one second, DTC 44

will set.

On 4-door models, after ignition switch is turned to ON position, a test signal is output at terminal GST.

During this time, if a trouble signal is detected for 0.5 seconds, DTC 44 will set.

Diagnostic Procedure

1. Check for open or short circuit in wiring harness between deceleration sensor and ABS ECU. Repair as

necessary. See WIRING DIAGRAMS

. If wiring harness is okay, go to next step.

2. Turn ignition off. Remove ABS ECU. Do not disconnect electrical connectors. Disconnect deceleration

sensor connector. Turn ignition switch to ON position. On 4-door models, go to next step. On 2-door

models, measure voltage between ground and terminals GL1, GL2 and VGS at ABS ECU harness

connector. See Fig. 3

. Voltage should be 0.5-4.5 volts at terminals GL1 and GL2. Voltage should be 4.5-

5.5 volts at terminal VGS. If voltage is as specified, check deceleration sensor. See DECELERATION

SENSOR CHECK under COMPONENT TESTS. If voltage is not as specified, replace ABS ECU.

3. On 4-door models, measure voltage between ground and terminals GS1, GS2 and GST at ABS ECU

harness connector. See Fig. 3

. Voltage should be 4-6 volts or 7-11 volts at terminal GS1. Voltage should

be 4-6 volts at terminal GS2. Voltage at terminal GST should pulse from 12 volts for 0.5 seconds to zero

volts, with a 1.5 second pause between pulses. If voltage is as specified, check deceleration sensor. See

DECELERATION SENSOR CHECK

under COMPONENT TESTS. If voltage is not as specified,

replace ABS ECU.

DTC 49: STOPLIGHT SWITCH

DTC Detection Condition

Detection of the following condition may set DTC 49:

Voltage at ABS ECU terminal STP is 1.2-1.7 volts and continues for 0.3 seconds or more.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 18 © 2005 Mitchell Repair Information Company, LLC.

Page 23 of 1632

battery.

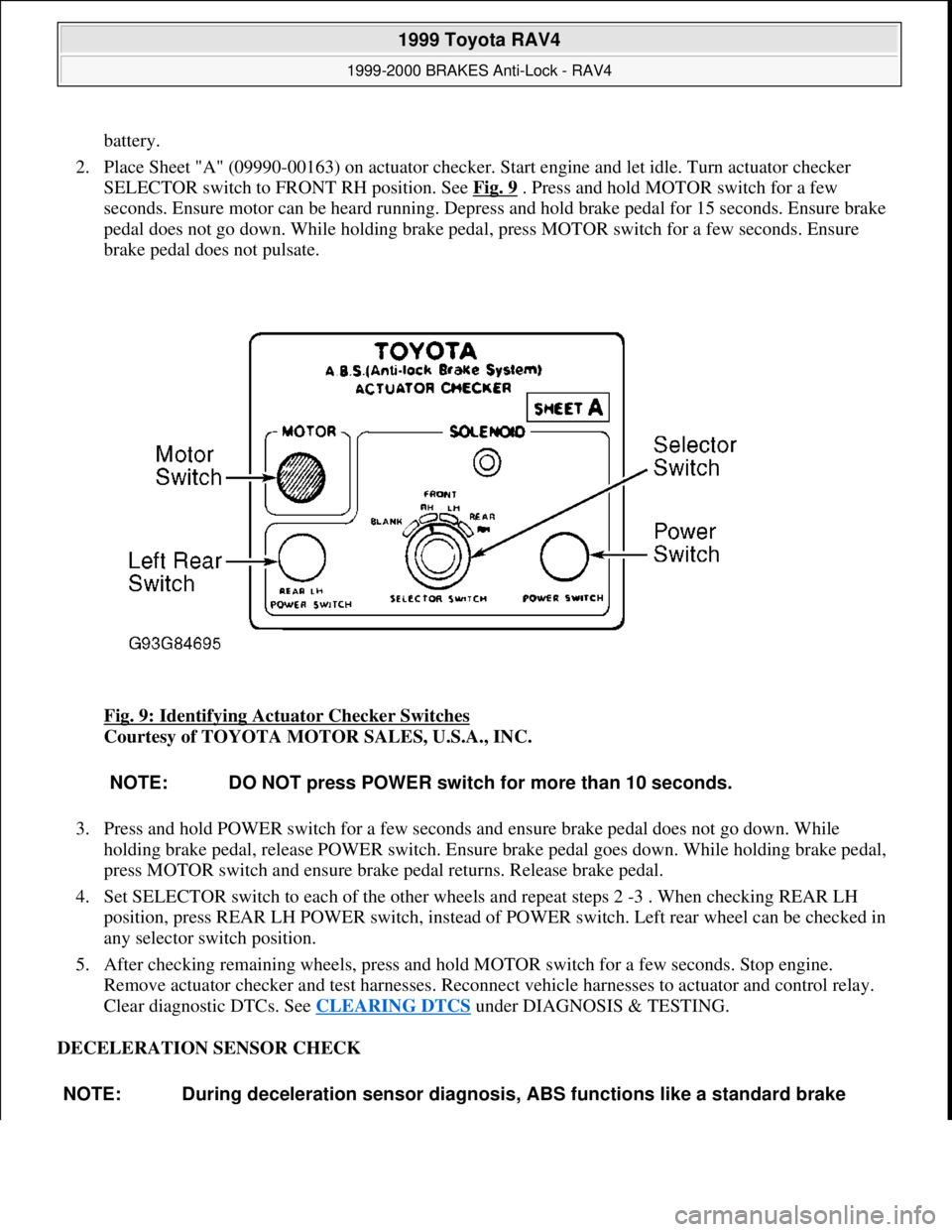

2. Place Sheet "A" (09990-00163) on actuator checker. Start engine and let idle. Turn actuator checker

SELECTOR switch to FRONT RH position. See Fig. 9

. Press and hold MOTOR switch for a few

seconds. Ensure motor can be heard running. Depress and hold brake pedal for 15 seconds. Ensure brake

pedal does not go down. While holding brake pedal, press MOTOR switch for a few seconds. Ensure

brake pedal does not pulsate.

Fig. 9: Identifying Actuator Checker Switches

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Press and hold POWER switch for a few seconds and ensure brake pedal does not go down. While

holding brake pedal, release POWER switch. Ensure brake pedal goes down. While holding brake pedal,

press MOTOR switch and ensure brake pedal returns. Release brake pedal.

4. Set SELECTOR switch to each of the other wheels and repeat steps 2 -3 . When checking REAR LH

position, press REAR LH POWER switch, instead of POWER switch. Left rear wheel can be checked in

any selector switch position.

5. After checking remaining wheels, press and hold MOTOR switch for a few seconds. Stop engine.

Remove actuator checker and test harnesses. Reconnect vehicle harnesses to actuator and control relay.

Clear diagnostic DTCs. See CLEARING DTCS

under DIAGNOSIS & TESTING.

DECELERATION SENSOR CHECK

NOTE: DO NOT press POWER switch for more than 10 seconds.

NOTE: During deceleration sensor diagnosis, ABS functions like a standard brake

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 23 © 2005 Mitchell Repair Information Company, LLC.

Page 24 of 1632

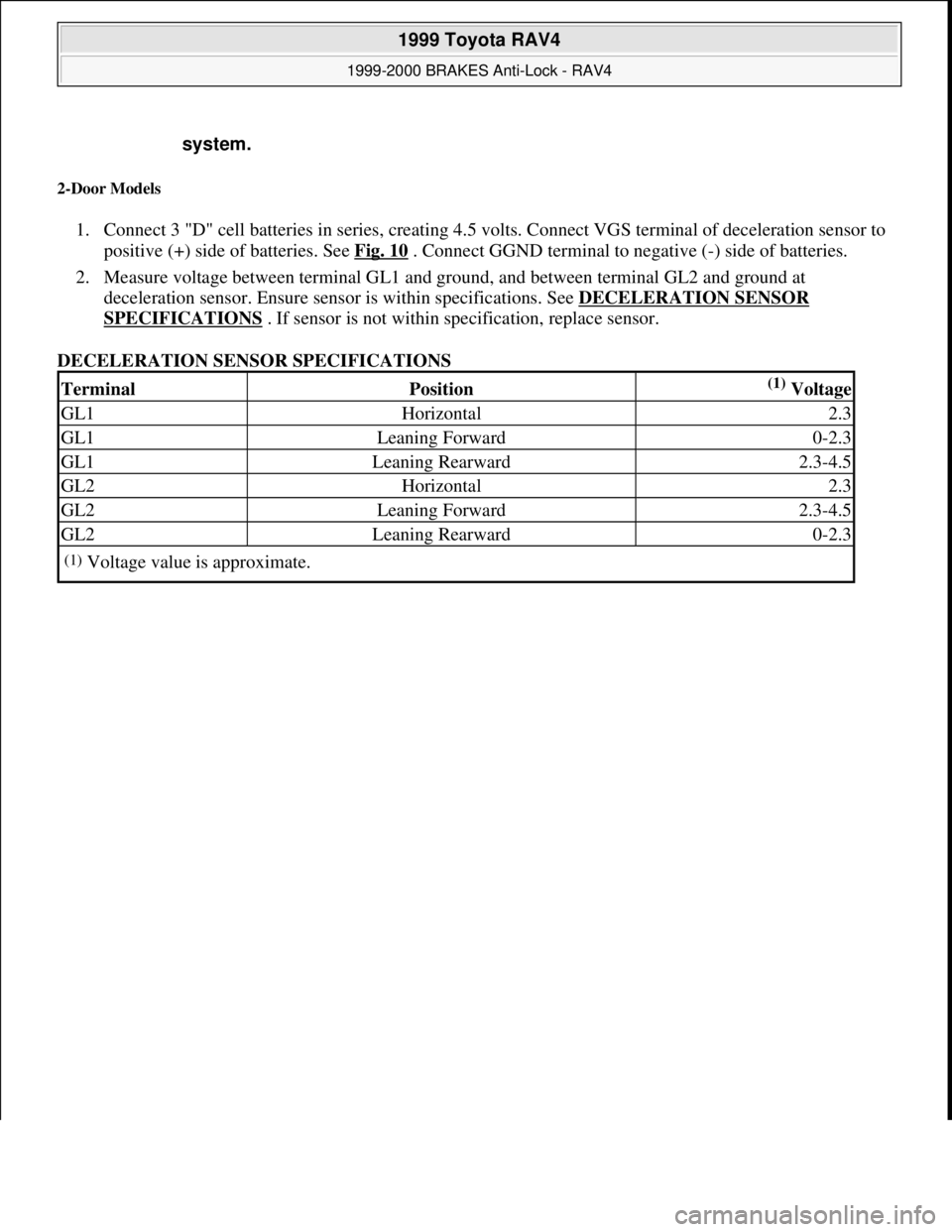

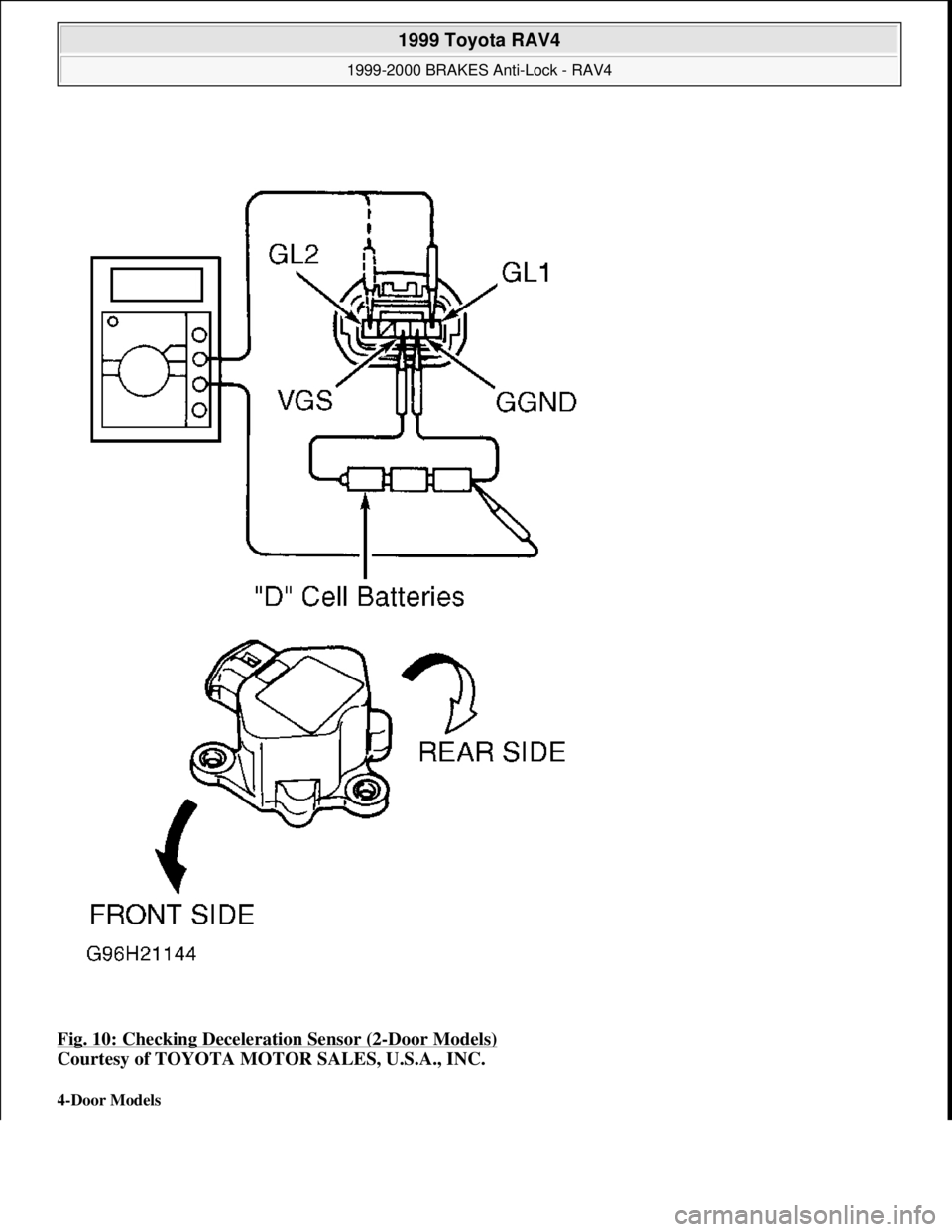

2-Door Models

1. Connect 3 "D" cell batteries in series, creating 4.5 volts. Connect VGS terminal of deceleration sensor to

positive (+) side of batteries. See Fig. 10

. Connect GGND terminal to negative (-) side of batteries.

2. Measure voltage between terminal GL1 and ground, and between terminal GL2 and ground at

deceleration sensor. Ensure sensor is within specifications. See DECELERATION SENSOR

SPECIFICATIONS . If sensor is not within specification, replace sensor.

DECELERATION SENSOR SPECIFICATIONS system.

TerminalPosition(1) Voltage

GL1Horizontal2.3

GL1Leaning Forward0-2.3

GL1Leaning Rearward2.3-4.5

GL2Horizontal2.3

GL2Leaning Forward2.3-4.5

GL2Leaning Rearward0-2.3

(1)Voltage value is approximate.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 24 © 2005 Mitchell Repair Information Company, LLC.

Page 25 of 1632

Fig. 10: Checking Deceleration Sensor (2-Door Models)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

4-Door Models

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 26 of 1632

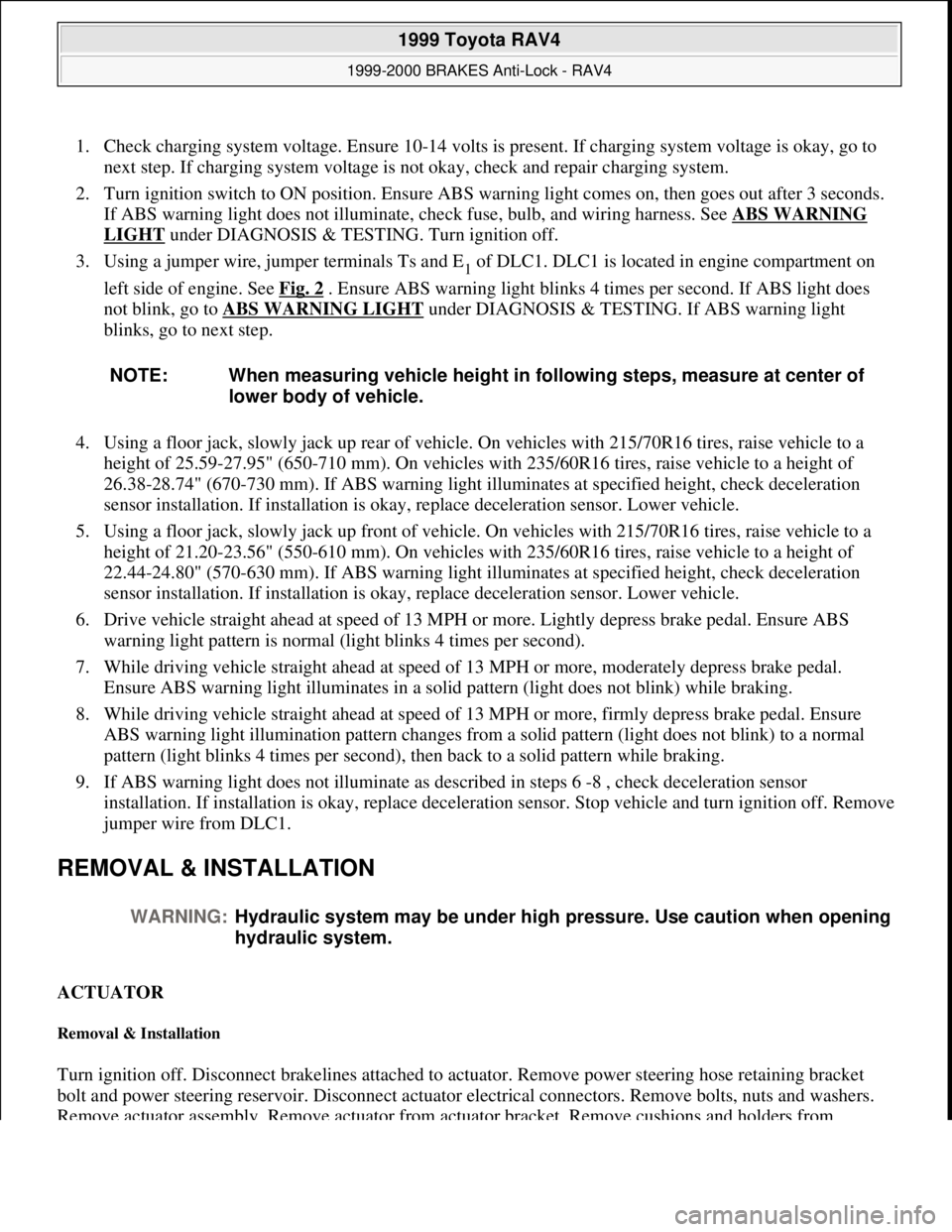

1. Check charging system voltage. Ensure 10-14 volts is present. If charging system voltage is okay, go to

next step. If charging system voltage is not okay, check and repair charging system.

2. Turn ignition switch to ON position. Ensure ABS warning light comes on, then goes out after 3 seconds.

If ABS warning light does not illuminate, check fuse, bulb, and wiring harness. See ABS WARNING

LIGHT under DIAGNOSIS & TESTING. Turn ignition off.

3. Using a jumper wire, jumper terminals Ts and E

1 of DLC1. DLC1 is located in engine compartment on

left side of engine. See Fig. 2

. Ensure ABS warning light blinks 4 times per second. If ABS light does

not blink, go to ABS WARNING LIGHT

under DIAGNOSIS & TESTING. If ABS warning light

blinks, go to next step.

4. Using a floor jack, slowly jack up rear of vehicle. On vehicles with 215/70R16 tires, raise vehicle to a

height of 25.59-27.95" (650-710 mm). On vehicles with 235/60R16 tires, raise vehicle to a height of

26.38-28.74" (670-730 mm). If ABS warning light illuminates at specified height, check deceleration

sensor installation. If installation is okay, replace deceleration sensor. Lower vehicle.

5. Using a floor jack, slowly jack up front of vehicle. On vehicles with 215/70R16 tires, raise vehicle to a

height of 21.20-23.56" (550-610 mm). On vehicles with 235/60R16 tires, raise vehicle to a height of

22.44-24.80" (570-630 mm). If ABS warning light illuminates at specified height, check deceleration

sensor installation. If installation is okay, replace deceleration sensor. Lower vehicle.

6. Drive vehicle straight ahead at speed of 13 MPH or more. Lightly depress brake pedal. Ensure ABS

warning light pattern is normal (light blinks 4 times per second).

7. While driving vehicle straight ahead at speed of 13 MPH or more, moderately depress brake pedal.

Ensure ABS warning light illuminates in a solid pattern (light does not blink) while braking.

8. While driving vehicle straight ahead at speed of 13 MPH or more, firmly depress brake pedal. Ensure

ABS warning light illumination pattern changes from a solid pattern (light does not blink) to a normal

pattern (light blinks 4 times per second), then back to a solid pattern while braking.

9. If ABS warning light does not illuminate as described in steps 6 -8 , check deceleration sensor

installation. If installation is okay, replace deceleration sensor. Stop vehicle and turn ignition off. Remove

jumper wire from DLC1.

REMOVAL & INSTALLATION

ACTUATOR

Removal & Installation

Turn ignition off. Disconnect brakelines attached to actuator. Remove power steering hose retaining bracket

bolt and power steering reservoir. Disconnect actuator electrical connectors. Remove bolts, nuts and washers.

Remove actuator assembly. Remove actuator from actuator bracket. Remove cushions and holders from NOTE: When measuring vehicle height in following steps, measure at center of

lower body of vehicle.

WARNING:Hydraulic system may be under high pressure. Use caution when opening

hydraulic system.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 26 © 2005 Mitchell Repair Information Company, LLC.

Page 29 of 1632

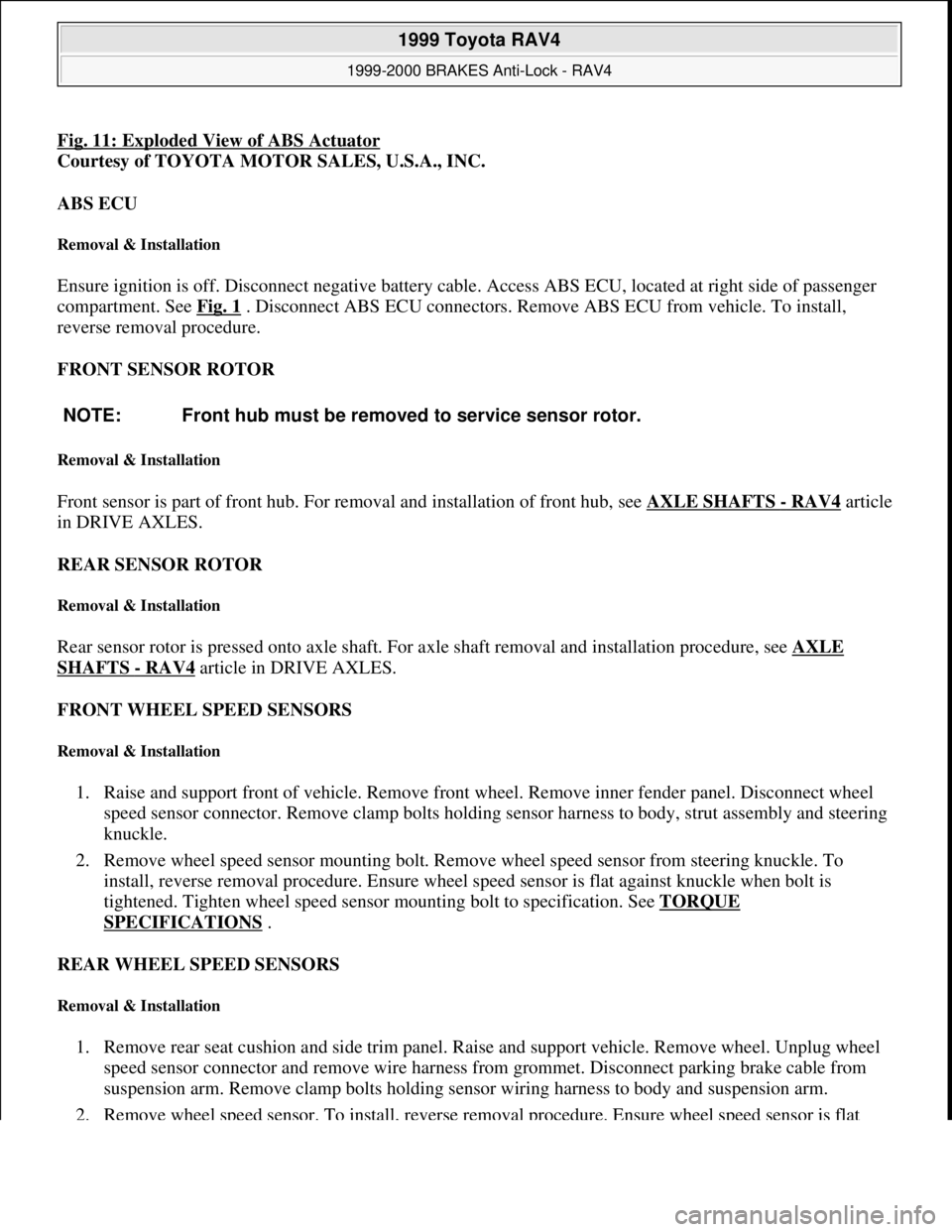

Fig. 11: Exploded View of ABS Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

ABS ECU

Removal & Installation

Ensure ignition is off. Disconnect negative battery cable. Access ABS ECU, located at right side of passenger

compartment. See Fig. 1

. Disconnect ABS ECU connectors. Remove ABS ECU from vehicle. To install,

reverse removal procedure.

FRONT SENSOR ROTOR

Removal & Installation

Front sensor is part of front hub. For removal and installation of front hub, see AXLE SHAFTS - RAV4 article

in DRIVE AXLES.

REAR SENSOR ROTOR

Removal & Installation

Rear sensor rotor is pressed onto axle shaft. For axle shaft removal and installation procedure, see AXLE

SHAFTS - RAV4 article in DRIVE AXLES.

FRONT WHEEL SPEED SENSORS

Removal & Installation

1. Raise and support front of vehicle. Remove front wheel. Remove inner fender panel. Disconnect wheel

speed sensor connector. Remove clamp bolts holding sensor harness to body, strut assembly and steering

knuckle.

2. Remove wheel speed sensor mounting bolt. Remove wheel speed sensor from steering knuckle. To

install, reverse removal procedure. Ensure wheel speed sensor is flat against knuckle when bolt is

tightened. Tighten wheel speed sensor mounting bolt to specification. See TORQUE

SPECIFICATIONS .

REAR WHEEL SPEED SENSORS

Removal & Installation

1. Remove rear seat cushion and side trim panel. Raise and support vehicle. Remove wheel. Unplug wheel

speed sensor connector and remove wire harness from grommet. Disconnect parking brake cable from

suspension arm. Remove clamp bolts holding sensor wiring harness to body and suspension arm.

2. Remove wheel speed sensor. To install, reverse removal procedure. Ensure wheel speed sensor is flat NOTE: Front hub must be removed to service sensor rotor.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 29 © 2005 Mitchell Repair Information Company, LLC.

Page 30 of 1632

against knuckle when bolt is tightened. Tighten wheel speed sensor and brake components to

specification. See TORQUE SPECIFICATIONS

.

ADJUSTMENTS

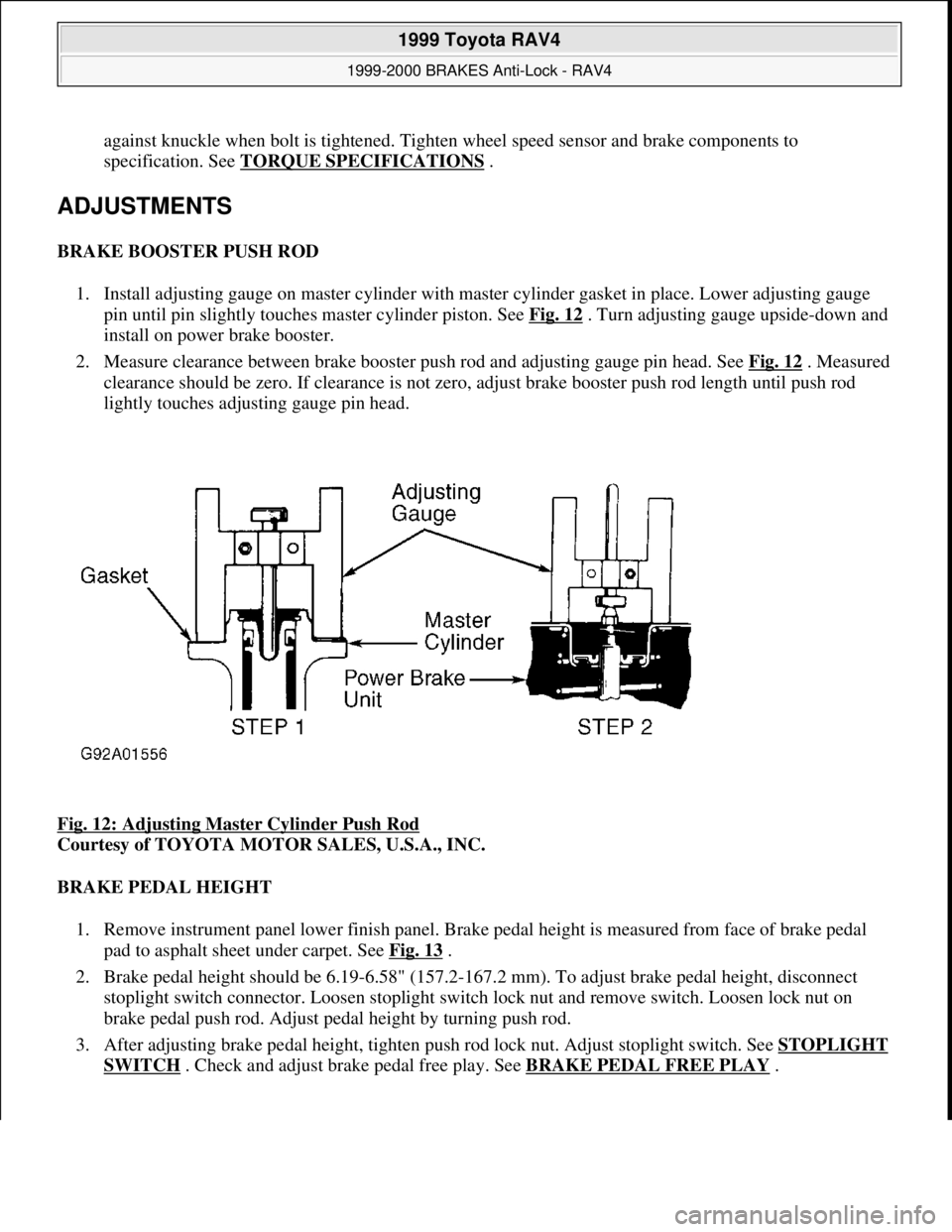

BRAKE BOOSTER PUSH ROD

1. Install adjusting gauge on master cylinder with master cylinder gasket in place. Lower adjusting gauge

pin until pin slightly touches master cylinder piston. See Fig. 12

. Turn adjusting gauge upside-down and

install on power brake booster.

2. Measure clearance between brake booster push rod and adjusting gauge pin head. See Fig. 12

. Measured

clearance should be zero. If clearance is not zero, adjust brake booster push rod length until push rod

lightly touches adjusting gauge pin head.

Fig. 12: Adjusting Master Cylinder Push Rod

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

BRAKE PEDAL HEIGHT

1. Remove instrument panel lower finish panel. Brake pedal height is measured from face of brake pedal

pad to asphalt sheet under carpet. See Fig. 13

.

2. Brake pedal height should be 6.19-6.58" (157.2-167.2 mm). To adjust brake pedal height, disconnect

stoplight switch connector. Loosen stoplight switch lock nut and remove switch. Loosen lock nut on

brake pedal push rod. Adjust pedal height by turning push rod.

3. After adjusting brake pedal height, tighten push rod lock nut. Adjust stoplight switch. See STOPLIGHT

SWITCH . Check and adjust brake pedal free play. See BRAKE PEDAL FREE PLAY.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 30 © 2005 Mitchell Repair Information Company, LLC.

Page 32 of 1632

Brake pedal depressed height is measured from face of brake pedal pad to asphalt sheet under carpet with

brakes applied. Measure brake pedal depressed height with engine running and weight of 110 lbs. (50 kg)

applied against brake pedal. Minimum brake pedal depressed height should be 2.95" (75.0 mm). If measured

distance is less than minimum height, inspect brake system.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

ApplicationFt. Lbs. (N.m)

Actuator Bracket Mounting Bolts14 (19)

Brakeline Fittings11 (15)

Hub Nut83 (110)

Push Rod Lock Nut18 (25)

Speed Sensor Harness-To-Rear Suspension Arm Bolts9 (13)

INCH Lbs. (N.m)

Actuator-To-Bracket Mounting Nuts48 (5.4)

Speed Sensor Harness-To-Body Bolts48 (5.4)

Wheel Speed Sensor Mounting Bolt71 (8)

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 32 © 2005 Mitchell Repair Information Company, LLC.

Page 37 of 1632

The air bag sensor, which deploys air bags, contains a back-up power supply, safing sensor and diagnostic code

memory. Spiral cable (clockspring) maintains a complete circuit to the steering wheel pad.

SYSTEM OPERATION CHECK

Turn ignition switch to ACC or ON position. Air bag warning light in instrument cluster should come on for

about 6 seconds and then go out. If light does not respond as specified, SRS is malfunctioning and needs repair.

See DIAGNOSIS

.

SERVICE PRECAUTIONS

Observe the following precautions when working on SRS:

Before servicing any SRS or steering column component, disable SRS. See DISABLING &

ACTIVATING AIR BAG SYSTEM . Failure to disable system could result in accidental air bag

deployment and personal injury.

When diagnosing SRS, always check for diagnostic codes before disconnecting battery.

After ignition switch is turned to LOCK position and negative battery cable is disconnected, wait at least

90 seconds before working on SRS. SRS is equipped with a back-up power source that may allow air bag

to deploy within 90 seconds of disconnecting negative battery cable.

In a minor collision in which air bags do not deploy, steering wheel pad must be inspected.

NEVER use air bag parts from another vehicle. Replace air bag parts with new parts.

Air bag sensor assembly contains mercury. After replacement, DO NOT destroy the old part. When

scrapping vehicle or replacing air bag sensor assembly, remove air bag sensor assembly and dispose of as

toxic waste.

Never disassemble or repair system components. Replace cracked, dented or otherwise damaged system

components.

Remove air bag sensor if shocks are likely to be applied to the sensor during repairs.

When diagnosing electrical circuits, use a Digital Volt/Ohmmeter (DVOM) with high impedance (10,000

ohms minimum).

Information labels are attached to air bag components. Follow all notices on labels.

After servicing SRS, check air bag warning light to ensure system is functioning properly. See SYSTEM

OPERATION CHECK .

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover up, away from

surface. This will reduce motion of module if accidentally deployed.

After deployment, air bag surface may contain deposits of sodium hydroxide which irritates skin. During

clean-up, always wear safety glasses, rubber gloves and long-sleeved shirt. After clean-up, wash hands

using mild soap and water.

When carrying a live air bag module, trim cover must be pointed away from your body to minimize

injury in case of accidental deployment.

If SRS is not fully functional for any reason, vehicle should not be driven until system is repaired and

a

gain becomes operational. DO NOTremove bulbs, modules, sensors or other components or in any way

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 3 © 2005 Mitchell Repair Information Company, LLC.