sensor TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 1149 of 1632

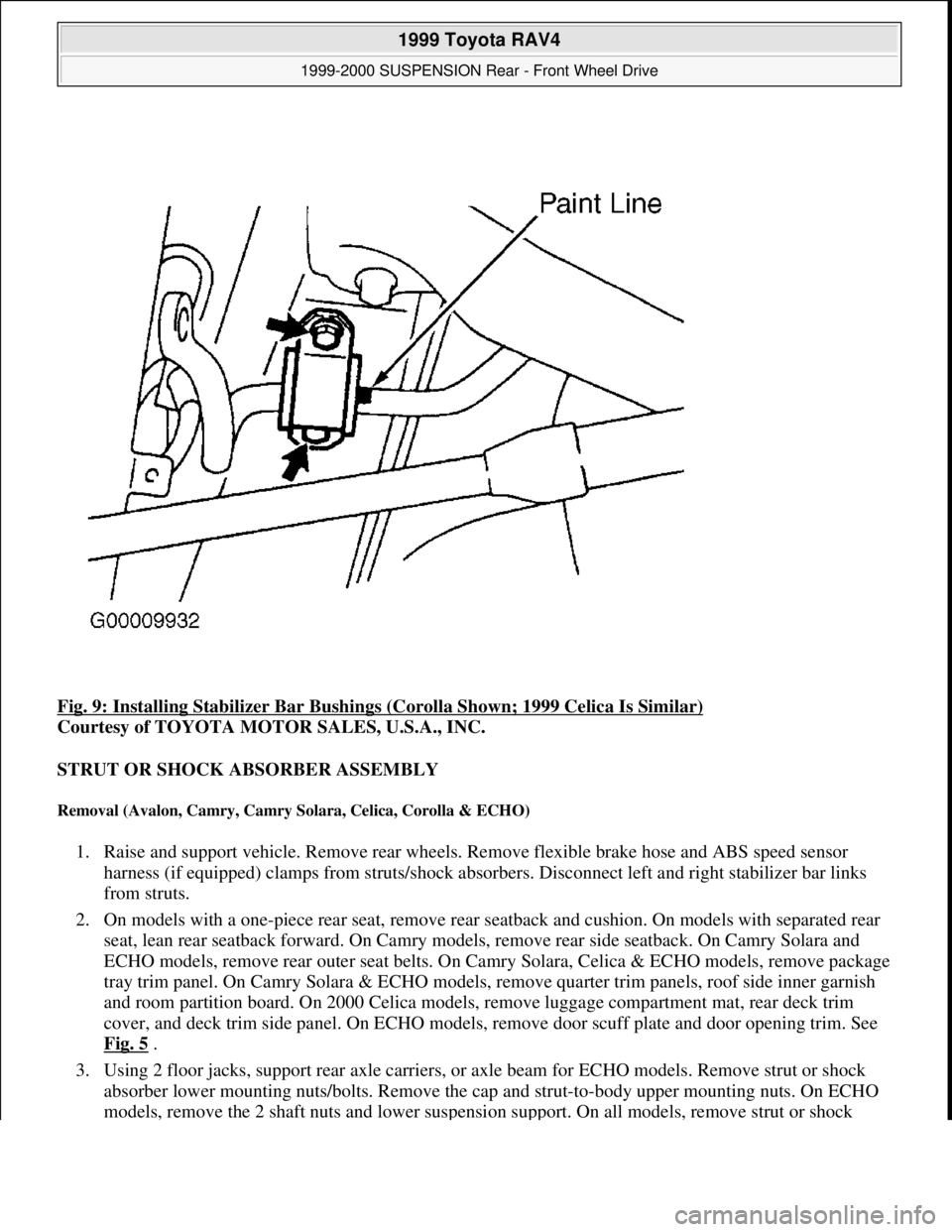

Fig. 9: Installing Stabilizer Bar Bushings (Corolla Shown; 1999 Celica Is Similar)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

STRUT OR SHOCK ABSORBER ASSEMBLY

Removal (Avalon, Camry, Camry Solara, Celica, Corolla & ECHO)

1. Raise and support vehicle. Remove rear wheels. Remove flexible brake hose and ABS speed sensor

harness (if equipped) clamps from struts/shock absorbers. Disconnect left and right stabilizer bar links

from struts.

2. On models with a one-piece rear seat, remove rear seatback and cushion. On models with separated rear

seat, lean rear seatback forward. On Camry models, remove rear side seatback. On Camry Solara and

ECHO models, remove rear outer seat belts. On Camry Solara, Celica & ECHO models, remove package

tray trim panel. On Camry Solara & ECHO models, remove quarter trim panels, roof side inner garnish

and room partition board. On 2000 Celica models, remove luggage compartment mat, rear deck trim

cover, and deck trim side panel. On ECHO models, remove door scuff plate and door opening trim. See

Fig. 5

.

3. Using 2 floor jacks, support rear axle carriers, or axle beam for ECHO models. Remove strut or shock

absorber lower mounting nuts/bolts. Remove the cap and strut-to-body upper mounting nuts. On ECHO

models, remove the 2 shaft nuts and lower suspension support. On all models, remove strut or shock

1999 Toyota RAV4

1999-2000 SUSPENSION Rear - Front Wheel Drive

Microsoft

Sunday, November 22, 2009 10:37:21 AMPage 11 © 2005 Mitchell Repair Information Company, LLC.

Page 1151 of 1632

2. Using a floor jack, support suspension member. Remove suspension member nuts, bolts and stoppers.

Lower suspension member. Remove No. 1 lower suspension arm.

Installation

1. To install, reverse removal procedure. Be sure to install components in their original locations. On all

models except Corolla, suspension arms are marked with paint. Install suspension arms with paint marks

facing rearward. On Corolla models, suspension arms have left hand threads on one side. Install

suspension arms with left hand threads to the axle carrier side.

2. Install all nuts and bolts, but DO NOT tighten. Install wheels. Lower vehicle. Bounce vehicle several

times to stabilize suspension. Tighten all nuts and bolts to specification, with vehicle weight on

suspension. See TORQUE SPECIFICATIONS

. Check rear wheel alignment. See SPECIFICATIONS

& PROCEDURES article in WHEEL ALIGNMENT.

WHEEL BEARINGS (HUBS)

Removal (Avalon, Camry, Camry Solara, Celica, Corolla & RAV4 FWD)

1. Raise and support vehicle. Remove rear wheels. On drum brake models, remove brake drum. On disc

brake models, remove rotor. Remove caliper, leaving flex hose attached, suspend aside. Disconnect ABS

sensor (if equipped).

2. On all models, check wheel hub axial play and runout. See WHEEL BEARING INSPECTION

under

ADJUSTMENTS & INSPECTION. Remove 4 bolts and remove axle hub and "O" ring.

Installation

Coat NEW "O" ring with grease and install hub. To complete installation, reverse removal procedure. Tighten

all nuts and bolts to specification. See TORQUE SPECIFICATIONS

.

Removal (RAV4 4WD)

1. Raise and support vehicle. Remove rear wheel and brake drum. Using a dial indicator, check wheel

bearing end play and runout. End play should not exceed .002" (.05 mm). Runout should not

exceed .0028" (.07 mm). If axle hub end play or runout exceed specification, replace hub with bearing.

2. Remove bolt and ABS sensor. Remove drive axle. Remove drive axle lock nut. Place matchmarks on

drive axle and differential side gear shaft. Remove 4 nuts and remove drive axle. Disassemble rear brake

shoes. Disconnect brakeline from wheel cylinder. Remove parking brake cable. Remove 4 bolts and

remove axle hub with bearing and backing plate. See Fig. 10

.

3. Using Puller (09950-40011) and Replacer Set (09950-60011), remove bearing from axle hub. Remove

bearing race from axle hub. See Fig. 11. NOTE: Wheel bearings and wheel hub, is a one piece assembly and must be replaced

as a single unit.

1999 Toyota RAV4

1999-2000 SUSPENSION Rear - Front Wheel Drive

Microsoft

Sunday, November 22, 2009 10:37:21 AMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 1155 of 1632

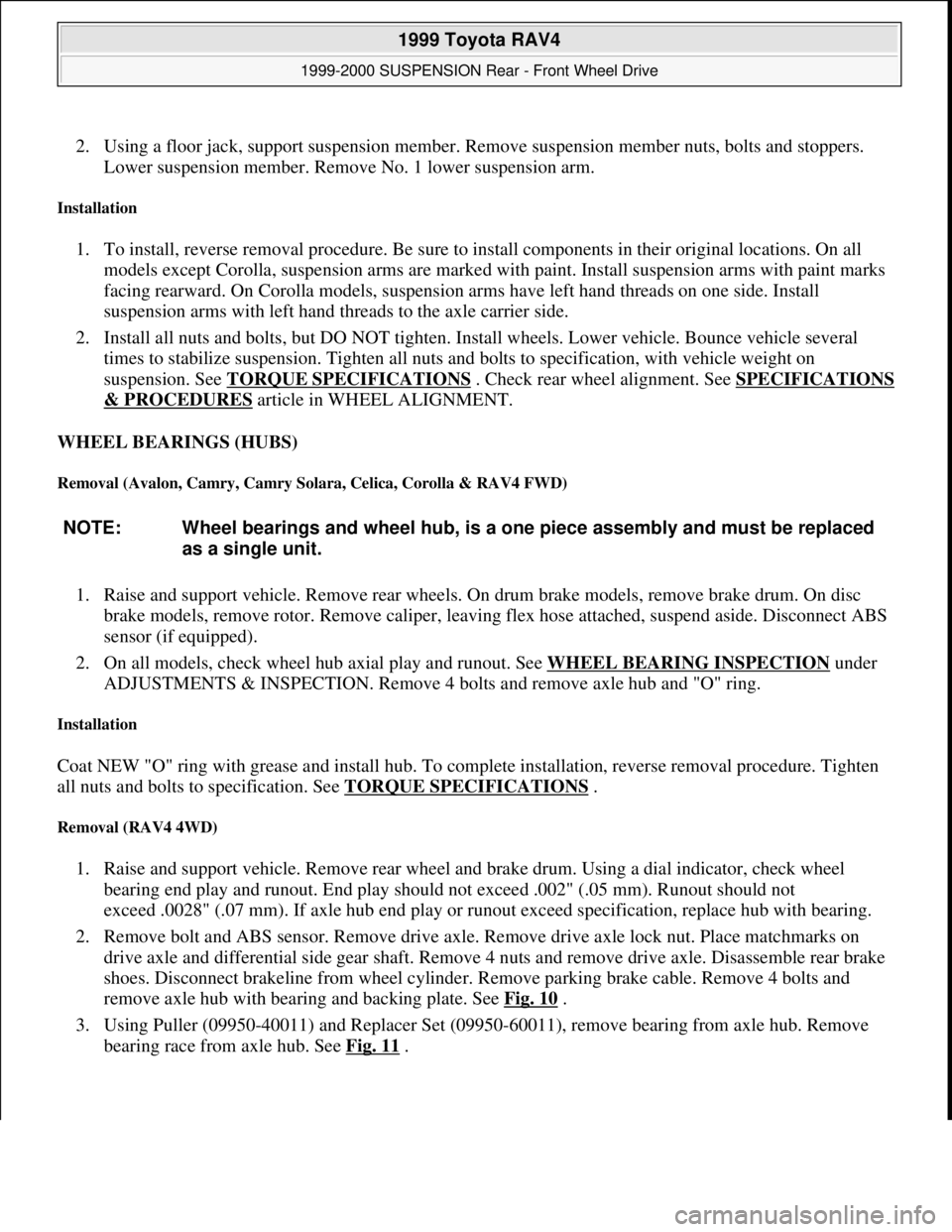

59 (80)

Camber Adjust Cam Bolt83 (113)

Drive Axle Lock Nut159 (216)

Drive Axle-To-Differential Side Gear41 (56)

Rear No.1 Suspension Arm Toe Adjust Cam Bolt97 (132)

Shock Absorber Shaft Nut11 (15)

Shock Absorber Lower Mounting Bolt27 (37)

Upper & Lower Suspension Arm Nuts76 (103)

INCH Lbs. (N.m)

ABS Speed Sensor Bolt

Avalon, Camry, Camry Solara, Celica & Corolla71 (8.0)

ECHO48 (5.4)

RAV469 (7.8)

1999 Toyota RAV4

1999-2000 SUSPENSION Rear - Front Wheel Drive

Microsoft

Sunday, November 22, 2009 10:37:21 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 1174 of 1632

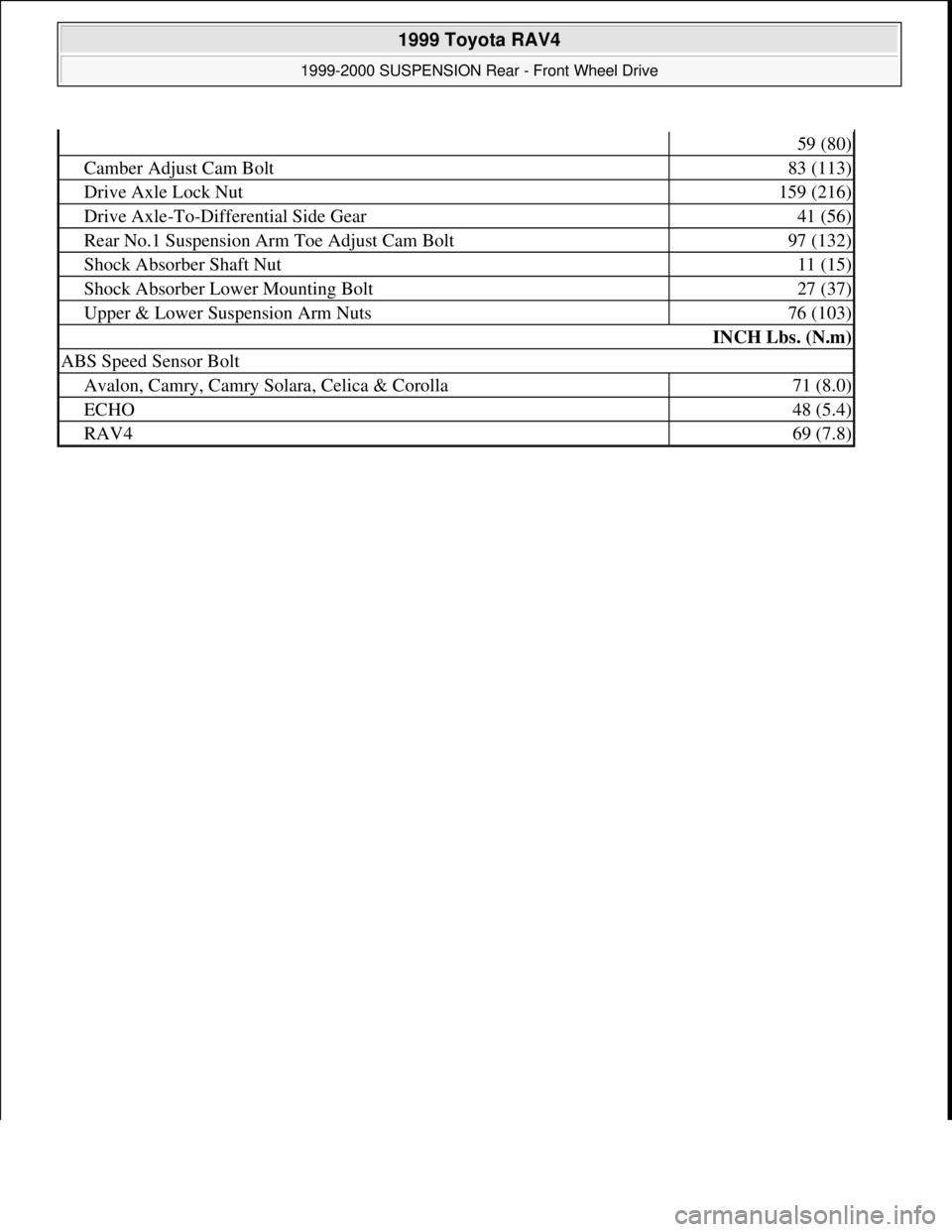

Fig. 15: Solenoid Drive Pinion Return Test (Celica Shown; Land Cruiser, RAV4, Tacoma 4-Cyl. &

4Runner 4-Cyl. Are Similar)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

REMOVAL & INSTALLATION

STARTER

Removal & Installation (Avalon, Camry, Camry Solara & Sienna)

1. Disconnect negative battery cable and then positive cable. Remove battery and tray. If equipped with

cruise control, remove cruise control actuator cover, cruise control actuator and actuator bracket from

body mount.

2. On all models, remove starter terminal/wire cover and remove starter wires. Remove starter. To install,

reverse removal procedure. Tighten starter bolts to specification. See TORQUE SPECIFICATIONS

.

Removal & Installation (Celica)

1. Disconnect negative battery cable. Disconnect air intake temperature sensor connector from air cleaner

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Starters

Microsoft

Sunday, November 22, 2009 10:19:18 AMPage 19 © 2005 Mitchell Repair Information Company, LLC.

Page 1175 of 1632

assembly. If equipped with cruise control, remove cruise control actuator cable from clamps.

2. On California models, remove air hose for idle-up from air cleaner hose. On all models, disconnect 4

clamps, and disconnect air cleaner cap from air cleaner case. Loosen hose clamp, and disconnect air

cleaner hose from throttle body.

3. Remove air cleaner cap and air cleaner hose assembly. Remove air filter. Disconnect 2 engine wires from

clamps on air cleaner case. Remove 3 bolts and air cleaner case. Remove battery. If equipped with cruise

control, disconnect cruise control actuator connector.

4. Remove 3 bolts, and disconnect actuator from body bracket. On all models, disconnect starter connector.

Remove nut, and disconnect starter cable. Remove 2 bolts, and disconnect oxygen sensor connector and

engine wire brackets from starter. Remove starter. To install, reverse removal procedure. Tighten starter

bolts to specification. See TORQUE SPECIFICATIONS

.

Removal & Installation (Corolla)

1. Disconnect negative battery cable and then positive cable. Remove battery and tray. Remove engine

coolant reservoir. Remove engine splash shield from underneath right side of compartment.

2. Remove starter terminal/wire cover and remove starter wires. Remove starter bolts and starter. Note

starter mounting bolt locations (bolts are different lengths). To install, reverse removal procedure. Tighten

starter bolts to specification. See TORQUE SPECIFICATIONS

.

Removal & Installation (Land Cruiser & Tundra V8)

1. Starter is located underneath intake manifold. See Fig. 16 . Disconnect negative battery cable. Remove

cover from top of engine. Remove air cleaner intake hose. Disconnect accelerator cable. Remove intake

manifold. See CYLINDER HEAD & MANIFOLDS

in 4.7L article in ENGINES.

2. Remove starter wires and remove starter. To install, reverse removal procedure. Tighten starter bolts to

specification. See TORQUE SPECIFICATIONS

.

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Starters

Microsoft

Sunday, November 22, 2009 10:19:18 AMPage 20 © 2005 Mitchell Repair Information Company, LLC.

Page 1177 of 1632

Removal & Installation (RAV4)

Disconnect negative battery cable. Remove engine coolant reservoir. Disconnect relay connectors, PCV hose,

intake air temperature sensor connector, air cleaner intake hose, remaining hoses and lines for air cleaner

removal. Remove air cleaner assembly. Disconnect starter connector. Remove starter wires and remove starter.

To install, reverse removal procedure. Tighten starter bolts to specification. See TORQUE

SPECIFICATIONS .

Removal & Installation (Tacoma, Tundra V6 & 4Runner)

Removal and installation is basically an unbolt and bolt-on procedure. Tighten starter bolts to specification. See

TORQUE SPECIFICATIONS

.

OVERHAUL

NOTE: See Fig. 17 for overhaul procedure.

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Starters

Microsoft

Sunday, November 22, 2009 10:19:18 AMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 1208 of 1632

1999-2000 STEERING

Steering Columns - Standard

DESCRIPTION & OPERATION

Steering column is a collapsible 2-piece design. Columns use shear pins to absorb collision impact. Steering

shaft is connected directly to steering gear with either a flexible coupling or "U" joint. Some models have an air

bag integral with the steering wheel pad.

SERVICE PRECAUTIONS

Observe the following precautions when servicing Supplemental Restraint System (SRS):

Disable SRS before servicing any SRS or steering column component. Failure to do this could result in

accidental air bag deployment and possible personal injury. See DISABLING & ACTIVATING AIR

BAG SYSTEM .

Remove air bag sensor assembly/center air bag sensor and front air bag sensors if repairing the vehicle

requires impacting (shocking) the vehicle.

Replace dropped, cracked, dented or otherwise damaged components.

DO NOT expose front air bag sensors, air bag sensor assembly/center air bag sensor or steering wheel

pad (air bag module) directly to heat or flame.

Information labels are attached to air bag components. Follow all notices on labels.

After work on SRS is completed, check air bag warning light to ensure system is functioning properly.

See appropriate AIR BAG RESTRAINT SYSTEMS article in ACCESSORIES & EQUIPMENT.

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover upward, away

from surface. This will reduce motion of module if it is accidentally deployed.

Carry a live air bag module with trim cover (air bag) pointed away from your body to minimize injury in

case of accidental deployment.

If SRS is not fully functional for any reason, vehicle should not be driven until system is repaired and

becomes operational. DO NOT remove bulbs, modules, sensors or other components or in any way

disable system from operating normally. If SRS is not functional, park vehicle until it is repaired and

functions properl

y. NOTE: For models with tilt wheel steering columns, see appropriate STEERING

COLUMNS - TILT WHEEL article.

WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all SERVICE PRECAUTIONS. Deactivate air bag system before

performing any repairs. See DISABLING & ACTIVATING AIR BAG

SYSTEM .

1999 Toyota RAV4

1999-2000 STEERING Steering Columns - Standard

1999 Toyota RAV4

1999-2000 STEERING Steering Columns - Standard

Microsoft

Sunday, November 22, 2009 10:34:51 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:34:55 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 1255 of 1632

1999-2000 STEERING

Steering Columns - Tilt Wheel - Trucks & Vans

DESCRIPTION & OPERATION

Tilt steering columns incorporate a main shaft, attached by a "U" joint to an intermediate steering shaft. Shafts

are held in place by upper and lower column tubes. Column tubes are pinned together so upper column can

move up or down. Upper column is locked in place by pawl attached to lever. Steering columns are collapsible.

SERVICE PRECAUTIONS

Observe the following precautions when servicing SRS:

Disable SRS before servicing any SRS or steering column component. Failure to do this could result in

accidental air bag deployment and possible personal injury. See DISABLING & ACTIVATING AIR

BAG SYSTEM .

Remove air bag sensor assembly/center air bag sensor and front air bag sensors if repairing the vehicle

requires impacting (shocking) the vehicle.

Replace dropped, cracked, dented or otherwise damaged components.

DO NOT expose front air bag sensors, air bag sensor assembly/center air bag sensor or steering wheel

pad (air bag module) directly to heat or flame.

Information labels are attached to air bag components. Follow all notices on labels.

After work on SRS is completed, check air bag warning light to ensure system is functioning properly.

See appropriate AIR BAG RESTRAINT SYSTEMS article in ACCESSORIES & EQUIPMENT.

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover upward, away

from surface. This will reduce motion of module if it is accidentally deployed.

Carry a live air bag module with trim cover (air bag) pointed away from your body to minimize injury in

case of accidental deployment.

If SRS is not fully functional for any reason, vehicle should not be driven until system is repaired and

becomes operational. DO NOT remove bulbs, modules, sensors or other components or in any way

disable system from operating normally. If SRS is not functional, park vehicle until it is repaired and

functions properly.

DISABLING & ACTIVATING AIR BAG SYSTEM

WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all SERVICE PRECAUTIONS

. Deactivate air bag system before

performing any repairs. See DISABLING & ACTIVATING AIR BAG

SYSTEM .

WARNING:Back-up power supply maintains SRS voltage for about 90 seconds after

1999 Toyota RAV4

1999-2000 STEERING Steering Columns - Tilt Wheel - Trucks & Vans

1999 Toyota RAV4

1999-2000 STEERING Steering Columns - Tilt Wheel - Trucks & Vans

Microsoft

Sunday, November 22, 2009 10:34:02 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:34:07 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 1404 of 1632

1. Remove mode select lever and rod (if equipped). Remove rear wheel speed sensor. Remove "O" ring

from speed sensor. Remove dynamic damper (if equipped). See Fig. 2

.

2. Remove dust deflector from extension housing. Remove 4 bolts. Remove "O" ring from housing. Remove

extension housing oil seal.

3. Remove 5 bolts from right case retainer. Using plastic hammer, remove right case retainer. Remove "O"

ring and apply gasket from retainer. Remove 3 bolts and inspection hole cover.

4. Using Lock Nut Wrench (09326-20011) and spring tension gauge, measure driven pinion preload and

backlash between driven pinion and ring gear. Driven pinion preload at starting point is 2.0-3.1 lbs. (.9-

1.4 kg).

5. Using lock nut wrench and spring gauge, measure total preload. Total preload at starting point is 1.1-2.0

lbs. (.5-.9 kg). Add driven pinion preload. Using dial indicator, measure ring gear backlash. Backlash

should be .0051-.0071" (.130-.180 mm).

6. Remove driven pinion bearing cage. Remove "O" ring and shims from bearing cage. Remove transfer

right case. Remove center differential assembly. Remove apply gasket from left case.

7. Remove oil pump driven gear and strainer. Remove "O" ring from oil pump strainer. Remove adjusting

nut lock plate. Remove "O" ring from bolt.

8. Using Adjusting Nut Wrench (09318-12010), remove adjusting nut and oil reservoir from right case.

Remove outer race with a brass bar and hammer. Remove outer race and plate washer. Remove left case

oil seal.

1999 Toyota RAV4

1999 TRANSFER CASES Toyota A-540H Overhaul

Microsoft

Sunday, November 22, 2009 10:49:16 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 1419 of 1632

6. Remove right case. Remove ring gear mounting case and center differential case. Remove driven pinion

bearing cage assembly. Using Oil Seal Puller (09308-00010), remove outer race and plate washer.

7. Using Bearing Replacer (09316-60010), install NEW oil seal. Oil seal depth is .12" (3 mm). Coat lip of

oil seal with grease. Install plate washer. Using Bearing Replacer (09316-60010) and an arbor press,

install left case bearing outer race.

8. Coat "O" ring with gear oil and install on driven pinion bearing cage assembly. Install driven pinion

bearing cage with adjusting shim to transfer left case. Install 6 bolts. Tighten bolts to 29 ft. lbs. (39 N.m).

Install ring gear mounting case and center differential case.

9. Install NEW apply gasket to left case. Coat "O" ring with gear oil. Install "O" ring to oil pump strainer.

Install strainer to right case. Install bolts. Tighten to 48 INCH lbs. (5.4 N.m) Install oil pump driven gear.

Apply Sealant (Three Bond 1281) to left case. Install right case as soon as seal packing is applied. Install

right case to left case. Install 10 bolts. Tighten to 32 ft. lbs. (44 N.m). Check total preload as shown in

step 3 .

10. Install lock plate so projection from lock plate fits properly into groove of adjusting nut. When lock plate

cannot be installed, tighten adjusting nut smallest amount possible. Coat NEW "O" ring with gear oil.

Install "O" ring on lock bolt. Install and tighten lock nut to 62 INCH lbs. (7 N.m).

11. Apply Sealant (Three Bond 1281) to left case. Install inspection hole cover as soon as seal packing is

applied. Install hole cover to transfer left case. Install 3 bolts. Tighten to 12 ft. lbs. (16 N.m).

12. Coat NEW "O" ring with gear oil. Install "O" ring and NEW apply gasket. Install right case retainer to

transfer right case. Install 5 bolts. Tighten bolts to 21 ft. lbs. (29 N.m).

13. Install NEW oil seal in extension housing. Coat lip of oil seal with grease. Install NEW "O" ring in

extension housing. Install extension housing to driven pinion bearing cage. Install 4 bolts. Tighten to 18

ft. lbs. (25 N.m). Using a hammer, install dust deflector (if equipped). Install dynamic damper. Tighten to

18 ft. lbs. (25 N.m).

14. Install NEW "O" ring on speed sensor. Install speed sensor to transfer left case. Tighten to 48 INCH lbs.

(5.4 N.m). Install transfer mode selector lever, rod and lever guide (if equipped). Tighten 2 lever bolts to

96 INCH lbs. (11 N.m). Tighten guide bolt to 48 INCH lbs. (5.4 N.m).

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

ApplicationFt. Lbs. (N.m)

Case-To-Case Bolts33 (44)

Differential Switch30 (40)

Drain Plug29 (39)

Dynamic Damper Bolts18 (25)

Extension Housing Bolts18 (25)

Inspection Cover Bolts12 (16)

Pinion Bearing Cage Bolts29 (39)

Shift Fork Bolt12 (16)

1999 Toyota RAV4

1999 TRANSFER CASES Toyota A-540H Overhaul

Microsoft

Sunday, November 22, 2009 10:49:16 AMPage 19 © 2005 Mitchell Repair Information Company, LLC.