air filter TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 177 of 1632

washer. Remove nut and washer. Remove Park/Neutral Position (PNP) switch.

3. Remove throttle cable retaining bolt. Remove solenoid harness connector retaining bolt (if applicable).

Remove vehicle speed sensor mounted in differential cover. Remove sensor adapter. Remove direct

clutch speed (T/M revolution) sensor mounted to upper case cover (if equipped). Remove upper case

cover. Remove transaxle oil pan. Examine any contamination in pan to aid in diagnosis.

4. Remove oil stainer (filter) and oil pipe hold-down bracket. Remove manual valve body including detent

spring. Gently remove all oil pipes by prying up on end of pipe with screwdriver.

5. Disconnect solenoid harness connectors. Remove connector clamp and apply pipe retainer. Remove 1st

and reverse apply pipe. Remove valve body bolts. Remove wiring harness clamp. Disconnect throttle

cable from cam and remove valve body.

6. Remove throttle cable and solenoid wiring harness. Remove 2nd brake apply gasket. Loosen accumulator

cover bolts in crisscross pattern. Remove cover and gasket. Remove forward clutch accumulator. See Fi

g.

10 .

7. Remove remaining accumulators by applying 14 psi (1kg/cm

2 ) of air pressure to apply hole. See Fig.

11 . Cover accumulator bores with a rag when applying air.

8. Mark 2nd coast brake servo apply piston rod where it meets case. Apply 57-114 psi (4-8 kg/cm

2 ) of air

pressure to apply hole and measure piston rod travel (stroke). See Fig. 12

. Piston rod travel should

be .079-.138" (2.0-3.5 mm). If rod travel is not within specification, further inspect band during

disassembly.

9. Remove 2nd coast brake piston cover snap ring. Apply air to oil hole and remove cover and piston

assembly. See Fig. 12

. Remove oil pump bolts. Using appropriate puller, remove oil pump.

10. Remove direct clutch and forward clutch. Separate components and remove thrust washer. Remove thrust

bearings from front and rear of forward clutch. Push out 2nd coast brake band anchor pin. Remove band

and inspect.

11. Remove front planetary ring gear. Remove front planetary gear with thrust bearings on either side.

Remove thrust bearings. Remove sun gear shell with thrust washer.

12. Apply compressed air to 2nd brake piston port and check operation of 2nd brake. See Fig. 13

. Remove

2nd coast brake band guide. DO NOT separate band guide and bolt. Remove snap ring securing 2nd

brake drum. Remove drum.

13. Remove 2nd brake piston return spring. Remove No. 1 one-way clutch. Remove 2nd brake clutch discs,

plates and flange. Note number and location of components. Remove snap ring securing No. 2 one-way

clutch and rear planetary gear. See Fig. 14

. Remove components.

14. Remove thrust washer from rear planetary gear. Remove rear planetary ring gear with thrust bearing.

Apply air into appropriate passage to check 1st and reverse brake operation. See Fig. 15

.

15. Using feeler gauge, check pack clearance of 1st and reverse brake assembly. Clearance should be .033-

.081" (.85-2.05 mm) for A-540E transaxle, .041-.085" (1.04-2.16 mm) for A-540H transaxle, or .076-

.106" (1.92-2.68 mm) for A-541E transaxle. Remove snap ring securing 1st and reverse brake. Remove

1st and reverse brake discs, plates and flange. Note number and location of components.

16. From back of transaxle, remove 13 bolts securing overdrive unit. Using soft-faced hammer, tap around

outside of case until overdrive unit loosens and can be removed.

17. Remove overdrive (OD) planetary gear from transaxle case. Remove OD brake drum. See Fig. 14

.

Remove gaskets for OD clutch apply and OD brake apply ports.

18. Usin

g appropriate compressor, compress 1st and reverse piston. See Fig. 16 . Remove snap ring. Apply

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:17 AMPage 23 © 2005 Mitchell Repair Information Company, LLC.

Page 678 of 1632

CONNECTORS

CONNECTORS

GROUNDS

GROUNDS

Junction Connector No. 11Behind right kick panel.

Junction Connector No. 12In left front door.

Junction Connectors No. 13 & 14In right front door.

Junction Connectors No. 15 & 16On left rear of luggage compartment.

Noise Filter (Ignition System)On left rear of engine. See Fig. 2 .

Pretensioner (Left)At left "B" pillar.

Pretensioner (Right)At right "B" pillar.

RheostatBehind left upper side of dash.

ComponentComponent Location

BK1 (Orange, 8 Pin)Beside right rear combination light.

BK2 (Blue, 4 Pin)Beside right rear combination light.

BM1 (White, 5 Pin)At right center pillar.

BN1 (White, 5 Pin)At left center pillar.

EA1 (White, 14 Pin)Inside J/B No. 2. See Fig. 2 .

IB1 (White, 17 Pin)At left kick panel.

IB2 (White, 20 Pin)At right kick panel.

IB3 (Yellow, 2 Pin)At left kick panel.

IB4 (Yellow, 2 Pin)At right kick panel.

IC1 (White, 16 Pin)At left kick panel.

ID1 (White, 12 Pin)At left kick panel.

ID2 (Gray, 4 Pin)At left kick panel.

IF1 (Black, 8 Pin)At left kick panel.

IG1 (White, 12 Pin)Under center of dash.

IG2 (Dark Gray, 19 Pin)Under center of dash.

IH1 (Gray, 2 Pin)At right kick panel.

II1 (Blue, 16 Pin)At right kick panel.

IJ1 (White, 10 Pin)At left kick panel.

IO1 (White, 5 Pin)Below center of dash, at left dash brace.

IP1 (White, 1 Pin)At right kick panel.

ComponentComponent Location

BH (2 Door)Under left center pillar.

BH (4 Door)At left rear quarterpanel.

BI (2 Door)Under right center pillar.

1999 Toyota RAV4

1999 TOYOTA RAV4

Microsoft

Sunday, November 22, 2009 10:17:32 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 701 of 1632

Removal

1. Release fuel pressure. See FUEL PRESSURE RELEASE . Drain cooling system. Raise and support

vehicle. Remove right lower engine cover.

2. Disconnect control cables at throttle body. Remove air cleaner assembly and air cleaner case. Remove

accessory drive belt and generator.

3. Remove front exhaust pipe. Remove exhaust manifold and heat insulator assembly. Disconnect oxygen

sensor (except California) or Air/Fuel (A/F) ratio sensor (California), and remove exhaust manifold and

heat shield. Remove sensors from exhaust manifold and front catalytic converter, if equipped.

4. Remove heat insulator from front exhaust pipe. Remove throttle body and gasket. Remove ignition coils

with spark plug wires attached.

5. Disconnect necessary electrical connectors, coolant hoses and vacuum hoses from cylinder head and

intake manifold. Remove coolant outlet, coolant by-pass pipe and gaskets.

6. Disconnect hoses and ground strap. Remove union bolt, and disconnect fuel line at fuel filter. Remove

EGR valve and vacuum modulator. Disconnect power steering idle-up hoses from air tube.

7. Remove 2 bolts and accelerator cable bracket. Disconnect PCV hoses, cable brackets and control cables

for access to valve cover. Disconnect engine wiring harness protector at rear of timing belt cover for

access to valve cover. Remove nuts, grommets, valve cover and gasket. Note location of grommets for

reassembly reference, as grommets must be installed in original location.

8. Remove bolts, and disconnect engine wiring harness protector from left side of intake manifold.

Disconnect electrical connectors at injectors, A/C compressor and crankshaft position sensor. Remove

engine wiring harness clamps from timing belt cover and generator drive belt adjusting bar.

9. Remove scuff plate from passenger-side door opening and passenger-side kick panel. Remove right side

cowl side trim and floor carpet center cover. Disconnect 2 electrical connectors from Engine Control

Module (ECM), and 2 electrical connectors on bracket. See Fig. 9

. Disconnect electrical connector for

relay box located behind passenger-side kick panel.

10. Disconnect engine wiring harness clamp located on engine wiring, near firewall. Pull engine wiring

harness out through firewall. Remove engine wiring harness from between cylinder head and intake

manifold.

11. Disconnect timing belt from camshaft timing pulley. Remove camshaft timing pulley. Remove No. 1 idler

pulley and tension spring. See TIMING BELT

. Remove 3 bolts and timing belt cover. See Fig. 14 .

After removing timing belt from camshaft sprocket, support timing belt so belt does not come off

crankshaft sprocket.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 18 © 2005 Mitchell Repair Information Company, LLC.

Page 705 of 1632

control cable to intake manifold. On all models, install NEW gasket and EGR valve with union nut and 2

nuts. Install vacuum modulator to clamp on intake manifold. Connect vacuum hoses to EGR VSV.

Connect fuel inlet hose to fuel filter

14. Connect vacuum sensor hose to gas filter, and brake booster vacuum hose to intake manifold. Install

throttle body. Install NEW "O" ring on coolant by-pass pipe, and NEW gasket on water pump cover

before installing coolant by-pass pipe. Apply soapy water solution to "O" ring before installing coolant

by-pass pipe. Install by-pass pipe.

15. Install NEW gasket and water outlet. Connect radiator, water by-pass and heater water hoses. Connect

ECT sensor and sender gauge connectors. Connect oil pressure switch.

16. Install ignition coils, manifold stay and spark plug wires. Connect wire clamp to manifold stay. Connect

spark plug wires to spark plugs and clamps on cylinder head cover. Connect ignition coil connectors.

17. Install 2 heat insulators. Install lower heat insulator. On California models, install A/F sensor to exhaust

manifold. All others, install oxygen sensor (bank 1 sensor 1) to exhaust manifold.

18. Using a new gasket, install exhaust manifold and heat insulator assembly. Install right-side exhaust

manifolds stay (California). Install left-side exhaust manifold stay. Install upper manifold heat insulator.

Connect A/F sensor connectors (California), or Oxygen sensor (bank 1 sensor 1).

19. Use NEW gasket and NEW nuts when installing front exhaust pipe. Ensure all bolts/nuts are loosely

installed on front exhaust pipe before tightening to specification. See TORQUE SPECIFICATIONS

20. Install generator and air cleaner and cap. Connect accelerator cable to throttle body and cable bracket. On

A/T models, connect throttle cable to throttle body and cable bracket. On all models, start engine and

check for leaks. Recheck engine coolant and oil level. Install right-side engine undercover.

CRANKSHAFT FRONT SEAL

Removal & Installation (Oil Pump Installed)

1. Remove timing belt and crankshaft sprocket. See TIMING BELT . Using a knife, cut lip from seal. Pry

seal from oil pump housing. DO NOT damage sealing surfaces.

2. To install, apply grease to lip of new seal. Using hammer and Seal Installer (SST 09226-10010), install

seal until seal surface is even with oil pump housing. To install remaining components, reverse removal

procedure.

Removal & Installation (Oil Pump Removed)

Using hammer and drift, remove seal from oil pump housing. To install, use hammer and Seal Installer (SST

09226-10010). Install seal until seal surface is even with oil pump housing. Apply grease to lip of new seal.

TIMING BELT

CAUTION: If reusing timing belt, mark direction of timing belt rotation, and place

reference mark on timing belt at camshaft sprocket for reassembly

reference. Also, place reference mark on timing belt at upper edge of No. 1

timing belt cover. DO NOT bend, twist or turn timing belt inside-out. DO

NOT expose timing to oil, water or steam.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 737 of 1632

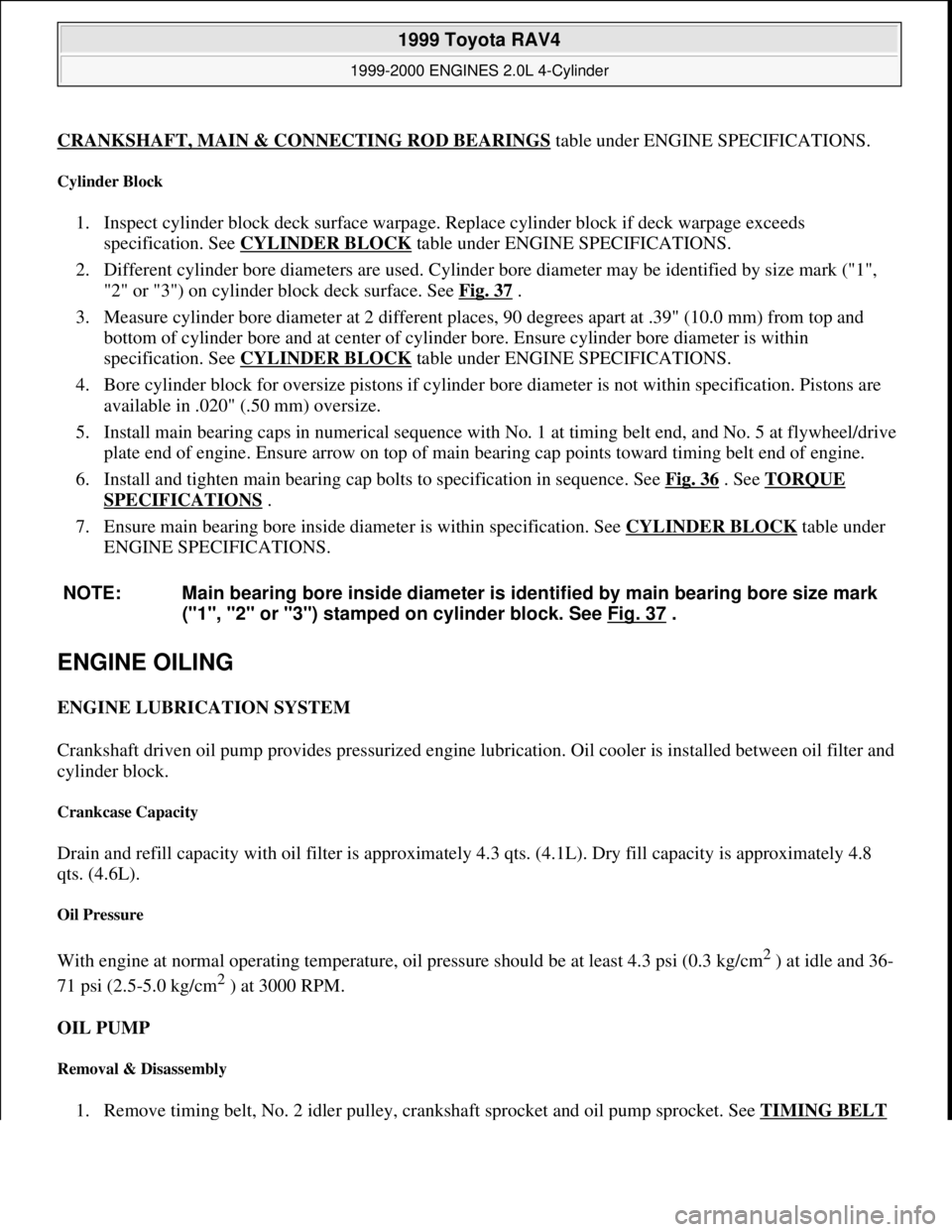

CRANKSHAFT, MAIN & CONNECTING ROD BEARINGStable under ENGINE SPECIFICATIONS.

Cylinder Block

1. Inspect cylinder block deck surface warpage. Replace cylinder block if deck warpage exceeds

specification. See CYLINDER BLOCK

table under ENGINE SPECIFICATIONS.

2. Different cylinder bore diameters are used. Cylinder bore diameter may be identified by size mark ("1",

"2" or "3") on cylinder block deck surface. See Fig. 37

.

3. Measure cylinder bore diameter at 2 different places, 90 degrees apart at .39" (10.0 mm) from top and

bottom of cylinder bore and at center of cylinder bore. Ensure cylinder bore diameter is within

specification. See CYLINDER BLOCK

table under ENGINE SPECIFICATIONS.

4. Bore cylinder block for oversize pistons if cylinder bore diameter is not within specification. Pistons are

available in .020" (.50 mm) oversize.

5. Install main bearing caps in numerical sequence with No. 1 at timing belt end, and No. 5 at flywheel/drive

plate end of engine. Ensure arrow on top of main bearing cap points toward timing belt end of engine.

6. Install and tighten main bearing cap bolts to specification in sequence. See Fig. 36

. See TORQUE

SPECIFICATIONS .

7. Ensure main bearing bore inside diameter is within specification. See CYLINDER BLOCK

table under

ENGINE SPECIFICATIONS.

ENGINE OILING

ENGINE LUBRICATION SYSTEM

Crankshaft driven oil pump provides pressurized engine lubrication. Oil cooler is installed between oil filter and

cylinder block.

Crankcase Capacity

Drain and refill capacity with oil filter is approximately 4.3 qts. (4.1L). Dry fill capacity is approximately 4.8

qts. (4.6L).

Oil Pressure

With engine at normal operating temperature, oil pressure should be at least 4.3 psi (0.3 kg/cm2 ) at idle and 36-

71 psi (2.5-5.0 kg/cm

2 ) at 3000 RPM.

OIL PUMP

Removal & Disassembly

1. Remove timing belt, No. 2 idler pulley, crankshaft sprocket and oil pump sprocket. See TIMING BELT

NOTE: Main bearing bore inside diameter is identified by main bearing bore size mark

("1", "2" or "3") stamped on cylinder block. See Fig. 37

.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 54 © 2005 Mitchell Repair Information Company, LLC.

Page 739 of 1632

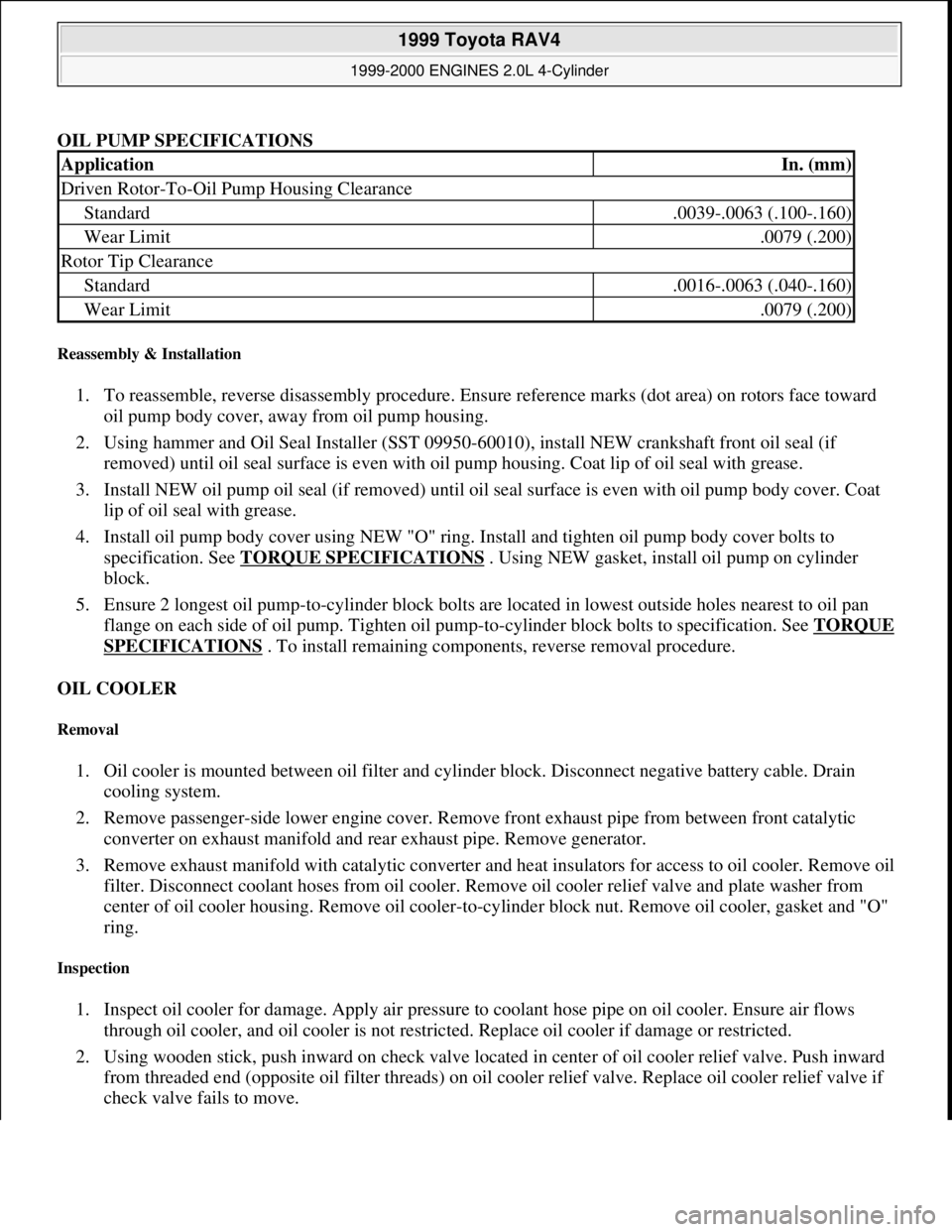

OIL PUMP SPECIFICATIONS

Reassembly & Installation

1. To reassemble, reverse disassembly procedure. Ensure reference marks (dot area) on rotors face toward

oil pump body cover, away from oil pump housing.

2. Using hammer and Oil Seal Installer (SST 09950-60010), install NEW crankshaft front oil seal (if

removed) until oil seal surface is even with oil pump housing. Coat lip of oil seal with grease.

3. Install NEW oil pump oil seal (if removed) until oil seal surface is even with oil pump body cover. Coat

lip of oil seal with grease.

4. Install oil pump body cover using NEW "O" ring. Install and tighten oil pump body cover bolts to

specification. See TORQUE SPECIFICATIONS

. Using NEW gasket, install oil pump on cylinder

block.

5. Ensure 2 longest oil pump-to-cylinder block bolts are located in lowest outside holes nearest to oil pan

flange on each side of oil pump. Tighten oil pump-to-cylinder block bolts to specification. See TORQUE

SPECIFICATIONS . To install remaining components, reverse removal procedure.

OIL COOLER

Removal

1. Oil cooler is mounted between oil filter and cylinder block. Disconnect negative battery cable. Drain

cooling system.

2. Remove passenger-side lower engine cover. Remove front exhaust pipe from between front catalytic

converter on exhaust manifold and rear exhaust pipe. Remove generator.

3. Remove exhaust manifold with catalytic converter and heat insulators for access to oil cooler. Remove oil

filter. Disconnect coolant hoses from oil cooler. Remove oil cooler relief valve and plate washer from

center of oil cooler housing. Remove oil cooler-to-cylinder block nut. Remove oil cooler, gasket and "O"

ring.

Inspection

1. Inspect oil cooler for damage. Apply air pressure to coolant hose pipe on oil cooler. Ensure air flows

through oil cooler, and oil cooler is not restricted. Replace oil cooler if damage or restricted.

2. Using wooden stick, push inward on check valve located in center of oil cooler relief valve. Push inward

from threaded end (opposite oil filter threads) on oil cooler relief valve. Replace oil cooler relief valve if

check valve fails to move.

ApplicationIn. (mm)

Driven Rotor-To-Oil Pump Housing Clearance

Standard.0039-.0063 (.100-.160)

Wear Limit.0079 (.200)

Rotor Tip Clearance

Standard.0016-.0063 (.040-.160)

Wear Limit.0079 (.200)

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 56 © 2005 Mitchell Repair Information Company, LLC.

Page 741 of 1632

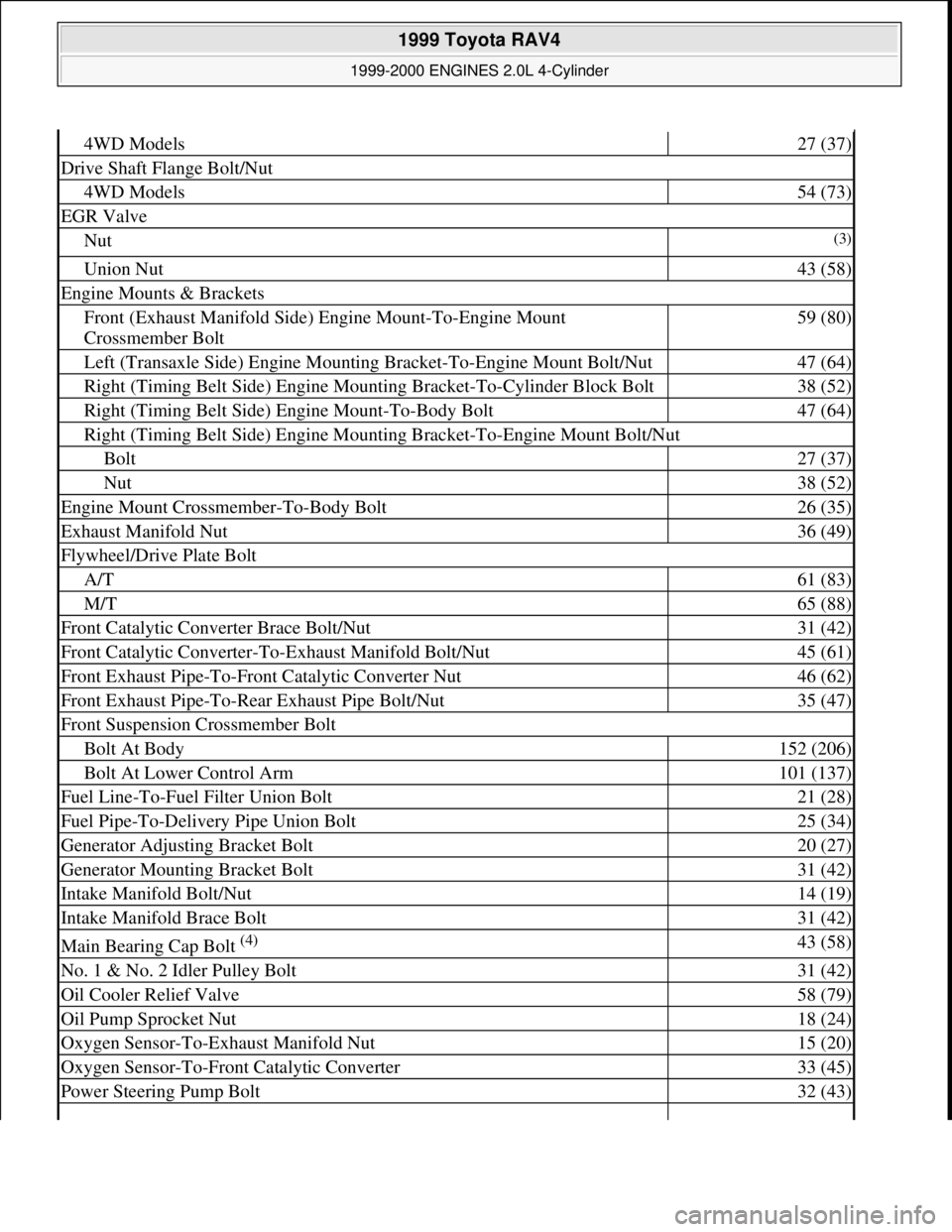

4WD Models27 (37)

Drive Shaft Flange Bolt/Nut

4WD Models54 (73)

EGR Valve

Nut(3)

Union Nut43 (58)

Engine Mounts & Brackets

Front (Exhaust Manifold Side) Engine Mount-To-Engine Mount

Crossmember Bolt59 (80)

Left (Transaxle Side) Engine Mounting Bracket-To-Engine Mount Bolt/Nut47 (64)

Right (Timing Belt Side) Engine Mounting Bracket-To-Cylinder Block Bolt38 (52)

Right (Timing Belt Side) Engine Mount-To-Body Bolt47 (64)

Right (Timing Belt Side) Engine Mounting Bracket-To-Engine Mount Bolt/Nut

Bolt27 (37)

Nut38 (52)

Engine Mount Crossmember-To-Body Bolt26 (35)

Exhaust Manifold Nut36 (49)

Flywheel/Drive Plate Bolt

A/T61 (83)

M/T65 (88)

Front Catalytic Converter Brace Bolt/Nut31 (42)

Front Catalytic Converter-To-Exhaust Manifold Bolt/Nut45 (61)

Front Exhaust Pipe-To-Front Catalytic Converter Nut46 (62)

Front Exhaust Pipe-To-Rear Exhaust Pipe Bolt/Nut35 (47)

Front Suspension Crossmember Bolt

Bolt At Body152 (206)

Bolt At Lower Control Arm101 (137)

Fuel Line-To-Fuel Filter Union Bolt21 (28)

Fuel Pipe-To-Delivery Pipe Union Bolt25 (34)

Generator Adjusting Bracket Bolt20 (27)

Generator Mounting Bracket Bolt31 (42)

Intake Manifold Bolt/Nut14 (19)

Intake Manifold Brace Bolt31 (42)

Main Bearing Cap Bolt (4) 43 (58)

No. 1 & No. 2 Idler Pulley Bolt31 (42)

Oil Cooler Relief Valve58 (79)

Oil Pump Sprocket Nut18 (24)

Oxygen Sensor-To-Exhaust Manifold Nut15 (20)

Oxygen Sensor-To-Front Catalytic Converter33 (45)

Power Steering Pump Bolt32 (43)

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 58 © 2005 Mitchell Repair Information Company, LLC.

Page 765 of 1632

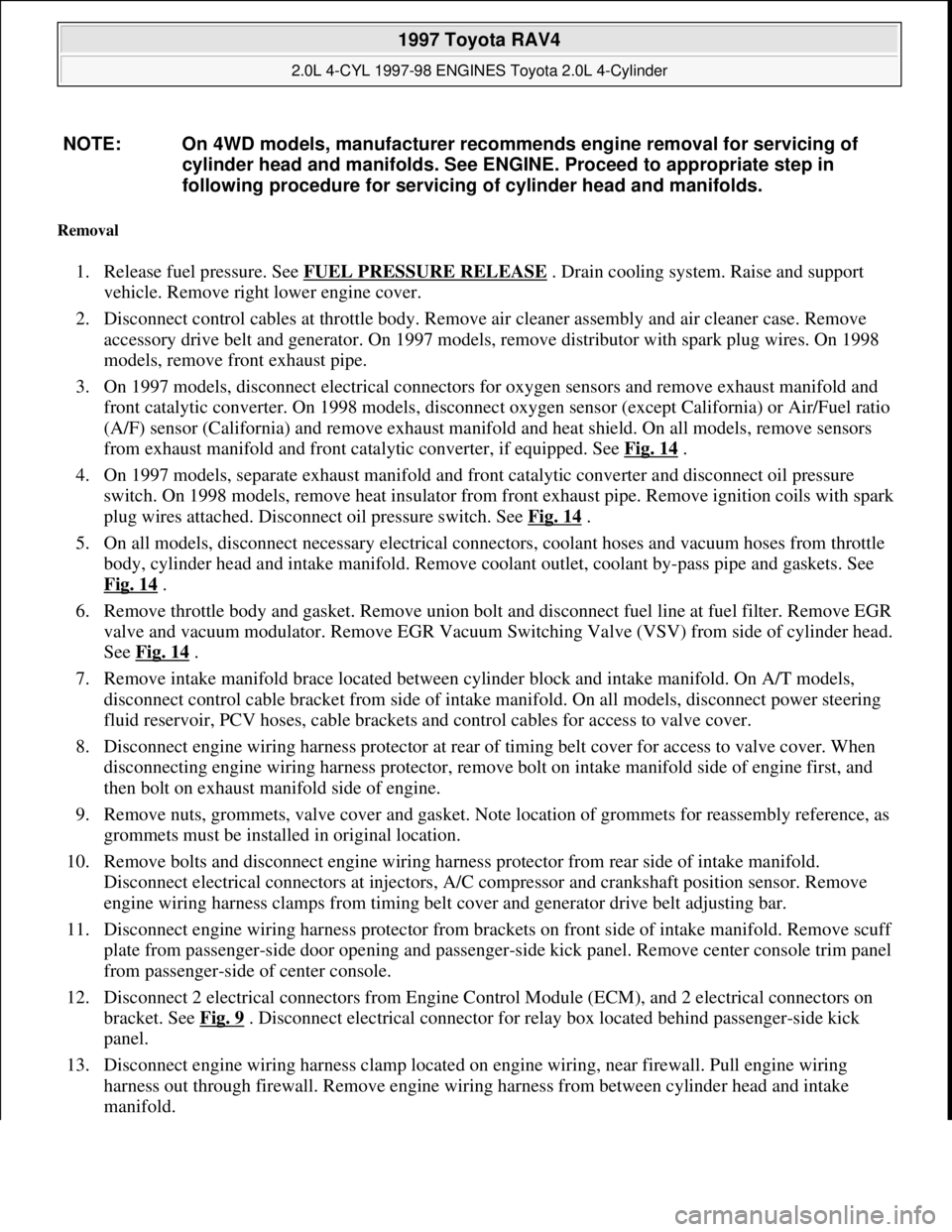

Removal

1. Release fuel pressure. See FUEL PRESSURE RELEASE . Drain cooling system. Raise and support

vehicle. Remove right lower engine cover.

2. Disconnect control cables at throttle body. Remove air cleaner assembly and air cleaner case. Remove

accessory drive belt and generator. On 1997 models, remove distributor with spark plug wires. On 1998

models, remove front exhaust pipe.

3. On 1997 models, disconnect electrical connectors for oxygen sensors and remove exhaust manifold and

front catalytic converter. On 1998 models, disconnect oxygen sensor (except California) or Air/Fuel ratio

(A/F) sensor (California) and remove exhaust manifold and heat shield. On all models, remove sensors

from exhaust manifold and front catalytic converter, if equipped. See Fig. 14

.

4. On 1997 models, separate exhaust manifold and front catalytic converter and disconnect oil pressure

switch. On 1998 models, remove heat insulator from front exhaust pipe. Remove ignition coils with spark

plug wires attached. Disconnect oil pressure switch. See Fig. 14

.

5. On all models, disconnect necessary electrical connectors, coolant hoses and vacuum hoses from throttle

body, cylinder head and intake manifold. Remove coolant outlet, coolant by-pass pipe and gaskets. See

Fig. 14

.

6. Remove throttle body and gasket. Remove union bolt and disconnect fuel line at fuel filter. Remove EGR

valve and vacuum modulator. Remove EGR Vacuum Switching Valve (VSV) from side of cylinder head.

See Fig. 14

.

7. Remove intake manifold brace located between cylinder block and intake manifold. On A/T models,

disconnect control cable bracket from side of intake manifold. On all models, disconnect power steering

fluid reservoir, PCV hoses, cable brackets and control cables for access to valve cover.

8. Disconnect engine wiring harness protector at rear of timing belt cover for access to valve cover. When

disconnecting engine wiring harness protector, remove bolt on intake manifold side of engine first, and

then bolt on exhaust manifold side of engine.

9. Remove nuts, grommets, valve cover and gasket. Note location of grommets for reassembly reference, as

grommets must be installed in original location.

10. Remove bolts and disconnect engine wiring harness protector from rear side of intake manifold.

Disconnect electrical connectors at injectors, A/C compressor and crankshaft position sensor. Remove

engine wiring harness clamps from timing belt cover and generator drive belt adjusting bar.

11. Disconnect engine wiring harness protector from brackets on front side of intake manifold. Remove scuff

plate from passenger-side door opening and passenger-side kick panel. Remove center console trim panel

from passenger-side of center console.

12. Disconnect 2 electrical connectors from Engine Control Module (ECM), and 2 electrical connectors on

bracket. See Fig. 9

. Disconnect electrical connector for relay box located behind passenger-side kick

panel.

13. Disconnect engine wiring harness clamp located on engine wiring, near firewall. Pull engine wiring

harness out through firewall. Remove engine wiring harness from between cylinder head and intake

manifold. NOTE: On 4WD models, manufacturer recommends engine removal for servicing of

cylinder head and manifolds. See ENGINE. Proceed to appropriate step in

following procedure for servicing of cylinder head and manifolds.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 805 of 1632

CRANKSHAFT, MAIN & CONNECTING ROD BEARINGSunder ENGINE SPECIFICATIONS.

Cylinder Block

1. Inspect cylinder block deck surface warpage. Replace cylinder block if deck warpage exceeds

specification. See CYLINDER BLOCK

under ENGINE SPECIFICATIONS.

2. Different cylinder bore diameters are used. Cylinder bore diameter may be identified by size mark ("1",

"2" or "3") on cylinder block deck surface. See Fig. 39

.

3. Measure cylinder bore diameter at 2 different places, 90 degrees apart at .39" (10.0 mm) from top and

bottom of cylinder bore and at center of cylinder bore. Ensure cylinder bore diameter is within

specification. See CYLINDER BLOCK

under ENGINE SPECIFICATIONS.

4. Bore cylinder block for oversize pistons if cylinder bore diameter is not within specification. Pistons are

available in .020" (.50 mm) oversize.

5. Install main bearing caps in numerical sequence with No. 1 at timing belt end and No. 5 at flywheel/drive

plate end of engine. Ensure arrow on top of main bearing cap points toward timing belt end of engine.

6. Install and tighten main bearing cap bolts to specification in sequence. See Fig. 38

. See TORQUE

SPECIFICATIONS .

7. Ensure main bearing bore inside diameter is within specification. See CYLINDER BLOCK

under

ENGINE SPECIFICATIONS.

ENGINE OILING

ENGINE LUBRICATION SYSTEM

Crankshaft driven oil pump provides pressurized engine lubrication. Oil cooler is installed between oil filter and

cylinder block.

Crankcase Capacity

On 1997 models, drain and refill capacity with oil filter is approximately 4.1 qts. (3.9L). Dry fill capacity is

approximately 4.7 qts. (4.4L). On 1998 models, drain and refill capacity with oil filter is approximately 4.3 qts.

(4.1L). Dry fill capacity is approximately 4.8 qts. (4.6L).

Oil Pressure

With engine at normal operating temperature, oil pressure should be at least 4.3 psi (0.3 kg/cm2 ) at idle and 36-

71 psi (2.5-5.0 kg/cm

2 ) at 3000 RPM.

OIL PUMP

Removal & Disassembly

NOTE: Main bearing bore inside diameter is identified by main bearing bore size mark

("1", "2" or "3") stamped on cylinder block. See Fig. 39

.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 57 © 2005 Mitchell Repair Information Company, LLC.

Page 807 of 1632

drive rotor is on outside of rotor and tip of driven rotor is on inside of rotor. Replace rotor assembly if

clearance exceeds specification. See OIL PUMP SPECIFICATIONS

.

OIL PUMP SPECIFICATIONS

Reassembly & Installation

1. To reassemble, reverse disassembly procedure. Ensure reference marks (dot area) on rotors face toward

oil pump body cover, away from oil pump housing.

2. Using hammer and Oil Seal Installer (SST 09226-10010), install NEW crankshaft front oil seal (if

removed) until oil seal surface is even with oil pump housing. Coat lip of oil seal with grease.

3. Install NEW oil pump oil seal (if removed) until oil seal surface is even with oil pump body cover. Coat

lip of oil seal with grease.

4. Install oil pump body cover using NEW "O" ring. Install and tighten oil pump body cover bolts to

specification. See TORQUE SPECIFICATIONS

. Using NEW gasket, install oil pump on cylinder

block using NEW gasket.

5. Ensure 2 longest oil pump-to-cylinder block bolts are located in lowest outside holes nearest to oil pan

flange on each side of oil pump. Tighten oil pump-to-cylinder block bolts to specification. See TORQUE

SPECIFICATIONS . To install remaining components, reverse removal procedure.

OIL COOLER

Removal

1. Oil cooler is mounted between oil filter and cylinder block. Disconnect negative battery cable. Drain

cooling system.

2. Remove passenger-side lower engine cover. Remove front exhaust pipe that fits between front catalytic

converter on exhaust manifold and rear exhaust pipe. Remove generator.

3. Remove exhaust manifold with catalytic converter and heat insulators for access to oil cooler. Remove oil

filter. Disconnect coolant hoses from oil cooler. Remove oil cooler relief valve and plate washer from

center of oil cooler housing. Remove oil cooler-to-cylinder block nut. Remove oil cooler, gasket and "O"

ring.

Inspection

1. Inspect oil cooler for damage. Apply air pressure on coolant hose pipe on oil cooler. Ensure air flows

through oil cooler and oil cooler is not restricted. Replace oil cooler if damage or restricted.

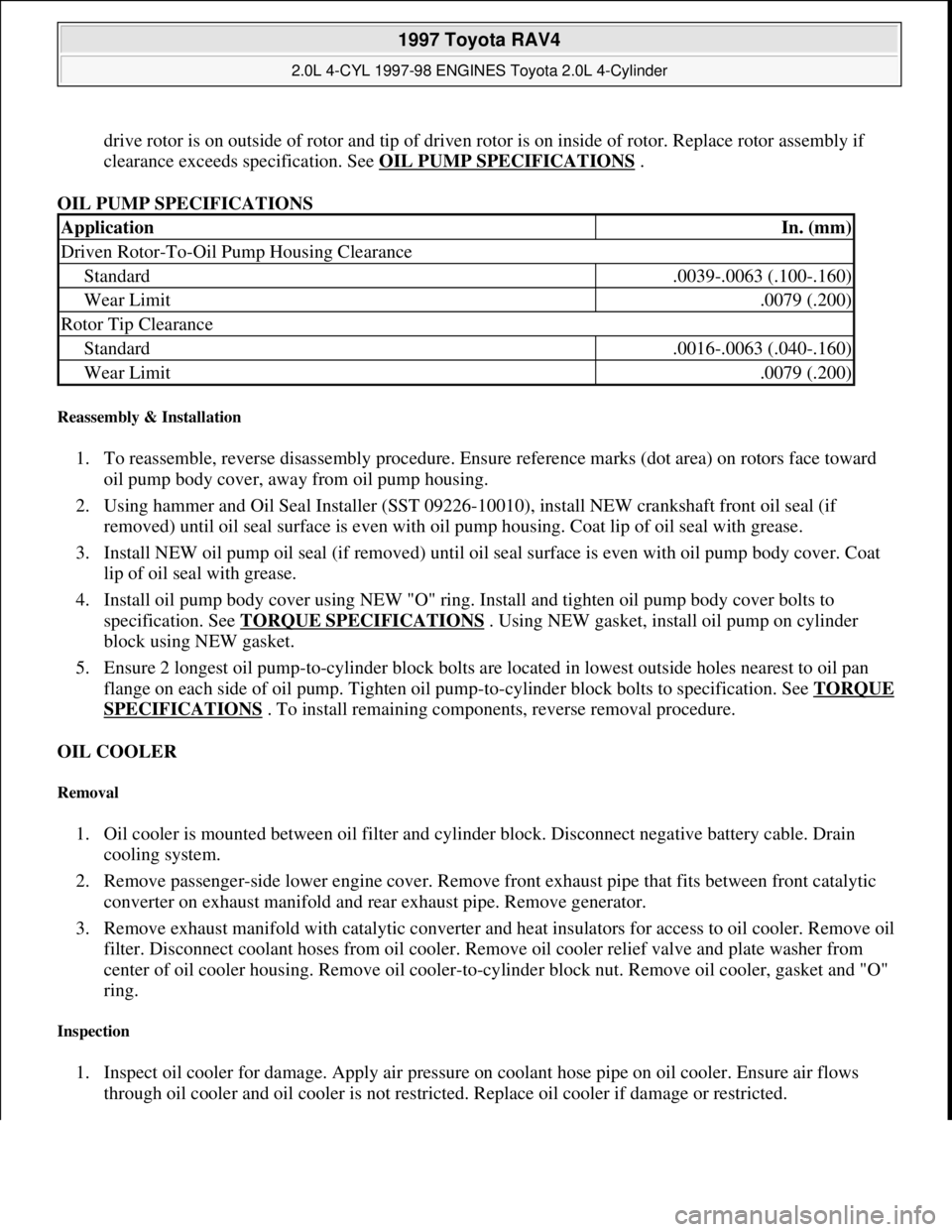

ApplicationIn. (mm)

Driven Rotor-To-Oil Pump Housing Clearance

Standard.0039-.0063 (.100-.160)

Wear Limit.0079 (.200)

Rotor Tip Clearance

Standard.0016-.0063 (.040-.160)

Wear Limit.0079 (.200)

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 59 © 2005 Mitchell Repair Information Company, LLC.