drain bolt TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 113 of 1632

TRANSMISSION SERVICING - A/T

1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal & Installation

REMOVAL & INSTALLATION

MANUAL

AUTOMATIC

Removal (Avalon)

1. Disconnect negative battery cable. Remove battery, battery tray, air cleaner assembly and air cleaner case.

Disconnect throttle valve cable from throttle body. Remove cruise control actuator with mounting

bracket.

2. Raise and support vehicle. Disconnect necessary electrical connectors and ground cables for transaxle

removal. Disconnect shift cable and oil cooler lines at transaxle. Remove shift cable clamp bracket from

transaxle.

3. Remove front (radiator side) engine mount shock absorber-to-lower frame assembly bolts. Remove front

(radiator side) engine mount-to-lower frame assembly bolts/nuts. Remove starter.

4. Remove front (radiator side) exhaust manifold brace from rear of exhaust manifolds. Brace fits between

rear of exhaust manifold and front of transaxle.

5. Remove upper transaxle-to-cylinder block bolts. Support engine with hoist. Steering gear assembly must

be supported in place during transaxle removal. Secure steering gear assembly to the engine hoist using

an attaching strap placed at each end of steering gear assembly.

6. Remove front wheels. Remove front exhaust pipe located between exhaust manifolds and rear exhaust

pipe. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD AXLE SHAFTS article in

DRIVE AXLES.

7. Disconnect shift control cable from mounting bracket. Remove rear (firewall side) engine mount-to-lower

frame assembly bolts/nuts. Remove transaxle mount-to-transaxle bolts at driver's side end of transaxle.

8. Remove stabilizer bar mount bracket-to-lower frame assembly bolts. Remove steering gear assembly-to-

lower frame assembly bolts/nuts. Support lower frame assembly with floor jack. Lower frame assembly is

located below the en

gine and transaxle. NOTE: For manual transmission/transaxle removal and installation procedures, see

appropriate CLUTCHES article.

WARNING:Ensure negative battery cable is disconnected at least 90 seconds before

working on vehicle to prevent air bag deployment.

CAUTION: When battery is disconnected, vehicle computer and memory systems

may lose memory data. Driveability problems may exist until computer

systems have completed a relearn cycle.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Helpmelearn

November-03-08 10:30:32 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 115 of 1632

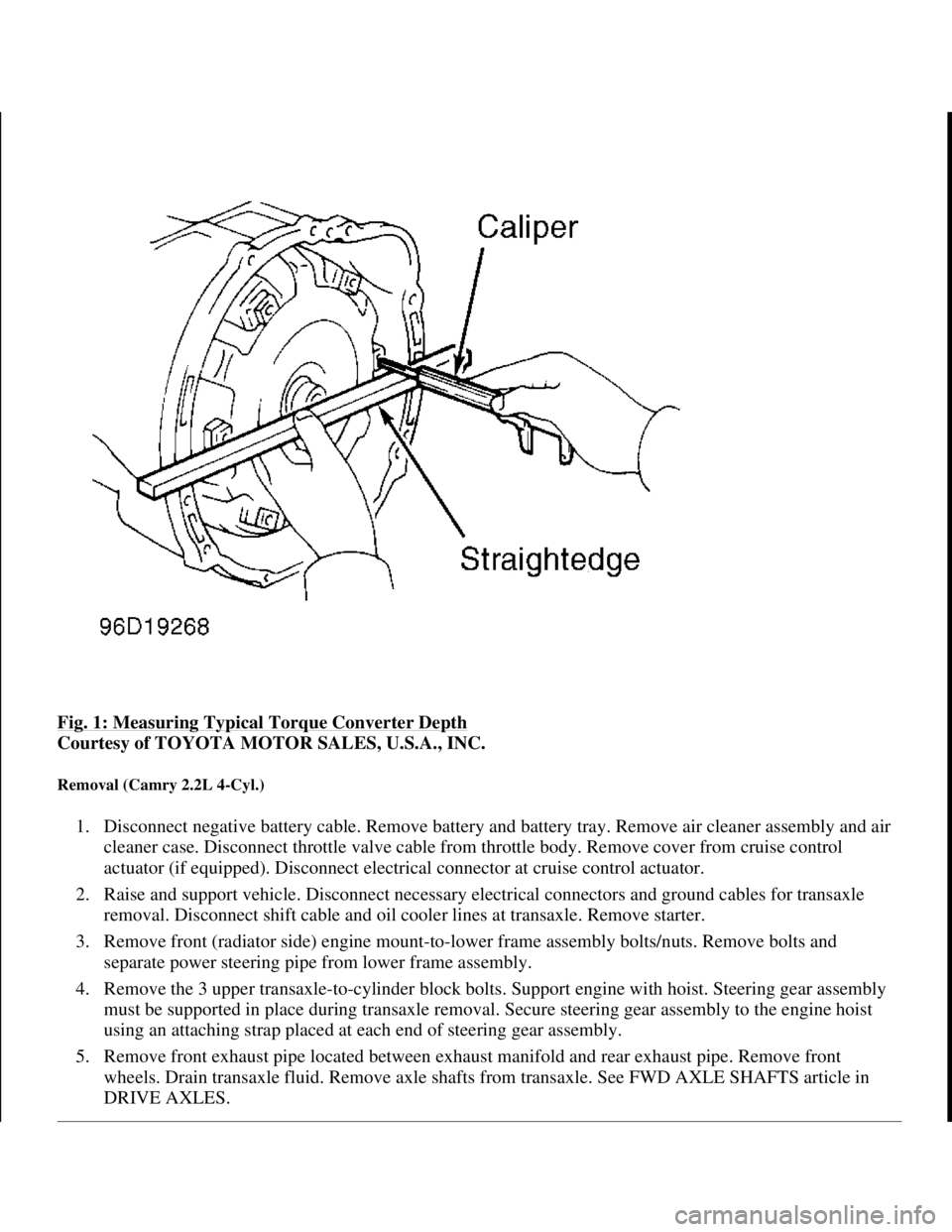

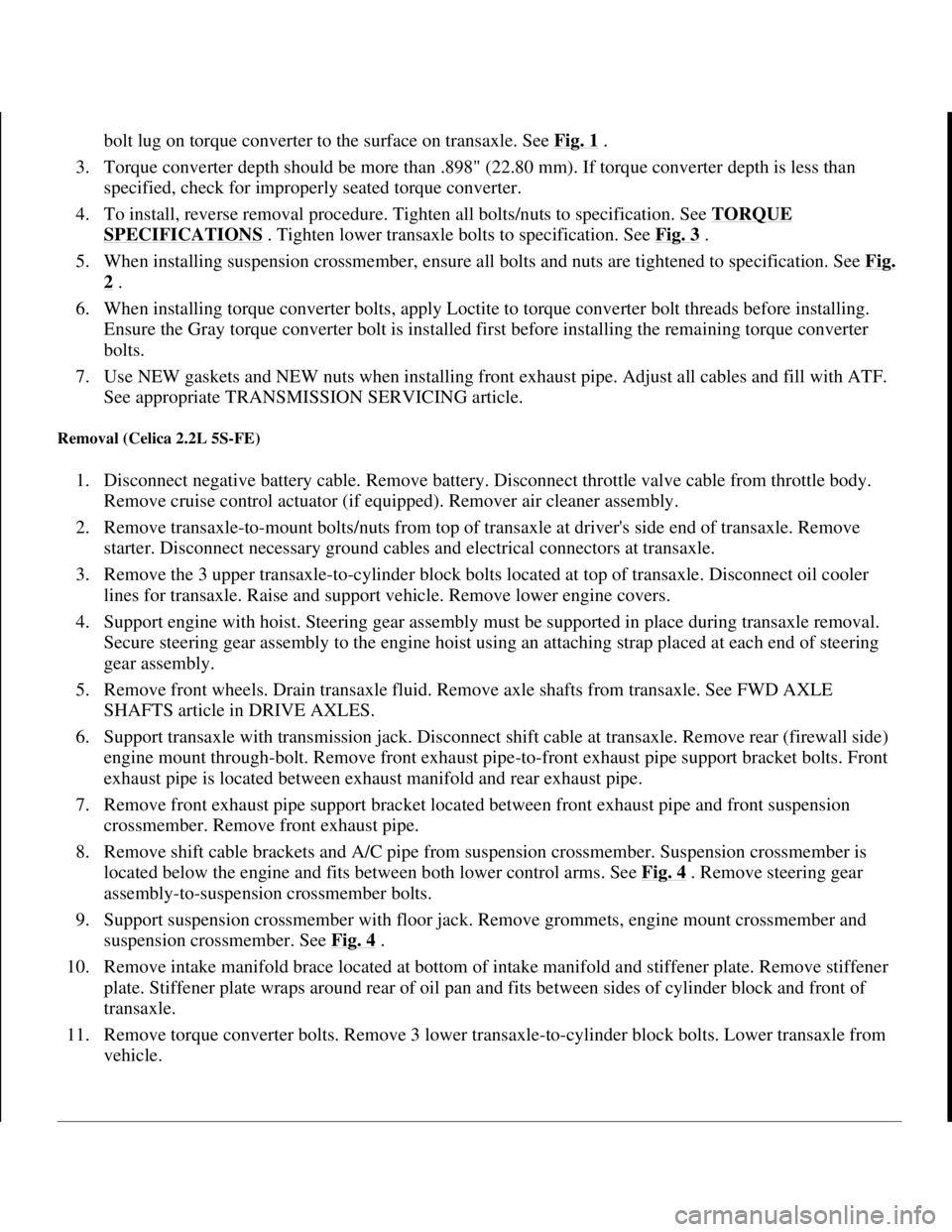

Fig. 1: Measuring Typical Torque Converter Depth

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Removal (Camry 2.2L 4-Cyl.)

1. Disconnect negative battery cable. Remove battery and battery tray. Remove air cleaner assembly and air

cleaner case. Disconnect throttle valve cable from throttle body. Remove cover from cruise control

actuator (if equipped). Disconnect electrical connector at cruise control actuator.

2. Raise and support vehicle. Disconnect necessary electrical connectors and ground cables for transaxle

removal. Disconnect shift cable and oil cooler lines at transaxle. Remove starter.

3. Remove front (radiator side) engine mount-to-lower frame assembly bolts/nuts. Remove bolts and

separate power steering pipe from lower frame assembly.

4. Remove the 3 upper transaxle-to-cylinder block bolts. Support engine with hoist. Steering gear assembly

must be supported in place during transaxle removal. Secure steering gear assembly to the engine hoist

using an attaching strap placed at each end of steering gear assembly.

5. Remove front exhaust pipe located between exhaust manifold and rear exhaust pipe. Remove front

wheels. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD AXLE SHAFTS article in

DRIVE AXLES.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 117 of 1632

pipe. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD AXLE SHAFTS article in

DRIVE AXLES.

6. Remove rear (firewall side) engine mount-to-lower frame assembly bolts/nuts. Remove transaxle mount-

to-transaxle bolts at driver's side end of transaxle.

7. Remove stabilizer bar mount bracket-to-lower frame assembly bolts. Remove steering gear assembly-to-

lower frame assembly bolts/nuts. Support lower frame assembly with floor jack. Lower frame assembly is

located below the engine and transaxle.

8. Remove bolts for each fender liner from lower frame assembly. Remove lower frame assembly mounting

brackets. Lower frame assembly mounting brackets are located on the front and rear of lower frame

assembly attaching the lower frame assembly to the body. Remove lower frame assembly.

9. Support transaxle with transmission jack. Remove torque converter cover from front of transaxle.

Remove torque converter bolts. Remove exhaust manifold support brace from rear of exhaust manifold.

Remove remaining transaxle-to-cylinder block bolts. Lower transaxle from vehicle.

Installation

1. Before installing transaxle, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transaxle. To ensure torque converter is fully seated, torque converter depth

should be checked. Using straightedge and caliper, measure torque converter depth from torque converter

bolt lug on torque converter to the surface on transaxle. See Fig. 1

.

3. Torque converter depth should be more than .539" (13.70 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Ensure the Black torque converter bolt is installed first before installing the

remaining torque converter bolts.

5. Use NEW gaskets when installing front exhaust pipe. Adjust all cables and fill with ATF. See appropriate

TRANSMISSION SERVICING article.

Removal (Celica 1.8L 7A-FE)

1. Disconnect negative battery cable. Remove transaxle oil dipstick and battery. Disconnect throttle cable

valve from throttle body. Remover air cleaner assembly. Remove transaxle-to-mount nut from top of

transaxle at driver's side end of transaxle.

2. Remove throttle valve cable mounting bracket and wiring harness clamp bolts from top of transaxle.

Remove upper mounting bolt from starter. Remove the 2 upper transaxle-to-cylinder block bolts located

at top of transaxle.

3. Remove transaxle oil dipstick tube and "O" ring from transaxle. Raise and support vehicle. Remove lower

engine covers. Disconnect necessary electrical connectors and ground cables for transaxle removal.

Disconnect oil cooler lines for transaxle.

4. Support engine with hoist. Steering gear assembly must be supported in place during transaxle removal.

Secure steering gear assembly to the engine hoist using an attaching strap placed at each end of steering

gear assembly.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 118 of 1632

5. Remove front wheels. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD AXLE

SHAFTS article in DRIVE AXLES.

6. Support transaxle with transmission jack. Remove rear (firewall side) engine mount through-bolt.

Remove front exhaust pipe-to-front exhaust pipe support bracket bolts. Front exhaust pipe is located

between exhaust manifold and rear exhaust pipe. Remove front exhaust pipe support bracket located

between front exhaust pipe and front suspension crossmember.

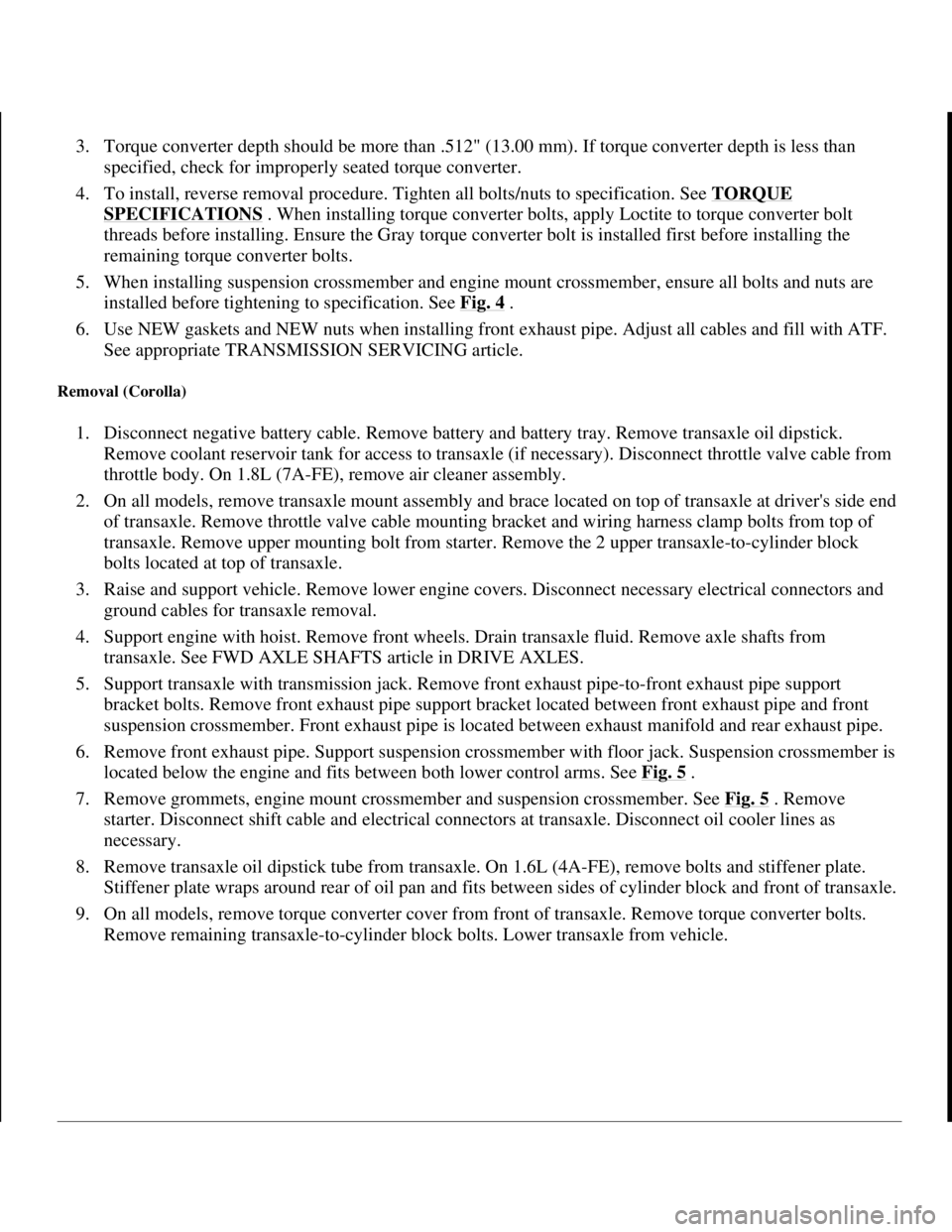

7. Remove steering gear assembly-to-suspension crossmember bolts. Remove front exhaust pipe. Remove

shift cable brackets and the A/C pipe from suspension crossmember. Suspension crossmember is located

below the engine and fits between both lower control arms. See Fig. 2

.

8. Remove engine mount crossmember located below the oil pan. Engine mount crossmember holds the

front and rear engine mounts, and is bolted to the body and suspension crossmember.

9. Support suspension crossmember with floor jack. Remove suspension crossmember bolts. See Fig. 2

.

Remove suspension crossmember. Remove starter. Disconnect shift cable and electrical connectors at

transaxle.

10. Remove torque converter cover from front of transaxle. Remove torque converter bolts. Remove

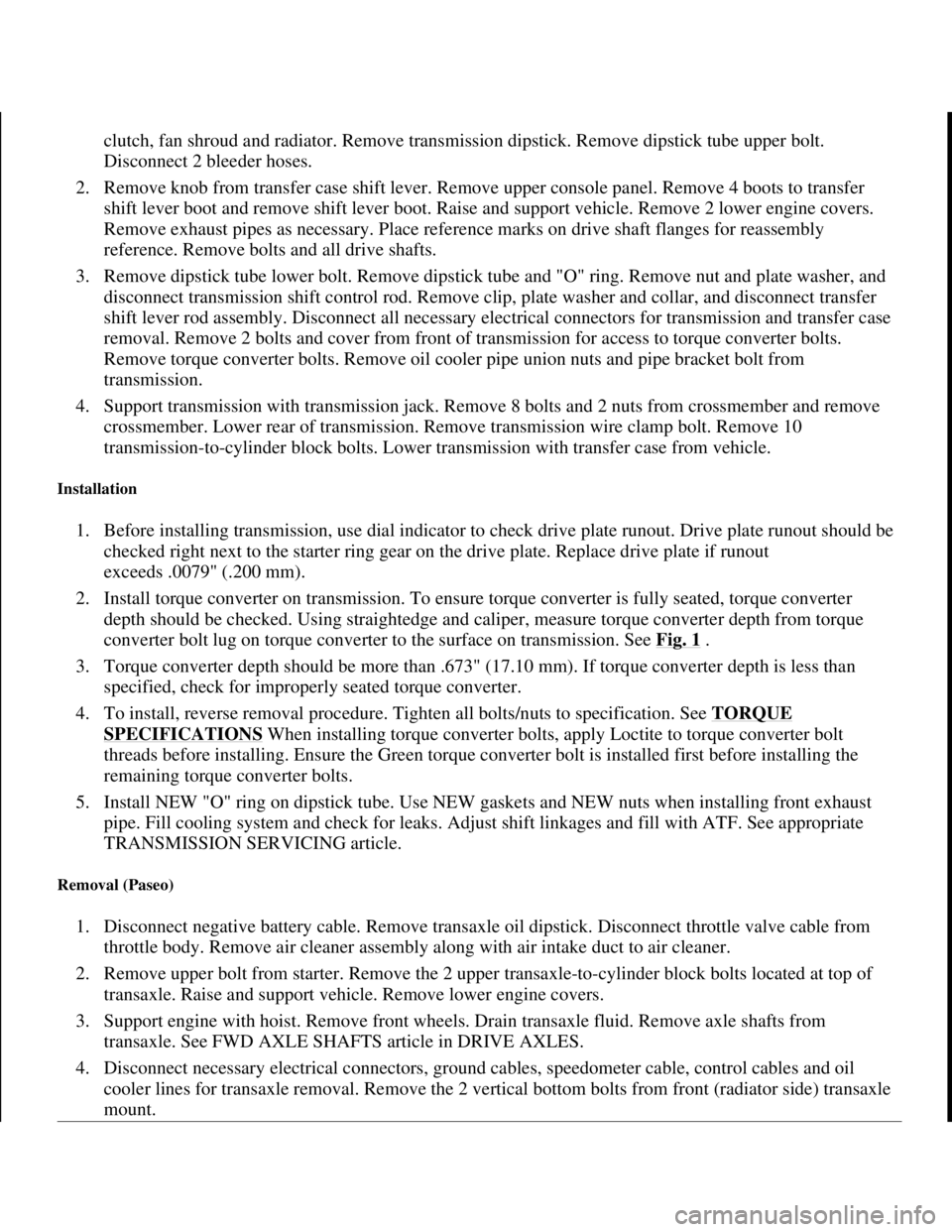

transaxle-to-mount bolts from top of transaxle at driver's side end of transaxle. Remove the 5 lower

transaxle-to-c

ylinder block bolts. See Fig. 3. Lower transaxle from vehicle.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 121 of 1632

bolt lug on torque converter to the surface on transaxle. See Fig. 1.

3. Torque converter depth should be more than .898" (22.80 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . Tighten lower transaxle bolts to specification. See Fig. 3 .

5. When installing suspension crossmember, ensure all bolts and nuts are tightened to specification. See Fi

g.

2 .

6. When installing torque converter bolts, apply Loctite to torque converter bolt threads before installing.

Ensure the Gray torque converter bolt is installed first before installing the remaining torque converter

bolts.

7. Use NEW gaskets and NEW nuts when installing front exhaust pipe. Adjust all cables and fill with ATF.

See appropriate TRANSMISSION SERVICING article.

Removal (Celica 2.2L 5S-FE)

1. Disconnect negative battery cable. Remove battery. Disconnect throttle valve cable from throttle body.

Remove cruise control actuator (if equipped). Remover air cleaner assembly.

2. Remove transaxle-to-mount bolts/nuts from top of transaxle at driver's side end of transaxle. Remove

starter. Disconnect necessary ground cables and electrical connectors at transaxle.

3. Remove the 3 upper transaxle-to-cylinder block bolts located at top of transaxle. Disconnect oil cooler

lines for transaxle. Raise and support vehicle. Remove lower engine covers.

4. Support engine with hoist. Steering gear assembly must be supported in place during transaxle removal.

Secure steering gear assembly to the engine hoist using an attaching strap placed at each end of steering

gear assembly.

5. Remove front wheels. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD AXLE

SHAFTS article in DRIVE AXLES.

6. Support transaxle with transmission jack. Disconnect shift cable at transaxle. Remove rear (firewall side)

engine mount through-bolt. Remove front exhaust pipe-to-front exhaust pipe support bracket bolts. Front

exhaust pipe is located between exhaust manifold and rear exhaust pipe.

7. Remove front exhaust pipe support bracket located between front exhaust pipe and front suspension

crossmember. Remove front exhaust pipe.

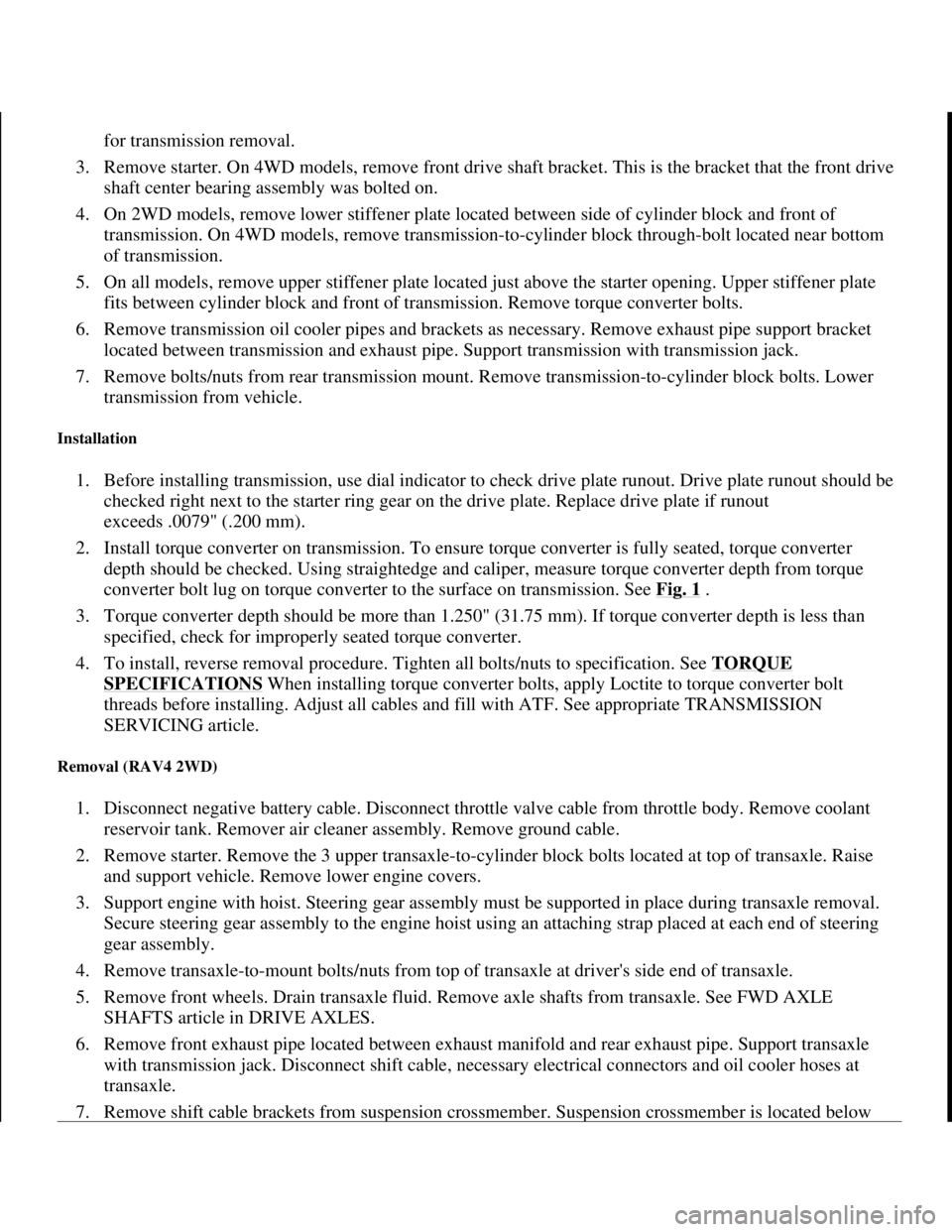

8. Remove shift cable brackets and A/C pipe from suspension crossmember. Suspension crossmember is

located below the engine and fits between both lower control arms. See Fig. 4

. Remove steering gear

assembly-to-suspension crossmember bolts.

9. Support suspension crossmember with floor jack. Remove grommets, engine mount crossmember and

suspension crossmember. See Fig. 4

.

10. Remove intake manifold brace located at bottom of intake manifold and stiffener plate. Remove stiffener

plate. Stiffener plate wraps around rear of oil pan and fits between sides of cylinder block and front of

transaxle.

11. Remove torque converter bolts. Remove 3 lower transaxle-to-cylinder block bolts. Lower transaxle from

vehicle.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 123 of 1632

3. Torque converter depth should be more than .512" (13.00 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Ensure the Gray torque converter bolt is installed first before installing the

remaining torque converter bolts.

5. When installing suspension crossmember and engine mount crossmember, ensure all bolts and nuts are

installed before tightening to specification. See Fig. 4

.

6. Use NEW gaskets and NEW nuts when installing front exhaust pipe. Adjust all cables and fill with ATF.

See appropriate TRANSMISSION SERVICING article.

Removal (Corolla)

1. Disconnect negative battery cable. Remove battery and battery tray. Remove transaxle oil dipstick.

Remove coolant reservoir tank for access to transaxle (if necessary). Disconnect throttle valve cable from

throttle body. On 1.8L (7A-FE), remove air cleaner assembly.

2. On all models, remove transaxle mount assembly and brace located on top of transaxle at driver's side end

of transaxle. Remove throttle valve cable mounting bracket and wiring harness clamp bolts from top of

transaxle. Remove upper mounting bolt from starter. Remove the 2 upper transaxle-to-cylinder block

bolts located at top of transaxle.

3. Raise and support vehicle. Remove lower engine covers. Disconnect necessary electrical connectors and

ground cables for transaxle removal.

4. Support engine with hoist. Remove front wheels. Drain transaxle fluid. Remove axle shafts from

transaxle. See FWD AXLE SHAFTS article in DRIVE AXLES.

5. Support transaxle with transmission jack. Remove front exhaust pipe-to-front exhaust pipe support

bracket bolts. Remove front exhaust pipe support bracket located between front exhaust pipe and front

suspension crossmember. Front exhaust pipe is located between exhaust manifold and rear exhaust pipe.

6. Remove front exhaust pipe. Support suspension crossmember with floor jack. Suspension crossmember is

located below the engine and fits between both lower control arms. See Fig. 5

.

7. Remove grommets, engine mount crossmember and suspension crossmember. See Fig. 5

. Remove

starter. Disconnect shift cable and electrical connectors at transaxle. Disconnect oil cooler lines as

necessary.

8. Remove transaxle oil dipstick tube from transaxle. On 1.6L (4A-FE), remove bolts and stiffener plate.

Stiffener plate wraps around rear of oil pan and fits between sides of cylinder block and front of transaxle.

9. On all models, remove torque converter cover from front of transaxle. Remove torque converter bolts.

Remove remainin

g transaxle-to-cylinder block bolts. Lower transaxle from vehicle.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 11 © 2005 Mitchell Repair Information Company, LLC.

Page 128 of 1632

clutch, fan shroud and radiator. Remove transmission dipstick. Remove dipstick tube upper bolt.

Disconnect 2 bleeder hoses.

2. Remove knob from transfer case shift lever. Remove upper console panel. Remove 4 boots to transfer

shift lever boot and remove shift lever boot. Raise and support vehicle. Remove 2 lower engine covers.

Remove exhaust pipes as necessary. Place reference marks on drive shaft flanges for reassembly

reference. Remove bolts and all drive shafts.

3. Remove dipstick tube lower bolt. Remove dipstick tube and "O" ring. Remove nut and plate washer, and

disconnect transmission shift control rod. Remove clip, plate washer and collar, and disconnect transfer

shift lever rod assembly. Disconnect all necessary electrical connectors for transmission and transfer case

removal. Remove 2 bolts and cover from front of transmission for access to torque converter bolts.

Remove torque converter bolts. Remove oil cooler pipe union nuts and pipe bracket bolt from

transmission.

4. Support transmission with transmission jack. Remove 8 bolts and 2 nuts from crossmember and remove

crossmember. Lower rear of transmission. Remove transmission wire clamp bolt. Remove 10

transmission-to-cylinder block bolts. Lower transmission with transfer case from vehicle.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than .673" (17.10 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Ensure the Green torque converter bolt is installed first before installing the

remaining torque converter bolts.

5. Install NEW "O" ring on dipstick tube. Use NEW gaskets and NEW nuts when installing front exhaust

pipe. Fill cooling system and check for leaks. Adjust shift linkages and fill with ATF. See appropriate

TRANSMISSION SERVICING article.

Removal (Paseo)

1. Disconnect negative battery cable. Remove transaxle oil dipstick. Disconnect throttle valve cable from

throttle body. Remove air cleaner assembly along with air intake duct to air cleaner.

2. Remove upper bolt from starter. Remove the 2 upper transaxle-to-cylinder block bolts located at top of

transaxle. Raise and support vehicle. Remove lower engine covers.

3. Support engine with hoist. Remove front wheels. Drain transaxle fluid. Remove axle shafts from

transaxle. See FWD AXLE SHAFTS article in DRIVE AXLES.

4. Disconnect necessary electrical connectors, ground cables, speedometer cable, control cables and oil

cooler lines for transaxle removal. Remove the 2 vertical bottom bolts from front (radiator side) transaxle

mount.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 131 of 1632

for transmission removal.

3. Remove starter. On 4WD models, remove front drive shaft bracket. This is the bracket that the front drive

shaft center bearing assembly was bolted on.

4. On 2WD models, remove lower stiffener plate located between side of cylinder block and front of

transmission. On 4WD models, remove transmission-to-cylinder block through-bolt located near bottom

of transmission.

5. On all models, remove upper stiffener plate located just above the starter opening. Upper stiffener plate

fits between cylinder block and front of transmission. Remove torque converter bolts.

6. Remove transmission oil cooler pipes and brackets as necessary. Remove exhaust pipe support bracket

located between transmission and exhaust pipe. Support transmission with transmission jack.

7. Remove bolts/nuts from rear transmission mount. Remove transmission-to-cylinder block bolts. Lower

transmission from vehicle.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than 1.250" (31.75 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Adjust all cables and fill with ATF. See appropriate TRANSMISSION

SERVICING article.

Removal (RAV4 2WD)

1. Disconnect negative battery cable. Disconnect throttle valve cable from throttle body. Remove coolant

reservoir tank. Remover air cleaner assembly. Remove ground cable.

2. Remove starter. Remove the 3 upper transaxle-to-cylinder block bolts located at top of transaxle. Raise

and support vehicle. Remove lower engine covers.

3. Support engine with hoist. Steering gear assembly must be supported in place during transaxle removal.

Secure steering gear assembly to the engine hoist using an attaching strap placed at each end of steering

gear assembly.

4. Remove transaxle-to-mount bolts/nuts from top of transaxle at driver's side end of transaxle.

5. Remove front wheels. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD AXLE

SHAFTS article in DRIVE AXLES.

6. Remove front exhaust pipe located between exhaust manifold and rear exhaust pipe. Support transaxle

with transmission jack. Disconnect shift cable, necessary electrical connectors and oil cooler hoses at

transaxle.

7. Remove shift cable brackets from suspension crossmember. Suspension crossmember is located below

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 19 © 2005 Mitchell Repair Information Company, LLC.

Page 134 of 1632

5. Once engine and transaxle are installed, adjust all cables and fill with ATF. See appropriate

TRANSMISSION SERVICING article.

Removal (Sienna)

1. Disconnect negative battery cable. Remove hood. Remove wiper arms. Remove hood-to-cowl top seal.

Remove cowl panel hole cover. Remove clips and left and right side cowl top ventilator louvers.

Disconnect washer hoses. Remove 2 washer nozzles from cowl top ventilator louvers. Remove 11 bolts

and outer front cowl top panel.

2. Remove battery, battery tray, air cleaner assembly and air cleaner case. Disconnect throttle valve cable

from throttle body. Remove cruise control actuator with mounting bracket from the body.

3. Raise and support vehicle. Disconnect necessary electrical connectors and ground cables for transaxle

removal. Remove starter. Disconnect shift cable and oil cooler lines at transaxle. Remove shift cable

clamp bracket from transaxle.

4. Remove front (radiator side) engine mount shock absorber-to-lower frame assembly bolts. Remove front

(radiator side) engine mount-to-lower frame assembly bolts/nuts.

5. Remove front (radiator side) exhaust manifold brace from rear of exhaust manifolds. Brace fits between

rear of exhaust manifold and front of transaxle.

6. Remove the 5 upper transaxle-to-cylinder block bolts. Support engine with hoist. Steering gear assembly

must be supported in place during transaxle removal. Secure steering gear assembly to the engine hoist

using an attaching strap placed at each end of steering gear assembly.

7. Remove front wheels. Remove engine undercover. Remove front exhaust pipe located between exhaust

manifolds and rear exhaust pipe. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD

AXLE SHAFTS article in DRIVE AXLES.

8. Disconnect shift control cable from mounting bracket. Remove rear (firewall side) engine mount-to-lower

frame assembly bolts/nuts. Remove transaxle mount-to-transaxle bolts/nuts at driver's side end of

transaxle.

9. Remove stabilizer bar mount bracket-to-lower frame assembly bolts. Remove steering gear assembly-to-

lower frame assembly bolts/nuts. Support lower frame assembly with floor jack. Lower frame assembly is

located below the engine and transaxle.

10. Disconnect power steering reservoir pipe mounting brackets from lower frame assembly. Remove lower

frame assembly mounting brackets. Lower frame assembly mounting brackets are located on the front

and rear of lower frame assembly attaching the lower frame assembly to the body. Remove lower frame

assembly.

11. Support transaxle with transmission jack. Remove torque converter bracket and cover bolts and nuts from

front of transaxle. Remove torque converter bolts. Remove remaining transaxle-to-cylinder block bolts.

Lower transaxle from vehicle.

Installation

NOTE: Wiper/washer components and output front cowl top panel must be

removed for clearance during transaxle removal and installation.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 138 of 1632

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than 1.250" (31.75 mm) on 2.7L 4-cylinder or .707" (17.95 mm)

on 3.4L V6. If torque converter depth is less than specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Ensure the Green torque converter bolt is installed first before installing the

remaining torque converter bolts.

5. Apply grease to transfer case shift lever before installing. Use NEW gasket when installing exhaust pipe.

Adjust all cables, shift linkages and fill with ATF. See appropriate TRANSMISSION SERVICING

article.

Removal (Tercel)

1. Disconnect negative battery cable. Remove battery. Disconnect throttle valve cable from throttle body.

Remove air cleaner assembly along with air intake duct to air cleaner.

2. Remove starter. Remove the 2 upper transaxle-to-cylinder block bolts, located at top of transaxle. Raise

and support vehicle. Remove lower engine covers.

3. Support engine with hoist. Remove front wheels. Drain transaxle fluid. Remove axle shafts from

transaxle. See FWD AXLE SHAFTS article in DRIVE AXLES.

4. Disconnect necessary electrical connectors, ground cables, speedometer cable, control cables and oil

cooler lines for transaxle removal. Remove exhaust pipe as necessary for access to transaxle.

5. Support transaxle with transmission jack. Remove the 2 vertical bottom bolts from front (radiator side)

transaxle mount.

6. Remove through-

bolt and rear (firewall side) engine mount assembly for transaxle removal. Remove plug

from front of transaxle for access to torque converter bolts. Remove torque converter bolts. Remove

remaining transaxle-to-cylinder block bolts. Lower transaxle from vehicle.

Installation

1. Before installing transaxle, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transaxle. To ensure torque converter is fully seated, torque converter depth

should be checked. Using straightedge and caliper, measure torque converter depth from torque converter

bolt lug on torque converter to the surface on transaxle. See Fig. 1

.

3. Torque converter depth on 3-speed transaxle should be more than .512" (13.00 mm). Torque converter

depth on 4-speed transaxle should be more than .538" (13.40 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . Tighten the lower transaxle-to-cylinder block bolts to specification as indicated.

See Fig. 9

and Fig. 10 .

5. When installing torque converter bolts, apply Loctite to torque converter bolt threads before installing.

Ad

just all cables and fill with ATF. See appropriate TRANSMISSION SERVICING article.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 26 © 2005 Mitchell Repair Information Company, LLC.