TOYOTA RAV4 1996 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1996,

Model line: RAV4,

Model: TOYOTA RAV4 1996

Pages: 1354, PDF Size: 30.43 MB

TOYOTA RAV4 1996 Service Repair Manual

RAV4 1996

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57462/w960_57462-0.png

TOYOTA RAV4 1996 Service Repair Manual

Trending: horn, transmission, radiator, width, roof, power steering fluid, Generator

Page 651 of 1354

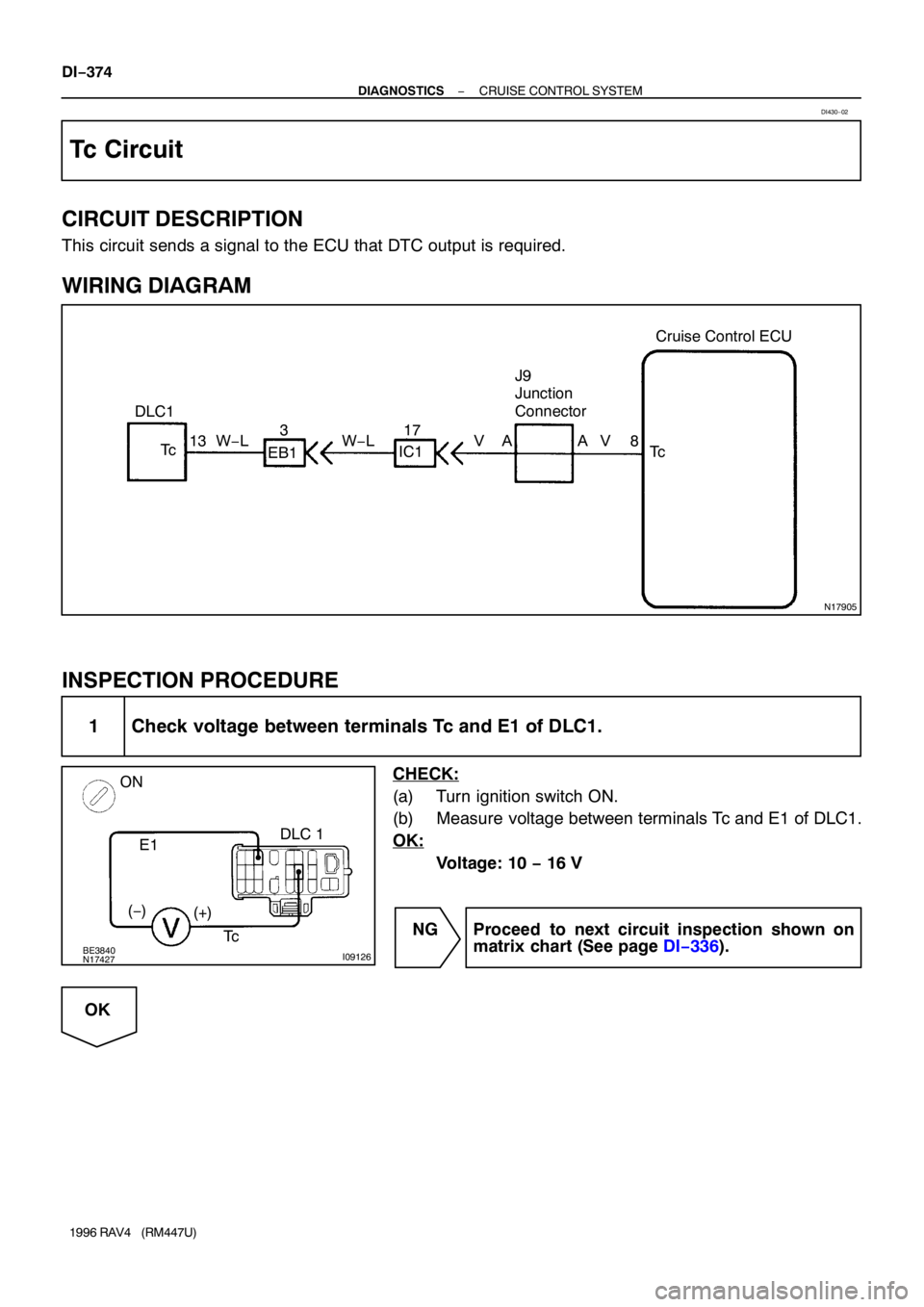

N17905

DLC1Cruise Control ECU

J9

Junction

Connector

13 W−L317

VA AV 8

Tc Tc

EB1IC1 W−L

BE3840N17427I09126

ON

DLC 1

E1

Tc (−)

(+)

DI−374

− DIAGNOSTICSCRUISE CONTROL SYSTEM

1996 RAV4 (RM447U)

Tc Circuit

CIRCUIT DESCRIPTION

This circuit sends a signal to the ECU that DTC output is required.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 Check voltage between terminals Tc and E1 of DLC1.

CHECK:

(a) Turn ignition switch ON.

(b) Measure voltage between terminals Tc and E1 of DLC1.

OK:

Voltage: 10 − 16 V

NG Proceed to next circuit inspection shown on

matrix chart (See page DI−336).

OK

DI430−02

Page 652 of 1354

− DIAGNOSTICSCRUISE CONTROL SYSTEM

DI−375

1996 RAV4 (RM447U)

2 Check for open and short in harness and connector between ECU and DLC1,

DLC1 and body ground (See page IN−30).

NG Repair or replace harness or connector.

OK

Check and replace ECU.

Page 653 of 1354

DI−376

− DIAGNOSTICSCRUISE CONTROL SYSTEM

1996 RAV4 (RM447U)

Actuator Control Cable Inspection

CHECK:

(a) Check that the actuator, control cable and throttle link are properly installed and that the cable and link

are connected correctly.

(b) Check that the actuator and bell crank are operating smoothly.

(c) Check that the cable is not loose or too tight.

HINT:

�If the control cable is very loose, the vehicle’s loss of speed going uphill will be large.

�If the control cable is too tight, the idle RPM will become high.

DI431−01

Page 654 of 1354

EC05E−01

− EMISSION CONTROLEMISSION CONTROL SYSTEM

EC−1

1996 RAV4 (RM447U)

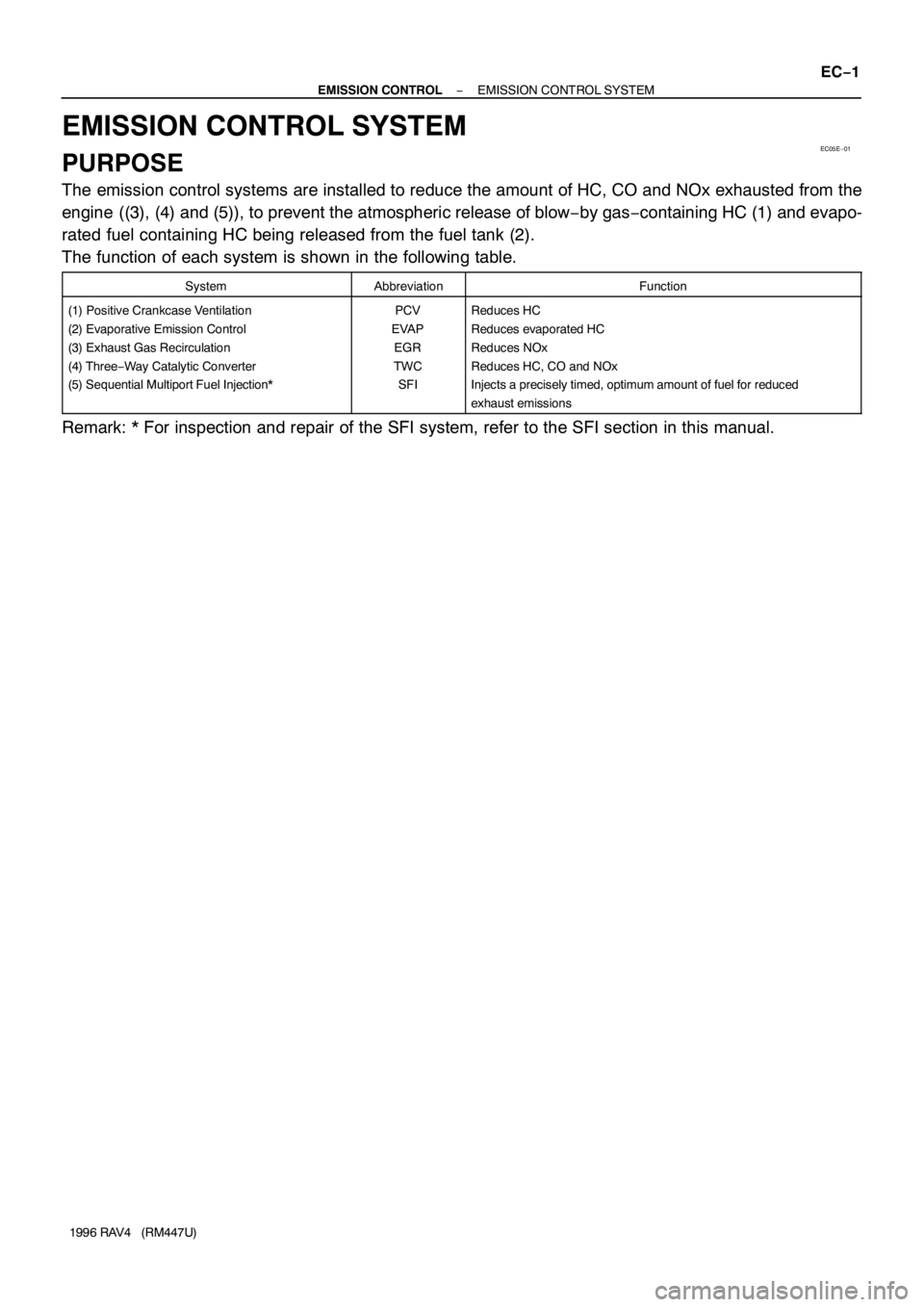

EMISSION CONTROL SYSTEM

PURPOSE

The emission control systems are installed to reduce the amount of HC, CO and NOx exhausted from the

engine ((3), (4) and (5)), to prevent the atmospheric release of blow−by gas−containing HC (1) and evapo-

rated fuel containing HC being released from the fuel tank (2).

The function of each system is shown in the following table.

SystemAbbreviationFunction

(1) Positive Crankcase Ventilation

(2) Evaporative Emission Control

(3) Exhaust Gas Recirculation

(4) Three−Way Catalytic Converter

(5) Sequential Multiport Fuel Injection*PCV

EVAP

EGR

TWC

SFIReduces HC

Reduces evaporated HC

Reduces NOx

Reduces HC, CO and NOx

Injects a precisely timed, optimum amount of fuel for reduced

exhaust emissions

Remark: * For inspection and repair of the SFI system, refer to the SFI section in this manual.

Page 655 of 1354

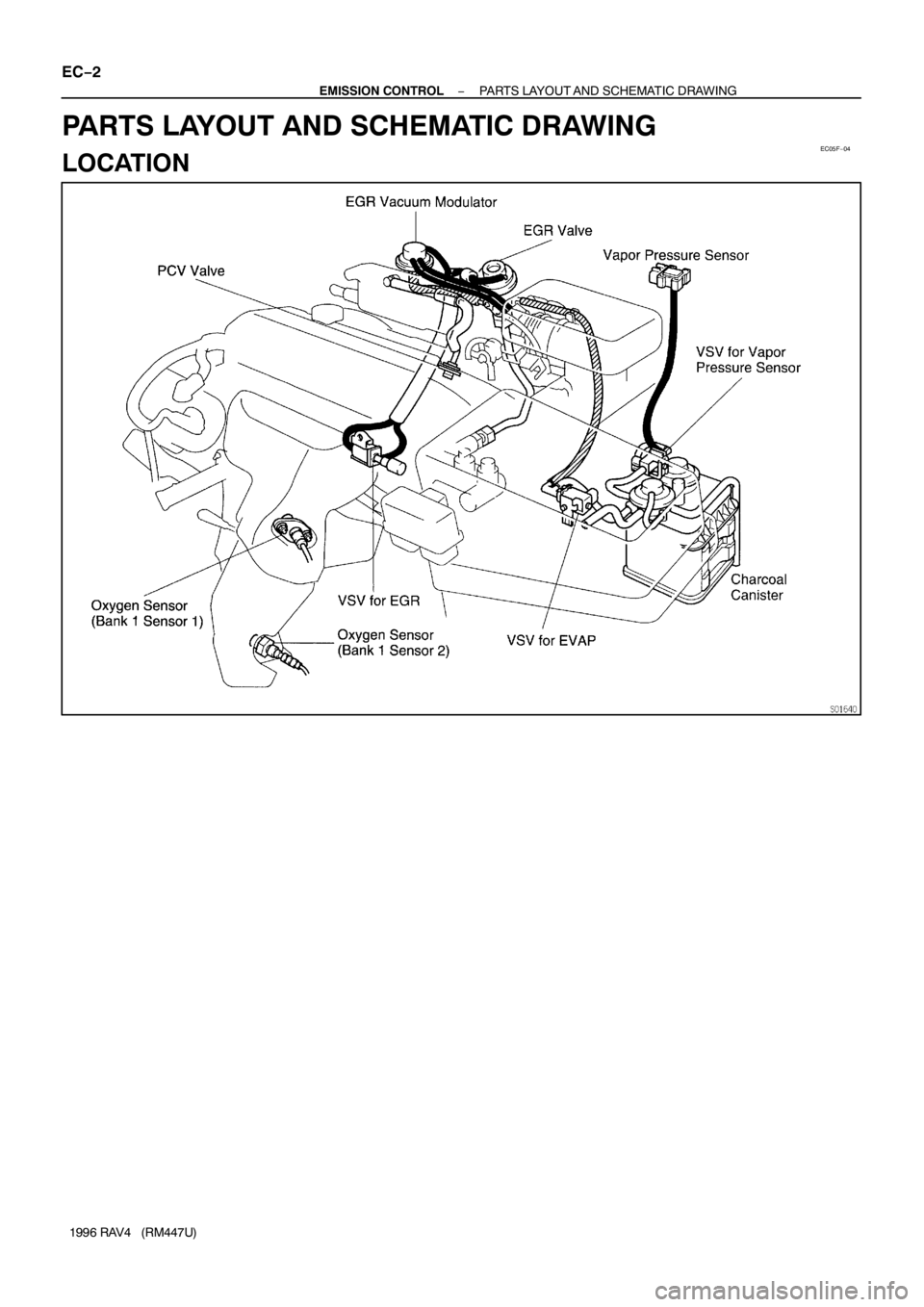

EC05F−04

EC−2

− EMISSION CONTROLPARTS LAYOUT AND SCHEMATIC DRAWING

1996 RAV4 (RM447U)

PARTS LAYOUT AND SCHEMATIC DRAWING

LOCATION

Page 656 of 1354

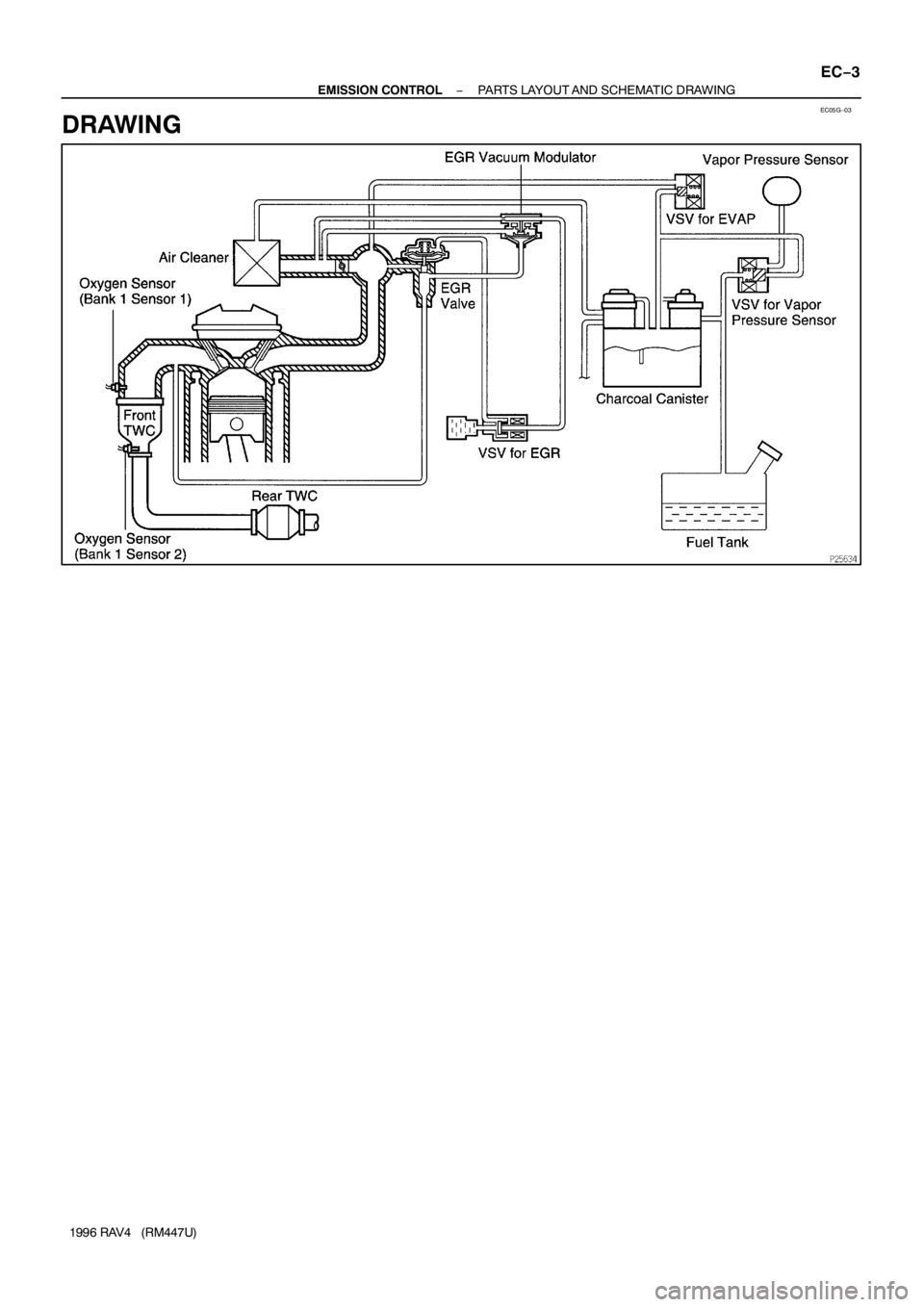

EC05G−03

− EMISSION CONTROLPARTS LAYOUT AND SCHEMATIC DRAWING

EC−3

1996 RAV4 (RM447U)

DRAWING

Page 657 of 1354

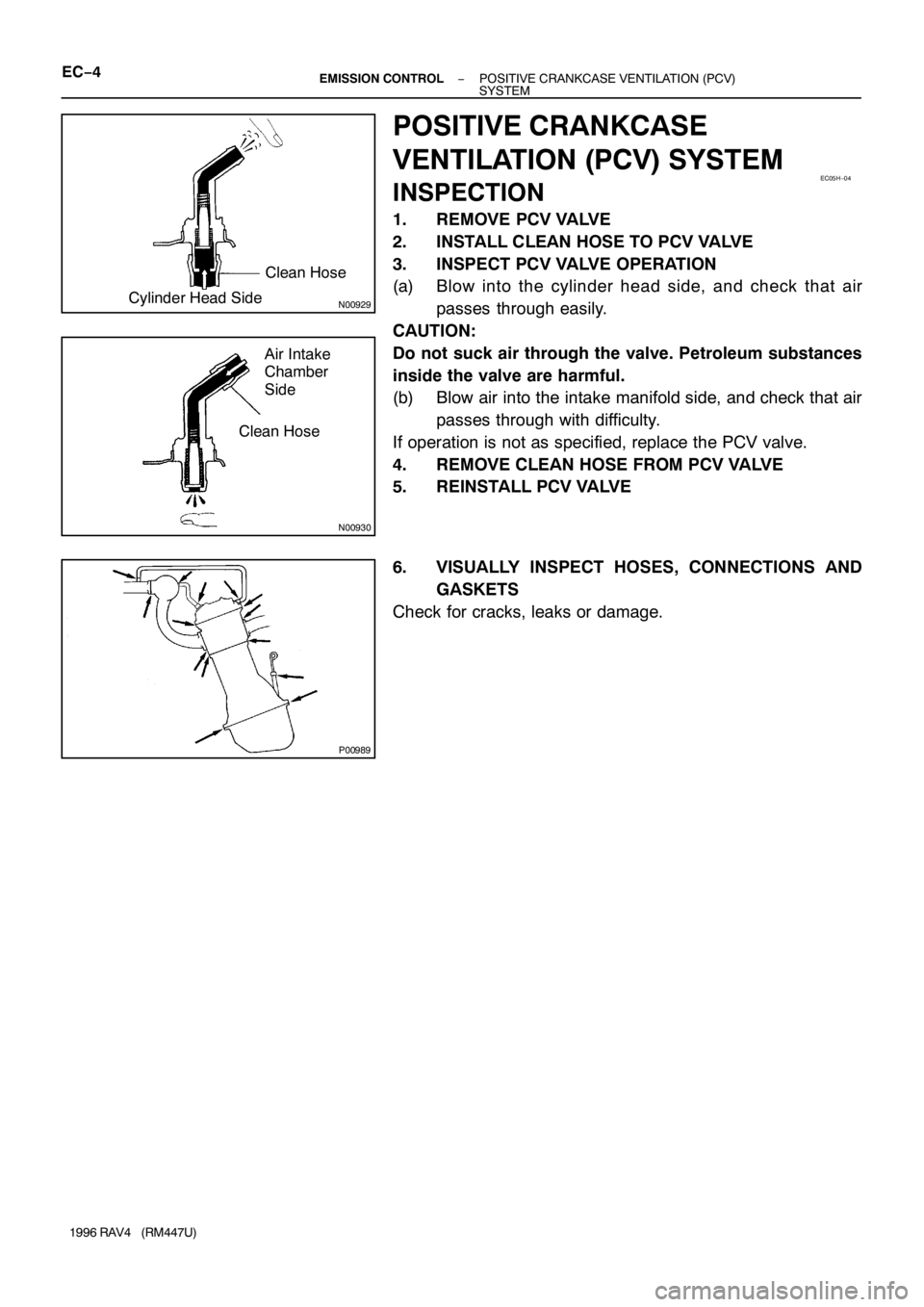

N00929

Clean Hose

Cylinder Head Side

N00930

Air Intake

Chamber

Side

Clean Hose

EC05H−04

P00989

EC−4− EMISSION CONTROLPOSITIVE CRANKCASE VENTILATION (PCV)

SYSTEM

1996 RAV4 (RM447U)

POSITIVE CRANKCASE

VENTILATION (PCV) SYSTEM

INSPECTION

1. REMOVE PCV VALVE

2. INSTALL CLEAN HOSE TO PCV VALVE

3. INSPECT PCV VALVE OPERATION

(a) Blow into the cylinder head side, and check that air

passes through easily.

CAUTION:

Do not suck air through the valve. Petroleum substances

inside the valve are harmful.

(b) Blow air into the intake manifold side, and check that air

passes through with difficulty.

If operation is not as specified, replace the PCV valve.

4. REMOVE CLEAN HOSE FROM PCV VALVE

5. REINSTALL PCV VALVE

6. VISUALLY INSPECT HOSES, CONNECTIONS AND

GASKETS

Check for cracks, leaks or damage.

Page 658 of 1354

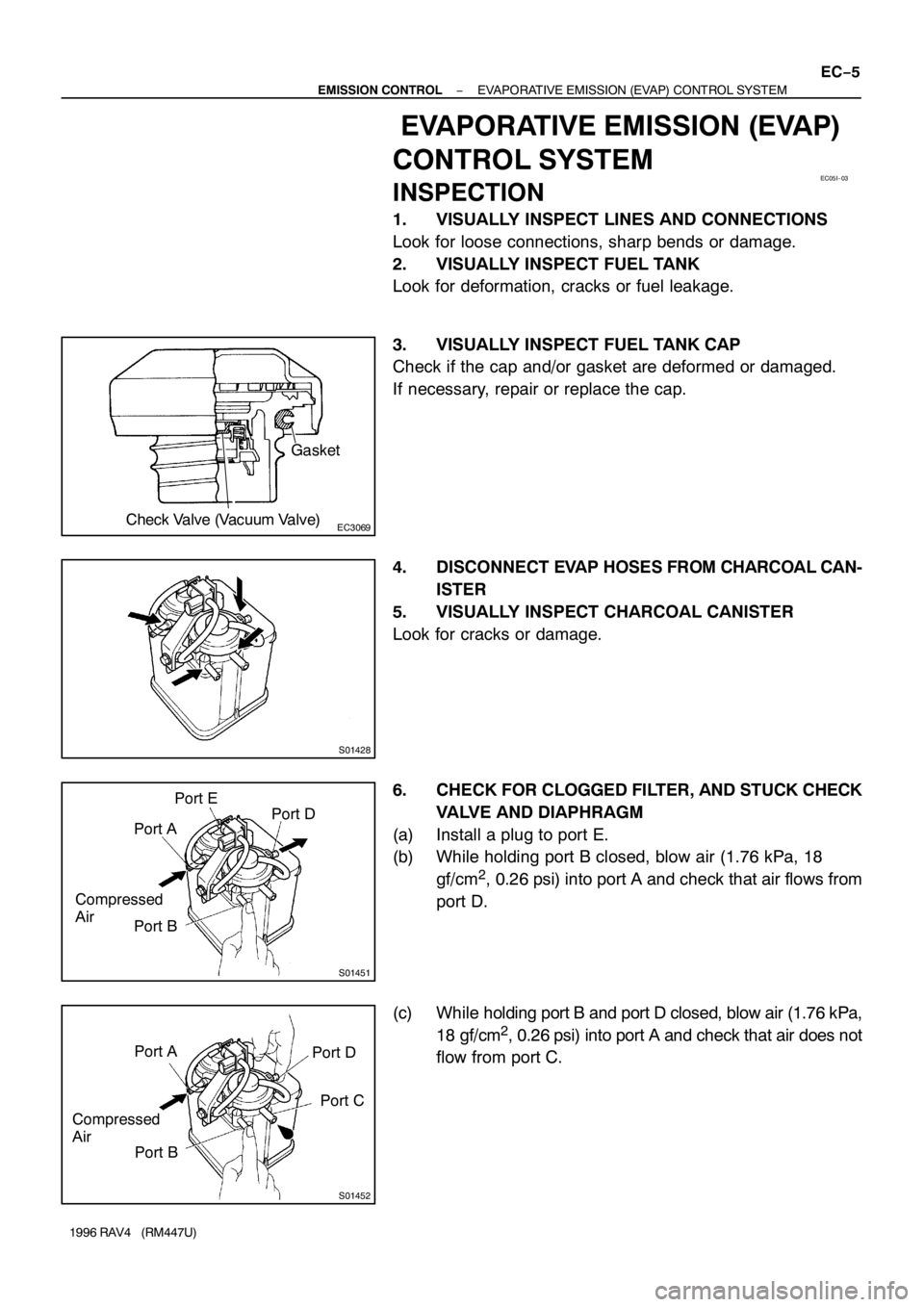

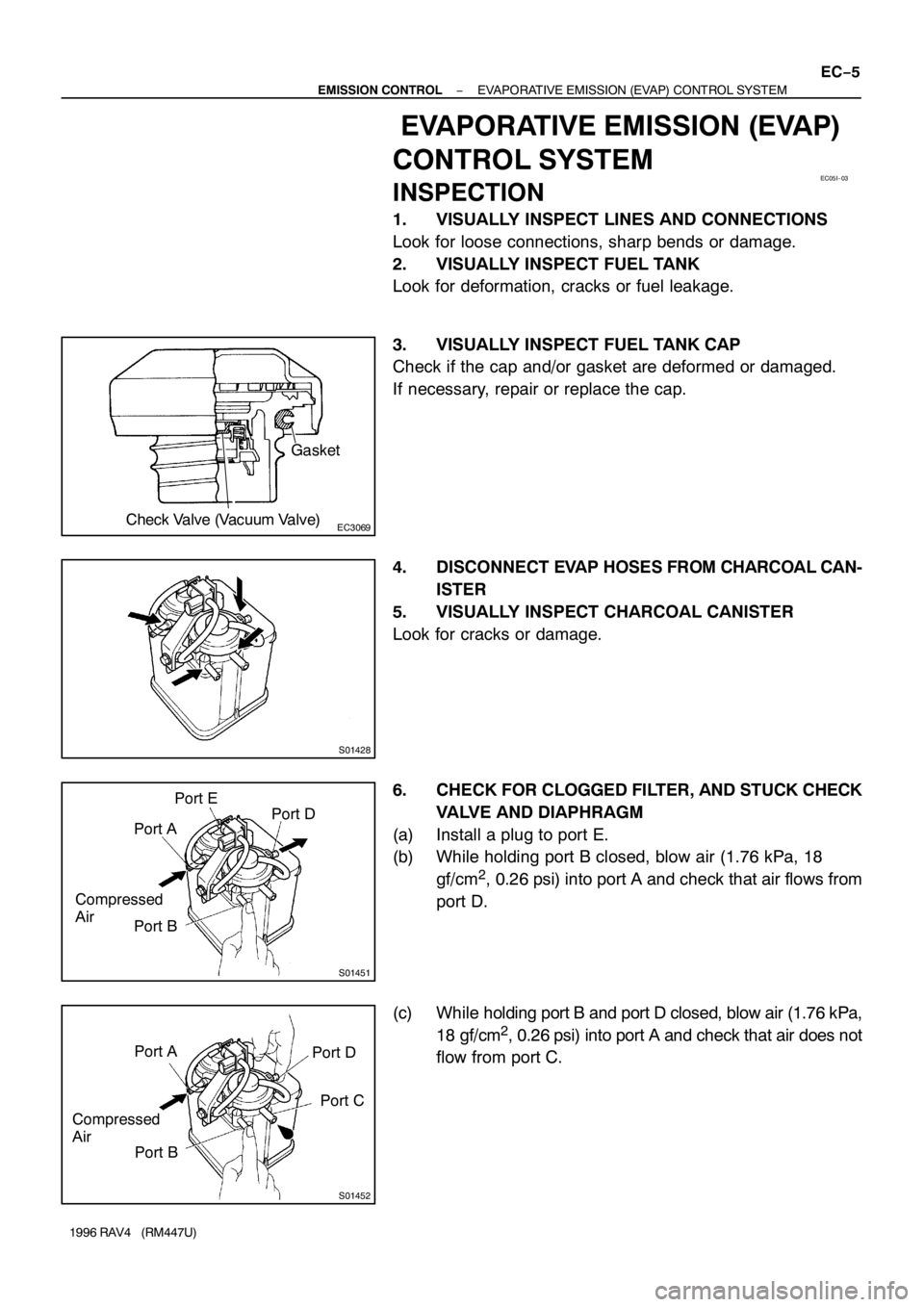

EC05I−03

EC3069Check Valve (Vacuum Valve)Gasket

S01428

S01451

Port E

Port D

Port A

Compressed

Air

Port B

S01452

Port C Port D Port A

Compressed

Air

Port B

− EMISSION CONTROLEVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM

EC−5

1996 RAV4 (RM447U)

EVAPORATIVE EMISSION (EVAP)

CONTROL SYSTEM

INSPECTION

1. VISUALLY INSPECT LINES AND CONNECTIONS

Look for loose connections, sharp bends or damage.

2. VISUALLY INSPECT FUEL TANK

Look for deformation, cracks or fuel leakage.

3. VISUALLY INSPECT FUEL TANK CAP

Check if the cap and/or gasket are deformed or damaged.

If necessary, repair or replace the cap.

4. DISCONNECT EVAP HOSES FROM CHARCOAL CAN-

ISTER

5. VISUALLY INSPECT CHARCOAL CANISTER

Look for cracks or damage.

6. CHECK FOR CLOGGED FILTER, AND STUCK CHECK

VALVE AND DIAPHRAGM

(a) Install a plug to port E.

(b) While holding port B closed, blow air (1.76 kPa, 18

gf/cm

2, 0.26 psi) into port A and check that air flows from

port D.

(c) While holding port B and port D closed, blow air (1.76 kPa,

18 gf/cm

2, 0.26 psi) into port A and check that air does not

flow from port C.

Page 659 of 1354

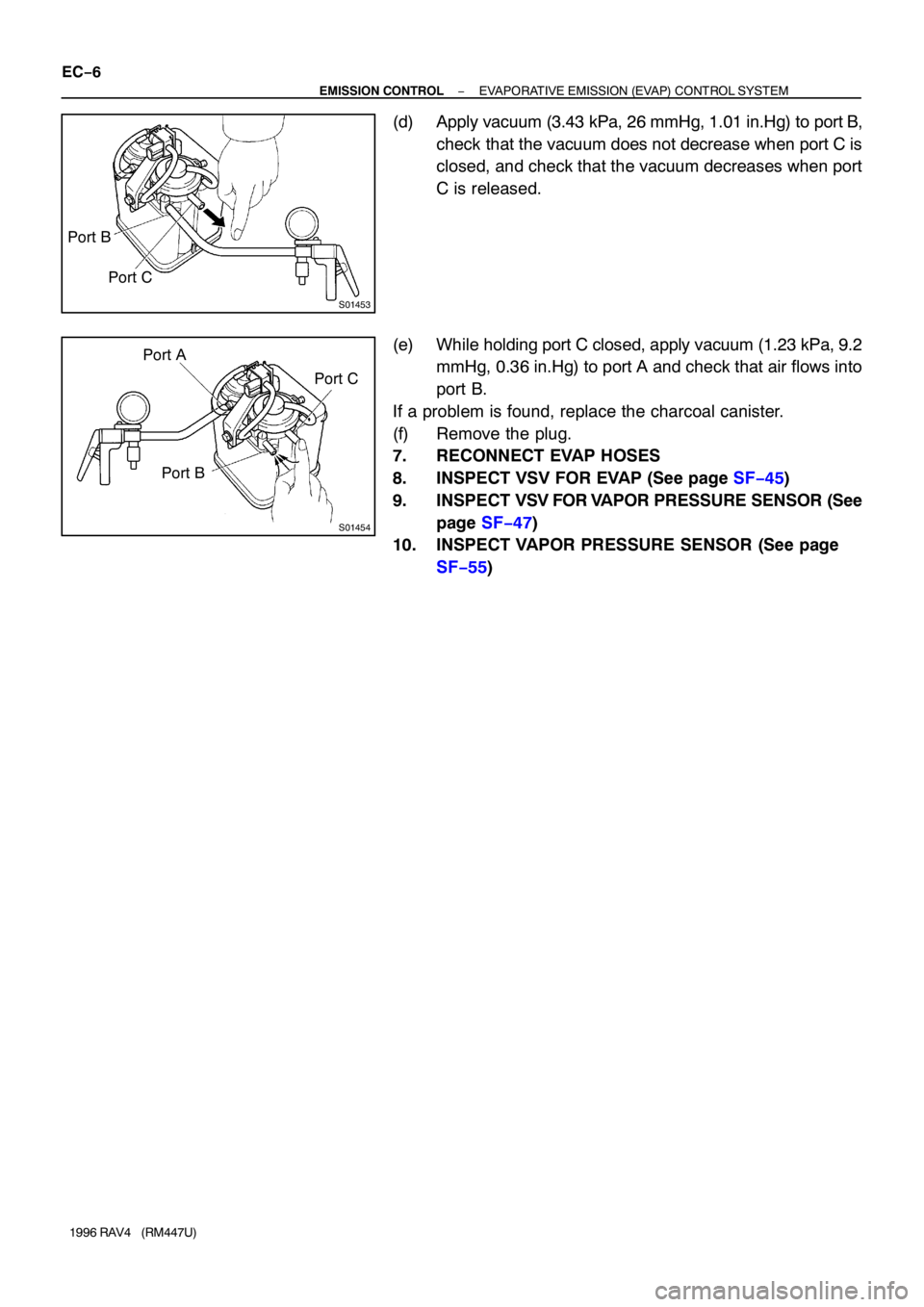

S01453

Port B

Port C

S01454

Port A

Port BPort C EC−6

− EMISSION CONTROLEVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM

1996 RAV4 (RM447U)

(d) Apply vacuum (3.43 kPa, 26 mmHg, 1.01 in.Hg) to port B,

check that the vacuum does not decrease when port C is

closed, and check that the vacuum decreases when port

C is released.

(e) While holding port C closed, apply vacuum (1.23 kPa, 9.2

mmHg, 0.36 in.Hg) to port A and check that air flows into

port B.

If a problem is found, replace the charcoal canister.

(f) Remove the plug.

7. RECONNECT EVAP HOSES

8. INSPECT VSV FOR EVAP (See page SF−45)

9. INSPECT VSV FOR VAPOR PRESSURE SENSOR (See

page SF−47)

10. INSPECT VAPOR PRESSURE SENSOR (See page

SF−55)

Page 660 of 1354

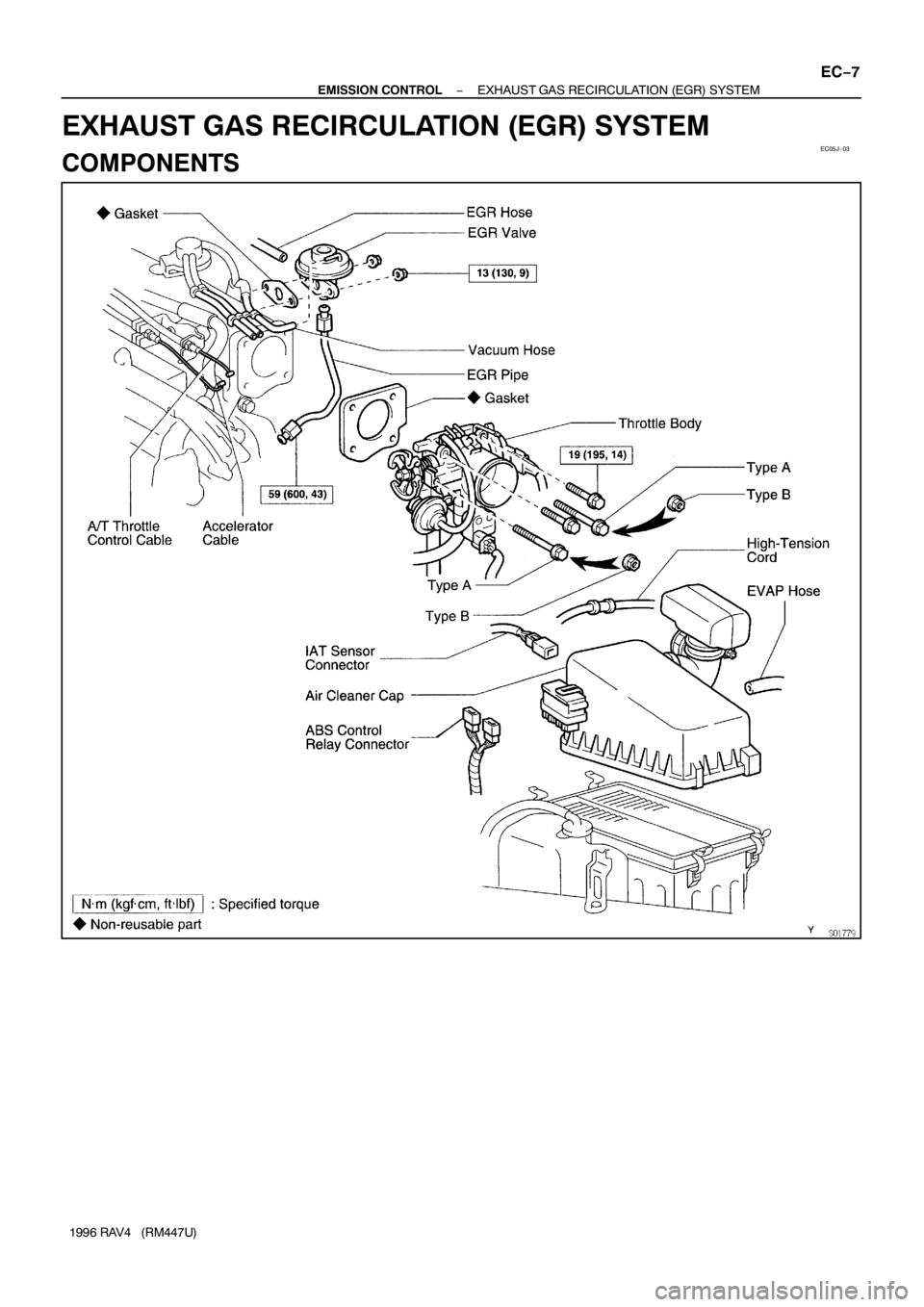

EC05J−03

− EMISSION CONTROLEXHAUST GAS RECIRCULATION (EGR) SYSTEM

EC−7

1996 RAV4 (RM447U)

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

COMPONENTS

Trending: engine, oil viscosity, Gage Assy, oil filter, driver seat adjustment, İdle, key