sensor TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 831 of 2000

EC–222AZ-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR

EC

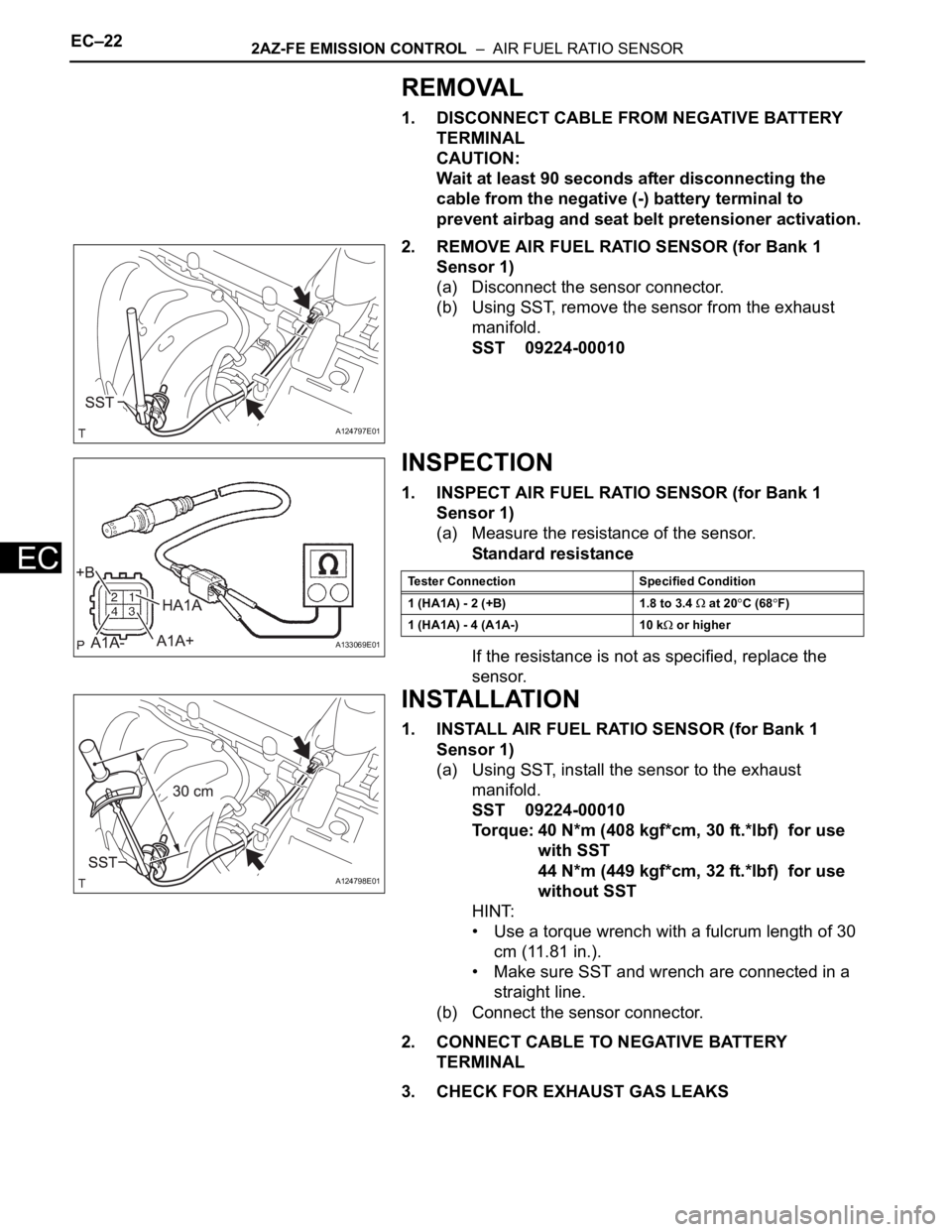

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE AIR FUEL RATIO SENSOR (for Bank 1

Sensor 1)

(a) Disconnect the sensor connector.

(b) Using SST, remove the sensor from the exhaust

manifold.

SST 09224-00010

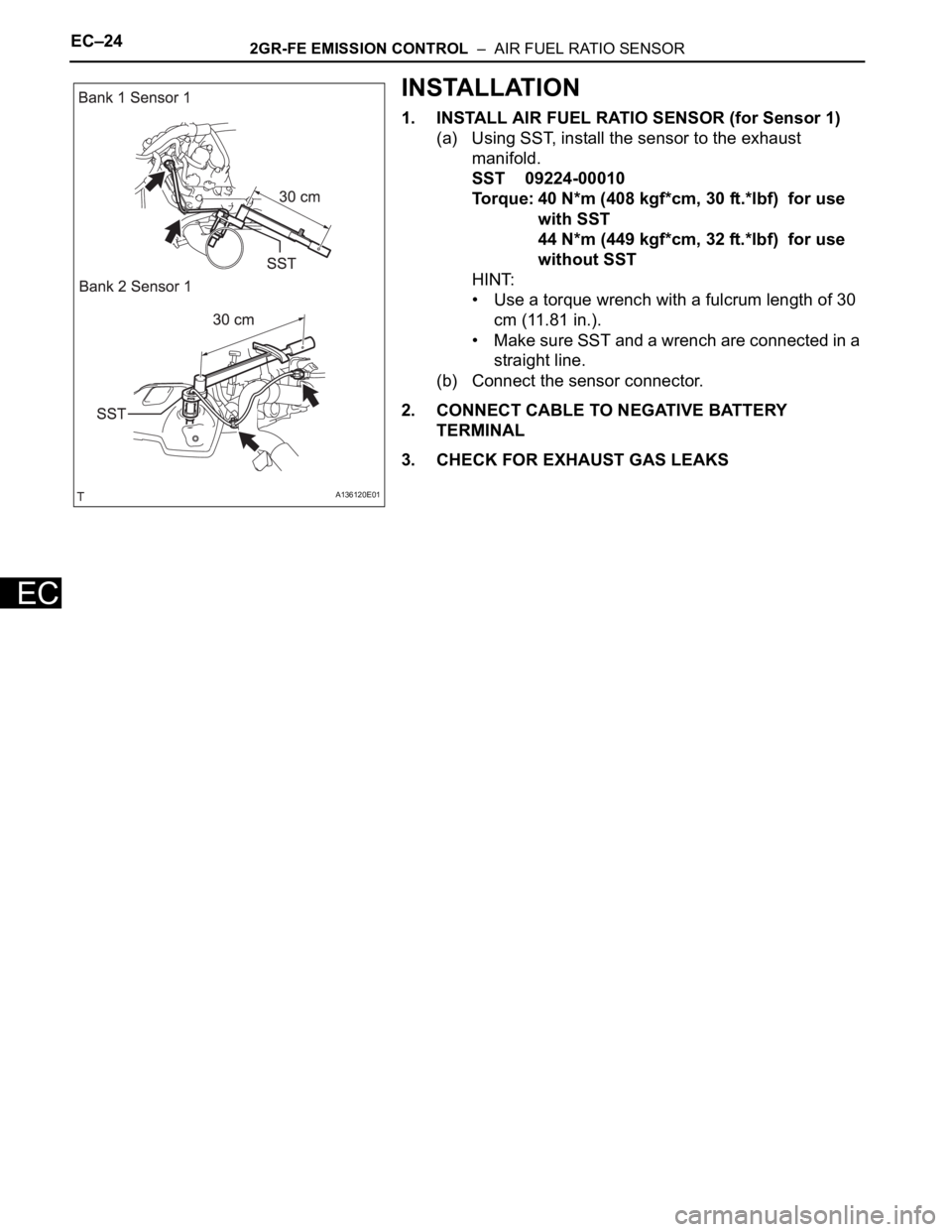

INSPECTION

1. INSPECT AIR FUEL RATIO SENSOR (for Bank 1

Sensor 1)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

INSTALLATION

1. INSTALL AIR FUEL RATIO SENSOR (for Bank 1

Sensor 1)

(a) Using SST, install the sensor to the exhaust

manifold.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure SST and wrench are connected in a

straight line.

(b) Connect the sensor connector.

2. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

3. CHECK FOR EXHAUST GAS LEAKS

A124797E01

A133069E01

Tester Connection Specified Condition

1 (HA1A) - 2 (+B) 1.8 to 3.4

at 20C (68F)

1 (HA1A) - 4 (A1A-) 10 k

or higher

A124798E01

Page 838 of 2000

EC–242GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR

EC

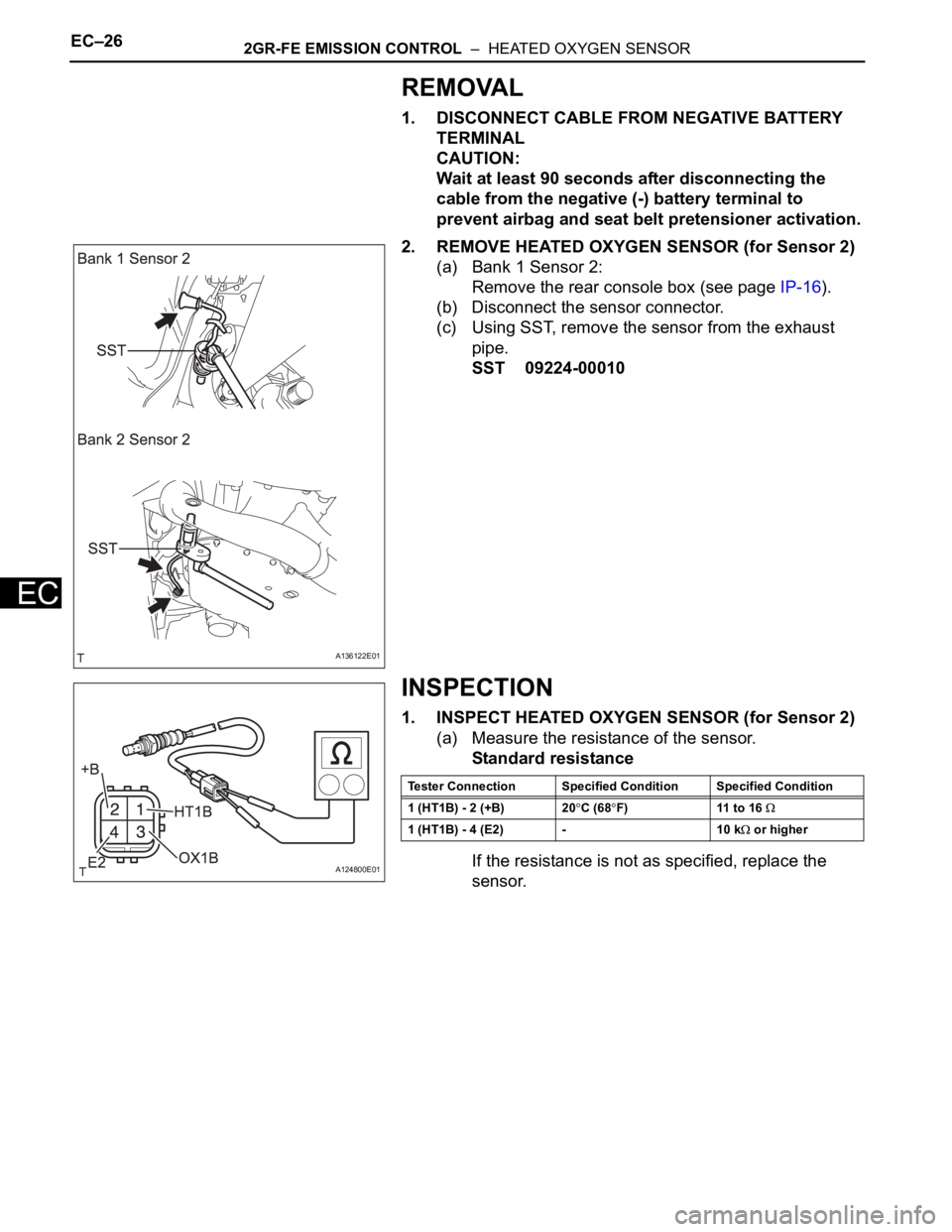

INSTALLATION

1. INSTALL AIR FUEL RATIO SENSOR (for Sensor 1)

(a) Using SST, install the sensor to the exhaust

manifold.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure SST and a wrench are connected in a

straight line.

(b) Connect the sensor connector.

2. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

3. CHECK FOR EXHAUST GAS LEAKS

A136120E01

Page 839 of 2000

EC–262GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR

EC

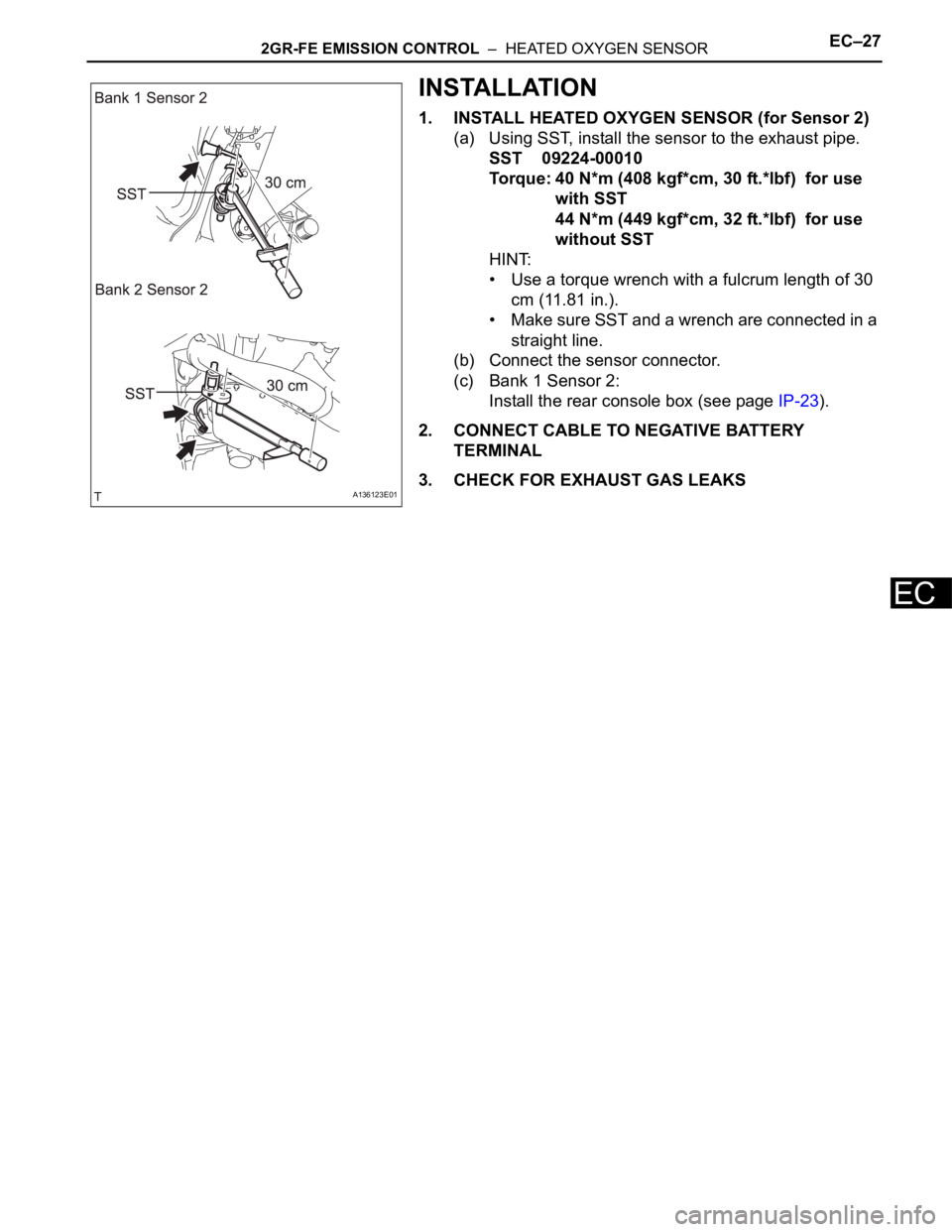

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE HEATED OXYGEN SENSOR (for Sensor 2)

(a) Bank 1 Sensor 2:

Remove the rear console box (see page IP-16).

(b) Disconnect the sensor connector.

(c) Using SST, remove the sensor from the exhaust

pipe.

SST 09224-00010

INSPECTION

1. INSPECT HEATED OXYGEN SENSOR (for Sensor 2)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

A136122E01

A124800E01

Tester Connection Specified Condition Specified Condition

1 (HT1B) - 2 (+B) 20

C (68F) 11 to 16

1 (HT1B) - 4 (E2) - 10 k or higher

Page 840 of 2000

2GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOREC–27

EC

INSTALLATION

1. INSTALL HEATED OXYGEN SENSOR (for Sensor 2)

(a) Using SST, install the sensor to the exhaust pipe.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure SST and a wrench are connected in a

straight line.

(b) Connect the sensor connector.

(c) Bank 1 Sensor 2:

Install the rear console box (see page IP-23).

2. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

3. CHECK FOR EXHAUST GAS LEAKS

A136123E01

Page 841 of 2000

2AZ-FE COOLING – WATER PUMPCO–11

CO

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE NO. 1 ENGINE UNDER COVER

3. REMOVE FRONT FENDER APRON RH

4. REMOVE RADIATOR SUPPORT OPENING COVER

5. DRAIN ENGINE COOLANT (See page CO-6)

6. REMOVE FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-6)

7. REMOVE FAN AND GENERATOR V BELT (See page

EM-6)

8. REMOVE GENERATOR ASSEMBLY (See page CH-9)

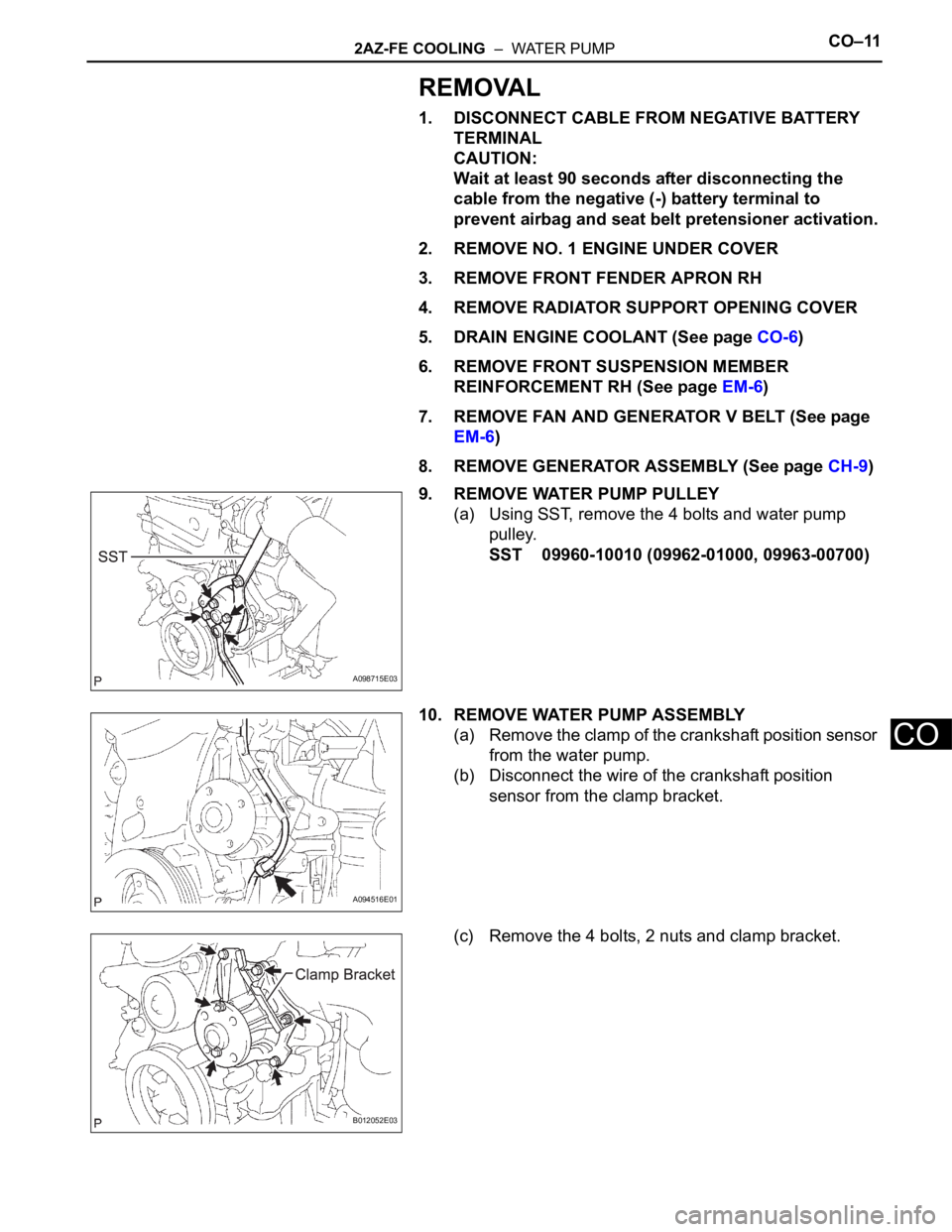

9. REMOVE WATER PUMP PULLEY

(a) Using SST, remove the 4 bolts and water pump

pulley.

SST 09960-10010 (09962-01000, 09963-00700)

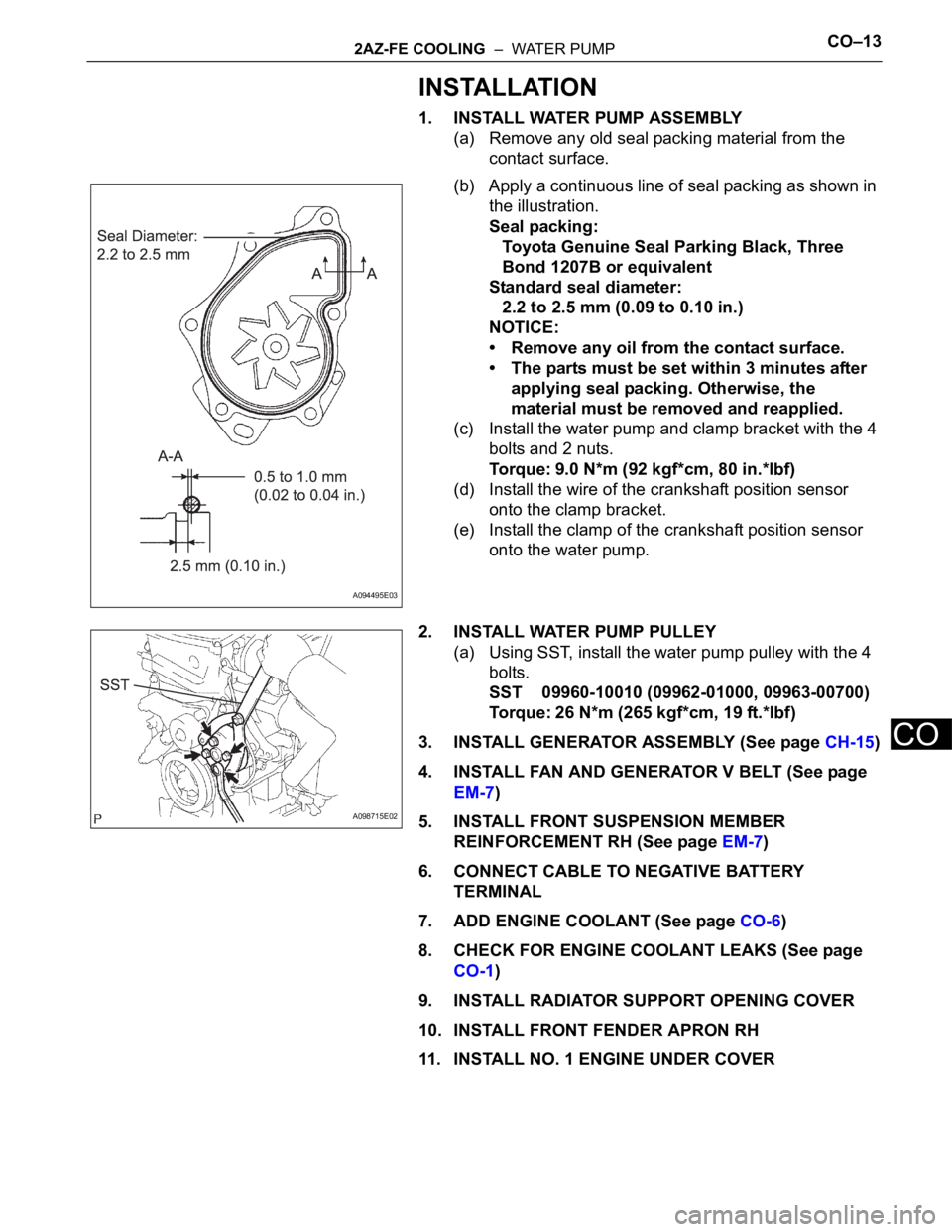

10. REMOVE WATER PUMP ASSEMBLY

(a) Remove the clamp of the crankshaft position sensor

from the water pump.

(b) Disconnect the wire of the crankshaft position

sensor from the clamp bracket.

(c) Remove the 4 bolts, 2 nuts and clamp bracket.

A098715E03

A094516E01

B012052E03

Page 843 of 2000

2AZ-FE COOLING – WATER PUMPCO–13

CO

INSTALLATION

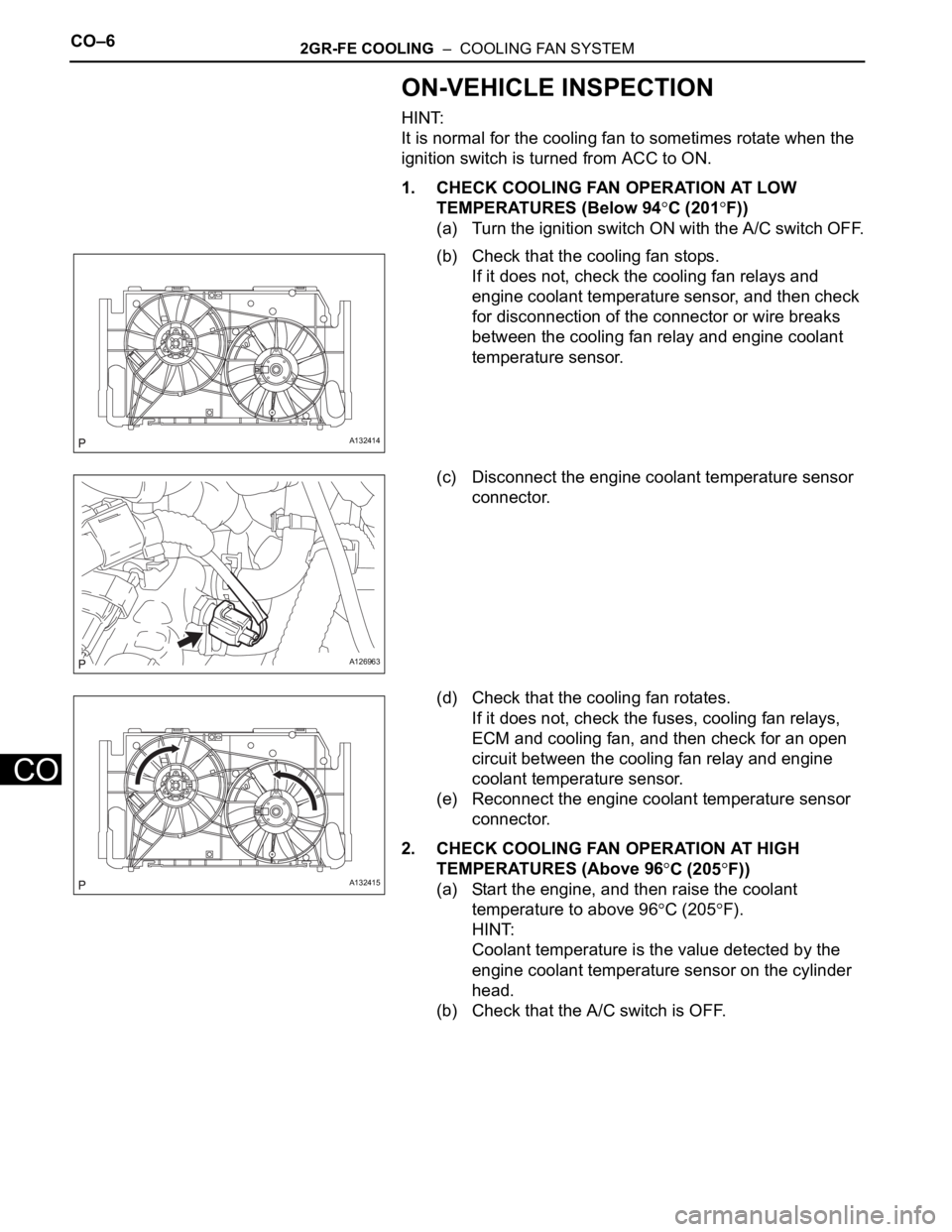

1. INSTALL WATER PUMP ASSEMBLY

(a) Remove any old seal packing material from the

contact surface.

(b) Apply a continuous line of seal packing as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Parking Black, Three

Bond 1207B or equivalent

Standard seal diameter:

2.2 to 2.5 mm (0.09 to 0.10 in.)

NOTICE:

• Remove any oil from the contact surface.

• The parts must be set within 3 minutes after

applying seal packing. Otherwise, the

material must be removed and reapplied.

(c) Install the water pump and clamp bracket with the 4

bolts and 2 nuts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

(d) Install the wire of the crankshaft position sensor

onto the clamp bracket.

(e) Install the clamp of the crankshaft position sensor

onto the water pump.

2. INSTALL WATER PUMP PULLEY

(a) Using SST, install the water pump pulley with the 4

bolts.

SST 09960-10010 (09962-01000, 09963-00700)

Torque: 26 N*m (265 kgf*cm, 19 ft.*lbf)

3. INSTALL GENERATOR ASSEMBLY (See page CH-15)

4. INSTALL FAN AND GENERATOR V BELT (See page

EM-7)

5. INSTALL FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-7)

6. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

7. ADD ENGINE COOLANT (See page CO-6)

8. CHECK FOR ENGINE COOLANT LEAKS (See page

CO-1)

9. INSTALL RADIATOR SUPPORT OPENING COVER

10. INSTALL FRONT FENDER APRON RH

11. INSTALL NO. 1 ENGINE UNDER COVER

A094495E03

A098715E02

Page 854 of 2000

CO–62GR-FE COOLING – COOLING FAN SYSTEM

CO

ON-VEHICLE INSPECTION

HINT:

It is normal for the cooling fan to sometimes rotate when the

ignition switch is turned from ACC to ON.

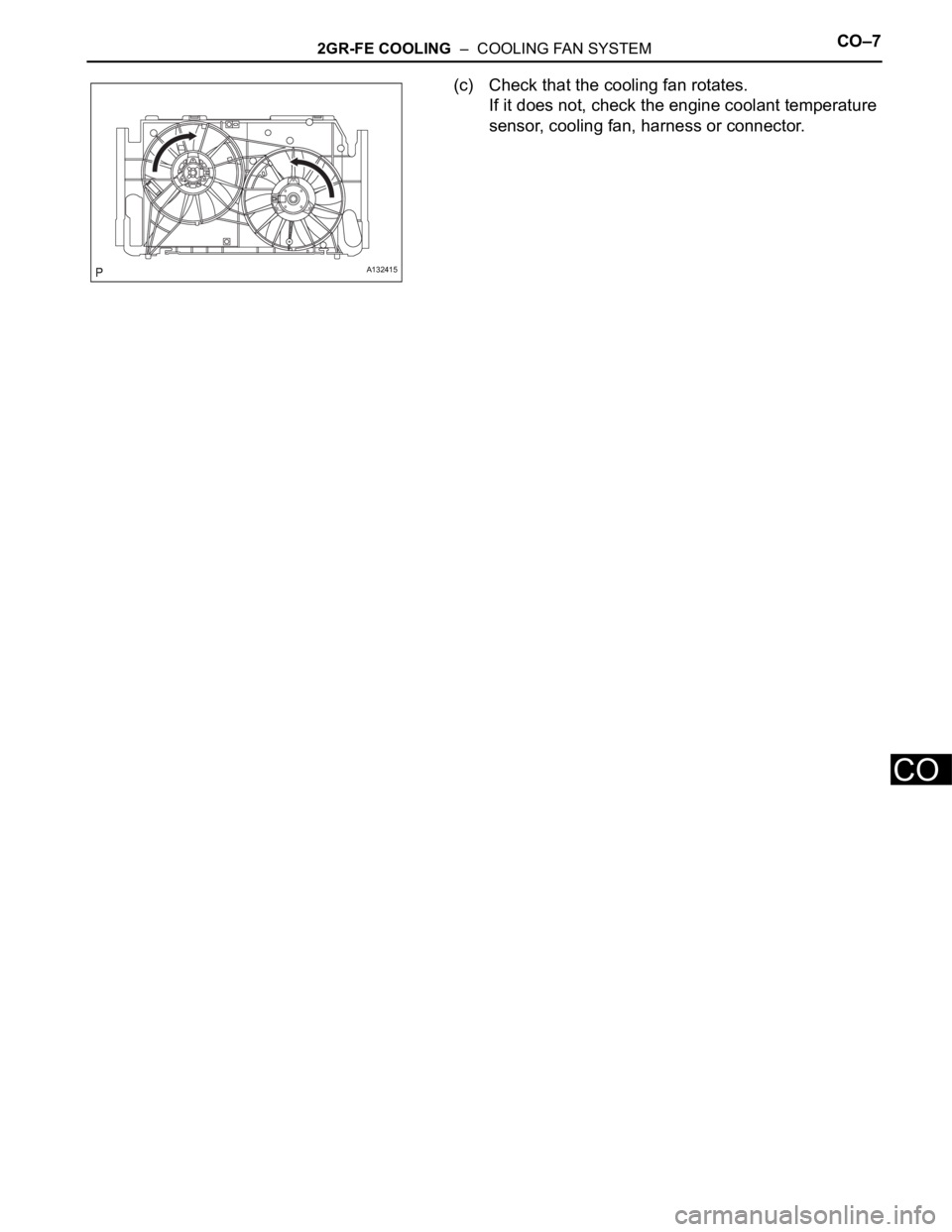

1. CHECK COOLING FAN OPERATION AT LOW

TEMPERATURES (Below 94

C (201F))

(a) Turn the ignition switch ON with the A/C switch OFF.

(b) Check that the cooling fan stops.

If it does not, check the cooling fan relays and

engine coolant temperature sensor, and then check

for disconnection of the connector or wire breaks

between the cooling fan relay and engine coolant

temperature sensor.

(c) Disconnect the engine coolant temperature sensor

connector.

(d) Check that the cooling fan rotates.

If it does not, check the fuses, cooling fan relays,

ECM and cooling fan, and then check for an open

circuit between the cooling fan relay and engine

coolant temperature sensor.

(e) Reconnect the engine coolant temperature sensor

connector.

2. CHECK COOLING FAN OPERATION AT HIGH

TEMPERATURES (Above 96

C (205F))

(a) Start the engine, and then raise the coolant

temperature to above 96

C (205F).

HINT:

Coolant temperature is the value detected by the

engine coolant temperature sensor on the cylinder

head.

(b) Check that the A/C switch is OFF.

A132414

A126963

A132415

Page 855 of 2000

2GR-FE COOLING – COOLING FAN SYSTEMCO–7

CO

(c) Check that the cooling fan rotates.

If it does not, check the engine coolant temperature

sensor, cooling fan, harness or connector.

A132415

Page 886 of 2000

IG–62AZ-FE IGNITION – IGNITION SYSTEM

IG

(9) Install the ignition coil with the bolt.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

(10) Connect the 4 fuel injector connectors.

(11) Install the No. 1 engine cover.

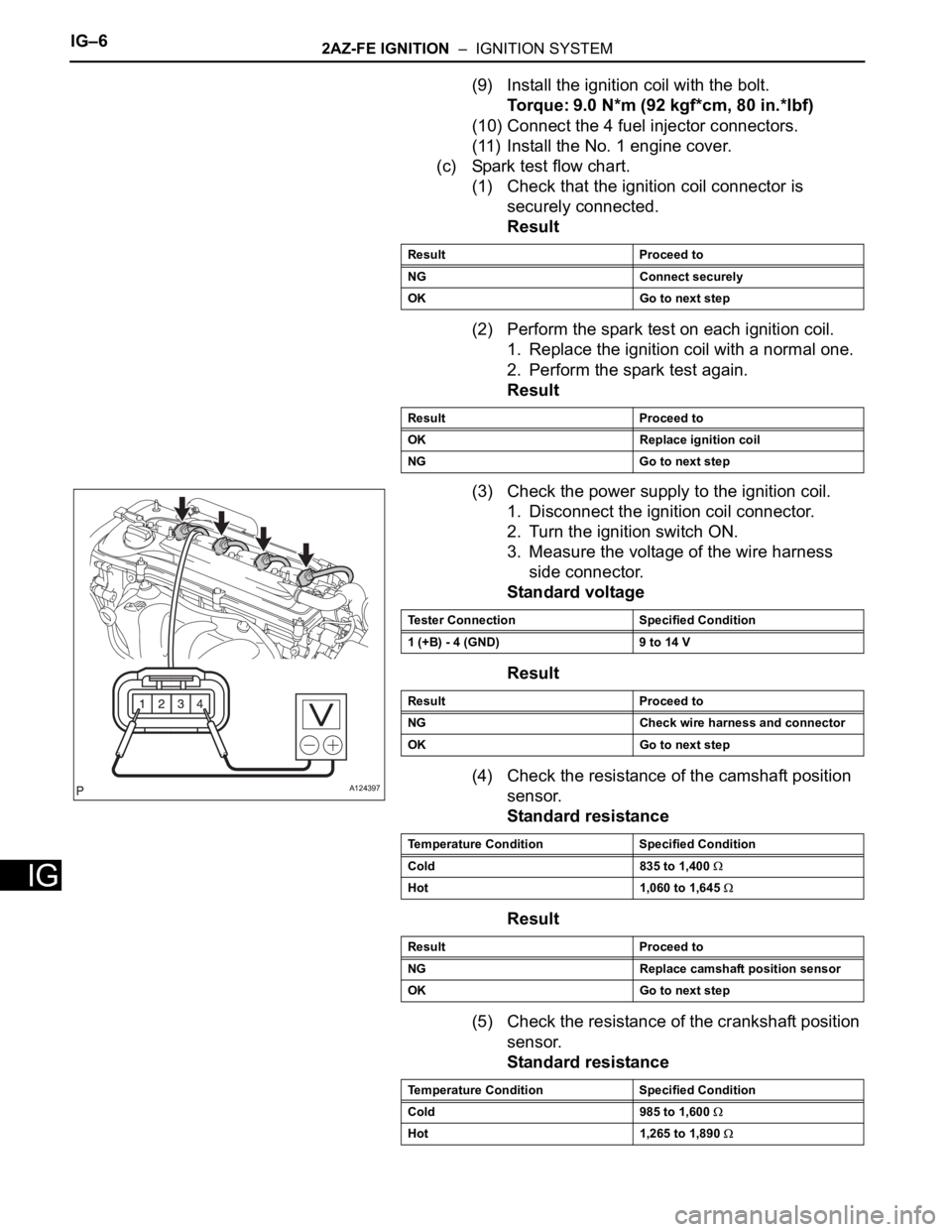

(c) Spark test flow chart.

(1) Check that the ignition coil connector is

securely connected.

Result

(2) Perform the spark test on each ignition coil.

1. Replace the ignition coil with a normal one.

2. Perform the spark test again.

Result

(3) Check the power supply to the ignition coil.

1. Disconnect the ignition coil connector.

2. Turn the ignition switch ON.

3. Measure the voltage of the wire harness

side connector.

Standard voltage

Result

(4) Check the resistance of the camshaft position

sensor.

Standard resistance

Result

(5) Check the resistance of the crankshaft position

sensor.

Standard resistance

Result Proceed to

NG Connect securely

OK Go to next step

Result Proceed to

OK Replace ignition coil

NG Go to next step

A124397

Tester Connection Specified Condition

1 (+B) - 4 (GND) 9 to 14 V

Result Proceed to

NG Check wire harness and connector

OK Go to next step

Temperature Condition Specified Condition

Cold 835 to 1,400

Hot 1,060 to 1,645

Result Proceed to

NG Replace camshaft position sensor

OK Go to next step

Temperature Condition Specified Condition

Cold 985 to 1,600

Hot 1,265 to 1,890

Page 887 of 2000

2AZ-FE IGNITION – IGNITION SYSTEMIG–7

IG

Result

(6) Check the IGT signal from the ECM.

Result

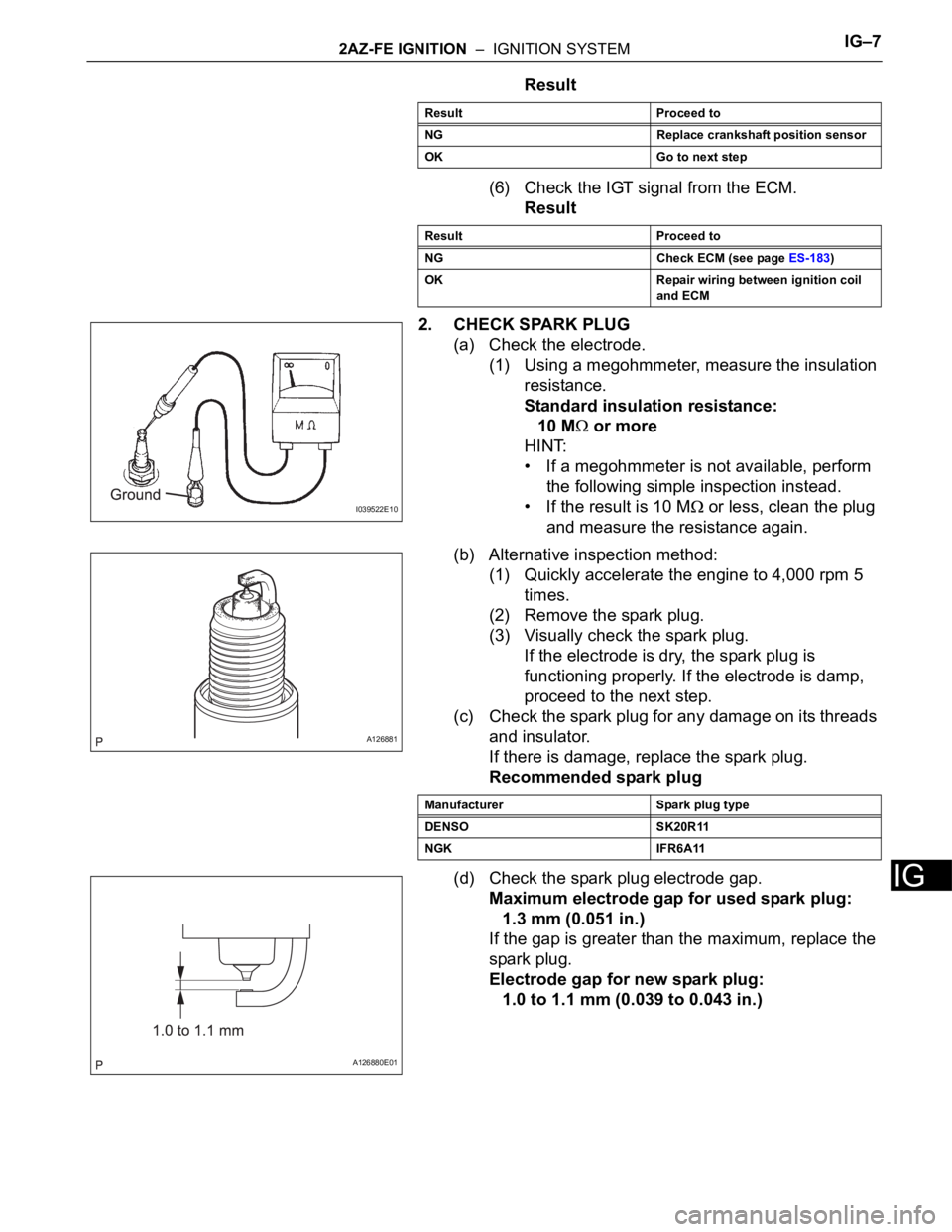

2. CHECK SPARK PLUG

(a) Check the electrode.

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or more

HINT:

• If a megohmmeter is not available, perform

the following simple inspection instead.

• If the result is 10 M

or less, clean the plug

and measure the resistance again.

(b) Alternative inspection method:

(1) Quickly accelerate the engine to 4,000 rpm 5

times.

(2) Remove the spark plug.

(3) Visually check the spark plug.

If the electrode is dry, the spark plug is

functioning properly. If the electrode is damp,

proceed to the next step.

(c) Check the spark plug for any damage on its threads

and insulator.

If there is damage, replace the spark plug.

Recommended spark plug

(d) Check the spark plug electrode gap.

Maximum electrode gap for used spark plug:

1.3 mm (0.051 in.)

If the gap is greater than the maximum, replace the

spark plug.

Electrode gap for new spark plug:

1.0 to 1.1 mm (0.039 to 0.043 in.)

Result Proceed to

NG Replace crankshaft position sensor

OK Go to next step

Result Proceed to

NG Check ECM (see page ES-183)

OK Repair wiring between ignition coil

and ECM

I039522E10

A126881

Manufacturer Spark plug type

DENSO SK20R11

NGK IFR6A11

A126880E01