sensor TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 650 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–123

EM

DISASSEMBLY

1. REMOVE IDLER PULLEY (See page EM-23)

2. REMOVE OIL DIPSTICK

3. REMOVE OIL DIPSTICK GUIDE (See page EM-57)

4. REMOVE MANIFOLD STAY (See page EM-57)

5. REMOVE NO. 2 MANIFOLD STAY (See page EM-58)

6. REMOVE NO. 1 EXHAUST MANIFOLD HEAT

INSULATOR (See page EM-58)

7. REMOVE EXHAUST MANIFOLD CONVERTER SUB-

ASSEMBLY (See page EM-58)

8. REMOVE WATER INLET (See page CO-15)

9. REMOVE THERMOSTAT

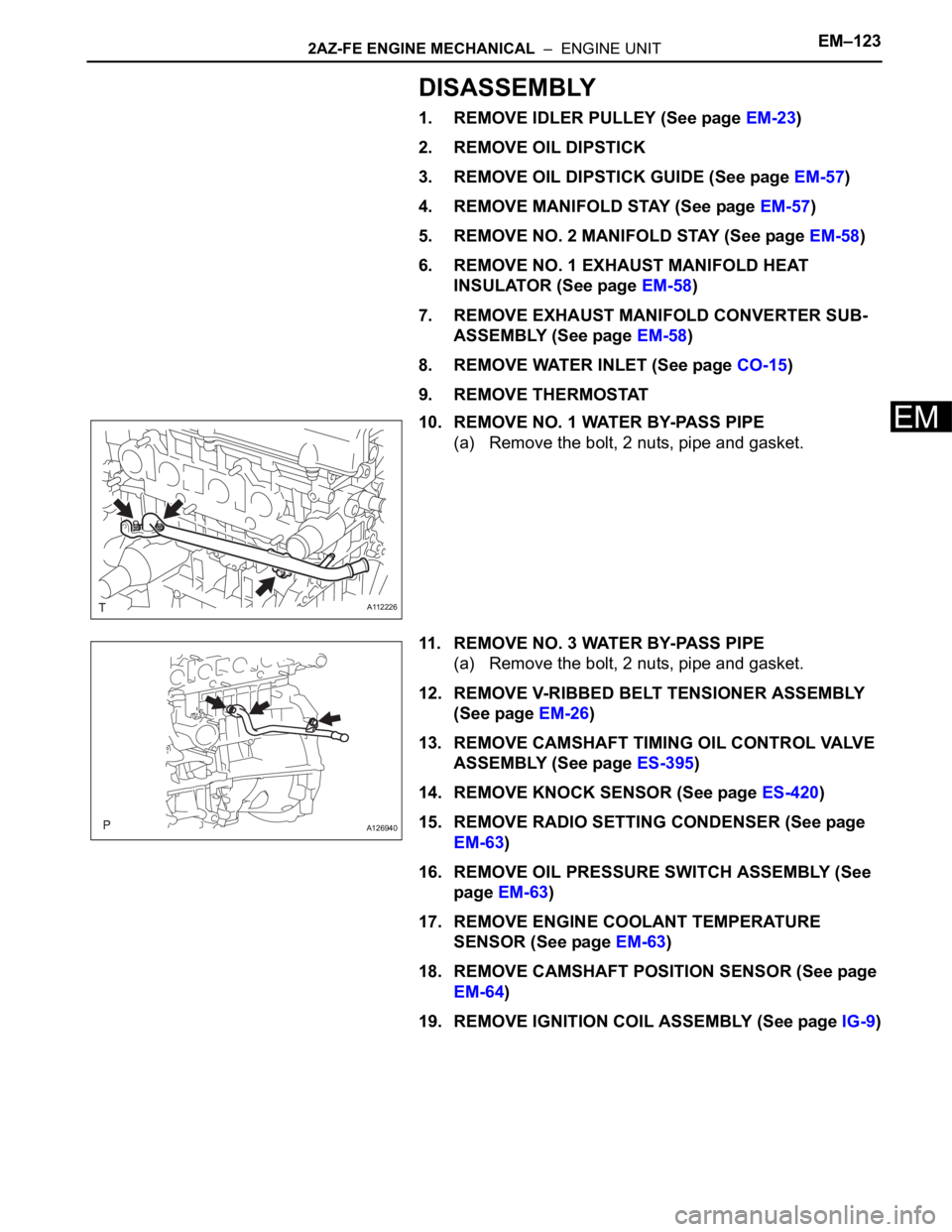

10. REMOVE NO. 1 WATER BY-PASS PIPE

(a) Remove the bolt, 2 nuts, pipe and gasket.

11. REMOVE NO. 3 WATER BY-PASS PIPE

(a) Remove the bolt, 2 nuts, pipe and gasket.

12. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(See page EM-26)

13. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (See page ES-395)

14. REMOVE KNOCK SENSOR (See page ES-420)

15. REMOVE RADIO SETTING CONDENSER (See page

EM-63)

16. REMOVE OIL PRESSURE SWITCH ASSEMBLY (See

page EM-63)

17. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR (See page EM-63)

18. REMOVE CAMSHAFT POSITION SENSOR (See page

EM-64)

19. REMOVE IGNITION COIL ASSEMBLY (See page IG-9)

A112226

A126940

Page 651 of 2000

EM–1242AZ-FE ENGINE MECHANICAL – ENGINE UNIT

EM

20. REMOVE SPARK PLUG

21. REMOVE OIL FILLER CAP SUB-ASSEMBLY

22. REMOVE OIL FILLER CAP GASKET

23. REMOVE VENTILATION VALVE SUB-ASSEMBLY

(See page EC-18)

24. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-24)

25. REMOVE CYLINDER HEAD COVER GASKET

26. REMOVE OIL FILTER SUB-ASSEMBLY (See page LU-

4)

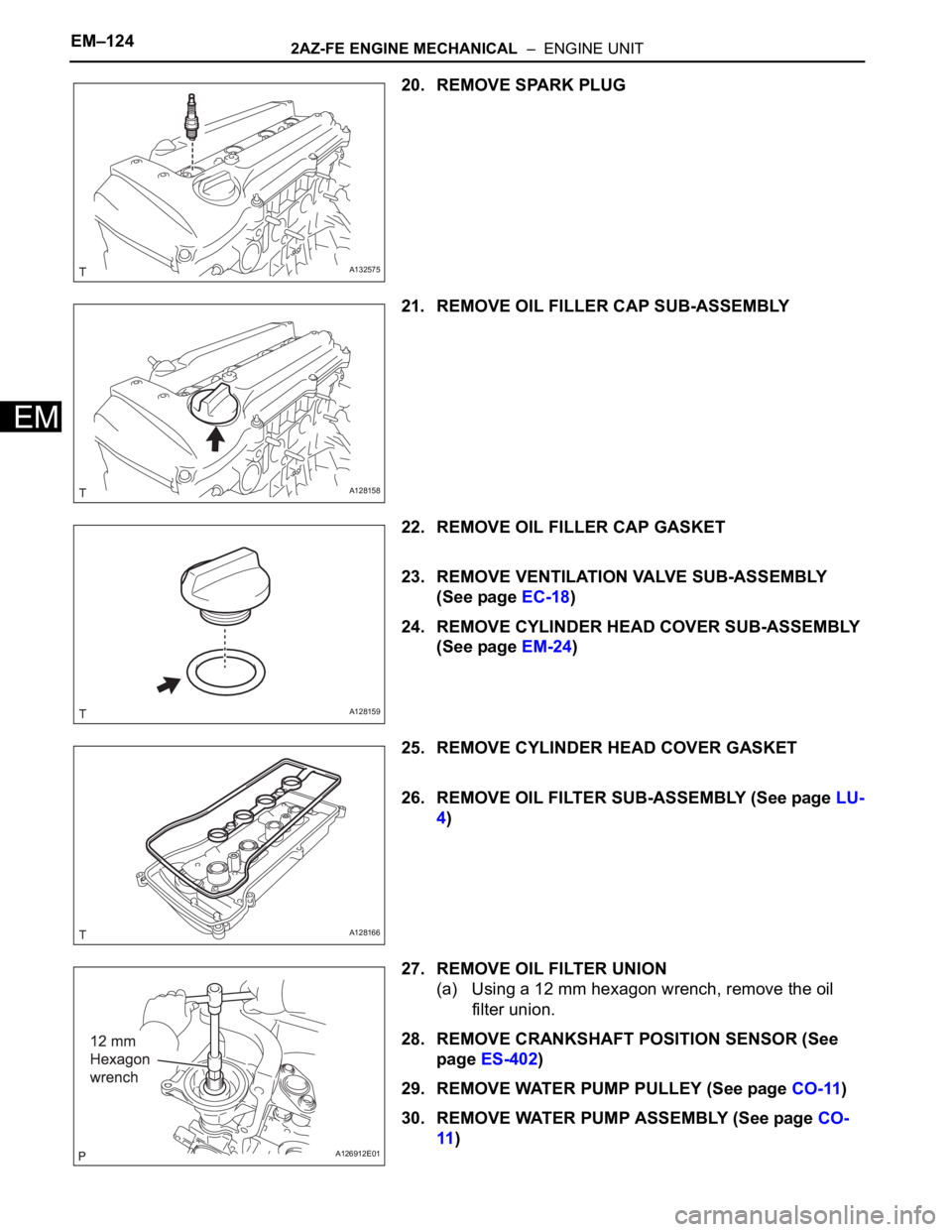

27. REMOVE OIL FILTER UNION

(a) Using a 12 mm hexagon wrench, remove the oil

filter union.

28. REMOVE CRANKSHAFT POSITION SENSOR (See

page ES-402)

29. REMOVE WATER PUMP PULLEY (See page CO-11)

30. REMOVE WATER PUMP ASSEMBLY (See page CO-

11)

A132575

A128158

A128159

A128166

A126912E01

Page 652 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–125

EM

31. REMOVE OIL PAN DRAIN PLUG

(a) Remove the oil pan drain plug and gasket.

32. REMOVE OIL PAN SUB-ASSEMBLY (See page EM-

24)

33. REMOVE CRANKSHAFT PULLEY (See page EM-25)

34. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY (See

page EM-26)

35. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

(See page EM-26)

36. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR

PLATE

37. REMOVE TIMING CHAIN GUIDE (See page EM-28)

38. REMOVE CHAIN TENSIONER SLIPPER (See page

EM-28)

39. REMOVE NO. 1 CHAIN VIBRATION DAMPER (See

page EM-28)

40. REMOVE CHAIN SUB-ASSEMBLY

41. REMOVE CRANKSHAFT TIMING SPROCKET

42. REMOVE NO. 2 CHAIN SUB-ASSEMBLY (See page

EM-29)

43. REMOVE OIL PUMP DRIVE GEAR

44. REMOVE OIL PUMP ASSEMBLY (See page LU-12)

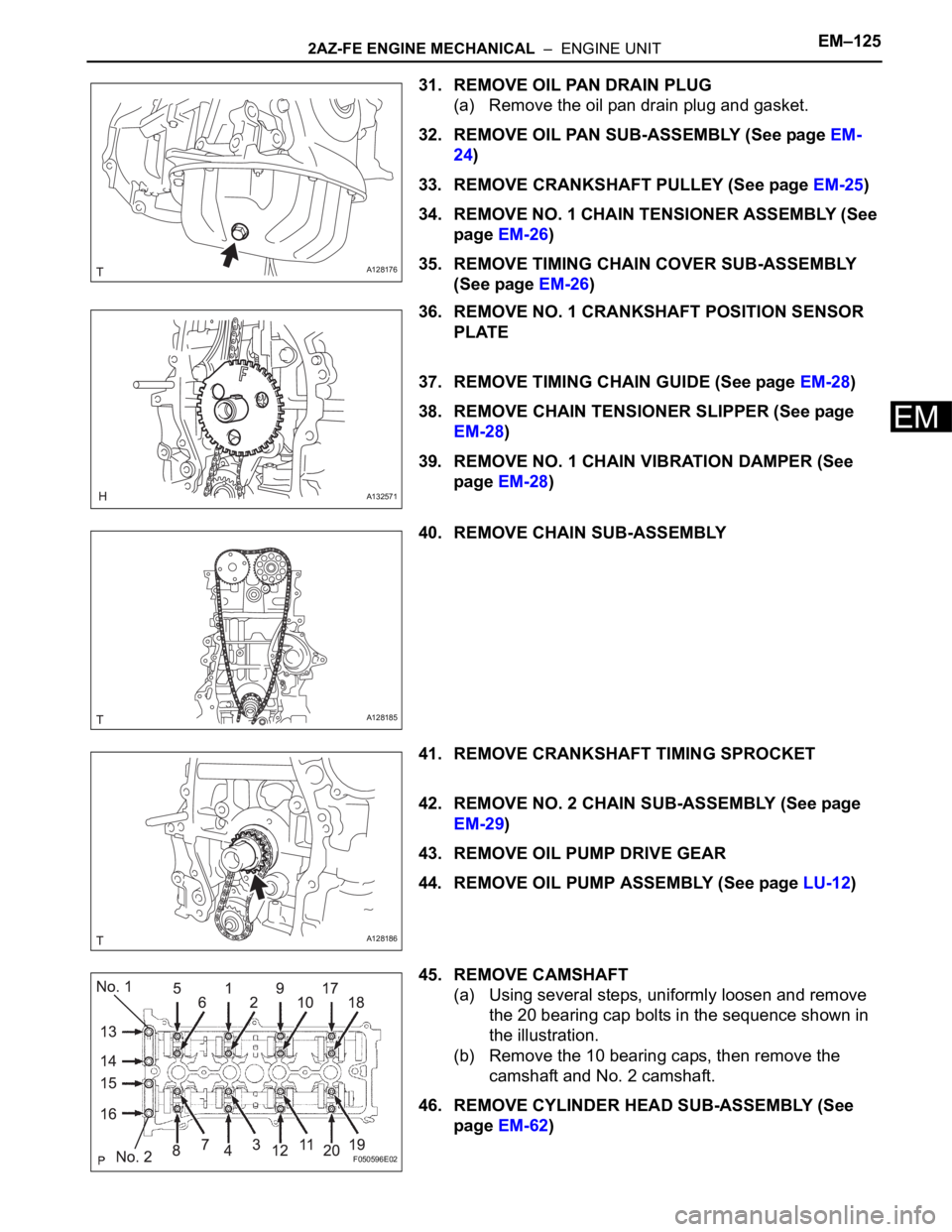

45. REMOVE CAMSHAFT

(a) Using several steps, uniformly loosen and remove

the 20 bearing cap bolts in the sequence shown in

the illustration.

(b) Remove the 10 bearing caps, then remove the

camshaft and No. 2 camshaft.

46. REMOVE CYLINDER HEAD SUB-ASSEMBLY (See

page EM-62)

A128176

A132571

A128185

A128186

F050596E02

Page 677 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–31

EM

INSTALLATION

1. INSTALL ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using a 19 mm deep socket wrench, install the

sensor and a new gasket.

Torque: 20 N*m (204 kgf*cm, 14 ft.*lbf)

2. INSTALL KNOCK SENSOR (See page ES-459)

3. INSTALL ENGINE OIL PRESSURE SWITCH

ASSEMBLY

(a) Clean the threads of the oil pressure switch. Apply

adhesive to 2 or 3 threads of the oil pressure switch.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond

1344 or Equivalent

(b) Using a 24 mm deep socket wrench, install the oil

pressure switch.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

4. INSTALL NO. 1 FRONT ENGINE MOUNTING

BRACKET LH

(a) Install the mounting bracket with the 6 bolts.

Torque: 54 N*m (551 kgf*cm, 40 ft.*lbf)

5. INSTALL WATER PUMP PULLEY (See page CO-14)

6. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Install the idler pulley and cover plate with the bolt.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

7. INSTALL NO. 2 TIMING GEAR COVER

(a) Install the gear cover with the 2 bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

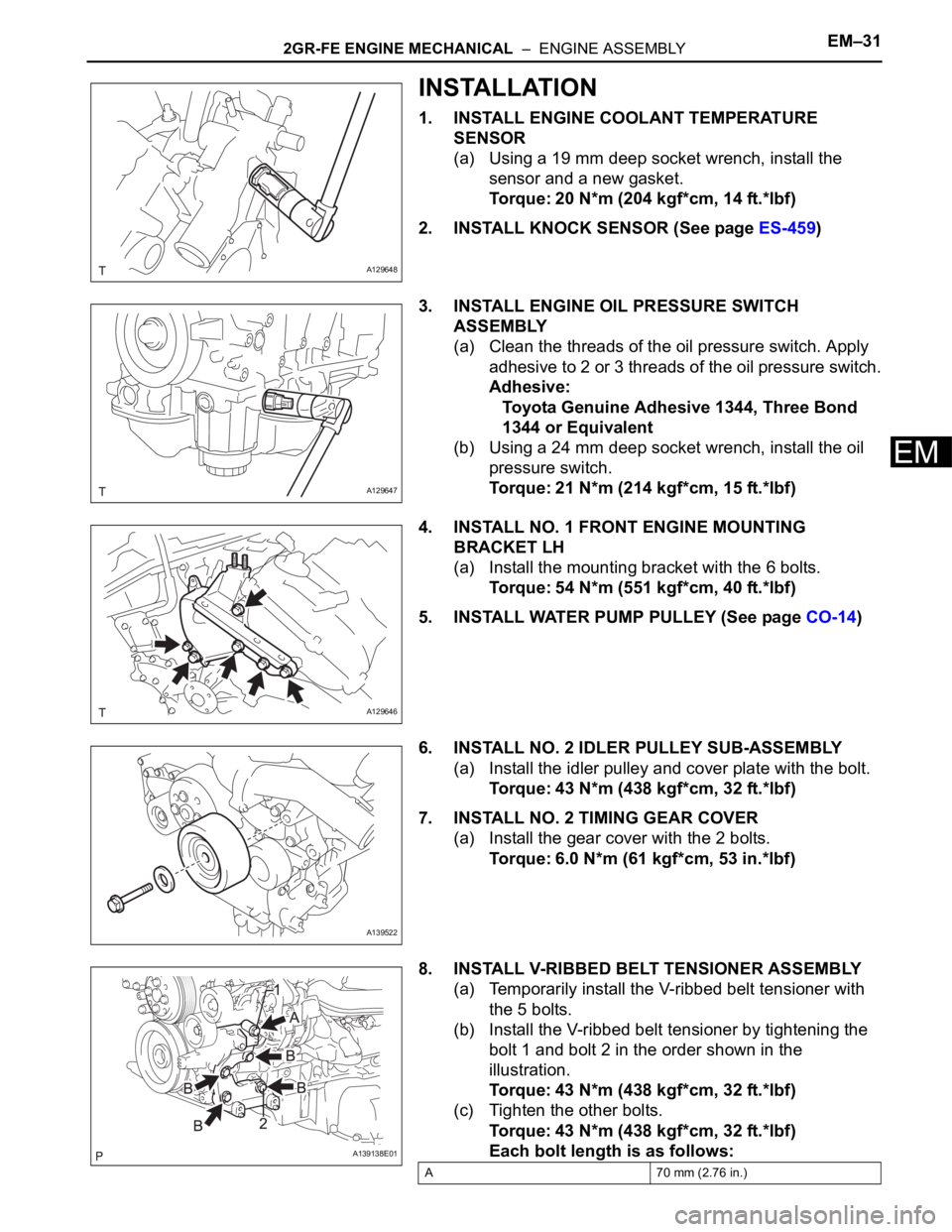

8. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(a) Temporarily install the V-ribbed belt tensioner with

the 5 bolts.

(b) Install the V-ribbed belt tensioner by tightening the

bolt 1 and bolt 2 in the order shown in the

illustration.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(c) Tighten the other bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

Each bolt length is as follows:

A129648

A129647

A129646

A139522

A139138E01

A 70 mm (2.76 in.)

Page 689 of 2000

EM–522GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

DISASSEMBLY

1. REMOVE OIL FILLER CAP SUB-ASSEMBLY

2. REMOVE SPARK PLUG

3. REMOVE CAMSHAFT TIMING CONTROL VALVE

ASSEMBLY (See page ES-440)

4. REMOVE VVT SENSOR (See page ES-443)

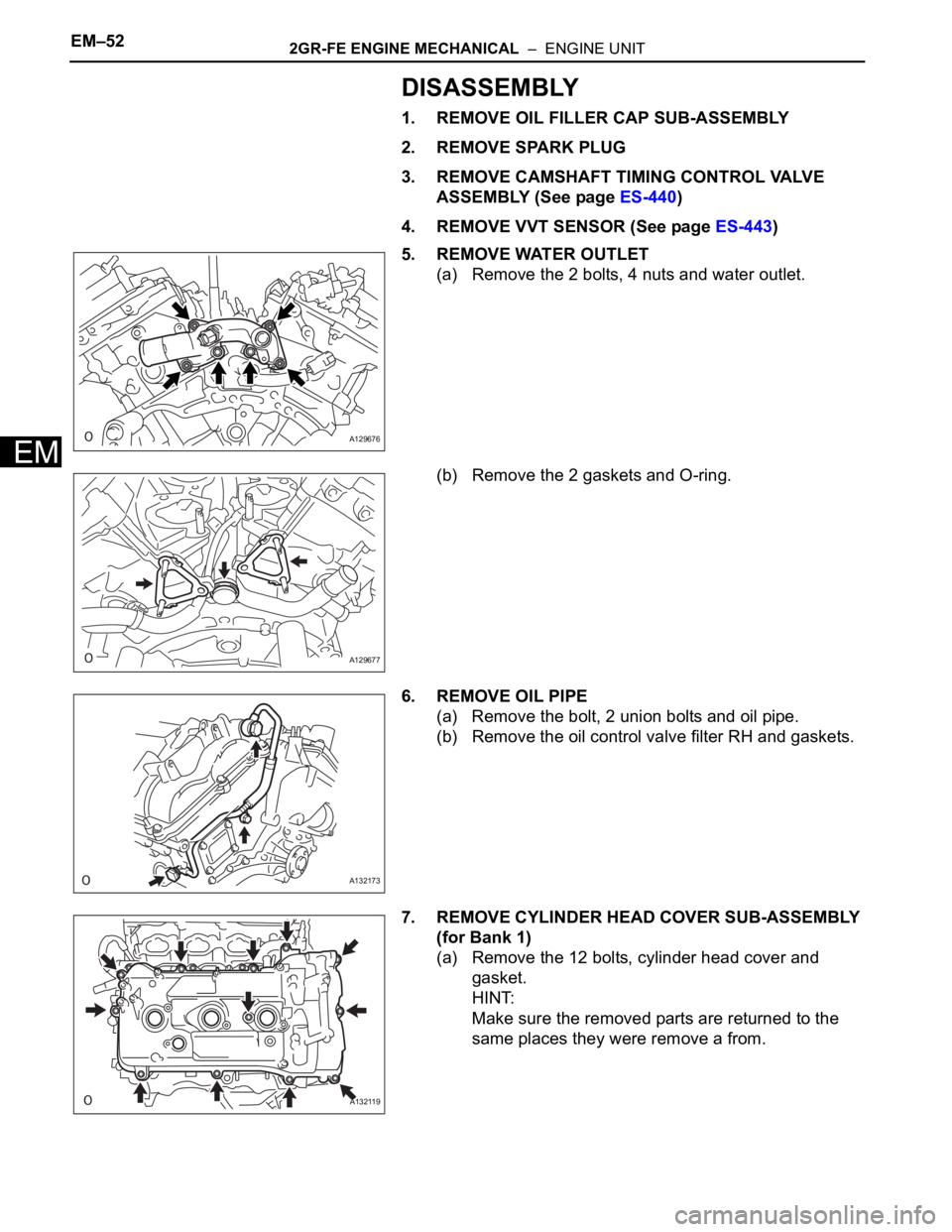

5. REMOVE WATER OUTLET

(a) Remove the 2 bolts, 4 nuts and water outlet.

(b) Remove the 2 gaskets and O-ring.

6. REMOVE OIL PIPE

(a) Remove the bolt, 2 union bolts and oil pipe.

(b) Remove the oil control valve filter RH and gaskets.

7. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(for Bank 1)

(a) Remove the 12 bolts, cylinder head cover and

gasket.

HINT:

Make sure the removed parts are returned to the

same places they were remove a from.

A129676

A129677

A132173

A132119

Page 692 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–55

EM

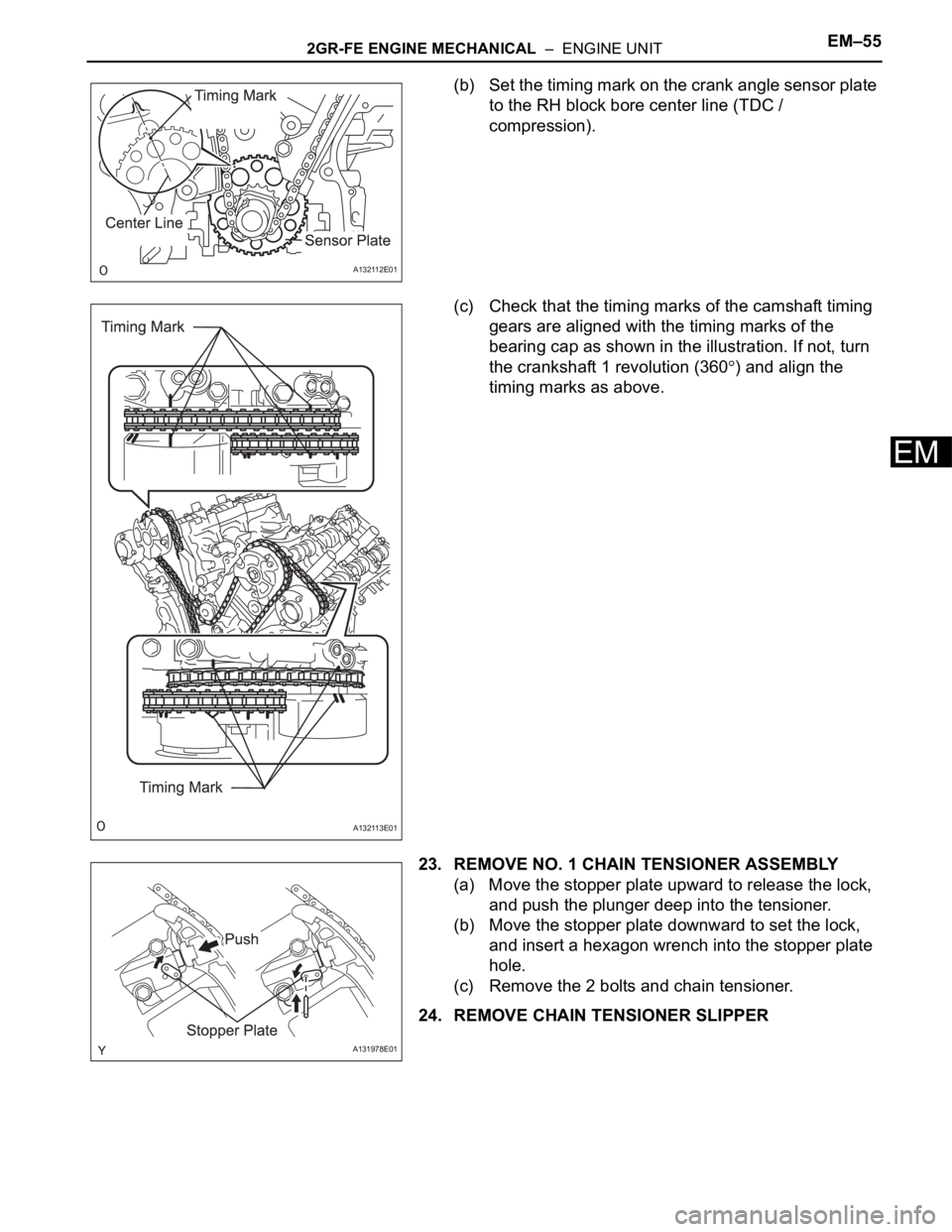

(b) Set the timing mark on the crank angle sensor plate

to the RH block bore center line (TDC /

compression).

(c) Check that the timing marks of the camshaft timing

gears are aligned with the timing marks of the

bearing cap as shown in the illustration. If not, turn

the crankshaft 1 revolution (360

) and align the

timing marks as above.

23. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Move the stopper plate upward to release the lock,

and push the plunger deep into the tensioner.

(b) Move the stopper plate downward to set the lock,

and insert a hexagon wrench into the stopper plate

hole.

(c) Remove the 2 bolts and chain tensioner.

24. REMOVE CHAIN TENSIONER SLIPPER

A132112E01

A132113E01

A131978E01

Page 698 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–61

EM

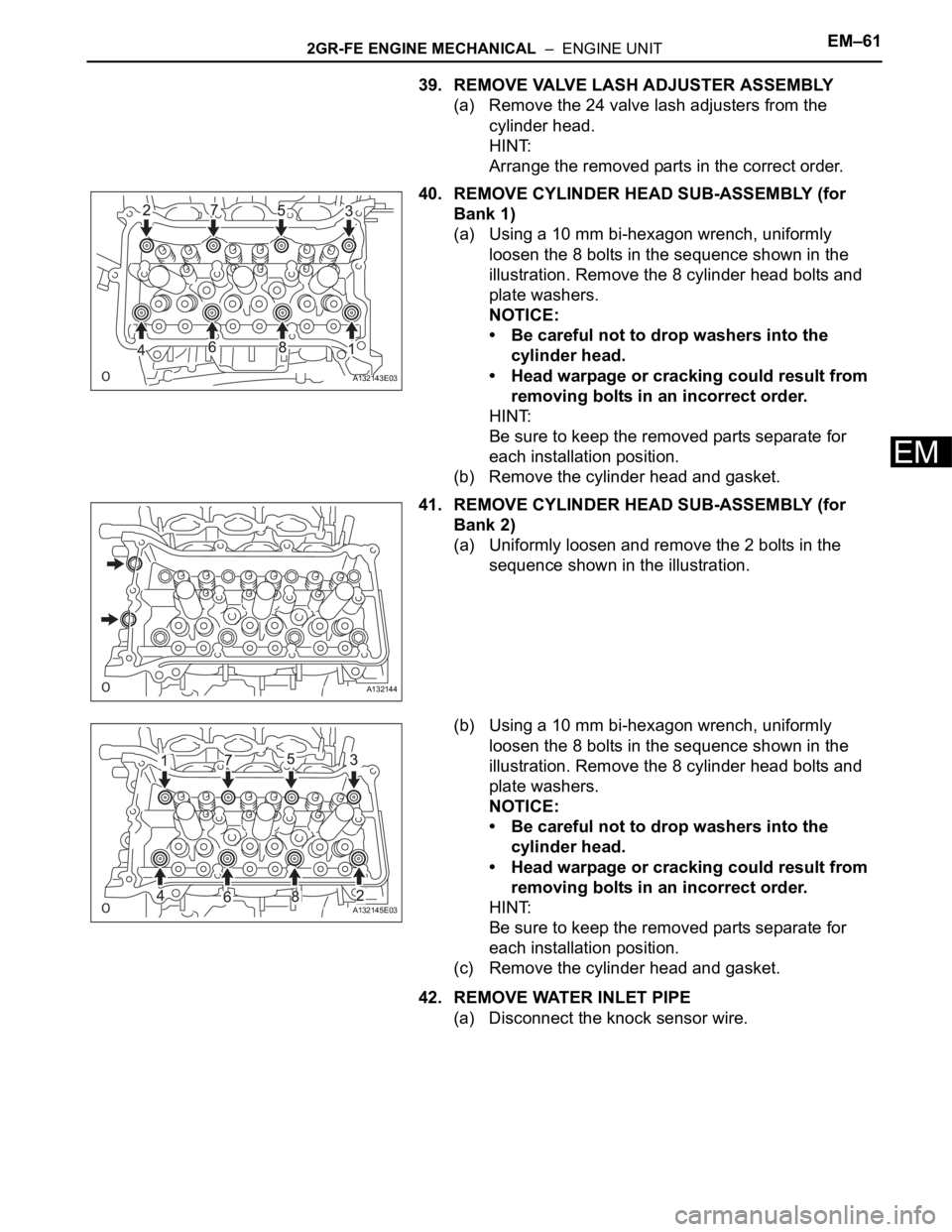

39. REMOVE VALVE LASH ADJUSTER ASSEMBLY

(a) Remove the 24 valve lash adjusters from the

cylinder head.

HINT:

Arrange the removed parts in the correct order.

40. REMOVE CYLINDER HEAD SUB-ASSEMBLY (for

Bank 1)

(a) Using a 10 mm bi-hexagon wrench, uniformly

loosen the 8 bolts in the sequence shown in the

illustration. Remove the 8 cylinder head bolts and

plate washers.

NOTICE:

• Be careful not to drop washers into the

cylinder head.

• Head warpage or cracking could result from

removing bolts in an incorrect order.

HINT:

Be sure to keep the removed parts separate for

each installation position.

(b) Remove the cylinder head and gasket.

41. REMOVE CYLINDER HEAD SUB-ASSEMBLY (for

Bank 2)

(a) Uniformly loosen and remove the 2 bolts in the

sequence shown in the illustration.

(b) Using a 10 mm bi-hexagon wrench, uniformly

loosen the 8 bolts in the sequence shown in the

illustration. Remove the 8 cylinder head bolts and

plate washers.

NOTICE:

• Be careful not to drop washers into the

cylinder head.

• Head warpage or cracking could result from

removing bolts in an incorrect order.

HINT:

Be sure to keep the removed parts separate for

each installation position.

(c) Remove the cylinder head and gasket.

42. REMOVE WATER INLET PIPE

(a) Disconnect the knock sensor wire.

A132143E03

A132144

A132145E03

Page 700 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–63

EM

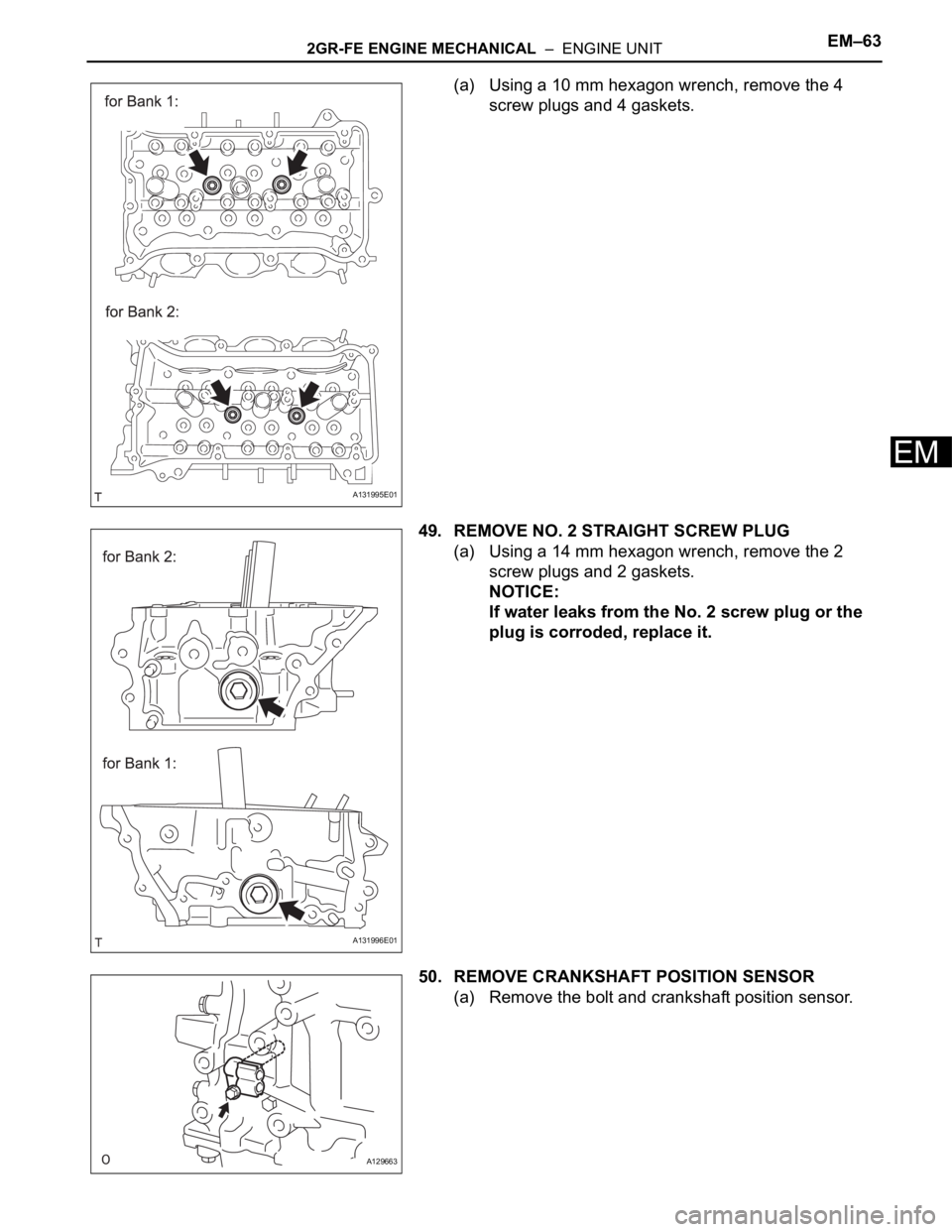

(a) Using a 10 mm hexagon wrench, remove the 4

screw plugs and 4 gaskets.

49. REMOVE NO. 2 STRAIGHT SCREW PLUG

(a) Using a 14 mm hexagon wrench, remove the 2

screw plugs and 2 gaskets.

NOTICE:

If water leaks from the No. 2 screw plug or the

plug is corroded, replace it.

50. REMOVE CRANKSHAFT POSITION SENSOR

(a) Remove the bolt and crankshaft position sensor.

A131995E01

A131996E01

A129663

Page 750 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–113

EM

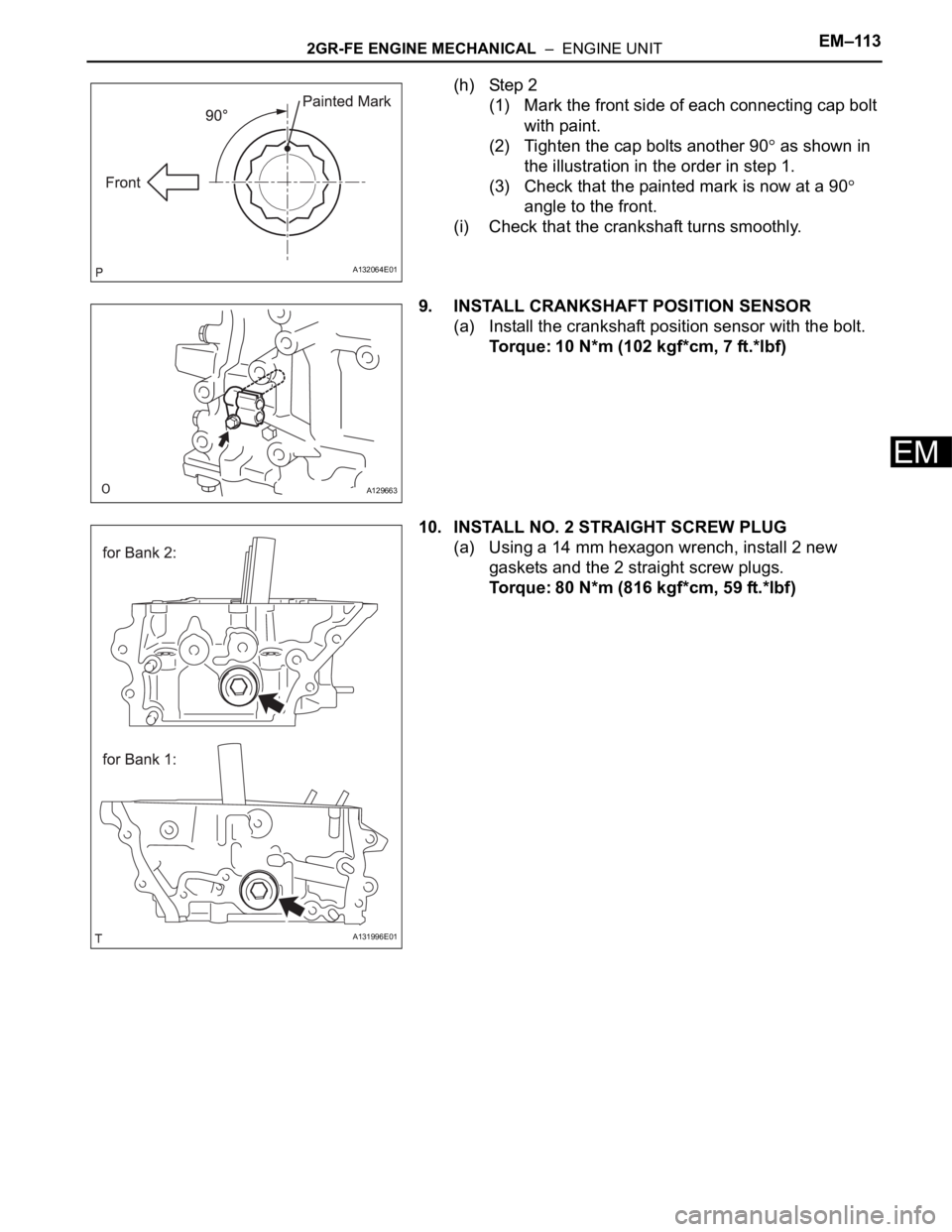

(h) Step 2

(1) Mark the front side of each connecting cap bolt

with paint.

(2) Tighten the cap bolts another 90

as shown in

the illustration in the order in step 1.

(3) Check that the painted mark is now at a 90

angle to the front.

(i) Check that the crankshaft turns smoothly.

9. INSTALL CRANKSHAFT POSITION SENSOR

(a) Install the crankshaft position sensor with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

10. INSTALL NO. 2 STRAIGHT SCREW PLUG

(a) Using a 14 mm hexagon wrench, install 2 new

gaskets and the 2 straight screw plugs.

Torque: 80 N*m (816 kgf*cm, 59 ft.*lbf)

A132064E01

A129663

A131996E01

Page 767 of 2000

EM–1302GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

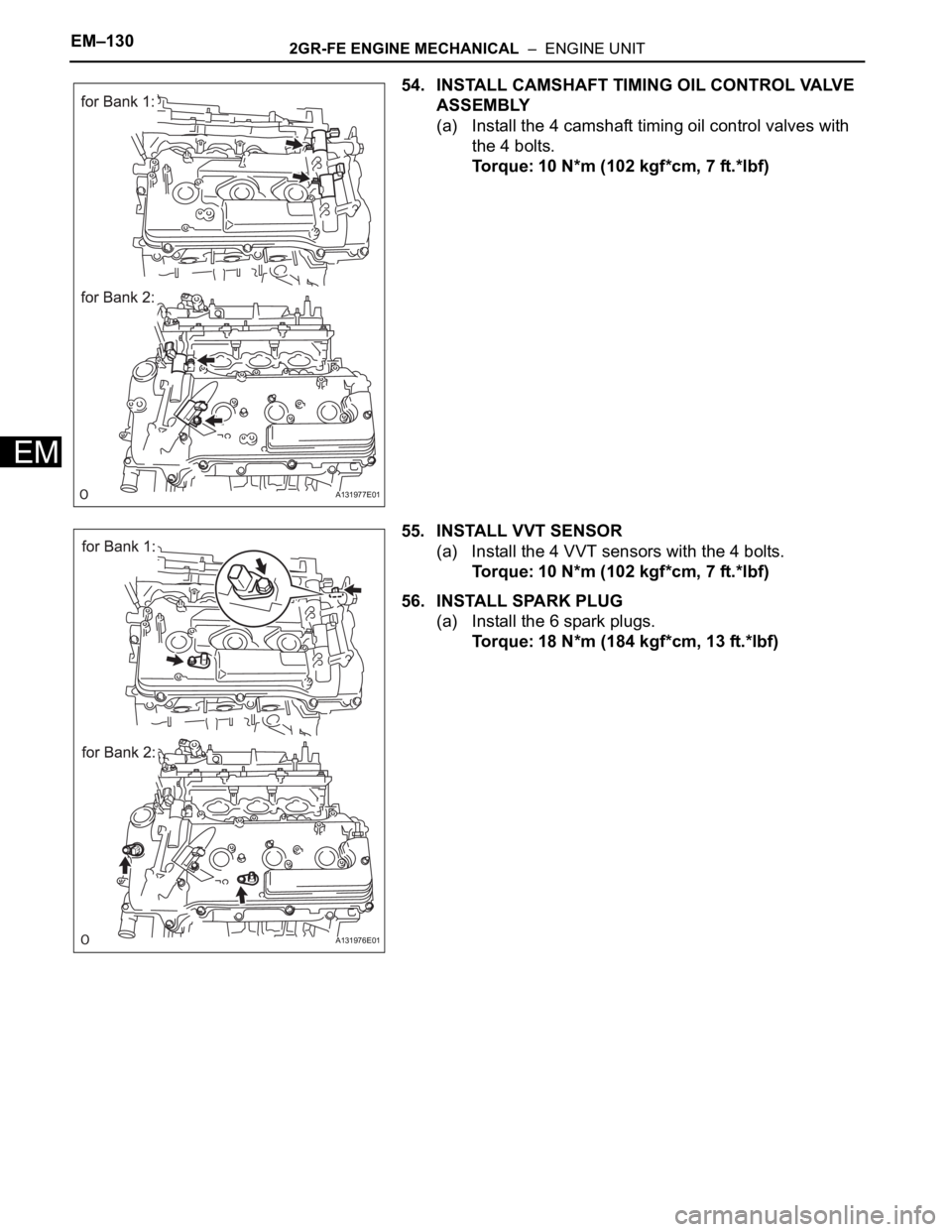

54. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY

(a) Install the 4 camshaft timing oil control valves with

the 4 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

55. INSTALL VVT SENSOR

(a) Install the 4 VVT sensors with the 4 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

56. INSTALL SPARK PLUG

(a) Install the 6 spark plugs.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

A131977E01

A131976E01