TOYOTA RAV4 2006 Service Repair Manual

RAV4 2006

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57463/w960_57463-0.png

TOYOTA RAV4 2006 Service Repair Manual

Page 241 of 2000

2AZ-FE COOLING – COOLING FAN SYSTEMCO–5

CO

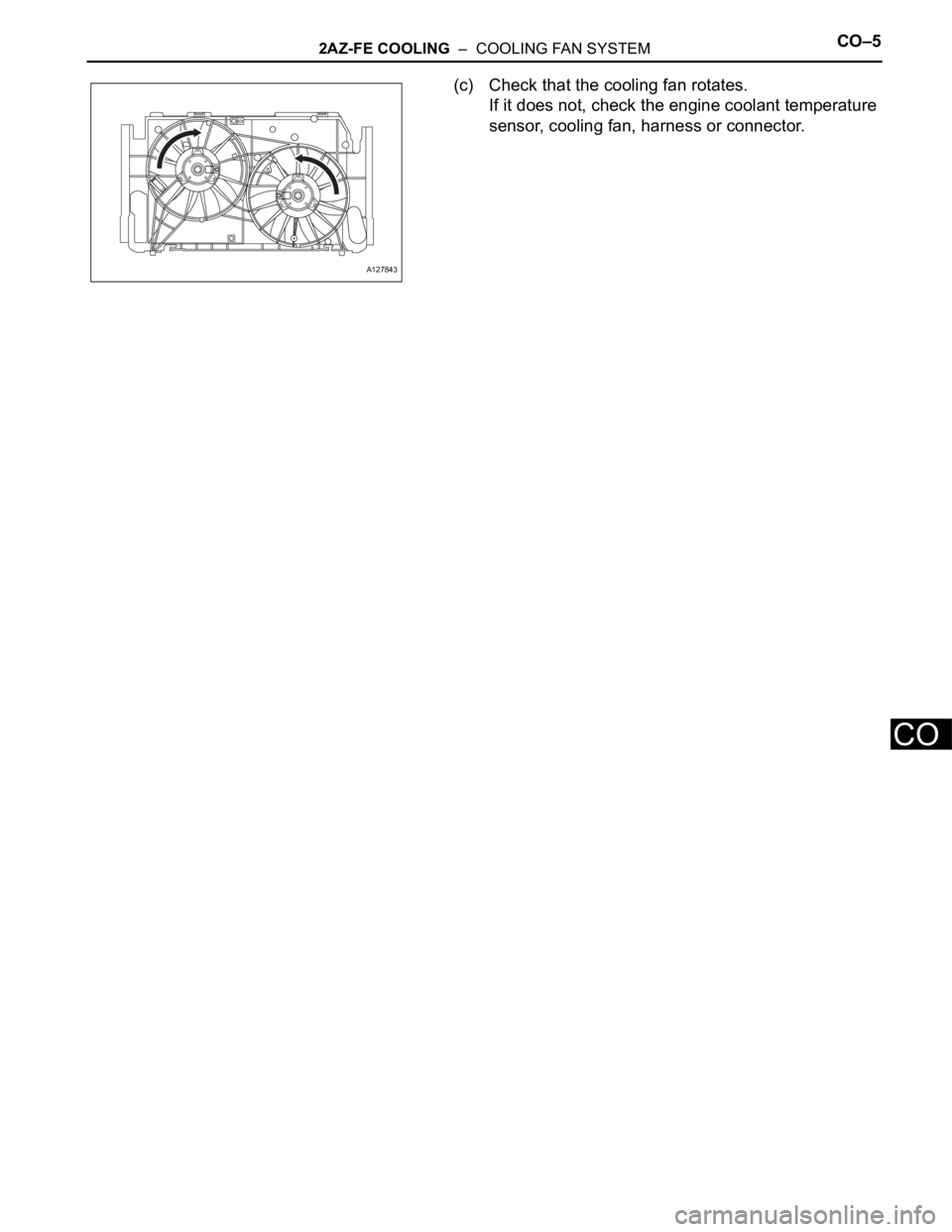

(c) Check that the cooling fan rotates.

If it does not, check the engine coolant temperature

sensor, cooling fan, harness or connector.

A127843

Page 245 of 2000

2AZ-FE LUBRICATION – OIL PUMPLU–13

LU

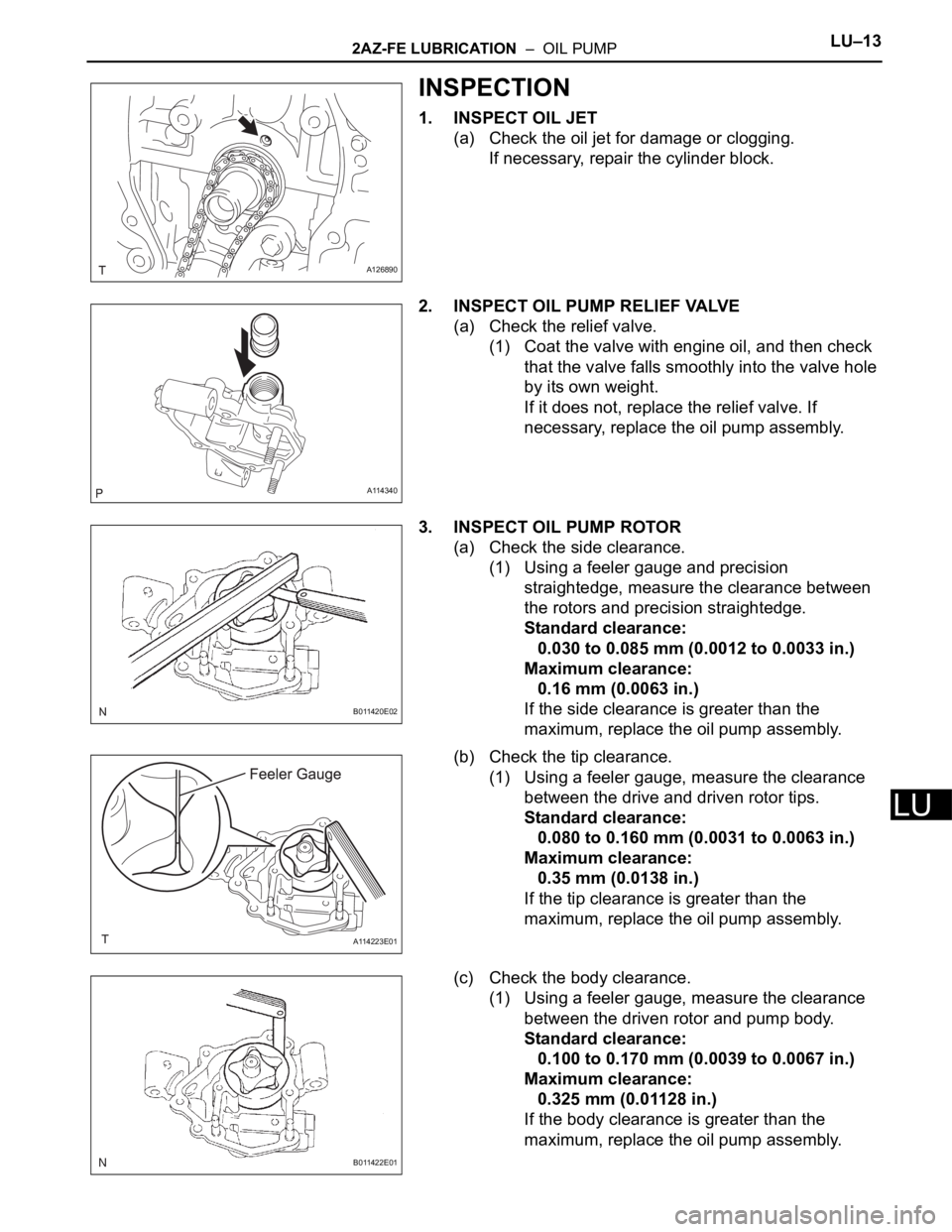

INSPECTION

1. INSPECT OIL JET

(a) Check the oil jet for damage or clogging.

If necessary, repair the cylinder block.

2. INSPECT OIL PUMP RELIEF VALVE

(a) Check the relief valve.

(1) Coat the valve with engine oil, and then check

that the valve falls smoothly into the valve hole

by its own weight.

If it does not, replace the relief valve. If

necessary, replace the oil pump assembly.

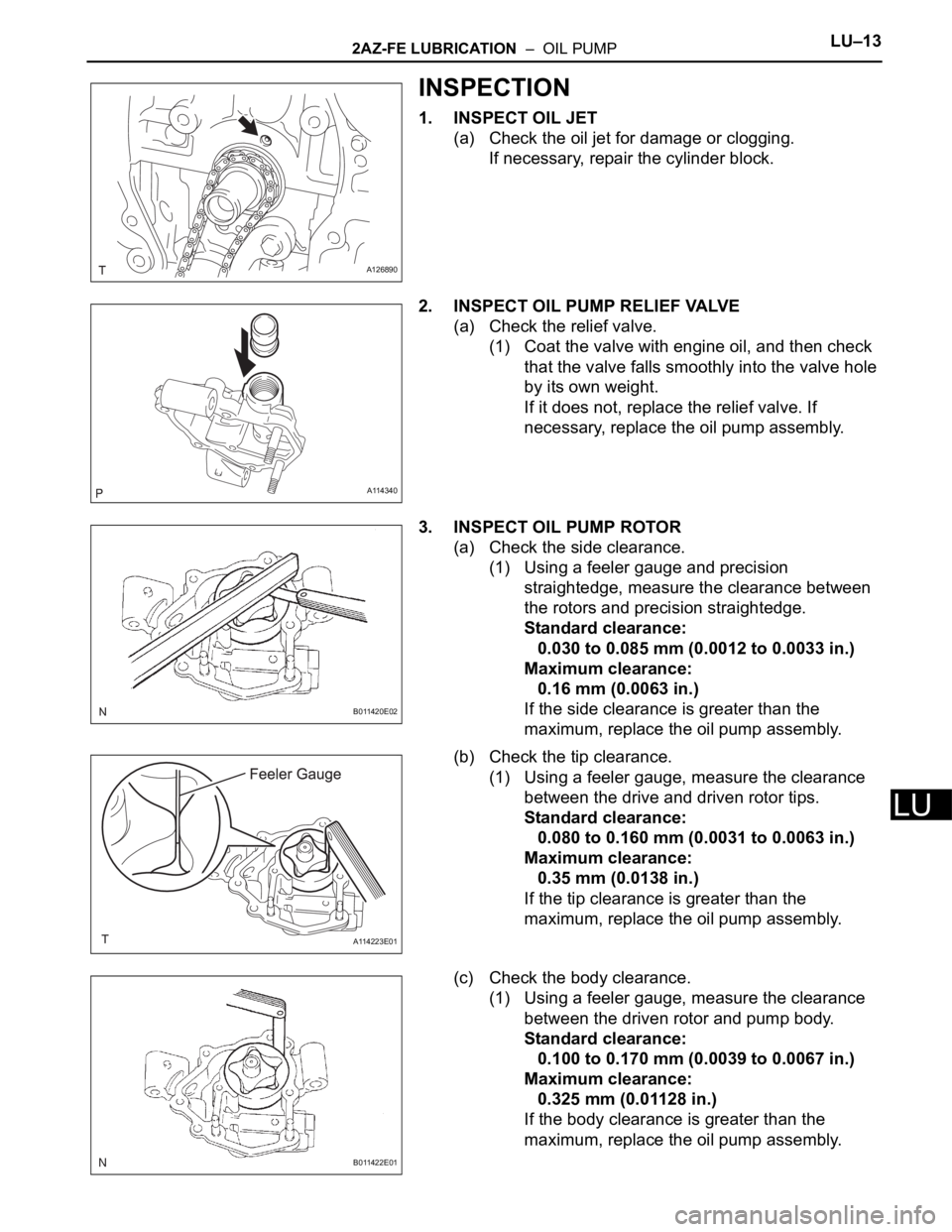

3. INSPECT OIL PUMP ROTOR

(a) Check the side clearance.

(1) Using a feeler gauge and precision

straightedge, measure the clearance between

the rotors and precision straightedge.

Standard clearance:

0.030 to 0.085 mm (0.0012 to 0.0033 in.)

Maximum clearance:

0.16 mm (0.0063 in.)

If the side clearance is greater than the

maximum, replace the oil pump assembly.

(b) Check the tip clearance.

(1) Using a feeler gauge, measure the clearance

between the drive and driven rotor tips.

Standard clearance:

0.080 to 0.160 mm (0.0031 to 0.0063 in.)

Maximum clearance:

0.35 mm (0.0138 in.)

If the tip clearance is greater than the

maximum, replace the oil pump assembly.

(c) Check the body clearance.

(1) Using a feeler gauge, measure the clearance

between the driven rotor and pump body.

Standard clearance:

0.100 to 0.170 mm (0.0039 to 0.0067 in.)

Maximum clearance:

0.325 mm (0.01128 in.)

If the body clearance is greater than the

maximum, replace the oil pump assembly.

A126890

A114340

B011420E02

A114223E01

B011422E01

Page 247 of 2000

LU–122GR-FE LUBRICATION – OIL PUMP

LU

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-9)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

3. REMOVE ENGINE ASSEMBLY

(a) Remove the engine from the vehicle (see page EM-

21).

4. INSTALL ENGINE TO STAND

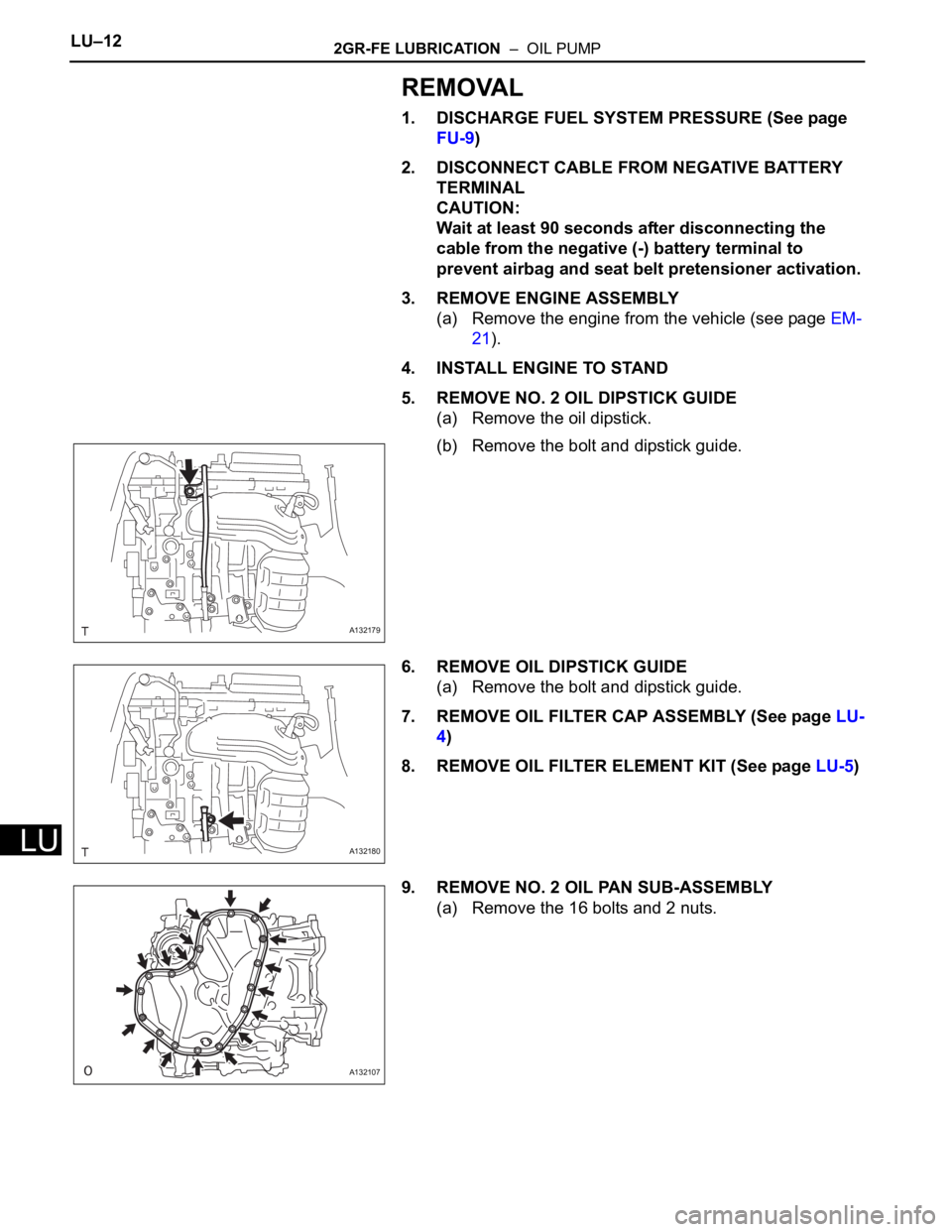

5. REMOVE NO. 2 OIL DIPSTICK GUIDE

(a) Remove the oil dipstick.

(b) Remove the bolt and dipstick guide.

6. REMOVE OIL DIPSTICK GUIDE

(a) Remove the bolt and dipstick guide.

7. REMOVE OIL FILTER CAP ASSEMBLY (See page LU-

4)

8. REMOVE OIL FILTER ELEMENT KIT (See page LU-5)

9. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

(a) Remove the 16 bolts and 2 nuts.

A132179

A132180

A132107

Page 251 of 2000

PP–6PREPARATION – 2AZ-FE ENGINE MECHANICAL

PP

RECOMMENDED TOOLS

09011-12301 Socket Wrench 30 mm -

09040-00011 Hexagon Wrench Set -

(09043-20060) Socket Hexagon Wrench 6 -

(09043-20120) Socket Hexagon Wrench 12 -

09043-50100 Bi-hexagon Wrench 10 mm -

09044-00020 Torx Socket E10 -

09090-04020 Engine Sling Device -

(09857-00031) Spark Plug Gap Gauge -

Page 252 of 2000

PREPARATION – 2AZ-FE ENGINE MECHANICALPP–7

PP

EQUIPMENT

V-block -

Piston ring compressor -

Piston ring expander -

Valve seat cutter -

Feeler gauge -

CO/HC meter -

Connecting rod aligner -

Cylinder gauge -

Micrometer -

Precision straight edge -

Radiator cap tester -

Steel square -

Tachometer -

Torque wrench -

Vernier calipers -

Dial indicator with magnetic base -

Alignment tester -

toe-in gauge -

Spring tension gauge -

Slide calipers -

Sandpaper (#400) -

Piston heater -

Wooden block -

Plastigage -

Angle gauge -

Timing light -

Page 255 of 2000

PP–8PREPARATION – 2AZ-FE ENGINE MECHANICAL

PP

SSM

Toyota Genuine Seal Packing Black, Three Bond 1207B or Equivalent -

Toyota Genuine Adhesive 1324, Three Bond 1324 or Equivalent -

Toyota Genuine Adhesive, Three Bond 1344 or Equivalent -

Page 256 of 2000

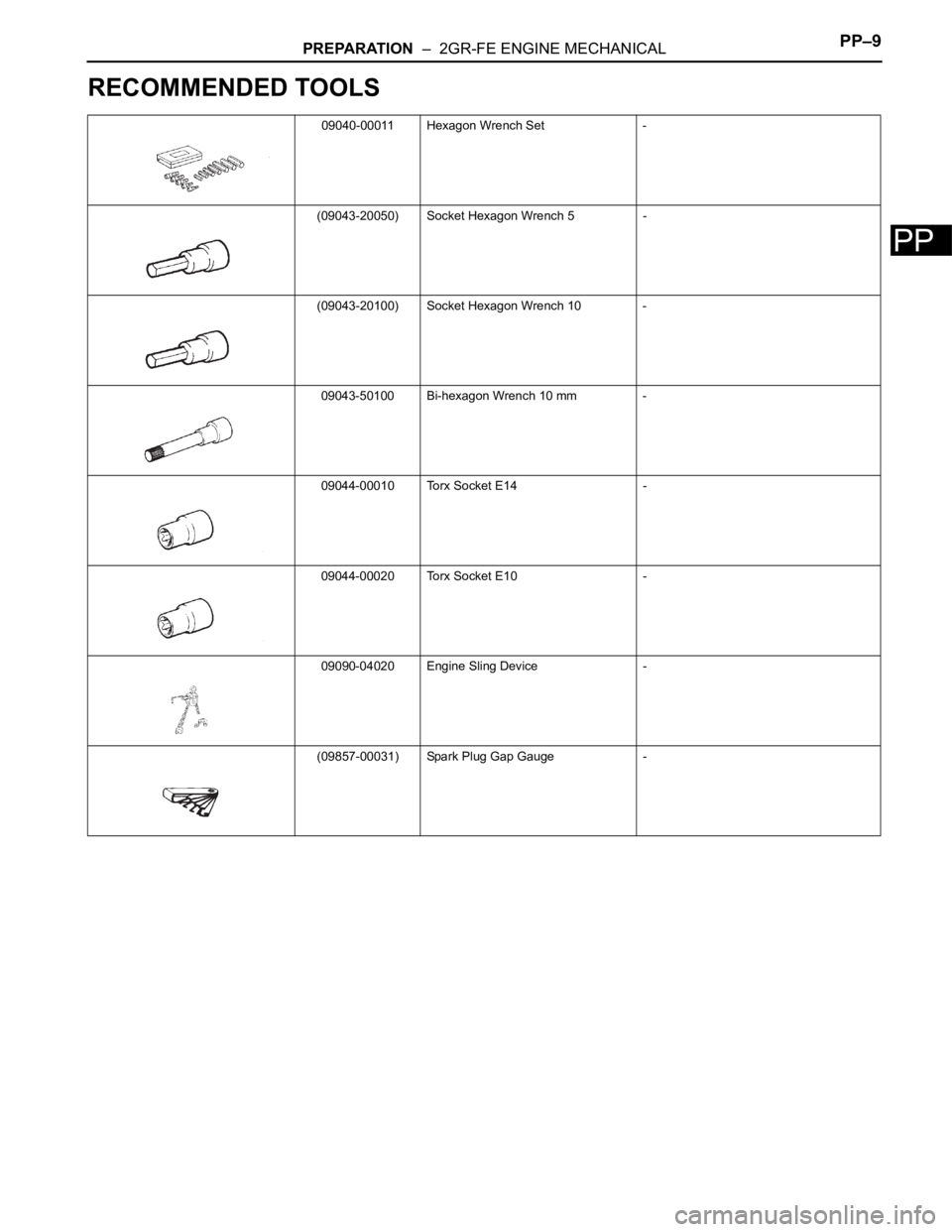

PREPARATION – 2GR-FE ENGINE MECHANICALPP–9

PP

RECOMMENDED TOOLS

09040-00011 Hexagon Wrench Set -

(09043-20050) Socket Hexagon Wrench 5 -

(09043-20100) Socket Hexagon Wrench 10 -

09043-50100 Bi-hexagon Wrench 10 mm -

09044-00010 Torx Socket E14 -

09044-00020 Torx Socket E10 -

09090-04020 Engine Sling Device -

(09857-00031) Spark Plug Gap Gauge -

Page 257 of 2000

PP–10PREPARATION – 2GR-FE ENGINE MECHANICAL

PP

EQUIPMENT

Alignment tester -

Angle gauge -

Brass bar -

Caliper gauge -

Chain block -

Compression gauge -

CO/HC meter -

Connecting rod aligner -

Cylinder gauge -

Dial indicator with magnetic base -

Engine stand -

Feeler gauge -

Gasket scraper -

Magnetic finger -

Micrometer -

Needle-nose pliers -

No. 1 engine hanger -

No. 2 engine hanger -

Pin hole grinder -

Piston ring compressor -

Piston ring expander -

Piston heater -

Plastigage -

Plastic-faced hammer -

Press -

Radiator cap tester -

Reamer (5.5 mm) -

Ridge reamer -

Rod aligner -

Sandpaper (#400) -

Slide calipers -

Straightedge -

Spring scale -

Spring tension gauge -

Steel square -

Tachometer -

Timing light -

Toe-in gauge -

To r q u e w r e n c h -

Valve seat cutter -

V-block -

Vernier calipers -

Vise -

Wooden block -

Page 258 of 2000

PREPARATION – 2GR-FE ENGINE MECHANICALPP–11

PP

SSM

Toyota Genuine Seal Packing Black, Three Bond 1207B or Equivalent -

Toyota Genuine Adhesive 1324, Three Bond 1324 or Equivalent -

Toyota Genuine Adhesive, Three Bond 1344 or Equivalent -

Page 303 of 2000

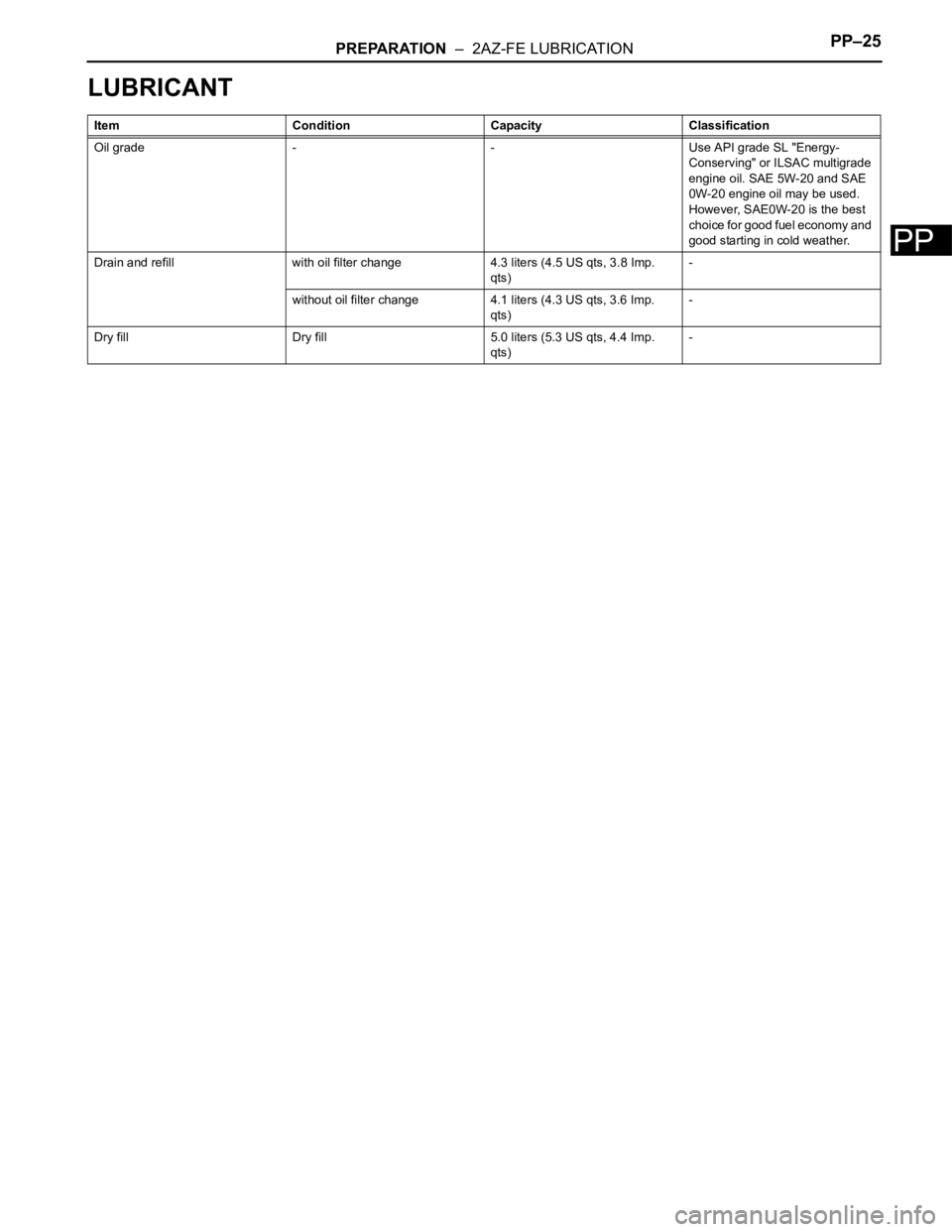

PREPARATION – 2AZ-FE LUBRICATIONPP–25

PP

LUBRICANT

Item Condition Capacity Classification

Oil grade - - Use API grade SL "Energy-

Conserving" or ILSAC multigrade

engine oil. SAE 5W-20 and SAE

0W-20 engine oil may be used.

However, SAE0W-20 is the best

choice for good fuel economy and

good starting in cold weather.

Drain and refill with oil filter change 4.3 liters (4.5 US qts, 3.8 Imp.

qts)-

without oil filter change 4.1 liters (4.3 US qts, 3.6 Imp.

qts)-

Dry fill Dry fill 5.0 liters (5.3 US qts, 4.4 Imp.

qts)-