engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 384 of 2000

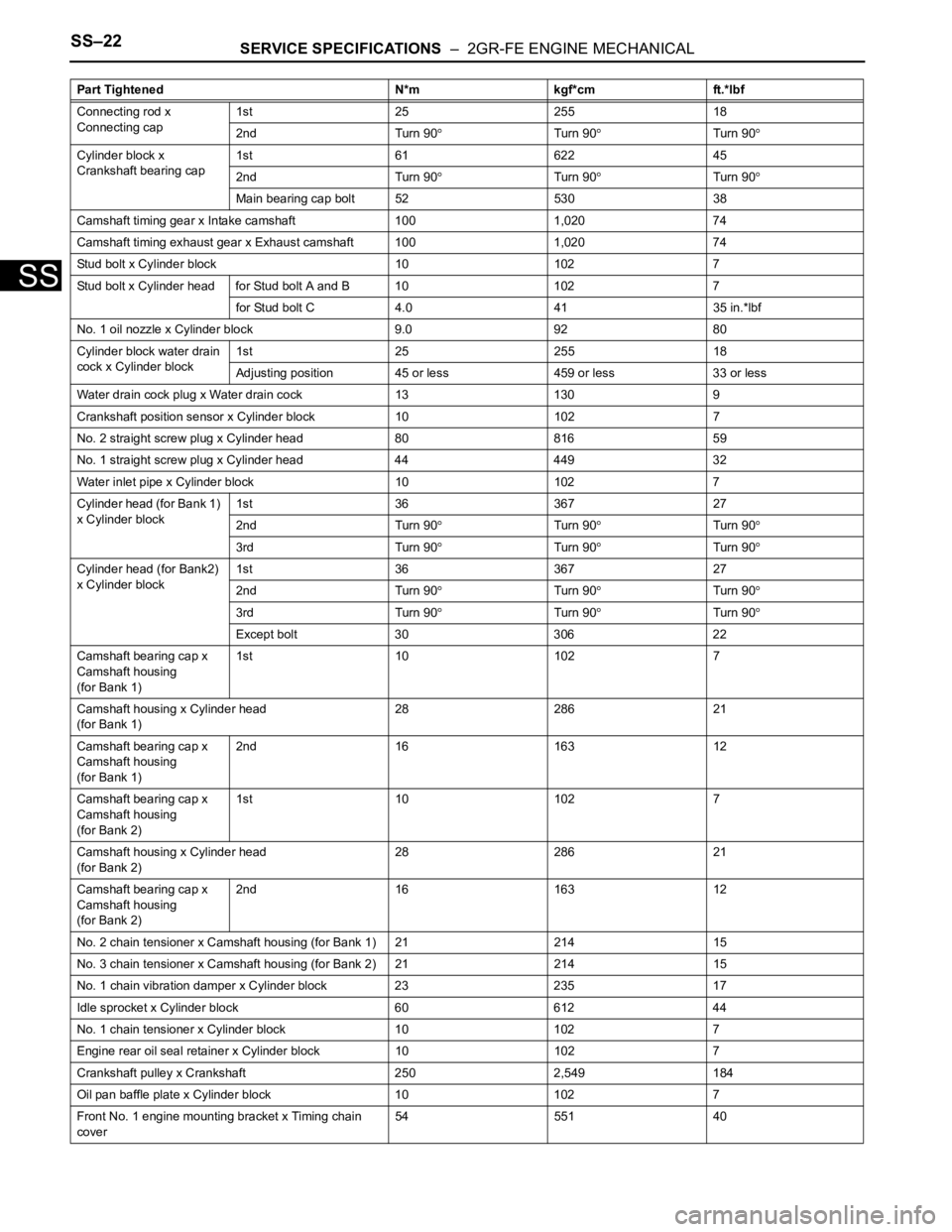

SS–22SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICAL

SS

Connecting rod x

Connecting cap1st 25 255 18

2nd Turn 90

Turn 90Turn 90

Cylinder block x

Crankshaft bearing cap1st 61 622 45

2nd Turn 90

Turn 90Turn 90

Main bearing cap bolt 52 530 38

Camshaft timing gear x Intake camshaft 100 1,020 74

Camshaft timing exhaust gear x Exhaust camshaft 100 1,020 74

Stud bolt x Cylinder block 10 102 7

Stud bolt x Cylinder head for Stud bolt A and B 10 102 7

for Stud bolt C 4.0 41 35 in.*lbf

No. 1 oil nozzle x Cylinder block 9.0 92 80

Cylinder block water drain

cock x Cylinder block1st 25 255 18

Adjusting position 45 or less 459 or less 33 or less

Water drain cock plug x Water drain cock 13 130 9

Crankshaft position sensor x Cylinder block 10 102 7

No. 2 straight screw plug x Cylinder head 80 816 59

No. 1 straight screw plug x Cylinder head 44 449 32

Water inlet pipe x Cylinder block 10 102 7

Cylinder head (for Bank 1)

x Cylinder block1st 36 367 27

2nd Turn 90

Turn 90Turn 90

3rd Turn 90Turn 90Turn 90

Cylinder head (for Bank2)

x Cylinder block1st 36 367 27

2nd Turn 90

Turn 90Turn 90

3rd Turn 90Turn 90Turn 90

Except bolt 30 306 22

Camshaft bearing cap x

Camshaft housing

(for Bank 1)1st 10 102 7

Camshaft housing x Cylinder head

(for Bank 1)28 286 21

Camshaft bearing cap x

Camshaft housing

(for Bank 1)2nd 16 163 12

Camshaft bearing cap x

Camshaft housing

(for Bank 2)1st 10 102 7

Camshaft housing x Cylinder head

(for Bank 2)28 286 21

Camshaft bearing cap x

Camshaft housing

(for Bank 2)2nd 16 163 12

No. 2 chain tensioner x Camshaft housing (for Bank 1) 21 214 15

No. 3 chain tensioner x Camshaft housing (for Bank 2) 21 214 15

No. 1 chain vibration damper x Cylinder block 23 235 17

Idle sprocket x Cylinder block 60 612 44

No. 1 chain tensioner x Cylinder block 10 102 7

Engine rear oil seal retainer x Cylinder block 10 102 7

Crankshaft pulley x Crankshaft 250 2,549 184

Oil pan baffle plate x Cylinder block 10 102 7

Front No. 1 engine mounting bracket x Timing chain

cover54 551 40 Part Tightened N*m kgf*cm ft.*lbf

Page 385 of 2000

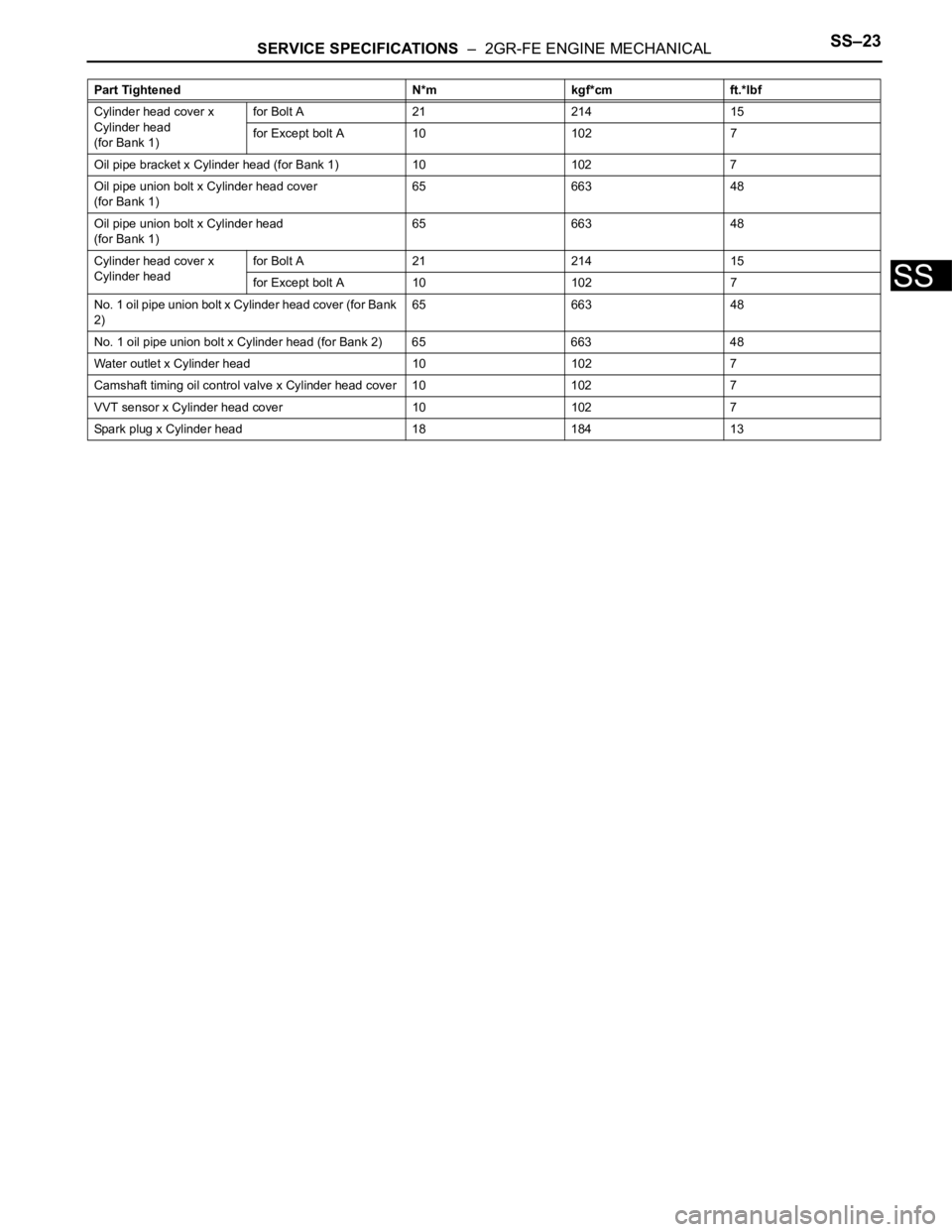

SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICALSS–23

SS

Cylinder head cover x

Cylinder head

(for Bank 1)for Bolt A 21 214 15

for Except bolt A 10 102 7

Oil pipe bracket x Cylinder head (for Bank 1) 10 102 7

Oil pipe union bolt x Cylinder head cover

(for Bank 1)65 663 48

Oil pipe union bolt x Cylinder head

(for Bank 1)65 663 48

Cylinder head cover x

Cylinder headfor Bolt A 21 214 15

for Except bolt A 10 102 7

No. 1 oil pipe union bolt x Cylinder head cover (for Bank

2)65 663 48

No. 1 oil pipe union bolt x Cylinder head (for Bank 2) 65 663 48

Water outlet x Cylinder head 10 102 7

Camshaft timing oil control valve x Cylinder head cover 10 102 7

VVT sensor x Cylinder head cover 10 102 7

Spark plug x Cylinder head 18 184 13 Part Tightened N*m kgf*cm ft.*lbf

Page 386 of 2000

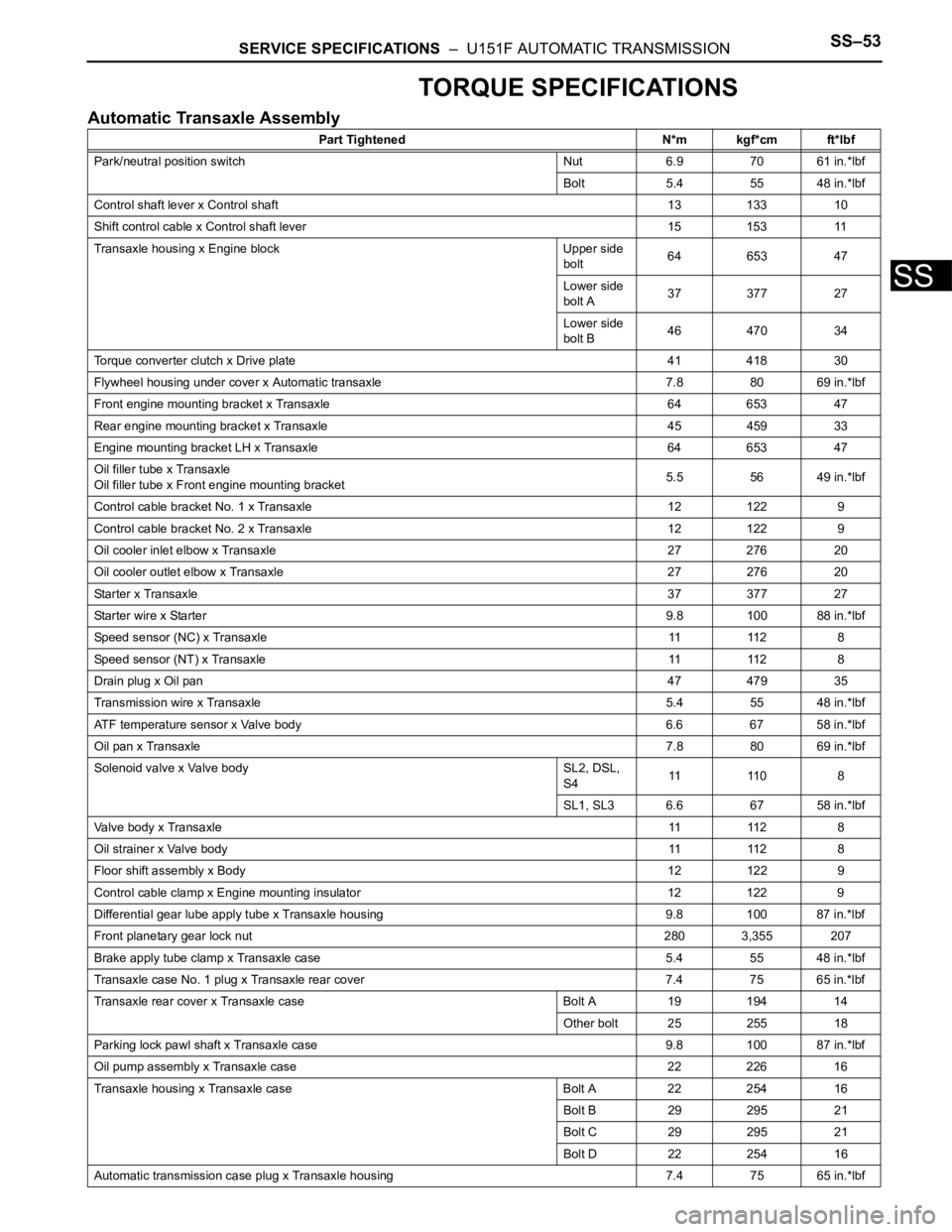

SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSMISSIONSS–53

SS

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 133 10

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block Upper side

bolt64 653 47

Lower side

bolt A37 377 27

Lower side

bolt B46 470 34

Torque converter clutch x Drive plate 41 418 30

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Front engine mounting bracket x Transaxle 64 653 47

Rear engine mounting bracket x Transaxle 45 459 33

Engine mounting bracket LH x Transaxle 64 653 47

Oil filler tube x Transaxle

Oil filler tube x Front engine mounting bracket5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler inlet elbow x Transaxle 27 276 20

Oil cooler outlet elbow x Transaxle 27 276 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 88 in.*lbf

Speed sensor (NC) x Transaxle11 11 2 8

Speed sensor (NT) x Transaxle11 11 2 8

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body SL2, DSL,

S411 11 0 8

SL1, SL3 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 2 8

Oil strainer x Valve body11 11 2 8

Floor shift assembly x Body12 122 9

Control cable clamp x Engine mounting insulator 12 122 9

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut280 3,355 207

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 194 14

Other bolt 25 255 18

Parking lock pawl shaft x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22 254 16

Bolt B 29 295 21

Bolt C 29 295 21

Bolt D 22 254 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Page 388 of 2000

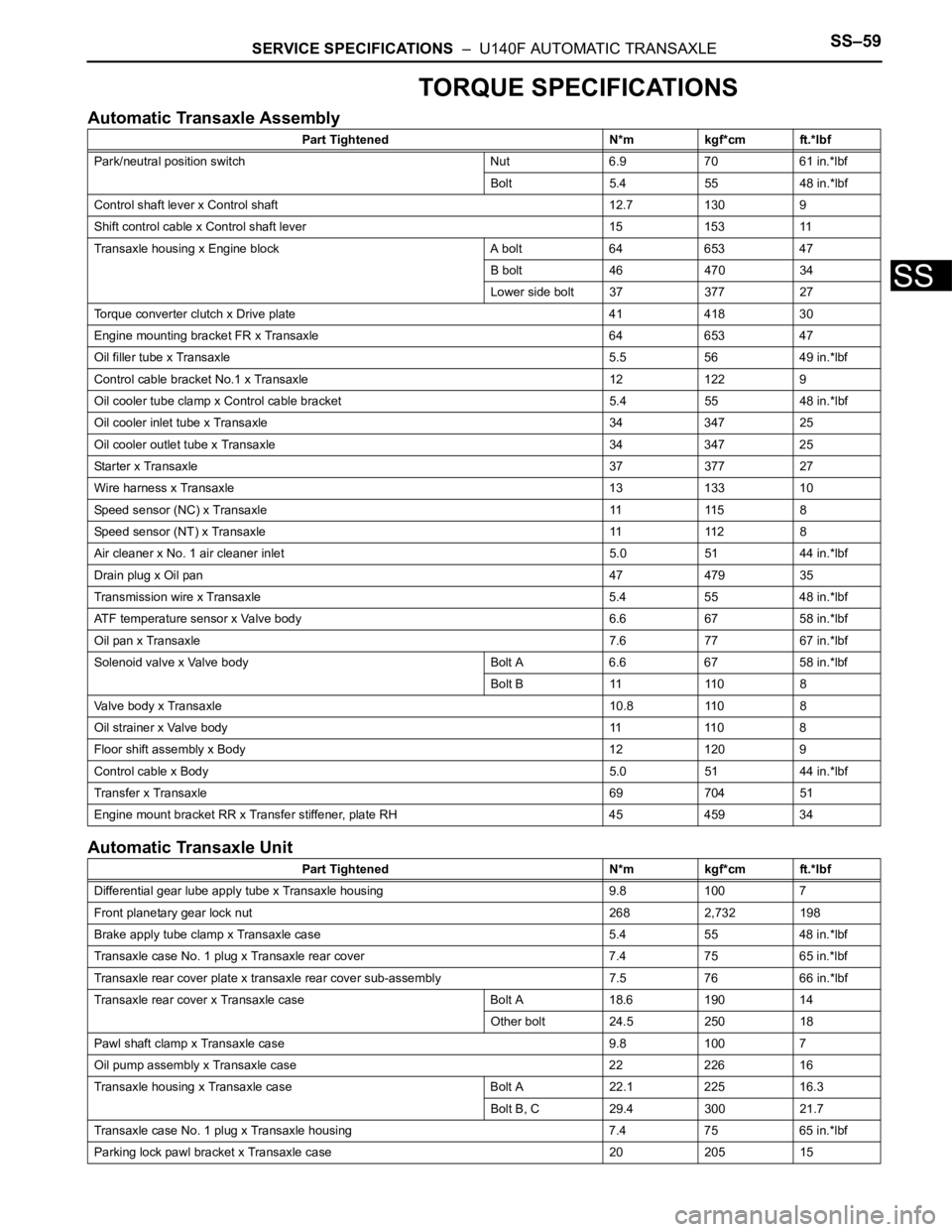

SERVICE SPECIFICATIONS – U140F AUTOMATIC TRANSAXLESS–59

SS

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Automatic Transaxle Unit

Part Tightened N*m kgf*cm ft.*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 12.7 130 9

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block A bolt 64 653 47

B bolt 46 470 34

Lower side bolt 37 377 27

Torque converter clutch x Drive plate 41 418 30

Engine mounting bracket FR x Transaxle 64 653 47

Oil filler tube x Transaxle 5.5 56 49 in.*lbf

Control cable bracket No.1 x Transaxle 12 122 9

Oil cooler tube clamp x Control cable bracket 5.4 55 48 in.*lbf

Oil cooler inlet tube x Transaxle 34 347 25

Oil cooler outlet tube x Transaxle 34 347 25

Starter x Transaxle37 377 27

Wire harness x Transaxle 13 133 10

Speed sensor (NC) x Transaxle 11 115 8

Speed sensor (NT) x Transaxle 11 112 8

Air cleaner x No. 1 air cleaner inlet 5.0 51 44 in.*lbf

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle 5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.6 77 67 in.*lbf

Solenoid valve x Valve body Bolt A 6.6 67 58 in.*lbf

Bolt B 11 110 8

Valve body x Transaxle 10.8 110 8

Oil strainer x Valve body 11 110 8

Floor shift assembly x Body 12 120 9

Control cable x Body5.0 51 44 in.*lbf

Transfer x Transaxle69 704 51

Engine mount bracket RR x Transfer stiffener, plate RH 45 459 34

Part Tightened N*m kgf*cm ft.*lbf

Differential gear lube apply tube x Transaxle housing 9.8 100 7

Front planetary gear lock nut 268 2,732 198

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover plate x transaxle rear cover sub-assembly 7.5 76 66 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 18.6 190 14

Other bolt 24.5 250 18

Pawl shaft clamp x Transaxle case 9.8 100 7

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22.1 225 16.3

Bolt B, C 29.4 300 21.7

Transaxle case No. 1 plug x Transaxle housing 7.4 75 65 in.*lbf

Parking lock pawl bracket x Transaxle case 20 205 15

Page 390 of 2000

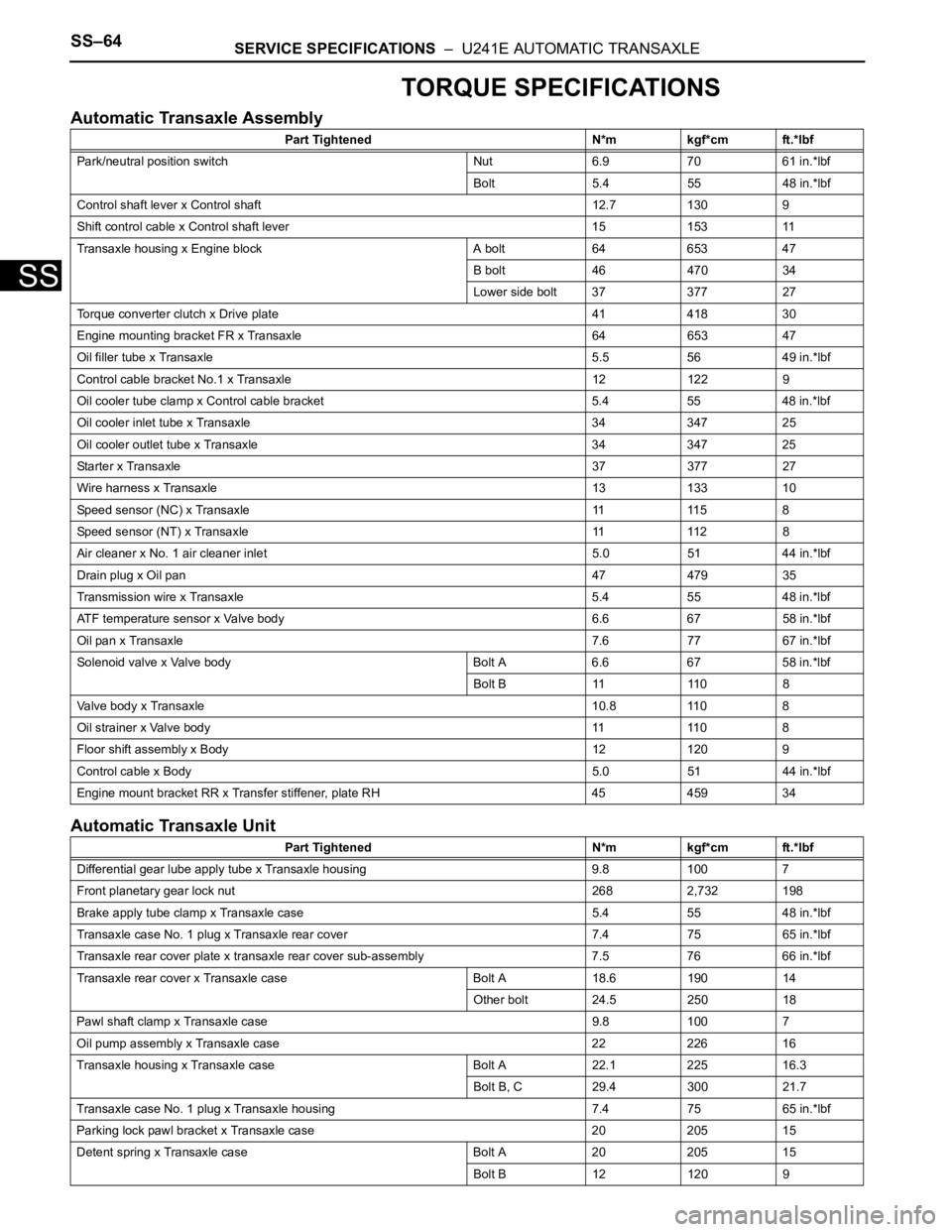

SS–64SERVICE SPECIFICATIONS – U241E AUTOMATIC TRANSAXLE

SS

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Automatic Transaxle Unit

Part Tightened N*m kgf*cm ft.*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 12.7 130 9

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block A bolt 64 653 47

B bolt 46 470 34

Lower side bolt 37 377 27

Torque converter clutch x Drive plate 41 418 30

Engine mounting bracket FR x Transaxle 64 653 47

Oil filler tube x Transaxle 5.5 56 49 in.*lbf

Control cable bracket No.1 x Transaxle 12 122 9

Oil cooler tube clamp x Control cable bracket 5.4 55 48 in.*lbf

Oil cooler inlet tube x Transaxle 34 347 25

Oil cooler outlet tube x Transaxle 34 347 25

Starter x Transaxle37 377 27

Wire harness x Transaxle 13 133 10

Speed sensor (NC) x Transaxle 11 115 8

Speed sensor (NT) x Transaxle 11 112 8

Air cleaner x No. 1 air cleaner inlet 5.0 51 44 in.*lbf

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle 5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.6 77 67 in.*lbf

Solenoid valve x Valve body Bolt A 6.6 67 58 in.*lbf

B o l t B 11 11 0 8

Valve body x Transaxle 10.8 110 8

Oil strainer x Valve body 11 110 8

Floor shift assembly x Body 12 120 9

Control cable x Body5.0 51 44 in.*lbf

Engine mount bracket RR x Transfer stiffener, plate RH 45 459 34

Part Tightened N*m kgf*cm ft.*lbf

Differential gear lube apply tube x Transaxle housing 9.8 100 7

Front planetary gear lock nut 268 2,732 198

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover plate x transaxle rear cover sub-assembly 7.5 76 66 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 18.6 190 14

Other bolt 24.5 250 18

Pawl shaft clamp x Transaxle case 9.8 100 7

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22.1 225 16.3

Bolt B, C 29.4 300 21.7

Transaxle case No. 1 plug x Transaxle housing 7.4 75 65 in.*lbf

Parking lock pawl bracket x Transaxle case 20 205 15

Detent spring x Transaxle case Bolt A 20 205 15

Bolt B 12 120 9

Page 393 of 2000

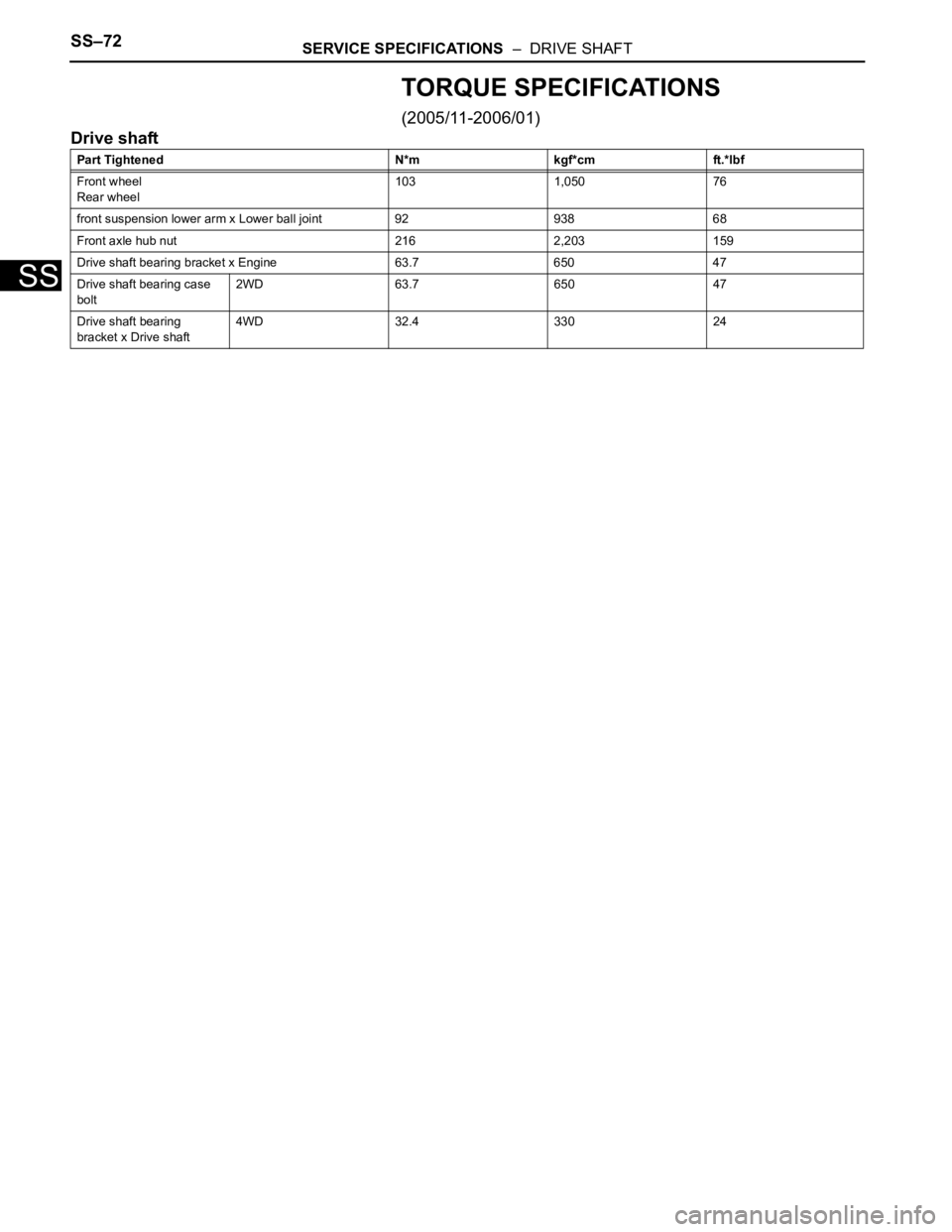

SS–72SERVICE SPECIFICATIONS – DRIVE SHAFT

SS

TORQUE SPECIFICATIONS

(2005/11-2006/01)

Drive shaft

Part Tightened N*m kgf*cm ft.*lbf

Front wheel

Rear wheel103 1,050 76

front suspension lower arm x Lower ball joint 92 938 68

Front axle hub nut 216 2,203 159

Drive shaft bearing bracket x Engine 63.7 650 47

Drive shaft bearing case

bolt2WD 63.7 650 47

Drive shaft bearing

bracket x Drive shaft4WD 32.4 330 24

Page 394 of 2000

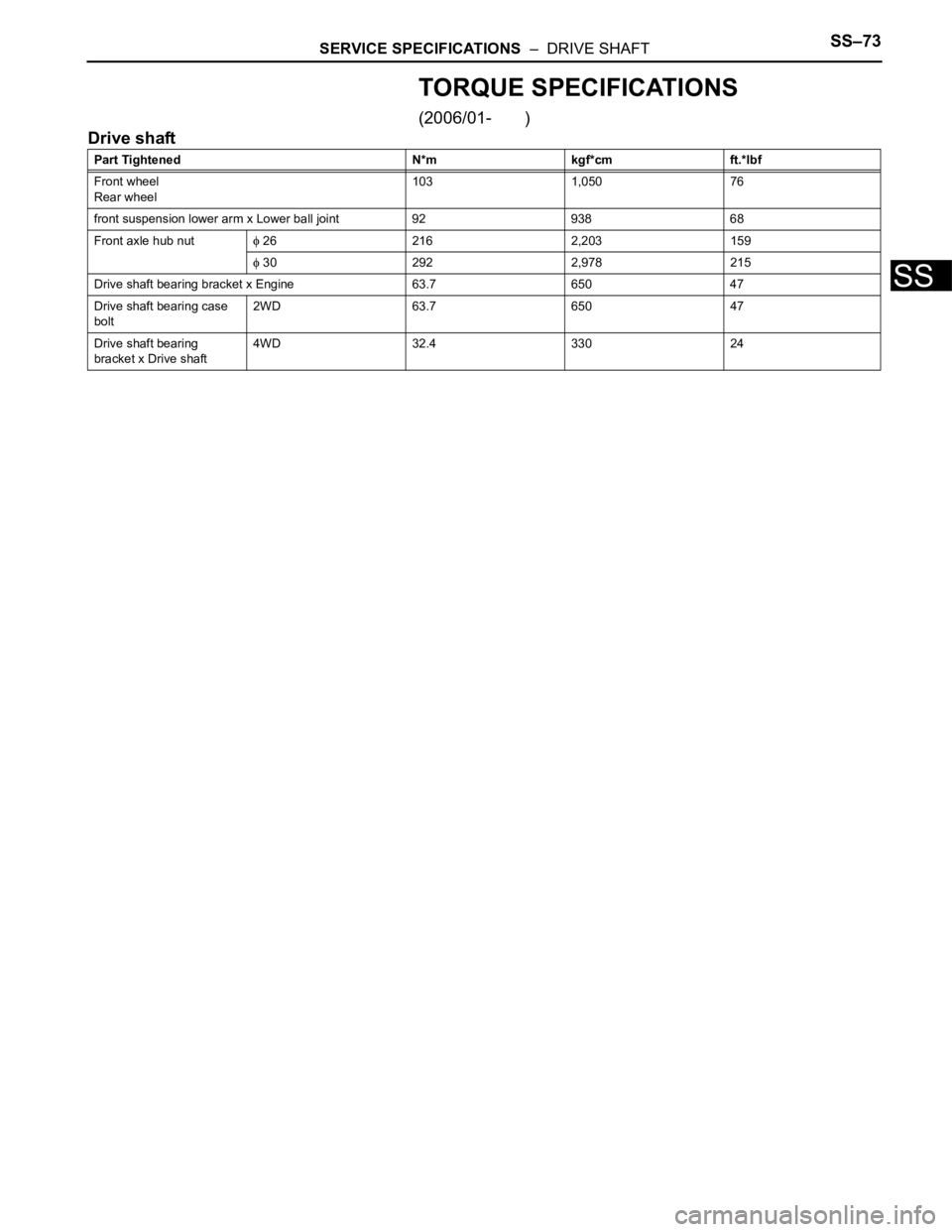

SERVICE SPECIFICATIONS – DRIVE SHAFTSS–73

SS

TORQUE SPECIFICATIONS

(2006/01- )

Drive shaft

Part Tightened N*m kgf*cm ft.*lbf

Front wheel

Rear wheel103 1,050 76

front suspension lower arm x Lower ball joint 92 938 68

Front axle hub nut

26 216 2,203 159

30 292 2,978 215

Drive shaft bearing bracket x Engine 63.7 650 47

Drive shaft bearing case

bolt2WD 63.7 650 47

Drive shaft bearing

bracket x Drive shaft4WD 32.4 330 24

Page 439 of 2000

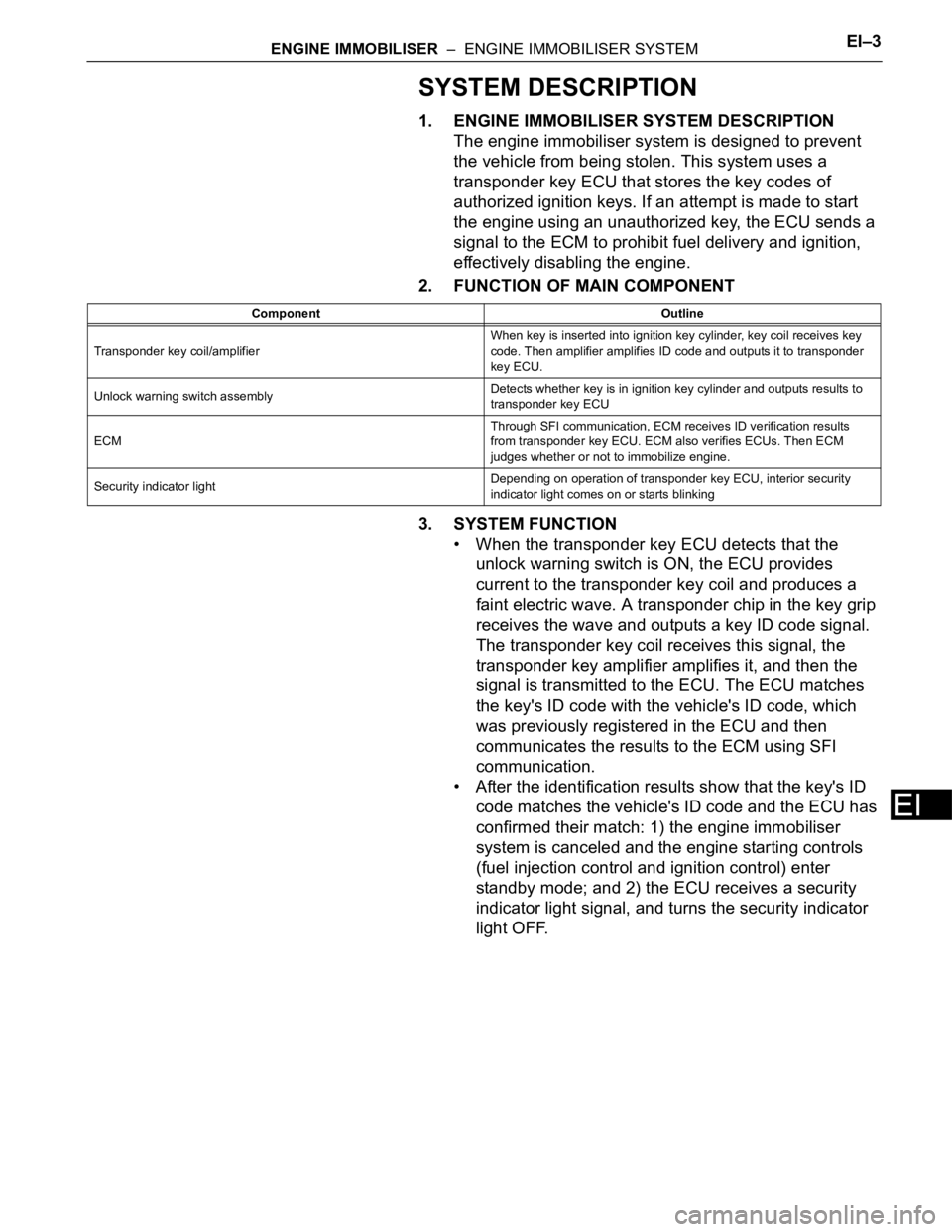

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEMEI–3

EI

SYSTEM DESCRIPTION

1. ENGINE IMMOBILISER SYSTEM DESCRIPTION

The engine immobiliser system is designed to prevent

the vehicle from being stolen. This system uses a

transponder key ECU that stores the key codes of

authorized ignition keys. If an attempt is made to start

the engine using an unauthorized key, the ECU sends a

signal to the ECM to prohibit fuel delivery and ignition,

effectively disabling the engine.

2. FUNCTION OF MAIN COMPONENT

3. SYSTEM FUNCTION

• When the transponder key ECU detects that the

unlock warning switch is ON, the ECU provides

current to the transponder key coil and produces a

faint electric wave. A transponder chip in the key grip

receives the wave and outputs a key ID code signal.

The transponder key coil receives this signal, the

transponder key amplifier amplifies it, and then the

signal is transmitted to the ECU. The ECU matches

the key's ID code with the vehicle's ID code, which

was previously registered in the ECU and then

communicates the results to the ECM using SFI

communication.

• After the identification results show that the key's ID

code matches the vehicle's ID code and the ECU has

confirmed their match: 1) the engine immobiliser

system is canceled and the engine starting controls

(fuel injection control and ignition control) enter

standby mode; and 2) the ECU receives a security

indicator light signal, and turns the security indicator

light OFF.

Component Outline

Transponder key coil/amplifierWhen key is inserted into ignition key cylinder, key coil receives key

code. Then amplifier amplifies ID code and outputs it to transponder

key ECU.

Unlock warning switch assemblyDetects whether key is in ignition key cylinder and outputs results to

transponder key ECU

ECMThrough SFI communication, ECM receives ID verification results

from transponder key ECU. ECM also verifies ECUs. Then ECM

judges whether or not to immobilize engine.

Security indicator lightDepending on operation of transponder key ECU, interior security

indicator light comes on or starts blinking

Page 440 of 2000

EI–4ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM

EI

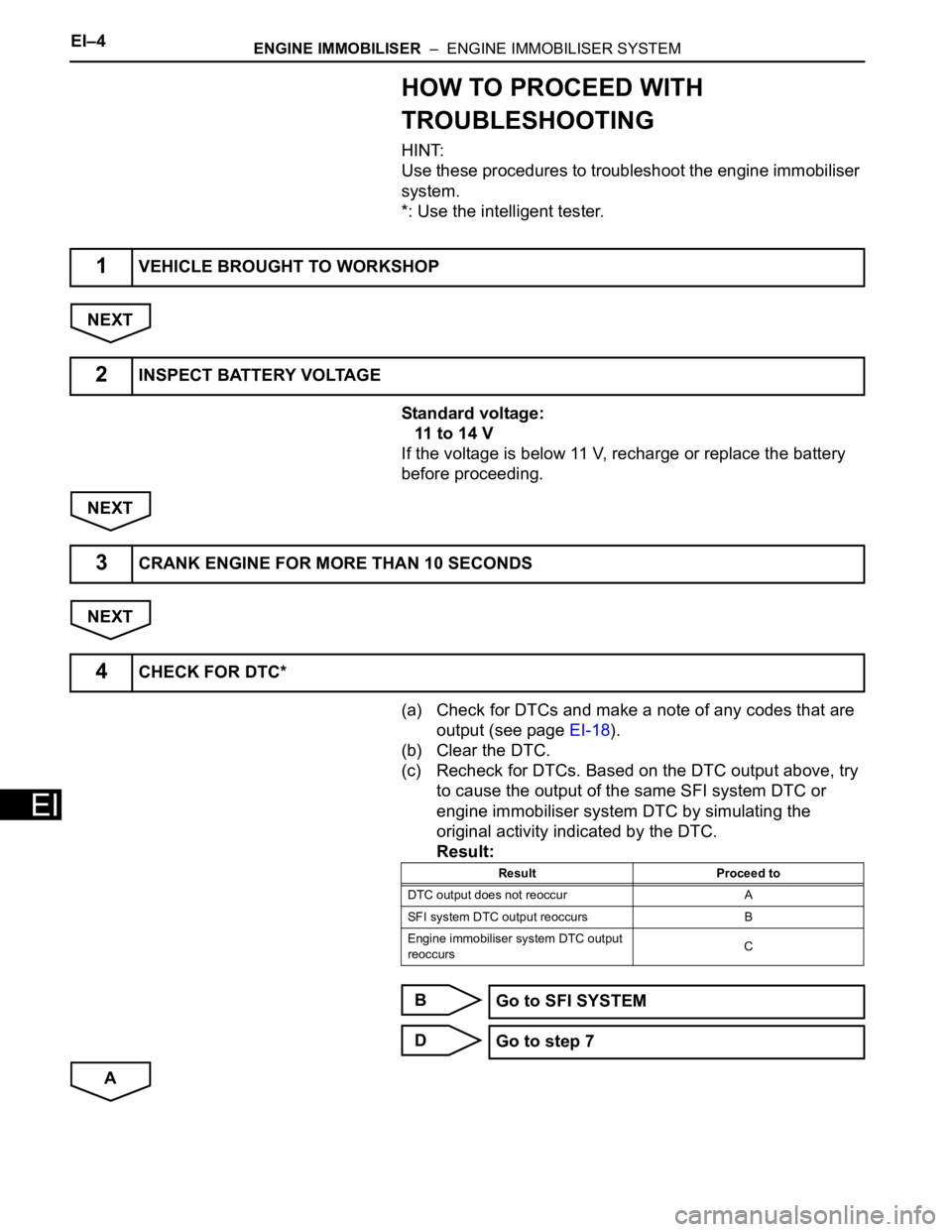

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

Use these procedures to troubleshoot the engine immobiliser

system.

*: Use the intelligent tester.

NEXT

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery

before proceeding.

NEXT

NEXT

(a) Check for DTCs and make a note of any codes that are

output (see page EI-18).

(b) Clear the DTC.

(c) Recheck for DTCs. Based on the DTC output above, try

to cause the output of the same SFI system DTC or

engine immobiliser system DTC by simulating the

original activity indicated by the DTC.

Result:

B

D

A

1VEHICLE BROUGHT TO WORKSHOP

2INSPECT BATTERY VOLTAGE

3CRANK ENGINE FOR MORE THAN 10 SECONDS

4CHECK FOR DTC*

Result Proceed to

DTC output does not reoccur A

SFI system DTC output reoccurs B

Engine immobiliser system DTC output

reoccursC

Go to SFI SYSTEM

Go to step 7

Page 441 of 2000

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEMEI–5

EI

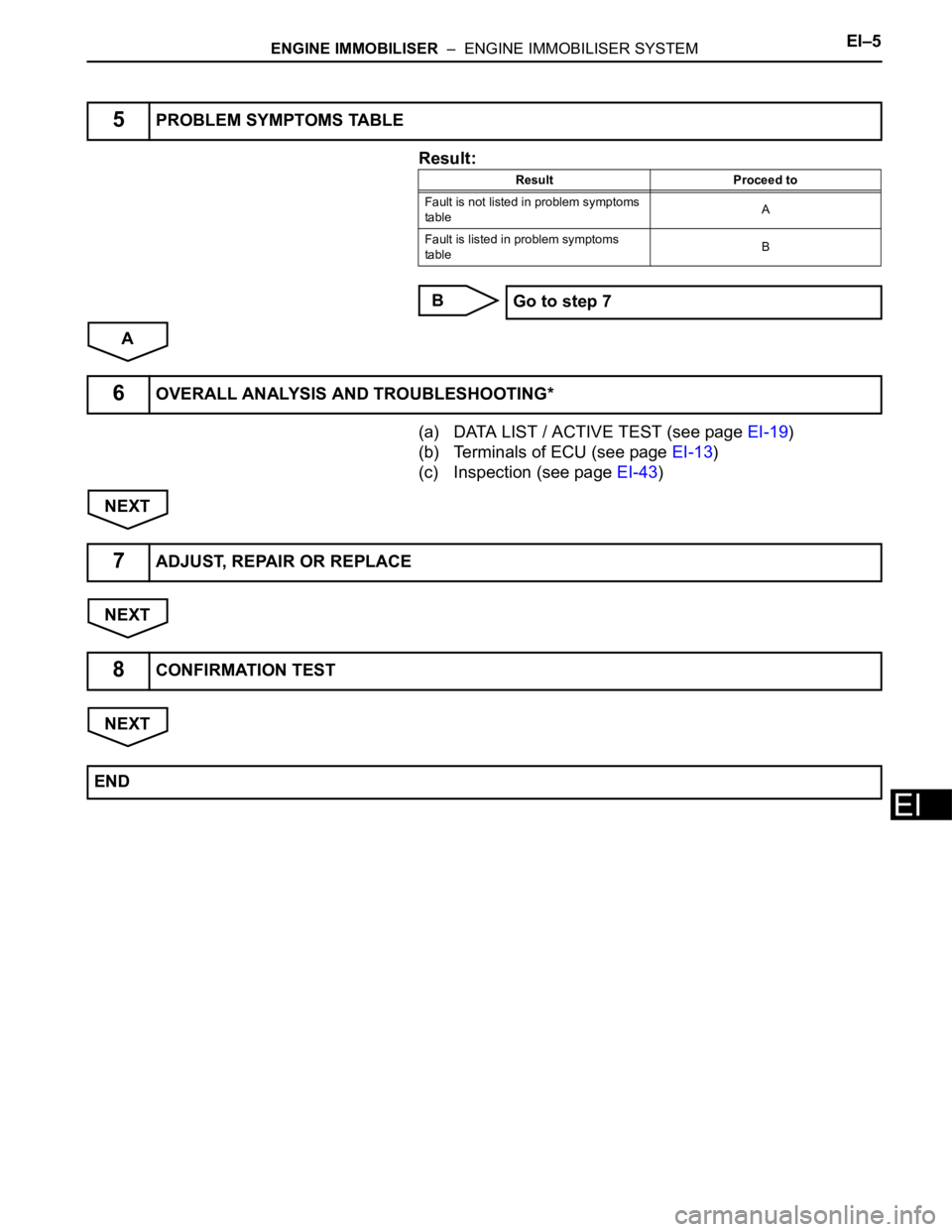

Result:

B

A

(a) DATA LIST / ACTIVE TEST (see page EI-19)

(b) Terminals of ECU (see page EI-13)

(c) Inspection (see page EI-43)

NEXT

NEXT

NEXT

5PROBLEM SYMPTOMS TABLE

Result Proceed to

Fault is not listed in problem symptoms

tableA

Fault is listed in problem symptoms

tableB

Go to step 7

6OVERALL ANALYSIS AND TROUBLESHOOTING*

7ADJUST, REPAIR OR REPLACE

8CONFIRMATION TEST

END