Position Switch TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 108 of 2000

ENGINE - 2GR-FE ENGINE

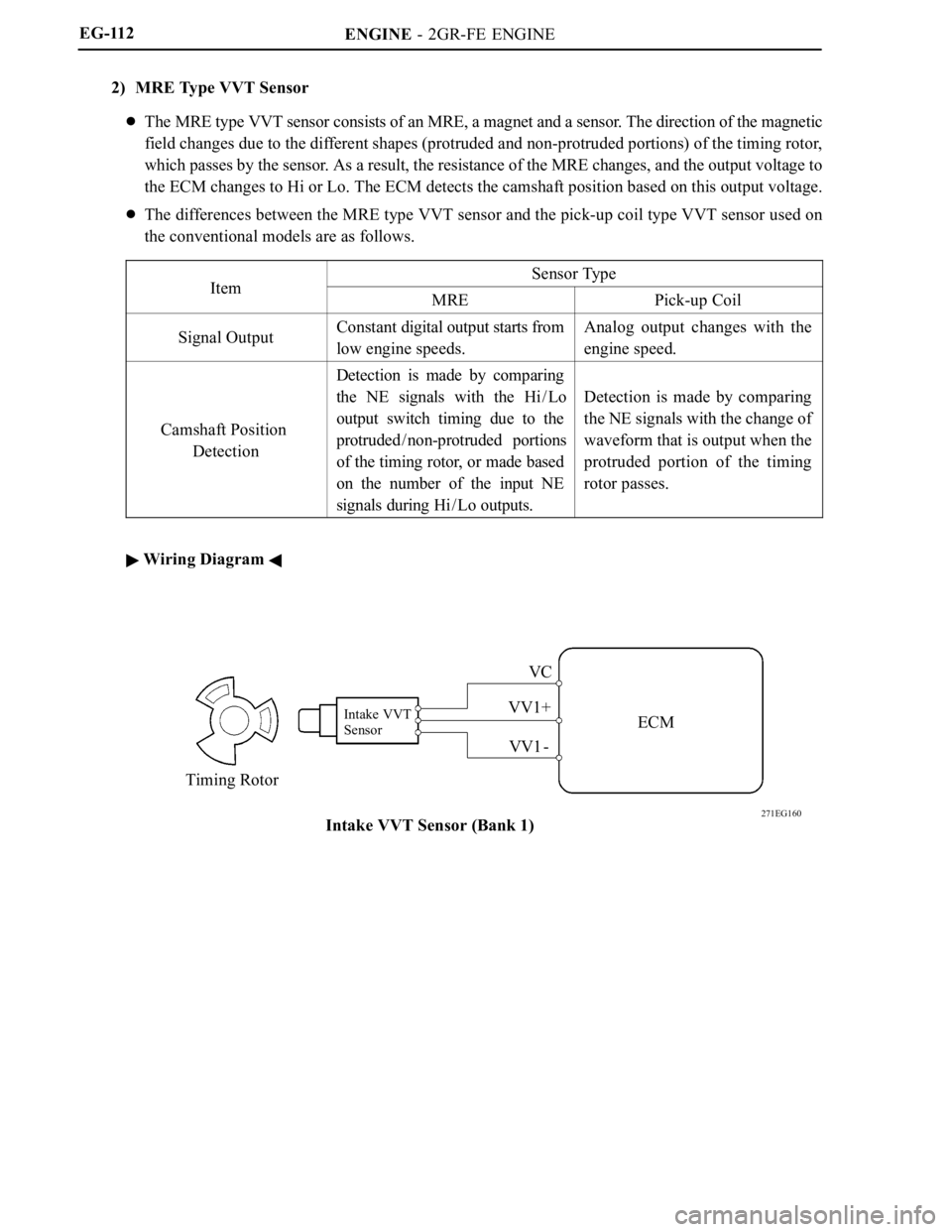

271EG160

Timing Rotor

Intake VVT

Sensor

VC

VV1+

VV1 -ECM

Intake VVT Sensor (Bank 1) EG-112

2) MRE Type VVT Sensor

The MRE type VVT sensor consists of an MRE, a magnet and a sensor. The direction of the magnetic

field changes due to the different shapes (protruded and non-protruded portions) of the timing rotor,

which passes by the sensor. As a result, the resistance of the MRE changes, and the output voltage to

the ECM changes to Hi or Lo. The ECM detects the camshaft position based on this output voltage.

The differences between the MRE type VVT sensor and the pick-up coil type VVT sensor used on

the conventional models are as follows.

ItemSensor TypeItemMREPick-up Coil

Signal OutputConstant digital output starts from

low engine speeds.Analog output changes with the

engine speed.

Camshaft Position

Detection

Detection is made by comparing

the NE signals with the Hi / Lo

output switch timing due to the

protruded / non-protruded portions

of the timing rotor, or made based

on the number of the input NE

signals during Hi / Lo outputs.

Detection is made by comparing

the NE signals with the change of

waveform that is output when the

protruded portion of the timing

rotor passes.

Wiring Diagram

Page 114 of 2000

ENGINE - 2GR-FE ENGINE

01MEG18Y

Accelerator Pedal

Position SensorThrottle ValveThrottle Position Sensor

Throttle Control

Motor

Mass Air

Flow Meter

Cruise Control

Switch

Skid Control

ECUECMIgnition Coil

Fuel Injection EG-118

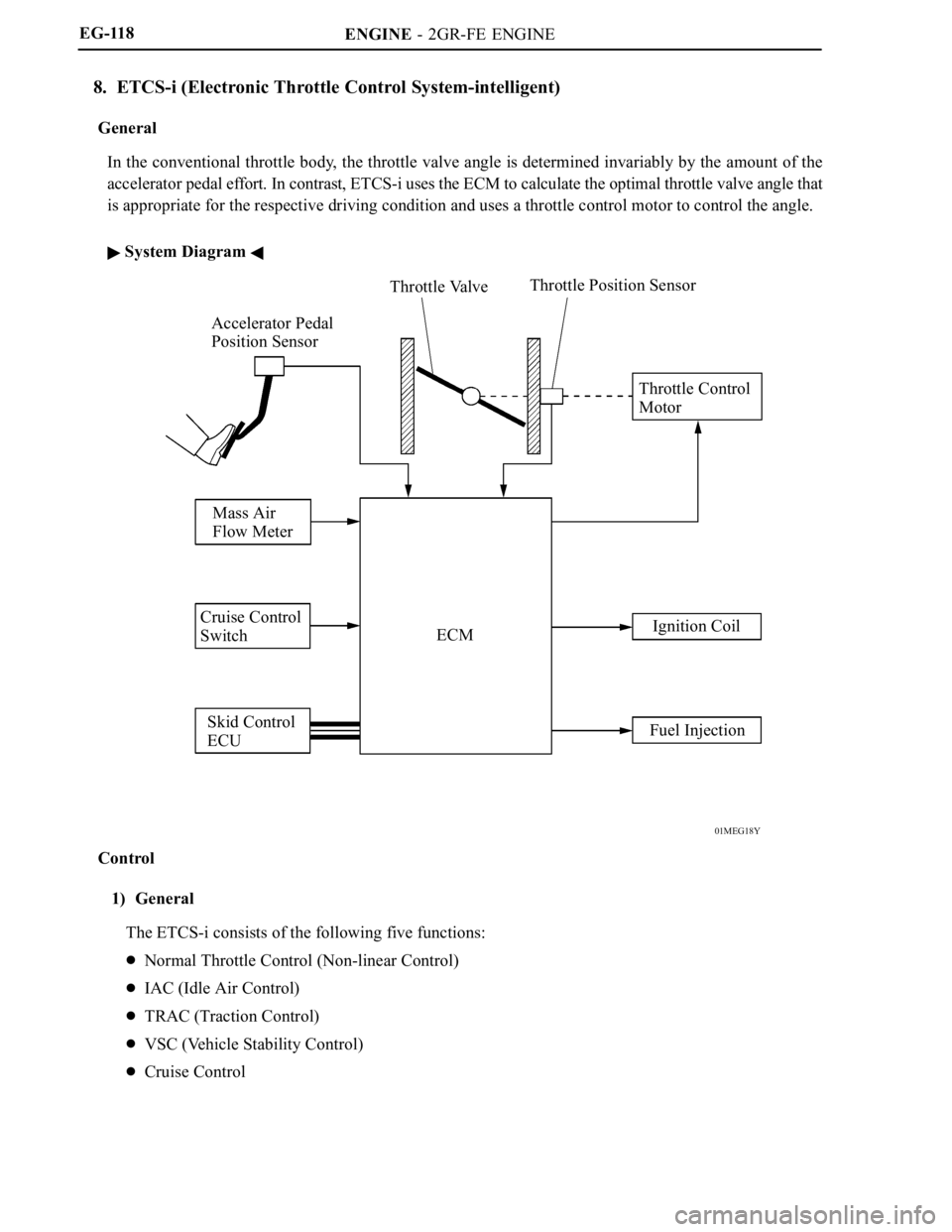

8. ETCS-i (Electronic Throttle Control System-intelligent)

General

In the conventional throttle body, the throttle valve angle is determined invariably by the amount of the

accelerator pedal effort. In contrast, ETCS-i uses the ECM to calculate the optimal throttle valve angle that

is appropriate for the respective driving condition and uses a throttle control motor to control the angle.

System Diagram

Control

1) General

The ETCS-i consists of the following five functions:

Normal Throttle Control (Non-linear Control)

IAC (Idle Air Control)

TRAC (Traction Control)

VSC (Vehicle Stability Control)

Cruise Control

Page 129 of 2000

ENGINE - 2GR-FE ENGINEEG-133

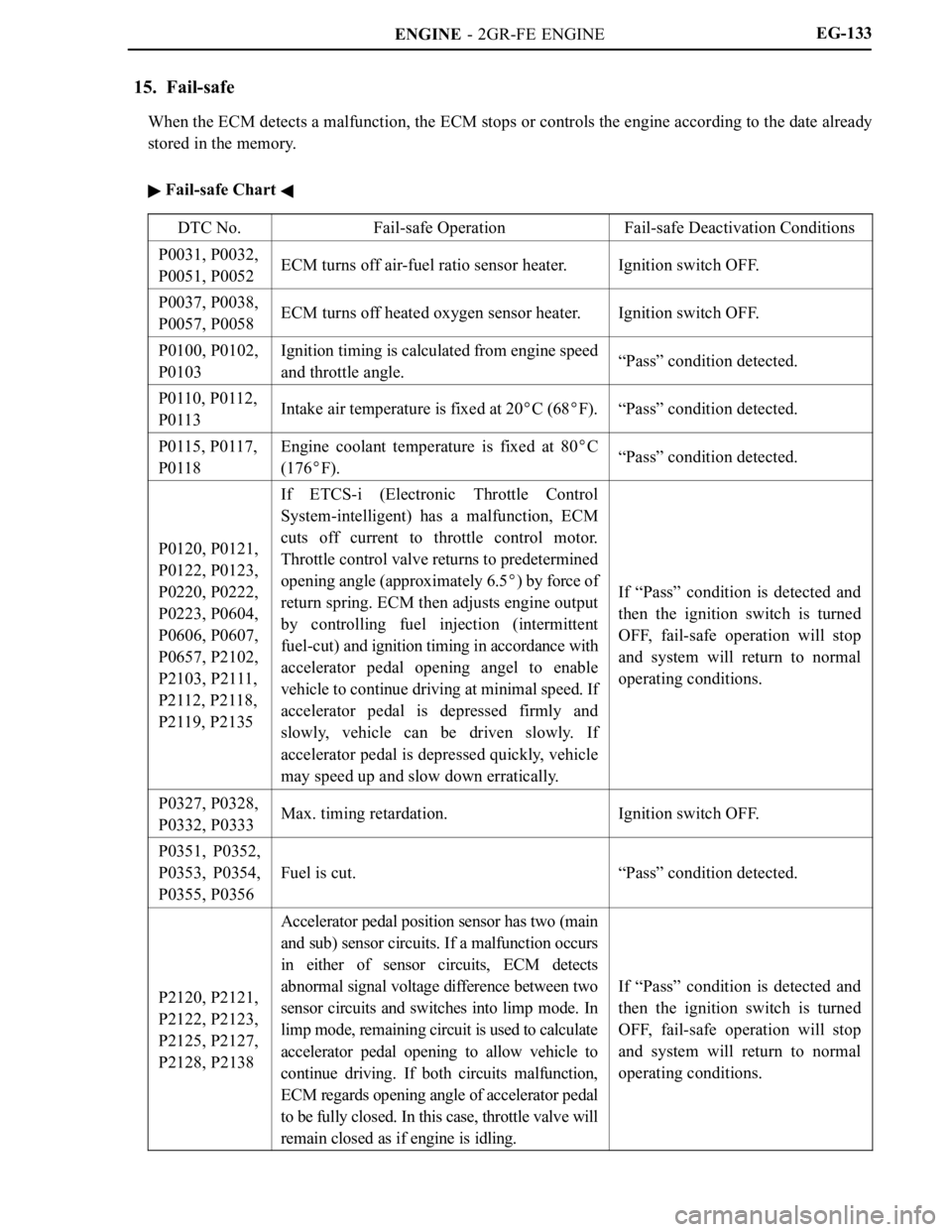

15. Fail-safe

When the ECM detects a malfunction, the ECM stops or controls the engine according to the date already

stored in the memory.

Fail-safe Chart

DTC No.Fail-safe OperationFail-safe Deactivation Conditions

P0031, P0032,

P0051, P0052ECM turns off air-fuel ratio sensor heater.Ignition switch OFF.

P0037, P0038,

P0057, P0058ECM turns off heated oxygen sensor heater.Ignition switch OFF.

P0100, P0102,

P0103Ignition timing is calculated from engine speed

and throttle angle.“Pass” condition detected.

P0110, P0112,

P0113Intake air temperature is fixed at 20C (68F).“Pass” condition detected.

P0115, P0117,

P0118Engine coolant temperature is fixed at 80C

(176

F).“Pass” condition detected.

P0120, P0121,

P0122, P0123,

P0220, P0222,

P0223, P0604,

P0606, P0607,

P0657, P2102,

P2103, P2111,

P2112, P2118,

P2119, P2135

If ETCS-i (Electronic Throttle Control

System-intelligent) has a malfunction, ECM

cuts off current to throttle control motor.

Throttle control valve returns to predetermined

opening angle (approximately 6.5

) by force of

return spring. ECM then adjusts engine output

by controlling fuel injection (intermittent

fuel-cut) and ignition timing in accordance with

accelerator pedal opening angel to enable

vehicle to continue driving at minimal speed. If

accelerator pedal is depressed firmly and

slowly, vehicle can be driven slowly. If

accelerator pedal is depressed quickly, vehicle

may speed up and slow down erratically.If “Pass” condition is detected and

then the ignition switch is turned

OFF, fail-safe operation will stop

and system will return to normal

operating conditions.

P0327, P0328,

P0332, P0333Max. timing retardation.Ignition switch OFF.

P0351, P0352,

P0353, P0354,

P0355, P0356

Fuel is cut.“Pass” condition detected.

P2120, P2121,

P2122, P2123,

P2125, P2127,

P2128, P2138

Accelerator pedal position sensor has two (main

and sub) sensor circuits. If a malfunction occurs

in either of sensor circuits, ECM detects

abnormal signal voltage difference between two

sensor circuits and switches into limp mode. In

limp mode, remaining circuit is used to calculate

accelerator pedal opening to allow vehicle to

continue driving. If both circuits malfunction,

ECM regards opening angle of accelerator pedal

to be fully closed. In this case, throttle valve will

remain closed as if engine is idling.

If “Pass” condition is detected and

then the ignition switch is turned

OFF, fail-safe operation will stop

and system will return to normal

operating conditions.

Page 134 of 2000

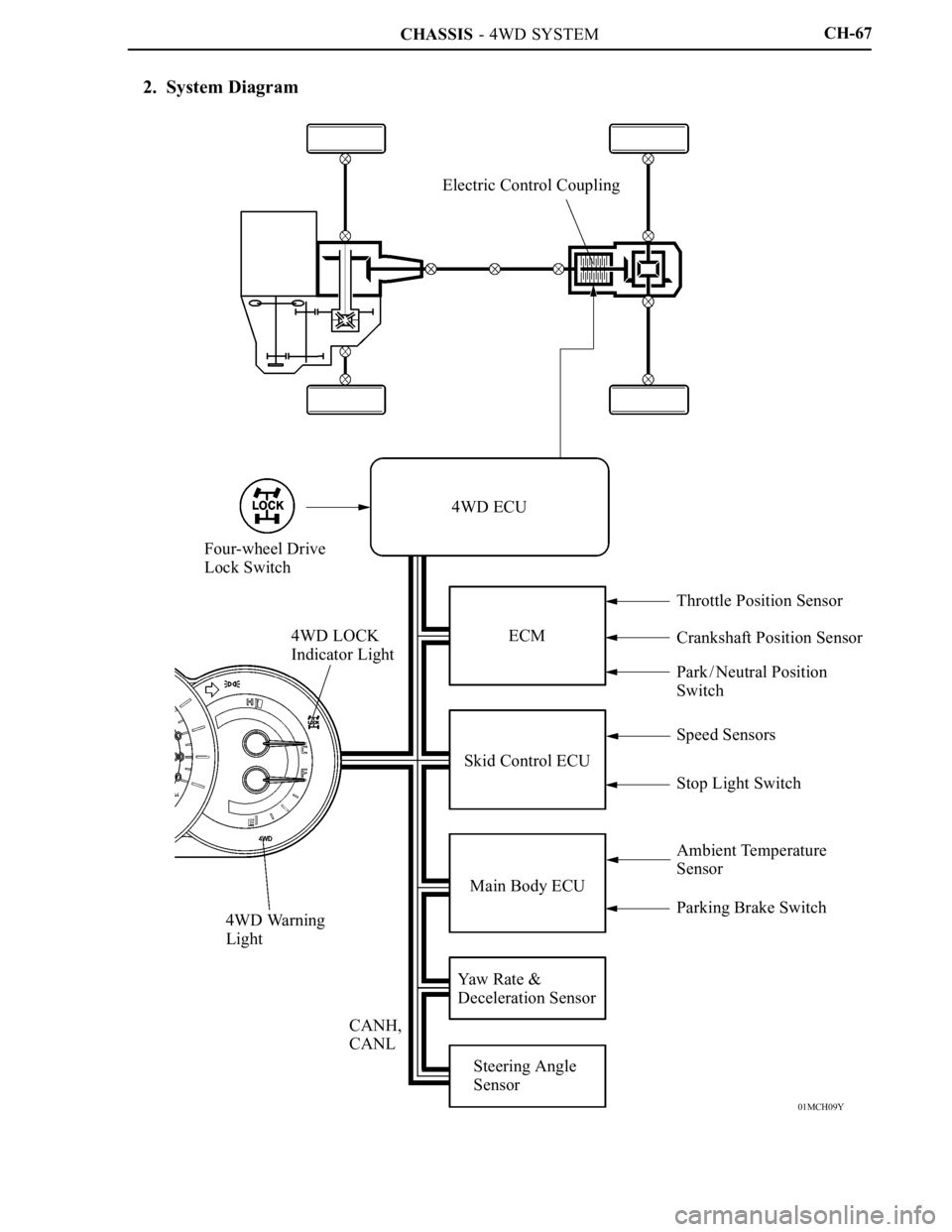

CHASSIS - 4WD SYSTEM

01MCH09Y

Electric Control Coupling

4WD ECU

Four-wheel Drive

Lock Switch

4WD LOCK

Indicator Light

4WD Warning

LightECM

Skid Control ECU

Main Body ECU

Ya w R a t e &

Deceleration Sensor

Steering Angle

SensorThrottle Position Sensor

Crankshaft Position Sensor

Park / Neutral Position

Switch

Speed Sensors

Stop Light Switch

Ambient Temperature

Sensor

Parking Brake Switch

CANH,

CANLCH-67

2. System Diagram

Page 136 of 2000

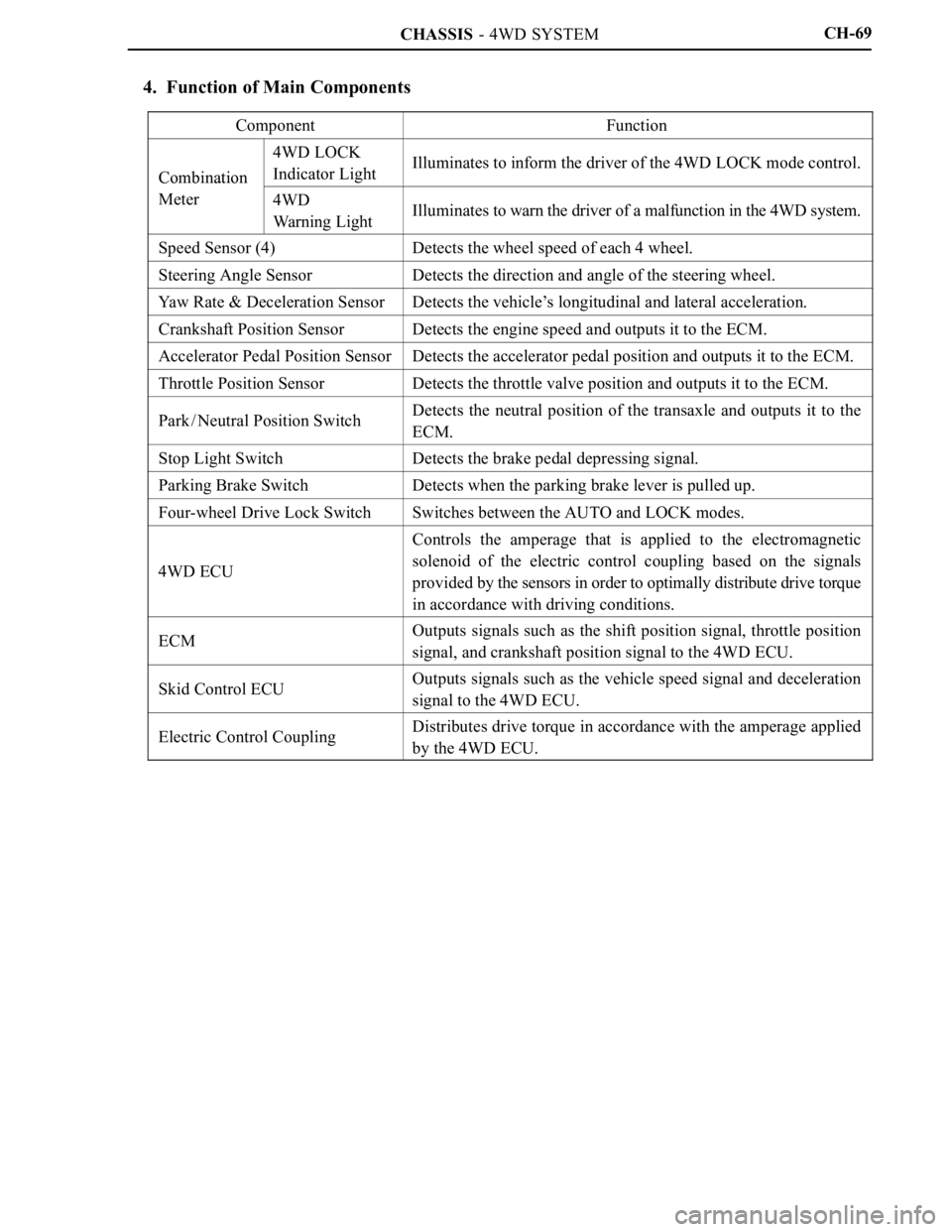

CHASSIS - 4WD SYSTEMCH-69

4. Function of Main Components

ComponentFunction

Combination

4WD LOCK

Indicator LightIlluminates to inform the driver of the 4WD LOCK mode control.Combination

Meter4WD

Warning LightIlluminates to warn the driver of a malfunction in the 4WD system.

Speed Sensor (4)Detects the wheel speed of each 4 wheel.

Steering Angle SensorDetects the direction and angle of the steering wheel.

Yaw Rate & Deceleration SensorDetects the vehicle’s longitudinal and lateral acceleration.

Crankshaft Position SensorDetects the engine speed and outputs it to the ECM.

Accelerator Pedal Position SensorDetects the accelerator pedal position and outputs it to the ECM.

Throttle Position SensorDetects the throttle valve position and outputs it to the ECM.

Park / Neutral Position SwitchDetects the neutral position of the transaxle and outputs it to the

ECM.

Stop Light SwitchDetects the brake pedal depressing signal.

Parking Brake SwitchDetects when the parking brake lever is pulled up.

Four-wheel Drive Lock SwitchSwitches between the AUTO and LOCK modes.

4WD ECU

Controls the amperage that is applied to the electromagnetic

solenoid of the electric control coupling based on the signals

provided by the sensors in order to optimally distribute drive torque

in accordance with driving conditions.

ECMOutputs signals such as the shift position signal, throttle position

signal, and crankshaft position signal to the 4WD ECU.

Skid Control ECUOutputs signals such as the vehicle speed signal and deceleration

signal to the 4WD ECU.

Electric Control CouplingDistributes drive torque in accordance with the amperage applied

by the 4WD ECU.

Page 179 of 2000

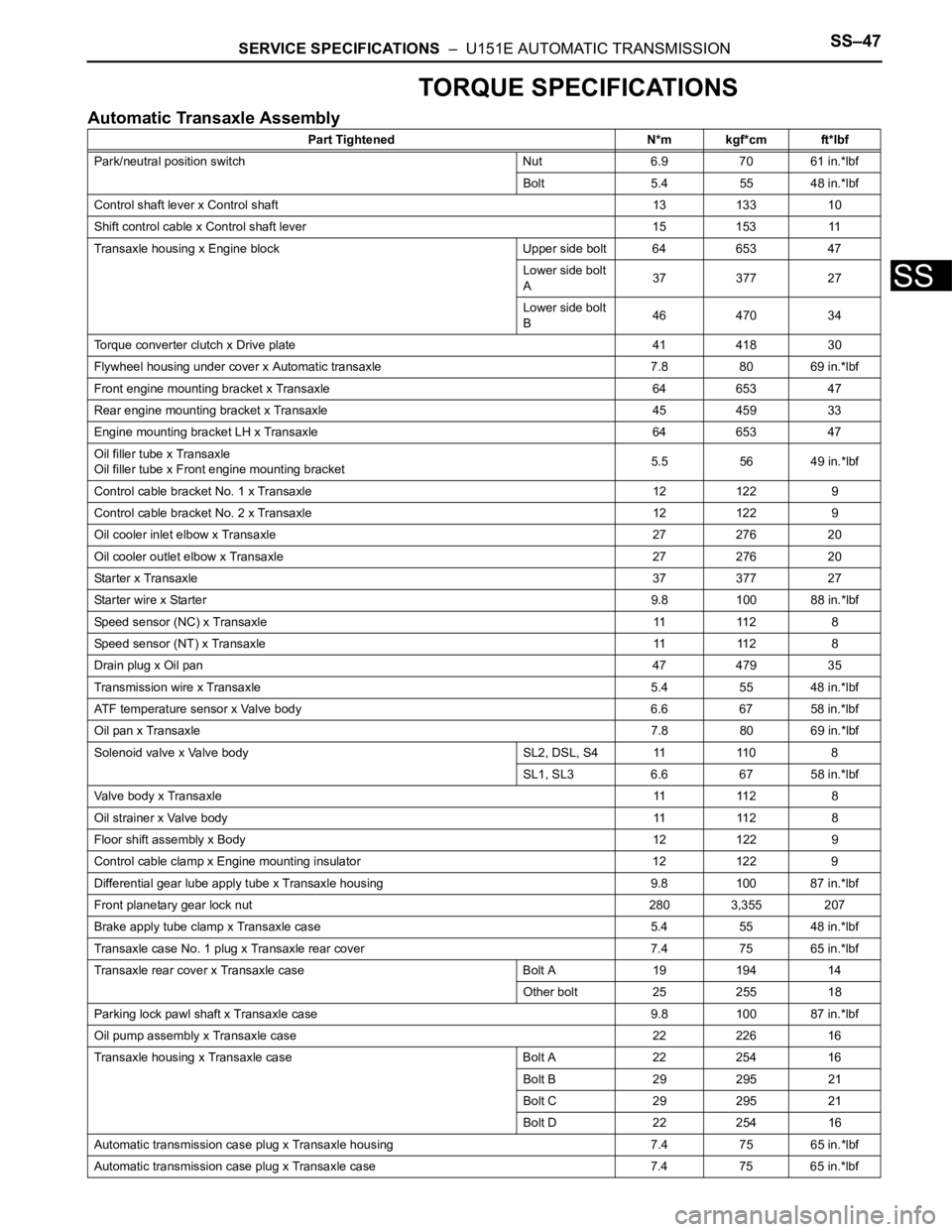

SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSMISSIONSS–47

SS

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 133 10

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block Upper side bolt 64 653 47

Lower side bolt

A37 377 27

Lower side bolt

B46 470 34

Torque converter clutch x Drive plate 41 418 30

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Front engine mounting bracket x Transaxle 64 653 47

Rear engine mounting bracket x Transaxle 45 459 33

Engine mounting bracket LH x Transaxle 64 653 47

Oil filler tube x Transaxle

Oil filler tube x Front engine mounting bracket5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler inlet elbow x Transaxle 27 276 20

Oil cooler outlet elbow x Transaxle 27 276 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 88 in.*lbf

Speed sensor (NC) x Transaxle 11 112 8

Speed sensor (NT) x Transaxle 11 112 8

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle 5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body SL2, DSL, S4 11 110 8

SL1, SL3 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 2 8

Oil strainer x Valve body11 11 2 8

Floor shift assembly x Body12 122 9

Control cable clamp x Engine mounting insulator 12 122 9

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut 280 3,355 207

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 194 14

Other bolt 25 255 18

Parking lock pawl shaft x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22 254 16

Bolt B 29 295 21

Bolt C 29 295 21

Bolt D 22 254 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Page 209 of 2000

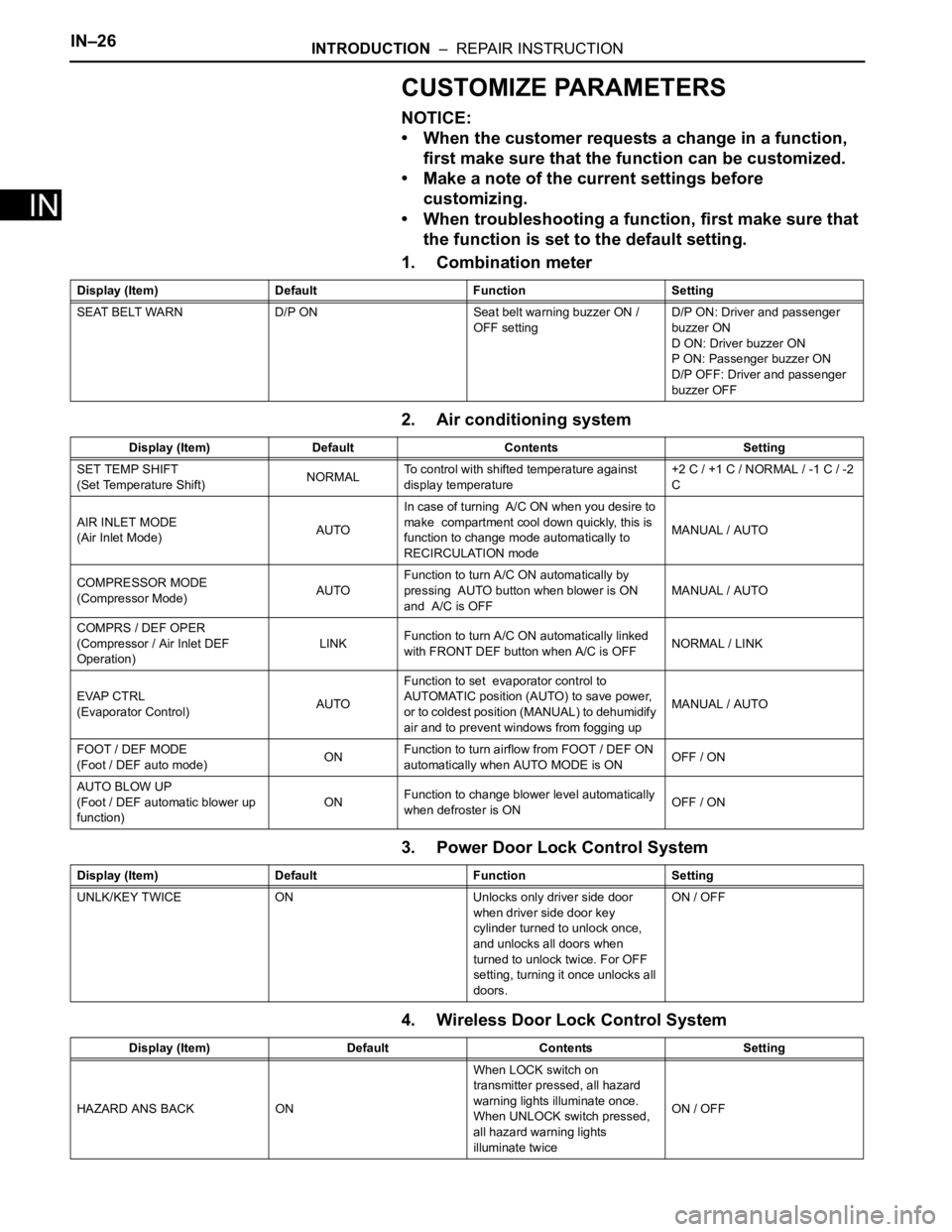

IN–26INTRODUCTION – REPAIR INSTRUCTION

IN

CUSTOMIZE PARAMETERS

NOTICE:

• When the customer requests a change in a function,

first make sure that the function can be customized.

• Make a note of the current settings before

customizing.

• When troubleshooting a function, first make sure that

the function is set to the default setting.

1. Combination meter

2. Air conditioning system

3. Power Door Lock Control System

4. Wireless Door Lock Control System

Display (Item) Default Function Setting

SEAT BELT WARN D/P ON Seat belt warning buzzer ON /

OFF settingD/P ON: Driver and passenger

buzzer ON

D ON: Driver buzzer ON

P ON: Passenger buzzer ON

D/P OFF: Driver and passenger

buzzer OFF

Display (Item) Default Contents Setting

SET TEMP SHIFT

(Set Temperature Shift)NORMALTo control with shifted temperature against

display temperature+2 C / +1 C / NORMAL / -1 C / -2

C

AIR INLET MODE

(Air Inlet Mode)AUTOIn case of turning A/C ON when you desire to

make compartment cool down quickly, this is

function to change mode automatically to

RECIRCULATION modeMANUAL / AUTO

COMPRESSOR MODE

(Compressor Mode)AUTOFunction to turn A/C ON automatically by

pressing AUTO button when blower is ON

and A/C is OFFMANUAL / AUTO

COMPRS / DEF OPER

(Compressor / Air Inlet DEF

Operation)LINKFunction to turn A/C ON automatically linked

with FRONT DEF button when A/C is OFFNORMAL / LINK

EVAP CTRL

(Evaporator Control)AUTOFunction to set evaporator control to

AUTOMATIC position (AUTO) to save power,

or to coldest position (MANUAL) to dehumidify

air and to prevent windows from fogging upMANUAL / AUTO

FOOT / DEF MODE

(Foot / DEF auto mode)ONFunction to turn airflow from FOOT / DEF ON

automatically when AUTO MODE is ONOFF / ON

AUTO BLOW UP

(Foot / DEF automatic blower up

function)ONFunction to change blower level automatically

when defroster is ONOFF / ON

Display (Item) Default Function Setting

UNLK/KEY TWICE ON Unlocks only driver side door

when driver side door key

cylinder turned to unlock once,

and unlocks all doors when

turned to unlock twice. For OFF

setting, turning it once unlocks all

doors.ON / OFF

Display (Item) Default Contents Setting

HAZARD ANS BACK ONWhen LOCK switch on

transmitter pressed, all hazard

warning lights illuminate once.

When UNLOCK switch pressed,

all hazard warning lights

illuminate twiceON / OFF

Page 210 of 2000

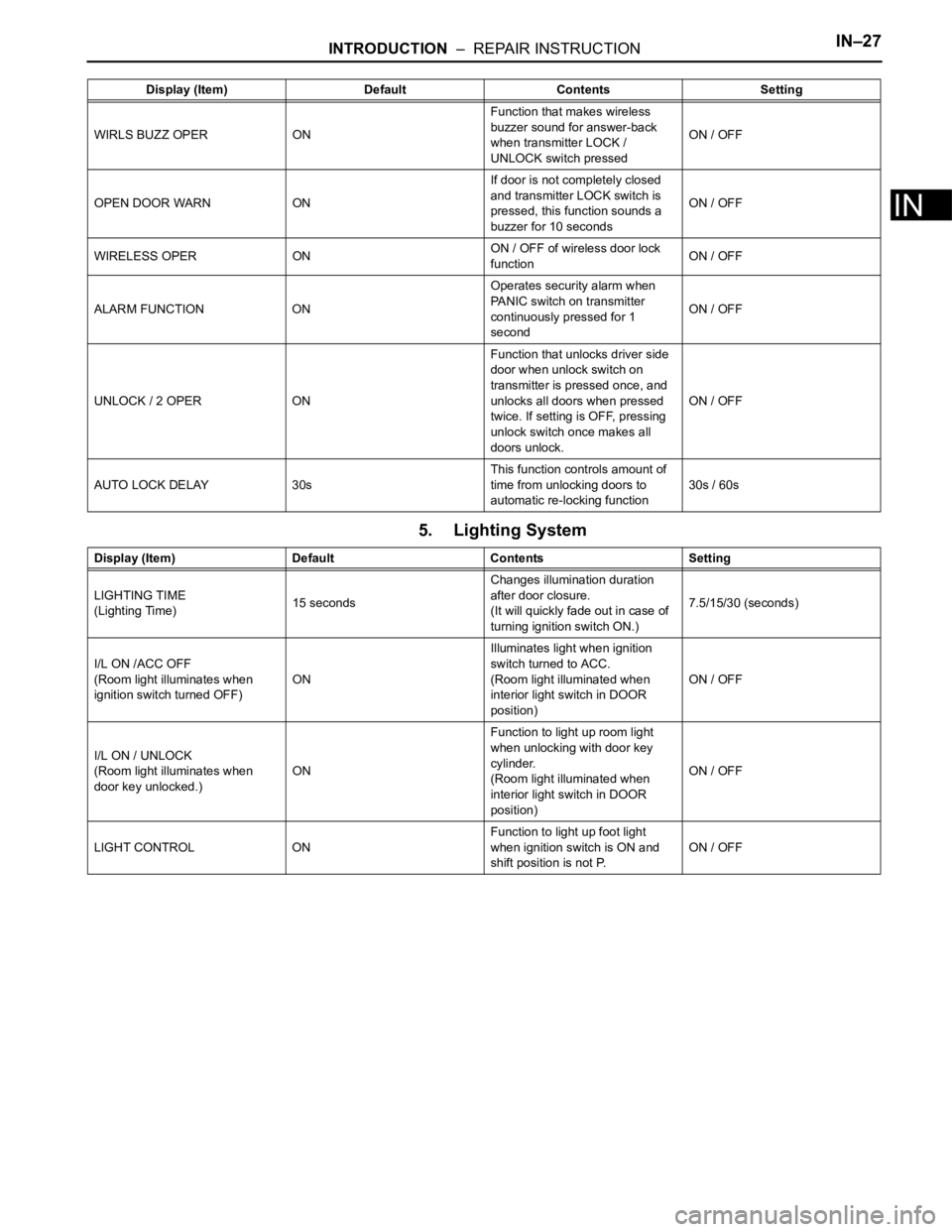

INTRODUCTION – REPAIR INSTRUCTIONIN–27

IN

5. Lighting System

WIRLS BUZZ OPER ONFunction that makes wireless

buzzer sound for answer-back

when transmitter LOCK /

UNLOCK switch pressedON / OFF

OPEN DOOR WARN ONIf door is not completely closed

and transmitter LOCK switch is

pressed, this function sounds a

buzzer for 10 secondsON / OFF

WIRELESS OPER ONON / OFF of wireless door lock

functionON / OFF

ALARM FUNCTION ONOperates security alarm when

PANIC switch on transmitter

continuously pressed for 1

secondON / OFF

UNLOCK / 2 OPER ONFunction that unlocks driver side

door when unlock switch on

transmitter is pressed once, and

unlocks all doors when pressed

twice. If setting is OFF, pressing

unlock switch once makes all

doors unlock.ON / OFF

AUTO LOCK DELAY 30sThis function controls amount of

time from unlocking doors to

automatic re-locking function30s / 60s Display (Item) Default Contents Setting

Display (Item) Default Contents Setting

LIGHTING TIME

(Lighting Time)15 secondsChanges illumination duration

after door closure.

(It will quickly fade out in case of

turning ignition switch ON.)7.5/15/30 (seconds)

I/L ON /ACC OFF

(Room light illuminates when

ignition switch turned OFF)ONIlluminates light when ignition

switch turned to ACC.

(Room light illuminated when

interior light switch in DOOR

position)ON / OFF

I/L ON / UNLOCK

(Room light illuminates when

door key unlocked.)ONFunction to light up room light

when unlocking with door key

cylinder.

(Room light illuminated when

interior light switch in DOOR

position)ON / OFF

LIGHT CONTROL ONFunction to light up foot light

when ignition switch is ON and

shift position is not P.ON / OFF

Page 221 of 2000

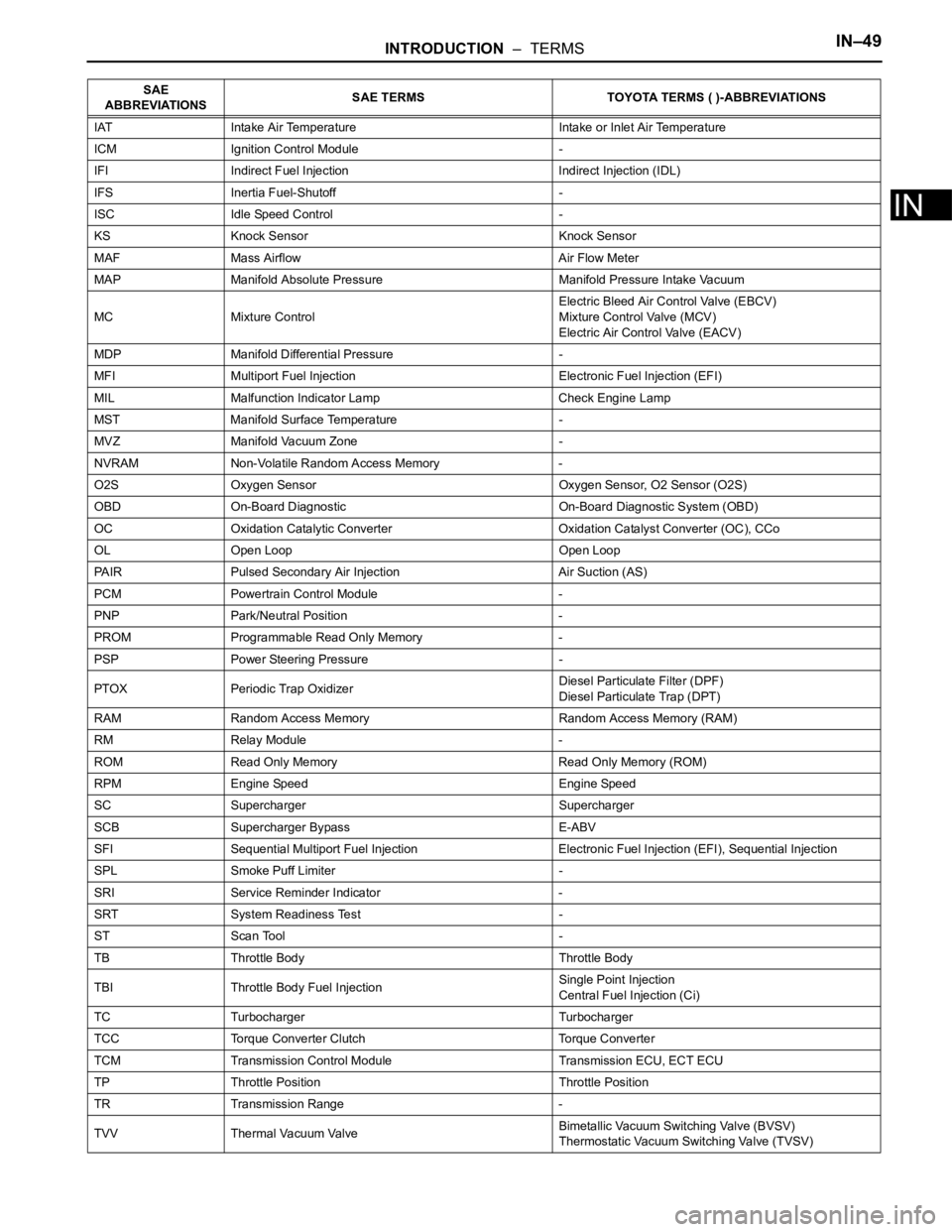

INTRODUCTION – TERMSIN–49

IN

IAT Intake Air Temperature Intake or Inlet Air Temperature

ICM Ignition Control Module -

IFI Indirect Fuel Injection Indirect Injection (IDL)

IFS Inertia Fuel-Shutoff -

ISC Idle Speed Control -

KS Knock Sensor Knock Sensor

MAF Mass Airflow Air Flow Meter

MAP Manifold Absolute Pressure Manifold Pressure Intake Vacuum

MC Mixture ControlElectric Bleed Air Control Valve (EBCV)

Mixture Control Valve (MCV)

Electric Air Control Valve (EACV)

MDP Manifold Differential Pressure -

MFI Multiport Fuel Injection Electronic Fuel Injection (EFI)

MIL Malfunction Indicator Lamp Check Engine Lamp

MST Manifold Surface Temperature -

MVZ Manifold Vacuum Zone -

NVRAM Non-Volatile Random Access Memory -

O2S Oxygen Sensor Oxygen Sensor, O2 Sensor (O2S)

OBD On-Board Diagnostic On-Board Diagnostic System (OBD)

OC Oxidation Catalytic Converter Oxidation Catalyst Converter (OC), CCo

OL Open Loop Open Loop

PAIR Pulsed Secondary Air Injection Air Suction (AS)

PCM Powertrain Control Module -

PNP Park/Neutral Position -

PROM Programmable Read Only Memory -

PSP Power Steering Pressure -

PTOX Periodic Trap OxidizerDiesel Particulate Filter (DPF)

Diesel Particulate Trap (DPT)

RAM Random Access Memory Random Access Memory (RAM)

RM Relay Module -

ROM Read Only Memory Read Only Memory (ROM)

RPM Engine Speed Engine Speed

SC Supercharger Supercharger

SCB Supercharger Bypass E-ABV

SFI Sequential Multiport Fuel Injection Electronic Fuel Injection (EFI), Sequential Injection

SPL Smoke Puff Limiter -

SRI Service Reminder Indicator -

SRT System Readiness Test -

ST Scan Tool -

TB Throttle Body Throttle Body

TBI Throttle Body Fuel InjectionSingle Point Injection

Central Fuel Injection (Ci)

TC Turbocharger Turbocharger

TCC Torque Converter Clutch Torque Converter

TCM Transmission Control Module Transmission ECU, ECT ECU

TP Throttle Position Throttle Position

TR Transmission Range -

TVV Thermal Vacuum ValveBimetallic Vacuum Switching Valve (BVSV)

Thermostatic Vacuum Switching Valve (TVSV) SAE

ABBREVIATIONSSAE TERMS TOYOTA TERMS ( )-ABBREVIATIONS

Page 341 of 2000

CH–62AZ-FE CHARGING – CHARGING SYSTEM

CH

8. INSPECT CHARGING CIRCUIT WITH LOAD

(a) With the engine running at 2,000 rpm, turn the high

beam headlights ON and turn the heater blower

switch to the "HI" position.

(b) Check the reading on the ammeter.

Standard amperage:

30 A or more

If the ammeter reading is less than the standard

amperage, repair the generator.

HINT:

If the battery is fully charged, the indication will

sometimes be less than the standard amperage. If

this is the case, add more electrical load (operate

the wipers, rear window defogger, etc.) and check

the reading on the ammeter again.