fuse TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 64 of 2000

ENGINE - 2AZ-FE ENGINE

Service Tip

To clear the DTC that is stored in the ECM, use a hand-held tester or disconnect the battery terminal

or remove the EFI fuse for 1 minute or longer.

EG-67

Fail-safe

Due to a failure in the battery current sensor or battery temperature sensor, the ECM may determine the

necessity of performing a fail-safe operation. Then, the ECM stops the charging control and the generator

switches to the normal power generation mode.

When the ECM detects a malfunction in a sensor, the ECM memorizes the DTC (Diagnostic Trouble Code).

The MIL (Malfunction Indicator Lamp) does not illuminate.

DTC Chart

DTC No.Detection ItemDTC No.Detection Item

P0516Battery Temperature Sensor

Circuit LowP1551Battery Current Sensor

Circuit Low

P0517Battery Temperature Sensor

Circuit HighP1552Battery Current Sensor

Circuit High

P0560System VoltageP1602Detection of Battery

P1550Battery Current Sensor

Circuit

12. Diagnosis

When the ECM detects a malfunction, the ECM makes a diagnosis and memorizes the failed section.

Furthermore, the MIL in the combination meter illuminates or blinks to inform the driver.

The ECM will also store the DTCs of the malfunctions. The DTCs can be accessed by the use of the

hand-held tester.

For details, refer to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

13. Fail-safe

When a malfunction is detected at any of the sensors, there is a possibility of an engine or other malfunction

occurring if the ECM were to continue to control the engine control system in the normal way. To prevent

such a problem, the fail-safe function of the ECM either relies on the data stored in memory to allow the

engine control system to continue operating, or stops the engine if a hazard is anticipated. For details, refer

to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

Page 128 of 2000

ENGINE - 2GR-FE ENGINE

Service Tip

The ECM of the ’06 RAV4 uses the CAN protocol for diagnostic communication. Therefore, a

hand-held tester and a dedicated adapter [CAN VIM (Vehicle Interface Module)] are required for

accessing diagnostic data. For details, refer to the 2006 RAV4 Repair Manual (Pub. No.

RM01M1U).

To clear the DTC that is stored in the ECM, use a hand-held tester, and disconnect the battery

terminal or remove the EFI fuse for 1 minute or longer.

EG-132

14. Diagnosis

When the ECM detects a malfunction, the ECM makes a diagnosis and memorizes the failed section.

Furthermore, the MIL (Malfunction Indicator Lamp) in the combination meter illuminates or blinks to

inform the driver.

The ECM will also store the DTCs (Diagnostic Trouble Codes) of the malfunctions. The DTCs can be

accessed by using the hand-held tester.

For details, refer to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

Page 240 of 2000

CO–42AZ-FE COOLING – COOLING FAN SYSTEM

CO

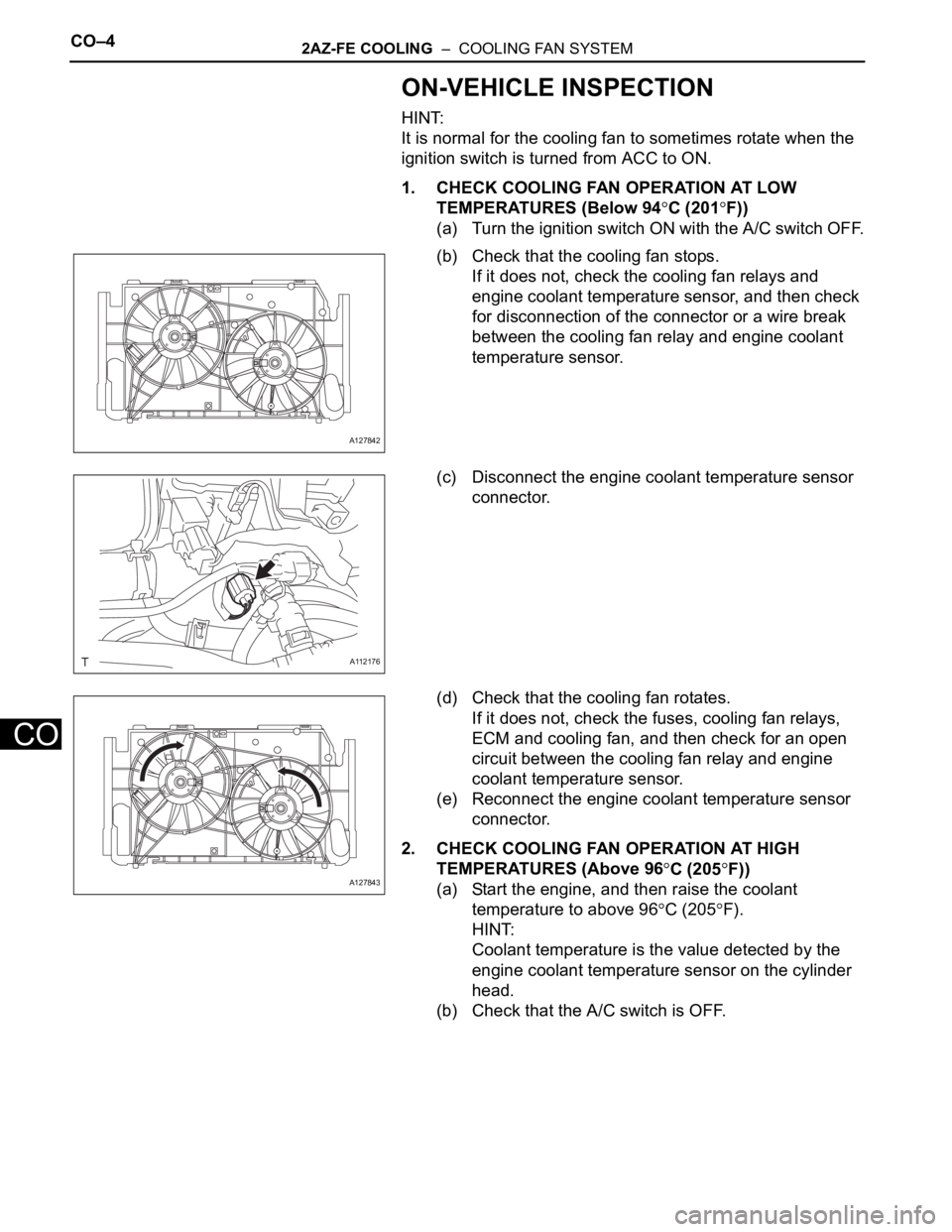

ON-VEHICLE INSPECTION

HINT:

It is normal for the cooling fan to sometimes rotate when the

ignition switch is turned from ACC to ON.

1. CHECK COOLING FAN OPERATION AT LOW

TEMPERATURES (Below 94

C (201F))

(a) Turn the ignition switch ON with the A/C switch OFF.

(b) Check that the cooling fan stops.

If it does not, check the cooling fan relays and

engine coolant temperature sensor, and then check

for disconnection of the connector or a wire break

between the cooling fan relay and engine coolant

temperature sensor.

(c) Disconnect the engine coolant temperature sensor

connector.

(d) Check that the cooling fan rotates.

If it does not, check the fuses, cooling fan relays,

ECM and cooling fan, and then check for an open

circuit between the cooling fan relay and engine

coolant temperature sensor.

(e) Reconnect the engine coolant temperature sensor

connector.

2. CHECK COOLING FAN OPERATION AT HIGH

TEMPERATURES (Above 96

C (205F))

(a) Start the engine, and then raise the coolant

temperature to above 96

C (205F).

HINT:

Coolant temperature is the value detected by the

engine coolant temperature sensor on the cylinder

head.

(b) Check that the A/C switch is OFF.

A127842

A112176

A127843

Page 339 of 2000

CH–42AZ-FE CHARGING – CHARGING SYSTEM

CH

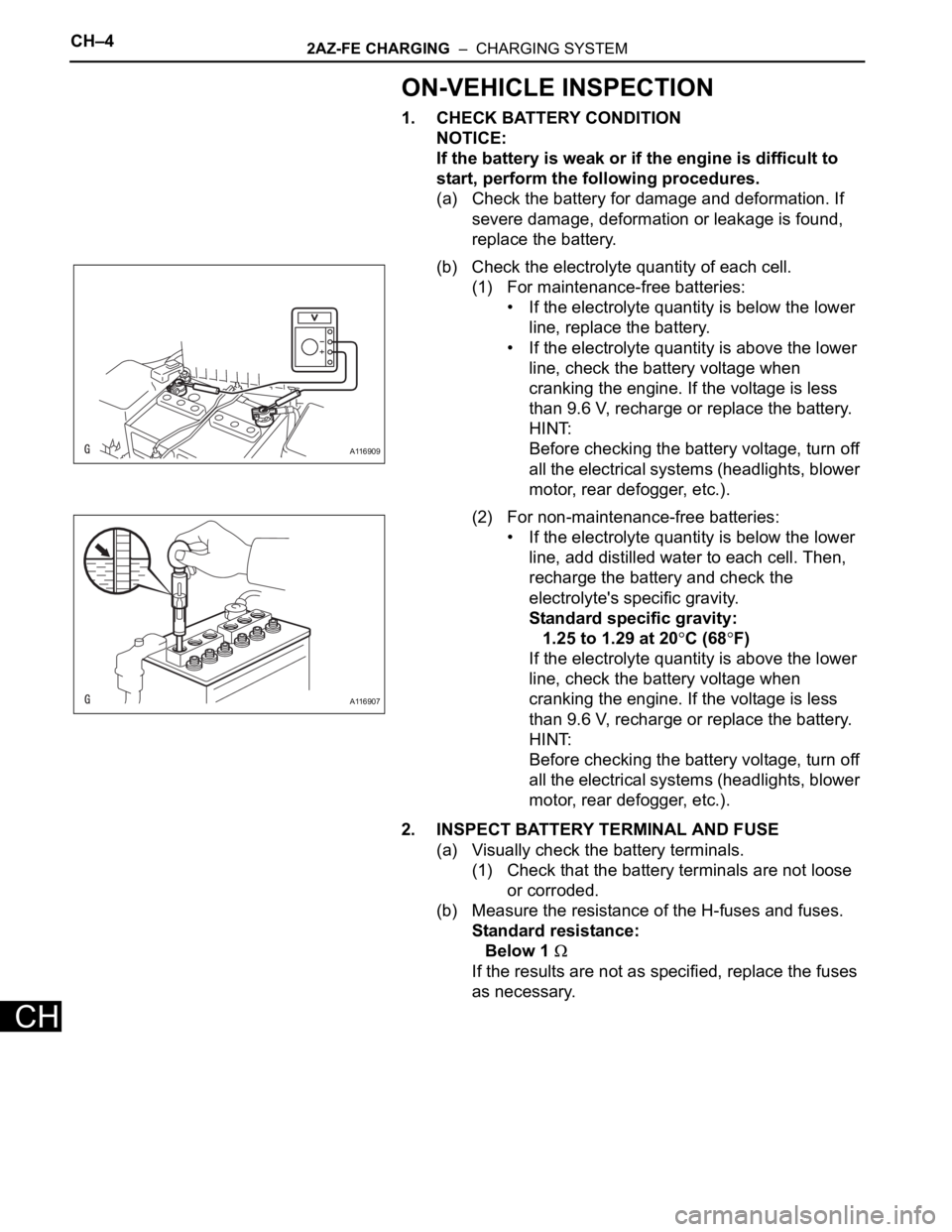

ON-VEHICLE INSPECTION

1. CHECK BATTERY CONDITION

NOTICE:

If the battery is weak or if the engine is difficult to

start, perform the following procedures.

(a) Check the battery for damage and deformation. If

severe damage, deformation or leakage is found,

replace the battery.

(b) Check the electrolyte quantity of each cell.

(1) For maintenance-free batteries:

• If the electrolyte quantity is below the lower

line, replace the battery.

• If the electrolyte quantity is above the lower

line, check the battery voltage when

cranking the engine. If the voltage is less

than 9.6 V, recharge or replace the battery.

HINT:

Before checking the battery voltage, turn off

all the electrical systems (headlights, blower

motor, rear defogger, etc.).

(2) For non-maintenance-free batteries:

• If the electrolyte quantity is below the lower

line, add distilled water to each cell. Then,

recharge the battery and check the

electrolyte's specific gravity.

Standard specific gravity:

1.25 to 1.29 at 20

C (68F)

If the electrolyte quantity is above the lower

line, check the battery voltage when

cranking the engine. If the voltage is less

than 9.6 V, recharge or replace the battery.

HINT:

Before checking the battery voltage, turn off

all the electrical systems (headlights, blower

motor, rear defogger, etc.).

2. INSPECT BATTERY TERMINAL AND FUSE

(a) Visually check the battery terminals.

(1) Check that the battery terminals are not loose

or corroded.

(b) Measure the resistance of the H-fuses and fuses.

Standard resistance:

Below 1

If the results are not as specified, replace the fuses

as necessary.

A116909

A116907

Page 454 of 2000

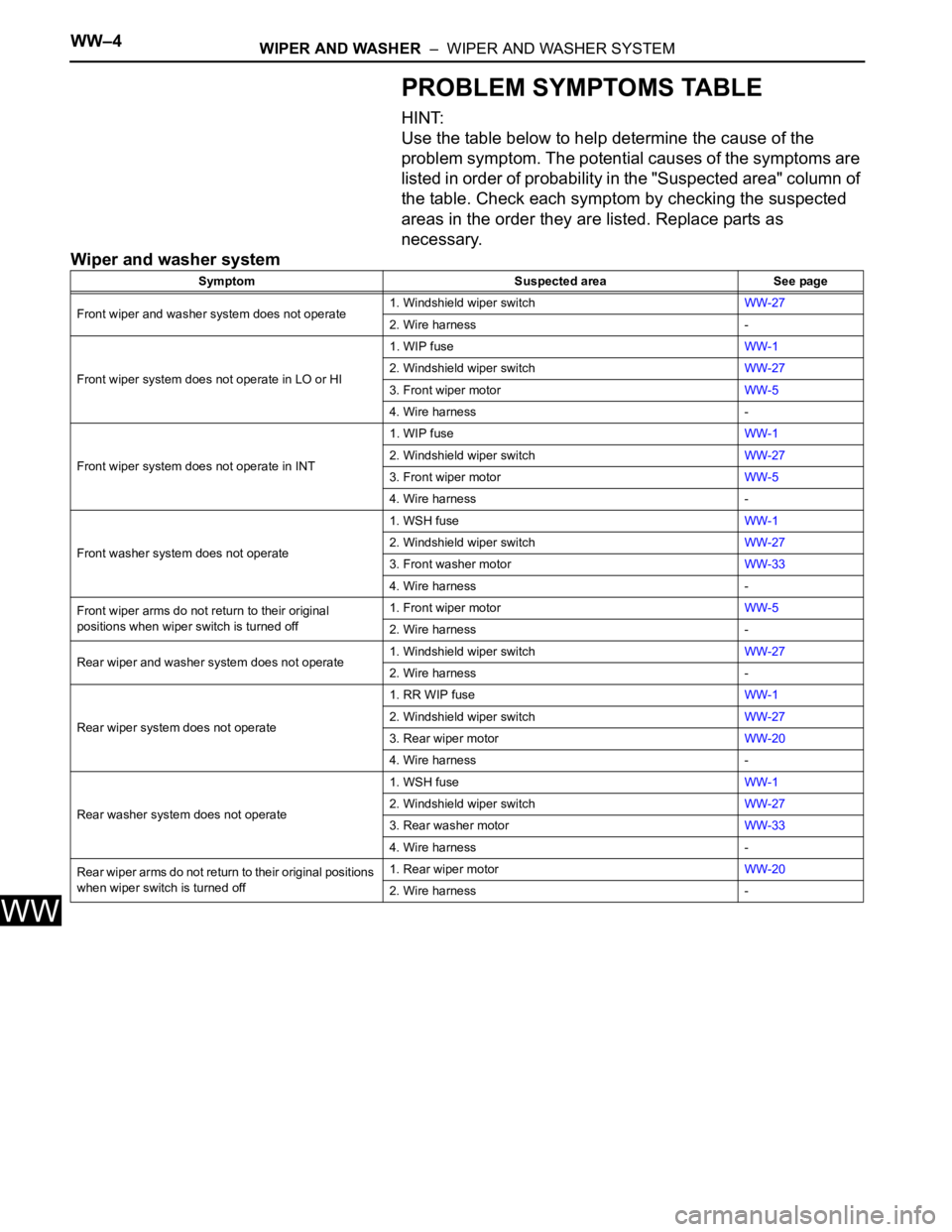

WW–4WIPER AND WASHER – WIPER AND WASHER SYSTEM

WW

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "Suspected area" column of

the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace parts as

necessary.

Wiper and washer system

Symptom Suspected area See page

Front wiper and washer system does not operate1. Windshield wiper switchWW-27

2. Wire harness -

Front wiper system does not operate in LO or HI1. WIP fuseWW-1

2. Windshield wiper switchWW-27

3. Front wiper motorWW-5

4. Wire harness -

Front wiper system does not operate in INT1. WIP fuseWW-1

2. Windshield wiper switchWW-27

3. Front wiper motorWW-5

4. Wire harness -

Front washer system does not operate1. WSH fuseWW-1

2. Windshield wiper switchWW-27

3. Front washer motorWW-33

4. Wire harness -

Front wiper arms do not return to their original

positions when wiper switch is turned off1. Front wiper motorWW-5

2. Wire harness -

Rear wiper and washer system does not operate1. Windshield wiper switchWW-27

2. Wire harness -

Rear wiper system does not operate1. RR WIP fuseWW-1

2. Windshield wiper switchWW-27

3. Rear wiper motorWW-20

4. Wire harness -

Rear washer system does not operate1. WSH fuseWW-1

2. Windshield wiper switchWW-27

3. Rear washer motorWW-33

4. Wire harness -

Rear wiper arms do not return to their original positions

when wiper switch is turned off1. Rear wiper motorWW-20

2. Wire harness -

Page 478 of 2000

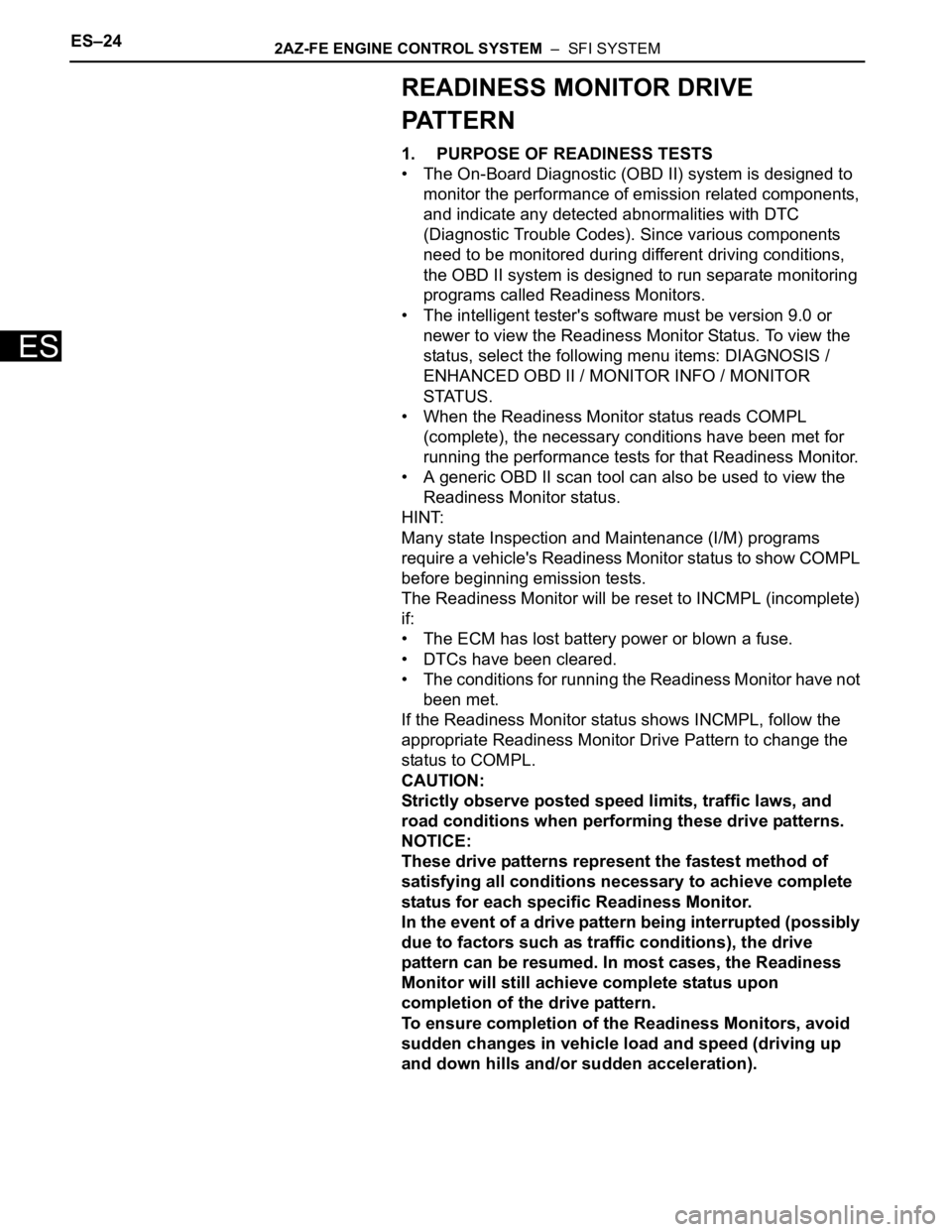

ES–242AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

READINESS MONITOR DRIVE

PAT T E R N

1. PURPOSE OF READINESS TESTS

• The On-Board Diagnostic (OBD II) system is designed to

monitor the performance of emission related components,

and indicate any detected abnormalities with DTC

(Diagnostic Trouble Codes). Since various components

need to be monitored during different driving conditions,

the OBD II system is designed to run separate monitoring

programs called Readiness Monitors.

• The intelligent tester's software must be version 9.0 or

newer to view the Readiness Monitor Status. To view the

status, select the following menu items: DIAGNOSIS /

ENHANCED OBD II / MONITOR INFO / MONITOR

STATUS.

• When the Readiness Monitor status reads COMPL

(complete), the necessary conditions have been met for

running the performance tests for that Readiness Monitor.

• A generic OBD II scan tool can also be used to view the

Readiness Monitor status.

HINT:

Many state Inspection and Maintenance (I/M) programs

require a vehicle's Readiness Monitor status to show COMPL

before beginning emission tests.

The Readiness Monitor will be reset to INCMPL (incomplete)

if:

• The ECM has lost battery power or blown a fuse.

• DTCs have been cleared.

• The conditions for running the Readiness Monitor have not

been met.

If the Readiness Monitor status shows INCMPL, follow the

appropriate Readiness Monitor Drive Pattern to change the

status to COMPL.

CAUTION:

Strictly observe posted speed limits, traffic laws, and

road conditions when performing these drive patterns.

NOTICE:

These drive patterns represent the fastest method of

satisfying all conditions necessary to achieve complete

status for each specific Readiness Monitor.

In the event of a drive pattern being interrupted (possibly

due to factors such as traffic conditions), the drive

pattern can be resumed. In most cases, the Readiness

Monitor will still achieve complete status upon

completion of the drive pattern.

To ensure completion of the Readiness Monitors, avoid

sudden changes in vehicle load and speed (driving up

and down hills and/or sudden acceleration).

Page 495 of 2000

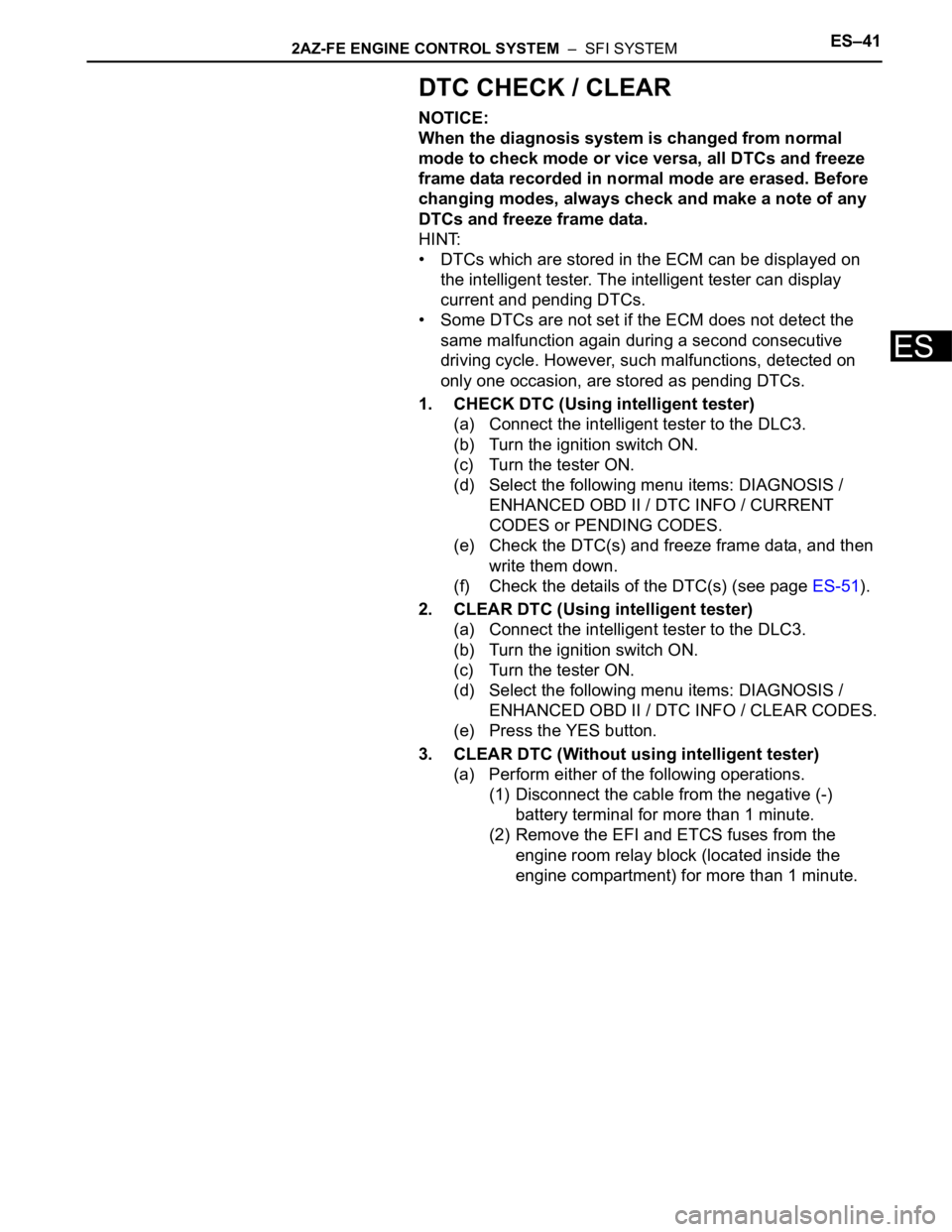

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–41

ES

DTC CHECK / CLEAR

NOTICE:

When the diagnosis system is changed from normal

mode to check mode or vice versa, all DTCs and freeze

frame data recorded in normal mode are erased. Before

changing modes, always check and make a note of any

DTCs and freeze frame data.

HINT:

• DTCs which are stored in the ECM can be displayed on

the intelligent tester. The intelligent tester can display

current and pending DTCs.

• Some DTCs are not set if the ECM does not detect the

same malfunction again during a second consecutive

driving cycle. However, such malfunctions, detected on

only one occasion, are stored as pending DTCs.

1. CHECK DTC (Using intelligent tester)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch ON.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT

CODES or PENDING CODES.

(e) Check the DTC(s) and freeze frame data, and then

write them down.

(f) Check the details of the DTC(s) (see page ES-51).

2. CLEAR DTC (Using intelligent tester)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch ON.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CLEAR CODES.

(e) Press the YES button.

3. CLEAR DTC (Without using intelligent tester)

(a) Perform either of the following operations.

(1) Disconnect the cable from the negative (-)

battery terminal for more than 1 minute.

(2) Remove the EFI and ETCS fuses from the

engine room relay block (located inside the

engine compartment) for more than 1 minute.

Page 501 of 2000

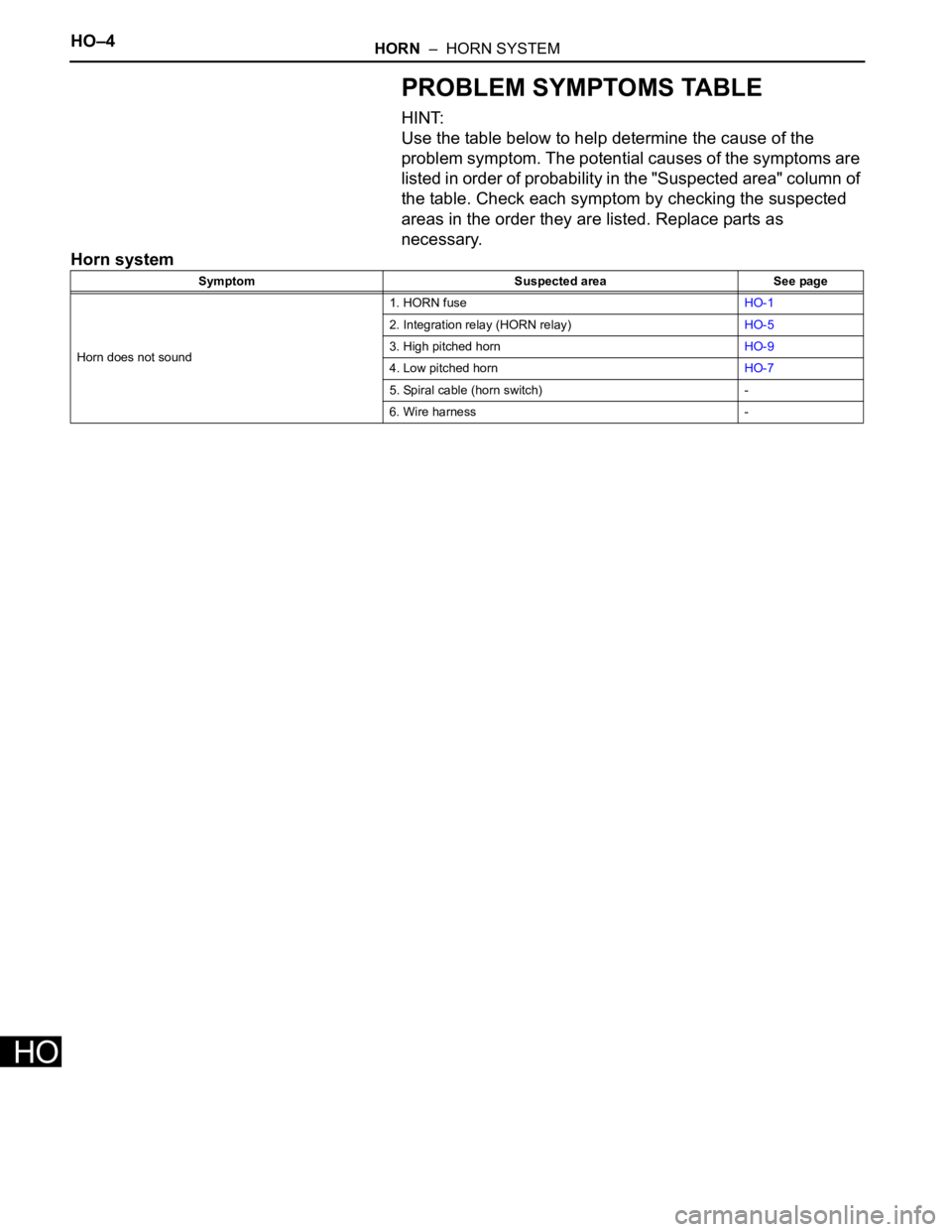

HO–4HORN – HORN SYSTEM

HO

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "Suspected area" column of

the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace parts as

necessary.

Horn system

Symptom Suspected area See page

Horn does not sound1. HORN fuseHO-1

2. Integration relay (HORN relay)HO-5

3. High pitched hornHO-9

4. Low pitched hornHO-7

5. Spiral cable (horn switch) -

6. Wire harness -

Page 504 of 2000

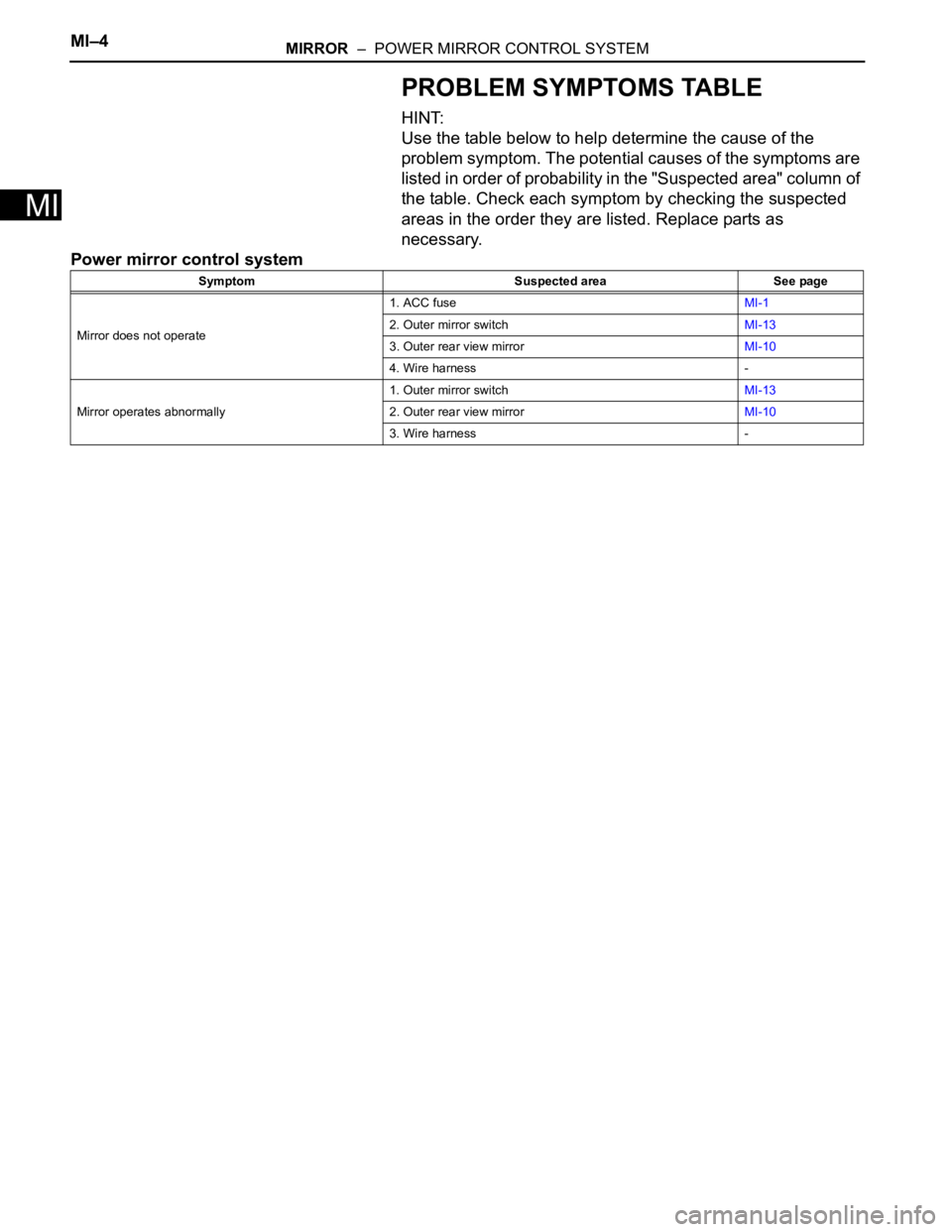

MI–4MIRROR – POWER MIRROR CONTROL SYSTEM

MI

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "Suspected area" column of

the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace parts as

necessary.

Power mirror control system

Symptom Suspected area See page

Mirror does not operate1. ACC fuseMI-1

2. Outer mirror switchMI-13

3. Outer rear view mirrorMI-10

4. Wire harness -

Mirror operates abnormally1. Outer mirror switchMI-13

2. Outer rear view mirrorMI-10

3. Wire harness -

Page 508 of 2000

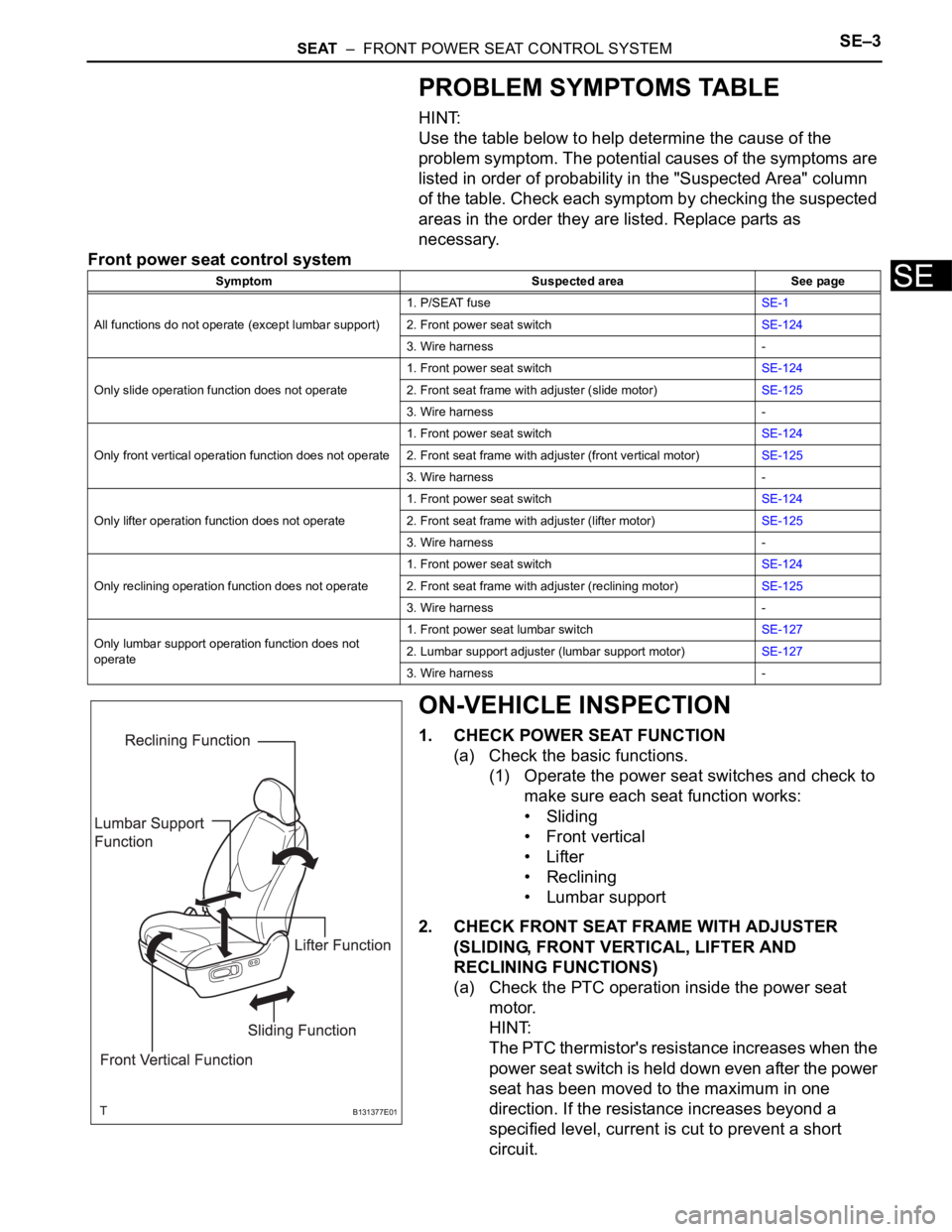

SEAT – FRONT POWER SEAT CONTROL SYSTEMSE–3

SE

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "Suspected Area" column

of the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace parts as

necessary.

Front power seat control system

ON-VEHICLE INSPECTION

1. CHECK POWER SEAT FUNCTION

(a) Check the basic functions.

(1) Operate the power seat switches and check to

make sure each seat function works:

• Sliding

•Front vertical

•Lifter

• Reclining

• Lumbar support

2. CHECK FRONT SEAT FRAME WITH ADJUSTER

(SLIDING, FRONT VERTICAL, LIFTER AND

RECLINING FUNCTIONS)

(a) Check the PTC operation inside the power seat

motor.

HINT:

The PTC thermistor's resistance increases when the

power seat switch is held down even after the power

seat has been moved to the maximum in one

direction. If the resistance increases beyond a

specified level, current is cut to prevent a short

circuit.

Symptom Suspected area See page

All functions do not operate (except lumbar support)1. P/SEAT fuseSE-1

2. Front power seat switchSE-124

3. Wire harness -

Only slide operation function does not operate1. Front power seat switchSE-124

2. Front seat frame with adjuster (slide motor)SE-125

3. Wire harness -

Only front vertical operation function does not operate1. Front power seat switchSE-124

2. Front seat frame with adjuster (front vertical motor)SE-125

3. Wire harness -

Only lifter operation function does not operate1. Front power seat switchSE-124

2. Front seat frame with adjuster (lifter motor)SE-125

3. Wire harness -

Only reclining operation function does not operate1. Front power seat switchSE-124

2. Front seat frame with adjuster (reclining motor)SE-125

3. Wire harness -

Only lumbar support operation function does not

operate1. Front power seat lumbar switchSE-127

2. Lumbar support adjuster (lumbar support motor)SE-127

3. Wire harness -

B131377E01