abs sensor TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1459 of 2000

AXLE – REAR AXLE HUB AND BEARINGAH–19

AH

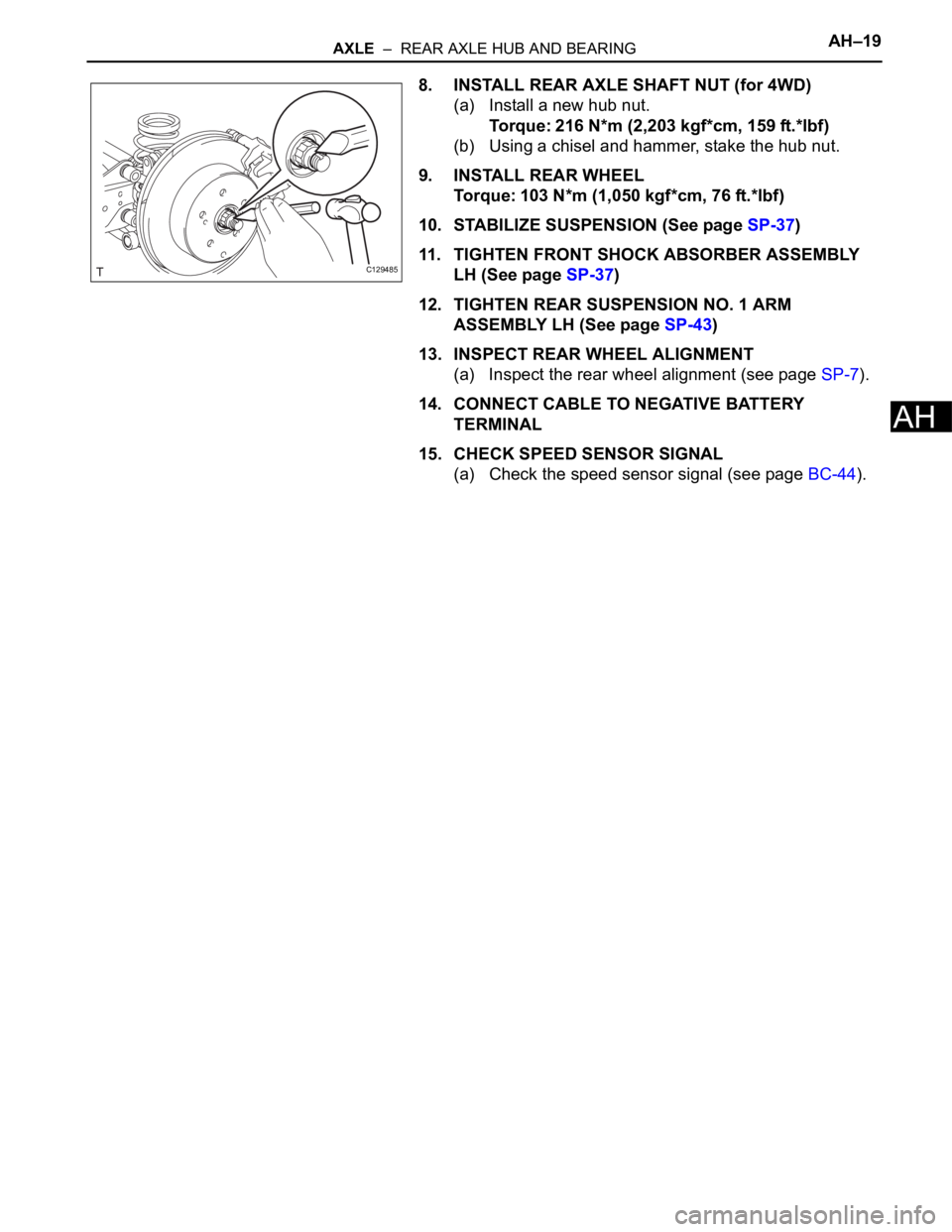

8. INSTALL REAR AXLE SHAFT NUT (for 4WD)

(a) Install a new hub nut.

Torque: 216 N*m (2,203 kgf*cm, 159 ft.*lbf)

(b) Using a chisel and hammer, stake the hub nut.

9. INSTALL REAR WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

10. STABILIZE SUSPENSION (See page SP-37)

11. TIGHTEN FRONT SHOCK ABSORBER ASSEMBLY

LH (See page SP-37)

12. TIGHTEN REAR SUSPENSION NO. 1 ARM

ASSEMBLY LH (See page SP-43)

13. INSPECT REAR WHEEL ALIGNMENT

(a) Inspect the rear wheel alignment (see page SP-7).

14. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

15. CHECK SPEED SENSOR SIGNAL

(a) Check the speed sensor signal (see page BC-44).

C129485

Page 1460 of 2000

SP–14SUSPENSION – FRONT SHOCK ABSORBER WITH COIL SPRING

SP

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

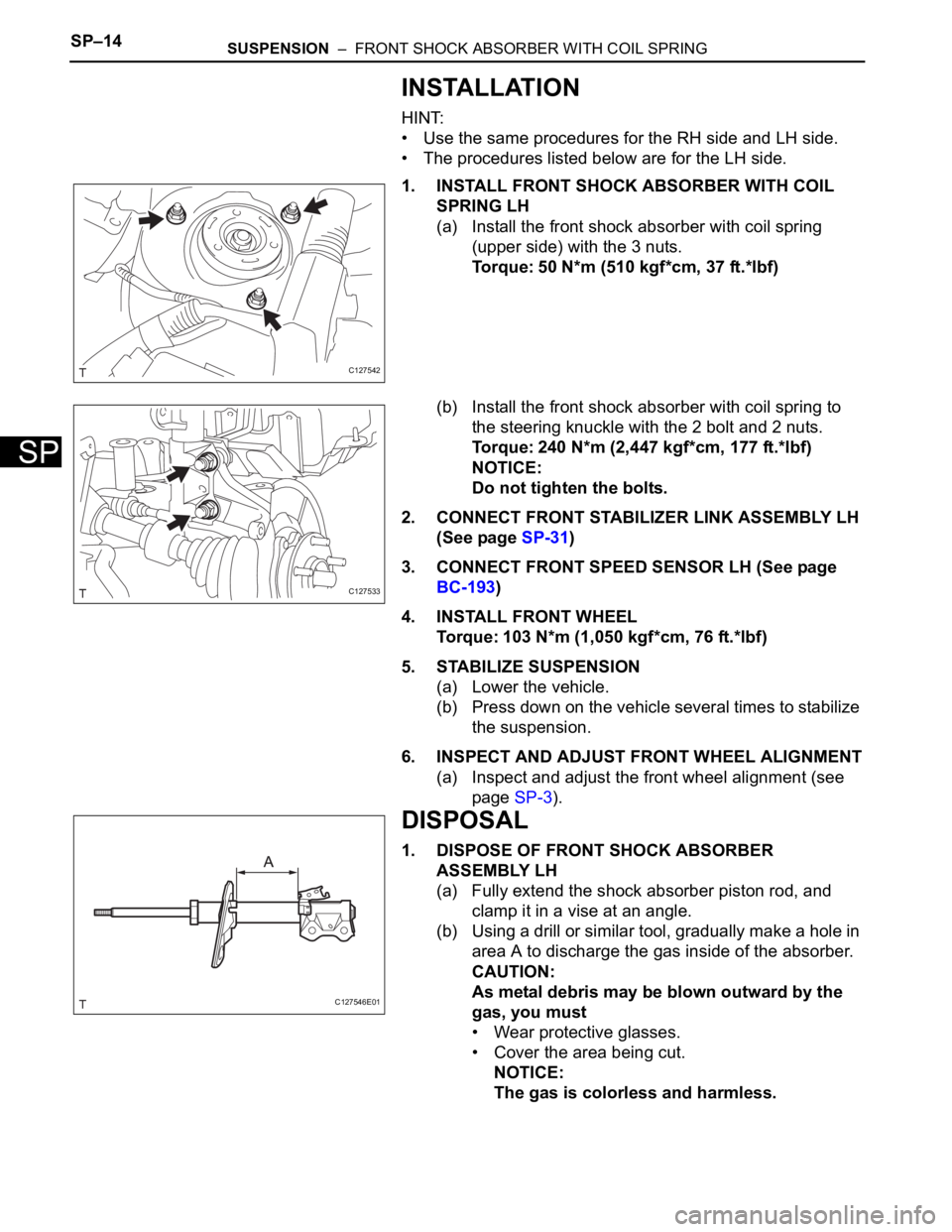

1. INSTALL FRONT SHOCK ABSORBER WITH COIL

SPRING LH

(a) Install the front shock absorber with coil spring

(upper side) with the 3 nuts.

Torque: 50 N*m (510 kgf*cm, 37 ft.*lbf)

(b) Install the front shock absorber with coil spring to

the steering knuckle with the 2 bolt and 2 nuts.

Torque: 240 N*m (2,447 kgf*cm, 177 ft.*lbf)

NOTICE:

Do not tighten the bolts.

2. CONNECT FRONT STABILIZER LINK ASSEMBLY LH

(See page SP-31)

3. CONNECT FRONT SPEED SENSOR LH (See page

BC-193)

4. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

5. STABILIZE SUSPENSION

(a) Lower the vehicle.

(b) Press down on the vehicle several times to stabilize

the suspension.

6. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

(a) Inspect and adjust the front wheel alignment (see

page SP-3).

DISPOSAL

1. DISPOSE OF FRONT SHOCK ABSORBER

ASSEMBLY LH

(a) Fully extend the shock absorber piston rod, and

clamp it in a vise at an angle.

(b) Using a drill or similar tool, gradually make a hole in

area A to discharge the gas inside of the absorber.

CAUTION:

As metal debris may be blown outward by the

gas, you must

• Wear protective glasses.

• Cover the area being cut.

NOTICE:

The gas is colorless and harmless.

C127542

C127533

C127546E01

Page 1465 of 2000

SP–20SUSPENSION – FRONT SHOCK ABSORBER WITH COIL SPRING (for Sport Package)

SP

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

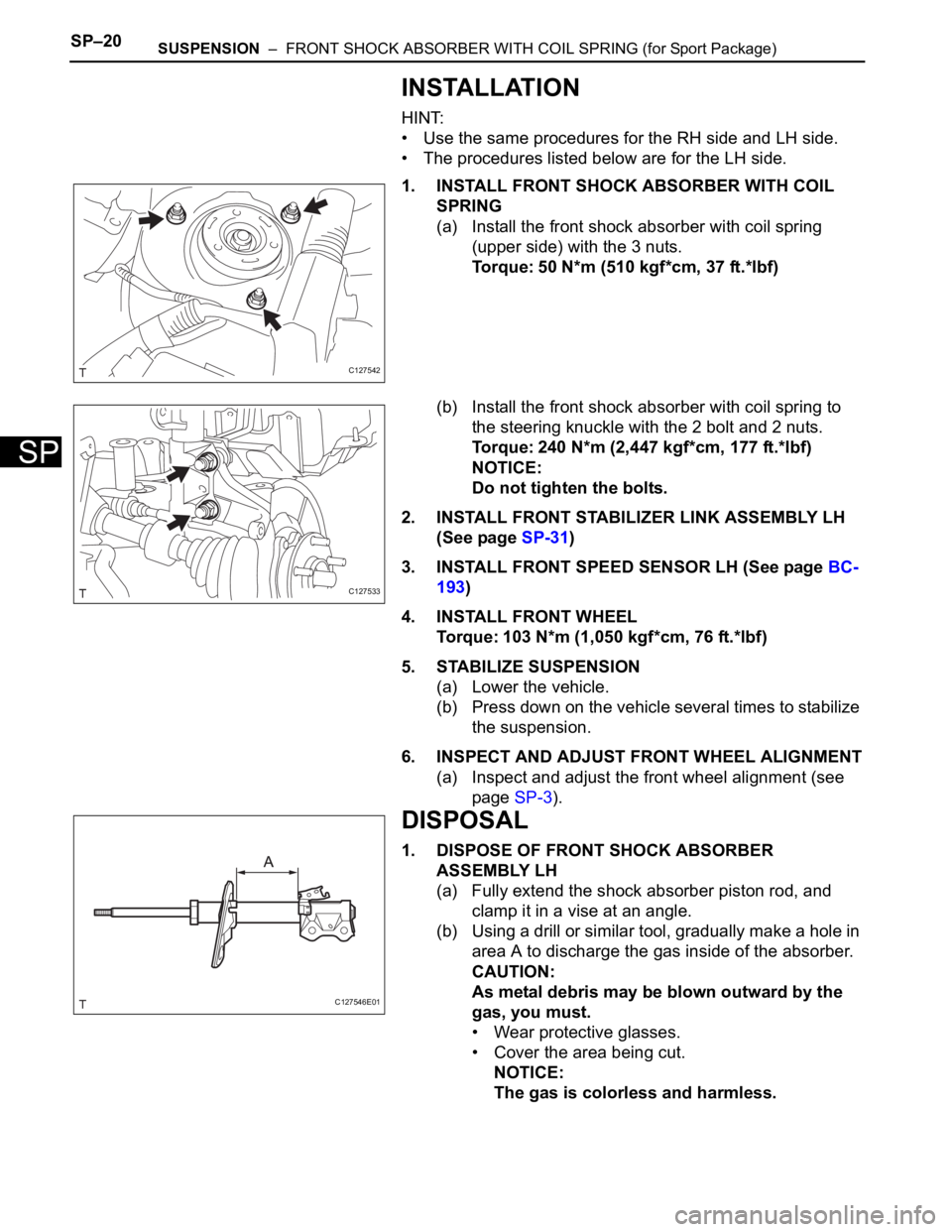

1. INSTALL FRONT SHOCK ABSORBER WITH COIL

SPRING

(a) Install the front shock absorber with coil spring

(upper side) with the 3 nuts.

Torque: 50 N*m (510 kgf*cm, 37 ft.*lbf)

(b) Install the front shock absorber with coil spring to

the steering knuckle with the 2 bolt and 2 nuts.

Torque: 240 N*m (2,447 kgf*cm, 177 ft.*lbf)

NOTICE:

Do not tighten the bolts.

2. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

(See page SP-31)

3. INSTALL FRONT SPEED SENSOR LH (See page BC-

193)

4. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

5. STABILIZE SUSPENSION

(a) Lower the vehicle.

(b) Press down on the vehicle several times to stabilize

the suspension.

6. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

(a) Inspect and adjust the front wheel alignment (see

page SP-3).

DISPOSAL

1. DISPOSE OF FRONT SHOCK ABSORBER

ASSEMBLY LH

(a) Fully extend the shock absorber piston rod, and

clamp it in a vise at an angle.

(b) Using a drill or similar tool, gradually make a hole in

area A to discharge the gas inside of the absorber.

CAUTION:

As metal debris may be blown outward by the

gas, you must.

• Wear protective glasses.

• Cover the area being cut.

NOTICE:

The gas is colorless and harmless.

C127542

C127533

C127546E01

Page 1509 of 2000

BC–6BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

SYSTEM DESCRIPTION

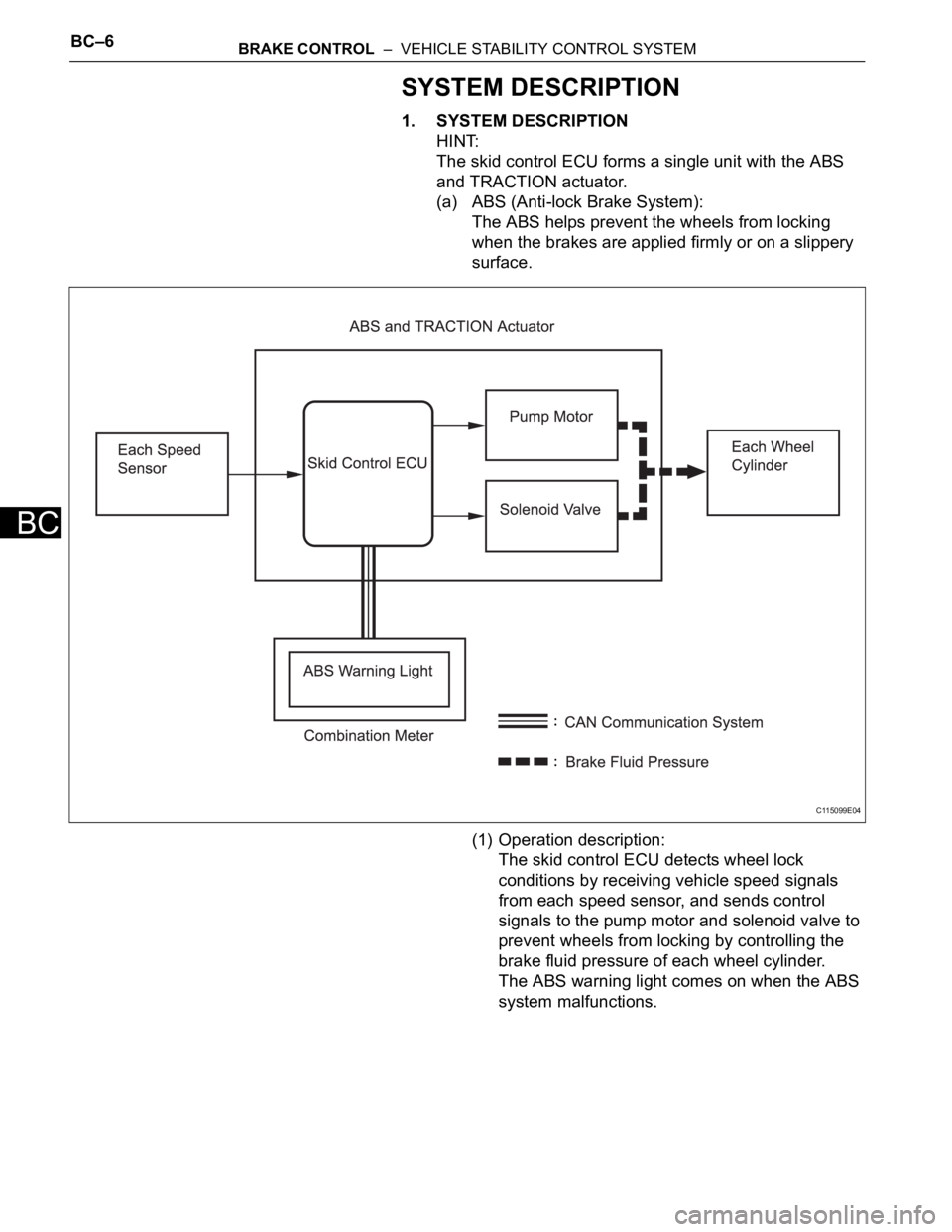

1. SYSTEM DESCRIPTION

HINT:

The skid control ECU forms a single unit with the ABS

and TRACTION actuator.

(a) ABS (Anti-lock Brake System):

The ABS helps prevent the wheels from locking

when the brakes are applied firmly or on a slippery

surface.

(1) Operation description:

The skid control ECU detects wheel lock

conditions by receiving vehicle speed signals

from each speed sensor, and sends control

signals to the pump motor and solenoid valve to

prevent wheels from locking by controlling the

brake fluid pressure of each wheel cylinder.

The ABS warning light comes on when the ABS

system malfunctions.

C115099E04

Page 1510 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–7

BC

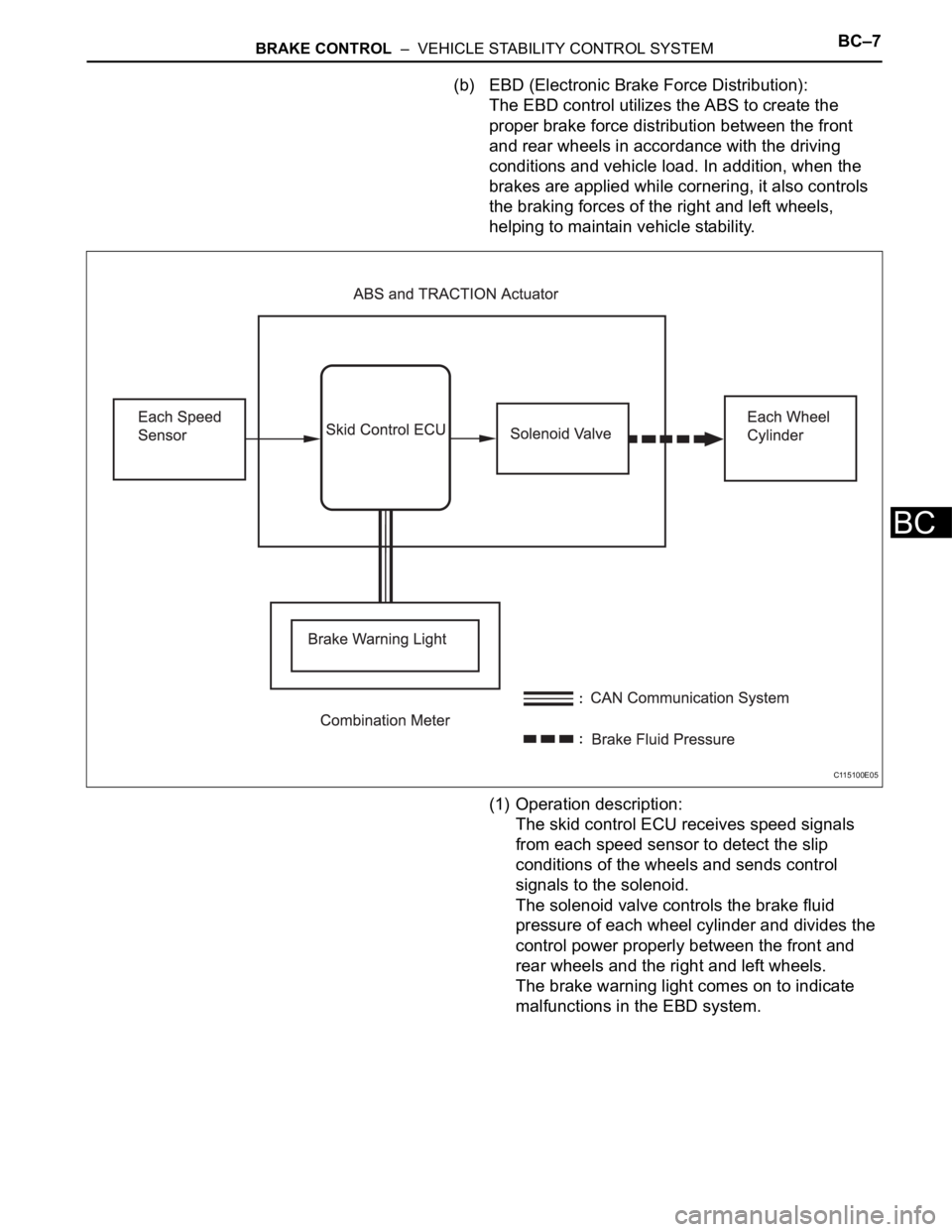

(b) EBD (Electronic Brake Force Distribution):

The EBD control utilizes the ABS to create the

proper brake force distribution between the front

and rear wheels in accordance with the driving

conditions and vehicle load. In addition, when the

brakes are applied while cornering, it also controls

the braking forces of the right and left wheels,

helping to maintain vehicle stability.

(1) Operation description:

The skid control ECU receives speed signals

from each speed sensor to detect the slip

conditions of the wheels and sends control

signals to the solenoid.

The solenoid valve controls the brake fluid

pressure of each wheel cylinder and divides the

control power properly between the front and

rear wheels and the right and left wheels.

The brake warning light comes on to indicate

malfunctions in the EBD system.

C115100E05

Page 1511 of 2000

BC–8BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

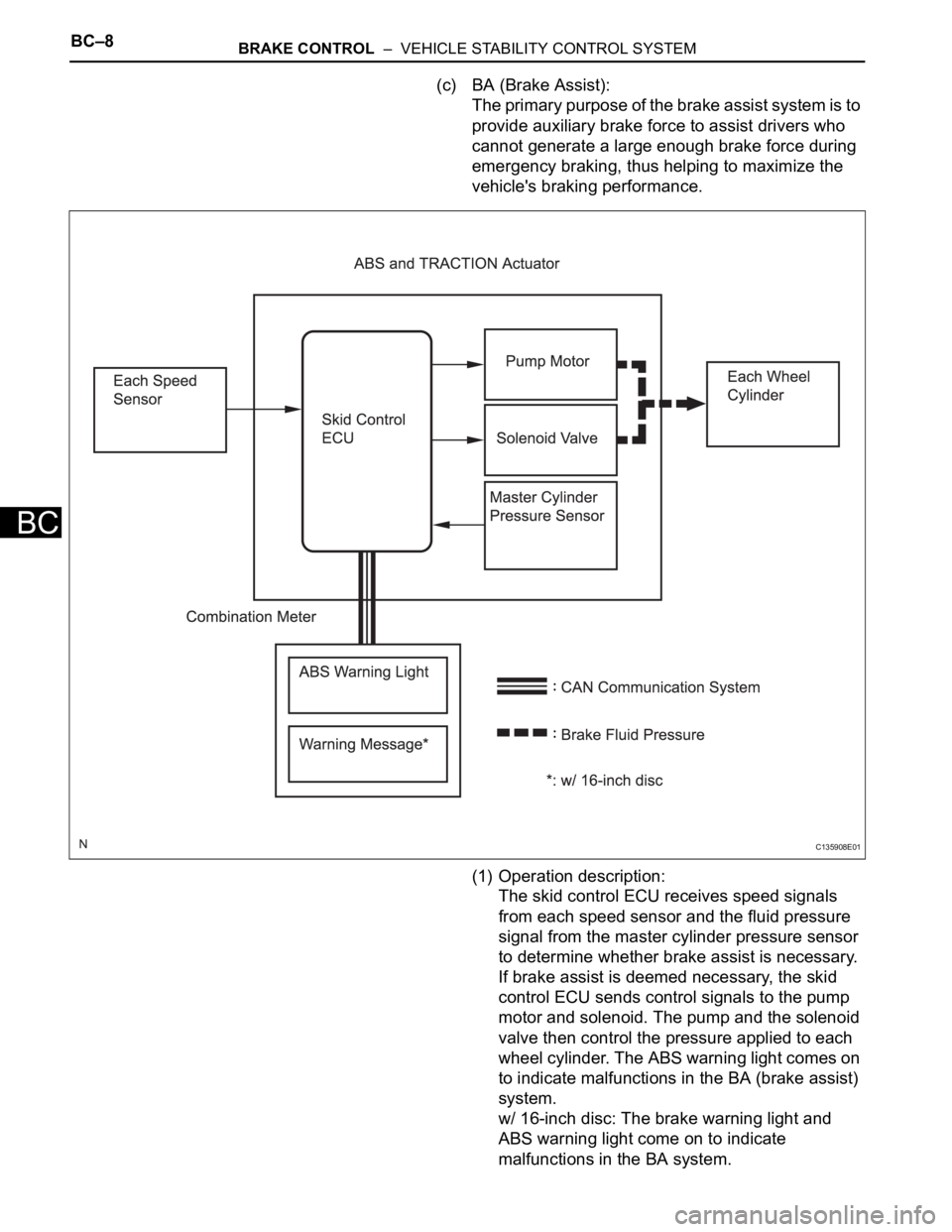

(c) BA (Brake Assist):

The primary purpose of the brake assist system is to

provide auxiliary brake force to assist drivers who

cannot generate a large enough brake force during

emergency braking, thus helping to maximize the

vehicle's braking performance.

(1) Operation description:

The skid control ECU receives speed signals

from each speed sensor and the fluid pressure

signal from the master cylinder pressure sensor

to determine whether brake assist is necessary.

If brake assist is deemed necessary, the skid

control ECU sends control signals to the pump

motor and solenoid. The pump and the solenoid

valve then control the pressure applied to each

wheel cylinder. The ABS warning light comes on

to indicate malfunctions in the BA (brake assist)

system.

w/ 16-inch disc: The brake warning light and

ABS warning light come on to indicate

malfunctions in the BA system.

C135908E01

Page 1521 of 2000

BC–18BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

(3) Front Wheel Skid Tendency

When the skid control ECU determines that

there is a front wheel skid tendency, it controls

the VSC to dampen the front wheel skid. At the

same time, it effects cooperative control with the

EPS to provide steering torque assist, which

facilitates the driver's steering maneuvers to

stabilize the vehicle posture. To prevent

excessive steering maneuvers, it provides a

steering torque assist. This assist increases the

resistance to counter the driver's steering effort,

if the driver turns the steering wheel excessively.

(4) Rear Wheel Skid Tendency

When the skid control ECU determines that

there is a rear wheel skid tendency, it controls

the VSC to dampen the rear wheel skid. At the

same time, it effects cooperative control with the

EPS to provide steering torque assist, which

facilitates the driver's steering maneuvers in the

direction to correct the rear wheel skid.

(5) Acceleration During Cornering

A sudden acceleration of the vehicle during

cornering may cause a drive wheel to freewheel,

which could cause the front wheels or rear

wheels to skid. If the skid control ECU

determines that there is freewheeling of a drive

wheel, a front wheel skid tendency, or a rear

wheel skid tendency, it effects cooperative

control with the 4WD system to optimally control

the drive torque distribution to the front and rear

wheels. Furthermore, it controls the TRC and

the VSC as needed to ensure driving stability

and acceleration performance.

(b) Operation

The operation of the solenoid valves under the

cooperative control is the same as the TRC or VSC

operation.

3. ABS WITH EBD, BA, TRC AND VSC OPERATION

(a) The skid control ECU calculates vehicle stability

tendency based on the signals from the 4 wheel

speed sensors, the yaw rate and deceleration

sensor and the steering sensor. In addition, it

evaluates the results of the calculations to

determine whether any control actions (control of

the engine output torque by electronic throttle

control and of the brake fluid pressure by the ABS

and TRACTION actuator) should be implemented.

(b) The slip indicator blinks and the skid control buzzer

sounds to inform the driver that the VSC system is

operating. The slip indicator also blinks when

traction control is operating, and the operation being

performed is displayed.

Page 1522 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–19

BC

4. FAIL SAFE FUNCTION

(a) When a failure occurs in the ABS with BA, TRC and

VSC systems, the ABS and VSC warning lights

illuminate, the slip indicator light comes on*1 or

remains off*2, and the operations of those systems

are prohibited. In addition to this, when a failure

which disables the EBD operation occurs, the brake

warning light comes on and its operation is

prohibited.

HINT:

*1: for 2WD

*2: for 4WD

(b) If control is prohibited due to a malfunction during

operation, control is disabled gradually to avoid

sudden vehicle instability.

5. INITIAL CHECK

(a) When the vehicle speed first reaches approximately

6 km/h (4 mph) or more after the ignition switch is

turned ON, each solenoid valve and the motor of the

ABS and TRACTION actuator are sequentially

activated to perform electrical checks. During the

initial check, the operating sound of the solenoid

valve and motor can be heard from the engine

compartment, but this does not indicate a

malfunction.

6. SERVICE MODE

(a) VSC operation can be disabled by operating the

intelligent tester.

HINT:

Refer to the intelligent tester operator's manual for

further details.

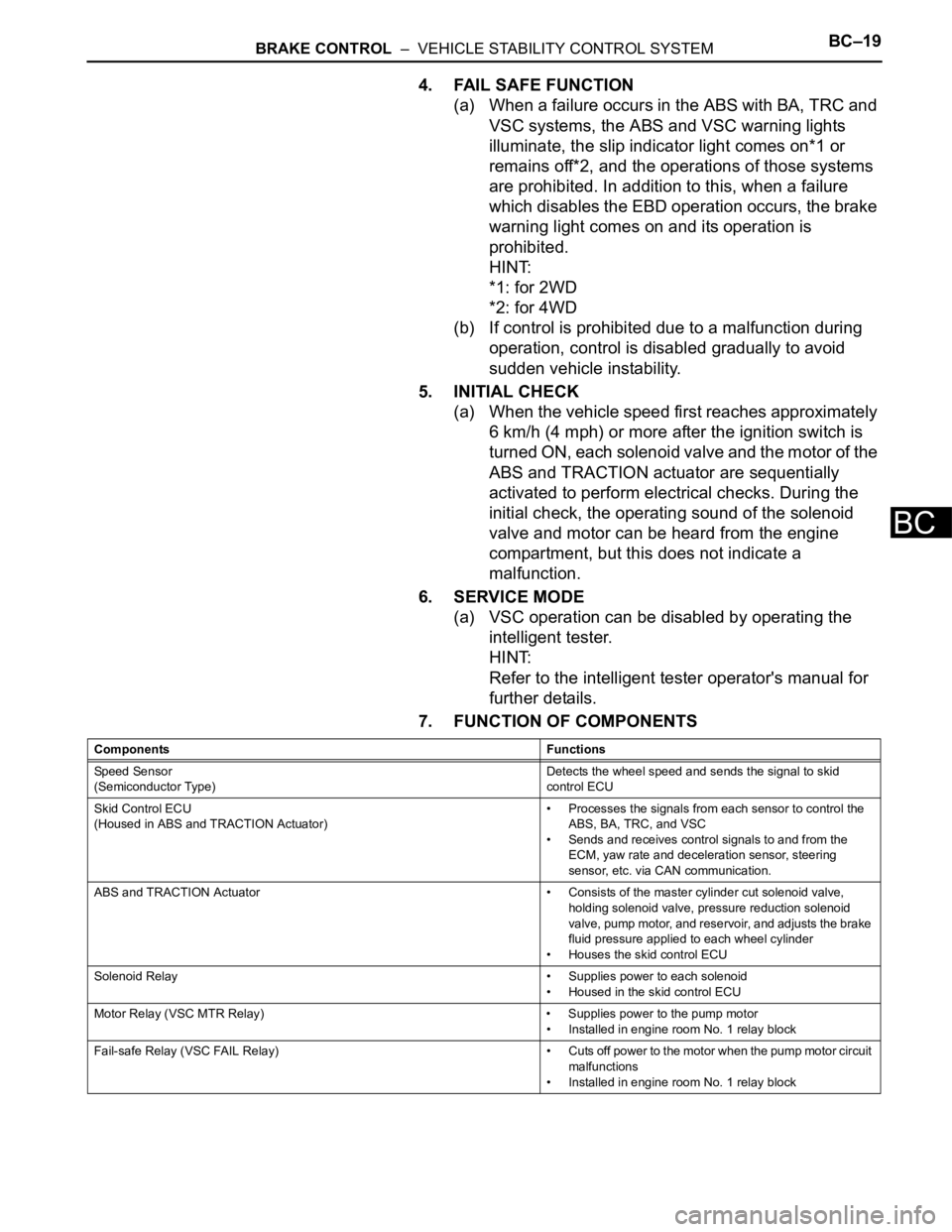

7. FUNCTION OF COMPONENTS

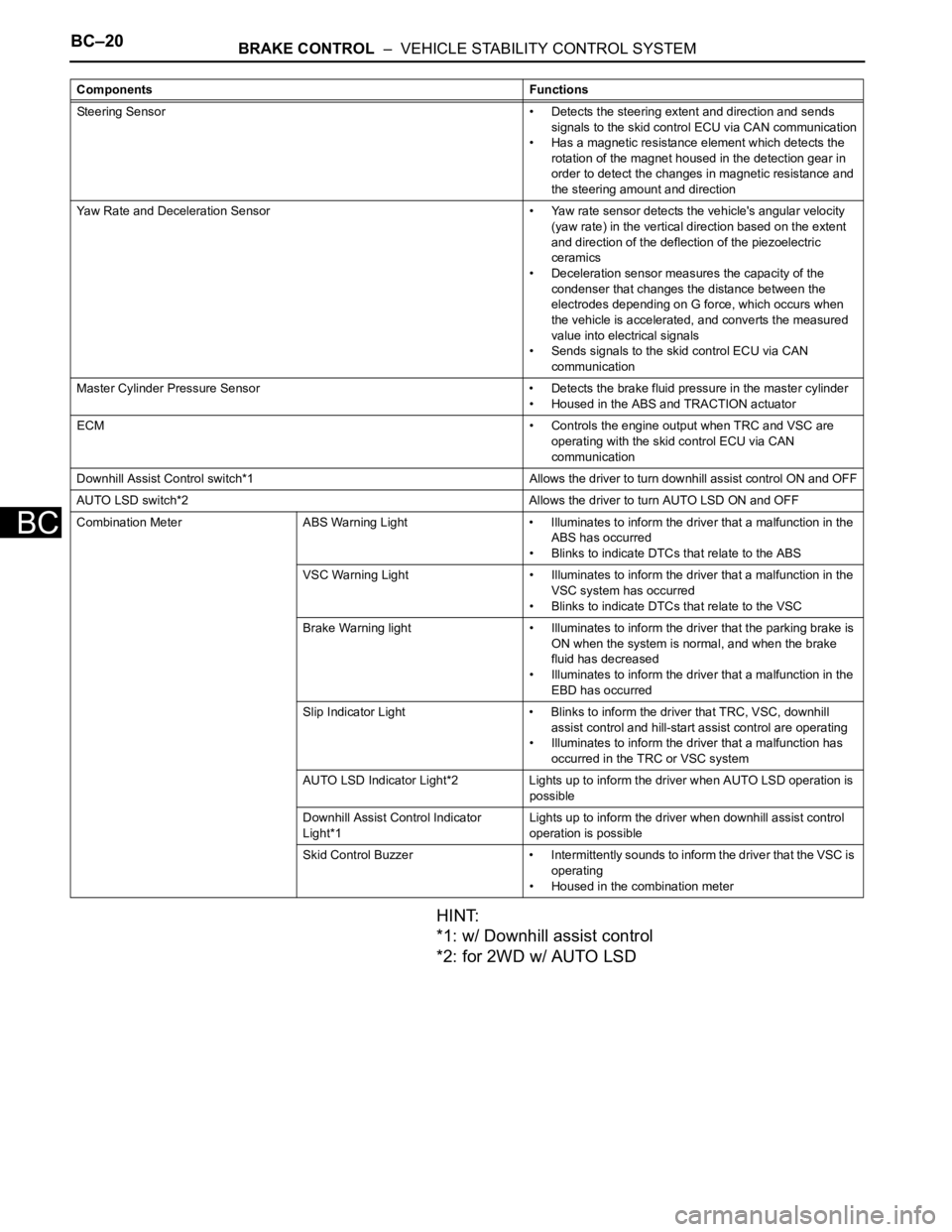

Components Functions

Speed Sensor

(Semiconductor Type)Detects the wheel speed and sends the signal to skid

control ECU

Skid Control ECU

(Housed in ABS and TRACTION Actuator)• Processes the signals from each sensor to control the

ABS, BA, TRC, and VSC

• Sends and receives control signals to and from the

ECM, yaw rate and deceleration sensor, steering

sensor, etc. via CAN communication.

ABS and TRACTION Actuator • Consists of the master cylinder cut solenoid valve,

holding solenoid valve, pressure reduction solenoid

valve, pump motor, and reservoir, and adjusts the brake

fluid pressure applied to each wheel cylinder

• Houses the skid control ECU

Solenoid Relay • Supplies power to each solenoid

• Housed in the skid control ECU

Motor Relay (VSC MTR Relay) • Supplies power to the pump motor

• Installed in engine room No. 1 relay block

Fail-safe Relay (VSC FAIL Relay) • Cuts off power to the motor when the pump motor circuit

malfunctions

• Installed in engine room No. 1 relay block

Page 1523 of 2000

BC–20BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

HINT:

*1: w/ Downhill assist control

*2: for 2WD w/ AUTO LSD

Steering Sensor • Detects the steering extent and direction and sends

signals to the skid control ECU via CAN communication

• Has a magnetic resistance element which detects the

rotation of the magnet housed in the detection gear in

order to detect the changes in magnetic resistance and

the steering amount and direction

Yaw Rate and Deceleration Sensor • Yaw rate sensor detects the vehicle's angular velocity

(yaw rate) in the vertical direction based on the extent

and direction of the deflection of the piezoelectric

ceramics

• Deceleration sensor measures the capacity of the

condenser that changes the distance between the

electrodes depending on G force, which occurs when

the vehicle is accelerated, and converts the measured

value into electrical signals

• Sends signals to the skid control ECU via CAN

communication

Master Cylinder Pressure Sensor • Detects the brake fluid pressure in the master cylinder

• Housed in the ABS and TRACTION actuator

ECM• Controls the engine output when TRC and VSC are

operating with the skid control ECU via CAN

communication

Downhill Assist Control switch*1 Allows the driver to turn downhill assist control ON and OFF

AUTO LSD switch*2 Allows the driver to turn AUTO LSD ON and OFF

Combination Meter ABS Warning Light • Illuminates to inform the driver that a malfunction in the

ABS has occurred

• Blinks to indicate DTCs that relate to the ABS

VSC Warning Light • Illuminates to inform the driver that a malfunction in the

VSC system has occurred

• Blinks to indicate DTCs that relate to the VSC

Brake Warning light • Illuminates to inform the driver that the parking brake is

ON when the system is normal, and when the brake

fluid has decreased

• Illuminates to inform the driver that a malfunction in the

EBD has occurred

Slip Indicator Light • Blinks to inform the driver that TRC, VSC, downhill

assist control and hill-start assist control are operating

• Illuminates to inform the driver that a malfunction has

occurred in the TRC or VSC system

AUTO LSD Indicator Light*2 Lights up to inform the driver when AUTO LSD operation is

possible

Downhill Assist Control Indicator

Light*1Lights up to inform the driver when downhill assist control

operation is possible

Skid Control Buzzer • Intermittently sounds to inform the driver that the VSC is

operating

• Housed in the combination meter Components Functions

Page 1534 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–31

BC

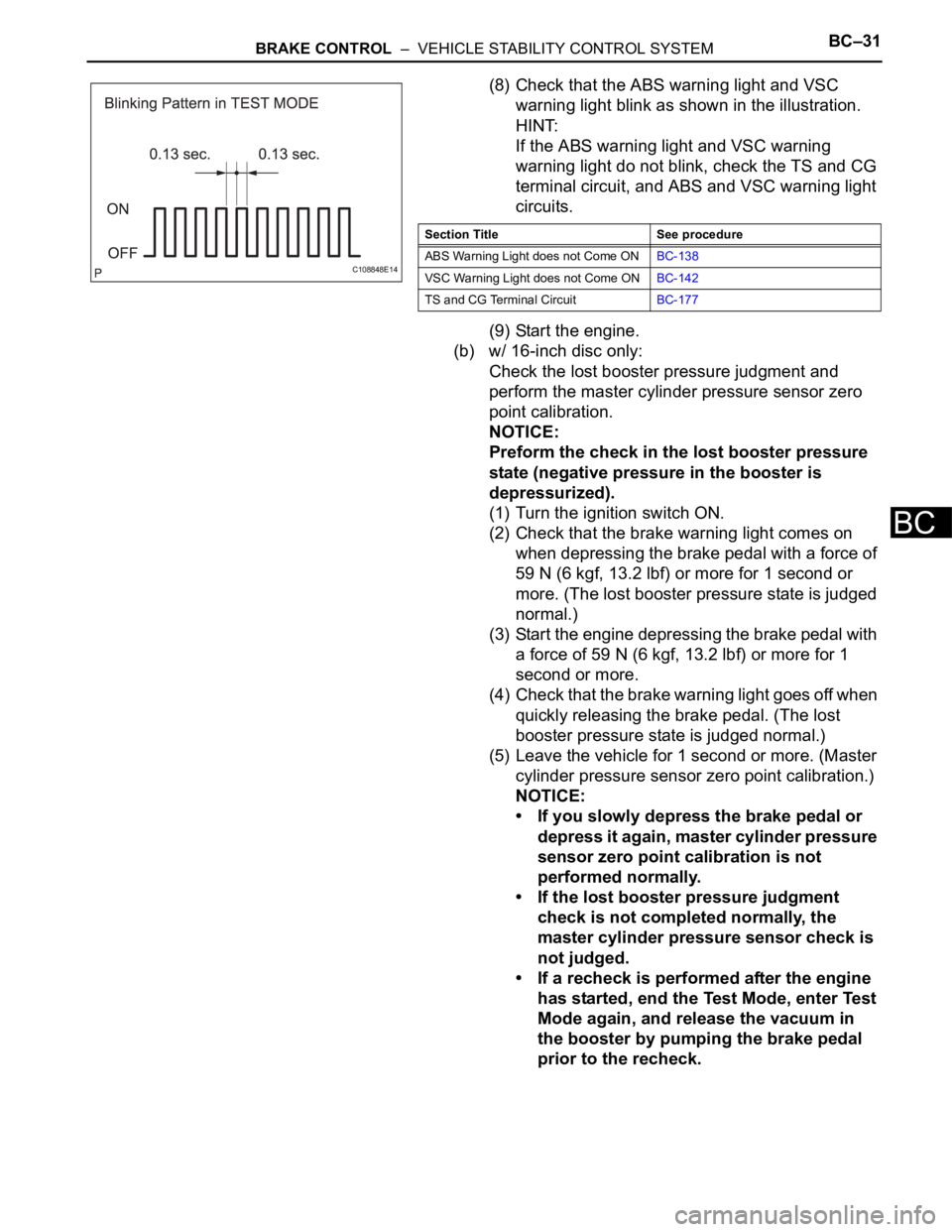

(8) Check that the ABS warning light and VSC

warning light blink as shown in the illustration.

HINT:

If the ABS warning light and VSC warning

warning light do not blink, check the TS and CG

terminal circuit, and ABS and VSC warning light

circuits.

(9) Start the engine.

(b) w/ 16-inch disc only:

Check the lost booster pressure judgment and

perform the master cylinder pressure sensor zero

point calibration.

NOTICE:

Preform the check in the lost booster pressure

state (negative pressure in the booster is

depressurized).

(1) Turn the ignition switch ON.

(2) Check that the brake warning light comes on

when depressing the brake pedal with a force of

59 N (6 kgf, 13.2 lbf) or more for 1 second or

more. (The lost booster pressure state is judged

normal.)

(3) Start the engine depressing the brake pedal with

a force of 59 N (6 kgf, 13.2 lbf) or more for 1

second or more.

(4) Check that the brake warning light goes off when

quickly releasing the brake pedal. (The lost

booster pressure state is judged normal.)

(5) Leave the vehicle for 1 second or more. (Master

cylinder pressure sensor zero point calibration.)

NOTICE:

• If you slowly depress the brake pedal or

depress it again, master cylinder pressure

sensor zero point calibration is not

performed normally.

• If the lost booster pressure judgment

check is not completed normally, the

master cylinder pressure sensor check is

not judged.

• If a recheck is performed after the engine

has started, end the Test Mode, enter Test

Mode again, and release the vacuum in

the booster by pumping the brake pedal

prior to the recheck.

C108848E14

Section Title See procedure

ABS Warning Light does not Come ONBC-138

VSC Warning Light does not Come ONBC-142

TS and CG Terminal CircuitBC-177