clock TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 921 of 2000

CH–102AZ-FE CHARGING – GENERATOR

CH

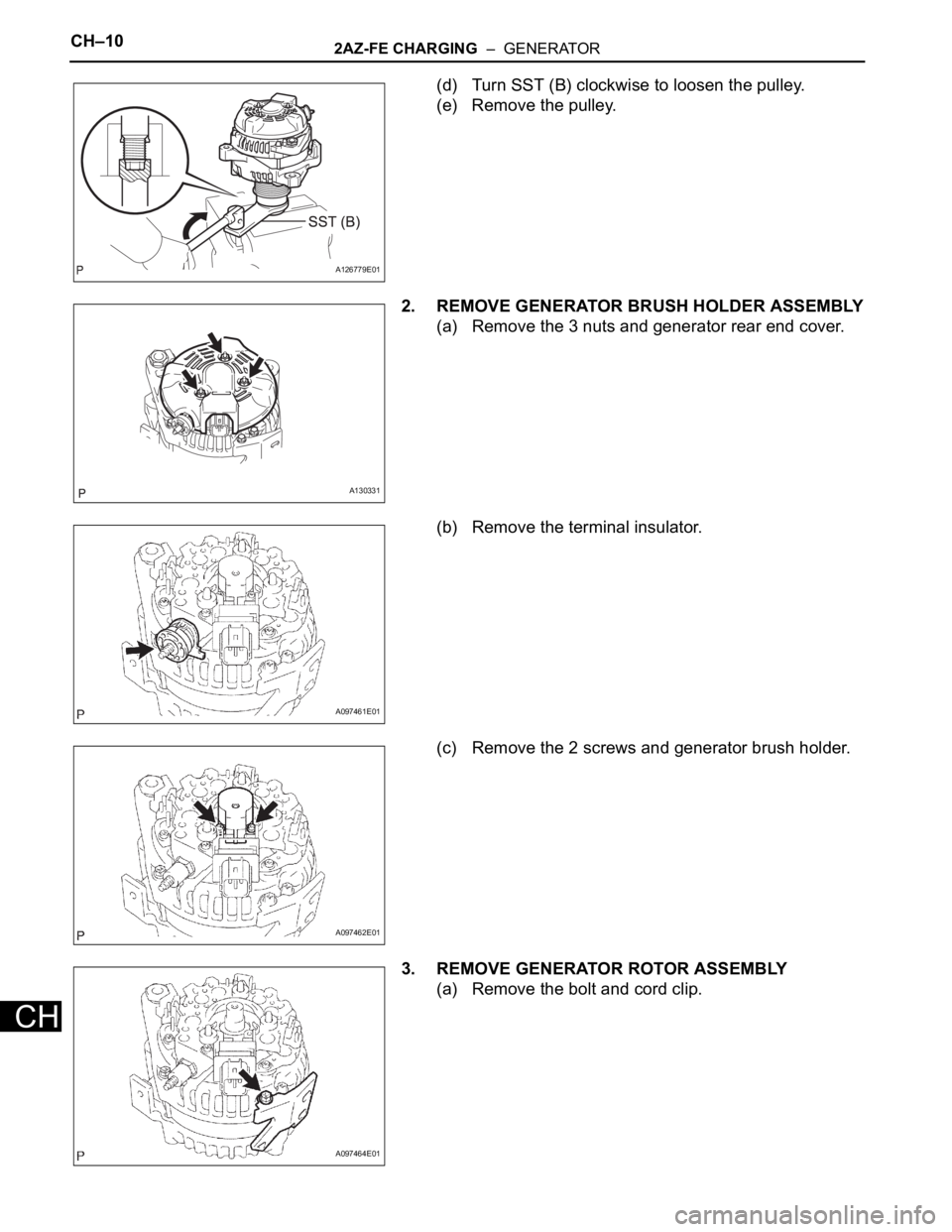

(d) Turn SST (B) clockwise to loosen the pulley.

(e) Remove the pulley.

2. REMOVE GENERATOR BRUSH HOLDER ASSEMBLY

(a) Remove the 3 nuts and generator rear end cover.

(b) Remove the terminal insulator.

(c) Remove the 2 screws and generator brush holder.

3. REMOVE GENERATOR ROTOR ASSEMBLY

(a) Remove the bolt and cord clip.

A126779E01

A130331

A097461E01

A097462E01

A097464E01

Page 923 of 2000

CH–122AZ-FE CHARGING – GENERATOR

CH

(b) Check the slip ring diameter.

(1) Using a vernier caliper, measure the slip ring

diameter.

Standard diameter:

14.2 to 14.4 mm (0.559 to 0.567 in.)

Minimum diameter:

14 mm (0.551 in.)

If the diameter is less than the minimum,

replace the generator rotor assembly.

(c) Check the appearance.

(1) Check that the bearing is not rough or worn.

OK:

The bearing rotates smoothly.

If the result is not as specified, replace the

generator rotor assembly.

3. INSPECT GENERATOR DRIVE END FRAME

BEARING

(a) Check that the bearing is not rough or worn.

OK:

The bearing rotates smoothly.

If the bearing does not rotate smoothly, replace the

bearing.

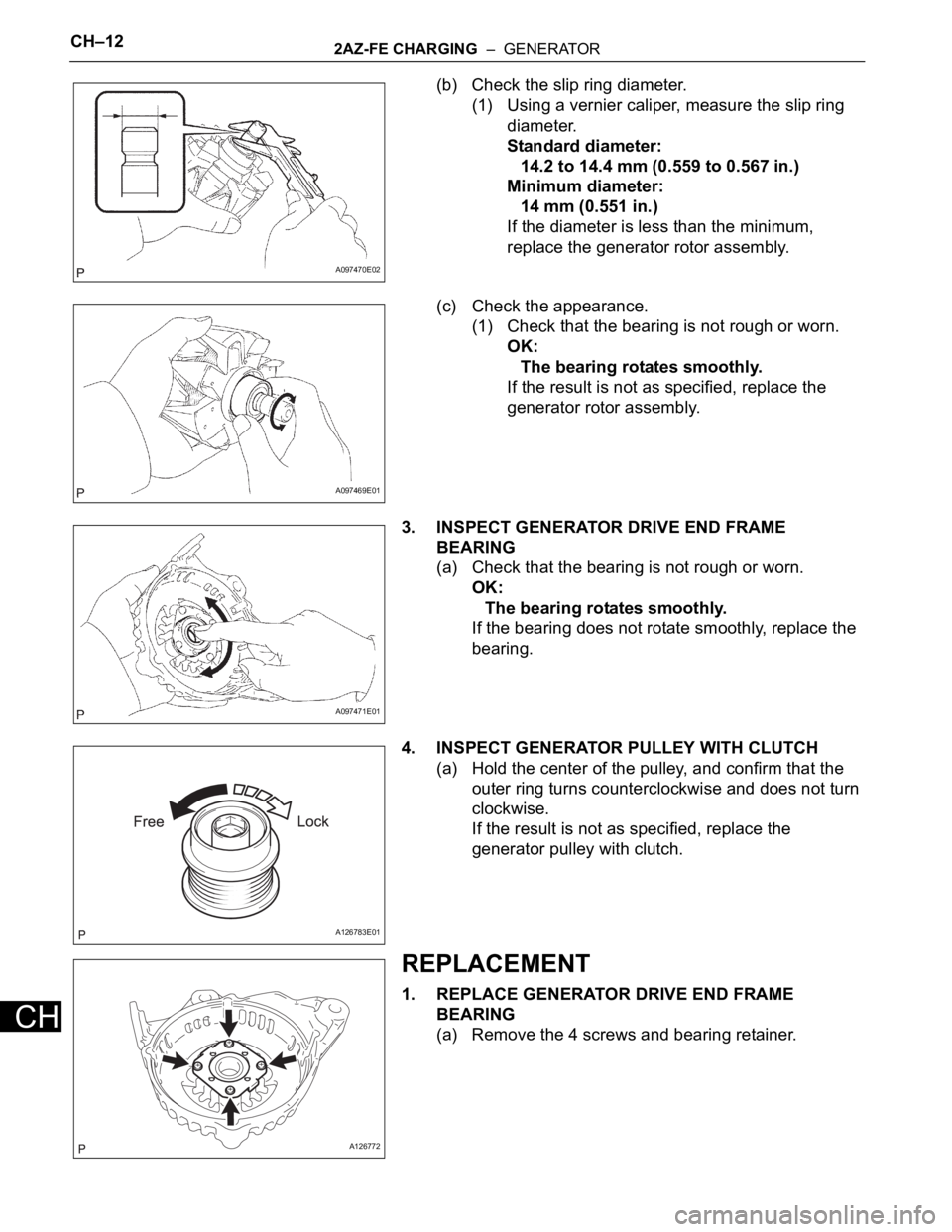

4. INSPECT GENERATOR PULLEY WITH CLUTCH

(a) Hold the center of the pulley, and confirm that the

outer ring turns counterclockwise and does not turn

clockwise.

If the result is not as specified, replace the

generator pulley with clutch.

REPLACEMENT

1. REPLACE GENERATOR DRIVE END FRAME

BEARING

(a) Remove the 4 screws and bearing retainer.

A097470E02

A097469E01

A097471E01

A126783E01

A126772

Page 926 of 2000

2AZ-FE CHARGING – GENERATORCH–15

CH

(d) Install the terminal insulator onto the generator

rectifier end frame.

(e) Install the generator rear end cover with the 3 nuts.

Torque: 4.6 N*m (47 kgf*cm, 41 in.*lbf)

3. INSTALL GENERATOR PULLEY WITH CLUTCH

(a) Install the pulley by hand.

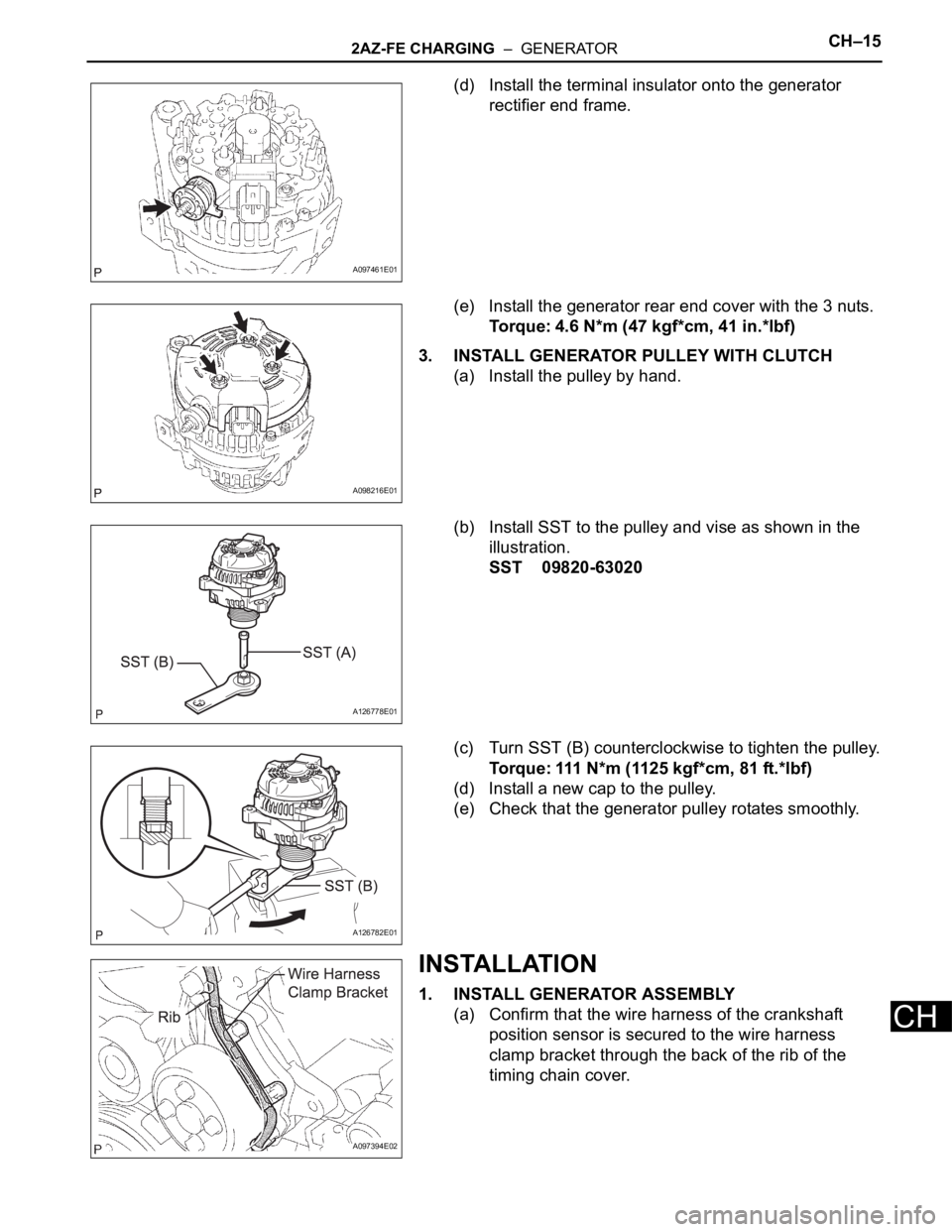

(b) Install SST to the pulley and vise as shown in the

illustration.

SST 09820-63020

(c) Turn SST (B) counterclockwise to tighten the pulley.

Torque: 111 N*m (1125 kgf*cm, 81 ft.*lbf)

(d) Install a new cap to the pulley.

(e) Check that the generator pulley rotates smoothly.

INSTALLATION

1. INSTALL GENERATOR ASSEMBLY

(a) Confirm that the wire harness of the crankshaft

position sensor is secured to the wire harness

clamp bracket through the back of the rib of the

timing chain cover.

A097461E01

A098216E01

A126778E01

A126782E01

A097394E02

Page 932 of 2000

2GR-FE CHARGING – GENERATORCH–13

CH

(f) Remove the 2 bolts and generator.

DISASSEMBLY

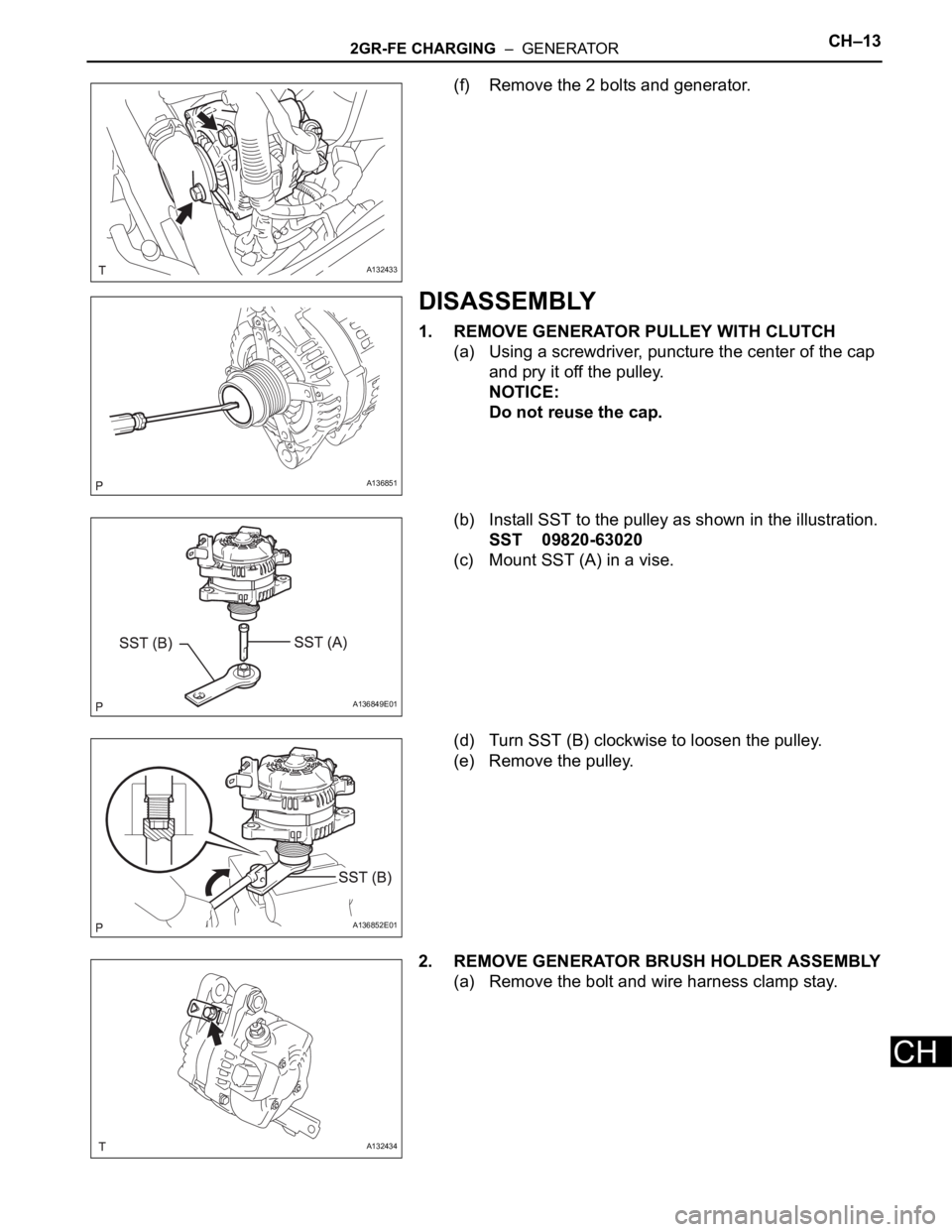

1. REMOVE GENERATOR PULLEY WITH CLUTCH

(a) Using a screwdriver, puncture the center of the cap

and pry it off the pulley.

NOTICE:

Do not reuse the cap.

(b) Install SST to the pulley as shown in the illustration.

SST 09820-63020

(c) Mount SST (A) in a vise.

(d) Turn SST (B) clockwise to loosen the pulley.

(e) Remove the pulley.

2. REMOVE GENERATOR BRUSH HOLDER ASSEMBLY

(a) Remove the bolt and wire harness clamp stay.

A132433

A136851

A136849E01

A136852E01

A132434

Page 935 of 2000

CH–162GR-FE CHARGING – GENERATOR

CH

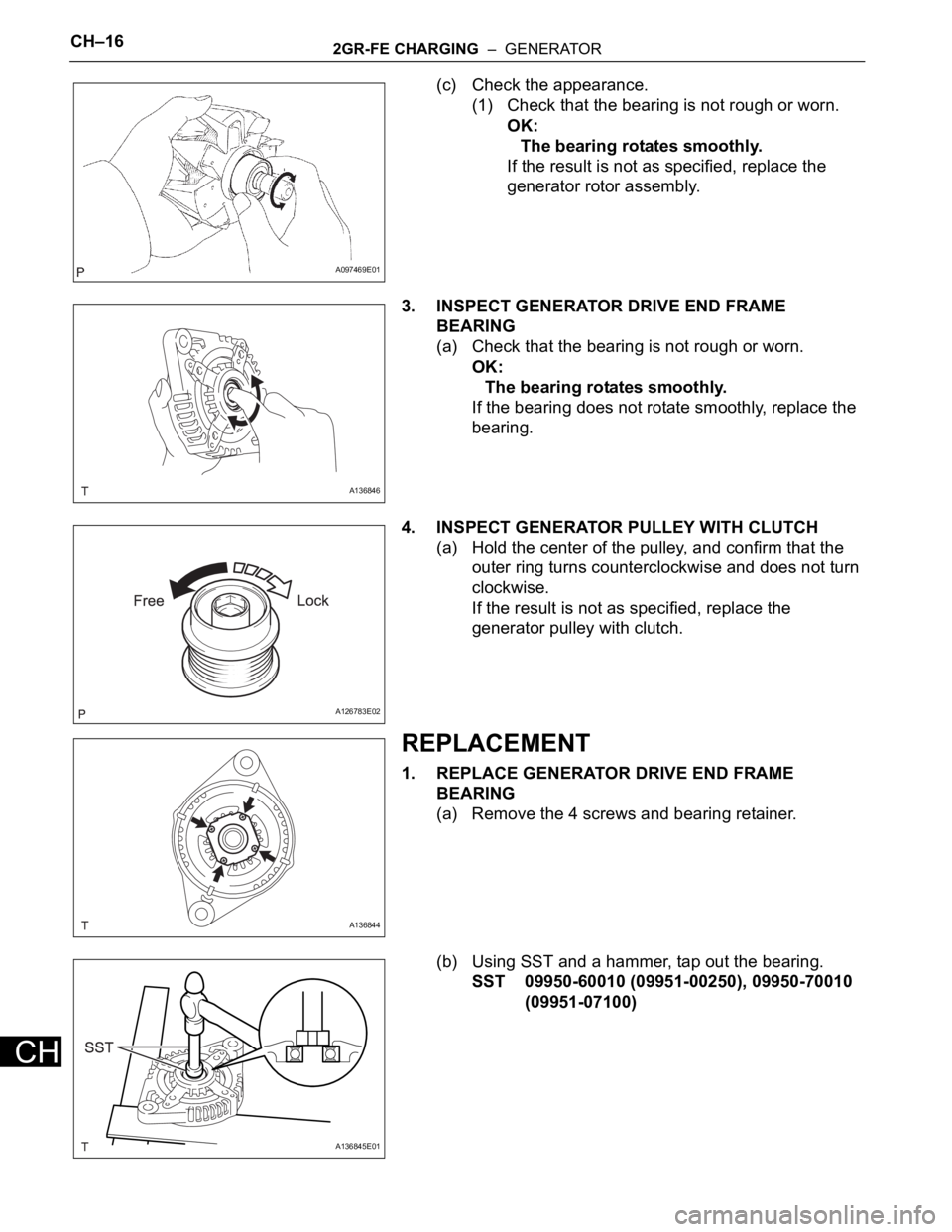

(c) Check the appearance.

(1) Check that the bearing is not rough or worn.

OK:

The bearing rotates smoothly.

If the result is not as specified, replace the

generator rotor assembly.

3. INSPECT GENERATOR DRIVE END FRAME

BEARING

(a) Check that the bearing is not rough or worn.

OK:

The bearing rotates smoothly.

If the bearing does not rotate smoothly, replace the

bearing.

4. INSPECT GENERATOR PULLEY WITH CLUTCH

(a) Hold the center of the pulley, and confirm that the

outer ring turns counterclockwise and does not turn

clockwise.

If the result is not as specified, replace the

generator pulley with clutch.

REPLACEMENT

1. REPLACE GENERATOR DRIVE END FRAME

BEARING

(a) Remove the 4 screws and bearing retainer.

(b) Using SST and a hammer, tap out the bearing.

SST 09950-60010 (09951-00250), 09950-70010

(09951-07100)

A097469E01

A136846

A126783E02

A136844

A136845E01

Page 938 of 2000

2GR-FE CHARGING – GENERATORCH–19

CH

(f) Install the bracket with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(g) Install the wire harness clamp stay.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

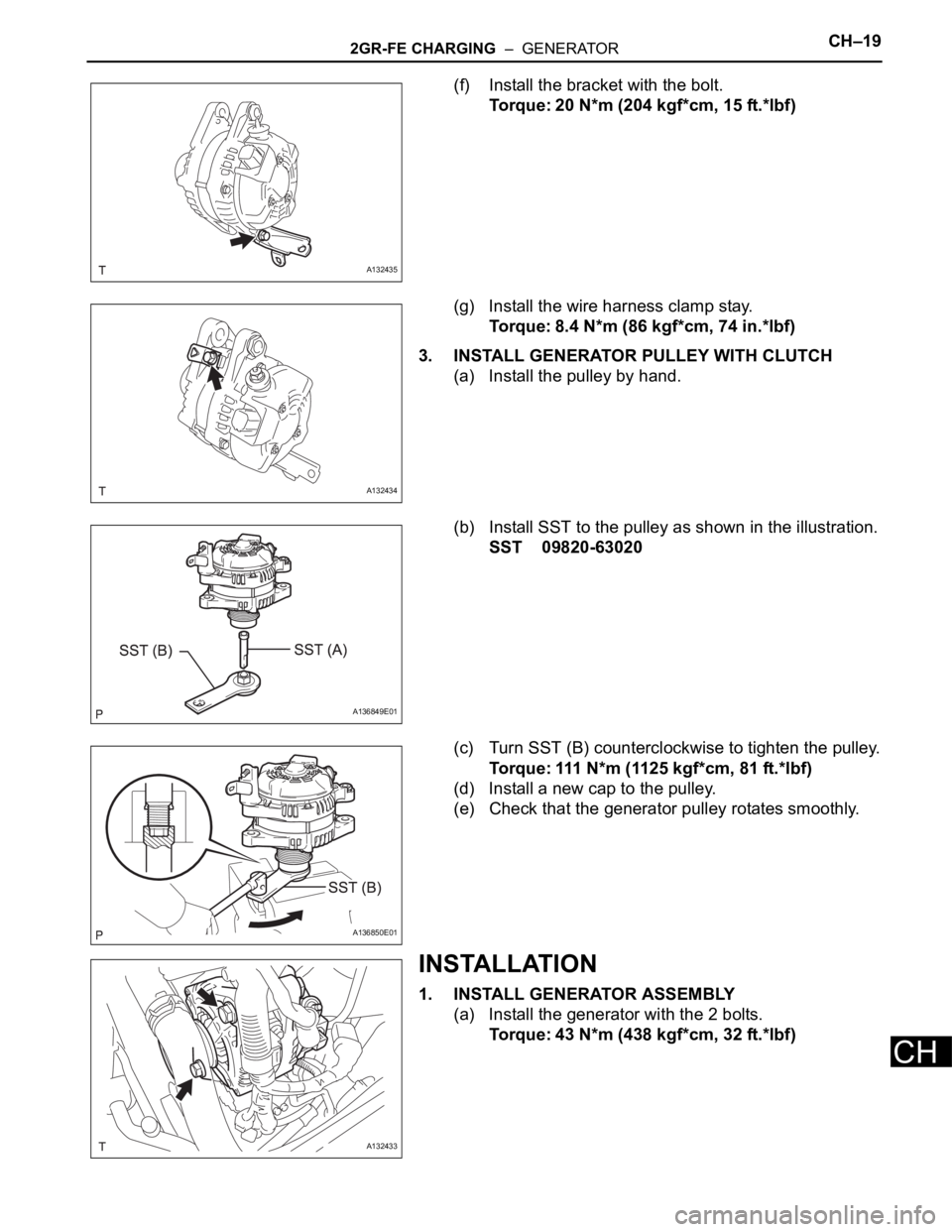

3. INSTALL GENERATOR PULLEY WITH CLUTCH

(a) Install the pulley by hand.

(b) Install SST to the pulley as shown in the illustration.

SST 09820-63020

(c) Turn SST (B) counterclockwise to tighten the pulley.

Torque: 111 N*m (1125 kgf*cm, 81 ft.*lbf)

(d) Install a new cap to the pulley.

(e) Check that the generator pulley rotates smoothly.

INSTALLATION

1. INSTALL GENERATOR ASSEMBLY

(a) Install the generator with the 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

A132435

A132434

A136849E01

A136850E01

A132433

Page 1008 of 2000

AX–214U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

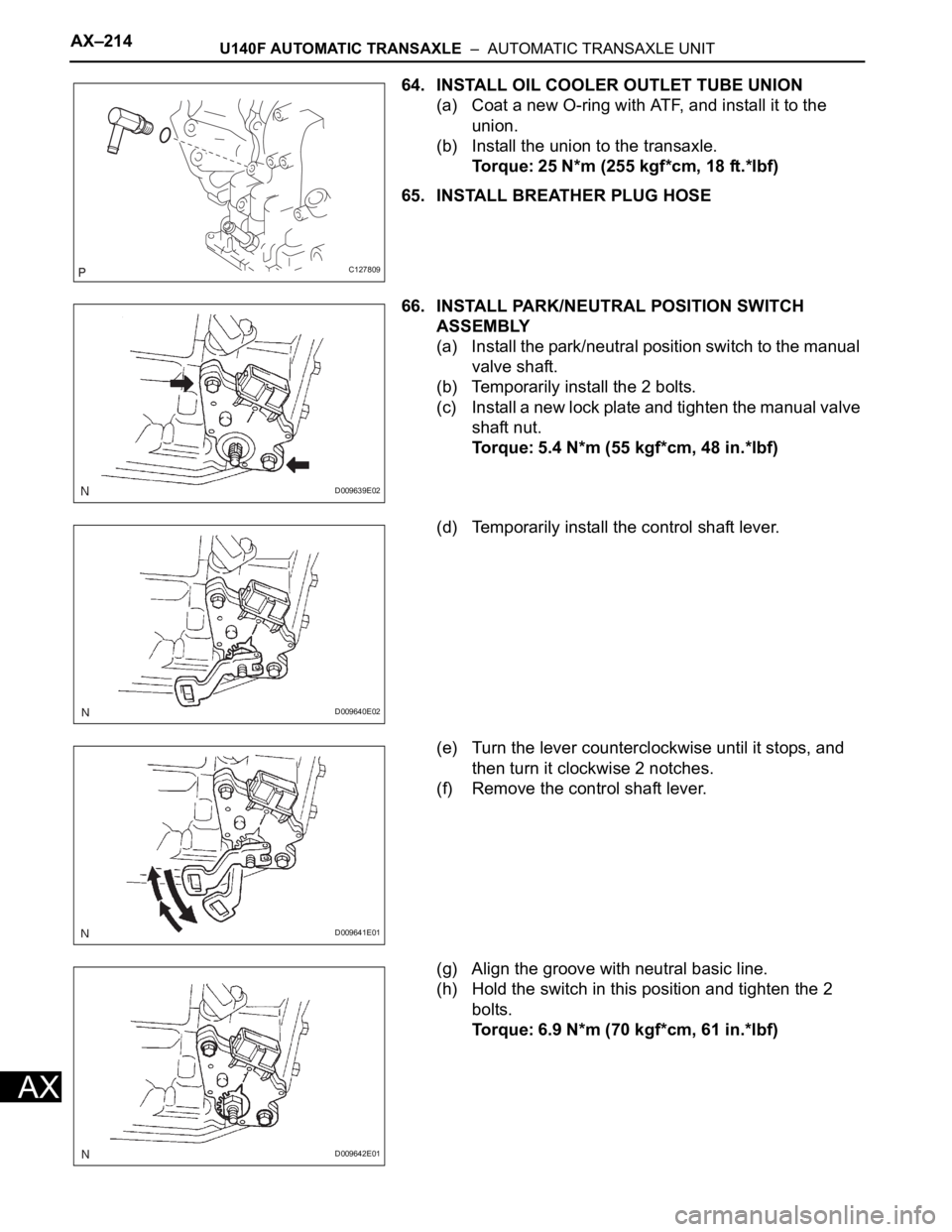

64. INSTALL OIL COOLER OUTLET TUBE UNION

(a) Coat a new O-ring with ATF, and install it to the

union.

(b) Install the union to the transaxle.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

65. INSTALL BREATHER PLUG HOSE

66. INSTALL PARK/NEUTRAL POSITION SWITCH

ASSEMBLY

(a) Install the park/neutral position switch to the manual

valve shaft.

(b) Temporarily install the 2 bolts.

(c) Install a new lock plate and tighten the manual valve

shaft nut.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

(d) Temporarily install the control shaft lever.

(e) Turn the lever counterclockwise until it stops, and

then turn it clockwise 2 notches.

(f) Remove the control shaft lever.

(g) Align the groove with neutral basic line.

(h) Hold the switch in this position and tighten the 2

bolts.

Torque: 6.9 N*m (70 kgf*cm, 61 in.*lbf)

C127809

D009639E02

D009640E02

D009641E01

D009642E01

Page 1085 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–211

AX

HINT:

Piston stroke = Dimension A - Flange thickness

Standard flange thickness

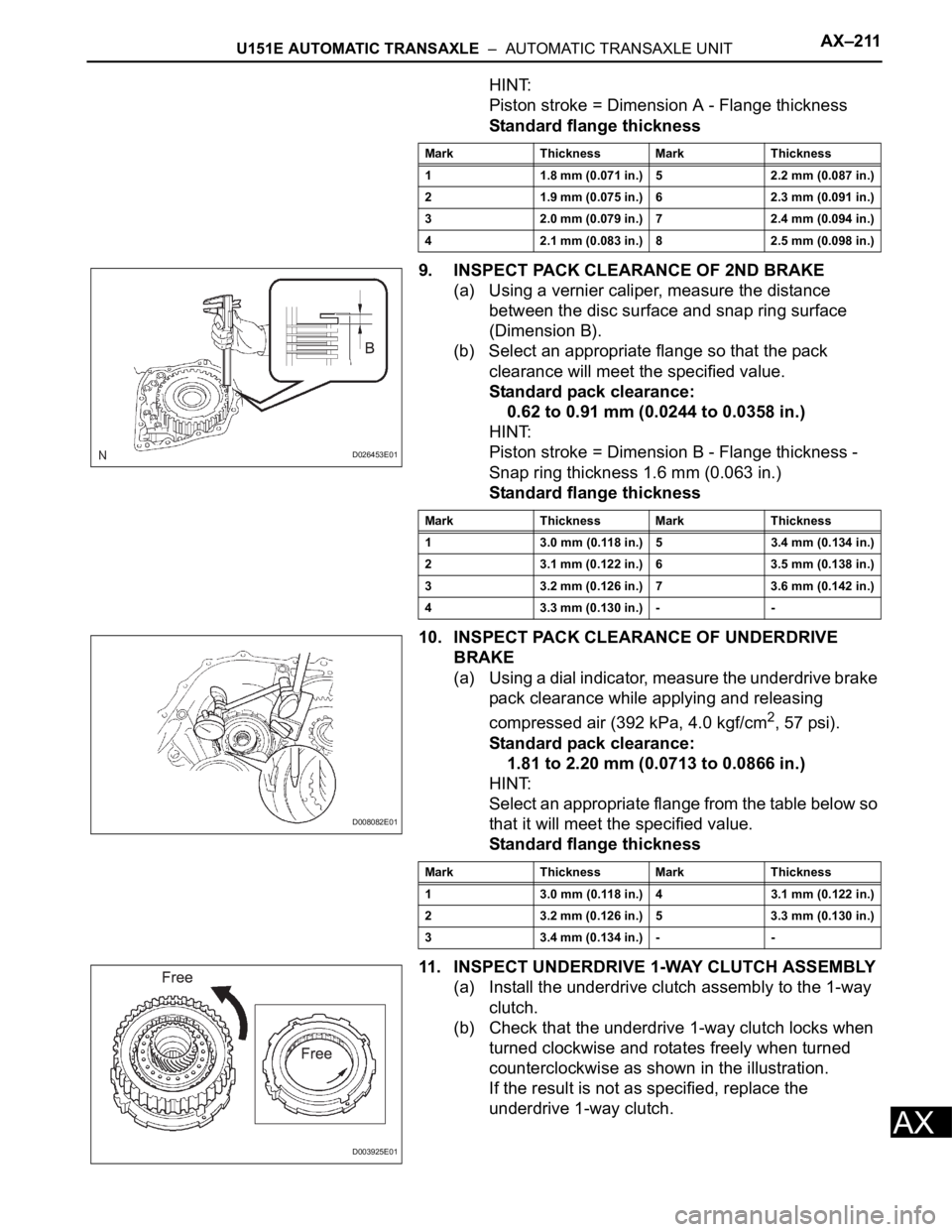

9. INSPECT PACK CLEARANCE OF 2ND BRAKE

(a) Using a vernier caliper, measure the distance

between the disc surface and snap ring surface

(Dimension B).

(b) Select an appropriate flange so that the pack

clearance will meet the specified value.

Standard pack clearance:

0.62 to 0.91 mm (0.0244 to 0.0358 in.)

HINT:

Piston stroke = Dimension B - Flange thickness -

Snap ring thickness 1.6 mm (0.063 in.)

Standard flange thickness

10. INSPECT PACK CLEARANCE OF UNDERDRIVE

BRAKE

(a) Using a dial indicator, measure the underdrive brake

pack clearance while applying and releasing

compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi).

Standard pack clearance:

1.81 to 2.20 mm (0.0713 to 0.0866 in.)

HINT:

Select an appropriate flange from the table below so

that it will meet the specified value.

Standard flange thickness

11. INSPECT UNDERDRIVE 1-WAY CLUTCH ASSEMBLY

(a) Install the underdrive clutch assembly to the 1-way

clutch.

(b) Check that the underdrive 1-way clutch locks when

turned clockwise and rotates freely when turned

counterclockwise as shown in the illustration.

If the result is not as specified, replace the

underdrive 1-way clutch.

Mark Thickness Mark Thickness

1 1.8 mm (0.071 in.) 5 2.2 mm (0.087 in.)

2 1.9 mm (0.075 in.) 6 2.3 mm (0.091 in.)

3 2.0 mm (0.079 in.) 7 2.4 mm (0.094 in.)

4 2.1 mm (0.083 in.) 8 2.5 mm (0.098 in.)

D026453E01

Mark Thickness Mark Thickness

1 3.0 mm (0.118 in.) 5 3.4 mm (0.134 in.)

2 3.1 mm (0.122 in.) 6 3.5 mm (0.138 in.)

3 3.2 mm (0.126 in.) 7 3.6 mm (0.142 in.)

4 3.3 mm (0.130 in.) - -

D008082E01

Mark Thickness Mark Thickness

1 3.0 mm (0.118 in.) 4 3.1 mm (0.122 in.)

2 3.2 mm (0.126 in.) 5 3.3 mm (0.130 in.)

3 3.4 mm (0.134 in.) - -

D003925E01

Page 1097 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–223

AX

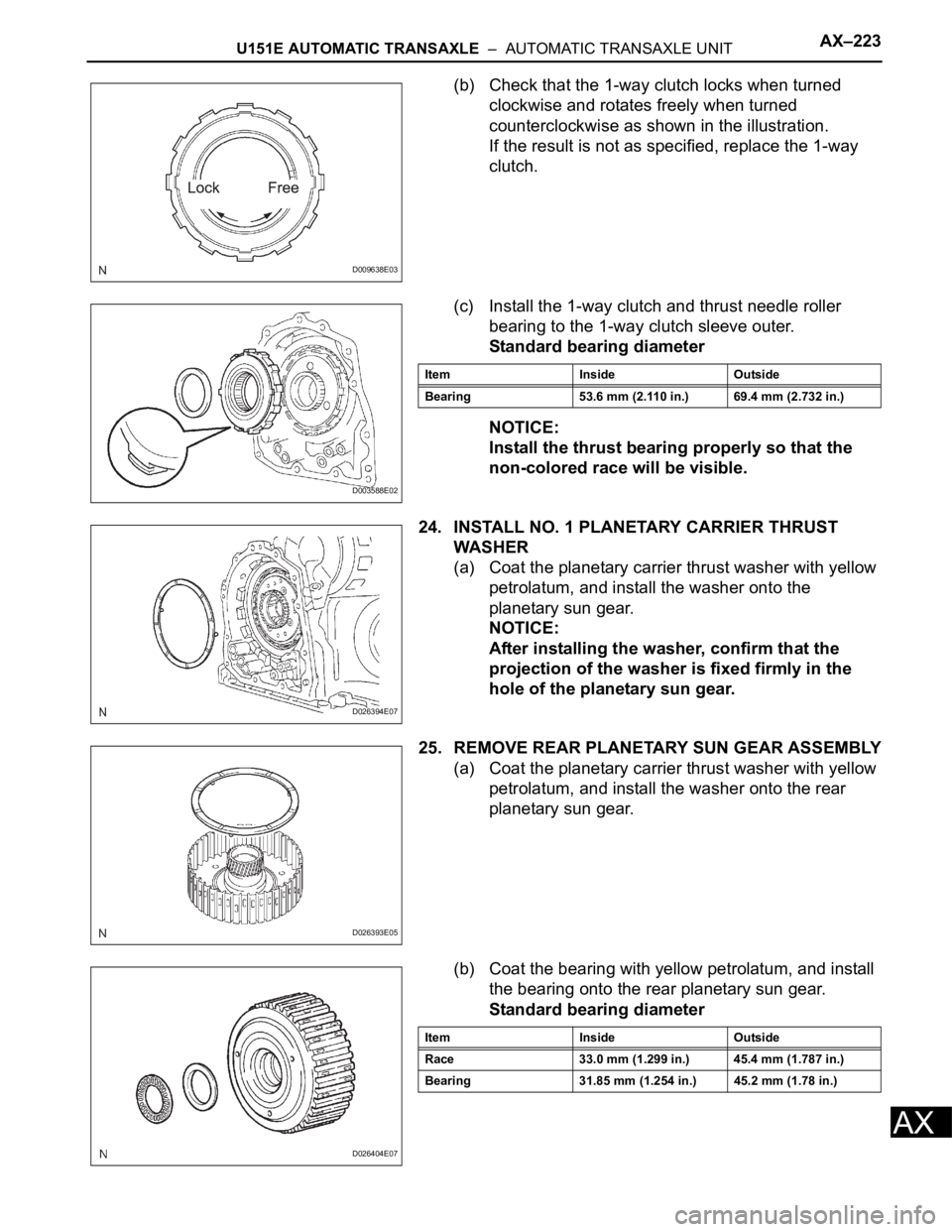

(b) Check that the 1-way clutch locks when turned

clockwise and rotates freely when turned

counterclockwise as shown in the illustration.

If the result is not as specified, replace the 1-way

clutch.

(c) Install the 1-way clutch and thrust needle roller

bearing to the 1-way clutch sleeve outer.

Standard bearing diameter

NOTICE:

Install the thrust bearing properly so that the

non-colored race will be visible.

24. INSTALL NO. 1 PLANETARY CARRIER THRUST

WASHER

(a) Coat the planetary carrier thrust washer with yellow

petrolatum, and install the washer onto the

planetary sun gear.

NOTICE:

After installing the washer, confirm that the

projection of the washer is fixed firmly in the

hole of the planetary sun gear.

25. REMOVE REAR PLANETARY SUN GEAR ASSEMBLY

(a) Coat the planetary carrier thrust washer with yellow

petrolatum, and install the washer onto the rear

planetary sun gear.

(b) Coat the bearing with yellow petrolatum, and install

the bearing onto the rear planetary sun gear.

Standard bearing diameter

D009638E03

D003588E02

Item Inside Outside

Bearing 53.6 mm (2.110 in.) 69.4 mm (2.732 in.)

D026394E07

D026393E05

D026404E07

Item Inside Outside

Race 33.0 mm (1.299 in.) 45.4 mm (1.787 in.)

Bearing 31.85 mm (1.254 in.) 45.2 mm (1.78 in.)

Page 1102 of 2000

AX–228U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

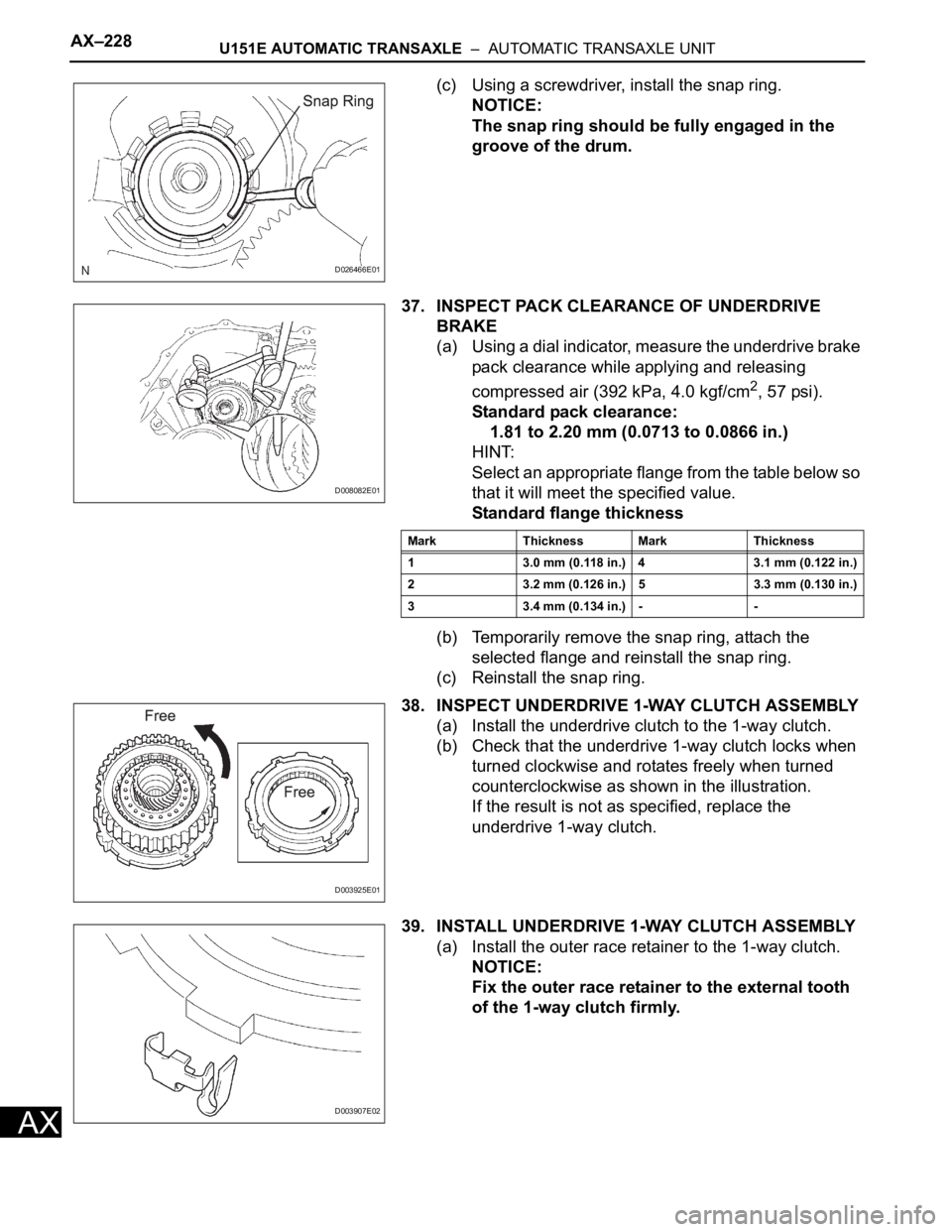

(c) Using a screwdriver, install the snap ring.

NOTICE:

The snap ring should be fully engaged in the

groove of the drum.

37. INSPECT PACK CLEARANCE OF UNDERDRIVE

BRAKE

(a) Using a dial indicator, measure the underdrive brake

pack clearance while applying and releasing

compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi).

Standard pack clearance:

1.81 to 2.20 mm (0.0713 to 0.0866 in.)

HINT:

Select an appropriate flange from the table below so

that it will meet the specified value.

Standard flange thickness

(b) Temporarily remove the snap ring, attach the

selected flange and reinstall the snap ring.

(c) Reinstall the snap ring.

38. INSPECT UNDERDRIVE 1-WAY CLUTCH ASSEMBLY

(a) Install the underdrive clutch to the 1-way clutch.

(b) Check that the underdrive 1-way clutch locks when

turned clockwise and rotates freely when turned

counterclockwise as shown in the illustration.

If the result is not as specified, replace the

underdrive 1-way clutch.

39. INSTALL UNDERDRIVE 1-WAY CLUTCH ASSEMBLY

(a) Install the outer race retainer to the 1-way clutch.

NOTICE:

Fix the outer race retainer to the external tooth

of the 1-way clutch firmly.

D026466E01

D008082E01

Mark Thickness Mark Thickness

1 3.0 mm (0.118 in.) 4 3.1 mm (0.122 in.)

2 3.2 mm (0.126 in.) 5 3.3 mm (0.130 in.)

3 3.4 mm (0.134 in.) - -

D003925E01

D003907E02