clock TOYOTA RAV4 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1116 of 2000

AX–242U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

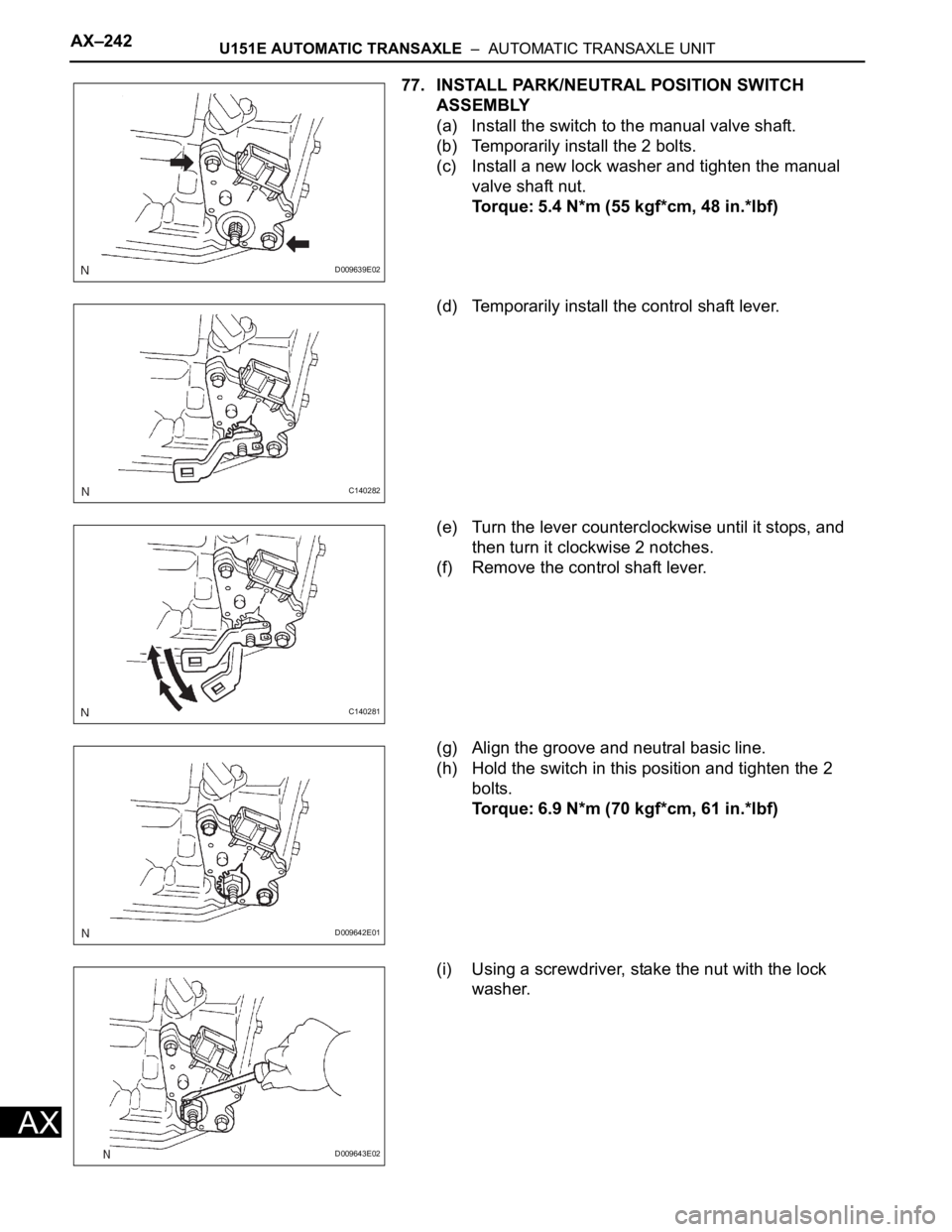

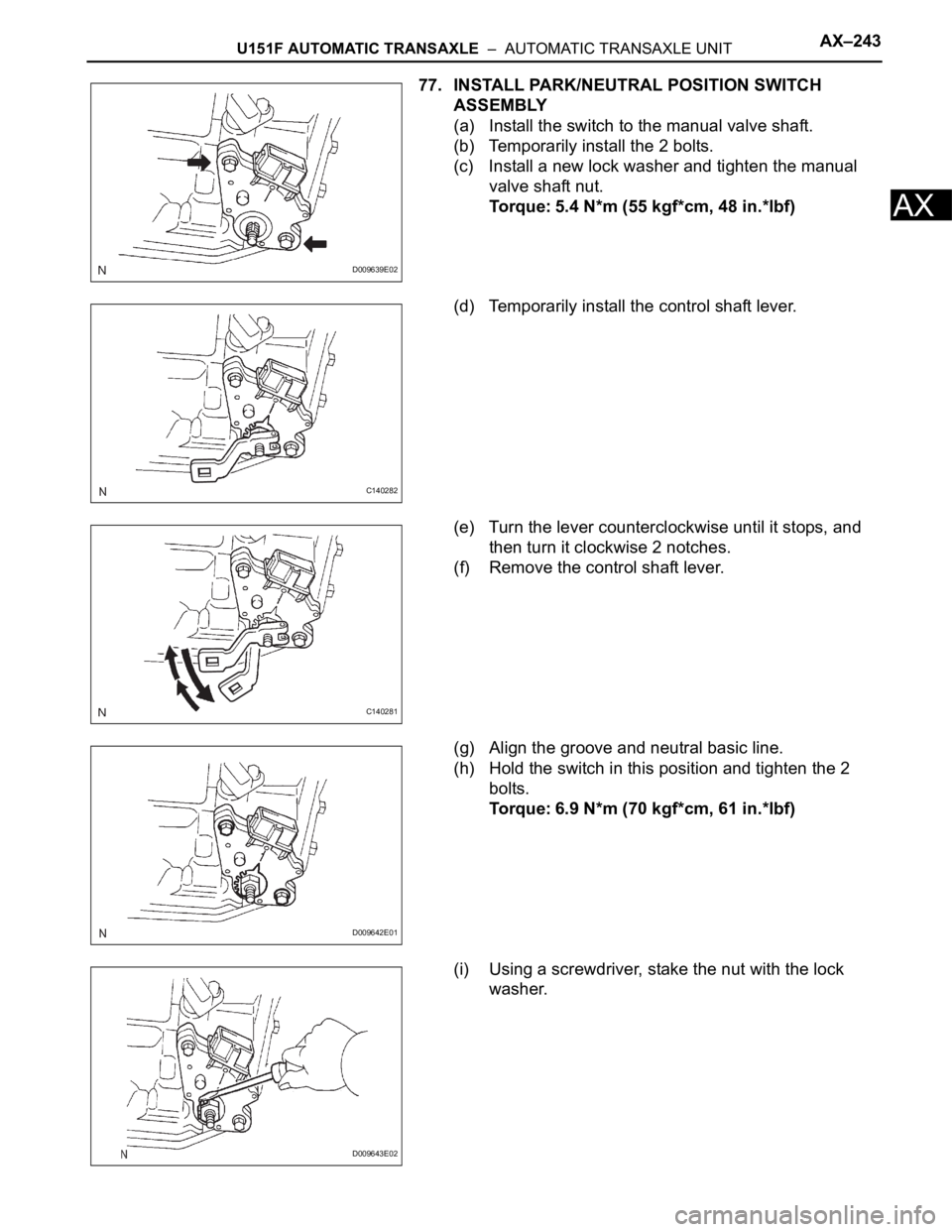

77. INSTALL PARK/NEUTRAL POSITION SWITCH

ASSEMBLY

(a) Install the switch to the manual valve shaft.

(b) Temporarily install the 2 bolts.

(c) Install a new lock washer and tighten the manual

valve shaft nut.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

(d) Temporarily install the control shaft lever.

(e) Turn the lever counterclockwise until it stops, and

then turn it clockwise 2 notches.

(f) Remove the control shaft lever.

(g) Align the groove and neutral basic line.

(h) Hold the switch in this position and tighten the 2

bolts.

Torque: 6.9 N*m (70 kgf*cm, 61 in.*lbf)

(i) Using a screwdriver, stake the nut with the lock

washer.

D009639E02

C140282

C140281

D009642E01

D009643E02

Page 1190 of 2000

AX–212U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

HINT:

Piston stroke = Dimension A - Flange thickness

Standard flange thickness

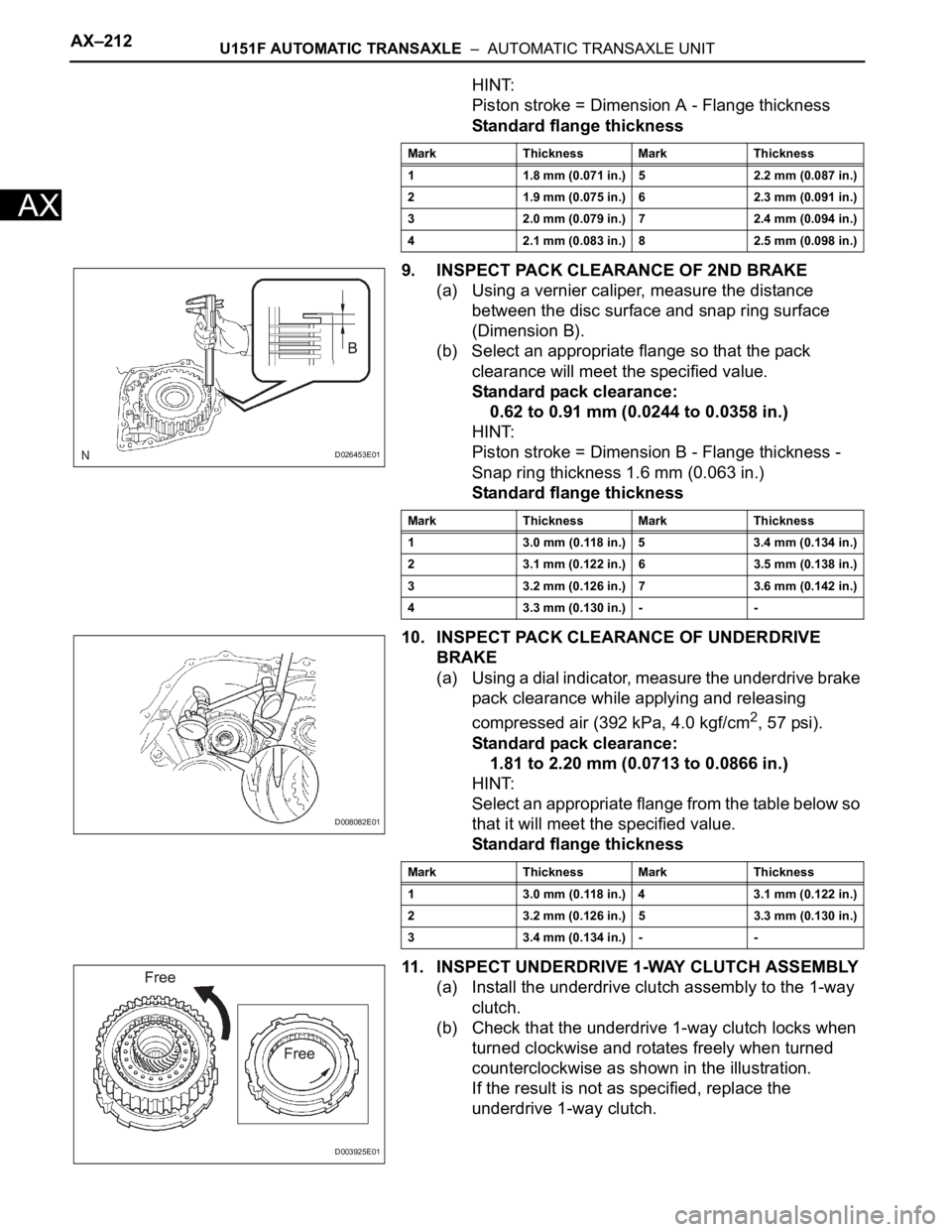

9. INSPECT PACK CLEARANCE OF 2ND BRAKE

(a) Using a vernier caliper, measure the distance

between the disc surface and snap ring surface

(Dimension B).

(b) Select an appropriate flange so that the pack

clearance will meet the specified value.

Standard pack clearance:

0.62 to 0.91 mm (0.0244 to 0.0358 in.)

HINT:

Piston stroke = Dimension B - Flange thickness -

Snap ring thickness 1.6 mm (0.063 in.)

Standard flange thickness

10. INSPECT PACK CLEARANCE OF UNDERDRIVE

BRAKE

(a) Using a dial indicator, measure the underdrive brake

pack clearance while applying and releasing

compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi).

Standard pack clearance:

1.81 to 2.20 mm (0.0713 to 0.0866 in.)

HINT:

Select an appropriate flange from the table below so

that it will meet the specified value.

Standard flange thickness

11. INSPECT UNDERDRIVE 1-WAY CLUTCH ASSEMBLY

(a) Install the underdrive clutch assembly to the 1-way

clutch.

(b) Check that the underdrive 1-way clutch locks when

turned clockwise and rotates freely when turned

counterclockwise as shown in the illustration.

If the result is not as specified, replace the

underdrive 1-way clutch.

Mark Thickness Mark Thickness

1 1.8 mm (0.071 in.) 5 2.2 mm (0.087 in.)

2 1.9 mm (0.075 in.) 6 2.3 mm (0.091 in.)

3 2.0 mm (0.079 in.) 7 2.4 mm (0.094 in.)

4 2.1 mm (0.083 in.) 8 2.5 mm (0.098 in.)

D026453E01

Mark Thickness Mark Thickness

1 3.0 mm (0.118 in.) 5 3.4 mm (0.134 in.)

2 3.1 mm (0.122 in.) 6 3.5 mm (0.138 in.)

3 3.2 mm (0.126 in.) 7 3.6 mm (0.142 in.)

4 3.3 mm (0.130 in.) - -

D008082E01

Mark Thickness Mark Thickness

1 3.0 mm (0.118 in.) 4 3.1 mm (0.122 in.)

2 3.2 mm (0.126 in.) 5 3.3 mm (0.130 in.)

3 3.4 mm (0.134 in.) - -

D003925E01

Page 1202 of 2000

AX–224U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

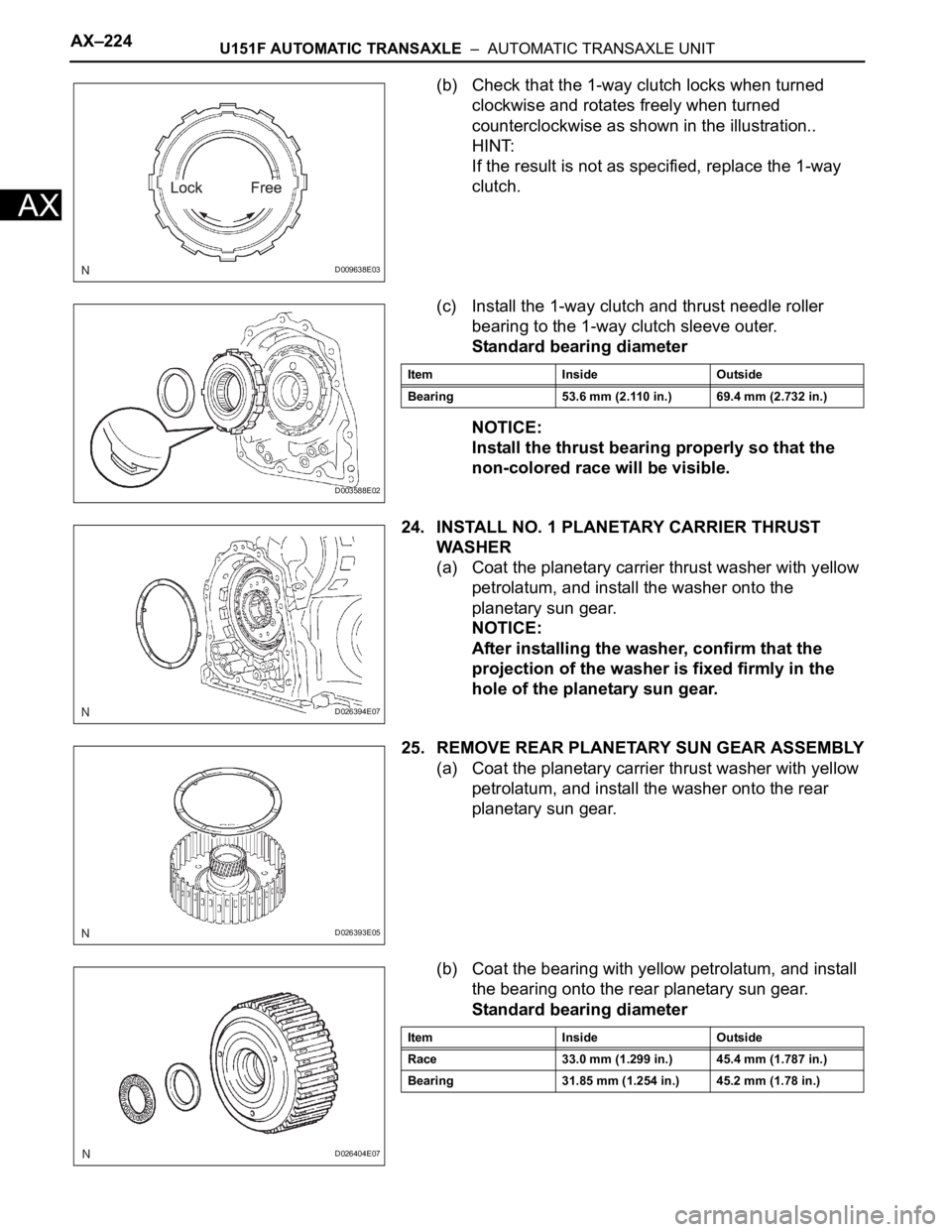

(b) Check that the 1-way clutch locks when turned

clockwise and rotates freely when turned

counterclockwise as shown in the illustration..

HINT:

If the result is not as specified, replace the 1-way

clutch.

(c) Install the 1-way clutch and thrust needle roller

bearing to the 1-way clutch sleeve outer.

Standard bearing diameter

NOTICE:

Install the thrust bearing properly so that the

non-colored race will be visible.

24. INSTALL NO. 1 PLANETARY CARRIER THRUST

WA S HE R

(a) Coat the planetary carrier thrust washer with yellow

petrolatum, and install the washer onto the

planetary sun gear.

NOTICE:

After installing the washer, confirm that the

projection of the washer is fixed firmly in the

hole of the planetary sun gear.

25. REMOVE REAR PLANETARY SUN GEAR ASSEMBLY

(a) Coat the planetary carrier thrust washer with yellow

petrolatum, and install the washer onto the rear

planetary sun gear.

(b) Coat the bearing with yellow petrolatum, and install

the bearing onto the rear planetary sun gear.

Standard bearing diameter

D009638E03

D003588E02

Item Inside Outside

Bearing 53.6 mm (2.110 in.) 69.4 mm (2.732 in.)

D026394E07

D026393E05

D026404E07

Item Inside Outside

Race 33.0 mm (1.299 in.) 45.4 mm (1.787 in.)

Bearing 31.85 mm (1.254 in.) 45.2 mm (1.78 in.)

Page 1207 of 2000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–229

AX

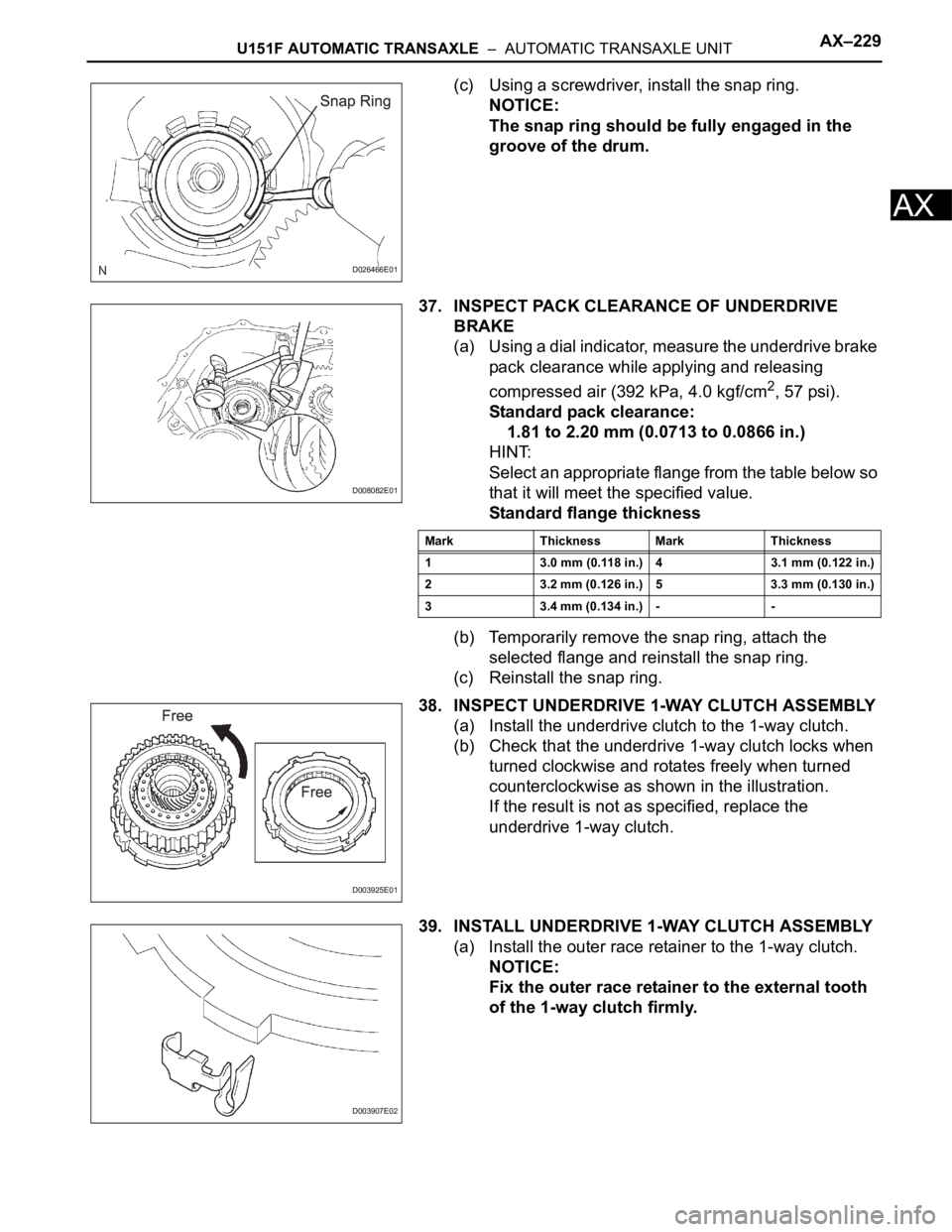

(c) Using a screwdriver, install the snap ring.

NOTICE:

The snap ring should be fully engaged in the

groove of the drum.

37. INSPECT PACK CLEARANCE OF UNDERDRIVE

BRAKE

(a) Using a dial indicator, measure the underdrive brake

pack clearance while applying and releasing

compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi).

Standard pack clearance:

1.81 to 2.20 mm (0.0713 to 0.0866 in.)

HINT:

Select an appropriate flange from the table below so

that it will meet the specified value.

Standard flange thickness

(b) Temporarily remove the snap ring, attach the

selected flange and reinstall the snap ring.

(c) Reinstall the snap ring.

38. INSPECT UNDERDRIVE 1-WAY CLUTCH ASSEMBLY

(a) Install the underdrive clutch to the 1-way clutch.

(b) Check that the underdrive 1-way clutch locks when

turned clockwise and rotates freely when turned

counterclockwise as shown in the illustration.

If the result is not as specified, replace the

underdrive 1-way clutch.

39. INSTALL UNDERDRIVE 1-WAY CLUTCH ASSEMBLY

(a) Install the outer race retainer to the 1-way clutch.

NOTICE:

Fix the outer race retainer to the external tooth

of the 1-way clutch firmly.

D026466E01

D008082E01

Mark Thickness Mark Thickness

1 3.0 mm (0.118 in.) 4 3.1 mm (0.122 in.)

2 3.2 mm (0.126 in.) 5 3.3 mm (0.130 in.)

3 3.4 mm (0.134 in.) - -

D003925E01

D003907E02

Page 1221 of 2000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–243

AX

77. INSTALL PARK/NEUTRAL POSITION SWITCH

ASSEMBLY

(a) Install the switch to the manual valve shaft.

(b) Temporarily install the 2 bolts.

(c) Install a new lock washer and tighten the manual

valve shaft nut.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

(d) Temporarily install the control shaft lever.

(e) Turn the lever counterclockwise until it stops, and

then turn it clockwise 2 notches.

(f) Remove the control shaft lever.

(g) Align the groove and neutral basic line.

(h) Hold the switch in this position and tighten the 2

bolts.

Torque: 6.9 N*m (70 kgf*cm, 61 in.*lbf)

(i) Using a screwdriver, stake the nut with the lock

washer.

D009639E02

C140282

C140281

D009642E01

D009643E02

Page 1320 of 2000

AX–216U241E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

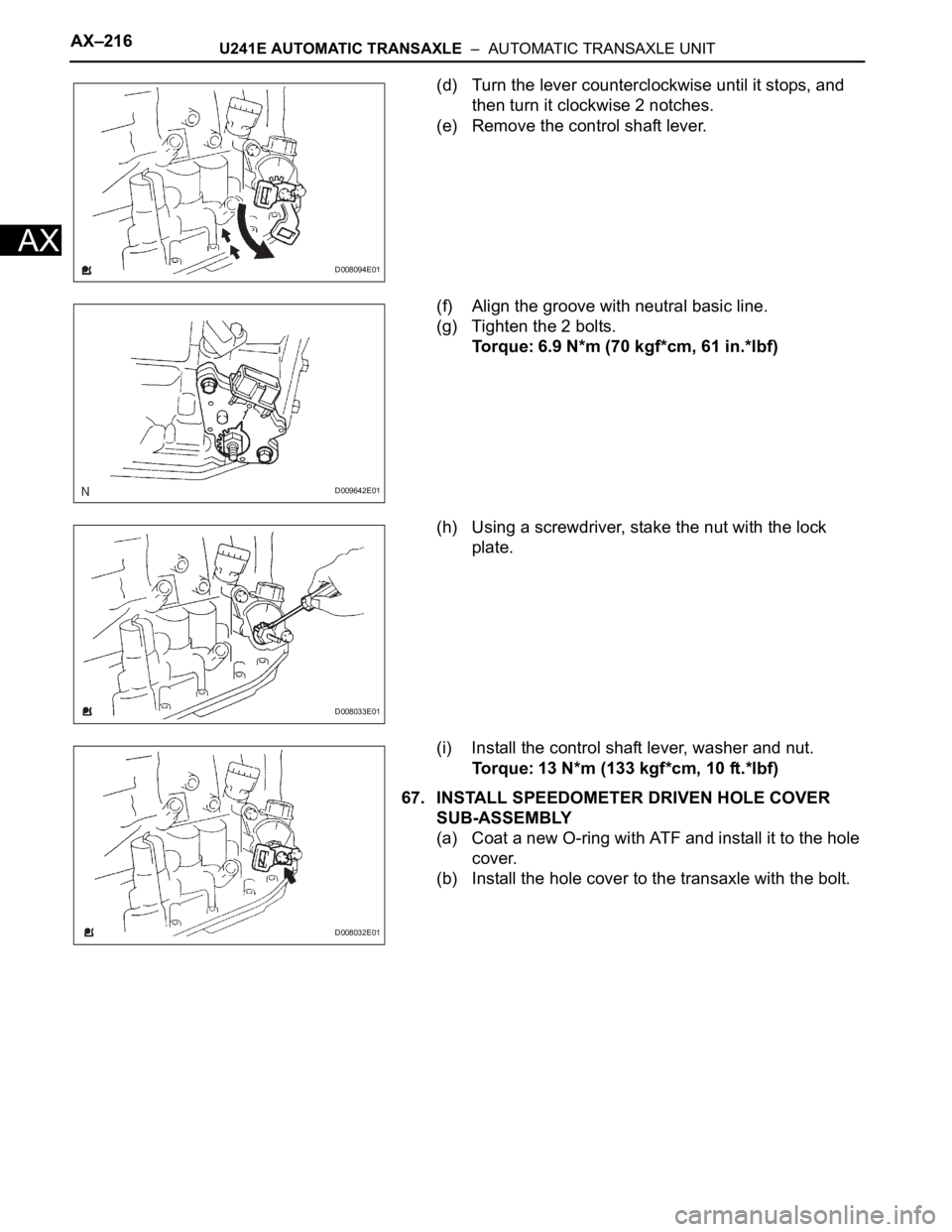

(d) Turn the lever counterclockwise until it stops, and

then turn it clockwise 2 notches.

(e) Remove the control shaft lever.

(f) Align the groove with neutral basic line.

(g) Tighten the 2 bolts.

Torque: 6.9 N*m (70 kgf*cm, 61 in.*lbf)

(h) Using a screwdriver, stake the nut with the lock

plate.

(i) Install the control shaft lever, washer and nut.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

67. INSTALL SPEEDOMETER DRIVEN HOLE COVER

SUB-ASSEMBLY

(a) Coat a new O-ring with ATF and install it to the hole

cover.

(b) Install the hole cover to the transaxle with the bolt.

D008094E01

D009642E01

D008033E01

D008032E01

Page 1567 of 2000

BR–12BRAKE – BRAKE PEDAL

BR

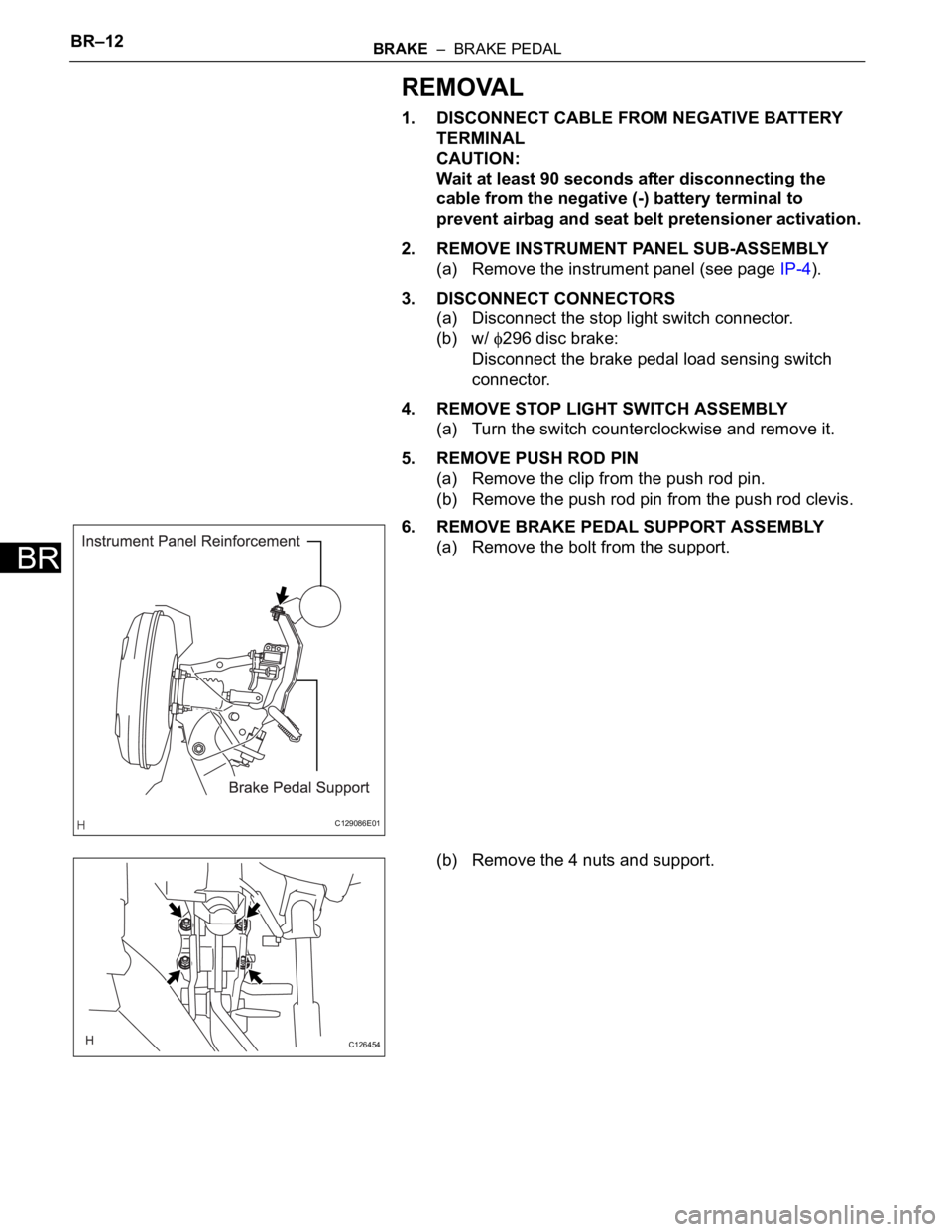

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE INSTRUMENT PANEL SUB-ASSEMBLY

(a) Remove the instrument panel (see page IP-4).

3. DISCONNECT CONNECTORS

(a) Disconnect the stop light switch connector.

(b) w/

296 disc brake:

Disconnect the brake pedal load sensing switch

connector.

4. REMOVE STOP LIGHT SWITCH ASSEMBLY

(a) Turn the switch counterclockwise and remove it.

5. REMOVE PUSH ROD PIN

(a) Remove the clip from the push rod pin.

(b) Remove the push rod pin from the push rod clevis.

6. REMOVE BRAKE PEDAL SUPPORT ASSEMBLY

(a) Remove the bolt from the support.

(b) Remove the 4 nuts and support.

C129086E01

C126454

Page 1569 of 2000

BR–14BRAKE – BRAKE PEDAL

BR

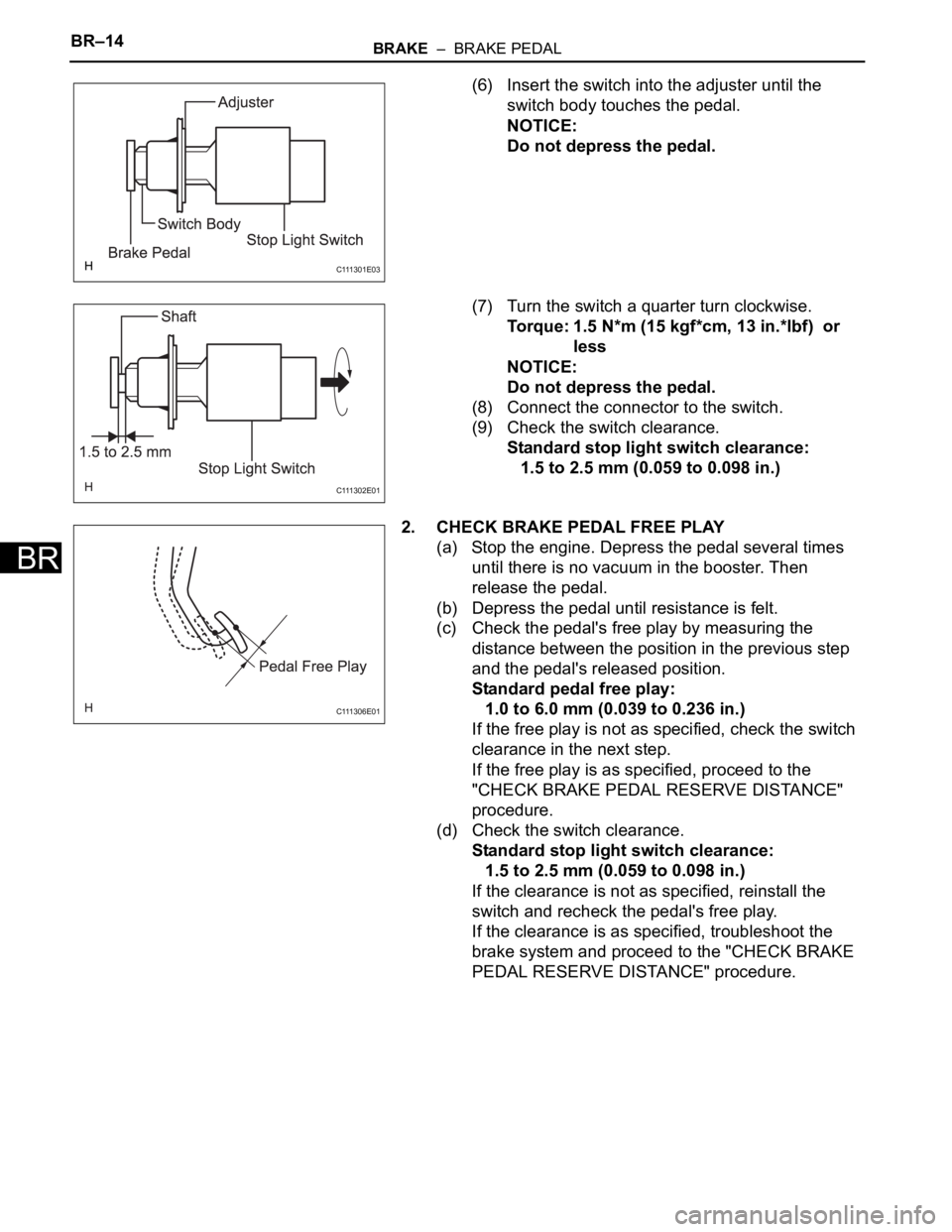

(6) Insert the switch into the adjuster until the

switch body touches the pedal.

NOTICE:

Do not depress the pedal.

(7) Turn the switch a quarter turn clockwise.

Torque: 1.5 N*m (15 kgf*cm, 13 in.*lbf) or

less

NOTICE:

Do not depress the pedal.

(8) Connect the connector to the switch.

(9) Check the switch clearance.

Standard stop light switch clearance:

1.5 to 2.5 mm (0.059 to 0.098 in.)

2. CHECK BRAKE PEDAL FREE PLAY

(a) Stop the engine. Depress the pedal several times

until there is no vacuum in the booster. Then

release the pedal.

(b) Depress the pedal until resistance is felt.

(c) Check the pedal's free play by measuring the

distance between the position in the previous step

and the pedal's released position.

Standard pedal free play:

1.0 to 6.0 mm (0.039 to 0.236 in.)

If the free play is not as specified, check the switch

clearance in the next step.

If the free play is as specified, proceed to the

"CHECK BRAKE PEDAL RESERVE DISTANCE"

procedure.

(d) Check the switch clearance.

Standard stop light switch clearance:

1.5 to 2.5 mm (0.059 to 0.098 in.)

If the clearance is not as specified, reinstall the

switch and recheck the pedal's free play.

If the clearance is as specified, troubleshoot the

brake system and proceed to the "CHECK BRAKE

PEDAL RESERVE DISTANCE" procedure.

C 111 3 0 1 E 0 3

C 111 3 0 2 E 0 1

C 111 3 0 6 E 0 1

Page 1571 of 2000

BR–16BRAKE – BRAKE PEDAL

BR

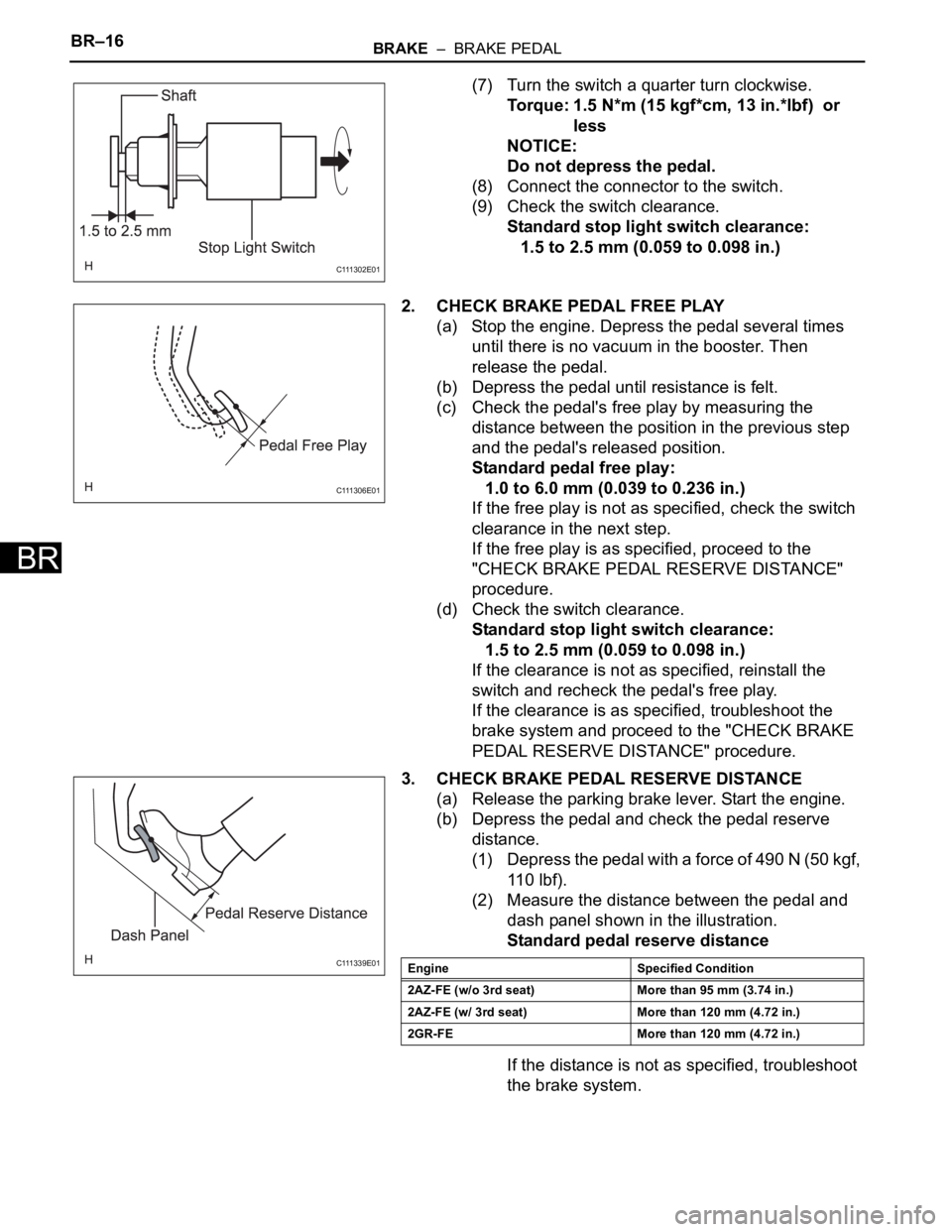

(7) Turn the switch a quarter turn clockwise.

Torque: 1.5 N*m (15 kgf*cm, 13 in.*lbf) or

less

NOTICE:

Do not depress the pedal.

(8) Connect the connector to the switch.

(9) Check the switch clearance.

Standard stop light switch clearance:

1.5 to 2.5 mm (0.059 to 0.098 in.)

2. CHECK BRAKE PEDAL FREE PLAY

(a) Stop the engine. Depress the pedal several times

until there is no vacuum in the booster. Then

release the pedal.

(b) Depress the pedal until resistance is felt.

(c) Check the pedal's free play by measuring the

distance between the position in the previous step

and the pedal's released position.

Standard pedal free play:

1.0 to 6.0 mm (0.039 to 0.236 in.)

If the free play is not as specified, check the switch

clearance in the next step.

If the free play is as specified, proceed to the

"CHECK BRAKE PEDAL RESERVE DISTANCE"

procedure.

(d) Check the switch clearance.

Standard stop light switch clearance:

1.5 to 2.5 mm (0.059 to 0.098 in.)

If the clearance is not as specified, reinstall the

switch and recheck the pedal's free play.

If the clearance is as specified, troubleshoot the

brake system and proceed to the "CHECK BRAKE

PEDAL RESERVE DISTANCE" procedure.

3. CHECK BRAKE PEDAL RESERVE DISTANCE

(a) Release the parking brake lever. Start the engine.

(b) Depress the pedal and check the pedal reserve

distance.

(1) Depress the pedal with a force of 490 N (50 kgf,

11 0 l b f ) .

(2) Measure the distance between the pedal and

dash panel shown in the illustration.

Standard pedal reserve distance

If the distance is not as specified, troubleshoot

the brake system.

C 111 3 0 2 E 0 1

C 111 3 0 6 E 0 1

C 111 3 3 9 E 0 1Engine Specified Condition

2AZ-FE (w/o 3rd seat) More than 95 mm (3.74 in.)

2AZ-FE (w/ 3rd seat) More than 120 mm (4.72 in.)

2GR-FE More than 120 mm (4.72 in.)

Page 1573 of 2000

BR–18BRAKE – BRAKE PEDAL

BR

(b) Install the push rod pin to the push rod clevis.

NOTICE:

The push rod pin must be installed as shown in

the illustration.

(c) Install the clip to the push rod pin.

NOTICE:

The clip must be installed as shown in the

illustration.

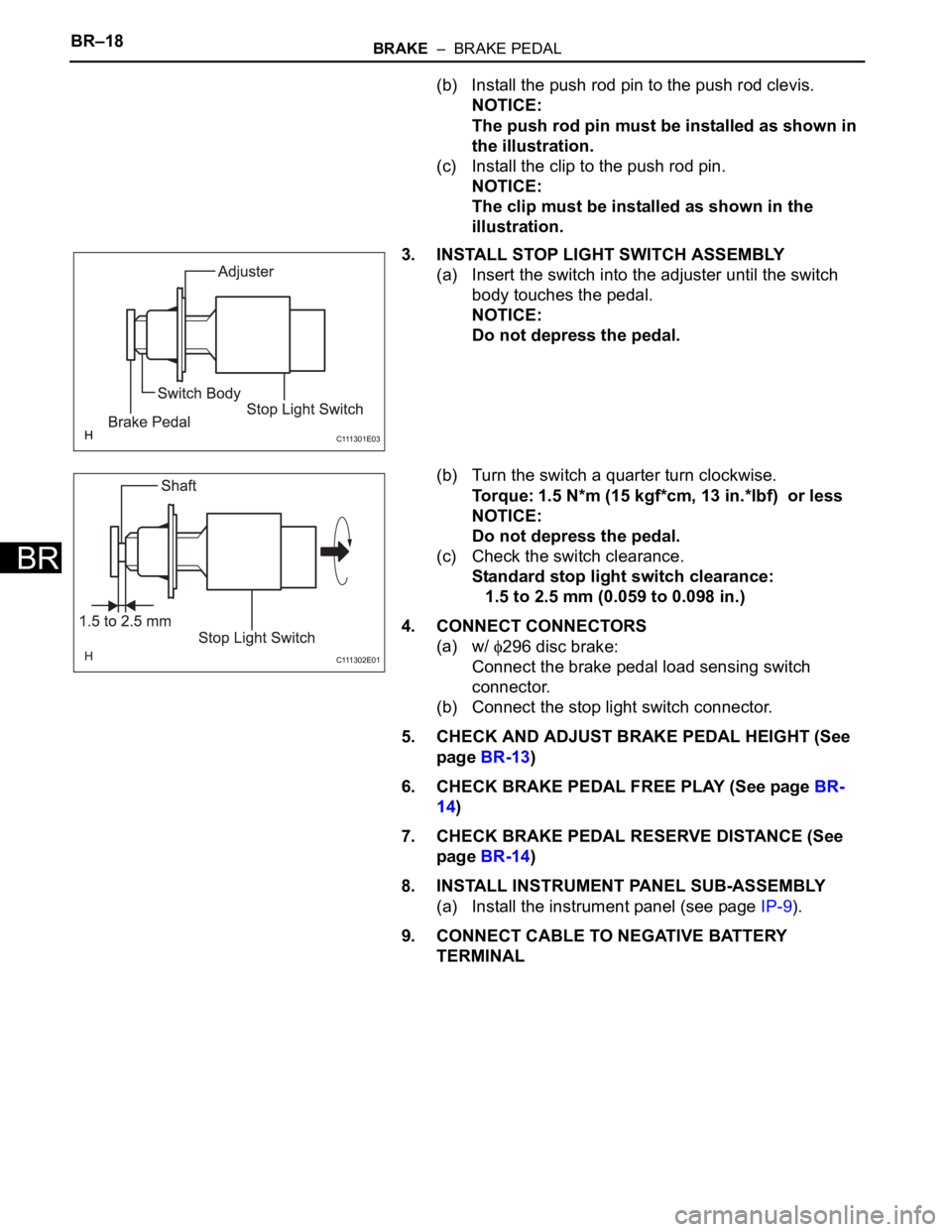

3. INSTALL STOP LIGHT SWITCH ASSEMBLY

(a) Insert the switch into the adjuster until the switch

body touches the pedal.

NOTICE:

Do not depress the pedal.

(b) Turn the switch a quarter turn clockwise.

Torque: 1.5 N*m (15 kgf*cm, 13 in.*lbf) or less

NOTICE:

Do not depress the pedal.

(c) Check the switch clearance.

Standard stop light switch clearance:

1.5 to 2.5 mm (0.059 to 0.098 in.)

4. CONNECT CONNECTORS

(a) w/

296 disc brake:

Connect the brake pedal load sensing switch

connector.

(b) Connect the stop light switch connector.

5. CHECK AND ADJUST BRAKE PEDAL HEIGHT (See

page BR-13)

6. CHECK BRAKE PEDAL FREE PLAY (See page BR-

14)

7. CHECK BRAKE PEDAL RESERVE DISTANCE (See

page BR-14)

8. INSTALL INSTRUMENT PANEL SUB-ASSEMBLY

(a) Install the instrument panel (see page IP-9).

9. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

C 111 3 0 1 E 0 3

C 111 3 0 2 E 0 1