sensor TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 34 of 2000

ENGINE - 2AZ-FE ENGINE

00REG21Y

D13N11

Air-fuel

Ratio

SensorA1A+

(3.3V)

A1A -

(2.9V)ECMHeated

Oxygen

SensorOX1B

EX1BECM

Air-fuel Ratio Sensor Circuit Heated Oxygen Sensor

: Air-fuel Ratio Sensor

: Heated Oxygen Sensor

Air-fuel Ratio Sensor Data

Displayed on Hand-held

Te s t e r4.2

2.2

11 (Rich) 14.7 19 (Lean)0.11

Heated Oxygen

Sensor Output (V)

Air-fuel RatioEG-37

Air-fuel Ratio Sensor and Heated Oxygen Sensor

1) General

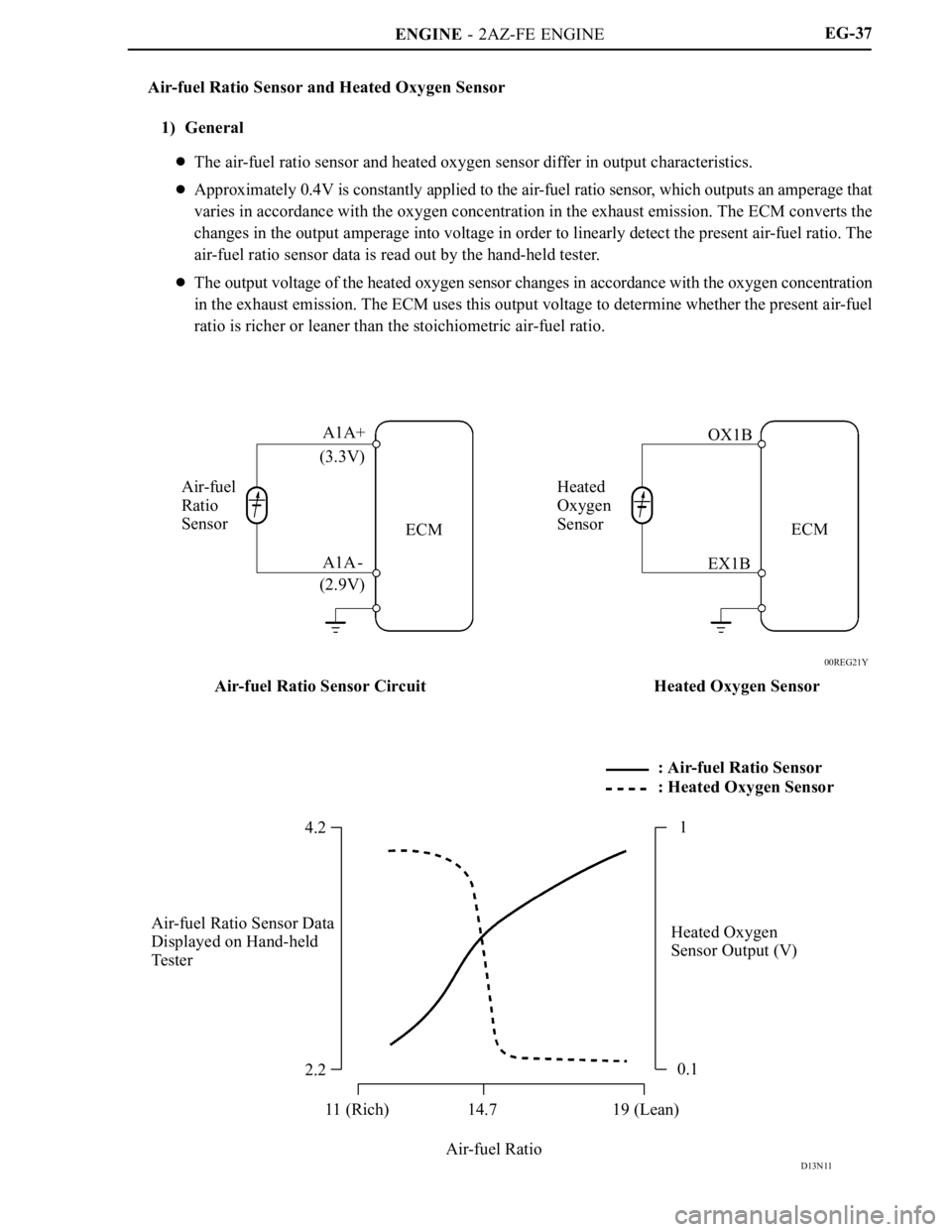

The air-fuel ratio sensor and heated oxygen sensor differ in output characteristics.

Approximately 0.4V is constantly applied to the air-fuel ratio sensor, which outputs an amperage that

varies in accordance with the oxygen concentration in the exhaust emission. The ECM converts the

changes in the output amperage into voltage in order to linearly detect the present air-fuel ratio. The

air-fuel ratio sensor data is read out by the hand-held tester.

The output voltage of the heated oxygen sensor changes in accordance with the oxygen concentration

in the exhaust emission. The ECM uses this output voltage to determine whether the present air-fuel

ratio is richer or leaner than the stoichiometric air-fuel ratio.

Page 35 of 2000

ENGINE - 2AZ-FE ENGINE

271EG45

Alumina

Dilation Layer

Alumina

Platinum

Electrode

Sensor Element (Zirconia)Heater AtmospherePlatinum

ElectrodeHeater

Atmosphere

Sensor Element

(Zirconia)

Planar Type Air-fuel Ratio Sensor Cup Type Heated Oxygen Sensor

204EG54

Temperature Sensing

Element

Platinum Hot-wire

ElementAir FlowIntake Air

Temperature

Sensor EG-38

2) Construction

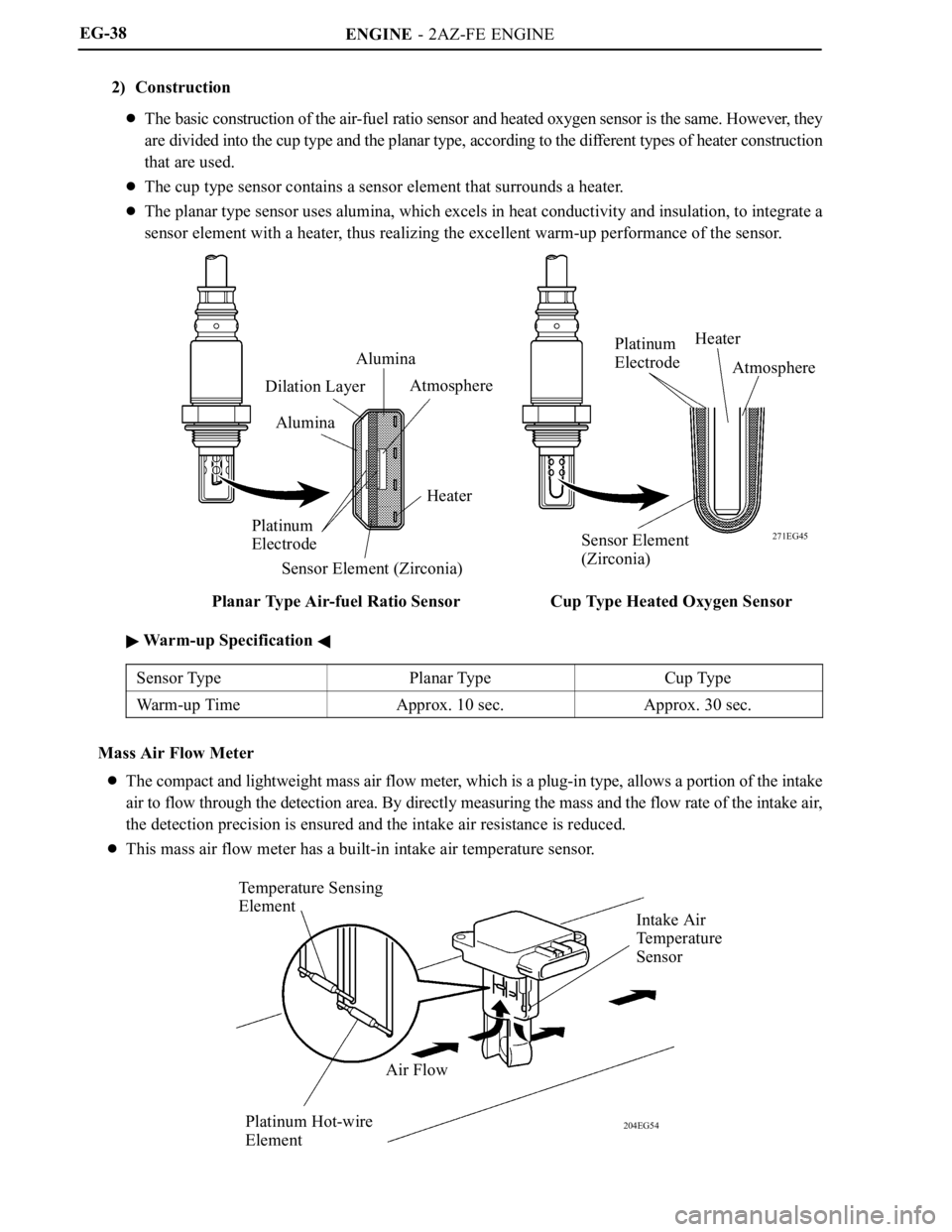

The basic construction of the air-fuel ratio sensor and heated oxygen sensor is the same. However, they

are divided into the cup type and the planar type, according to the different types of heater construction

that are used.

The cup type sensor contains a sensor element that surrounds a heater.

The planar type sensor uses alumina, which excels in heat conductivity and insulation, to integrate a

sensor element with a heater, thus realizing the excellent warm-up performance of the sensor.

Warm-up Specification

Sensor TypePlanar TypeCup Type

Warm-up TimeApprox. 10 sec.Approx. 30 sec.

Mass Air Flow Meter

The compact and lightweight mass air flow meter, which is a plug-in type, allows a portion of the intake

air to flow through the detection area. By directly measuring the mass and the flow rate of the intake air,

the detection precision is ensured and the intake air resistance is reduced.

This mass air flow meter has a built-in intake air temperature sensor.

Page 36 of 2000

ENGINE - 2AZ-FE ENGINE

214CE04

: Conventional Type

: Flat Type

(V)

Vo l t a g e

Frequency (Hz)A

BA: Detection Band of

Conventional Type

B: Detection Band of

Flat Type

Characteristic of Knock Sensor

214CE01214CE02

Steel Weight

Insulator

Piezoelectric

ElementOpen / Short Circuit

Detection Resistor

Flat Type Knock Sensor

(Non-resonant Type)Piezoelectric

Element

Vibration Plate

Conventional Type Knock Sensor

(Resonant Type)EG-39

Knock Sensor (Flat Type)

1) General

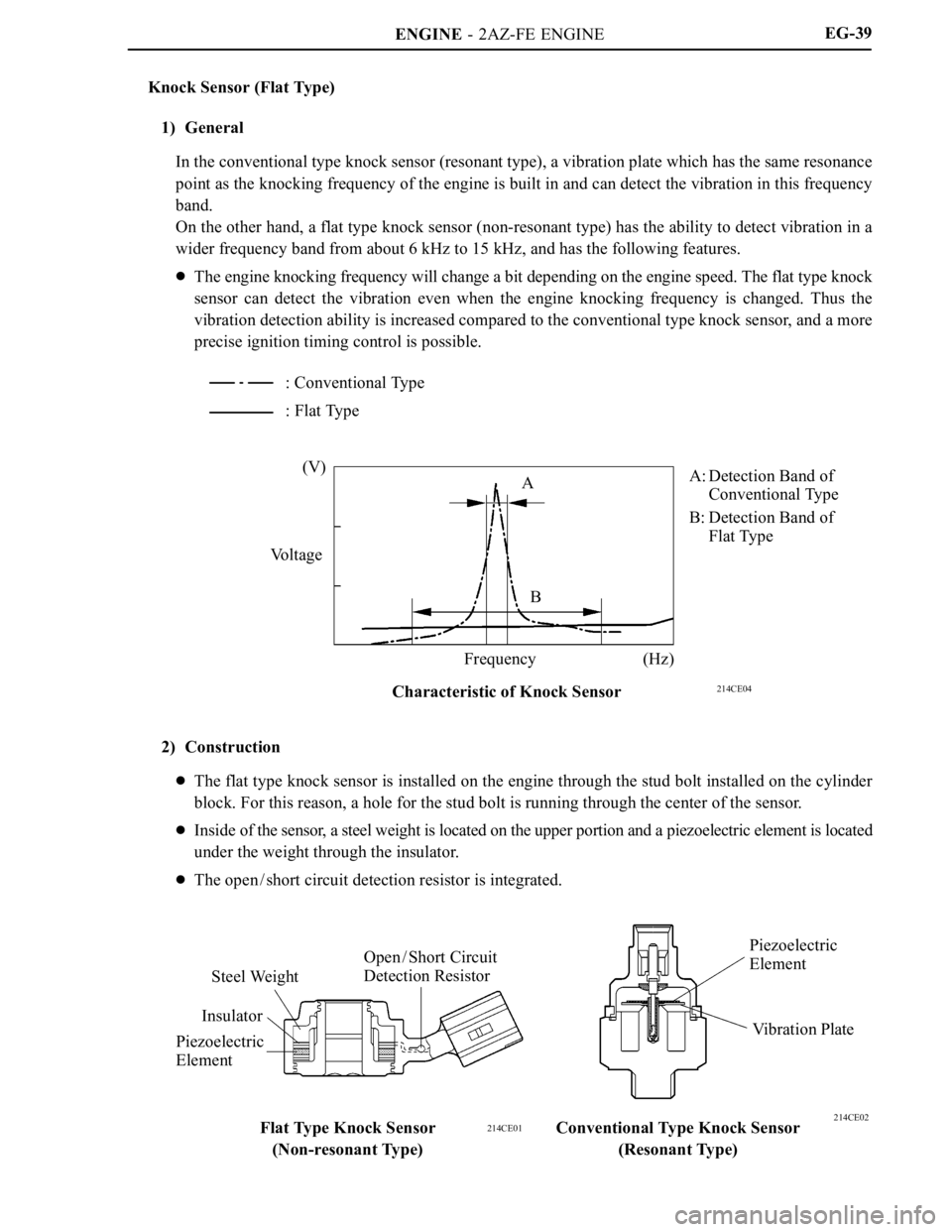

In the conventional type knock sensor (resonant type), a vibration plate which has the same resonance

point as the knocking frequency of the engine is built in and can detect the vibration in this frequency

band.

On the other hand, a flat type knock sensor (non-resonant type) has the ability to detect vibration in a

wider frequency band from about 6 kHz to 15 kHz, and has the following features.

The engine knocking frequency will change a bit depending on the engine speed. The flat type knock

sensor can detect the vibration even when the engine knocking frequency is changed. Thus the

vibration detection ability is increased compared to the conventional type knock sensor, and a more

precise ignition timing control is possible.

2) Construction

The flat type knock sensor is installed on the engine through the stud bolt installed on the cylinder

block. For this reason, a hole for the stud bolt is running through the center of the sensor.

Inside of the sensor, a steel weight is located on the upper portion and a piezoelectric element is located

under the weight through the insulator.

The open / short circuit detection resistor is integrated.

Page 37 of 2000

ENGINE - 2AZ-FE ENGINE

214CE08

Steel Weight

Inertia

Piezoelectric

Element

214CE06

Knock Sensor

200 k

Piezoelectric

ElementOpen / Short Circuit

Detection ResistorKNK1

EKNKECM

5 V

200 k

IC

Service Tip

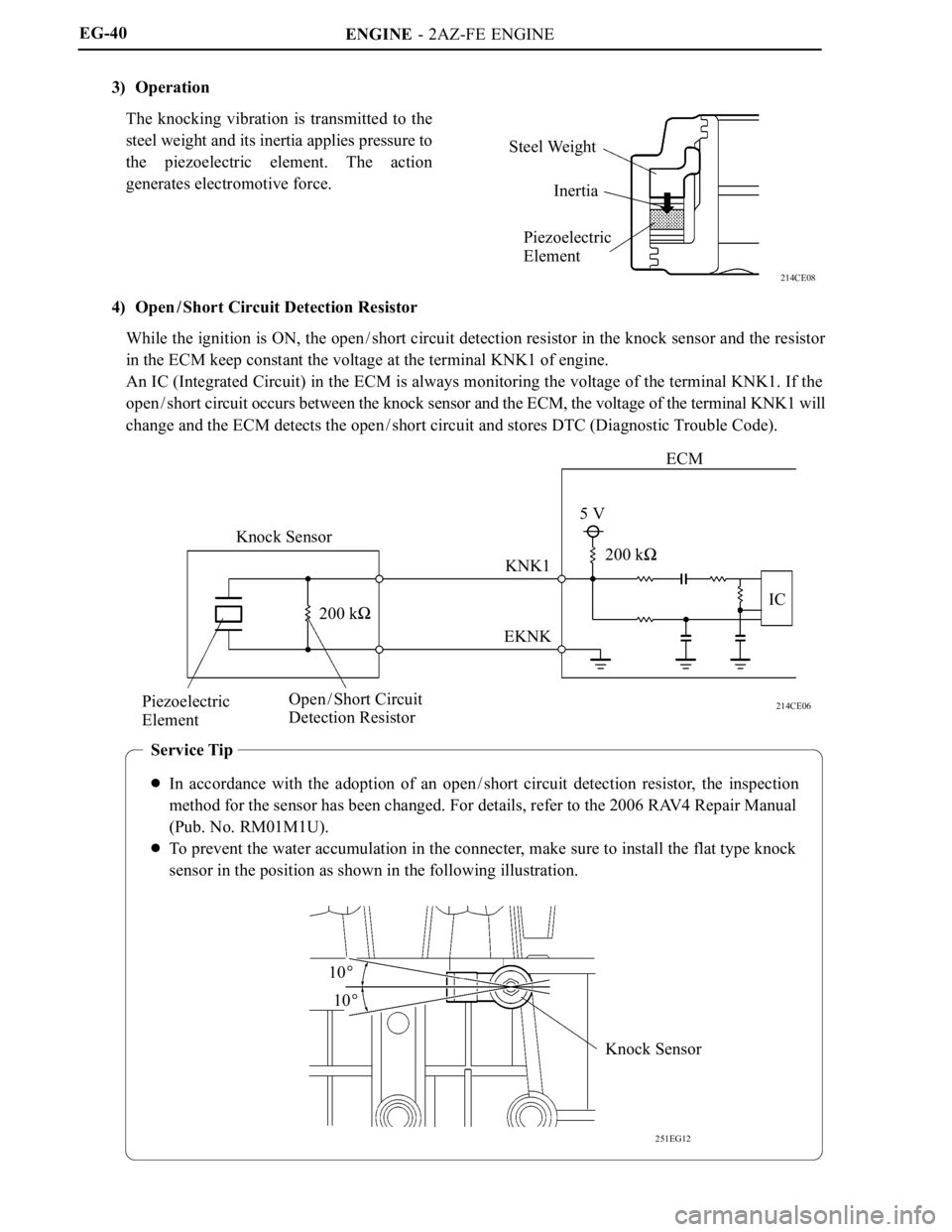

In accordance with the adoption of an open / short circuit detection resistor, the inspection

method for the sensor has been changed. For details, refer to the 2006 RAV4 Repair Manual

(Pub. No. RM01M1U).

To prevent the water accumulation in the connecter, make sure to install the flat type knock

sensor in the position as shown in the following illustration.

251EG12

10

10

Knock Sensor EG-40

3) Operation

The knocking vibration is transmitted to the

steel weight and its inertia applies pressure to

the piezoelectric element. The action

generates electromotive force.

4) Open / Short Circuit Detection Resistor

While the ignition is ON, the open / short circuit detection resistor in the knock sensor and the resistor

in the ECM keep constant the voltage at the terminal KNK1 of engine.

An IC (Integrated Circuit) in the ECM is always monitoring the voltage of the terminal KNK1. If the

open / short circuit occurs between the knock sensor and the ECM, the voltage of the terminal KNK1 will

change and the ECM detects the open / short circuit and stores DTC (Diagnostic Trouble Code).

Page 38 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG43Y

238EG79

230LX12

Throttle Body

Throttle Position

Sensor Portion

Throttle Control

MotorMagnetic

Yo k e

Hall IC

Cross Section

Throttle Position

Sensor

Magnetic Yoke

Hall

IC

Hall

IC

VTA1

ETA

VCTA

VTA2ECMOutput

Voltage(V)

5

0

Fully Close10 90 (

)

Fully Open VTA2

VTA1

Throttle Valve Opening Angle

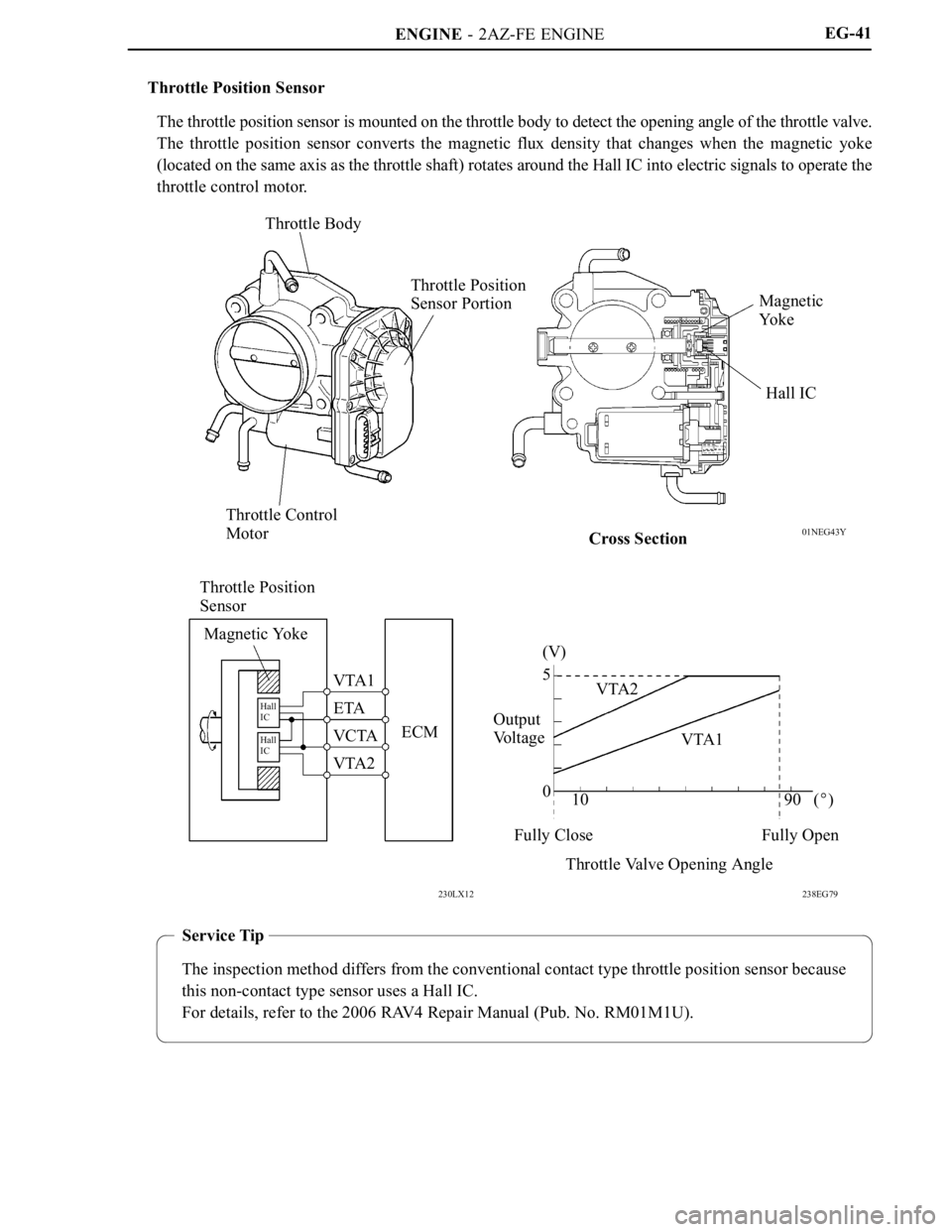

Service Tip

The inspection method differs from the conventional contact type throttle position sensor because

this non-contact type sensor uses a Hall IC.

For details, refer to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

EG-41

Throttle Position Sensor

The throttle position sensor is mounted on the throttle body to detect the opening angle of the throttle valve.

The throttle position sensor converts the magnetic flux density that changes when the magnetic yoke

(located on the same axis as the throttle shaft) rotates around the Hall IC into electric signals to operate the

throttle control motor.

Page 39 of 2000

ENGINE - 2AZ-FE ENGINE

00SEG39Y

228TU25 228TU24

A

AInternal Construction

A - A Cross SectionAccelerator

Pedal Arm

Hall IC

Magnetic Yoke

Accelerator Pedal

Position Sensor

Magnetic Yoke

Hall

IC

Hall

IC

VPA

EPA

VCPA

VPA2

EPA2ECM

Output

Voltage(V)

5

0VPA2

VPA

Fully Close Fully Open90

Accelerator Pedal Depressed Angle VCP2

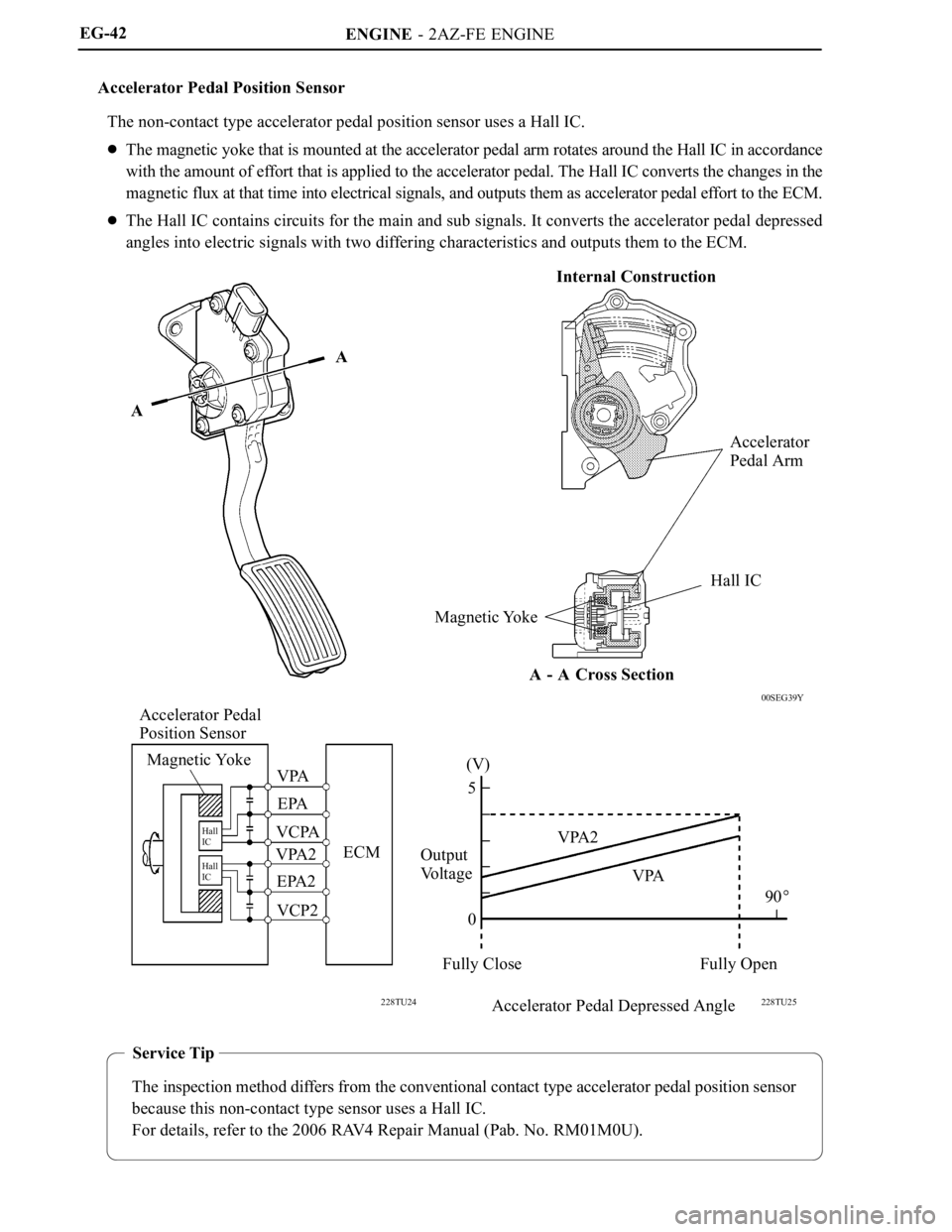

Service Tip

The inspection method differs from the conventional contact type accelerator pedal position sensor

because this non-contact type sensor uses a Hall IC.

For details, refer to the 2006 RAV4 Repair Manual (Pab. No. RM01M0U).

EG-42

Accelerator Pedal Position Sensor

The non-contact type accelerator pedal position sensor uses a Hall IC.

The magnetic yoke that is mounted at the accelerator pedal arm rotates around the Hall IC in accordance

with the amount of effort that is applied to the accelerator pedal. The Hall IC converts the changes in the

magnetic flux at that time into electrical signals, and outputs them as accelerator pedal effort to the ECM.

The Hall IC contains circuits for the main and sub signals. It converts the accelerator pedal depressed

angles into electric signals with two differing characteristics and outputs them to the ECM.

Page 40 of 2000

ENGINE - 2AZ-FE ENGINE

00REG17Y

Accelerator Pedal

Position SensorThrottle Valve

Throttle Position SensorThrottle

Control

Motor

Mass Air

Flow MeterECMSkid

Control

ECU

Ignition

CoilFuel

Injector

: CANEG-43

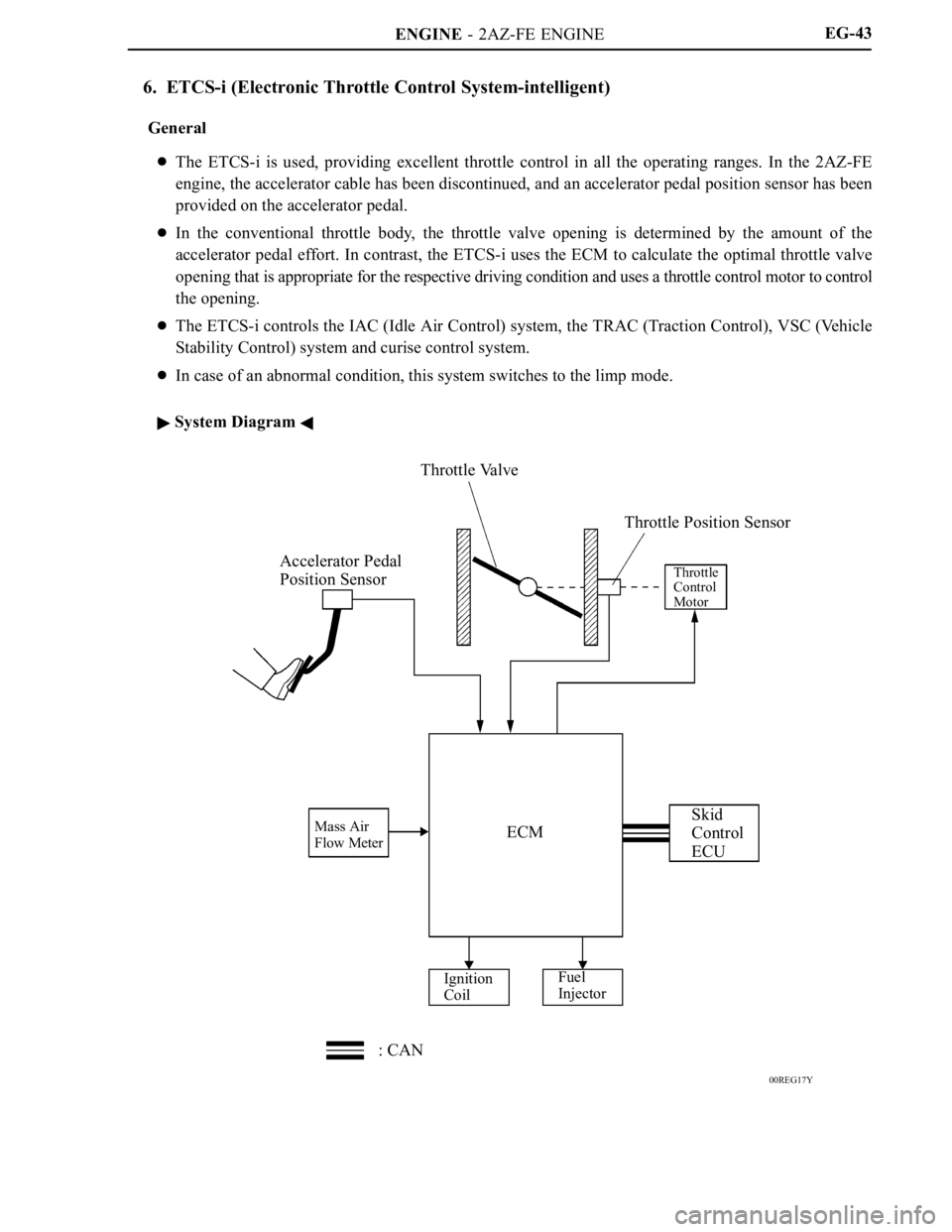

6. ETCS-i (Electronic Throttle Control System-intelligent)

General

The ETCS-i is used, providing excellent throttle control in all the operating ranges. In the 2AZ-FE

engine, the accelerator cable has been discontinued, and an accelerator pedal position sensor has been

provided on the accelerator pedal.

In the conventional throttle body, the throttle valve opening is determined by the amount of the

accelerator pedal effort. In contrast, the ETCS-i uses the ECM to calculate the optimal throttle valve

opening that is appropriate for the respective driving condition and uses a throttle control motor to control

the opening.

The ETCS-i controls the IAC (Idle Air Control) system, the TRAC (Traction Control), VSC (Vehicle

Stability Control) system and curise control system.

In case of an abnormal condition, this system switches to the limp mode.

System Diagram

Page 41 of 2000

ENGINE - 2AZ-FE ENGINE

Throttle Body

Throttle Position

Sensor Portion

Reduction

Gears

Throttle ValveMagnetic Yoke

Hall IC

Throttle Control

Motor A

View from A

Cross Section

01NEG44Y

EG-44

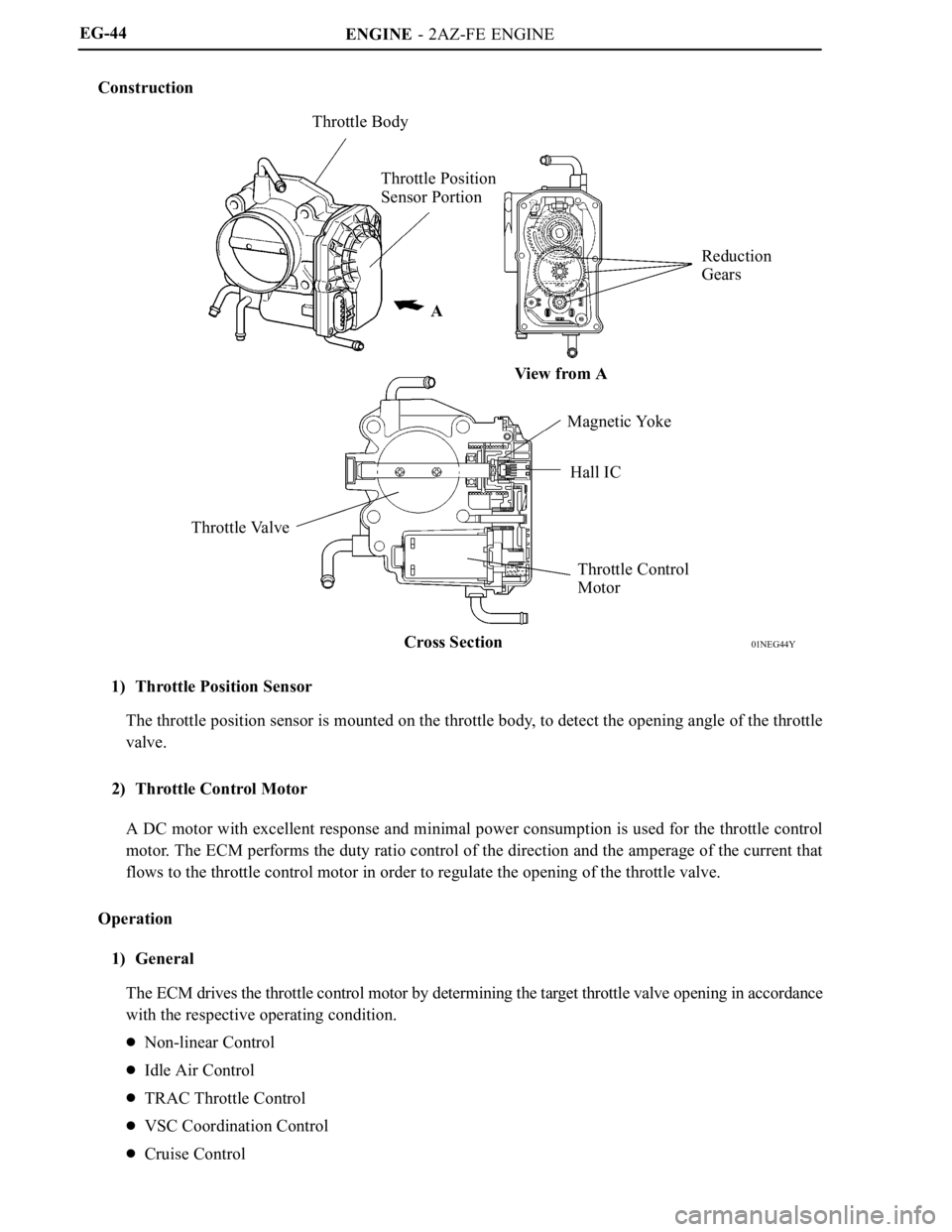

Construction

1) Throttle Position Sensor

The throttle position sensor is mounted on the throttle body, to detect the opening angle of the throttle

valve.

2) Throttle Control Motor

A DC motor with excellent response and minimal power consumption is used for the throttle control

motor. The ECM performs the duty ratio control of the direction and the amperage of the current that

flows to the throttle control motor in order to regulate the opening of the throttle valve.

Operation

1) General

The ECM drives the throttle control motor by determining the target throttle valve opening in accordance

with the respective operating condition.

Non-linear Control

Idle Air Control

TRAC Throttle Control

VSC Coordination Control

Cruise Control

Page 43 of 2000

ENGINE - 2AZ-FE ENGINE

199EG45

ECM

Accelerator Pedal

Position Sensor

Main

Sub

Main

Sub

Throttle

Position

Sensor

Open

Throttle ValveReturn

SpringThrottle

Control

Motor

Accelerator Pedal Throttle Body

199EG46

Accelerator Pedal Throttle BodyECM

Accelerator Pedal

Position Sensor

Main

Sub

Close by

Return Spring

Main

Sub

Throttle

Position

SensorThrottle ValveReturn

SpringThrottle

Control

Motor EG-46

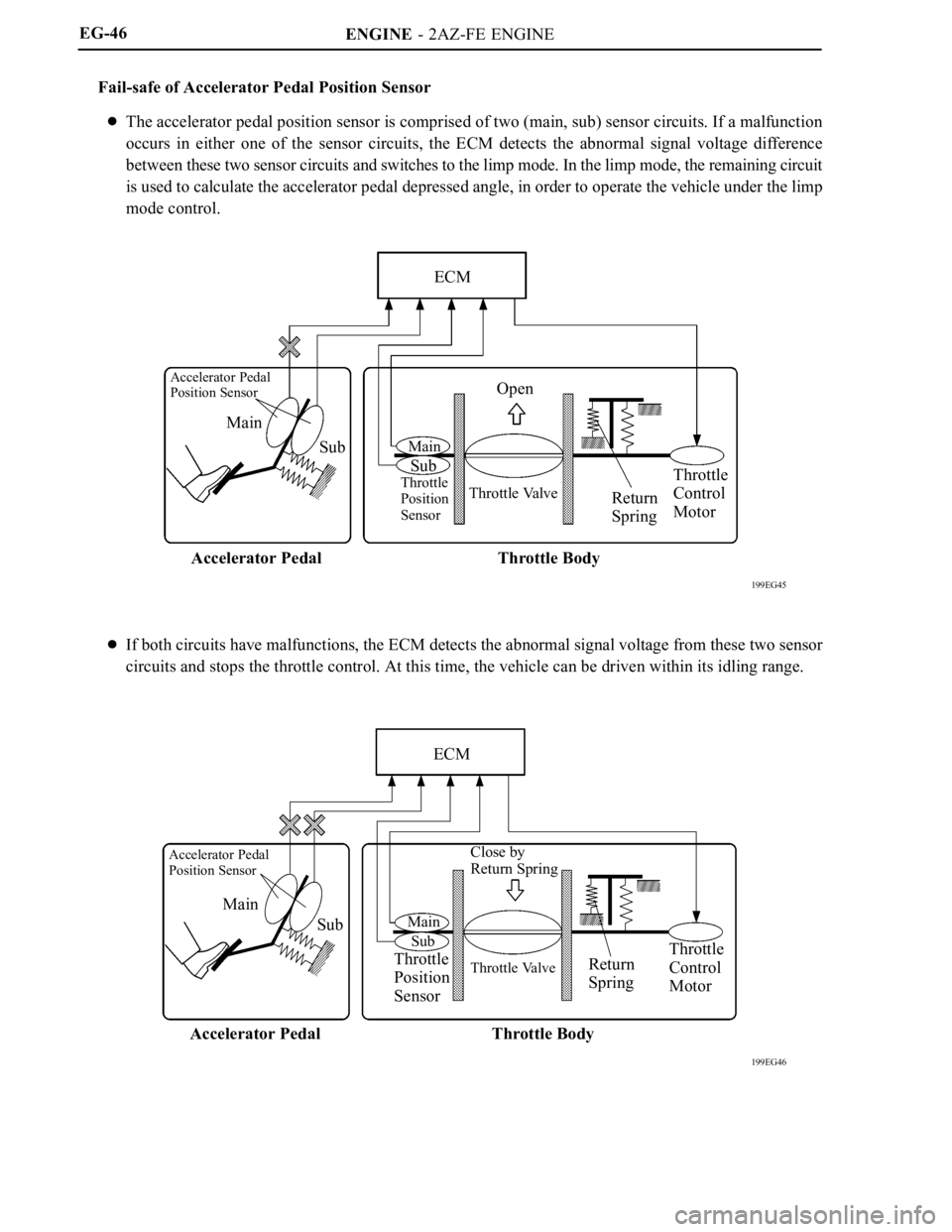

Fail-safe of Accelerator Pedal Position Sensor

The accelerator pedal position sensor is comprised of two (main, sub) sensor circuits. If a malfunction

occurs in either one of the sensor circuits, the ECM detects the abnormal signal voltage difference

between these two sensor circuits and switches to the limp mode. In the limp mode, the remaining circuit

is used to calculate the accelerator pedal depressed angle, in order to operate the vehicle under the limp

mode control.

If both circuits have malfunctions, the ECM detects the abnormal signal voltage from these two sensor

circuits and stops the throttle control. At this time, the vehicle can be driven within its idling range.

Page 44 of 2000

ENGINE - 2AZ-FE ENGINE

199EG47

Injectors

ECMIgnition Coils

Accelerator Pedal

Position Sensor

Main

Sub

Main

Sub

Return to

Prescribed Angle

Throttle ValveReturn

SpringThrottle

Control

Motor

Accelerator Pedal Throttle BodyEG-47

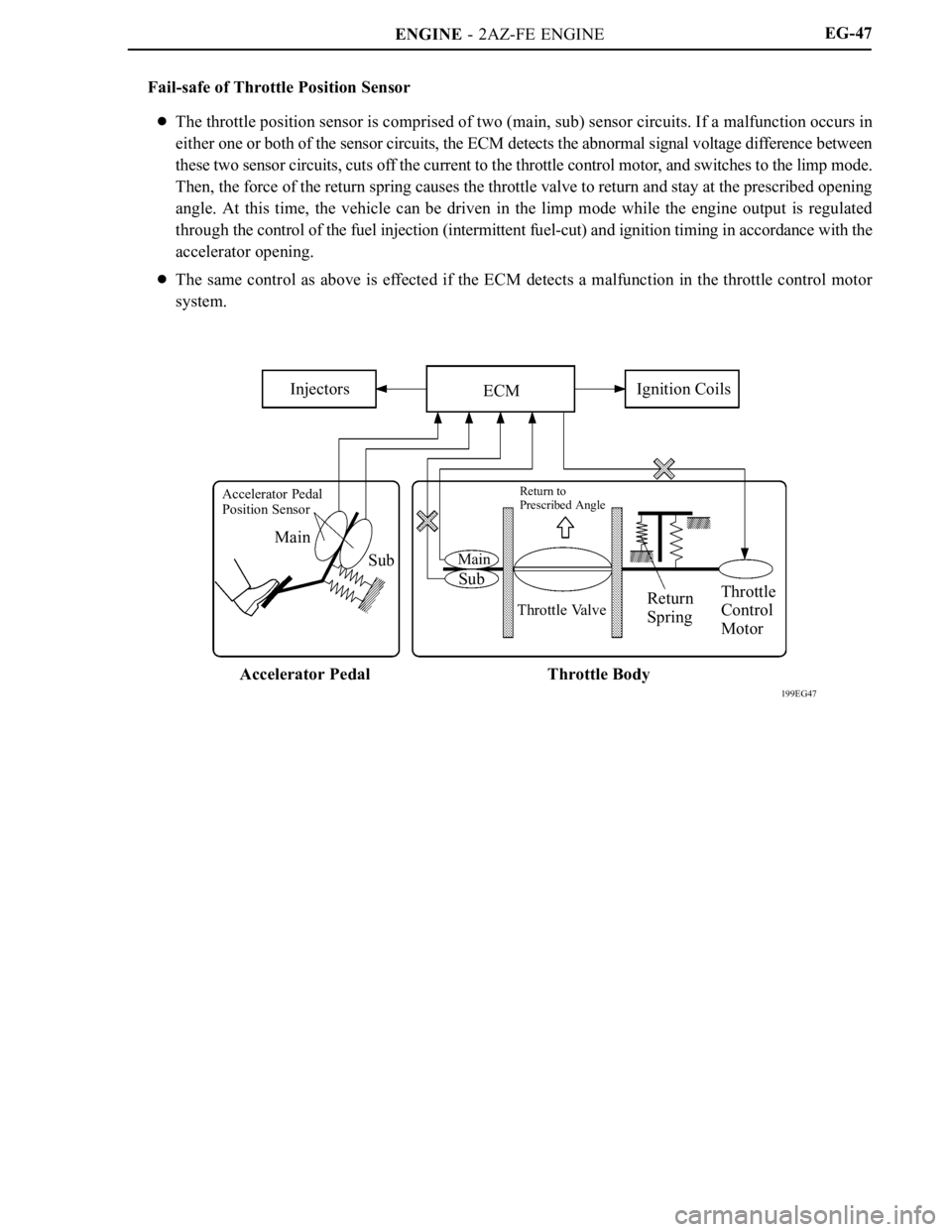

Fail-safe of Throttle Position Sensor

The throttle position sensor is comprised of two (main, sub) sensor circuits. If a malfunction occurs in

either one or both of the sensor circuits, the ECM detects the abnormal signal voltage difference between

these two sensor circuits, cuts off the current to the throttle control motor, and switches to the limp mode.

Then, the force of the return spring causes the throttle valve to return and stay at the prescribed opening

angle. At this time, the vehicle can be driven in the limp mode while the engine output is regulated

through the control of the fuel injection (intermittent fuel-cut) and ignition timing in accordance with the

accelerator opening.

The same control as above is effected if the ECM detects a malfunction in the throttle control motor

system.