TOYOTA RAV4 2006 Service Repair Manual

RAV4 2006

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57463/w960_57463-0.png

TOYOTA RAV4 2006 Service Repair Manual

Page 12 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG34Y

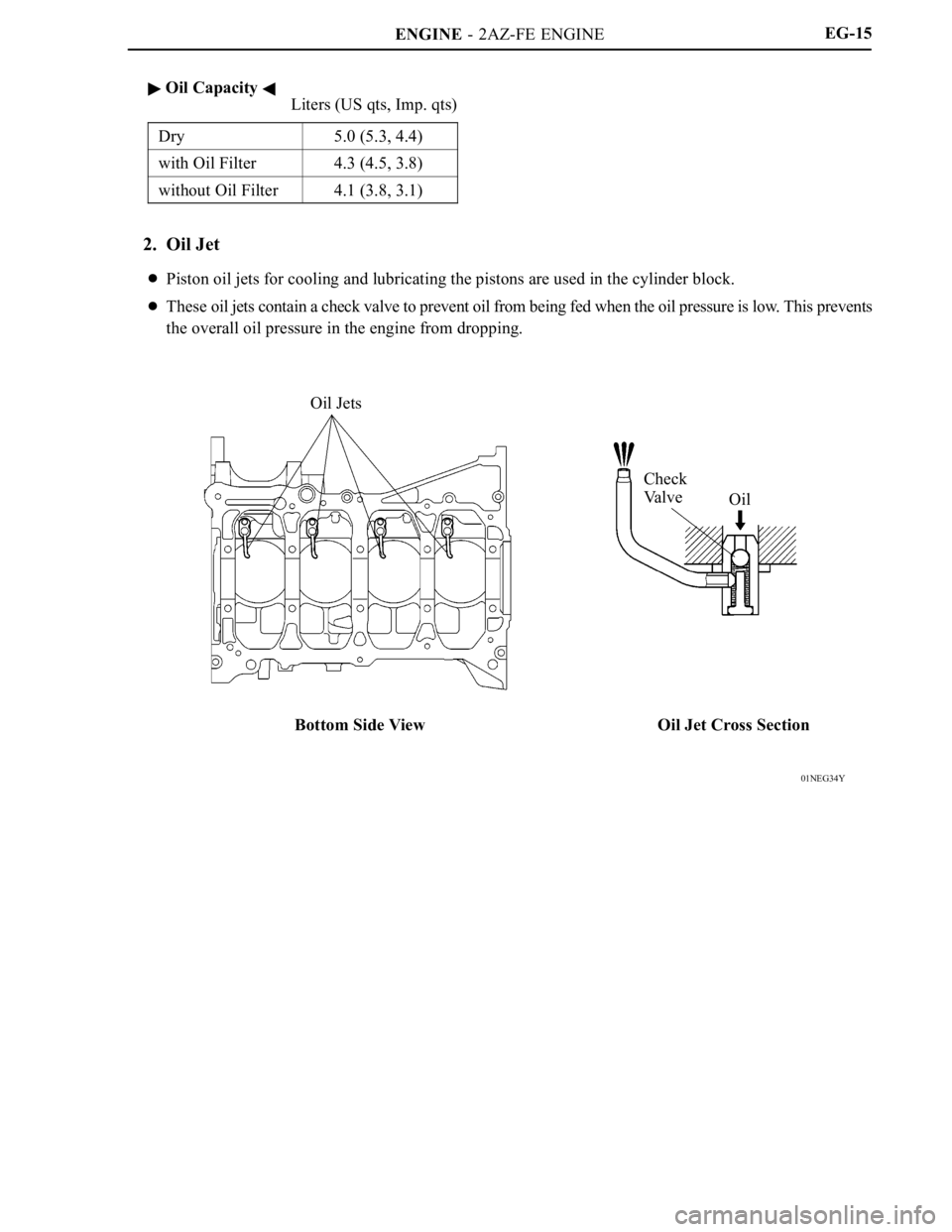

Oil Jets

Check

Va l v e

Oil

Bottom Side View Oil Jet Cross SectionEG-15

Oil Capacity

Liters (US qts, Imp. qts)

Dry

5.0 (5.3, 4.4)

with Oil Filter4.3 (4.5, 3.8)

without Oil Filter4.1 (3.8, 3.1)

2. Oil Jet

Piston oil jets for cooling and lubricating the pistons are used in the cylinder block.

These oil jets contain a check valve to prevent oil from being fed when the oil pressure is low. This prevents

the overall oil pressure in the engine from dropping.

Page 80 of 2000

ENGINE - 2GR-FE ENGINE

285EG23

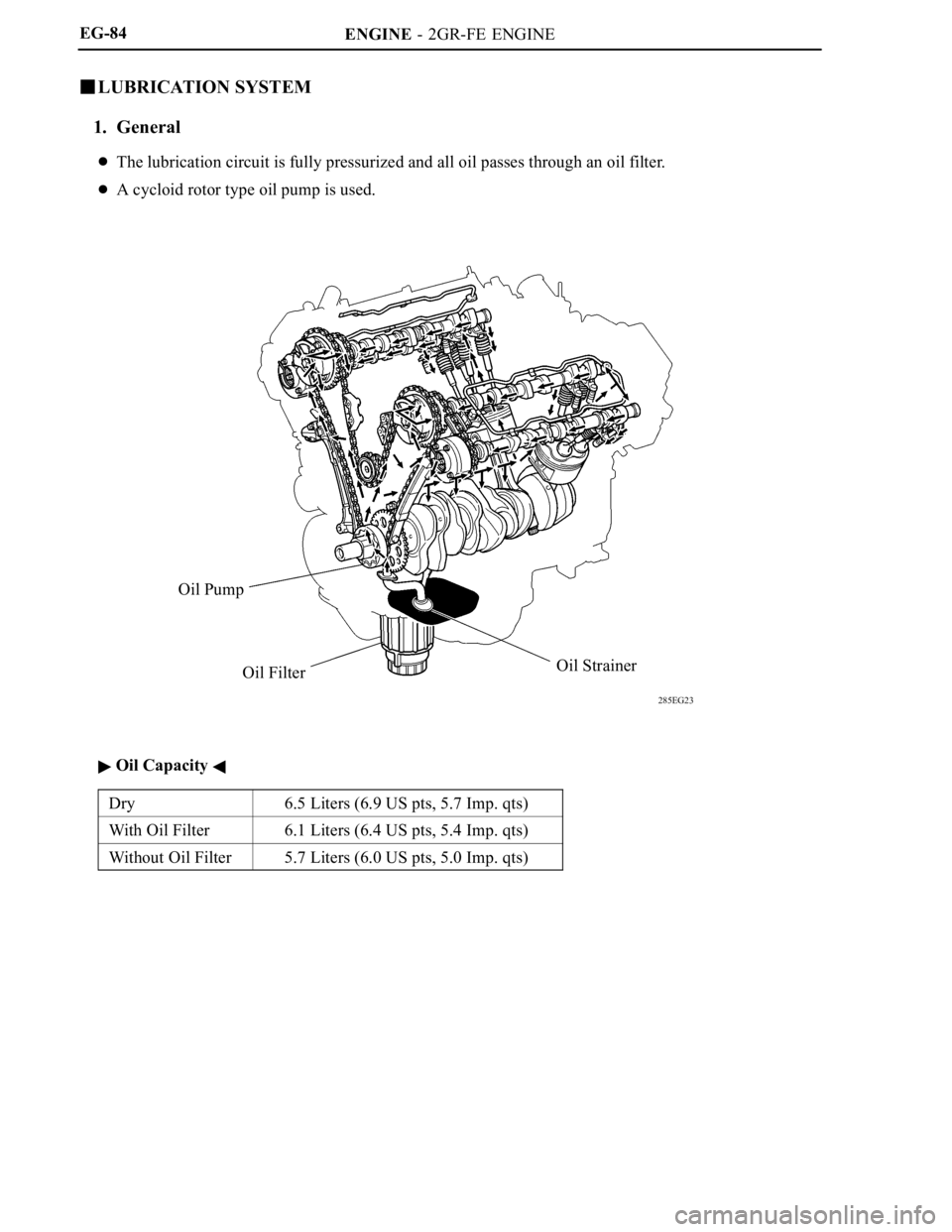

Oil Pump

Oil FilterOil Strainer EG-84

LUBRICATION SYSTEM

1. General

The lubrication circuit is fully pressurized and all oil passes through an oil filter.

A cycloid rotor type oil pump is used.

Oil Capacity

Dry6.5 Liters (6.9 US pts, 5.7 Imp. qts)

With Oil Filter6.1 Liters (6.4 US pts, 5.4 Imp. qts)

Without Oil Filter5.7 Liters (6.0 US pts, 5.0 Imp. qts)

Page 303 of 2000

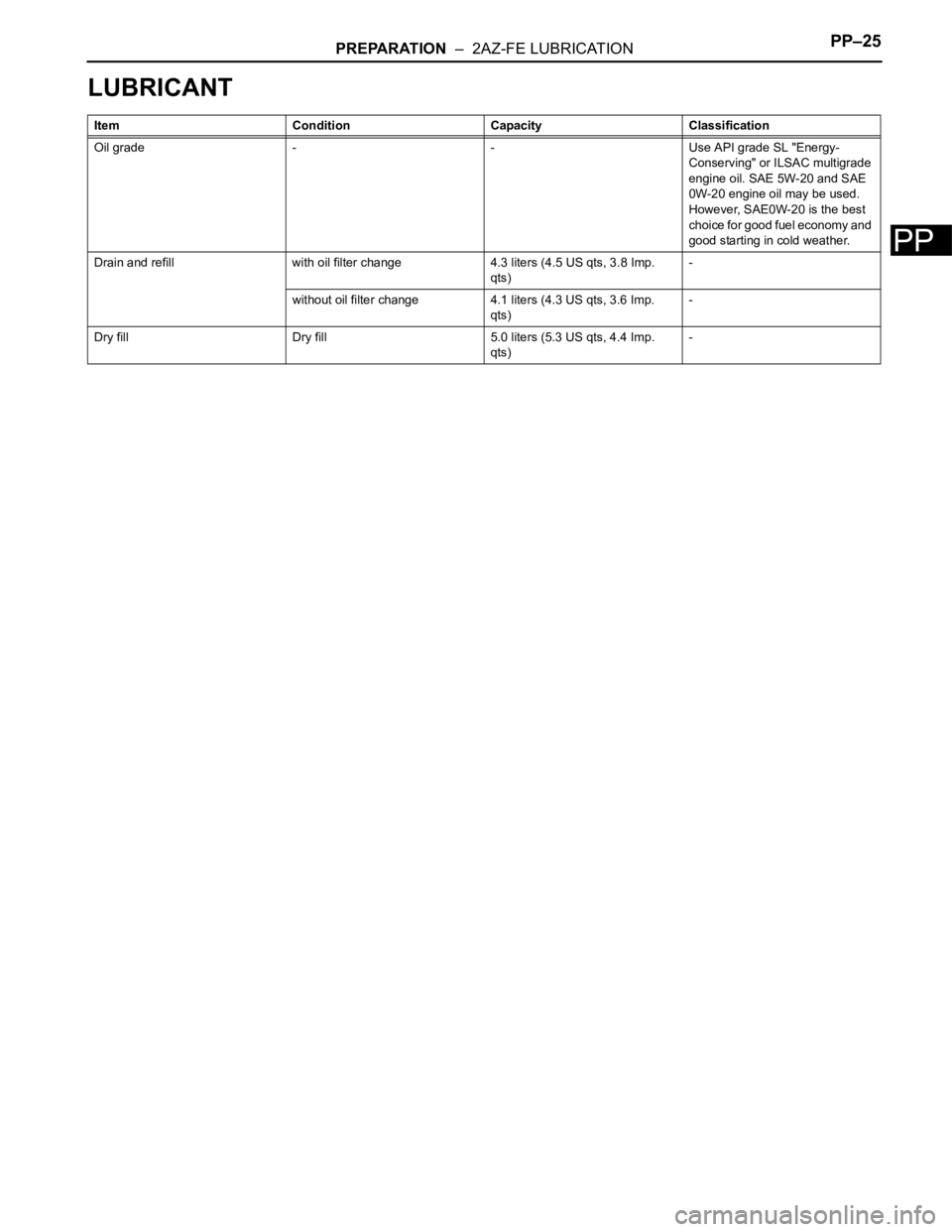

PREPARATION – 2AZ-FE LUBRICATIONPP–25

PP

LUBRICANT

Item Condition Capacity Classification

Oil grade - - Use API grade SL "Energy-

Conserving" or ILSAC multigrade

engine oil. SAE 5W-20 and SAE

0W-20 engine oil may be used.

However, SAE0W-20 is the best

choice for good fuel economy and

good starting in cold weather.

Drain and refill with oil filter change 4.3 liters (4.5 US qts, 3.8 Imp.

qts)-

without oil filter change 4.1 liters (4.3 US qts, 3.6 Imp.

qts)-

Dry fill Dry fill 5.0 liters (5.3 US qts, 4.4 Imp.

qts)-

Page 306 of 2000

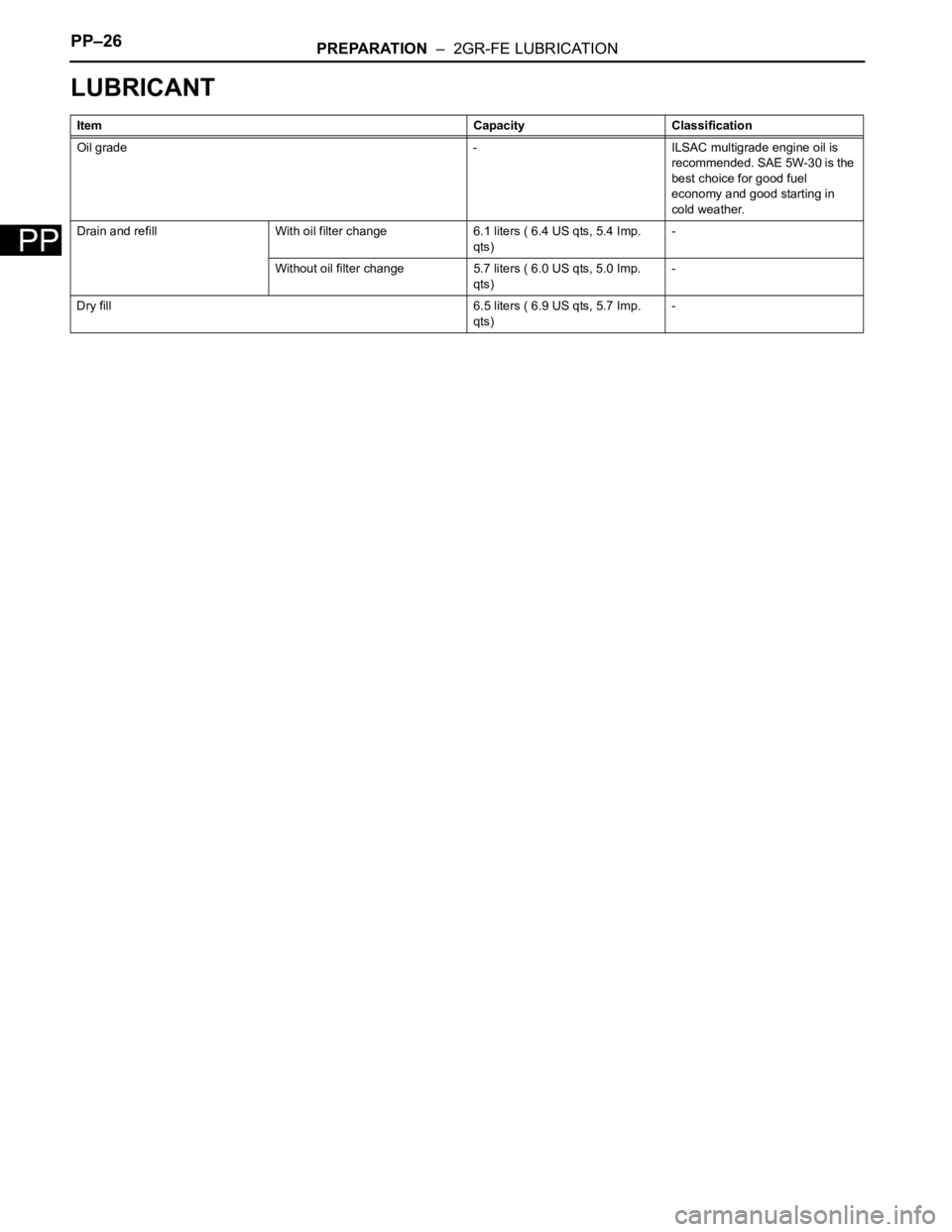

PP–26PREPARATION – 2GR-FE LUBRICATION

PP

LUBRICANT

Item Capacity Classification

Oil grade - ILSAC multigrade engine oil is

recommended. SAE 5W-30 is the

best choice for good fuel

economy and good starting in

cold weather.

Drain and refill With oil filter change 6.1 liters ( 6.4 US qts, 5.4 Imp.

qts)-

Without oil filter change 5.7 liters ( 6.0 US qts, 5.0 Imp.

qts)-

Dry fill 6.5 liters ( 6.9 US qts, 5.7 Imp.

qts)-

Page 331 of 2000

PREPARATION – AIR CONDITIONINGPP–83

PP

LUBRICANT

Item Capacity Classification

Compressor oil - ND-OIL 8 or equivalent

Page 889 of 2000

PREPARATION – GF1A TRANSFERPP–65

PP

LUBRICANT

Item Capacity Classification

Transfer oil 0.5 liters (0.5 US qts, 0.4 Imp. qts) API GL-5 SAE 75W-90

Page 893 of 2000

PP–72PREPARATION – DIFFERENTIAL

PP

LUBRICANT

Item Capacity Classification

Rear differential oil 0.45 to 0.55 liters (0.48 to 0.58 US qts., 0.40

to 0.48 Imp. qts.)Hypoid gear oil API GL-5 or equivalent

Page 1662 of 2000

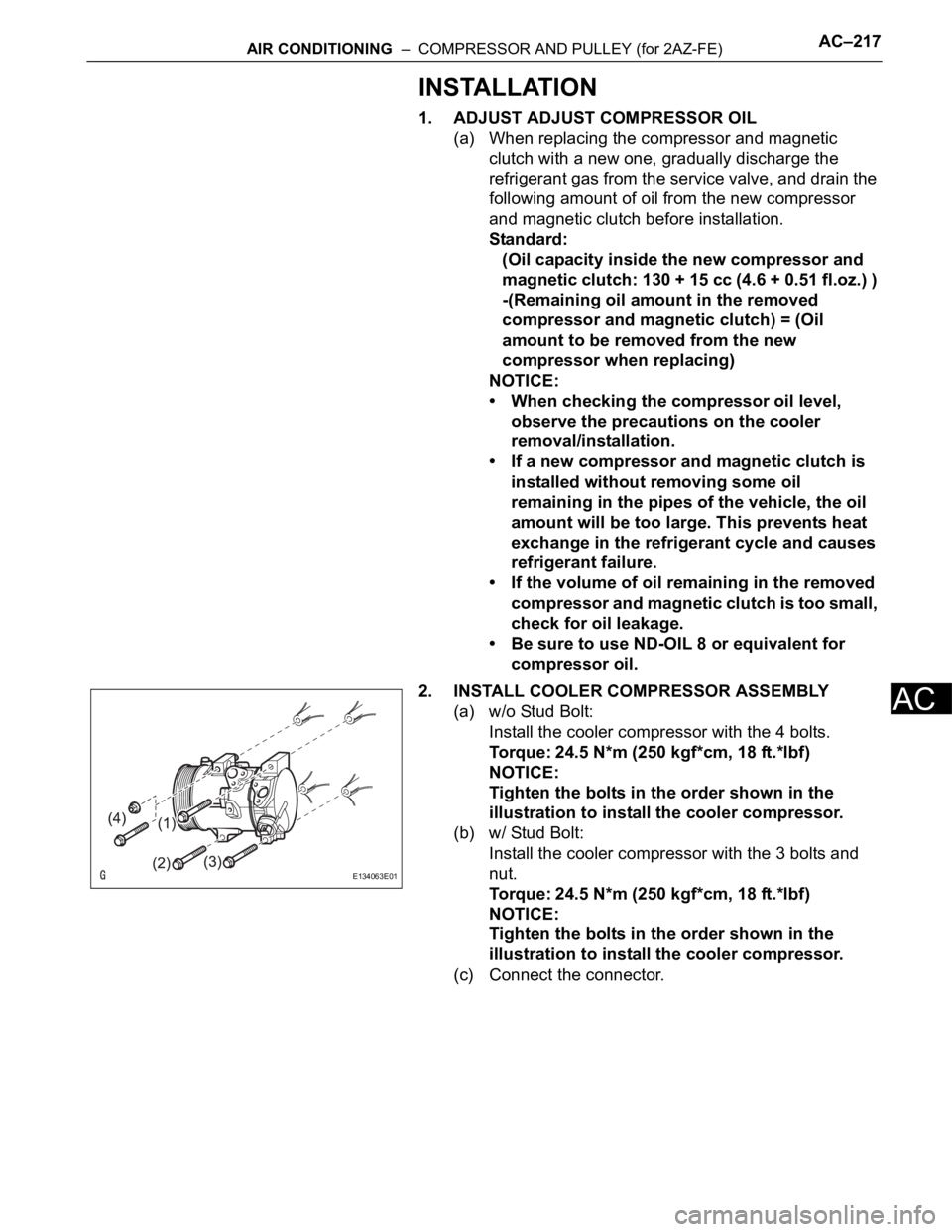

AIR CONDITIONING – COMPRESSOR AND PULLEY (for 2AZ-FE)AC–217

AC

INSTALLATION

1. ADJUST ADJUST COMPRESSOR OIL

(a) When replacing the compressor and magnetic

clutch with a new one, gradually discharge the

refrigerant gas from the service valve, and drain the

following amount of oil from the new compressor

and magnetic clutch before installation.

Standard:

(Oil capacity inside the new compressor and

magnetic clutch: 130 + 15 cc (4.6 + 0.51 fl.oz.) )

-(Remaining oil amount in the removed

compressor and magnetic clutch) = (Oil

amount to be removed from the new

compressor when replacing)

NOTICE:

• When checking the compressor oil level,

observe the precautions on the cooler

removal/installation.

• If a new compressor and magnetic clutch is

installed without removing some oil

remaining in the pipes of the vehicle, the oil

amount will be too large. This prevents heat

exchange in the refrigerant cycle and causes

refrigerant failure.

• If the volume of oil remaining in the removed

compressor and magnetic clutch is too small,

check for oil leakage.

• Be sure to use ND-OIL 8 or equivalent for

compressor oil.

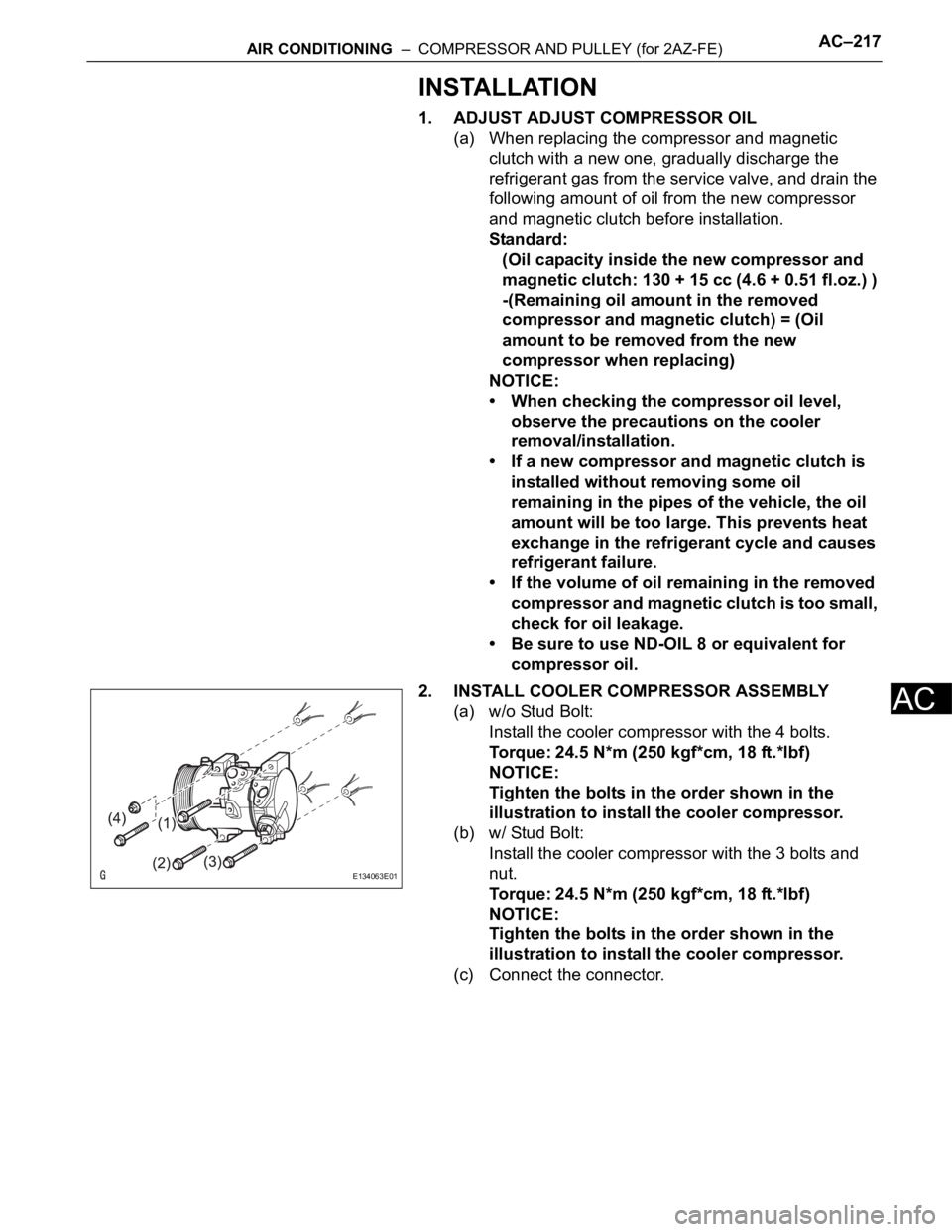

2. INSTALL COOLER COMPRESSOR ASSEMBLY

(a) w/o Stud Bolt:

Install the cooler compressor with the 4 bolts.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*lbf)

NOTICE:

Tighten the bolts in the order shown in the

illustration to install the cooler compressor.

(b) w/ Stud Bolt:

Install the cooler compressor with the 3 bolts and

nut.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*lbf)

NOTICE:

Tighten the bolts in the order shown in the

illustration to install the cooler compressor.

(c) Connect the connector.

E134063E01