sensor TOYOTA RAV4 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 60 of 2000

ENGINE - 2AZ-FE ENGINE

00REG28Y

275TU50 M

P

Atmosphere

Atmosphere

Purge VSV

(ON)

ECMCanister Pump Module

Vent Valve

(ON)

Leak Detection Pump

& Pump Motor

Canister

Pressure Sensor

Purge VSV Monitor

P0441

Normal

Purge VSV

Vent Valve

Pump Motor

System PressureON (Open)

OFF (Close)

ON

OFF (Vent)

ON

OFF

Atmospheric Pressure

0.02 in. Leak PressureEG-63

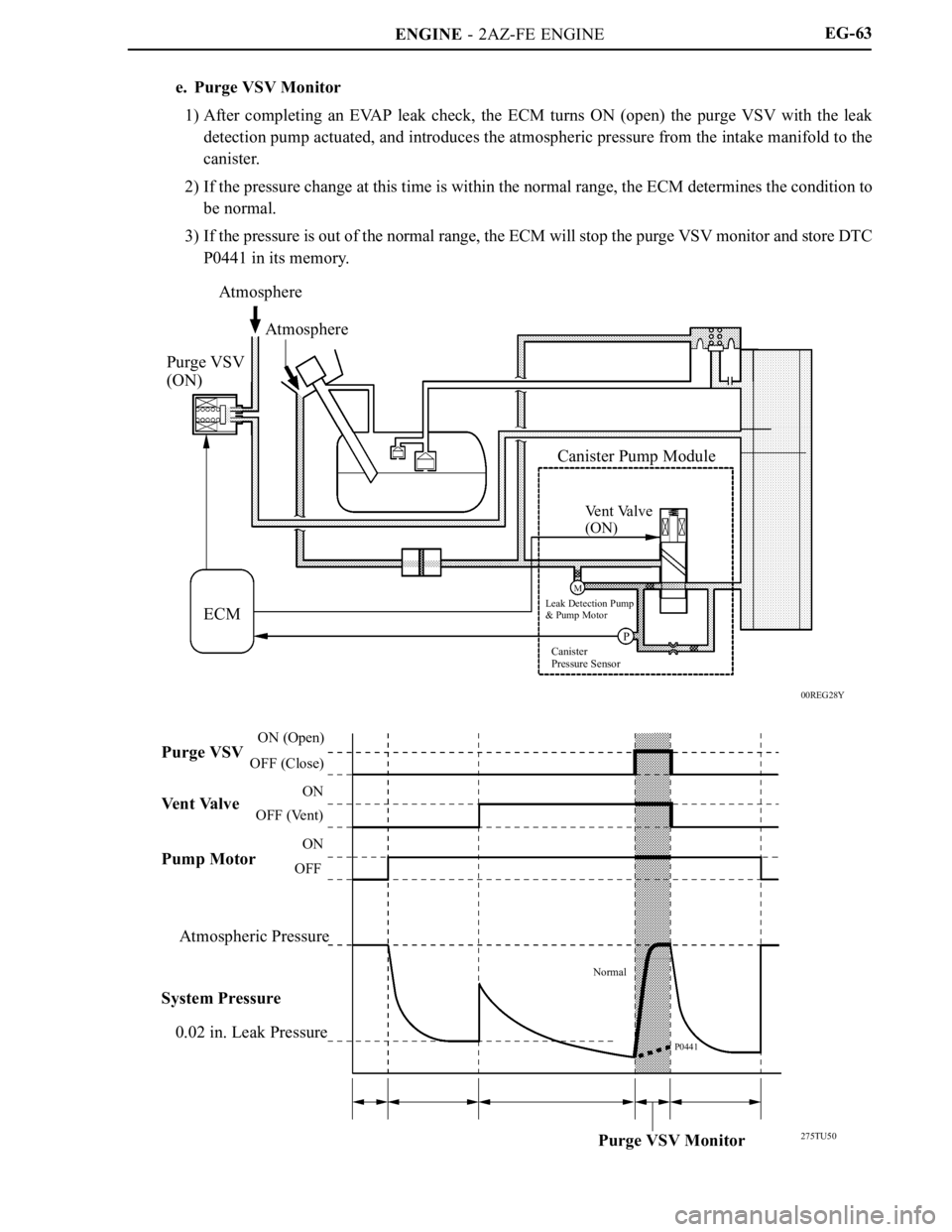

e. Purge VSV Monitor

1) After completing an EVAP leak check, the ECM turns ON (open) the purge VSV with the leak

detection pump actuated, and introduces the atmospheric pressure from the intake manifold to the

canister.

2) If the pressure change at this time is within the normal range, the ECM determines the condition to

be normal.

3) If the pressure is out of the normal range, the ECM will stop the purge VSV monitor and store DTC

P0441 in its memory.

Page 61 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG03Y

275TU51

Repeat 0.02 in. Leak Pressure Measurement Atmosphere

Purge VSV

(OFF)

ECMCanister Pump Module

Ve n t Va l v e

(OFF)

Leak Detection Pump

& Pump Motor

Canister Pressure

SensorReference Orifice

Purge VSV

Ve n t Va l v e

Pump Motor

System PressureON (Open)

OFF (Close)

ON

OFF (Vent)

ON

OFF

Atmospheric Pressure

0.02 in. Leak Pressure

P0456

Normal

M

P

EG-64

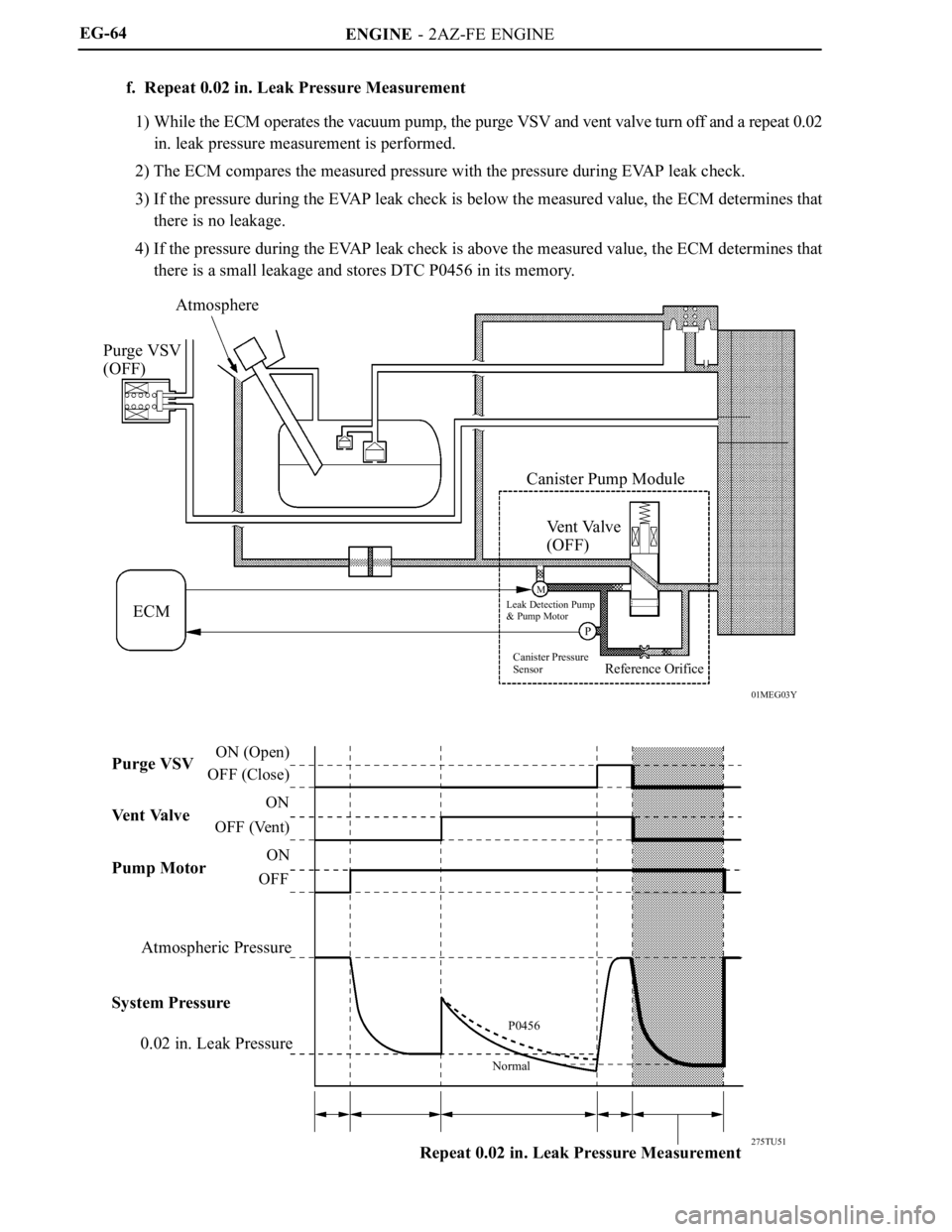

f. Repeat 0.02 in. Leak Pressure Measurement

1) While the ECM operates the vacuum pump, the purge VSV and vent valve turn off and a repeat 0.02

in. leak pressure measurement is performed.

2) The ECM compares the measured pressure with the pressure during EVAP leak check.

3) If the pressure during the EVAP leak check is below the measured value, the ECM determines that

there is no leakage.

4) If the pressure during the EVAP leak check is above the measured value, the ECM determines that

there is a small leakage and stores DTC P0456 in its memory.

Page 62 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG13Y

Generator

RegulatorB

DF

RLOECM

Various Electrical

Loads

Battery Current Sensor

Battery Temperature Sensor

Battery Voltage

Battery

Various Sensors and Switches

Throttle Position Sensor

Crankshaft Position Sensor

Accelerator Pedal Position

SensorEG-65

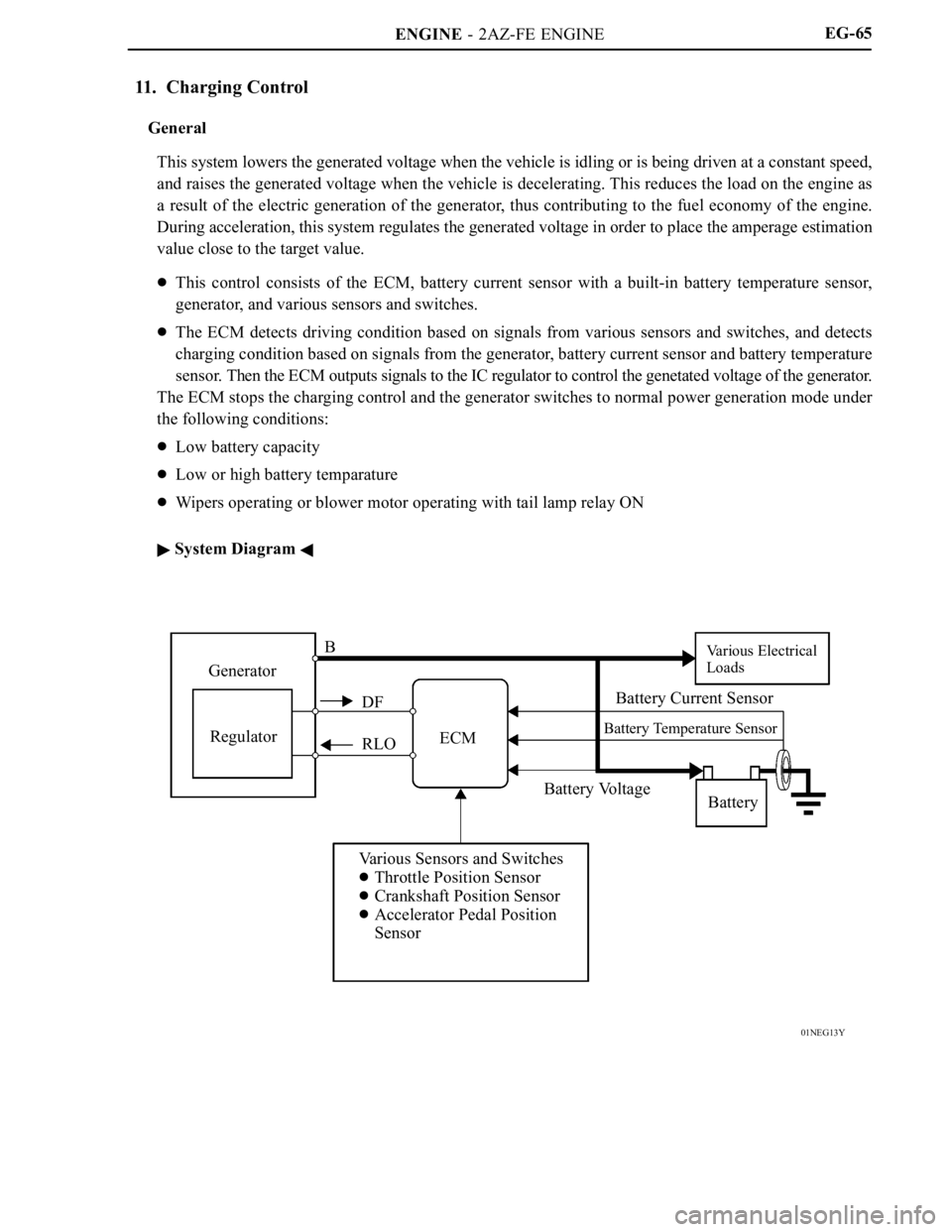

11. Charging Control

General

This system lowers the generated voltage when the vehicle is idling or is being driven at a constant speed,

and raises the generated voltage when the vehicle is decelerating. This reduces the load on the engine as

a result of the electric generation of the generator, thus contributing to the fuel economy of the engine.

During acceleration, this system regulates the generated voltage in order to place the amperage estimation

value close to the target value.

This control consists of the ECM, battery current sensor with a built-in battery temperature sensor,

generator, and various sensors and switches.

The ECM detects driving condition based on signals from various sensors and switches, and detects

charging condition based on signals from the generator, battery current sensor and battery temperature

sensor. Then the ECM outputs signals to the IC regulator to control the genetated voltage of the generator.

The ECM stops the charging control and the generator switches to normal power generation mode under

the following conditions:

Low battery capacity

Low or high battery temparature

Wipers operating or blower motor operating with tail lamp relay ON

System Diagram

Page 63 of 2000

ENGINE - 2AZ-FE ENGINE

258AS61 281EG86

Output

Voltage5 (V)

0

-100

Current+100 (A)

Characteristic of Current Sensor

288EG61C

(C) 60

Battery Temperature 0 Resistance(k

)

6 EG-66

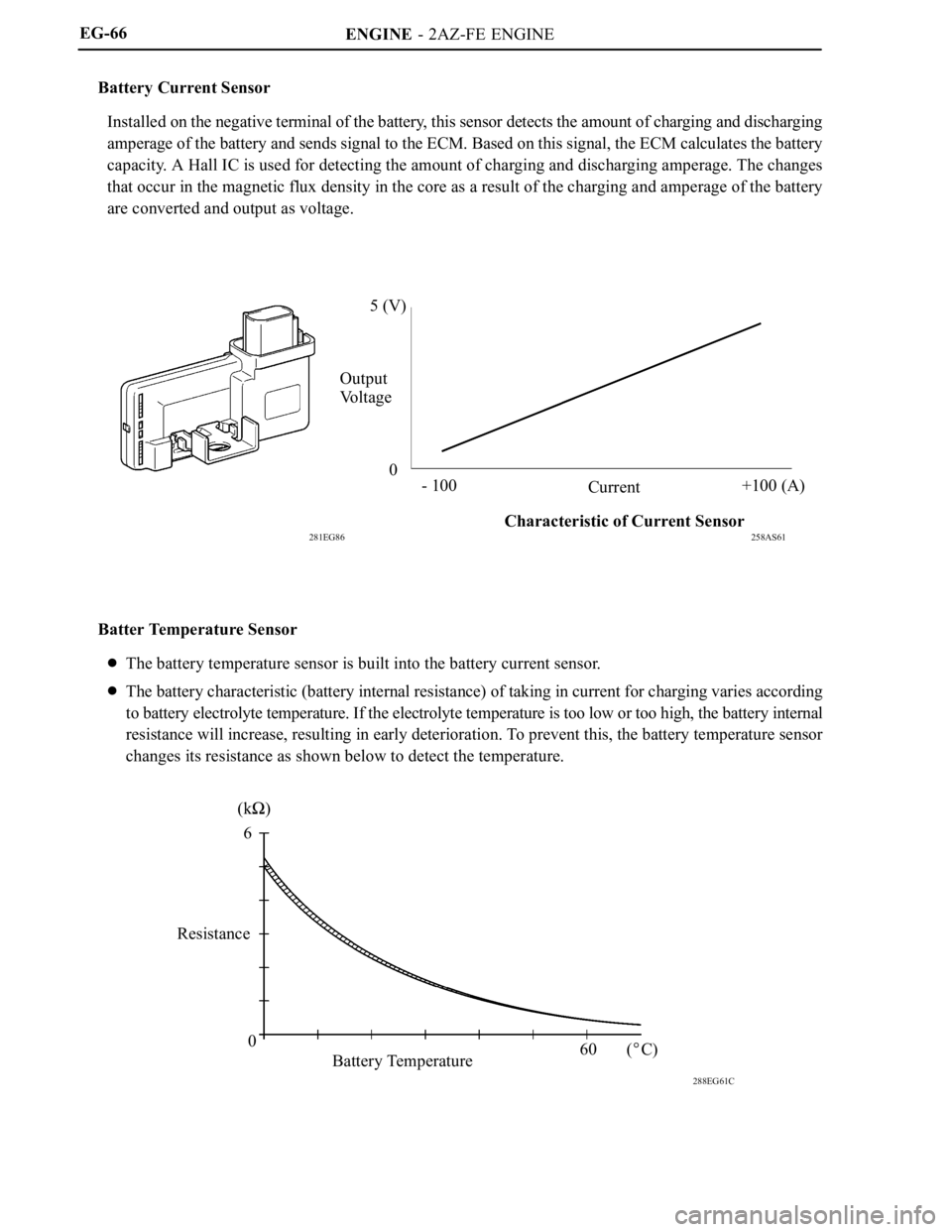

Battery Current Sensor

Installed on the negative terminal of the battery, this sensor detects the amount of charging and discharging

amperage of the battery and sends signal to the ECM. Based on this signal, the ECM calculates the battery

capacity. A Hall IC is used for detecting the amount of charging and discharging amperage. The changes

that occur in the magnetic flux density in the core as a result of the charging and amperage of the battery

are converted and output as voltage.

Batter Temperature Sensor

The battery temperature sensor is built into the battery current sensor.

The battery characteristic (battery internal resistance) of taking in current for charging varies according

to battery electrolyte temperature. If the electrolyte temperature is too low or too high, the battery internal

resistance will increase, resulting in early deterioration. To prevent this, the battery temperature sensor

changes its resistance as shown below to detect the temperature.

Page 64 of 2000

ENGINE - 2AZ-FE ENGINE

Service Tip

To clear the DTC that is stored in the ECM, use a hand-held tester or disconnect the battery terminal

or remove the EFI fuse for 1 minute or longer.

EG-67

Fail-safe

Due to a failure in the battery current sensor or battery temperature sensor, the ECM may determine the

necessity of performing a fail-safe operation. Then, the ECM stops the charging control and the generator

switches to the normal power generation mode.

When the ECM detects a malfunction in a sensor, the ECM memorizes the DTC (Diagnostic Trouble Code).

The MIL (Malfunction Indicator Lamp) does not illuminate.

DTC Chart

DTC No.Detection ItemDTC No.Detection Item

P0516Battery Temperature Sensor

Circuit LowP1551Battery Current Sensor

Circuit Low

P0517Battery Temperature Sensor

Circuit HighP1552Battery Current Sensor

Circuit High

P0560System VoltageP1602Detection of Battery

P1550Battery Current Sensor

Circuit

12. Diagnosis

When the ECM detects a malfunction, the ECM makes a diagnosis and memorizes the failed section.

Furthermore, the MIL in the combination meter illuminates or blinks to inform the driver.

The ECM will also store the DTCs of the malfunctions. The DTCs can be accessed by the use of the

hand-held tester.

For details, refer to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

13. Fail-safe

When a malfunction is detected at any of the sensors, there is a possibility of an engine or other malfunction

occurring if the ECM were to continue to control the engine control system in the normal way. To prevent

such a problem, the fail-safe function of the ECM either relies on the data stored in memory to allow the

engine control system to continue operating, or stops the engine if a hazard is anticipated. For details, refer

to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

Page 68 of 2000

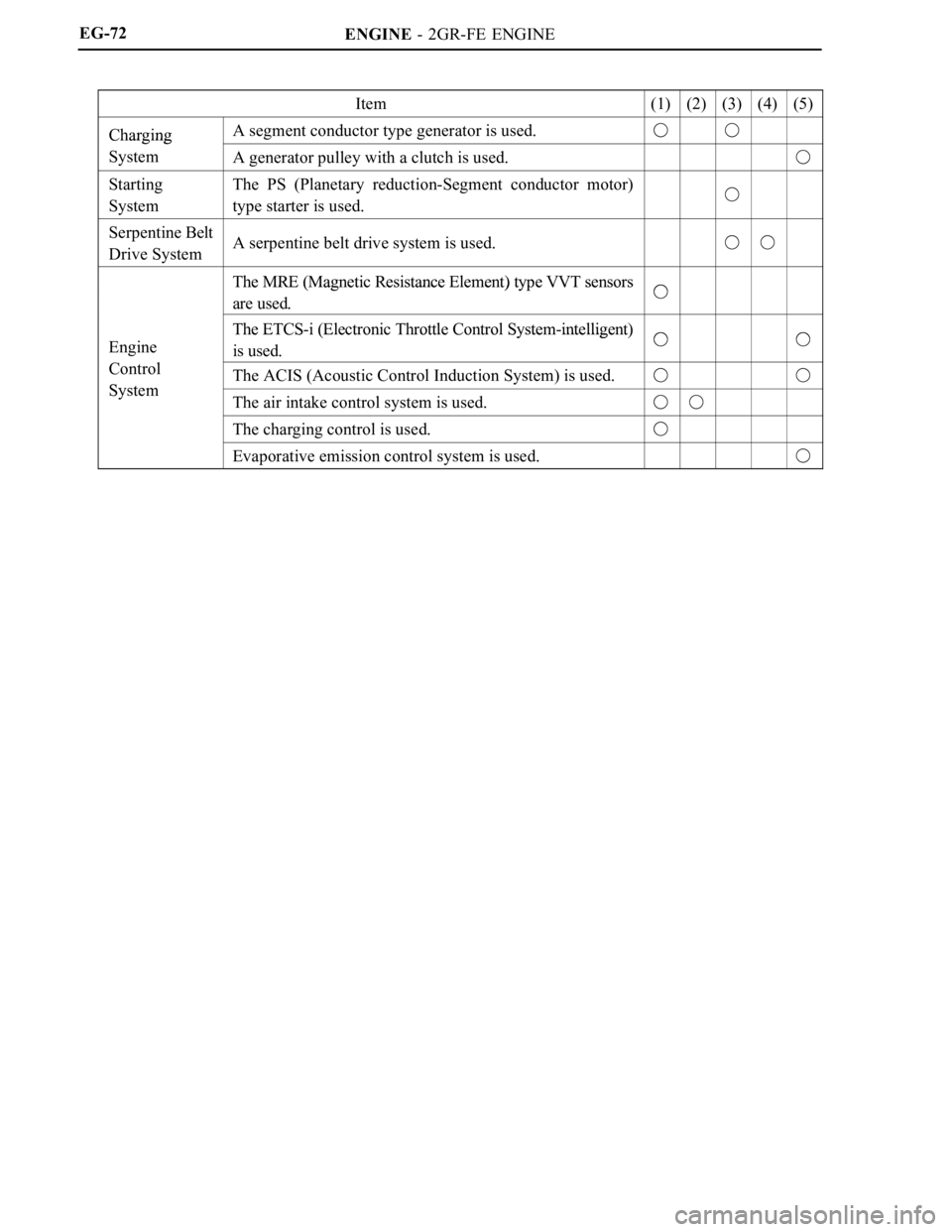

ENGINE - 2GR-FE ENGINE EG-72

Item

(1)(2)(3)(4)(5)

ChargingA segment conductor type generator is used.Charging

SystemA generator pulley with a clutch is used.

Starting

SystemThe PS (Planetary reduction-Segment conductor motor)

type starter is used.

Serpentine Belt

Drive SystemA serpentine belt drive system is used.

The MRE (Magnetic Resistance Element) type VVT sensorsThe MRE (Magnetic Resistance Element) type VVT sensors

are used.

The ETCS-i (Electronic Throttle Control System-intelligent)

Engine

The ETCS i (Electronic Throttle Control System intelligent)

is used.

Control

SystemThe ACIS (Acoustic Control Induction System) is used.SystemThe air intake control system is used.

The charging control is used.

Evaporative emission control system is used.

Page 71 of 2000

ENGINE - 2GR-FE ENGINE

285EG10 285EG09

60

Knock Sensor Bosses

36.6 mm

(1.441 in.)

105.5 mm

(4.15 in.)

View from Top Side

285EG11

Wa t e r P a s s a g eEG-75

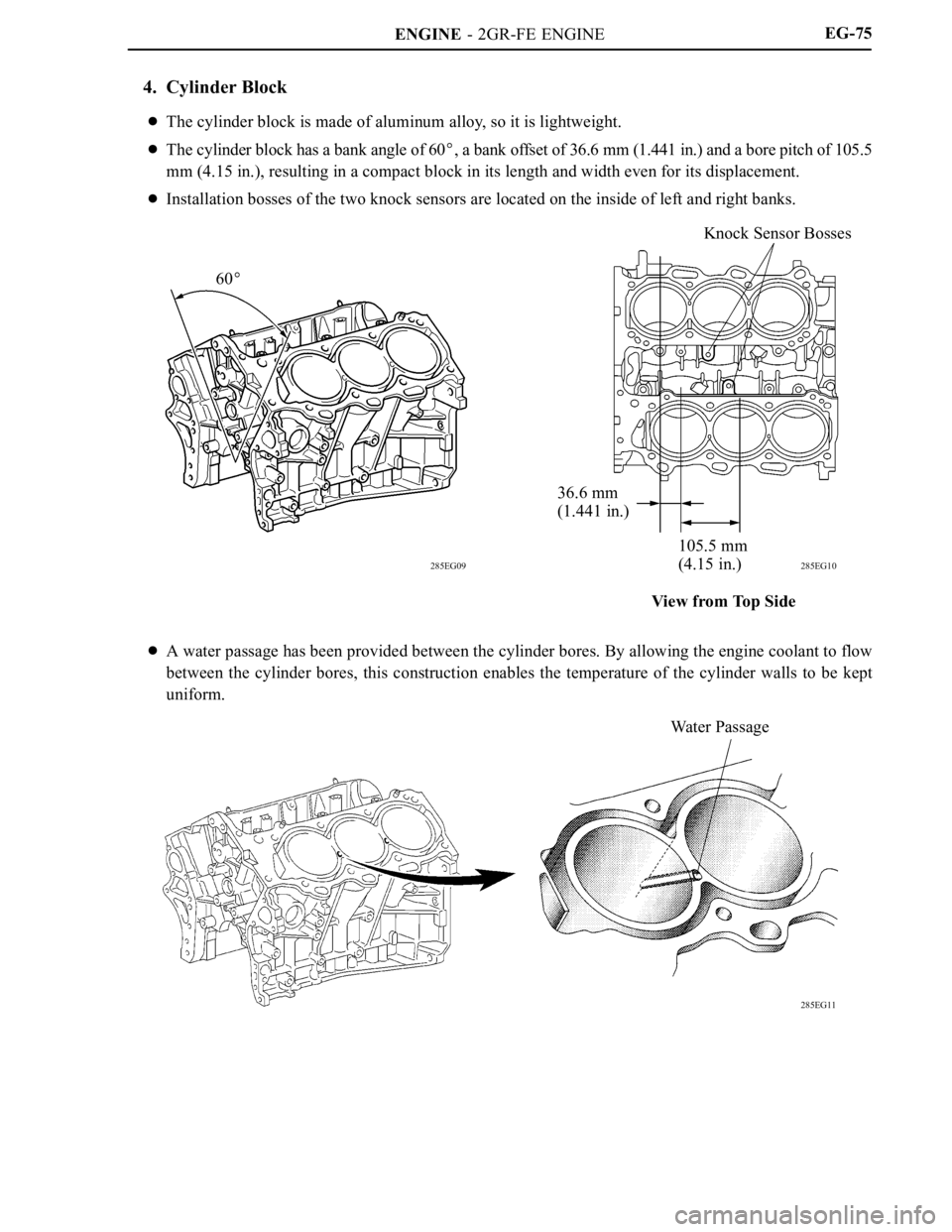

4. Cylinder Block

The cylinder block is made of aluminum alloy, so it is lightweight.

The cylinder block has a bank angle of 60, a bank offset of 36.6 mm (1.441 in.) and a bore pitch of 105.5

mm (4.15 in.), resulting in a compact block in its length and width even for its displacement.

Installation bosses of the two knock sensors are located on the inside of left and right banks.

A water passage has been provided between the cylinder bores. By allowing the engine coolant to flow

between the cylinder bores, this construction enables the temperature of the cylinder walls to be kept

uniform.

Page 87 of 2000

ENGINE - 2GR-FE ENGINE

01MEG13Y

Air Cleaner Hose with

Resonator

Air Cleaner Cap

Charcoal Filter

Air Cleaner Element

(Nonwoven Fabric)

Air Cleaner Case

Actuator

(For Air Intake Control)

Air Cleaner Inlet

Resonator

285EG32

Throttle Position Sensor

Throttle Control MotorEG-91

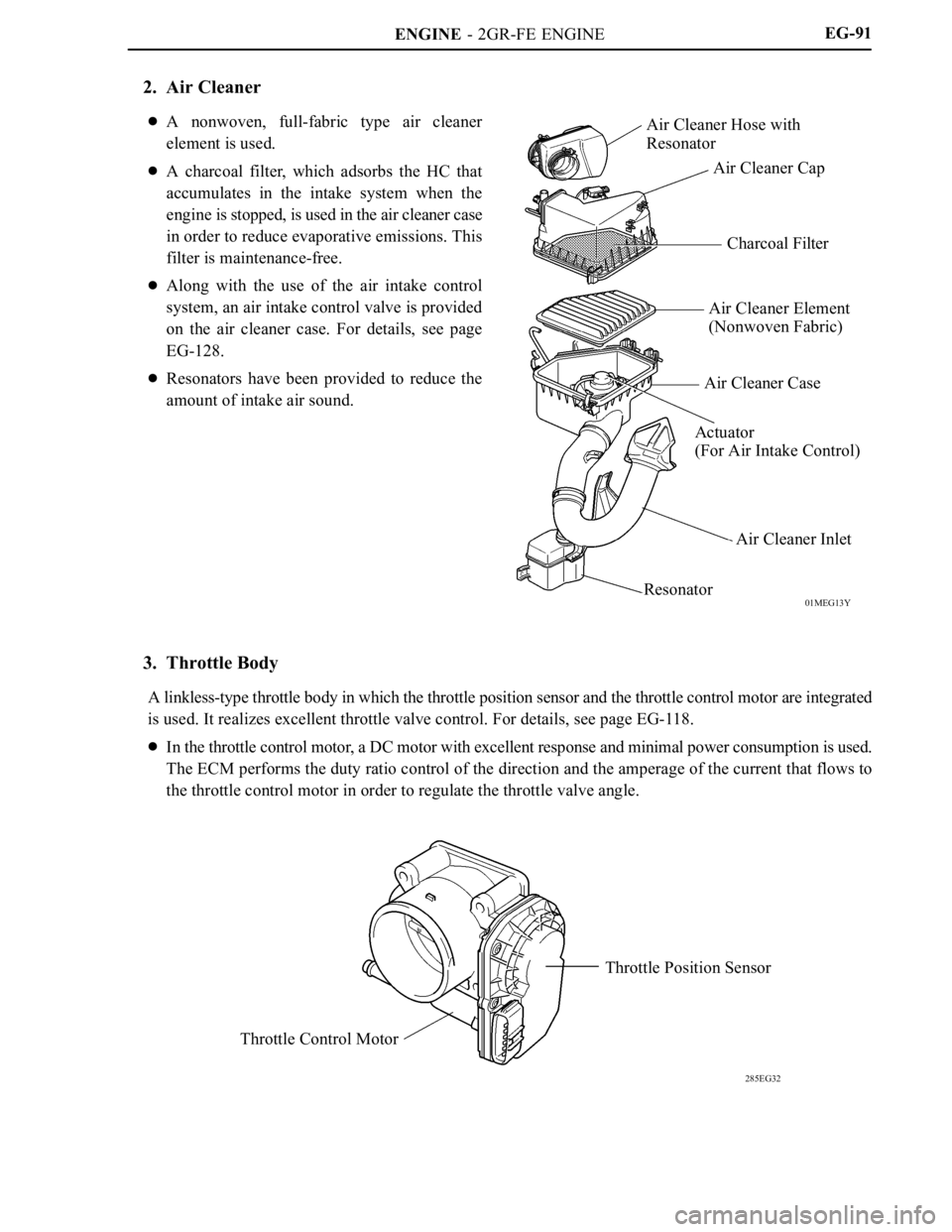

2. Air Cleaner

A nonwoven, full-fabric type air cleaner

element is used.

A charcoal filter, which adsorbs the HC that

accumulates in the intake system when the

engine is stopped, is used in the air cleaner case

in order to reduce evaporative emissions. This

filter is maintenance-free.

Along with the use of the air intake control

system, an air intake control valve is provided

on the air cleaner case. For details, see page

EG-128.

Resonators have been provided to reduce the

amount of intake air sound.

3. Throttle Body

A linkless-type throttle body in which the throttle position sensor and the throttle control motor are integrated

is used. It realizes excellent throttle valve control. For details, see page EG-118.

In the throttle control motor, a DC motor with excellent response and minimal power consumption is used.

The ECM performs the duty ratio control of the direction and the amperage of the current that flows to

the throttle control motor in order to regulate the throttle valve angle.

Page 92 of 2000

ENGINE - 2GR-FE ENGINE

238EG68

VVT Sensors

Crankshaft

Position

Sensor

Va r i o u s

SensorsVV1

VV2

NE

ECMIGT1

IGT2

IGT3

IGT4

IGT5

IGT6

IGF+B Ignition Coil (with Igniter)

No. 1 Cylinder

No. 2 Cylinder

No. 3 Cylinder

No. 4 Cylinder

No. 5 Cylinder

No. 6 Cylinder

285EG39

Igniter

Iron Core

Secondary

Coil

Primary Coil

Plug Cap EG-96

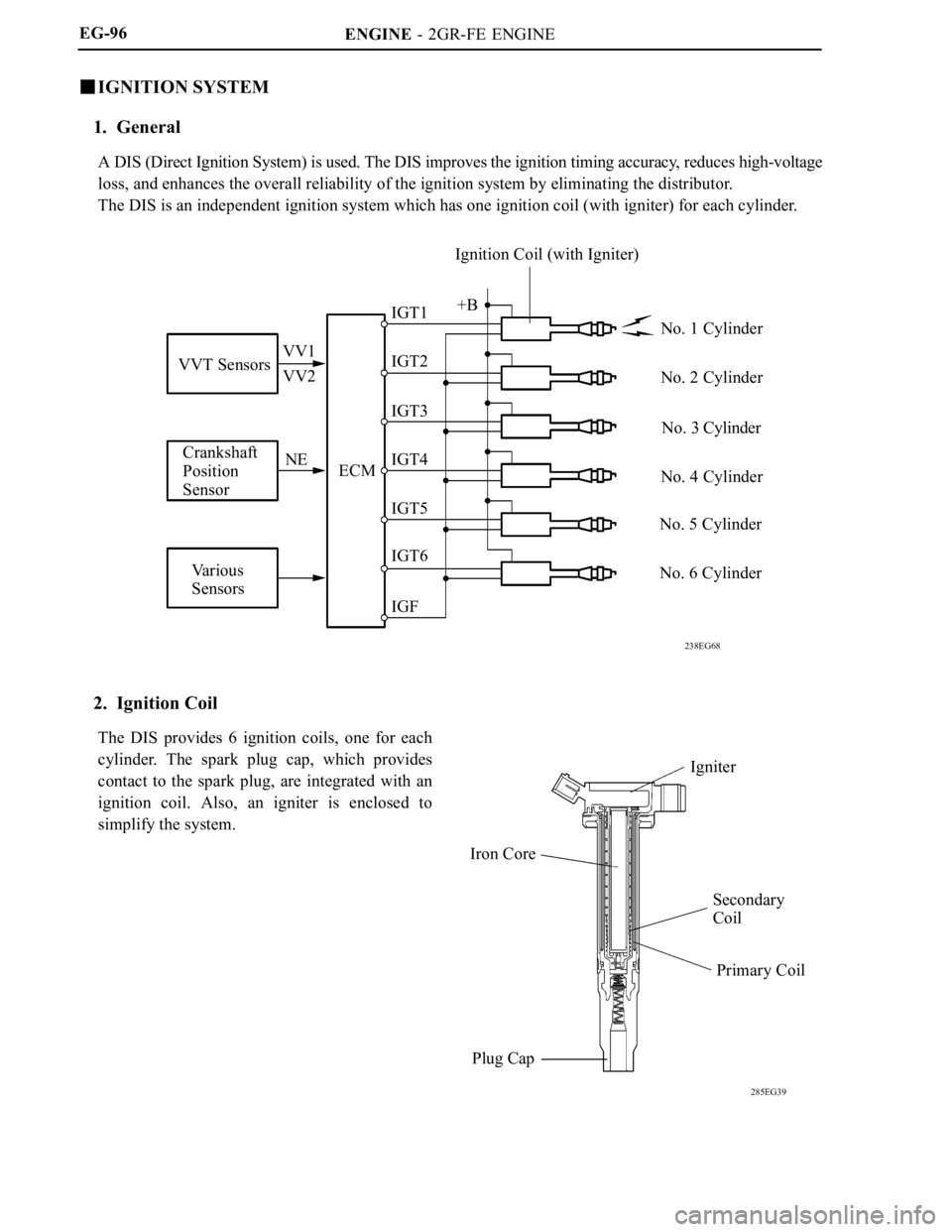

IGNITION SYSTEM

1. General

A DIS (Direct Ignition System) is used. The DIS improves the ignition timing accuracy, reduces high-voltage

loss, and enhances the overall reliability of the ignition system by eliminating the distributor.

The DIS is an independent ignition system which has one ignition coil (with igniter) for each cylinder.

2. Ignition Coil

The DIS provides 6 ignition coils, one for each

cylinder. The spark plug cap, which provides

contact to the spark plug, are integrated with an

ignition coil. Also, an igniter is enclosed to

simplify the system.

Page 97 of 2000

ENGINE - 2GR-FE ENGINEEG-101

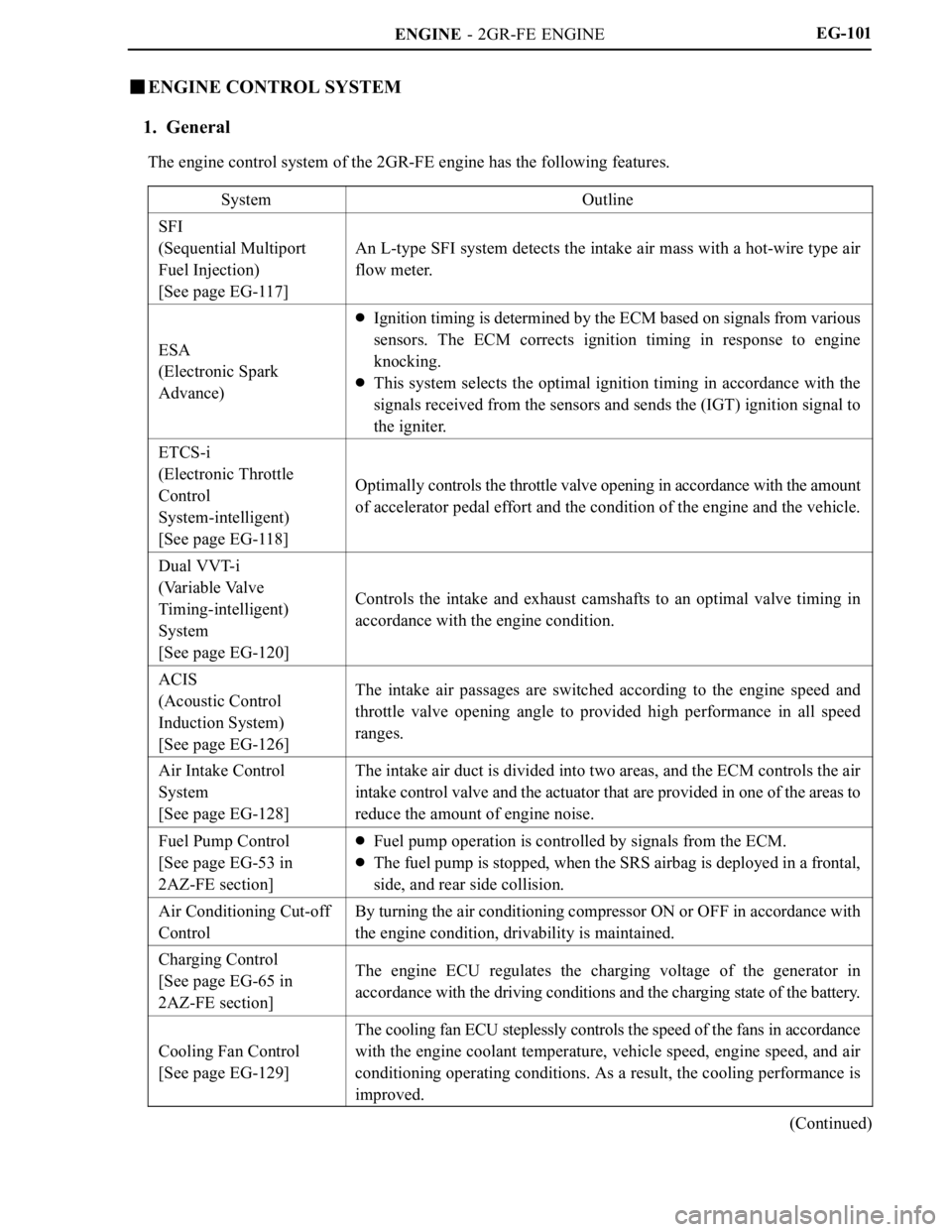

ENGINE CONTROL SYSTEM

1. General

The engine control system of the 2GR-FE engine has the following features.

System

Outline

SFI

(Sequential Multiport

Fuel Injection)

[See page EG-117]

An L-type SFI system detects the intake air mass with a hot-wire type air

flow meter.

ESA

(Electronic Spark

Advance)

Ignition timing is determined by the ECM based on signals from various

sensors. The ECM corrects ignition timing in response to engine

knocking.

This system selects the optimal ignition timing in accordance with the

signals received from the sensors and sends the (IGT) ignition signal to

the igniter.

ETCS-i

(Electronic Throttle

Control

System-intelligent)

[See page EG-118]

Optimally controls the throttle valve opening in accordance with the amount

of accelerator pedal effort and the condition of the engine and the vehicle.

Dual VVT-i

(Variable Valve

Timing-intelligent)

System

[See page EG-120]

Controls the intake and exhaust camshafts to an optimal valve timing in

accordance with the engine condition.

ACIS

(Acoustic Control

Induction System)

[See page EG-126]The intake air passages are switched according to the engine speed and

throttle valve opening angle to provided high performance in all speed

ranges.

Air Intake Control

System

[See page EG-128]The intake air duct is divided into two areas, and the ECM controls the air

intake control valve and the actuator that are provided in one of the areas to

reduce the amount of engine noise.

Fuel Pump Control

[See page EG-53 in

2AZ-FE section]Fuel pump operation is controlled by signals from the ECM.

The fuel pump is stopped, when the SRS airbag is deployed in a frontal,

side, and rear side collision.

Air Conditioning Cut-off

ControlBy turning the air conditioning compressor ON or OFF in accordance with

the engine condition, drivability is maintained.

Charging Control

[See page EG-65 in

2AZ-FE section]The engine ECU regulates the charging voltage of the generator in

accordance with the driving conditions and the charging state of the battery.

Cooling Fan Control

[See page EG-129]

The cooling fan ECU steplessly controls the speed of the fans in accordance

with the engine coolant temperature, vehicle speed, engine speed, and air

conditioning operating conditions. As a result, the cooling performance is

improved.

(Continued)