sensor TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1352 of 2000

TF–24GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

DESCRIPTION

If a malfunction in the power source circuit occurs, or a malfunction in communication with the skid control

ECU or in a speed sensor occurs, the 4WD control ECU will prohibit operations by the fail-safe function.

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Check the condition of each related circuit connector before troubleshooting (see page IN-37).

DTC C1241/94 Low Power Supply Voltage

DTC No. DTC Detection Condition Trouble Area

C1241/94 When one of following conditions is met:

1. When following continues for 10 seconds

or more:

- At a vehicle speed of 3 km/h (2 mph) or

more, voltage of IG1 terminal is 9.5 V or

less.

2. When both of following continue for 60

seconds or more:

- With the voltage of IG1 terminal 9.5 V or

less, communication with the skid control

ECU cannot be performed.

- A malfunction in communication with

skid control ECU.

3. When following continue for 3 seconds or

more:

- With the voltage of IG1 terminal 9.5 V or

more, communication with the skid control

ECU cannot be performed.•Battery

• Generator

•ECU-IG1

• Wire harness (IG1 circuit, GND circuit)

• 4WD control ECU

C128626E02

Page 1353 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–25

TF

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch ON and check that no CAN

communication system DTC is output.

(c) Start the engine.

(d) Drive the vehicle, accelerate to a speed of 3 km/h (2

mph) or more, and check that no speed sensor DTC

(brake control system DTC) is output (see page BC-57).

Result

B

C

A

(a) Remove the ECU-IG1 fuse from the instrument junction

block

(b) Measure the resistance of the fuse.

Standard resistance:

Below 1

HINT:

Check for short circuits in all harnesses and connector

connected to the ECU-IG1 fuse (see page IN-5).

NG

OK

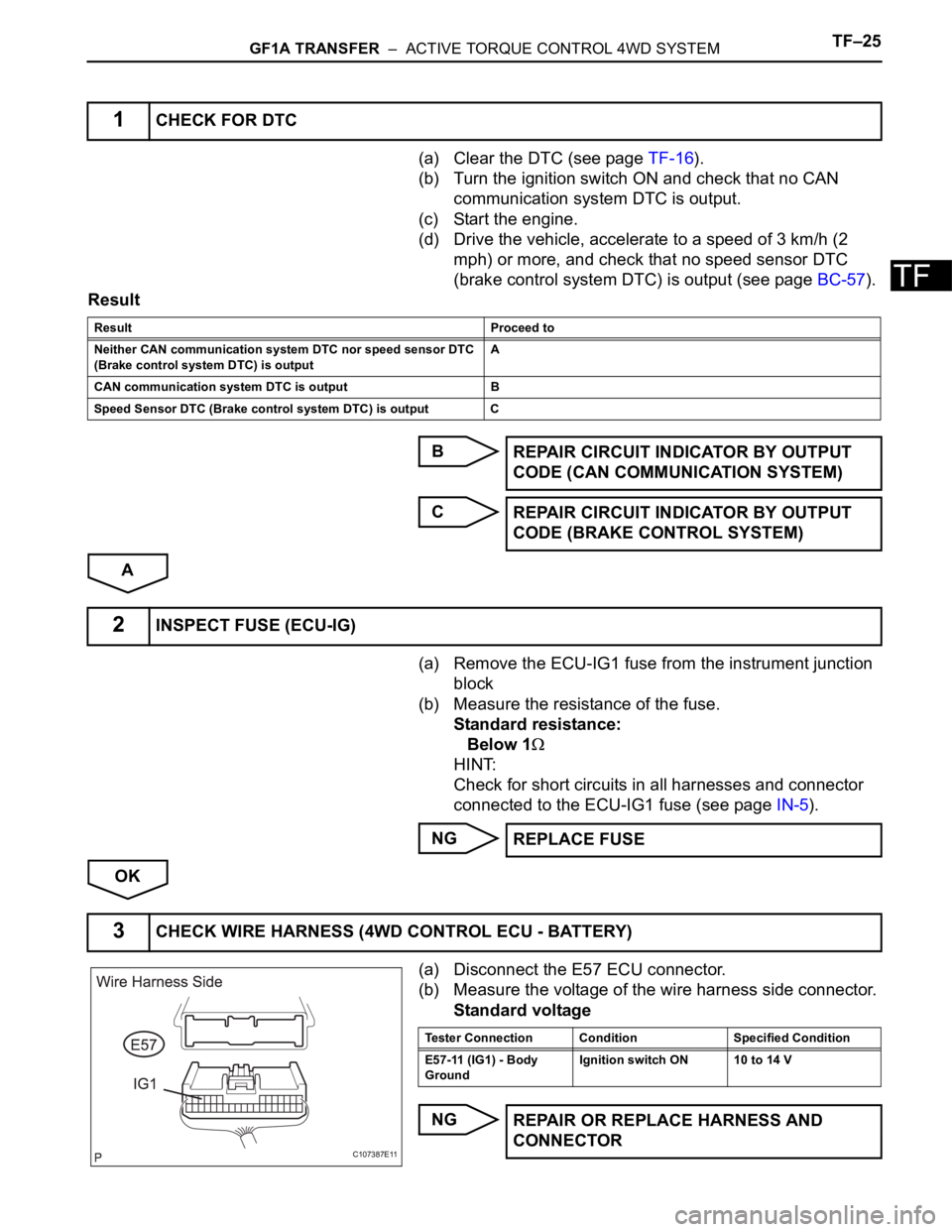

(a) Disconnect the E57 ECU connector.

(b) Measure the voltage of the wire harness side connector.

Standard voltage

NG

1CHECK FOR DTC

Result Proceed to

Neither CAN communication system DTC nor speed sensor DTC

(Brake control system DTC) is outputA

CAN communication system DTC is output B

Speed Sensor DTC (Brake control system DTC) is output C

REPAIR CIRCUIT INDICATOR BY OUTPUT

CODE (CAN COMMUNICATION SYSTEM)

REPAIR CIRCUIT INDICATOR BY OUTPUT

CODE (BRAKE CONTROL SYSTEM)

2INSPECT FUSE (ECU-IG)

REPLACE FUSE

3CHECK WIRE HARNESS (4WD CONTROL ECU - BATTERY)

C107387E11

Tester Connection Condition Specified Condition

E57-11 (IG1) - Body

GroundIgnition switch ON 10 to 14 V

REPAIR OR REPLACE HARNESS AND

CONNECTOR

Page 1354 of 2000

TF–26GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

OK

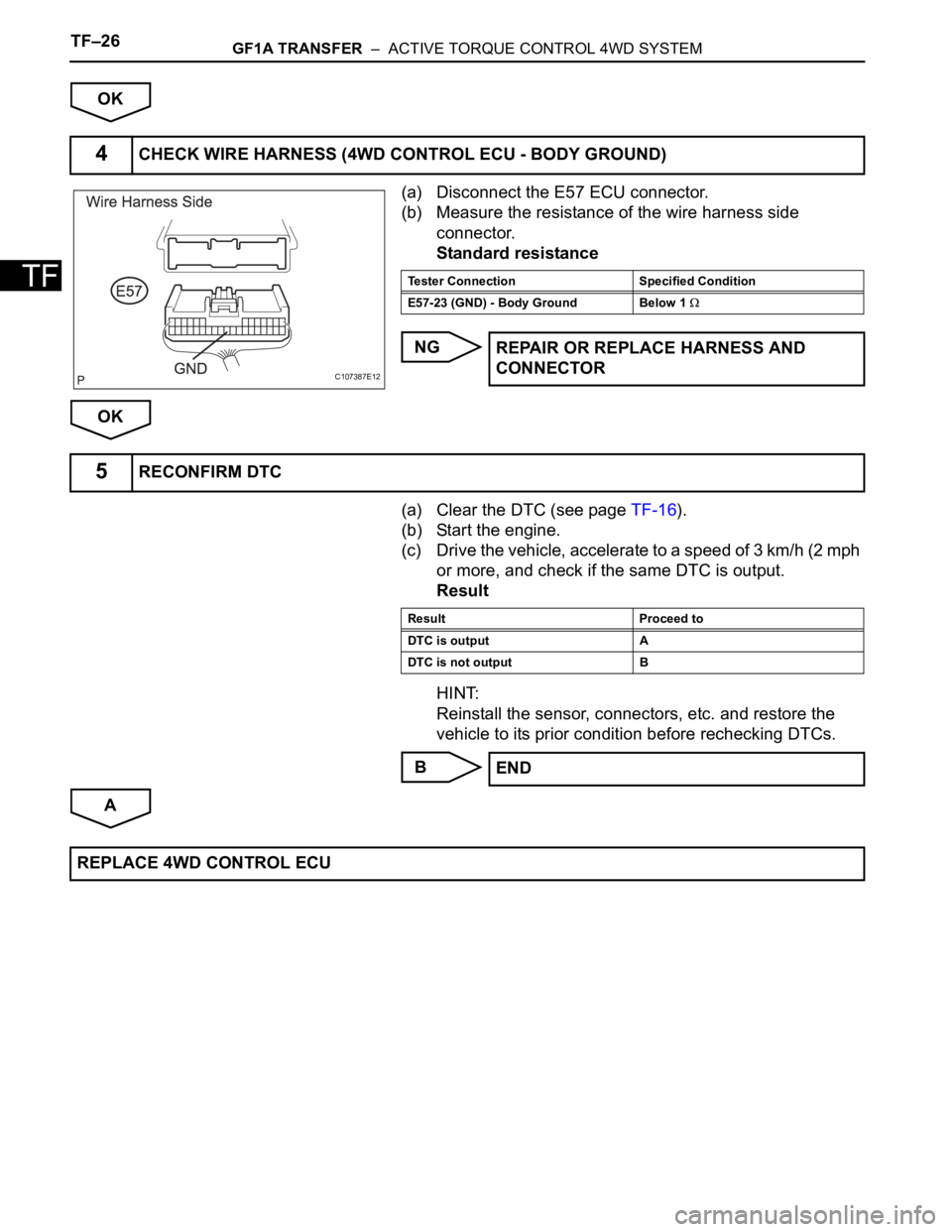

(a) Disconnect the E57 ECU connector.

(b) Measure the resistance of the wire harness side

connector.

Standard resistance

NG

OK

(a) Clear the DTC (see page TF-16).

(b) Start the engine.

(c) Drive the vehicle, accelerate to a speed of 3 km/h (2 mph

or more, and check if the same DTC is output.

Result

HINT:

Reinstall the sensor, connectors, etc. and restore the

vehicle to its prior condition before rechecking DTCs.

B

A

4CHECK WIRE HARNESS (4WD CONTROL ECU - BODY GROUND)

C107387E12

Tester Connection Specified Condition

E57-23 (GND) - Body Ground Below 1

REPAIR OR REPLACE HARNESS AND

CONNECTOR

5RECONFIRM DTC

Result Proceed to

DTC is output A

DTC is not output B

END

REPLACE 4WD CONTROL ECU

Page 1355 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–27

TF

DESCRIPTION

If a malfunction in the engine control ECU circuit occurs, the 4WD control ECU will output this DTC.

INSPECTION PROCEDURE

HINT:

Check the condition of each related circuit connector before troubleshooting (see page IN-37).

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch OFF.

(c) Turn the ignition switch ON and check that can

communication system DTC is not output.

Result

B

A

DTC C1280/82 Engine Circuit Malfunction

DTC No. DTC Detection Condition Trouble Area

C1280/82 When the following continues for 5 seconds

or more:

- Communication with engine control ECU is

operating normally, but throttle position

sensor is malfunctioning.• Throttle position sensor

• Throttle position sensor wire harness and

connector

• CAN communication system

1CHECK FOR DTC

Result Proceed to

CAN communication system DTC is

outputA

Engine control DTC is output B

GO TO ENGINE CONTROL SYSTEM

GO TO CAN COMMUNICATION SYSTEM

Page 1356 of 2000

TF–28GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

DESCRIPTION

If a malfunction in the speed sensor signal circuit yaw rate sensor circuit occurs, the 4WD control ECU will

output this DTC.

INSPECTION PROCEDURE

HINT:

Check the condition of each related circuit connector before troubleshooting (see page IN-37).

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch OFF.

(c) Turn the ignition switch ON again and check that CAN

communication system DTC(s) is not output.

(d) Drive the vehicle, accelerate to a speed of 20 km/h (12

mph) or more, and check if the speed sensor DTC (brake

control system DTC) is output (see page BC-57).

Result

HINT:

When DTCs indicating a CAN communication system

malfunction are output, repair the CAN communication

system before repairing each corresponding sensor.

B

C

A

(a) Replace the 4WD control ECU with a normally

functioning or new one.

(b) Reconfirm DTC.

DTC C1296/96 ABS Malfunction

DTC No. DTC Detection Condition Trouble Area

C1296/96 When either condition below is met:

1. Wheel speed sensor malfunction is

received from skid control ECU

2. Deceleration sensor malfunction us

received from skid control ECU• CAN communication line

• Skid control ECU

• Speed sensor

• 4WD control ECU

• Yaw rate sensor

• Wire harness

1CHECK FOR DTC

Result Proceed to

Neither CAN communication system

DTC nor brake control system DTC is

out putA

CAN communication system DTC is

outputB

Brake control system DTC (speed

sensor DTC) is outputC

REPAIR CIRCUIT INDICATOR BY OUTPUT

CODE (CAN COMMUNICATION SYSTEM)

REPAIR CIRCUIT INDICATOR BY OUTPUT

CODE (BRAKE CONTROL SYSTEM)

2CHECK OPERATION OF 4WD CONTROL ECU

Page 1358 of 2000

TF–30GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

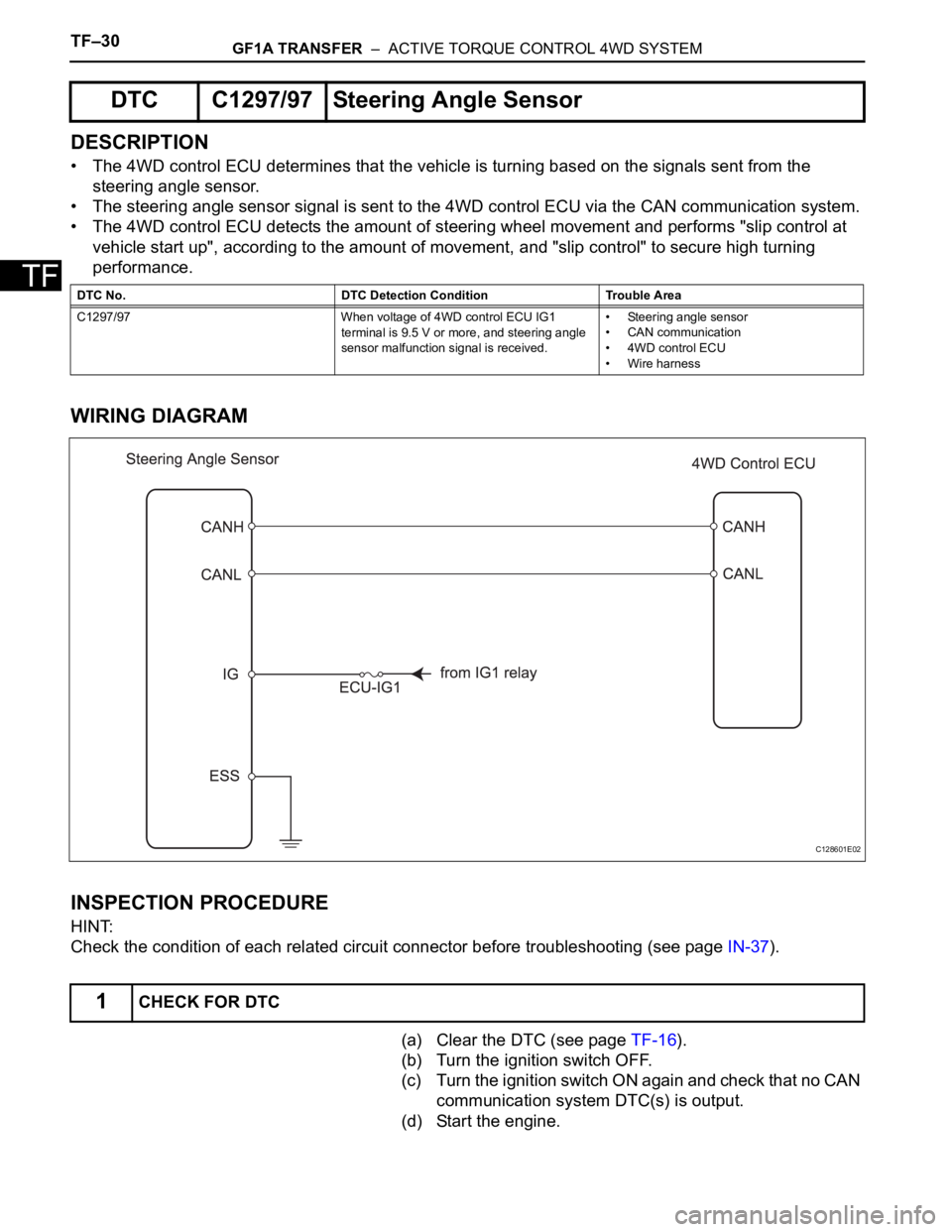

DESCRIPTION

• The 4WD control ECU determines that the vehicle is turning based on the signals sent from the

steering angle sensor.

• The steering angle sensor signal is sent to the 4WD control ECU via the CAN communication system.

• The 4WD control ECU detects the amount of steering wheel movement and performs "slip control at

vehicle start up", according to the amount of movement, and "slip control" to secure high turning

performance.

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Check the condition of each related circuit connector before troubleshooting (see page IN-37).

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch OFF.

(c) Turn the ignition switch ON again and check that no CAN

communication system DTC(s) is output.

(d) Start the engine.

DTC C1297/97 Steering Angle Sensor

DTC No. DTC Detection Condition Trouble Area

C1297/97 When voltage of 4WD control ECU IG1

terminal is 9.5 V or more, and steering angle

sensor malfunction signal is received.• Steering angle sensor

• CAN communication

• 4WD control ECU

• Wire harness

1CHECK FOR DTC

C128601E02

Page 1359 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–31

TF

(e) Drive the vehicle and turn the steering wheel to the right

and left at a speed of 35 km/h (24 mph) and check that

no brake control system (steering angle sensor) DTC

(C1231/31) is output (see page BC-57).

Result

HINT:

When DTCs indicating a CAN communication system

malfunction are output, repair the CAN communication

system before repairing each corresponding sensor.

B

C

A

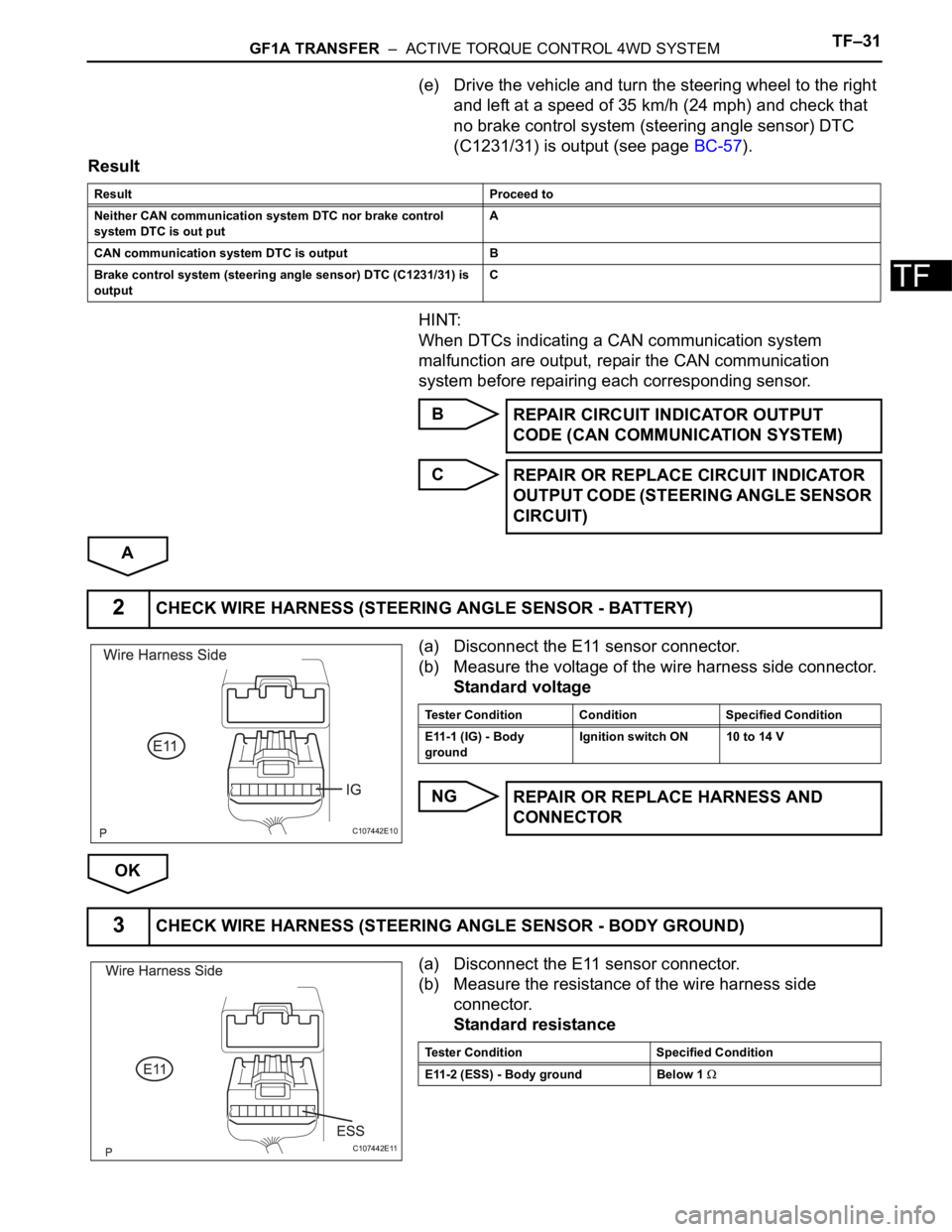

(a) Disconnect the E11 sensor connector.

(b) Measure the voltage of the wire harness side connector.

Standard voltage

NG

OK

(a) Disconnect the E11 sensor connector.

(b) Measure the resistance of the wire harness side

connector.

Standard resistance

Result Proceed to

Neither CAN communication system DTC nor brake control

system DTC is out putA

CAN communication system DTC is output B

Brake control system (steering angle sensor) DTC (C1231/31) is

output C

REPAIR CIRCUIT INDICATOR OUTPUT

CODE (CAN COMMUNICATION SYSTEM)

REPAIR OR REPLACE CIRCUIT INDICATOR

OUTPUT CODE (STEERING ANGLE SENSOR

CIRCUIT)

2CHECK WIRE HARNESS (STEERING ANGLE SENSOR - BATTERY)

C107442E10

Tester Condition Condition Specified Condition

E11-1 (IG) - Body

groundIgnition switch ON 10 to 14 V

REPAIR OR REPLACE HARNESS AND

CONNECTOR

3CHECK WIRE HARNESS (STEERING ANGLE SENSOR - BODY GROUND)

C107442E11

Tester Condition Specified Condition

E11-2 (ESS) - Body ground Below 1

Page 1360 of 2000

TF–32GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

Result

B

C

A

Result Proceed to

OK (When troubleshooting according to PROBLEM SYMPTOMS

TABLE)A

OK (When troubleshooting according to DTC chart) B

NG C

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

REPAIR OR REPLACE HARNESS AND

CONNECTOR

REPLACE STEERING ANGLE SENSOR

Page 1361 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–33

TF

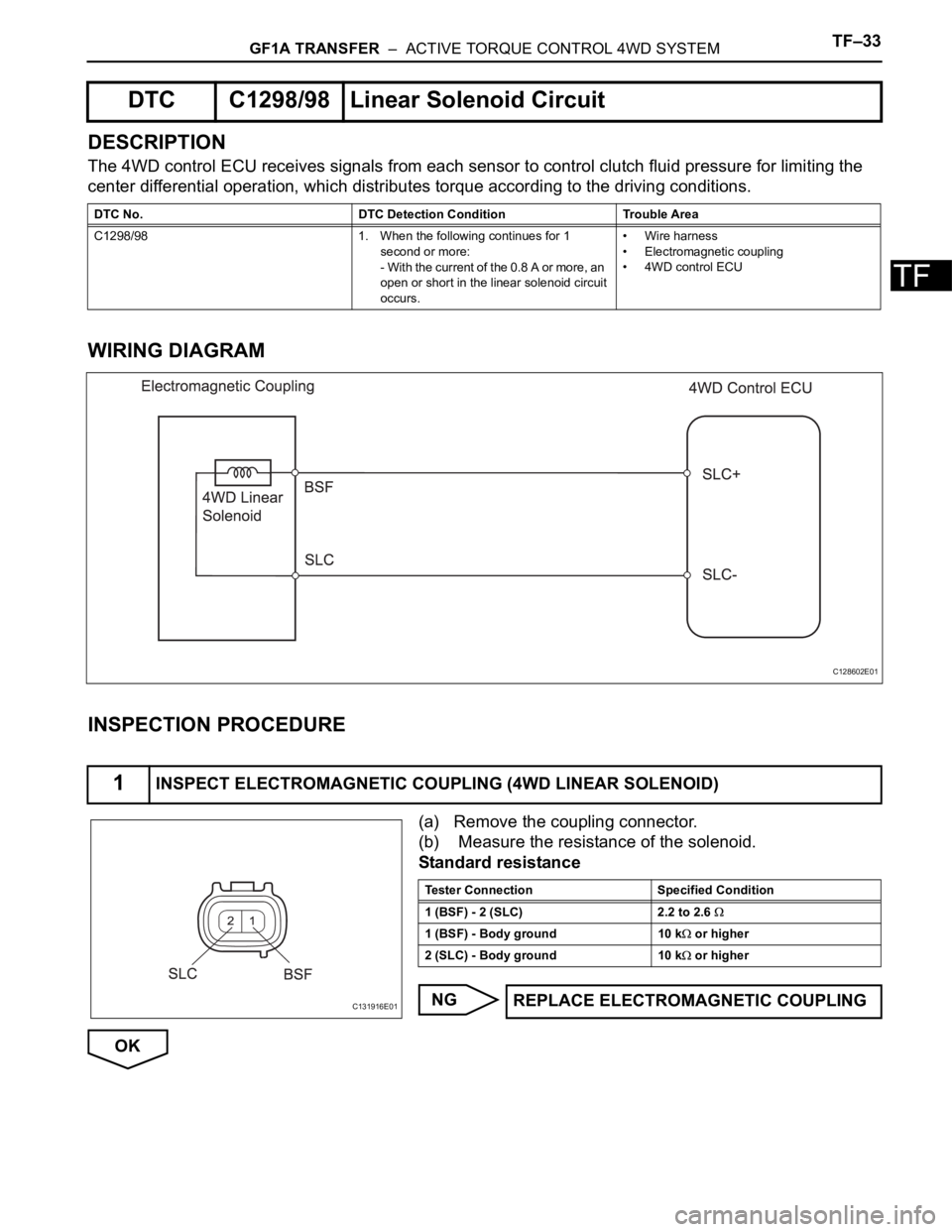

DESCRIPTION

The 4WD control ECU receives signals from each sensor to control clutch fluid pressure for limiting the

center differential operation, which distributes torque according to the driving conditions.

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) Remove the coupling connector.

(b) Measure the resistance of the solenoid.

Standard resistance

NG

OK

DTC C1298/98 Linear Solenoid Circuit

DTC No. DTC Detection Condition Trouble Area

C1298/98 1. When the following continues for 1

second or more:

- With the current of the 0.8 A or more, an

open or short in the linear solenoid circuit

occurs.• Wire harness

• Electromagnetic coupling

• 4WD control ECU

1INSPECT ELECTROMAGNETIC COUPLING (4WD LINEAR SOLENOID)

C128602E01

C131916E01

Tester Connection Specified Condition

1 (BSF) - 2 (SLC) 2.2 to 2.6

1 (BSF) - Body ground 10 k or higher

2 (SLC) - Body ground 10 k

or higher

REPLACE ELECTROMAGNETIC COUPLING

Page 1363 of 2000

DRIVE SHAFT – FRONT DRIVE SHAFT ASSEMBLY (for 2WD)DS–7

DS

REMOVAL

(2005/11-2006/01)

1. REMOVE FRONT WHEEL

2. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Drain the automatic transaxle fluid for U140F (see

page AX-147).

(b) Drain the automatic transaxle fluid for U241E (see

page AX-146).

3. REMOVE FRONT AXLE HUB NUT (See page AH-6)

4. DISCONNECT FRONT SPEED SENSOR LH

(a) Disconnect the speed sensor (see page BC-191).

5. DISCONNECT FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

6. DISCONNECT FRONT DISC BRAKE CYLINDER

ASSEMBLY LH (See page BR-40)

7. DISCONNECT FRONT DISC BRAKE CALIPER

ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

8. REMOVE FRONT STABILIZER LINK ASSEMBLY LH

(See page SP-30)

9. REMOVE FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

10. DISCONNECT FRONT SUSPENSION LOWER NO. 1

ARM SUB-ASSEMBLY LH (See page AH-7)

11. DISCONNECT FRONT SUSPENSION LOWER NO. 1

ARM SUB-ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

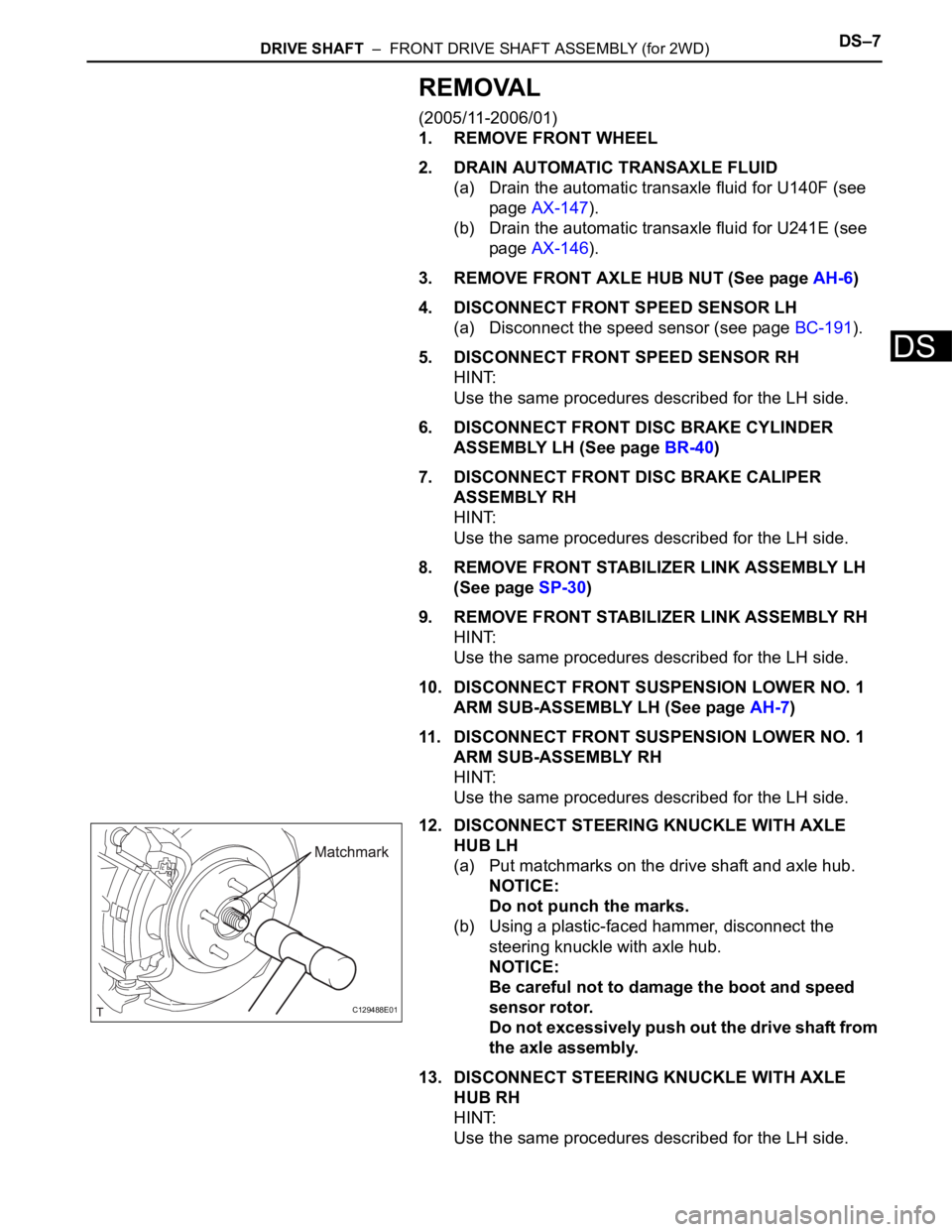

12. DISCONNECT STEERING KNUCKLE WITH AXLE

HUB LH

(a) Put matchmarks on the drive shaft and axle hub.

NOTICE:

Do not punch the marks.

(b) Using a plastic-faced hammer, disconnect the

steering knuckle with axle hub.

NOTICE:

Be careful not to damage the boot and speed

sensor rotor.

Do not excessively push out the drive shaft from

the axle assembly.

13. DISCONNECT STEERING KNUCKLE WITH AXLE

HUB RH

HINT:

Use the same procedures described for the LH side.

C129488E01