check engine TOYOTA RAV4 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 341 of 2000

CH–62AZ-FE CHARGING – CHARGING SYSTEM

CH

8. INSPECT CHARGING CIRCUIT WITH LOAD

(a) With the engine running at 2,000 rpm, turn the high

beam headlights ON and turn the heater blower

switch to the "HI" position.

(b) Check the reading on the ammeter.

Standard amperage:

30 A or more

If the ammeter reading is less than the standard

amperage, repair the generator.

HINT:

If the battery is fully charged, the indication will

sometimes be less than the standard amperage. If

this is the case, add more electrical load (operate

the wipers, rear window defogger, etc.) and check

the reading on the ammeter again.

Page 440 of 2000

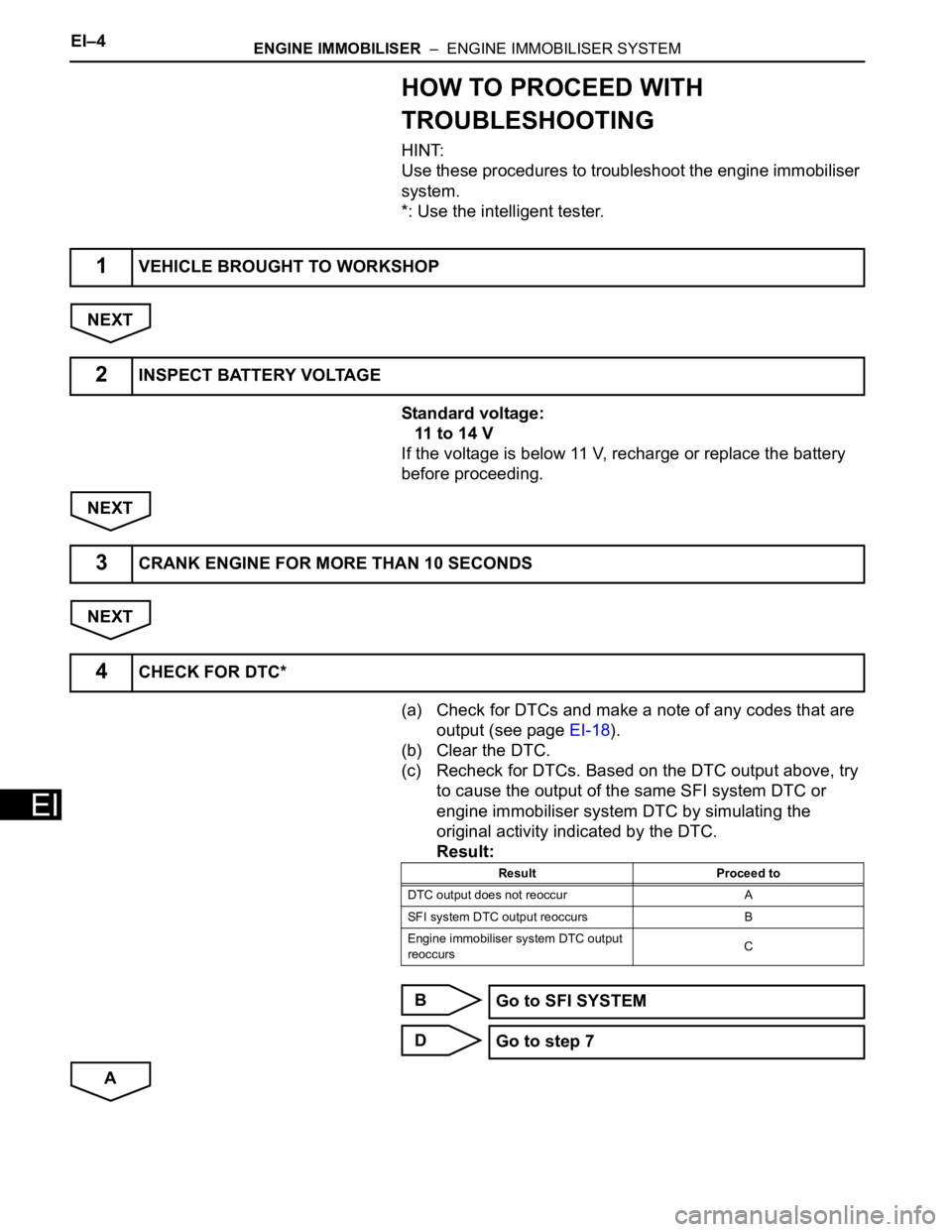

EI–4ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM

EI

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

Use these procedures to troubleshoot the engine immobiliser

system.

*: Use the intelligent tester.

NEXT

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery

before proceeding.

NEXT

NEXT

(a) Check for DTCs and make a note of any codes that are

output (see page EI-18).

(b) Clear the DTC.

(c) Recheck for DTCs. Based on the DTC output above, try

to cause the output of the same SFI system DTC or

engine immobiliser system DTC by simulating the

original activity indicated by the DTC.

Result:

B

D

A

1VEHICLE BROUGHT TO WORKSHOP

2INSPECT BATTERY VOLTAGE

3CRANK ENGINE FOR MORE THAN 10 SECONDS

4CHECK FOR DTC*

Result Proceed to

DTC output does not reoccur A

SFI system DTC output reoccurs B

Engine immobiliser system DTC output

reoccursC

Go to SFI SYSTEM

Go to step 7

Page 463 of 2000

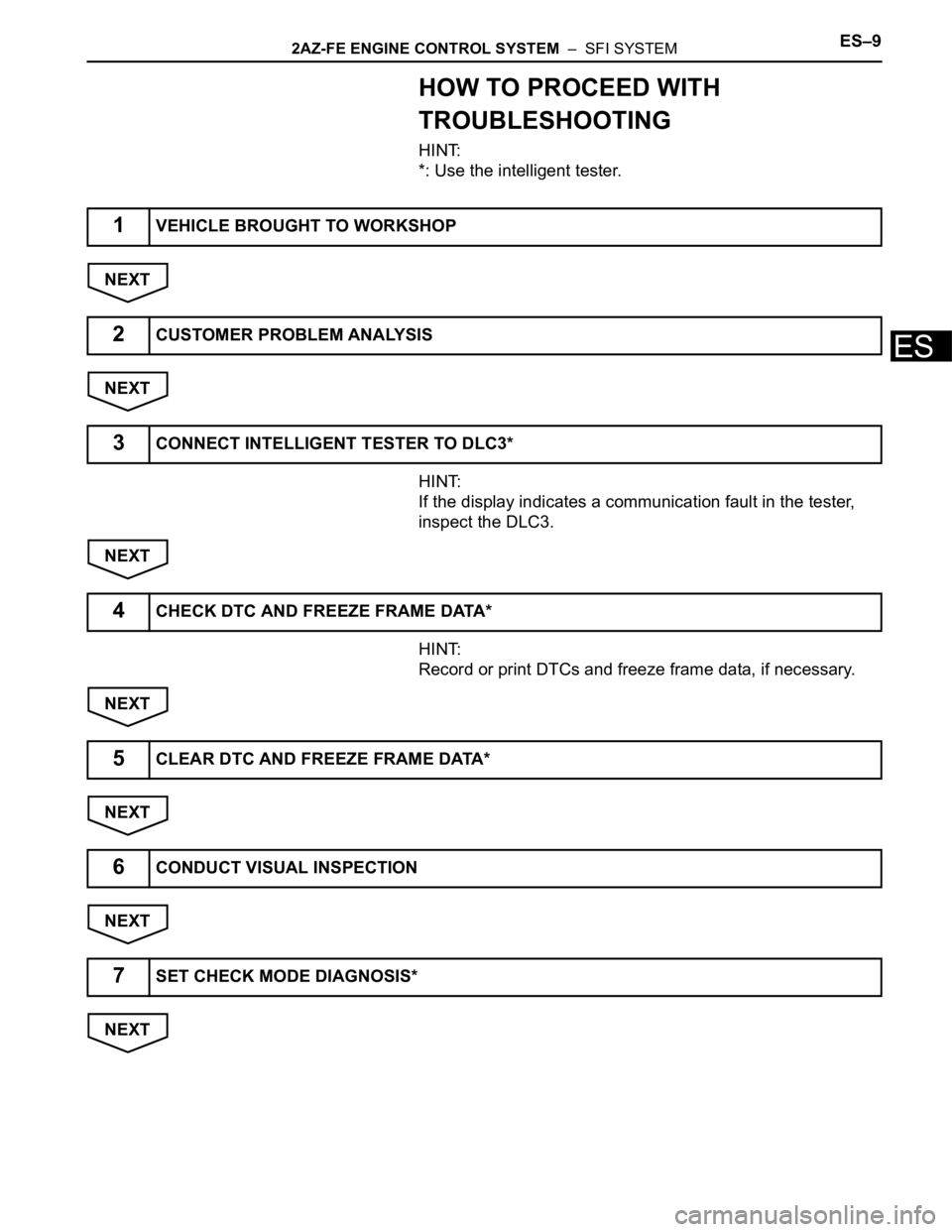

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–9

ES

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

*: Use the intelligent tester.

NEXT

NEXT

HINT:

If the display indicates a communication fault in the tester,

inspect the DLC3.

NEXT

HINT:

Record or print DTCs and freeze frame data, if necessary.

NEXT

NEXT

NEXT

NEXT

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS

3CONNECT INTELLIGENT TESTER TO DLC3*

4CHECK DTC AND FREEZE FRAME DATA*

5CLEAR DTC AND FREEZE FRAME DATA*

6CONDUCT VISUAL INSPECTION

7SET CHECK MODE DIAGNOSIS*

Page 464 of 2000

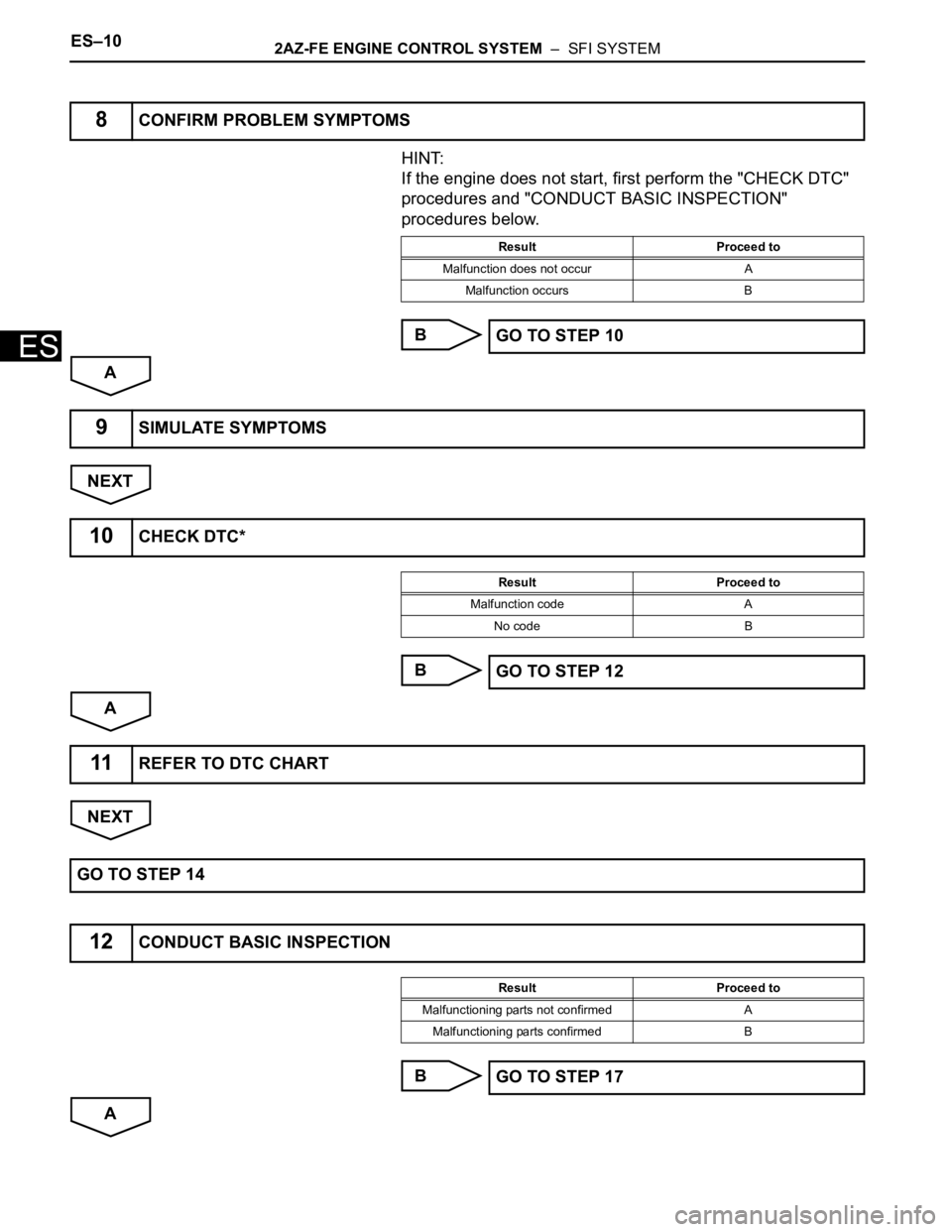

ES–102AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

HINT:

If the engine does not start, first perform the "CHECK DTC"

procedures and "CONDUCT BASIC INSPECTION"

procedures below.

B

A

NEXT

B

A

NEXT

B

A

8CONFIRM PROBLEM SYMPTOMS

Result Proceed to

Malfunction does not occur A

Malfunction occurs B

GO TO STEP 10

9SIMULATE SYMPTOMS

10CHECK DTC*

Result Proceed to

Malfunction code A

No code B

GO TO STEP 12

11REFER TO DTC CHART

GO TO STEP 14

12CONDUCT BASIC INSPECTION

Result Proceed to

Malfunctioning parts not confirmed A

Malfunctioning parts confirmed B

GO TO STEP 17

Page 465 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–11

ES

B

A

NEXT

B

A

NEXT

NEXT

NEXT

NEXT

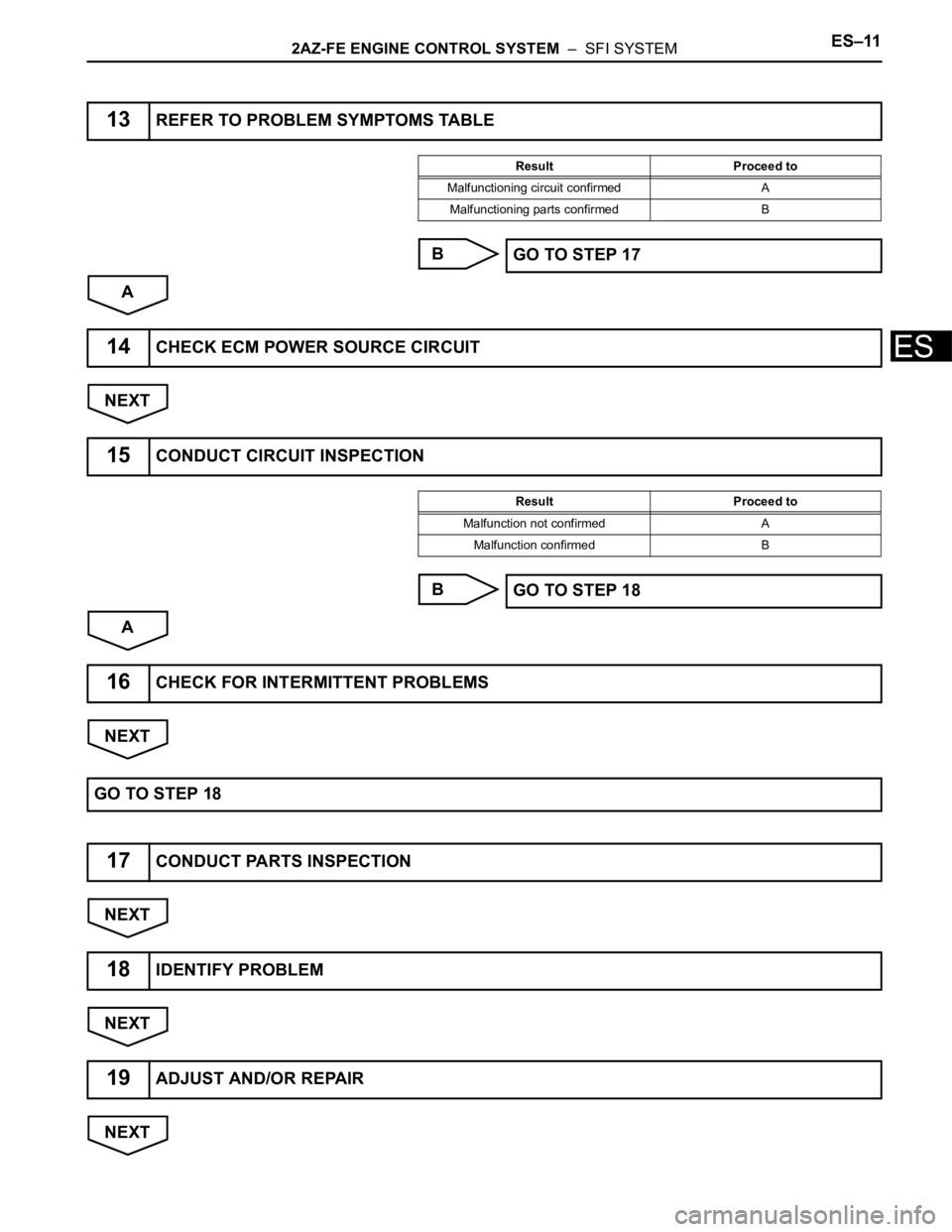

13REFER TO PROBLEM SYMPTOMS TABLE

Result Proceed to

Malfunctioning circuit confirmed A

Malfunctioning parts confirmed B

GO TO STEP 17

14CHECK ECM POWER SOURCE CIRCUIT

15CONDUCT CIRCUIT INSPECTION

Result Proceed to

Malfunction not confirmed A

Malfunction confirmed B

GO TO STEP 18

16CHECK FOR INTERMITTENT PROBLEMS

GO TO STEP 18

17CONDUCT PARTS INSPECTION

18IDENTIFY PROBLEM

19ADJUST AND/OR REPAIR

Page 467 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–13

ES

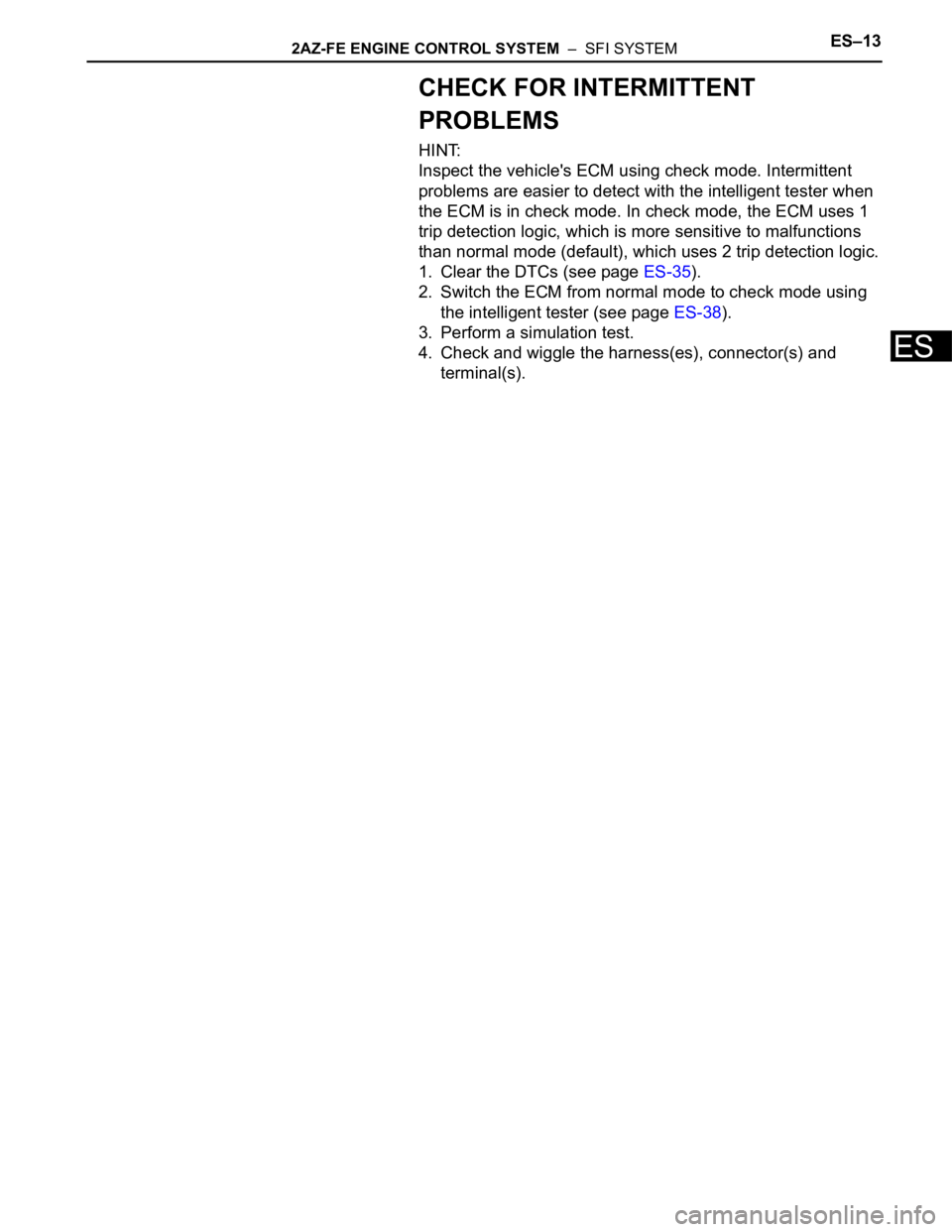

CHECK FOR INTERMITTENT

PROBLEMS

HINT:

Inspect the vehicle's ECM using check mode. Intermittent

problems are easier to detect with the intelligent tester when

the ECM is in check mode. In check mode, the ECM uses 1

trip detection logic, which is more sensitive to malfunctions

than normal mode (default), which uses 2 trip detection logic.

1. Clear the DTCs (see page ES-35).

2. Switch the ECM from normal mode to check mode using

the intelligent tester (see page ES-38).

3. Perform a simulation test.

4. Check and wiggle the harness(es), connector(s) and

terminal(s).

Page 468 of 2000

ES–142AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

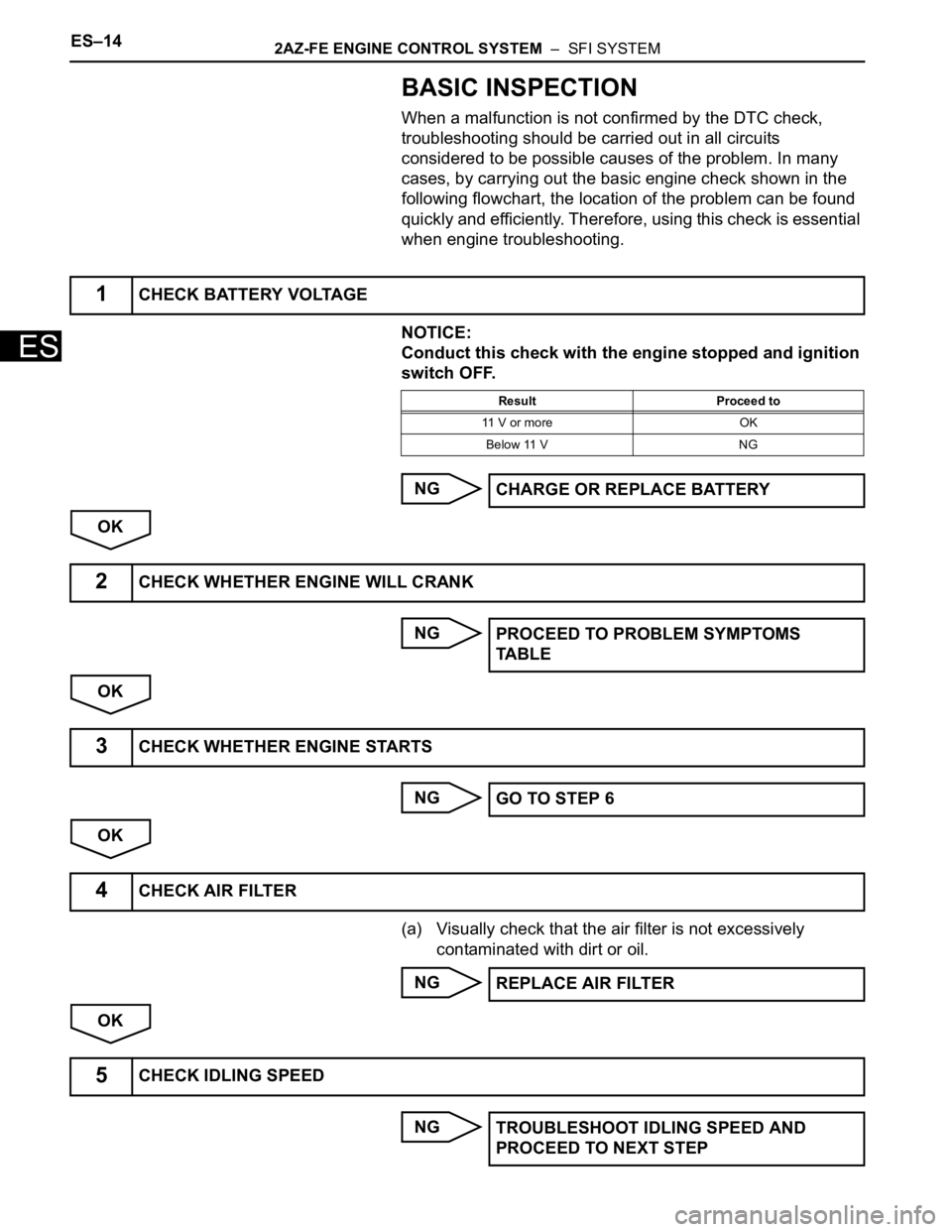

BASIC INSPECTION

When a malfunction is not confirmed by the DTC check,

troubleshooting should be carried out in all circuits

considered to be possible causes of the problem. In many

cases, by carrying out the basic engine check shown in the

following flowchart, the location of the problem can be found

quickly and efficiently. Therefore, using this check is essential

when engine troubleshooting.

NOTICE:

Conduct this check with the engine stopped and ignition

switch OFF.

NG

OK

NG

OK

NG

OK

(a) Visually check that the air filter is not excessively

contaminated with dirt or oil.

NG

OK

NG

1CHECK BATTERY VOLTAGE

Result Proceed to

11 V or more OK

Below 11 V NG

CHARGE OR REPLACE BATTERY

2CHECK WHETHER ENGINE WILL CRANK

PROCEED TO PROBLEM SYMPTOMS

TA B L E

3CHECK WHETHER ENGINE STARTS

GO TO STEP 6

4CHECK AIR FILTER

REPLACE AIR FILTER

5CHECK IDLING SPEED

TROUBLESHOOT IDLING SPEED AND

PROCEED TO NEXT STEP

Page 469 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–15

ES

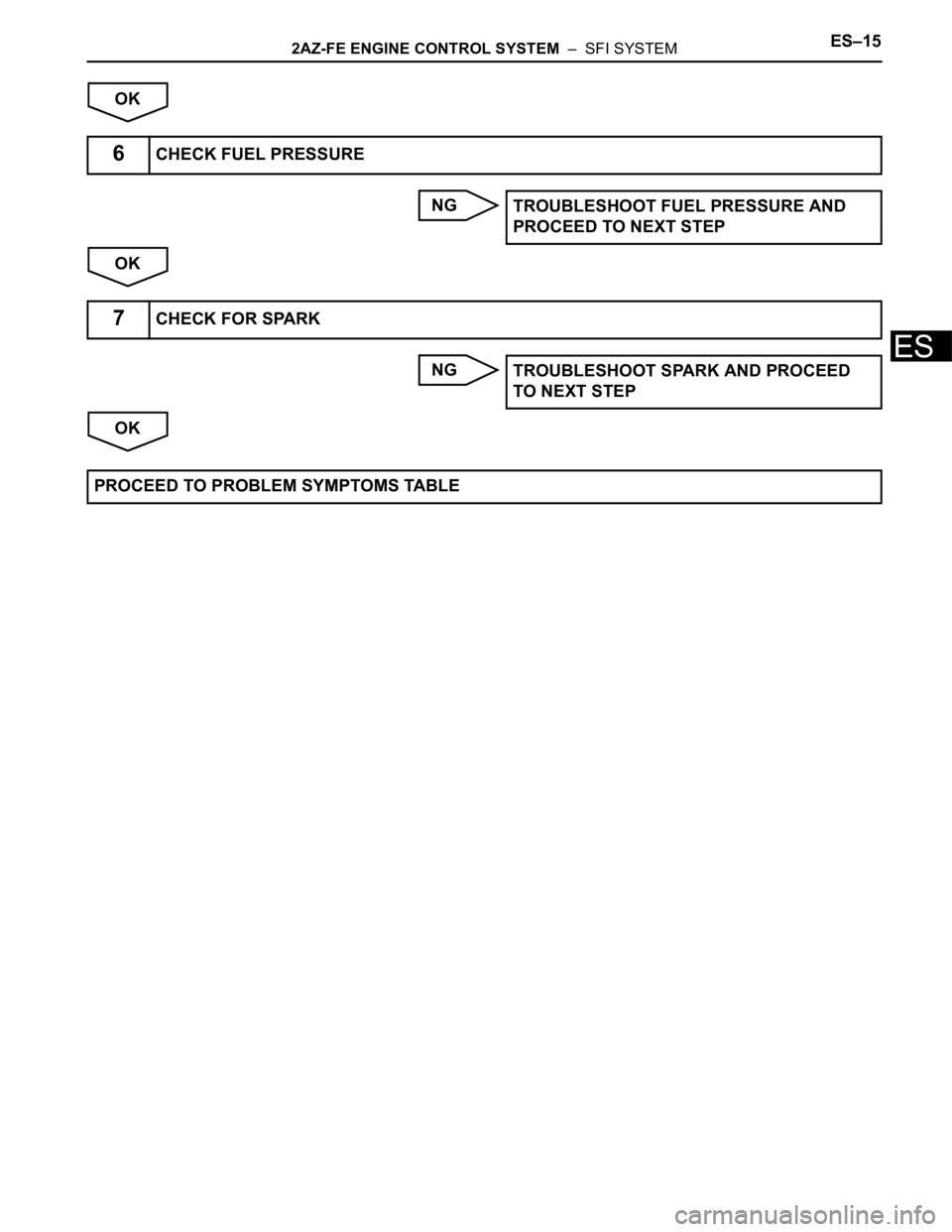

OK

NG

OK

NG

OK

6CHECK FUEL PRESSURE

TROUBLESHOOT FUEL PRESSURE AND

PROCEED TO NEXT STEP

7CHECK FOR SPARK

TROUBLESHOOT SPARK AND PROCEED

TO NEXT STEP

PROCEED TO PROBLEM SYMPTOMS TABLE

Page 475 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–21

ES

CHECKING MONITOR STATUS

The purpose of the monitor result (mode 06) is to allow

access to the results of on-board diagnostic monitoring tests

of specific components/systems that are not continuously

monitored. Examples are catalysts, evaporative emissions

(EVAP) and thermostats.

The monitor result allows the OBD II scan tool to display the

monitor status, test value, minimum test limit and maximum

test limit. These data are displayed after the vehicle has been

driven to run the monitor.

When the test value is not between the minimum and

maximum test limits, the ECM (PCM) interprets this as a

malfunction. If the test value is on the borderline of the test

limits, the component is likely to malfunction in the near

future.

Perform the following instruction to view the monitor status.

Although this instruction refers to the Lexus/Toyota diagnostic

tester, it can be checked using a generic OBD II scan tool.

Refer to your scan tool operator's manual for specific

procedural information.

1. PERFORM MONITOR DRIVE PATTERN

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch and the tester ON.

(c) Clear the DTCs (see page ES-35).

(d) Run the vehicle in accordance with the applicable

drive pattern described in READINESS MONITOR

DRIVE PATTERN (see page ES-19). Do not turn the

ignition switch OFF.

NOTE:

The test results will be lost if the ignition

switch is turned OFF.

2. ACCESS MONITOR RESULT

(a) Select the following items from the intelligent tester

menus: DIAGNOSIS, ENHANCED OBD II,

MONITOR INFO and MONITOR RESULT. The

monitor status appears after the component name.

• INCMP: The component has not been monitored

yet.

• PASS: The component is functioning normally.

• FAIL: The component is malfunctioning.

(b) Confirm that the component is either PASS or FAIL.

(c) Select the component and press ENTER. The

accuracy test value appears if the monitor status is

either PASS or FAIL.

3. CHECK COMPONENT STATUS

(a) Compare the test value with the minimum test limit

(MIN LIMIT) and maximum test limit (MAX LIMIT).

Page 479 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–25

ES

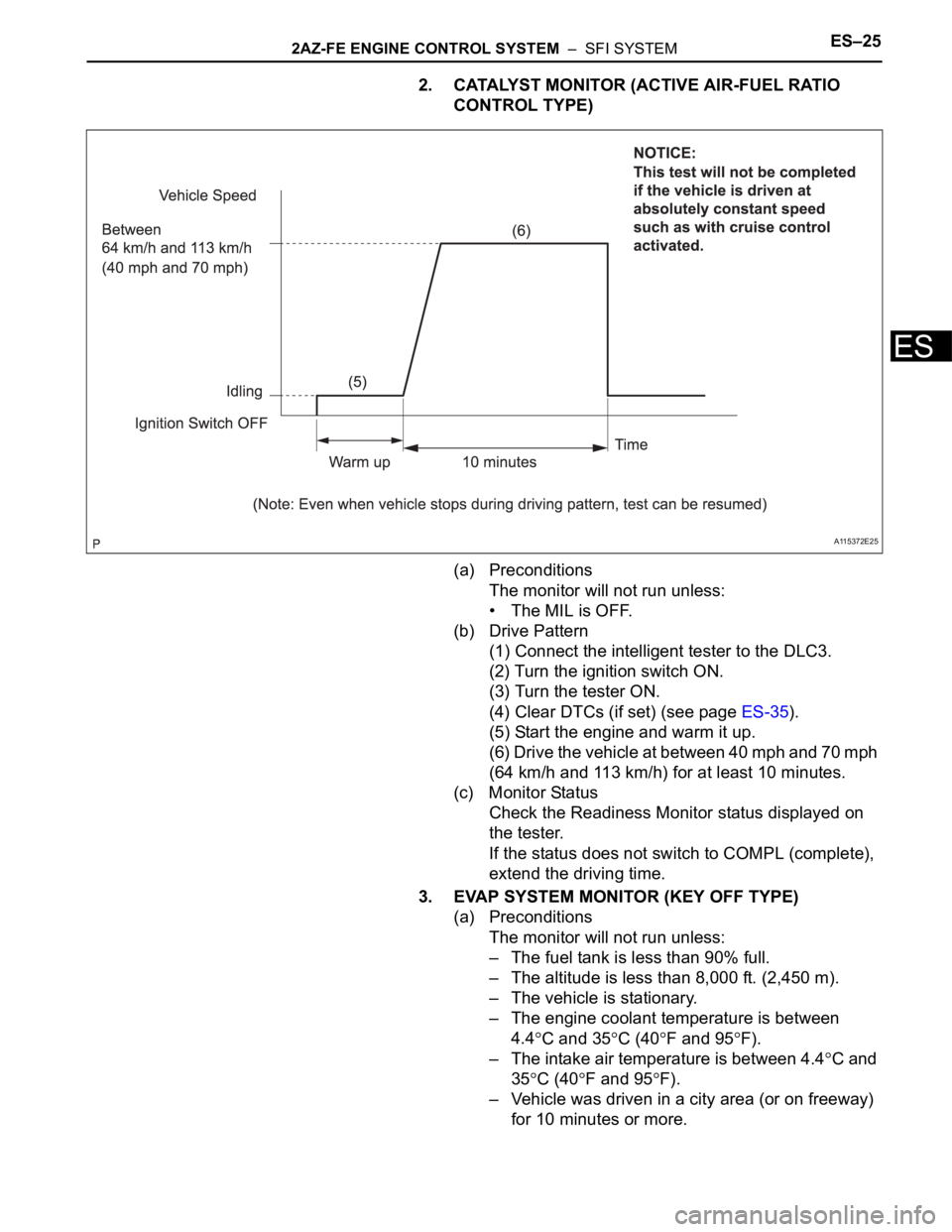

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch ON.

(3) Turn the tester ON.

(4) Clear DTCs (if set) (see page ES-35).

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70 mph

(64 km/h and 113 km/h) for at least 10 minutes.

(c) Monitor Status

Check the Readiness Monitor status displayed on

the tester.

If the status does not switch to COMPL (complete),

extend the driving time.

3. EVAP SYSTEM MONITOR (KEY OFF TYPE)

(a) Preconditions

The monitor will not run unless:

– The fuel tank is less than 90% full.

– The altitude is less than 8,000 ft. (2,450 m).

– The vehicle is stationary.

– The engine coolant temperature is between

4.4

C and 35C (40F and 95F).

– The intake air temperature is between 4.4

C and

35

C (40F and 95F).

– Vehicle was driven in a city area (or on freeway)

for 10 minutes or more.

A115372E25