torque TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1663 of 2000

AC–218AIR CONDITIONING – COMPRESSOR AND PULLEY (for 2AZ-FE)

AC

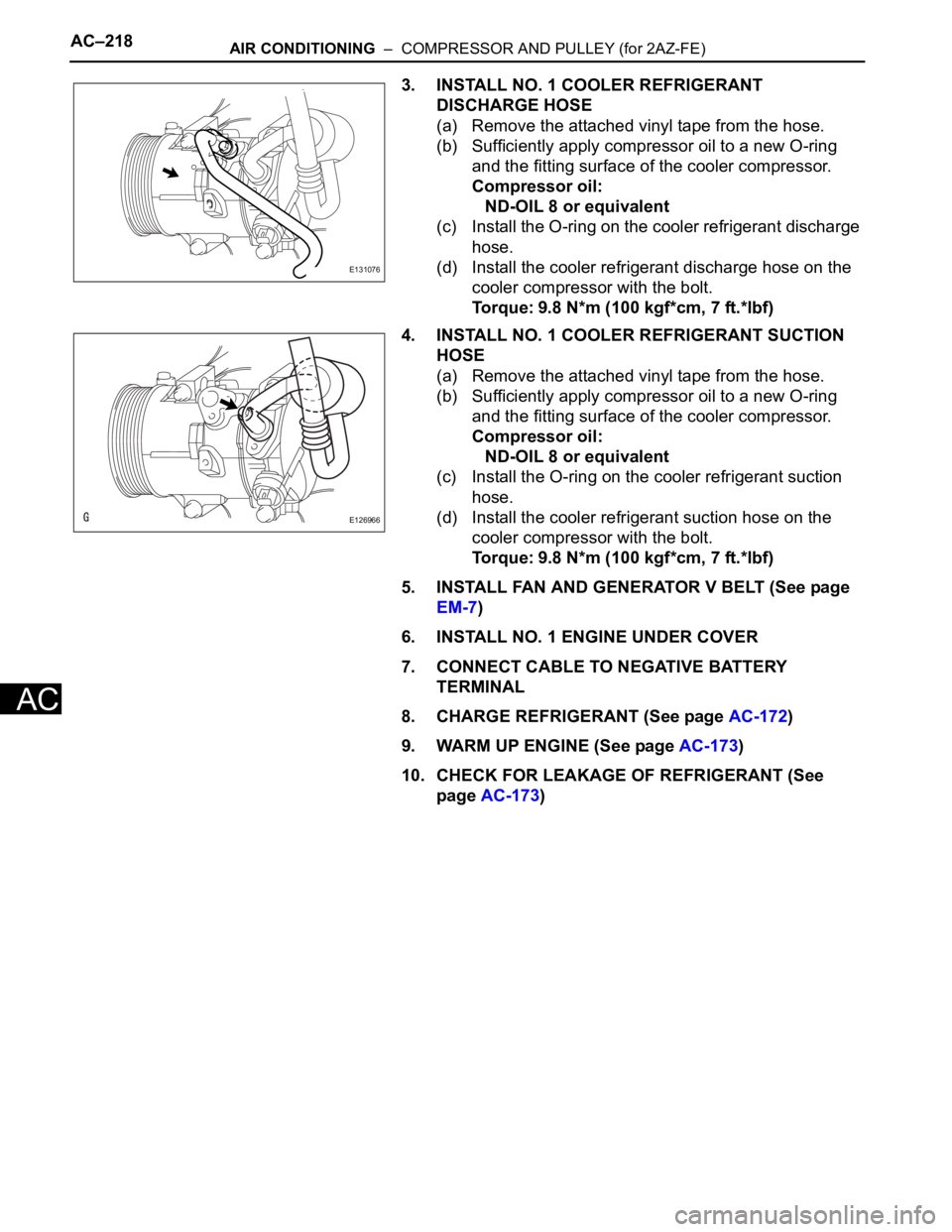

3. INSTALL NO. 1 COOLER REFRIGERANT

DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant discharge

hose.

(d) Install the cooler refrigerant discharge hose on the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

4. INSTALL NO. 1 COOLER REFRIGERANT SUCTION

HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant suction

hose.

(d) Install the cooler refrigerant suction hose on the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

5. INSTALL FAN AND GENERATOR V BELT (See page

EM-7)

6. INSTALL NO. 1 ENGINE UNDER COVER

7. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

8. CHARGE REFRIGERANT (See page AC-172)

9. WARM UP ENGINE (See page AC-173)

10. CHECK FOR LEAKAGE OF REFRIGERANT (See

page AC-173)

E131076

E126966

Page 1664 of 2000

AIR CONDITIONING – COMPRESSOR AND PULLEY (for 2GR-FE)AC–221

AC

INSTALLATION

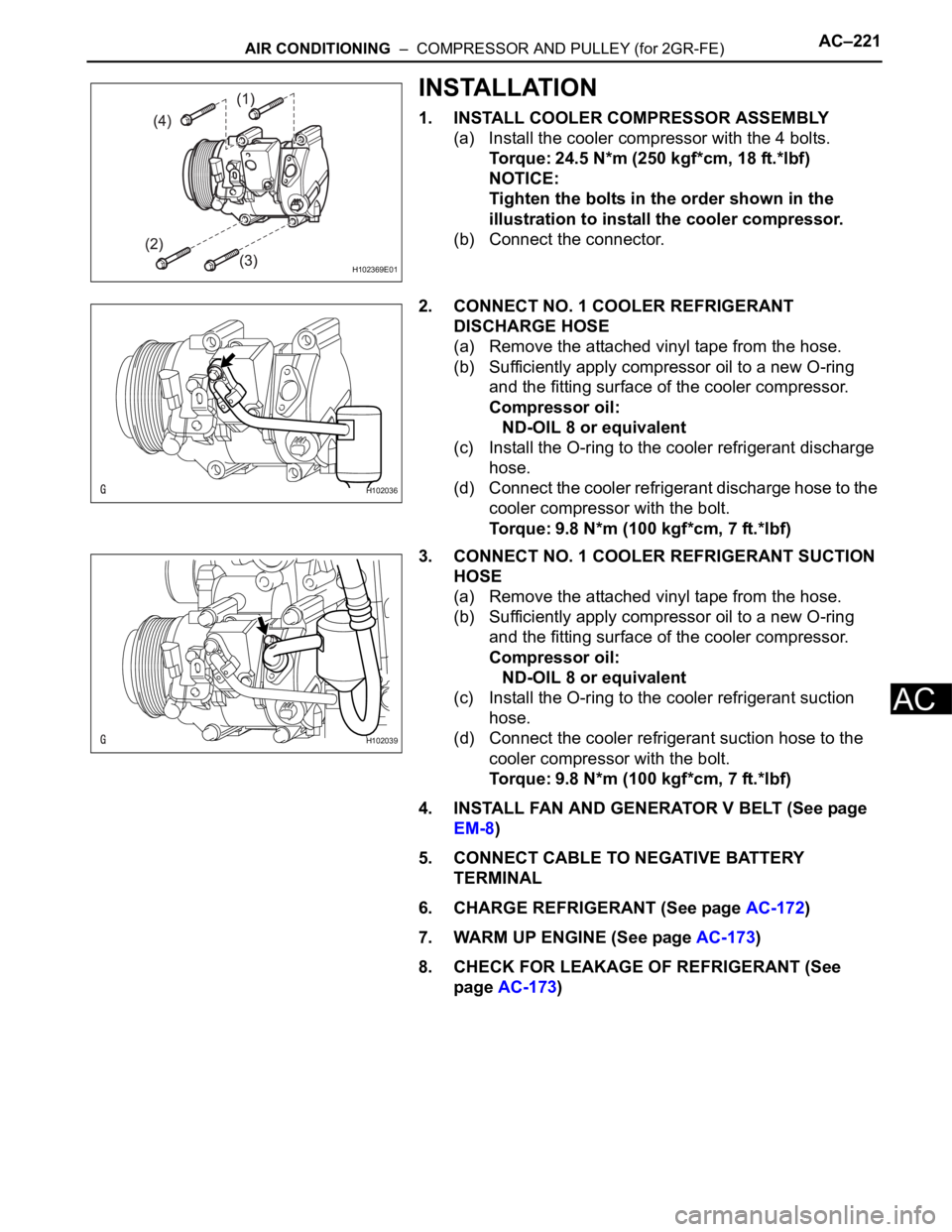

1. INSTALL COOLER COMPRESSOR ASSEMBLY

(a) Install the cooler compressor with the 4 bolts.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*lbf)

NOTICE:

Tighten the bolts in the order shown in the

illustration to install the cooler compressor.

(b) Connect the connector.

2. CONNECT NO. 1 COOLER REFRIGERANT

DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring to the cooler refrigerant discharge

hose.

(d) Connect the cooler refrigerant discharge hose to the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

3. CONNECT NO. 1 COOLER REFRIGERANT SUCTION

HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring to the cooler refrigerant suction

hose.

(d) Connect the cooler refrigerant suction hose to the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

4. INSTALL FAN AND GENERATOR V BELT (See page

EM-8)

5. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

6. CHARGE REFRIGERANT (See page AC-172)

7. WARM UP ENGINE (See page AC-173)

8. CHECK FOR LEAKAGE OF REFRIGERANT (See

page AC-173)

H102369E01

H102036

H102039

Page 1665 of 2000

AC–224AIR CONDITIONING – CONDENSER

AC

ON-VEHICLE INSPECTION

1. INSPECT COOLER CONDENSER ASSEMBLY

(a) If the fins of the cooler condenser are dirty, clean

them with water. Dry the fins with compressed air.

NOTICE:

Do not damage the fins of the condenser.

(b) If a fin of the cooler condenser is bent, straighten it

using a screwdriver or pliers.

2. CHECK CONDENSER FOR LEAKAGE OF

REFRIGERANT

(a) Using a halogen leak detector, check the pipe joints

for gas leakage.

(b) If gas leakage is detected in a joint, check the

torque of the joint.

Page 1668 of 2000

AIR CONDITIONING – CONDENSERAC–227

AC

INSTALLATION

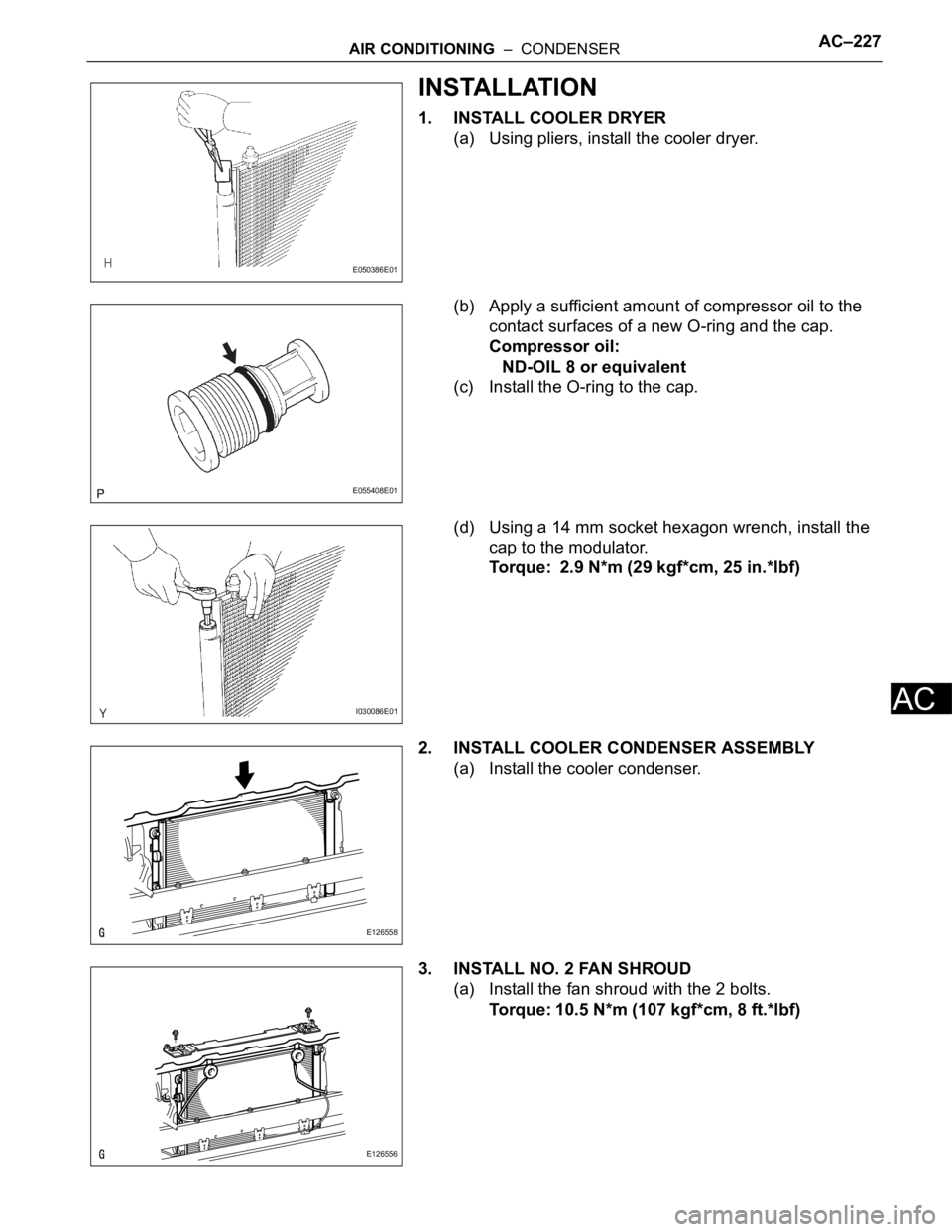

1. INSTALL COOLER DRYER

(a) Using pliers, install the cooler dryer.

(b) Apply a sufficient amount of compressor oil to the

contact surfaces of a new O-ring and the cap.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring to the cap.

(d) Using a 14 mm socket hexagon wrench, install the

cap to the modulator.

Torque: 2.9 N*m (29 kgf*cm, 25 in.*lbf)

2. INSTALL COOLER CONDENSER ASSEMBLY

(a) Install the cooler condenser.

3. INSTALL NO. 2 FAN SHROUD

(a) Install the fan shroud with the 2 bolts.

Torque: 10.5 N*m (107 kgf*cm, 8 ft.*lbf)

E050386E01

E055408E01

I030086E01

E126558

E126556

Page 1669 of 2000

AC–228AIR CONDITIONING – CONDENSER

AC

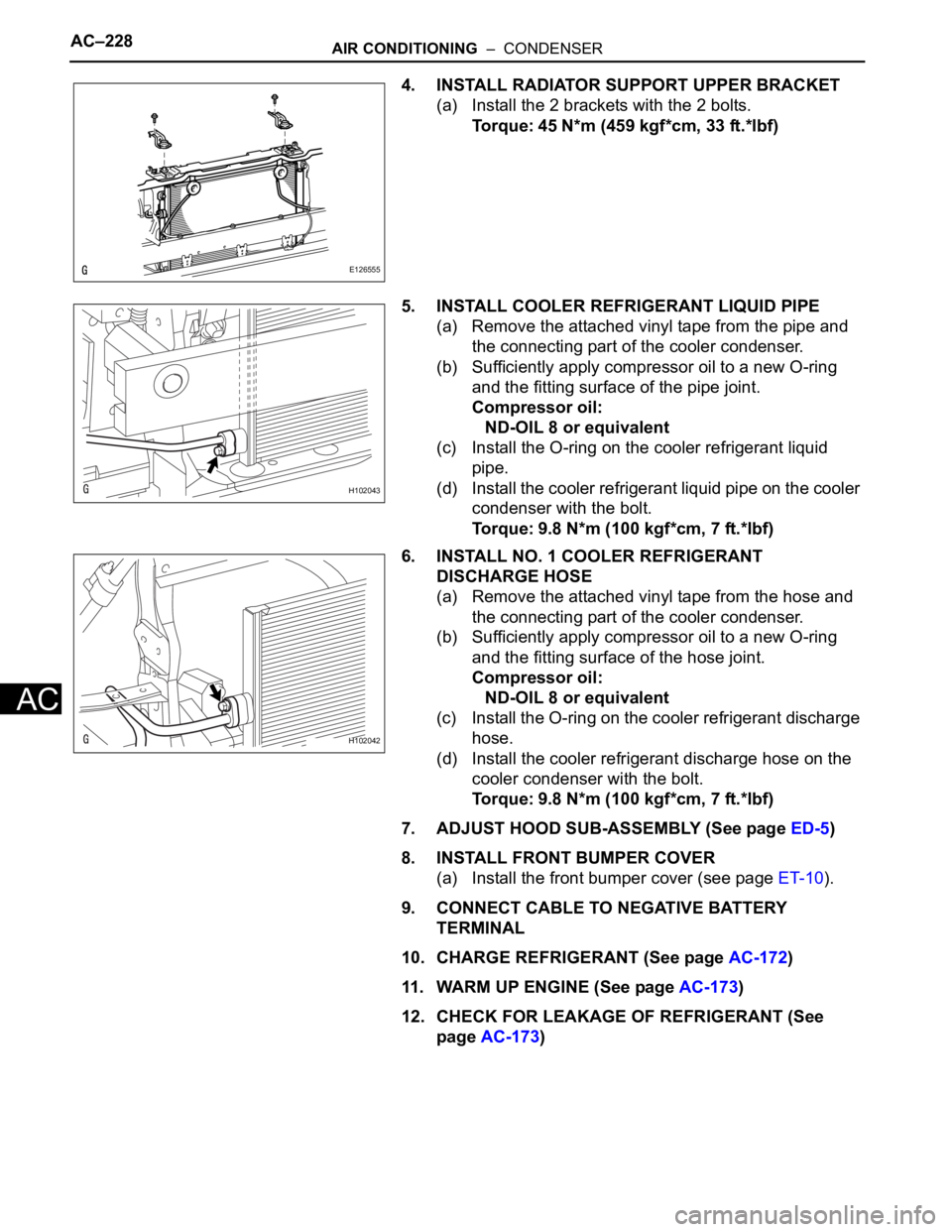

4. INSTALL RADIATOR SUPPORT UPPER BRACKET

(a) Install the 2 brackets with the 2 bolts.

Torque: 45 N*m (459 kgf*cm, 33 ft.*lbf)

5. INSTALL COOLER REFRIGERANT LIQUID PIPE

(a) Remove the attached vinyl tape from the pipe and

the connecting part of the cooler condenser.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the pipe joint.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant liquid

pipe.

(d) Install the cooler refrigerant liquid pipe on the cooler

condenser with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

6. INSTALL NO. 1 COOLER REFRIGERANT

DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose and

the connecting part of the cooler condenser.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the hose joint.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant discharge

hose.

(d) Install the cooler refrigerant discharge hose on the

cooler condenser with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

7. ADJUST HOOD SUB-ASSEMBLY (See page ED-5)

8. INSTALL FRONT BUMPER COVER

(a) Install the front bumper cover (see page ET-10).

9. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

10. CHARGE REFRIGERANT (See page AC-172)

11. WARM UP ENGINE (See page AC-173)

12. CHECK FOR LEAKAGE OF REFRIGERANT (See

page AC-173)

E126555

H102043

H102042

Page 1737 of 2000

RS–388SUPPLEMENTAL RESTRAINT SYSTEM – REAR AIRBAG SENSOR

RS

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

CAUTION:

Be sure to read the precautionary notices concerning the

SRS airbag system before servicing it (see page RS-1).

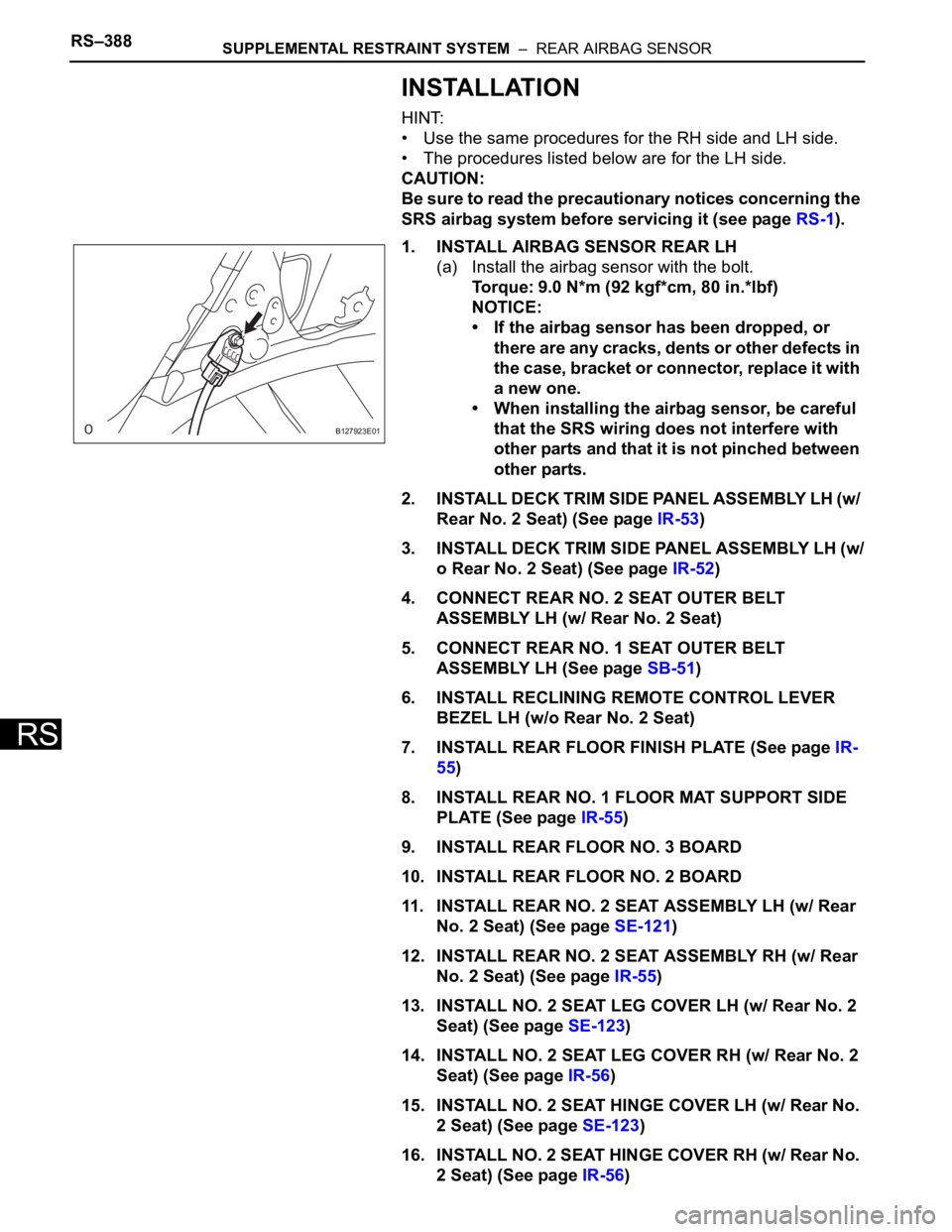

1. INSTALL AIRBAG SENSOR REAR LH

(a) Install the airbag sensor with the bolt.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

NOTICE:

• If the airbag sensor has been dropped, or

there are any cracks, dents or other defects in

the case, bracket or connector, replace it with

a new one.

• When installing the airbag sensor, be careful

that the SRS wiring does not interfere with

other parts and that it is not pinched between

other parts.

2. INSTALL DECK TRIM SIDE PANEL ASSEMBLY LH (w/

Rear No. 2 Seat) (See page IR-53)

3. INSTALL DECK TRIM SIDE PANEL ASSEMBLY LH (w/

o Rear No. 2 Seat) (See page IR-52)

4. CONNECT REAR NO. 2 SEAT OUTER BELT

ASSEMBLY LH (w/ Rear No. 2 Seat)

5. CONNECT REAR NO. 1 SEAT OUTER BELT

ASSEMBLY LH (See page SB-51)

6. INSTALL RECLINING REMOTE CONTROL LEVER

BEZEL LH (w/o Rear No. 2 Seat)

7. INSTALL REAR FLOOR FINISH PLATE (See page IR-

55)

8. INSTALL REAR NO. 1 FLOOR MAT SUPPORT SIDE

PLATE (See page IR-55)

9. INSTALL REAR FLOOR NO. 3 BOARD

10. INSTALL REAR FLOOR NO. 2 BOARD

11. INSTALL REAR NO. 2 SEAT ASSEMBLY LH (w/ Rear

No. 2 Seat) (See page SE-121)

12. INSTALL REAR NO. 2 SEAT ASSEMBLY RH (w/ Rear

No. 2 Seat) (See page IR-55)

13. INSTALL NO. 2 SEAT LEG COVER LH (w/ Rear No. 2

Seat) (See page SE-123)

14. INSTALL NO. 2 SEAT LEG COVER RH (w/ Rear No. 2

Seat) (See page IR-56)

15. INSTALL NO. 2 SEAT HINGE COVER LH (w/ Rear No.

2 Seat) (See page SE-123)

16. INSTALL NO. 2 SEAT HINGE COVER RH (w/ Rear No.

2 Seat) (See page IR-56)

B127923E01

Page 1740 of 2000

RS–392SUPPLEMENTAL RESTRAINT SYSTEM – SEAT POSITION SENSOR

RS

INSTALLATION

CAUTION:

Be sure to read the precautionary notices concerning the

SRS airbag system before servicing it (see page RS-1).

1. INSTALL SEAT POSITION AIRBAG SENSOR

(a) Using a 1 mm (0.039 in.) feeler gauge, install the

seat position sensor.

NOTICE:

• If the seat position sensor has been dropped,

or there are any cracks, dents or other

defects in the case or connector, replace the

seat position sensor with a new one.

• When installing the seat position sensor, be

careful that the SRS wiring does not interfere

with other parts and that it is not pinched

between other parts.

HINT:

Be sure that the clearance between the seat

position sensor and the seat rail is within 0.6 mm to

1.4 mm (0.023 to 0.055 in.).

(b) Using a T30 "torx" socket, tighten the "torx" screw to

install the seat position sensor.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

(c) Make sure that the clearance between the seat

position sensor and the seat rail is within 0.6 mm to

1.4 mm (0.023 to 0.055 in.).

(d) Connect the connector.

Page 1761 of 2000

SB–24SEAT BELT – FRONT SEAT INNER BELT ASSEMBLY

SB

INSTALLATION

HINT:

A bolt without a torque specification is shown in the standard

bolt chart (see page SS-2).

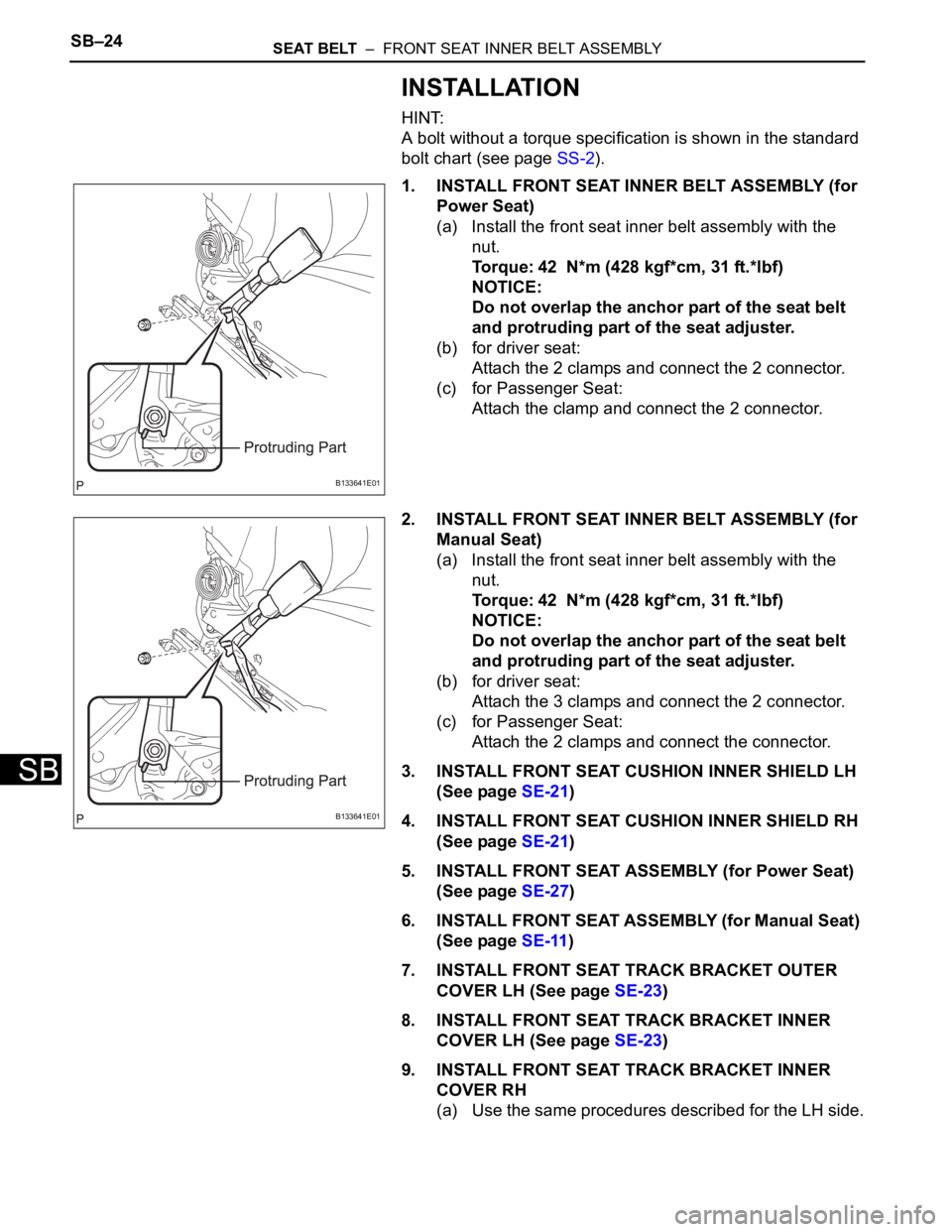

1. INSTALL FRONT SEAT INNER BELT ASSEMBLY (for

Power Seat)

(a) Install the front seat inner belt assembly with the

nut.

Torque: 42 N*m (428 kgf*cm, 31 ft.*lbf)

NOTICE:

Do not overlap the anchor part of the seat belt

and protruding part of the seat adjuster.

(b) for driver seat:

Attach the 2 clamps and connect the 2 connector.

(c) for Passenger Seat:

Attach the clamp and connect the 2 connector.

2. INSTALL FRONT SEAT INNER BELT ASSEMBLY (for

Manual Seat)

(a) Install the front seat inner belt assembly with the

nut.

Torque: 42 N*m (428 kgf*cm, 31 ft.*lbf)

NOTICE:

Do not overlap the anchor part of the seat belt

and protruding part of the seat adjuster.

(b) for driver seat:

Attach the 3 clamps and connect the 2 connector.

(c) for Passenger Seat:

Attach the 2 clamps and connect the connector.

3. INSTALL FRONT SEAT CUSHION INNER SHIELD LH

(See page SE-21)

4. INSTALL FRONT SEAT CUSHION INNER SHIELD RH

(See page SE-21)

5. INSTALL FRONT SEAT ASSEMBLY (for Power Seat)

(See page SE-27)

6. INSTALL FRONT SEAT ASSEMBLY (for Manual Seat)

(See page SE-11)

7. INSTALL FRONT SEAT TRACK BRACKET OUTER

COVER LH (See page SE-23)

8. INSTALL FRONT SEAT TRACK BRACKET INNER

COVER LH (See page SE-23)

9. INSTALL FRONT SEAT TRACK BRACKET INNER

COVER RH

(a) Use the same procedures described for the LH side.

B133641E01

B133641E01

Page 1766 of 2000

SB–30SEAT BELT – FRONT SEAT OUTER BELT ASSEMBLY

SB

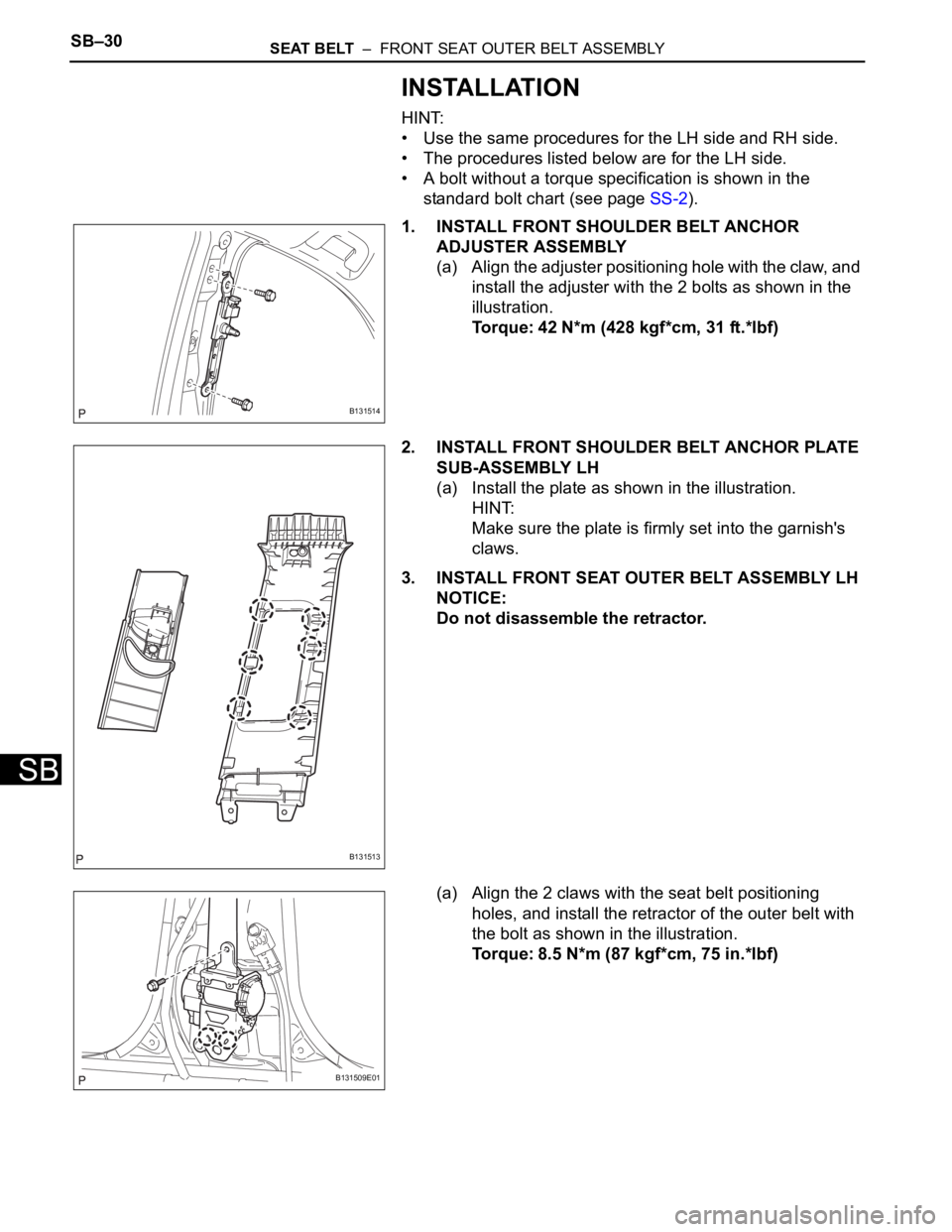

INSTALLATION

HINT:

• Use the same procedures for the LH side and RH side.

• The procedures listed below are for the LH side.

• A bolt without a torque specification is shown in the

standard bolt chart (see page SS-2).

1. INSTALL FRONT SHOULDER BELT ANCHOR

ADJUSTER ASSEMBLY

(a) Align the adjuster positioning hole with the claw, and

install the adjuster with the 2 bolts as shown in the

illustration.

Torque: 42 N*m (428 kgf*cm, 31 ft.*lbf)

2. INSTALL FRONT SHOULDER BELT ANCHOR PLATE

SUB-ASSEMBLY LH

(a) Install the plate as shown in the illustration.

HINT:

Make sure the plate is firmly set into the garnish's

claws.

3. INSTALL FRONT SEAT OUTER BELT ASSEMBLY LH

NOTICE:

Do not disassemble the retractor.

(a) Align the 2 claws with the seat belt positioning

holes, and install the retractor of the outer belt with

the bolt as shown in the illustration.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*lbf)

B131514

B131513

B131509E01

Page 1767 of 2000

SEAT BELT – FRONT SEAT OUTER BELT ASSEMBLYSB–31

SB

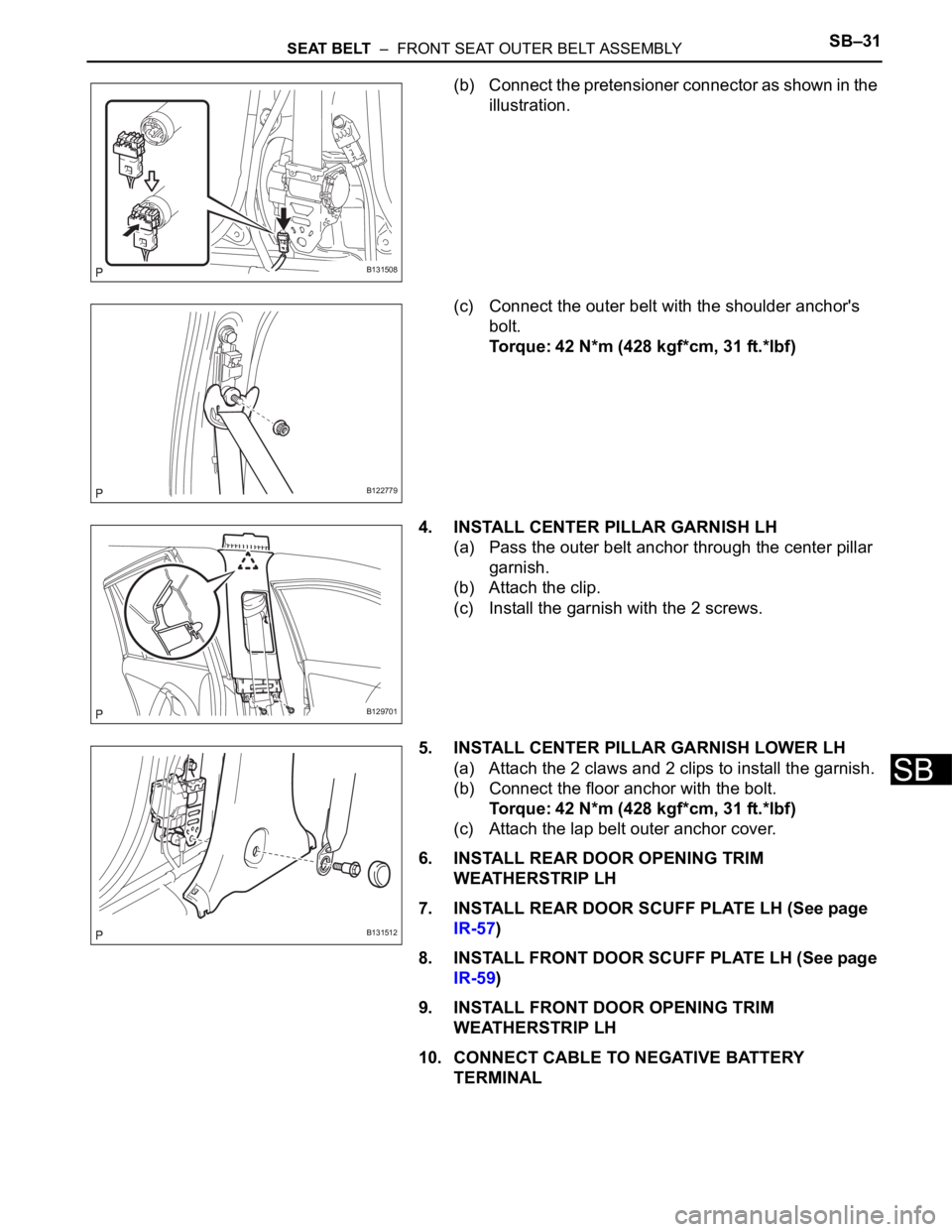

(b) Connect the pretensioner connector as shown in the

illustration.

(c) Connect the outer belt with the shoulder anchor's

bolt.

Torque: 42 N*m (428 kgf*cm, 31 ft.*lbf)

4. INSTALL CENTER PILLAR GARNISH LH

(a) Pass the outer belt anchor through the center pillar

garnish.

(b) Attach the clip.

(c) Install the garnish with the 2 screws.

5. INSTALL CENTER PILLAR GARNISH LOWER LH

(a) Attach the 2 claws and 2 clips to install the garnish.

(b) Connect the floor anchor with the bolt.

Torque: 42 N*m (428 kgf*cm, 31 ft.*lbf)

(c) Attach the lap belt outer anchor cover.

6. INSTALL REAR DOOR OPENING TRIM

WEATHERSTRIP LH

7. INSTALL REAR DOOR SCUFF PLATE LH (See page

IR-57)

8. INSTALL FRONT DOOR SCUFF PLATE LH (See page

IR-59)

9. INSTALL FRONT DOOR OPENING TRIM

WEATHERSTRIP LH

10. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

B131508

B122779

B129701

B131512