torque TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1893 of 2000

WIPER AND WASHER – FRONT WIPER MOTOR AND LINKWW–13

WW

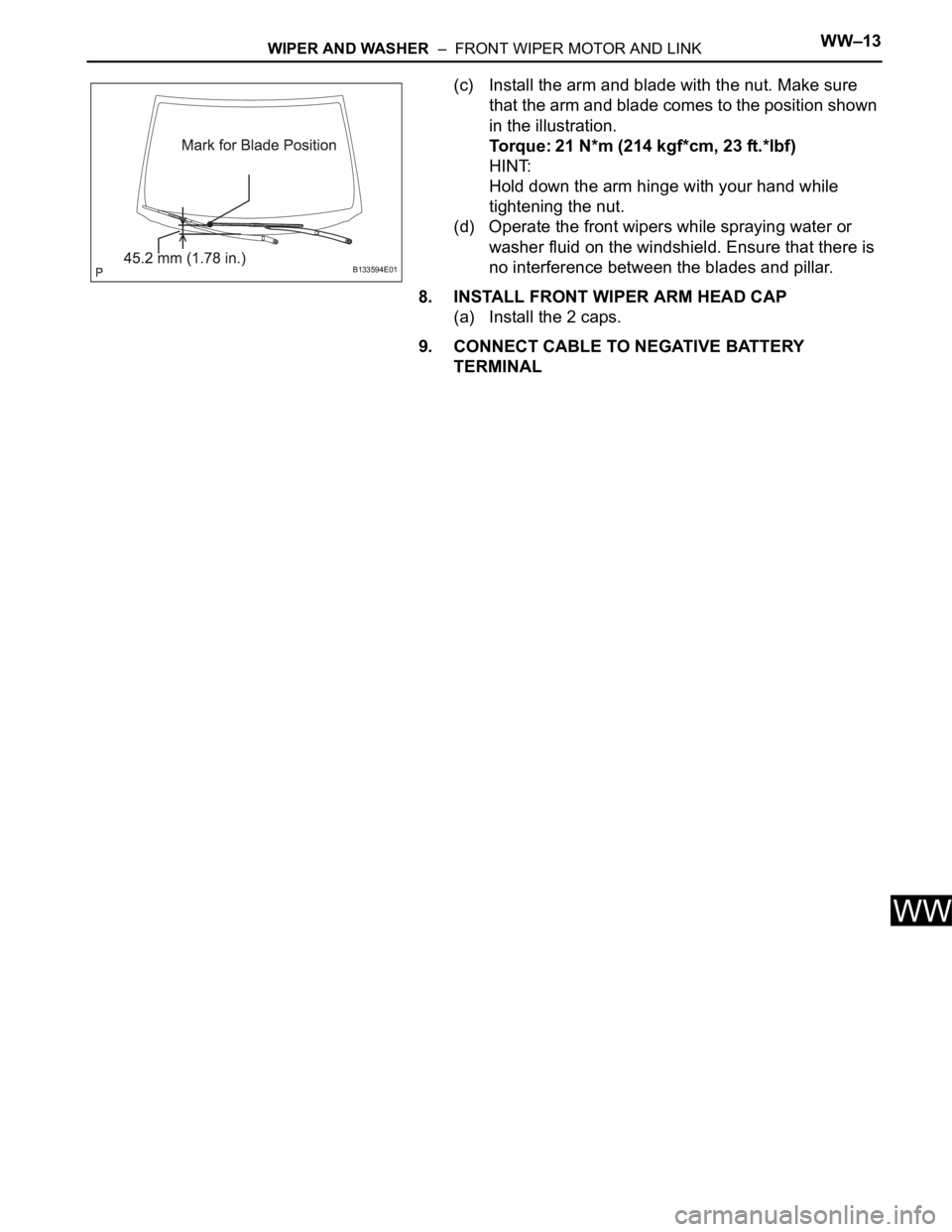

(c) Install the arm and blade with the nut. Make sure

that the arm and blade comes to the position shown

in the illustration.

Torque: 21 N*m (214 kgf*cm, 23 ft.*lbf)

HINT:

Hold down the arm hinge with your hand while

tightening the nut.

(d) Operate the front wipers while spraying water or

washer fluid on the windshield. Ensure that there is

no interference between the blades and pillar.

8. INSTALL FRONT WIPER ARM HEAD CAP

(a) Install the 2 caps.

9. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

B133594E01

Page 1894 of 2000

WW–20WIPER AND WASHER – REAR WIPER MOTOR

WW

(d) Remove the nut and arm and blade.

7. REMOVE REAR WIPER MOTOR GROMMET

8. REMOVE REAR WIPER MOTOR ASSEMBLY

(a) Disconnect the connector.

(b) Remove the 3 bolts and wiper motor.

INSPECTION

1. INSPECT REAR WIPER MOTOR

(a) Connect the battery's positive (+) lead to terminal 3

(+B) and the negative (-) lead to terminal 1 (LS).

(b) Check that the rear wiper motor operates.

OK:

Rear wiper motor operates.

NOTICE:

Check that the body ground is connected.

If the result is not as specified, replace the motor.

INSTALLATION

1. INSTALL REAR WIPER MOTOR ASSEMBLY

(a) Install the wiper motor with the 3 bolts.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(b) Connect the connector.

2. INSTALL REAR WIPER MOTOR GROMMET

3. INSTALL REAR WIPER ARM AND BLADE

ASSEMBLY

(a) Stop the wiper motor at the automatic stop position.

B131464

B131460

E118528E01

B131460

Page 1895 of 2000

WIPER AND WASHER – REAR WIPER MOTORWW–21

WW

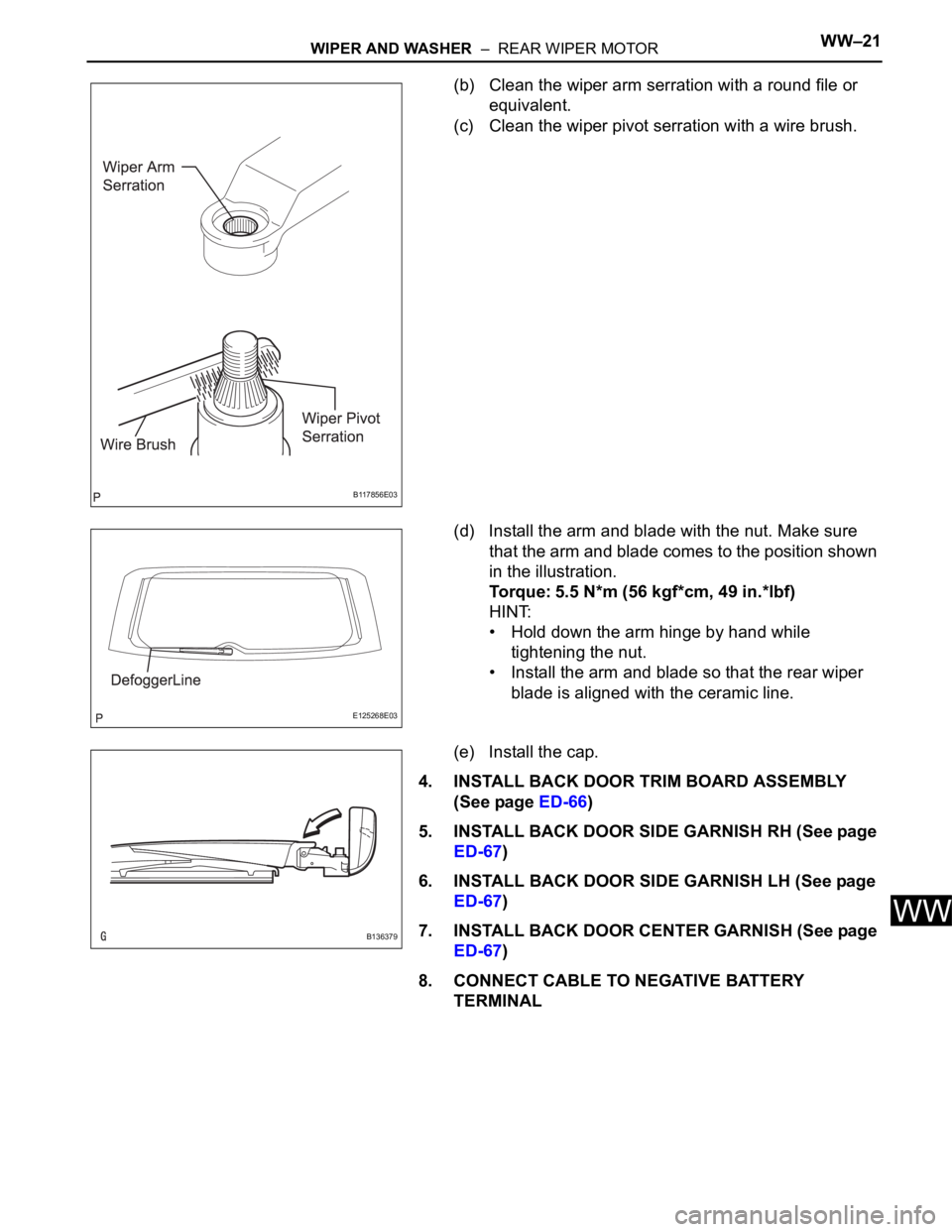

(b) Clean the wiper arm serration with a round file or

equivalent.

(c) Clean the wiper pivot serration with a wire brush.

(d) Install the arm and blade with the nut. Make sure

that the arm and blade comes to the position shown

in the illustration.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

HINT:

• Hold down the arm hinge by hand while

tightening the nut.

• Install the arm and blade so that the rear wiper

blade is aligned with the ceramic line.

(e) Install the cap.

4. INSTALL BACK DOOR TRIM BOARD ASSEMBLY

(See page ED-66)

5. INSTALL BACK DOOR SIDE GARNISH RH (See page

ED-67)

6. INSTALL BACK DOOR SIDE GARNISH LH (See page

ED-67)

7. INSTALL BACK DOOR CENTER GARNISH (See page

ED-67)

8. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

B117856E03

E125268E03

B136379

Page 1957 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–69

ES

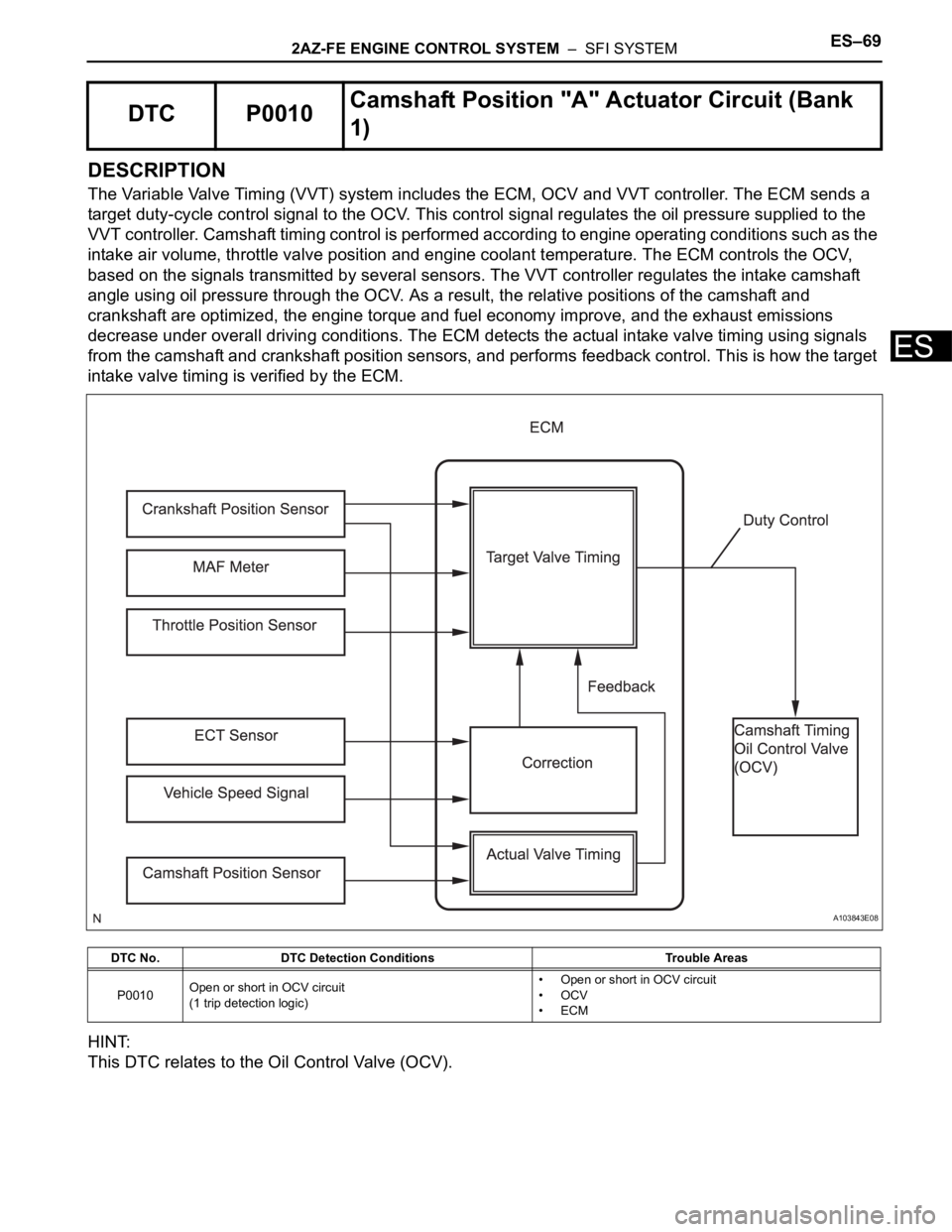

DESCRIPTION

The Variable Valve Timing (VVT) system includes the ECM, OCV and VVT controller. The ECM sends a

target duty-cycle control signal to the OCV. This control signal regulates the oil pressure supplied to the

VVT controller. Camshaft timing control is performed according to engine operating conditions such as the

intake air volume, throttle valve position and engine coolant temperature. The ECM controls the OCV,

based on the signals transmitted by several sensors. The VVT controller regulates the intake camshaft

angle using oil pressure through the OCV. As a result, the relative positions of the camshaft and

crankshaft are optimized, the engine torque and fuel economy improve, and the exhaust emissions

decrease under overall driving conditions. The ECM detects the actual intake valve timing using signals

from the camshaft and crankshaft position sensors, and performs feedback control. This is how the target

intake valve timing is verified by the ECM.

HINT:

This DTC relates to the Oil Control Valve (OCV).

DTC P0010Camshaft Position "A" Actuator Circuit (Bank

1)

DTC No. DTC Detection Conditions Trouble Areas

P0010Open or short in OCV circuit

(1 trip detection logic)• Open or short in OCV circuit

•OCV

•ECM

A103843E08

Page 1961 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–73

ES

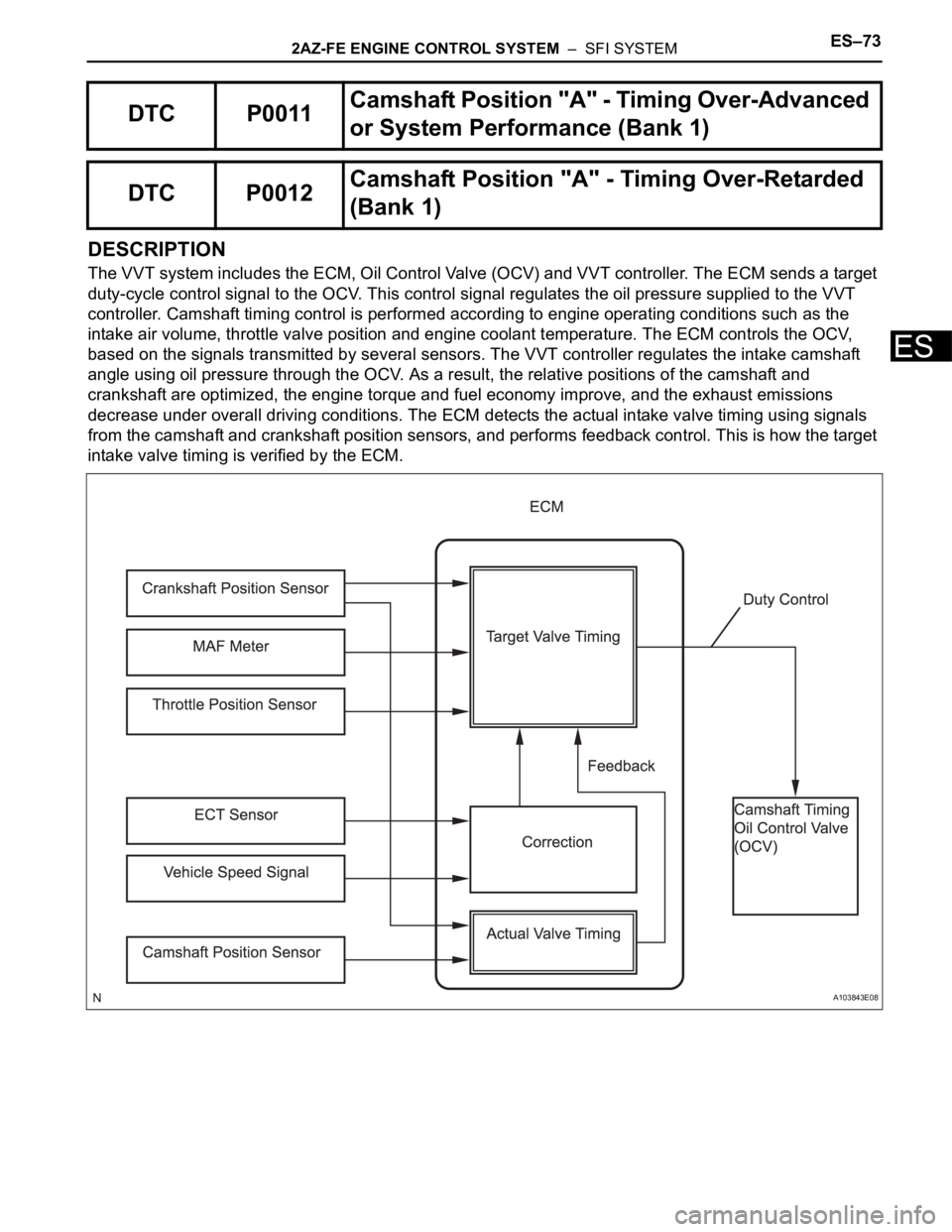

DESCRIPTION

The VVT system includes the ECM, Oil Control Valve (OCV) and VVT controller. The ECM sends a target

duty-cycle control signal to the OCV. This control signal regulates the oil pressure supplied to the VVT

controller. Camshaft timing control is performed according to engine operating conditions such as the

intake air volume, throttle valve position and engine coolant temperature. The ECM controls the OCV,

based on the signals transmitted by several sensors. The VVT controller regulates the intake camshaft

angle using oil pressure through the OCV. As a result, the relative positions of the camshaft and

crankshaft are optimized, the engine torque and fuel economy improve, and the exhaust emissions

decrease under overall driving conditions. The ECM detects the actual intake valve timing using signals

from the camshaft and crankshaft position sensors, and performs feedback control. This is how the target

intake valve timing is verified by the ECM.

DTC P0011Camshaft Position "A" - Timing Over-Advanced

or System Performance (Bank 1)

DTC P0012Camshaft Position "A" - Timing Over-Retarded

(Bank 1)

A103843E08